Page 1

HI-FLOW™

Pentair Water Pool and Spa

®

IMPORTANT SAFETY INSTRUCTIONS

For Installation of Electrical Controls at Equipment Pad

Install all electrical controls at equipment pad, such as on/off

switches, timers, and control systems, etc. to allow the

operation (startup, shut-down, or servicing) of any pump or

filter so the user does not place any portion of his/her body

over or near the pump strainer lid, filter lid or valve closures.

This installation should allow the user enough space to stand

clear of the filter and pump during system start-up, shut down

or servicing of the system filter.

SIDE MOUNTED BACKWASH VALVE

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

TABLE OF CONTENTS

Valve Positions Overview ....................................................................................... 2

Valve Installation ..................................................................................................... 3

Winterizing ............................................................................................................... 3

Replacement of Valve Top and Diverter Assembly ............................................... 3

Complete Disassembly ........................................................................................... 3

Technical Data ......................................................................................................... 4

additional free copies of these instructions.

IMPORTANT NOTICE!

Attention Installer: This manual contains important information about the installation, operation and safe use of this product. This

information should be given to the owner/operator of this equipment.

For Installation of Electrical Controls at Equipment Pad

(ON/OFF Switches, Timers and Automation Load Center)

Install all electrical controls at equipment pad, such as on/off switches, timers, and control systems, etc. to allow the

operation (startup, shut-down, or servicing) of any pump or filter so the user does not place any portion of his/her body

over or near the pump strainer lid, filter lid or valve closures. This installation should allow the user enough space to stand

clear of the filter and pump during system start-up, shut down or servicing of the system filter.

Before installing this product, read and follow all warning notices and instructions accompanying this valve. Failure to

follow safety warning and instructions can result in severe injury, death, or property damage. Call (800) 831-7133 for

The valve must be installed by a qualified serviceman in accordance with the National Electrical Code and all

applicable local codes and ordinances.

Always disconnect power to the equipment at the circuit breaker before servicing any of the equipment. Ensure that the

disconnected circuit is locked out or properly tagged so that it cannot be switched on while you are working on the equipment.

Failure to do so could result in serious injury or death to serviceman, operator users or others due to electric shock.

Position the filter and the air relief valve to safely direct water drainage and purged air or water. Water discharged from

an improperly positioned filter or valve can create an electrical hazard that can cause severe personal injury as well as

damage property.

Page 2

2

FILTER OPERATES UNDER HIGH PRESSURE.

When any part of the circulating system, (e.g., clamp, pump, filter, valve(s), etc.), is serviced, air can enter the

system and become pressurized. Pressurized air can cause the lid to separate which can result in severe injury,

death, or property damage. To avoid this potential hazard, follow these instructions:

1. Before repositioning valve(s) and before beginning the assembly, disassembly, or adjustment of

the clamp or any other service of the circulating system: (A) Turn the pump OFF and shut OFF any

automatic controls to ensure the system is NOT inadvertently started during the servicing; (B) open the

manual air relief valve; (C) wait until all pressure is relieved.

2. Whenever installing the filter clamp FOLLOW THE FILTER CLAMP INSTALLATION INSTRUCTIONS

EXACTLY.

3. Once service on the circulating system is complete FOLLOW SYSTEM RESTART INSTRUCTIONS

EXACTLY.

4. Maintain circulation system properly. Replace worn or damaged parts immediately, [e.g., clamp,

pressure gauge, valve(s), o-rings, etc].

5. Be sure that the filter is properly mounted and positioned according to instructions provided.

Valve Positions Overview

FLOW PATH

SETTING Function

Filter Pump > Sand Top / DE Bottom > Through Filter > DE Top / Sand Bottom > Return

For normal filter action and vacuuming pool thru filter.

Backwash Pump > DE Top / Sand Bottom > Through Filter > Sand Top / DE Bottom > Waste

For cleaning filter by reversing flow

Rinse Pump > DE Top / Sand Bottom > Through Filter > DE Top / Sand Bottom > Waste

For start-up cleaning and resetting filter bed after backwashing

Waste Pump > Waste

For vacuuming directly to waste, lowering pool level or draining pool

Closed No Circulation - DO NOT USE THIS SETTING WITH PUMP OPERATING!

Recirculate Pump > Return

For circulating water without going through filter

HI-FLOW™ Side Mounted Backwash Valve Installation and User's Guide

Page 3

Valve Installation

This valve is available in two models for use with sand type or diatomaceous earth (DE) type pool filters. Be

sure that you have the correct model for your filter. Installing the incorrect model may cause your pump to

dead head, or drain the pool when in backwash position.

1. Confirm correct valve is being used; DE valves for DE filters and Sand valves for Sand filters.

2. Install valve to filter by securing bulkhead nuts on valve to fittings on the filter.

Tighten the nuts by hand only! No additional tightness is required.

3. Plumb pump piping to center pipe in valve.

4. Plumb return and waste lines.

Winterizing

1. Drain and winterize pump and filter per manufacturer's instructions.

2. Depress valve handle and rotate so pointer on handle is between any two settings.

Replacement of Valve Top and Diverter Assembly

1. Set valve handle in any setting.

2. Remove cover screws.

3. Lift off valve top and diverter assembly.

4. Install new valve top and diverter assembly. Be sure arrows on valve top and bottom are aligned.

5. Tighten cover screws evenly and alternately. Do not over tighten.

3

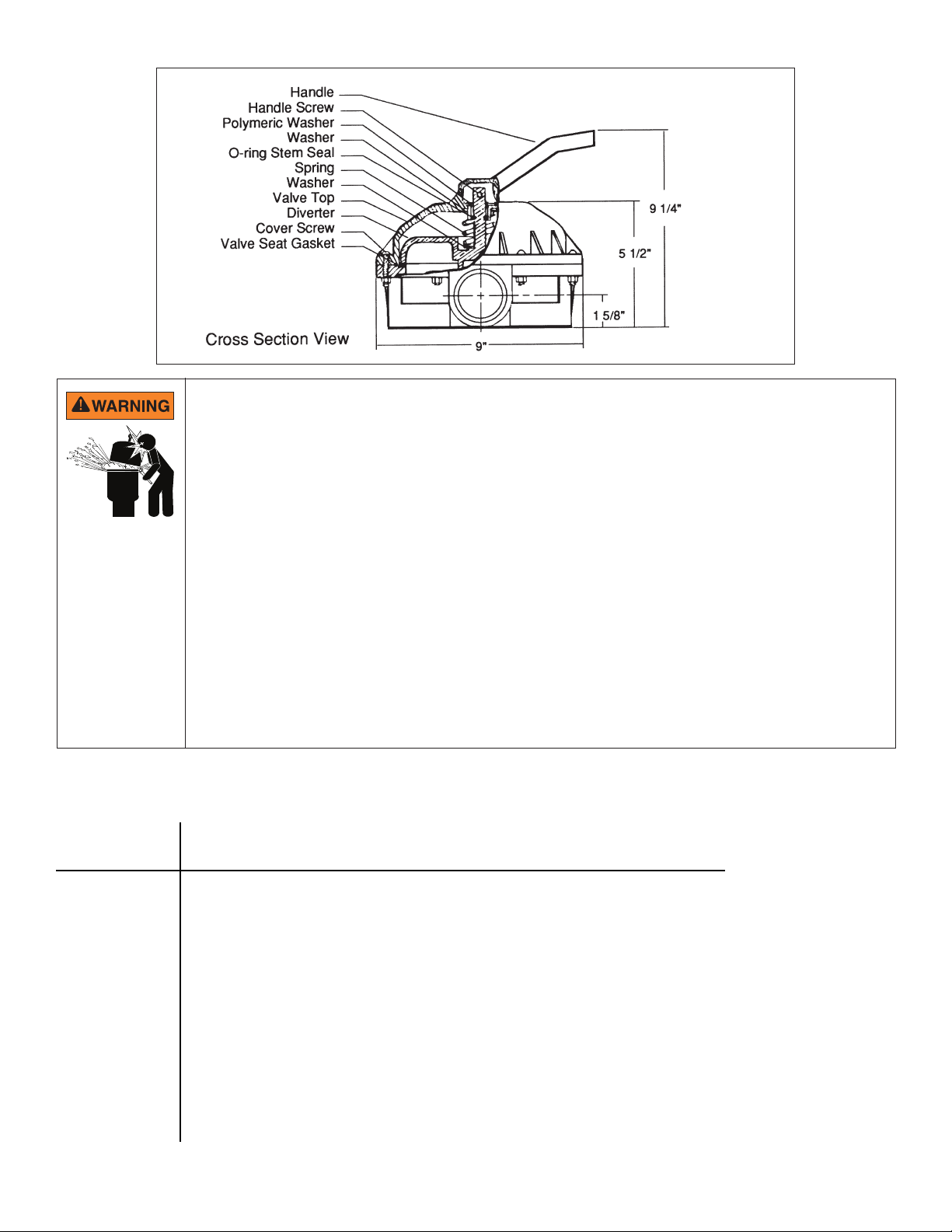

Complete Disassembly

1. Remove Handle to diverter screw. Note arrow on top of diverter stem as handle is removed.

2. Evenly and alternately loosen cover screws.

Top is under spring load. Loosen all screws before removing any of them.

3. Remove cover screws and valve top.

4. Note location of O-ring and spring, and number of washers on diverter stem. Remove O-Ring, spring and washers.

5. Re-assemble in reverse order.

Note: Prior to assembly, be sure bottom gasket and diverter sealing surface are clean and free from nicks to insure

positive sealing.

6. When replacing valve handle, be sure arrow on diverter stem and pointer on handle are pointed in the same direction.

DO NOT over tighten the screws or use motorized screwdrivers; as this can cause damage to the threads.

HI-FLOW™ Side Mounted Backwash Valve Installation and User's Guide

Page 4

4

Technical Data

Replacement Parts

12

11

Covers Assemblies P/Ns 261049, 261050 and 261142

Item P/N Description Qty.

1

2

3

4

5

6

7

5

8

9

1 272520 Handle 1

2 272405 Screw - Handle 1

3 272402 Washer, Plastic 1

4 272412 Valve Top 1

5 271193 Washer - 18 GA 2

6 272400 Spring - Compression 1

7 272406 O-ring - Diverter 1

8 272413Z Diverter 1

9 272409 Seal -Diverter 1

10 98211400 Nut - 1/4" - 20 Hex 8

11 272415 Plat - 2" Valve Bottom 1

12 272403 Screw - 1/4" - 20 8

* 272422 Valve Top Assembly 1

*This part number includes items 1 thru 9

10

Note: When replacing gasket P/N 272409, secure it

to valve bottom with an instant cyanocrylate adhesive

suitable for bonding rubber to plastic.

Head Loss Curves

HiFlow 2” Valve Head Loss Curve

35

30

O)

2

25

20

15

10

Total Head Loss (FT of H

5

0

0 20 40 60 80 100 120 140

Filter Mode

Flow Rate (GPM)

HiFlow 2” Valve Head Loss Curve

35

30

O)

2

25

20

15

10

Total Head Loss (FT of H

5

0

0 20 40 60 80 100 120 140

Backwash Mode

Flow Rate (GPM)

1620 HAWKINS AVE., SANFORD, NC 27330 • (919) 566-8000

10951 WEST LOS ANGELES AVE., MOORPARK, CA 93021 • (805) 553-5000

WWW.PENTAIR.COM

All Pentair trademarks and logos are owned by Pentair or one of its global aliates. Hi-Flow™ is a trademark of Pentair Water Pool and Spa, Inc. and/or its aliated

companies in the United States and/ or other countries. Unless expressly noted, names and brands of third parties that may be used in this document are not used

to indicate an aliation or endorsement between the owners of these names and brands and Pentair Water Pool and Spa, Inc. Those names and brands may be

the trademarks or registered trademarks of those third parties. Because we are continuously improving our products and services, Pentair reserves the right to

change specications without prior notice. Pentair is an equal opportunity employer.

© 2018 Pentair Water Pool and Spa, Inc. All rights reserved. This document is subject to change without notice.

P/N 272133 REV. G 11/28/18

Loading...

Loading...