Page 1

HBM200/HBMX200* SERIES

*For use in Hazardous Locations Class I, Division 1, Groups C & D

SUBMERSIBLE BASIN MIXER

INSTALLATION AND SERVICE MANUAL

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Item # E-03-545 | Part # 5625-545-1 | © 2014 Pentair Pump Group, Inc. | 09/05 /14

*

Page 2

General

WHITE W/BLACK STRIPE - P1

BLUE - P2

ORANGE - SEAL PROBE

SENSOR LEADS

MOTOR LEADS

(YELLOW) (BLACK) (LAVENDER)

WHITE W/BLACK STRIPE - P1

BLUE - P2

ORANGE - SEAL PROBE

SENSOR LEADS

MOTOR LEADS

ORANGE - SEAL PROBE

Information

Attention:

This manual contains important

information for the safe use of

this product. Read this manual

completely before using this

product and refer to it often for

continued safe product use. Do

not throw away this manual. Keep

it in a safe place so that you may

refer to it often.

Reasonable care and safe methods

should be practiced. Check the

local codes and requirements

before installation.

WARNING: Before handling

electrical equipment, always

disconnect the power first. Do not

smoke or use sparkable electrical

devices or flames in a septic

(gaseous) or possible septic sump.

CALIFORNIA PROPOSITION

65 WARNING:

This product

and related accessories contain

chemicals known to the State of

California to cause cancer, birth

defects or other reproductive harm.

CAUTION: To reduce risk of

electrical shock, do not remove

cord or strain relief. Do not

connect conduit to mixer.

Electrical installations shall be

in accordance with the National

Electrical Code and all applicable

local codes and ordinances.

For use with maximum

140°F water.

Septic tank should be vented in

accordance with local plumbing

codes and should not be installed

in locations classified as

hazardous, in accordance with the

National Electrical Code, ANSI/

NFPA 70-1999.

2

WARNING: Severe injury may

result from accidental contact

with moving propeller. Keep

clothing, hands and feet away

from propeller any time power is

connected to the mixer.

The Mixer

Description:

The integral stainless steel motor

shaft is sealed by two mechanical

seals with an oil chamber between

the seals to provide lubrication

for both seal faces.

Two ball bearings are used to

handle the loads. The upper

bearing takes radial load, while

the larger lower bearing handles

both thrust and radial loads.

Both bearings are permanently

lubricated by the dielectric oil in

the motor housing. The motor is

fixed within the motor housing

and is completely submerged in

the dielectric oil for maximum

heat transfer. The motor housing

and seal chamber are completely

sealed with O-rings located at

mating part faces.

The power cord entry system is

designed to give double sealing.

The chamfered pilot of the motor

housing mates with the molded

cord end to form the first seal.

The cord grip forms the second

seal around the molded cord end

and provides strain relief. The

cable includes the leads for both

heat sensors (motor protection)

and the seal sensor lead for seal

leakage detection.

Application:

The submersible basin mixer is

used to break up crusts and solids

that float at the top of a solids

handling basin. The unit can also

be used for mixing and stirring

applications in industrial areas

and waste management facilities.

Mixer Installation

Unpacking:

Remove from carton. When

un pack ing unit, check for

concealed damage. Claims

for damage must be made at

the receiving end through the

delivery carrier. Dam age cannot

be processed from the factory.

Location:

If mixers are installed in an

existing basin or concrete sump,

they may either be connected

permanently or rails and brackets

can be fur nished for mounting

to walls of basin. The complete

factory built packaged system

is recommended for the most

satisfactory in stalla tion and

generally for the low est cost

where expensive in stalla tion

labor is involved.

SENSOR LEADS

WHITE W/BLACK STRIPE - P1

BLUE - P2

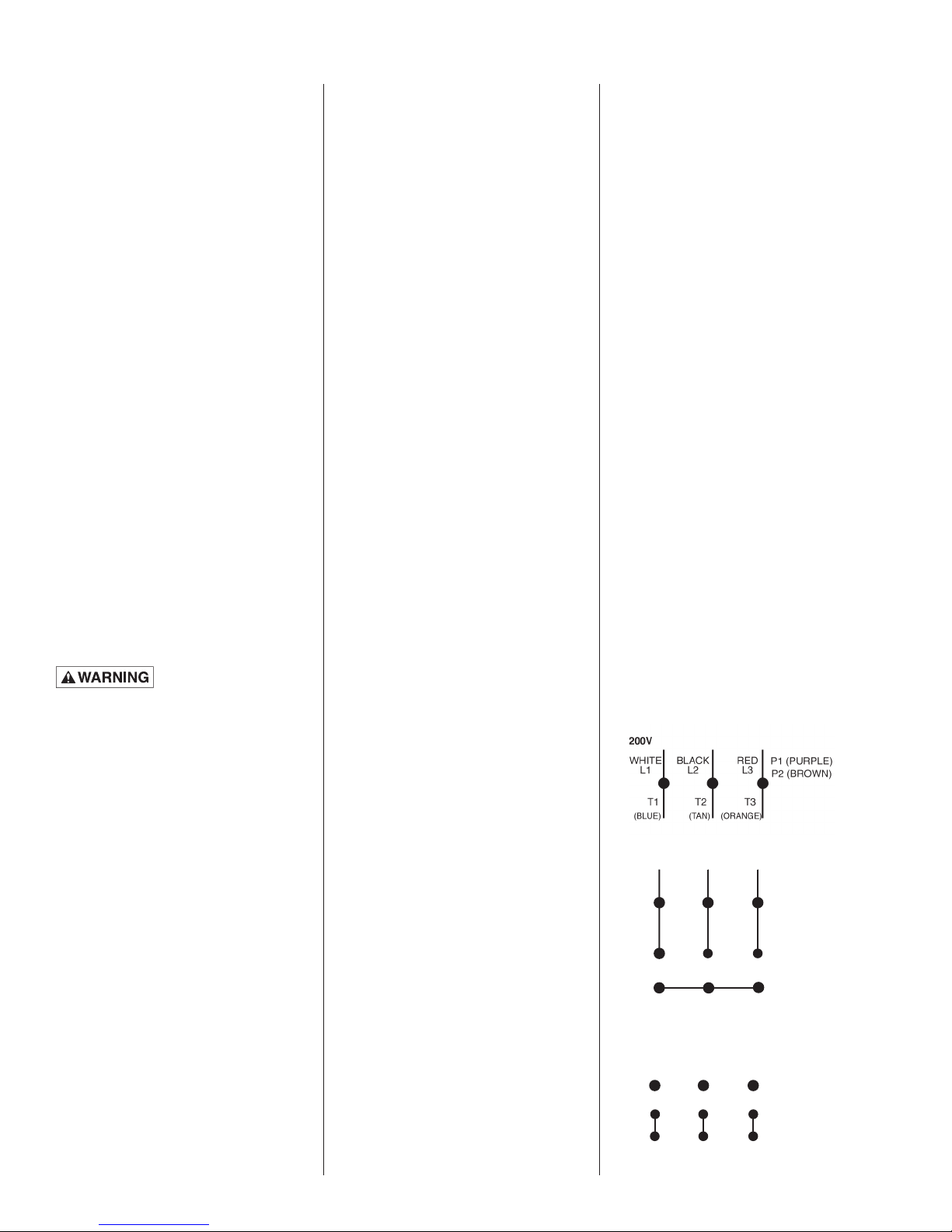

230V (DUAL VOLTAGE) THREE PHASE

WHITE

(BLUE) (TAN) (ORANGE)

(YELLOW) (BLACK) (LAVENDER)

460V (DUAL VOLTAGE) THREE PHASE

(BLUE) (TAN) (ORANGE)

T7

(PINK)

BLACK

L1

T1 T2 T3

T7

T4

WHITE

T1 T2 T3

T4

L2

T8 T9

(PINK) (RED) (LT. BROWN)

T5 T6

BLACK

L1

T8 T9

(RED)

T5 T6

L2

(LT. BROWN)

RED

L3

RED

L3

P1 (PURPLE)

P2 (DARK BROWN)

PL (PURPLE)

P2 (DARK BROWN)

Page 3

Electrical Connections:

Make all connections from motor

to control panel to com ply with

local codes.

NOTE: Hydromatic

control panels supply the correct

circuitry for moisture and heat

sensor connections. Failure

to install the correct circuitry

with proper connection would

negate warranty and factory

mutual approval.

CAUTION: Make sure that

the ground wire is securely

connected and that the unit is

properly grounded in accordance

with local codes.

®

built

Mixer Operations

Starting the Mixer:

WARNING: Severe injury may

result from accidental contact

with moving propeller. Keep

clothing, hands and feet away

from propeller any time power is

connected to the unit.

To start the mixer, perform the

following steps in order:

If mixer is three phase, the

rotation of the propeller must

first be checked. Lift mixer from

sump, lay it down, and quickly

turn on and then off.

The propeller should turn

counterclockwise when viewed

from the suction. If rotation is

wrong, turn off main breaker and

interchange any two line leads to

motor to correct rotation. If mixer

is single phase, no rotation check

is necessary.

After installing mixer in basin in

desired location, run water into

basin until mixer is covered.

Turn mixer on and observe

mixing action at the surface of

the water. If required, adjust

position of mixer mounting

brackets until desired mixing

action is achieved in the basin.

If problems occur check the

power source. Make sure a

separate supply line is available.

Verify the voltage supply.

Mixer

Maintenance

Disassembly, Inspection,

Reassembly:

For Hazardous Location Service:

These pumps are to be used for

handling sewage, wastewater

and storm water only. Do not

use in other hazardous locations.

These motors must be repaired

and serviced only at Hydromatic

authorized service centers or at

the factory. Any unauthorized

field repair voids the warranty

and the hazardous location rating.

Turn off circuit break er.

Remove mixer from sump.

Replacing Seals:

Drain the oil in the seal cham ber

by removing the drain plug on

the side of the unit. If it con tains

water, the lower seal has failed

and should be replaced. The

mo tor hous ing should be drained

and the upper seal replaced if

the lower seal has failed, since

foreign material in the seal

chamber may have dam aged the

upper seal.

Remove the propeller after first

removing center set screw at the

end of the motor shaft.

Using a pair of snap ring pliers,

remove the snap ring that secures

the lower seal. Remove the lower

seal rotating elements by sliding

the spring off the shaft. Then

using two screwdrivers, slide the

carbon assembly off by prying on

the retaining ring.

Loosen and remove the cap

screws that hold on the seal

housing, then re move the seal

housing. Using a socket that will

fit onto the back of the seal, tap

the sta tion ary seal assembly out

of the seal housing.

Using a pair of snap ring pliers,

remove the snap ring that secures

the up per seal. Remove the spring

retainer and spring from the shaft,

and using the same method as

used for the lower seal, remove

the carbon seal assembly.

With a pair of screwdrivers, pry

up on the seal/bearing plate.

®

Remove the seal/bearing plate

until you have access to the

seal sensor wire, then carefully

pull the seal sensor wire off the

seal probe which will allow the

complete removal of the seal/

bearing plate.

Take a socket and tap out the

stationary portion of the seal from

the seal/bearing plate in the same

manner as used for the lower

stationary seal.

After checking both of the

O-rings, replace the seal bearing

plate in the motor housing,

making sure that the seal sensor

wire has been reattached to the

seal probe. Use O-ring lube to

prevent cutting in assembly.

Take the sta tion ary portion of

the new seal, and lube the rubber

material with a good quality

dielectric oil. Press the stationary

portion of the new seal into the

seal/bearing plate.

CAUTION: Do not reuse old seal

parts. Replace all parts with new.

Mixing old and new parts could

cause im me di ate seal failure.

3

Page 4

Using a good quality dielectric

oil, lube the rubber material on

the carbon seal assembly and

press it on the shaft. Place the

spring and the seal retainer on

the shaft as removed. Replace the

snap ring.

Carefully place the seal housing

onto the seal bearing plate,

re place the cap screws, and

evenly tighten.

Troubleshooting

Below is a list of troubles and

their probable causes:

Insufficient mixing

1. Mixer orientation

needs adjusted

2. Wrong rotation

3. Speed too low

Using a pressure gauge with a

fill stem, pres sur ize the motor

housing to no more than 7 psi

with dried air and check for

leaks. If after several minutes the

gauge reads the same, the seal

is good and you can con tin ue

with assembly.

NOTE: It is normal to observe

some air bubbles in the seal area

initially as the seal seats. If the

bubbles do not stop within a few

seconds, the seal is either not

properly installed or is damaged.

Following the same procedure

outlined previously to install the

lower seal assembly. Re place

the impeller using a re mov able

locking adhesive.

Reassemble the propeller set

screw onto mixer.

Mixer overloads motor

1. Wrong rotation

2. Specific gravity or vis cos i ty

of liquid too high

3. Speed too high

4. Mixer clogged

5. Defective bearings

Mixer is noisy

1. Defective bearings

2. No axial clearance be tween

propeller and seal housing

Refill all cham bers with a good

quality di elec tric oil. Fill the

motor housing so that the tops

of the motor windings have been

covered (2500 ml), but leave an

air gap to allow for ex pan sion of

the oil. Fill the seal chamber with

700 ml of oil so that an air gap

also exists.

4

Page 5

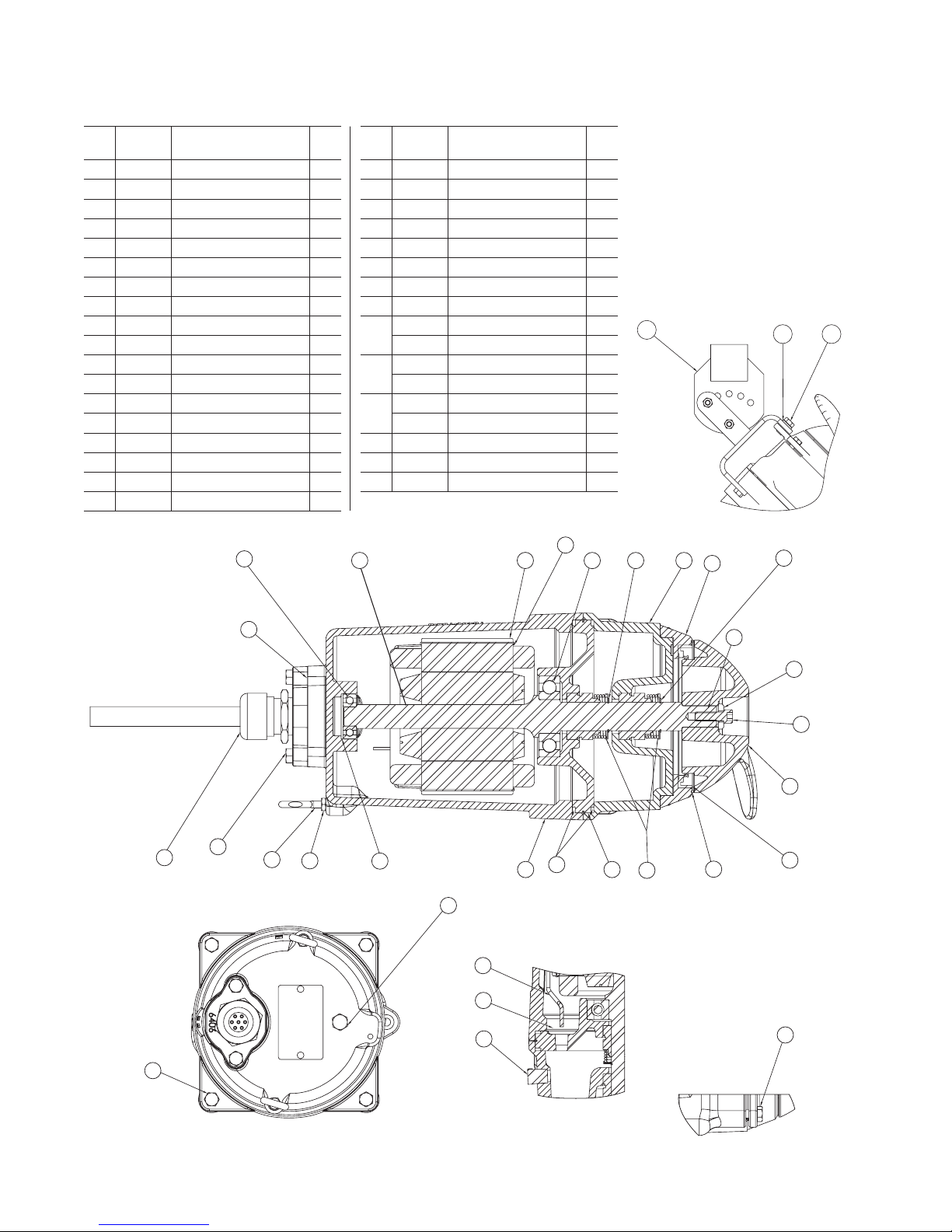

HBM200 Parts List

Item Eng. No.

1 144240115 Cord Assembly 1

2 000640011 Spring – Bearing Adj. 1

3 000650011 Bearing – Ball (Upper) 1

4 000650271 Bearing – Ball (Lower) 1

5 001010111 Screw – HHC 5/16-18 x 1-3/4 4

6 101020011 Key 1

7 003000001 Seal – Shaft 1" 2

8 005890101 Bolt – Eye 1/4-20 2

9 008340151 O-ring 3/32 Dia. 1.737 I.D. 1

10 009750021 Ring – Retaining 2

11 05022A092 Plug-Pipe 1/4 2

12 05876A120 O-ring 1/8 Dia. 6-1/4 I.D. 2

13 060000141 Wire w/Terminal 14 Ga Red 1

14 084720015 Seal Failure Ass’y 1

15 134880002 Plate/Bearing Seal 1

16 134890012 Housing – Seal 1

17 134893002 Housing – Lip Seal 1

18 134941002 Housing – Motor 1

Description Qty.

3

Part

Item Eng. No.

19 152120002 Propeller – Mixer 1

20 152220001 Seal – Lip 4" 1

21 19100A004 Screw – Cap 5/16 SST x 3/4 2

22 19100A029 Screw – Cap 5/16 SST x 1 4

23 001780041 Screw – Cap 5/16 SST x 1 1

24 19109A077 Nut – Hex 1/4 2

25 005190001 Washer 1

26 27755A000 Teflon Ring Seal 1

27 001450291 Stator bolt, 1750 rpm 4

001450101 Stator bolt, 1150 rpm 4

28 152150111 Rotor & Shaft 1750 rpm 1

152230111 Rotor & Shaft 1150 rpm 1

29 152150031 Stator 1750 rpm 1

152230031 Stator 1150 rpm 1

30 526033035 Bracket - Lower Mixer 1

31 05454A015 Washer – Lock SST 3/8 1

32 19101A003 Screw – Cap 3/8-16 1

28

Description Qty.

29

Part

30

27

10

4

16

17

31 32

10

9

1

5

21

8

24

2

11

13

14

11

12

18

15

7

6

25

23

19

26

20

22

Page 6

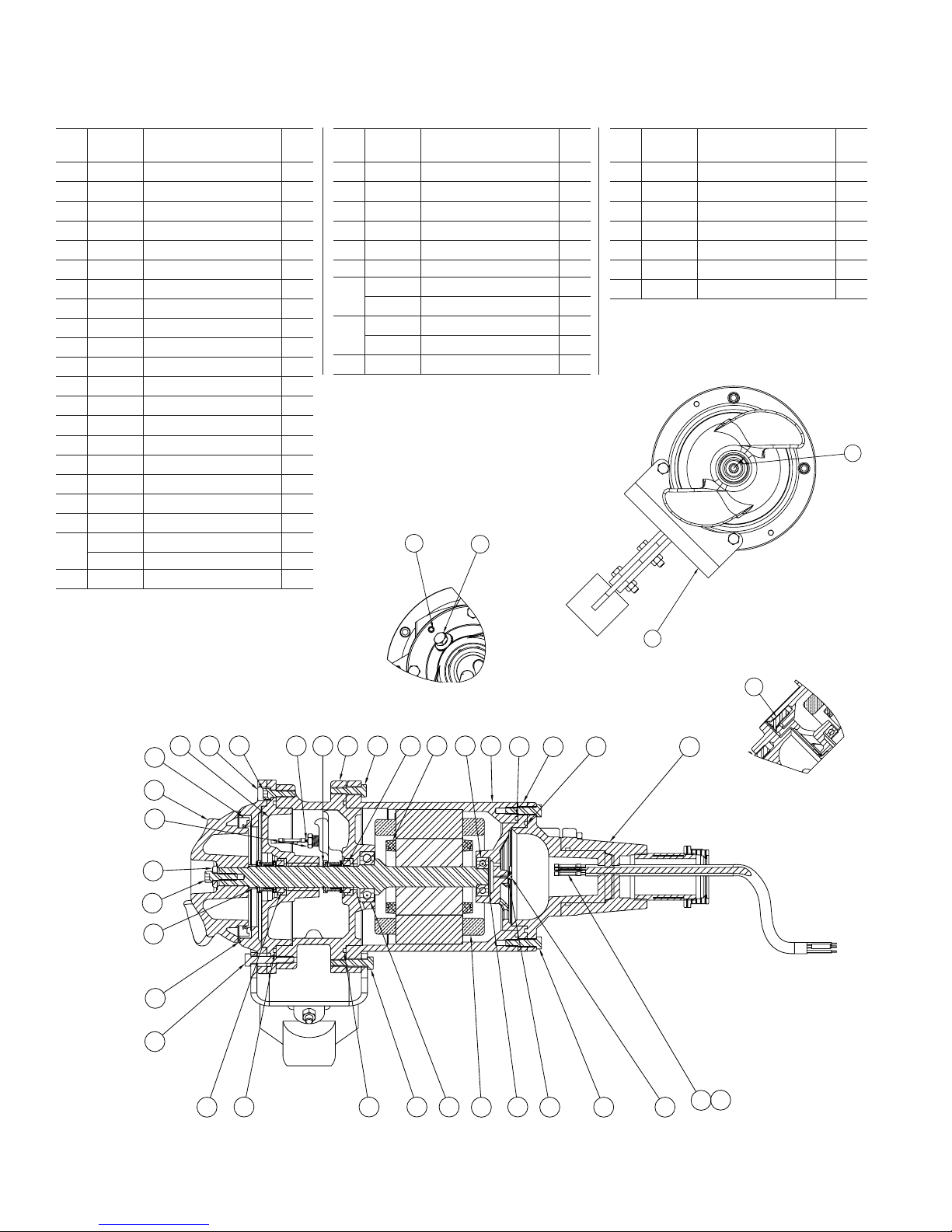

HBMX200 Parts List

22

33

4

29

25

14

30

15

77

8

26

10

18

23

13

28

24

17

16156

9

11

22

33

33

4

30

1

11

Item Eng. No.

1 22407C607 Cord Cap – 35 Ft. 1

05013A027

2

05022A092

3

05434A043

4

05876A122

5

05876A123

6

05876A125

7

06107A015

8

07597A017

9

12558A006

10

11 12672A002 Connector – Butt 22-16 2

12 19100A012 Screw – HHC 5/16-18 x 1-1/4 8

13 19100A033 Screw – Cap 5/16 X 7/8 8

14 19101A017 Screw – Cap 3/8-16 X 1-1/4 2

15 19331A005 Washer – Spring 2

16 21570B100X Cap – Upper Bearing 1

17 21571D100X Housing – Motor 1

18 21574D100X Housing – Upper Seal 1

19 21577A000 Plug – Special 1/2 Hex 1

20 21578C100X Housing – Lower Seal 1

22579A000 Ferrule – Rubber .312 O.D. X .265 I.D. 1

21 27799A000 Spacer – Propeller 1

Description Qty.

Screw – Set 5/16-18

Plug – Pipe 1/4

Screw – Machine 10-24 X 3/8

O-ring

O-ring

O-ring

Washer – Lock

Screw – Machine 5/16-18 X 1

Ring – Retaining

Part

2

2

1

1

1

2

1

2

1

Item Eng. No.

22 526033065 Bracket – Mixer 1

23 21576A010 Seal – 7/8" 2

24 08565A013 Bearing – Ball 1

25 08565A018 Bearing – Ball 1

26 22578A003 Electrode – with Resistor 1

27 001010111 Screw – HHC 5/16 – 18UNC x 1-3/4 2

28 152260111 Rotor/Shaft – 1750 rpm 1

152270111 Rotor/Shaft – 1150 rpm 1

29 152260031 Stator – 1750 rpm 1

152270031 Stator – 1150 rpm 1

30 12672A001 Connector 3

Description Qty.

2

3

Part

Item Eng. No.

31 001780041 Screw – Cap 5/16-18 1

32 005190001 Washer – Propeller 1

33 101020011 Key 3/16 Sq. X .69 1

34 134894002 Housing – Lip Seal 1

35 152220001 Lip Seal 1

36 152120002 Propeller 1

37 27755A000 Ring – Propeller 1

Description Qty.

33

Part

22

20

35

34 12

26

18

10

13

28

23

17

24

16

56

1

9

36

19

32

31

21

37

27

23 13

6

6

11

14

77

25

15

29

8

30

4

Page 7

THIS PAGE INTENTIONALLY LEFT BLANK

Page 8

STANDARD LIMITED WARRANTY

Pentair Hydromatic® warrants its products against defects in material and workmanship for a period of 12 months

from the date of shipment from Pentair Hydromatic or 18 months from the manufacturing date, whichever

occurs first – provided that such products are used in compliance with the requirements of the Pentair Hydromatic

catalog and technical manuals for use in pumping raw sewage, municipal wastewater or similar, abrasive-free,

noncorrosive liquids.

During the warranty period and subject to the conditions set forth, Pentair Hydromatic, at its discretion, will repair

or replace to the original user, the parts that prove defective in materials and workmanship. Pentair Hydromatic

reserves the right to change or improve its products or any portions thereof without being obligated to provide such

a change or improvement for prior sold and/or shipped units.

Start-up reports and electrical schematics may be required to support warranty claims. Submit at the time of start up

through the Pentair Hydromatic website: http://forms.pentairliterature.com/startupform/startupform.asp?type=h.

Warranty is effective only if Pentair Hydromatic authorized control panels are used. All seal fail and heat sensing

devices must be hooked up, functional and monitored or this warranty will be void. Pentair Hydromatic will cover

only the lower seal and labor thereof for all dual seal pumps. Under no circumstance will Pentair Hydromatic be

responsible for the cost of field labor, travel expenses, rented equipment, removal/reinstallation costs or freight

expenses to and from the factory or an authorized Pentair Hydromatic service facility.

This limited warranty will not apply: (a) to defects or malfunctions resulting from failure to properly install, operate or

maintain the unit in accordance with the printed instructions provided; (b) to failures resulting from abuse, accident

or negligence; (c) to normal maintenance services and parts used in connection with such service; (d) to units that

are not installed in accordance with applicable local codes, ordinances and good trade practices; (e) if the unit is

moved from its original installation location; (f) if unit is used for purposes other than for what it is designed and

manufactured; (g) to any unit that has been repaired or altered by anyone other than Pentair Hydromatic or an

authorized Pentair Hydromatic service provider; (h) to any unit that has been repaired using non factory specified/

OEM parts.

Warranty Exclusions: PENTAIR HYDROMATIC MAKES NO EXPRESS OR IMPLIED WARRANTIES THAT EXTEND

BEYOND THE DESCRIPTION ON THE FACE HEREOF. PENTAIR HYDROMATIC SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE.

Liability Limitation: IN NO EVENT SHALL PENTAIR HYDROMATIC BE LIABLE OR RESPONSIBLE FOR

CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES RESULTING FROM OR RELATED IN ANY MANNER TO

ANY PENTAIR HYDROMATIC PRODUCT OR PARTS THEREOF. PERSONAL INJURY AND/OR PROPERTY DAMAGE

MAY RESULT FROM IMPROPER INSTALLATION. PENTAIR HYDROMATIC DISCLAIMS ALL LIABILITY, INCLUDING

LIABILITY UNDER THIS WARRANTY, FOR IMPROPER INSTALLATION. PENTAIR HYDROMATIC RECOMMENDS

INSTALLATION BY PROFESSIONALS.

Some states do not permit some or all of the above warranty limitations or the exclusion or limitation of incidental or

consequential damages and therefore such limitations may not apply to you. No warranties or representations at any

time made by any representatives of Pentair Hydromatic shall vary or expand the provision hereof.

740 EAST 9TH STREET 490 PINEBUSH ROAD, U NIT #4

ASHLAND, OHIO, USA 44805 CAMBRIDGE, ONTARIO, CANADA N1T 0A5

419-289-1144 800-363-PUMP

WWW.HYDROMATIC.COM

Warranty Rev. 12/13

Page 9

MODELS HBM200/HBMX200

BASIN MIXER CONTROL PANEL

INSTALLATION AND SERVICE MANUAL

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Item # E-03-520 | Part # 5625-520-1 | © 2012 Pentair Pump Group, Inc. | 11/05/12

Page 10

General

Information

Thank you for purchasing your

Hydromatic® Basin Mixer Control

Panel. To help ensure years of

trouble-free operation, please read

the following manual carefully.

Before Operation:

Read the following in structions

care ful ly. Reasonable care

and safe meth ods should be

practiced. Check local codes and

requirements before installation.

Attention:

This manual contains important

information for the safe use of

this product. Read this manual

completely before using this

product and refer to it often

for con tin ued safe product use.

DO NOT THROW AWAY OR

LOSE THIS MAN U AL. Keep

it in a safe place so that you may

refer to it often.

Unpacking Panel:

Remove panel from carton.

When un pack ing unit, check

for concealed damage. Claims

for damage must be made at

the receiving end through the

delivery carrier. Damage cannot

be processed from the factory.

CALIFORNIA PROPOSITION

65 WARNING:

This product and

related accessories contain

chemicals known to the State of

California to cause cancer, birth

defects or other reproductive

harm.

Power

Supply

WARNING: Do not attempt to

wire this control box unless you

have a good working knowledge

of electricity and are familiar

with the state and local codes. If

you are in doubt about anything,

contact a qualified electrician.

Do not attempt to operate this

unit on any other voltage or

power distribution other than

for which it was originally

designed (check nameplate).

Failure to comply with this

will result in the immediate

cancellation of all warranties

and claims.

It is advisable to put the panel

on its own circuit using a circuit

breaker adequately sized to protect

the mixer. Check state and local

codes for the correct wire size and

circuit protection to use. The wire

should be sized large enough to

handle the full load current of the

mixer you are operating and any

voltage drop that might occur due

to long service runs.

Run power supply lines to the

control box and secure (knockouts

are not supplied in this box).

Select a convenient location on

the bottom to enter the box with

the power supply. Cut a hole with

a chassis punch. Caution should

be taken not to get metal chips

in the components while cutting

hole. After the hole is cut, any

metal particles must be removed

from the box. Failure to do so may

result in premature component

failure.

the bottom right of the box. The

ground lug should be fastened to

a good driven earth ground by

one of the methods described in

the National Electric Code. NEC

does not permit using ground

as a current-carrying conductor,

therefore a neutral must be

provided for 115 volt 1 phase, 208

volt 1 phase, 230 volt 1 phase, or

208 volt 3 phase systems.

WARNING: Before handling

these mixers and controls,

always disconnect the power

first. Do not smoke or use

sparkable electrical devices or

flames in a septic (gaseous) or

possible septic sump.

Electrical Connections:

The contractor must conform

to the latest requirements of the

National Electrical Code. All

conduit and ca bles shall be in

accordance with NEC Code

NFPA #70. To maintain UL and

CSA ENCL rating, use the same

type UL and CSA weatherproof

con duit hubs when connecting to

this en clo sure. Prior to conducting

any in stal la tion, repair or service

with re gard to the control panel,

refer to the schematic appropriate

for that panel. The schematic will

provide guidance with regard to

the terminal block con nec tions.

CAUTION: A nonmetallic

enclosure does not provide

grounding conduit con nec tions.

Use grounding bush ing and

jumper wires.

Make the Following

Electrical Con nec tions:

a. Connect the mixer leads to the

control panel.

2

Connect incoming power to the

terminal blocks per the included

schematic and all necessary

ground wires to the ground lug at

b. Connect the mixer heat sensor

and seal failure leads (if

available on the mixer) to the

Page 11

appropriate ter mi nal blocks in

the control panel.

HBM (Pre December 2011)

c. Before connecting power to

the control panel, make sure all

con trol switches (e.g. H-O-A

switch) and protective devices

(e.g. breakers) are in the Off

po si tion. Now connect power

to the terminal block or the

circuit break er as directed by

the sche mat ic.

d. Control panel must be

grounded properly per

NEC and/or local codes. To

facilitate this, a ground lug is

provided on the control panel.

HBM (Pre December 2011)

Terminal Mixer Wire Color Function

M1 White Mixer Power

M2 Black Mixer Power

M3 Red Mixer Power

G Green Ground

1 Orange Seal Leak Sensor

2 Blue Heat Sensor

3 White w/Black Stripe Sensor Common Wire

1

2

3

Mixer Seal Leak and

Heat Sensor Terminals

M1

Mixer Motor

Power Terminals

M2

M3

Incoming Power

HBM (Post December 2011)

L1

Terminals

L2

L3

Ground

HBM (Post December 2011)

Terminal Mixer Wire Color Function

T1 White Mixer Power

T2 Black Mixer Power

T3 Red Mixer Power

G Green Ground

S1 Orange Seal Leak Sensor

H1 Blue Heat Sensor

H2 White w/Black Stripe Sensor Common Wire

HBMX (Post December 2011)

Terminal Mixer Wire Color Function

T1 White Mixer Power

T2 Black Mixer Power

T3 Red Mixer Power

G Green Ground

S1 Red Seal Leak Sensor

S2 Orange Seal Leak Sensor

H1 Black Heat Sensor

H2 White/Blue Tracer Heat Sensor

HBMX (Post December 2011)

3

Page 12

Start-up

Operation

on hit the Menu button

until the pointer is above

main menu.

iii. Set 1-29 AMT; set to 2

and follow instructions

then set back to 0.

1. Check junction box for

moisture. Moisture may cause

chattering of relays/contactors.

2. WARNING! Live voltage

can kill! Check incoming

power volt age to make sure

that it is correct for panel

and mixer model.

3. Energize control panel. (Turn

on power to panel.)

4. WARNING! Live voltage

can kill! Check voltage to the

panel and at secondary of

control trans form er using a

voltmeter. If no transformer

is supplied, check volt age at

the circuit breakers.

5. Set the application specific

parameters for the VFD.

a. With power to the VFD

and the H-O-A switch in

the Off position, power

Mixer Model Amps Speed Voltage

HBM200M6-4/HBMX200DC 8 1750 200

HBM200M3-4/HBMX200EC 7 1750 230

HBM200M4-4/HBMX200FC 3.5 1750 460

HBM200M6-6/HMBX200DB 5.5 1150 200

HBM200M3-6/HBMX200EB 4.8 1150 230

HBM200M4-6/HBMX200FB 2.4 1150 460

Speed charts – FOR REFERENCE ONLY.

4

b. Use up and down key to

switch parameter groups.

Hit OK to set a parameter

group.

c. Use up and down key to

switch parameters. Hit OK

to set a parameter group.

Use up and down key to

change parameters. After

each change hit OK again

to set the value.

d. Use the back button to

get back to the parameter

groups.

e. Parameters to be set at

installation:

i. Set 1-24 motor current;

see chart below.

ii. Set 1-25 motor nominal

speed; 1150 or 1750;

see chart below.

iv. Set 3-02 speed in Hz;

30–60 Hz.

f. Hit auto on button and

move H-O-A switch to

Auto position. When timer

contact is closed motor

should run.

WARNING: Do not exceed

60 Hz or go below 30 Hz.

Exceeding 60 Hz will draw

more horsepower from the

motor than it was designed for.

Running at lower than 30 Hz

may not supply enough starting

torque to the mixer unit.

6. With H-O-A switch in Hand,

check mixer to ver i fy the

mixer is run ning. On three

phase power, check to see if

each mixer has prop er ro tation.

7. Check full load current with

amp probe and compare it

with the name plate rat ing.

On three phase mixers, check

all three phases. Use a true

RMS meter to obtain accurate

readings.

8. Set range and adjustment

settings on timer.

a. Select one of the 16 built-in

time ranges by setting the

rotary switch per a chart on

Page 13

“On Time” adjustment

within range selected

“Off Time” adjustment

within range selected

ON TIME

MIN MAX

MIN MAX

OFF TIME

I

HJ

GK

FL

EM

DN

CO

BP

A

A

PB

OC

ND

ME

LF

KG

JH

I

“On Time”

range selection

Example dial positions

On Time

Off Time ~ 18 sec

“Off Time”

range selection

shown:

~

10 sec

Dial Setting Timing Range

A 0.6 – 2.5 Sec.

B 1.5 – 5 Sec.

C 2.5 – 10.5 Sec.

D 5 – 21 Sec.

E 10 – 42 Sec.

F 0.4 – 1.4 Min.

the unit and adjust within

that range using the knob

on top.

9. With H-O-A switch in Auto,

check timer op er a tion. For

sequence of op er a tion, refer to

design specification.

10. Make sure H-O-A switch is

left in the Auto position after

start-up is completed.

Mixer Start-Up:

Refer to mixer Installation and

Service Manual.

Mixer

Maintenance

WARNING: Before handling

these mixers and controls,

always dis con nect the power

first. Do not smoke or use

sparkable electrical devices or

flames in a septic (gaseous) or

possible septic sump.

The maintenance schedule

will vary with operating and

Dial Setting Timing Range

G 0.7 – 2.8 Min.

H 1.5 – 5.5 Min.

I 3 – 11 Min.

J 5.5 – 22.5 Min.

K 11 – 45 Min.

environmental con di tions. It will

also vary with the specific type of

control supplied. The list herein is

a guide only.

1. Exercise breaker through

one cy cle. Be careful not to

overexercise as the breaker

is not a switch ing device.

Excessive operations tend to

affect the trip curve of the

breaker.

Programming with LCP12 keypad

The LCP is divided into four functional groups:

1. Numeric display

2. Menu key

3. Navigation keys

4. Operation keys and LEDS

1.

2.

3.

4.

Menu

On

Warn.

Alarm

Hand

On

Status Quick

k

c

a

B

OK

Off

Reset

Menu

Main

Menu

Auto

On

Dial Setting Timing Range

L 0.4 – 1.5 Hr.

M 0.8 – 3 Hr.

N 1.5 – 6 Hr.

O 3 – 12 Hr.

P 6 – 24 Hr.

2. Check relay for excessive

humming. This can be

accomplished by turning

mixer on and off in the Hand

mode with the H-O-A switch.

3. Check mixer run light by

running mixer in Hand mode.

Check bulb(s) in any other

light(s).

4. With the power off, check

con ti nu ity of all control fuses.

5. Check voltage at primary

and sec ond ary of control

transformer.

6. Check the mixer full load

amps.

7. Check junction boxes for

moisture. Moisture may

cause chattering of relays and

contactors.

8. Check for moisture inside

control panel enclosure.

Moisture can cause damage to

electrical com ponents. Check

door gasket for prop er seal.

5

Page 14

9. Check labels to verify they

have not been damaged.

10. Lubricate enclosure hinges.

Spare Parts List:

The following is a list of

recommended spare parts.

However, conditions of ser vice

vary significantly and a general

list may not in its entirety be

applicable to a given installation.

The user should ex er cise judgment

in defining specific re quire ments

based on this guide

1. Fuses for control transformer

primary and secondary. (If

required.)

2. VFD.

3. Bulbs for any light requiring

a bulb.

4. Control transformer. (If

required.)

5. Control and time delay relay.

(If required.)

.

Timer

Controls

Your control panel is equipped

with a repeat cycle time delay

relay (On time first followed by

Off time and repeating). The On

and Off times have rotary switch

selectable timing ranges and

adjustment knobs for selecting the

time withn that range. Select one

of the 16 built-in ranges by setting

the rotary switch per a chart on

the time delay relay and adjust

within that range using the

appropriate knob.

Seal

Failure

Your mixer is equipped with a

seal fail (moisture) sensor. The

presence of water energizes the

seal leak warning output. This

activates a warning light or alarm

only, and does not stop the motor.

It indicates a leak has occurred

and the mixer must be repaired.

For standard location mixers the

resistance across the moisture seal

(seal failure) probe and ground

wire should be checked after a

seal leak warning light has lit.

For hazardous location mixers

the resistance across the moisture

seal (seal failure) probes should

be checked after a seal warning

light has lit. This can be done

by disconnecting the control

wires from the control panel

and measuring the resistance

with an ohmmeter between the

wires. Refer to the control panel

schematic for wire identification.

For a standard, non-hazardous

location mixer the reading should

be 100,000 ohms or greater, and

for a hazardous location mixer the

reading should be above 33,000

ohms. If the measured values are

below those indicated above, then

the mixer may have a lower seal

failure and require service.

On control panels for hazardous

location applications the seal

leak test switch tests the seal leak

circuitry continuity. When pushed

the seal leak test bulb should light.

If the test bulb does not light, it

means either the wiring circuitry

to the seal leak probes has been

broken or the bulb has burned out.

Temperature

Failures

NOTE: Hydromatic® control

panels supply the correct

circuitry for moisture and heat

sensor connections.

Your mixer is equipped with

temperature fail sensor thermostats

attached directly to the motor

windings. The thermostats open if

the motor windings see excessive

heat and, in turn, open the motor

contactor in the control panel,

breaking the power to the mixer.

When the motor is stopped due

to an overheated condition, it will

not start until the motor has cooled

and the heat sensor reset button is

manually pushed on the front of

the control panel.

NOTE: Failure to use proper

circuitry and to connect the

motor overheat protection in the

control panel would negate all

warranties and Factory Mutual

Approval.

WARNING: Before handling

the mixer and controls, always

dis con nect the pow er first. Do

not smoke or use sparkable

electrical devices or flames in

a septic (gas eous) or possible

septic sump.

Troubleshooting

1. Mixer does not run in

Hand position.

a. Check mixer circuit breaker

and control fuse for trip ping

or blown condition.

b. Check incoming power

volt age and control cir cuit

volt age.

c. Check VFD to see if it is

tripped. Reset VFD if

tripped and check mixer

current with ammeter.

6

Page 15

d. With the power off, check

motor heat sensor continuity.

e. Check wiring of mixer to

con trol panel. It should

agree with the sche mat ic.

2. Mixer does not run in Auto

position.

a. Check items (a.) through

(e.) per Item #1 above.

b. Check knob settings on

timer to ensure proper

sequencing. Check both On

and Off time range selector

knobs as well as On and Off

time adjustment knobs.

c. If mixer does not run in

Auto mode, check Auto

circuit wiring in panel.

3. Mixer runs, but run light

does not energize.

a. Re move light and check

with an ohmmeter.

b. Check run light wir ing.

4. Severe humming/chat ter ing

of control relay.

a. There may be low voltage.

Check voltage at primary

and secondary of control

transformer us ing a

volt me ter. This low voltage

condition may cause severe

chat ter ing and burnout of

relay.

b. Relay may have dust around

magnet of coil struc ture.

Dry or clean as re quired.

c. Check voltage to the

control panel. Relays

require a minimum of

80% of full volt age to pull

in without chatter. If the

problem is a re cur ring

one, measure voltage with

recorder on a 24 hour basis.

d. Dry out the junction box

(if furnished); moisture

in the junction box may

cause relays to energize

intermittent ly.

5. Short cycling mixer.

a. Check timer controls.

6. Run light stays on.

a. Selector switch may be in

the Hand position.

7. Nuisance tripping of overload

on VFD or cir cuit break ers.

a. Check mixer amp draw with

amp probe and compare to

nameplate amps on mixer.

b. The propeller may be locked

up due to excessive debris

or solids.

c. Possible motor failure (fault

in windings).

d. Mixer may be miswired to

ter mi nal block.

e. Voltage and current

unbalance. Voltage

un balance on three

phase power sources can

cause motor current to

become un bal anced and

exces sive heating will

re sult. Trip ping of the

over load protection and

premature motor failures

can be expected if the

current unbalance exceeds

five percent.

Percent Maximum Current

Current = Difference from x 100

Unbalance Average Current

_______________

Average Current

To determine if motor current

un bal ance is a function of the

motor or the power supply:

1. Label the leads and the terminals

1, 2, and 3 respectively.

2. Record the amperage for each

lead.

3. Move each lead to the next

terminal (1 to 2, 2 to 3, 3 to 1).

4. Again read the amperage of

each lead.

5. Move each lead to the next

terminal (1 to 3, 2 to 1, 3 to 2).

6. Again read the amperage of

each lead.

7. If the unbalance moves with

the motor leads, the un bal ance

is caused by the mo tor. If the

unbalance remains with the

terminals, the un bal ance is in

the pow er supply.

8. If the current unbalance

exceeds five percent, nui sance

tripping or ex ces sive heating

will result.

9. Connect leads for the lowest

percent of current un bal ance.

Factory Set

Parameters for VFD

Parameters set at factory for 230V panels

1) Set 1-20 motor power 1.5 kW or 2 HP

2) Set 1-22 motor voltage 230 volts

3) Set 1-24 motor current 4.8 amps

4) Set 1-25 motor nominal speed 1150

5) Set 3-02 min. speed in Hz 30

6) Set 3-03 max. speed in Hz 60

7) Set 3-15 0

8) Set 3-16 0

9) Set 3-41 ramp up time 3.00 sec.

10) Set 3-42 ramp down time 3.00 sec.

Parameters set at factory for 460V panels

1) Set 1-20 motor power 1.5 kW or 2 HP

2) Set 1-22 motor voltage 460 volts

3) Set 1-24 motor current 2.4 amps

4) Set 1-25 motor nominal speed 1150

5) Set 3-02 min. speed in Hz 30

6) Set 3-03 max. speed in Hz 60

7) Set 3-15 0

8) Set 3-16 0

9) Set 3-41 ramp up time 3.00 sec.

10) Set 3-42 ramp down time 3.00 sec.

7

Page 16

HBM (Pre December 2011)

230V, 3 Phase, 60 Hz

230 VAC, 3 PHASE, 60 HZ

CUSTOMER

SUPPLIED

POWER

GLG1

TB5

L1

L2

L3 M3

DS1

102A

1 2

103A

3 4

104A

5 6

15A

PB1

T1-3

T2-3

T3-3

115B 115A

115B 118A 115A

Wiring Schematic

102B

103B

104B

110A

112A

TB1

115B

1A

1B

1C

TS2

175A 1x4

L1-1

L2-1

L3-1

PB1

(108)

43

T1-1

T1-2

T2-1

T2-2

T3-1

T3-2

F1A

1 2

F1B

1 2

F1C

1 2

102C

103C

104C

105A

230V-2.0HP

VFD10

L1

L2

GND

L3

GND10

MB

H3

(133)

230V PRI.

115V

SEC.

TB3

4A

TB1

GND

M1

M2

HTR

1 2

30W

1 2

U

V

W

102D

103D

104D

T1

100VA

H1H4

H2

X2X1

TS1

2 1

115A

115A

TB1

4B

MIXER_MOTOR

T1

T2

M

3

T3

142A

142A

142B

R1

3 4

(126)

TB2

3

Motor Heat Sensor

MHS

L1

x1 x2

R

OFF

HAND AUTO

S1

115B 126A 126A 115A

115B 128A

VFD10

(101)

TB2

4

142C

1 2

3 4

XOO

OOX

TMR1

MB

2

115B

(137)

1 3 4

55 42

120A115B

7

865

TB2

1

2605350332920 3127191812

126A 115B

(124)

SLC

Seal Leak Contact

128A

124A115B 115A

L2

x1 x2

G

1 5

FAN

R1

115A115B

8

Page 17

HBM (Pre December 2011)

460V, 3 Phase, 60 Hz

460 VAC, 3 PHASE, 60 HZ

CUSTOMER

SUPPLIED

POWER

GLG1

TB5

L1

L2

L3 M3

102A

103A

104A

T1-3

T2-3

T3-3

DS1

1 2

3 4

5 6

PB1

Wiring Schematic

102B

103B

104B

15A

110A

112A

TB1

115B

1A

1B

1C

115B 115A

115B 118A 115A

TS2

175A 1x4

L1-1

L2-1

L3-1

PB1

(108)

1 2

1 2

1 2

43

T1-1

T1-2

T2-1

T2-2

T3-1

T3-2

F1A

F1B

F1C

102C

103C

104C

105A

460V-2.0HP

VFD10

L1

L2

GND

L3

GND10

MB

H3

(133)

W

460V PRI.

115V

SEC.

TB3

4A

TB1

GND

M1

M2

HTR

1 2

30W

1 2

U

V

102D

103D

104D

T1

100VA

H1H4

H2

X2X1

TS1

2 1

115A

115A

TB1

4B

MIXER_MOTOR

T1

T2

M

3

T3

142A

142A

142B

R1

3 4

(126)

TB2

3

Motor Heat Sensor

MHS

L1

x1 x2

R

OFF

HAND AUTO

S1

115B 126A 126A 115A

115B 128A

VFD10

(101)

TB2

4

142C

1 2

3 4

XOO

OOX

TMR1

MB

2

115B

(137)

1 3 4

55 42

120A115B

7

865

TB2

1

126A 115B

(124)

SLC

Seal Leak Contact

128A

2605350332920 3127191812

124A115B 115A

L2

x1 x2

G

1 5

FAN

R1

115A115B

9

Page 18

HBM (Post December 2011)

230V, 3 Phase, 60 Hz

Wiring Schematic

10

Page 19

HBM (Post December 2011)

460V, 3 Phase, 60 Hz

Wiring Schematic

11

Page 20

HBMX (Post December 2011)

230V, 3 Phase, 60 Hz

Wiring Schematic

12

Page 21

HBMX (Post December 2011)

460V, 3 Phase, 60 Hz

Wiring Schematic

13

Page 22

THIS PAGE INTENTIONALLY LEFT BLANK

Page 23

THIS PAGE INTENTIONALLY LEFT BLANK

Page 24

STANDARD LIMITED WARRANTY

Pentair Hydromatic® warrants its products against defects in material and workmanship for a period of 12 months

from the date of shipment from Pentair Hydromatic or 18 months from the manufacturing date, whichever

occurs first – provided that such products are used in compliance with the requirements of the Pentair Hydromatic

catalog and technical manuals for use in pumping raw sewage, municipal wastewater or similar, abrasive-free,

noncorrosive liquids.

During the warranty period and subject to the conditions set forth, Pentair Hydromatic, at its discretion, will repair

or replace to the original user, the parts that prove defective in materials and workmanship. Pentair Hydromatic

reserves the right to change or improve its products or any portions thereof without being obligated to provide such

a change or improvement for prior sold and/or shipped units.

Start-up reports and electrical schematics may be required to support warranty claims. Submit at the time of start up

through the Pentair Hydromatic website: http://forms.pentairliterature.com/startupform/startupform.asp?type=h.

Warranty is effective only if Pentair Hydromatic authorized control panels are used. All seal fail and heat sensing

devices must be hooked up, functional and monitored or this warranty will be void. Pentair Hydromatic will cover

only the lower seal and labor thereof for all dual seal pumps. Under no circumstance will Pentair Hydromatic be

responsible for the cost of field labor, travel expenses, rented equipment, removal/reinstallation costs or freight

expenses to and from the factory or an authorized Pentair Hydromatic service facility.

This limited warranty will not apply: (a) to defects or malfunctions resulting from failure to properly install, operate or

maintain the unit in accordance with the printed instructions provided; (b) to failures resulting from abuse, accident

or negligence; (c) to normal maintenance services and parts used in connection with such service; (d) to units that

are not installed in accordance with applicable local codes, ordinances and good trade practices; (e) if the unit is

moved from its original installation location; (f) if unit is used for purposes other than for what it is designed and

manufactured; (g) to any unit that has been repaired or altered by anyone other than Pentair Hydromatic or an

authorized Pentair Hydromatic service provider; (h) to any unit that has been repaired using non factory specified/

OEM parts.

Warranty Exclusions: PENTAIR HYDROMATIC MAKES NO EXPRESS OR IMPLIED WARRANTIES THAT EXTEND

BEYOND THE DESCRIPTION ON THE FACE HEREOF. PENTAIR HYDROMATIC SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE.

Liability Limitation: IN NO EVENT SHALL PENTAIR HYDROMATIC BE LIABLE OR RESPONSIBLE FOR

CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES RESULTING FROM OR RELATED IN ANY MANNER TO

ANY PENTAIR HYDROMATIC PRODUCT OR PARTS THEREOF. PERSONAL INJURY AND/OR PROPERTY DAMAGE

MAY RESULT FROM IMPROPER INSTALLATION. PENTAIR HYDROMATIC DISCLAIMS ALL LIABILITY, INCLUDING

LIABILITY UNDER THIS WARRANTY, FOR IMPROPER INSTALLATION. PENTAIR HYDROMATIC RECOMMENDS

INSTALLATION BY PROFESSIONALS.

Some states do not permit some or all of the above warranty limitations or the exclusion or limitation of incidental or

consequential damages and therefore such limitations may not apply to you. No warranties or representations at any

time made by any representatives of Pentair Hydromatic shall vary or expand the provision hereof.

740 EAST 9TH STREET 490 PINEBUSH ROAD, UNIT #4

ASHLAND, OHIO, USA 44805 CAMBRIDGE, ONTARIO, CANADA N1T 0A5

419-289-1144 800-363-PUMP

WWW.HYDROMATIC.COM

Warranty Rev. 12/13

Loading...

Loading...