Page 1

HAFFMANS

HAFFMANS

INSTRUCTION MANUAL

REDPOST PU MONITOR

TYPE RPU-352/353

W W W.HA FF MA NS.NL

W W W.HA FF MA NS.NL

Page 2

Page 3

Essential reading!

Haffmans BV is not responsible for any damage caused by the owner’s failure to follow the instructions given in this

manual. Haffmans BV is not responsible for print or translation errors in this edition of the manual. The specifications

and design of this product are subject of change without notice. All rights reserved. No part of this publication may be

reproduced or distributed in any form or by any means, or stored in a database or retrieval system, without the prior

written permission of Haffmans BV.

Art. no. : 107.035

Release date : 15-07-2010

Version : D

Page 4

Page 5

2

Table of contents

1

Technical specifications 9

2

Safety 11

2.1

Symbols 11

2.2

Precautions and safety instructions 11

3

Installation 13

3.1

Unpacking 13

4

Operation 15

4.1

Controls 15

4.2

I/O switch 15

4.3

Indicator 15

4.4

Display illumination 16

4.5

Switch functions and icons 16

4.6

Auto power on 16

4.7

Auto power off 16

4.8

Low battery condition 17

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

5

Starting 19

5.1

Preparing the instrument 19

5.2

Pressure zero setting Only for PRU-353 21

5.3

Thermometer 21

5.4

Starting the recording 21

6

Recording 23

6.1

Stopping the recording 23

6.2

Screen temperature 23

7

Results 25

7.1

Results displays 25

7.2

Main menu 25

7.3

Calculated results 25

7.4

Erasing a file 26

8

Calculated Results 27

8.1

Total PU achieved 27

8.2

Unique ID number 27

8.3

Total recording time 27

8.4

Maximum temperature 27

8.5

Time near maximum temperature 27

8.6

Temperature at pasteuriser exit 28

8.7

PU cut-off temperature 28

8.8

Time adding PU’s 28

8.9

Maximum pressure Only for PRU-353 28

RPU 352, RPU 353, RPC 80, RPC 50 Page 5 of 112

Page 6

2

9

10

11

12

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

8.10 Time near maximum pressure Only for PRU-353 28

8.11 Reason for stopping 28

Graph 29

9.1

Cursor movement 29

9.2

Graph lines 30

9.3

Off-scale records 30

Full List 31

10.1 Time line movement 31

Battery Charging 33

11.1 Battery information 33

11.2 Battery temperature 33

Menus 35

12.1 Moving the highlight 35

12.2 Selecting an item 35

13

14

Key Plug (Configuration) 37

13.1 Output to other equipment 37

13.2 Language 37

13.3 Display contrast 37

13.4 Clock 38

13.5 Display units 38

13.6 Active channels 39

13.7 PU cut-off temperature 39

13.8 PU calculation – Base 39

13.9 PU calculation – Z 39

13.10 PU calculation – Fahrenheit 39

13.11 Recording interval 40

13.12 Equipment number 40

13.13 Mains frequency 40

13.14 Leaving configuration 40

Output 41

14.1 Stand alone operation 41

14.2 Connection to RPC-80 41

14.3 Connection to PC 41

15

Maintenance 43

16

Frequently Asked Questions 45

16.1 Battery and battery charging 45

16.2 Controls 47

16.3 Results 48

Instruction manual RPC-80 Printer/charger 51

Page 6 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 7

2

17

18

19

20

21

22

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

Technical specifications 53

Introduction 55

Unpacking 57

Control panel 59

Use 61

21.1 Switching on 61

21.2 Connecting the monitor 61

21.3 Printing recorded files 62

21.4 After printing 62

21.4.1 200 Series P.U. monitors. 62

21.4.2 100 Series P.U. Monitors. 62

Configuration settings 63

22.1 Clock setting 63

22.2 Report printing 63

22.3 Template setting 63

23

24

Configuration MENU section 65

23.1 General format set-up 65

23.1.1 Select language 65

23.1.2 Select decimal point 65

23.1.3 Set graph formats 65

23.1.4 P.U.-user 65

23.2 P.U. calculation Set-up 66

23.3 Template set-up 67

23.3.1 Template recording 68

23.4 Template exchange 69

23.5 Editing a template name 70

23.6 Monitor set-up 70

23.7 RPC-80 Set-up 70

23.8 Full list set-up 71

23.9 Printer set-up 71

23.10 External link set-up 72

23.11 Finished set-up : exit 73

Printed results 75

24.1 Results 75

24.2 Status report 75

25

System errors 77

25.1 System error 02 & 04. 77

25.2 System error 08 & 09. 77

26

Faulty operation 79

RPU 352, RPU 353, RPC 80, RPC 50 Page 7 of 112

Page 8

2

27

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

26.1 B-messages 79

26.2 C-messages 79

26.3 M-messages 81

26.4 P-messages 82

26.5 T-messages 83

Back-up battery 85

Instruction manual RPC-50, charger interface 87

28

Technical specifications 89

29

Unpacking 91

30

Operating 93

30.1 Battery Charging 93

30.2 Connection to PC 93

31

Safety 95

Appendix I Background information 97

Appendix II Diagrams 99

Appendix III Customer service 101

Appendix IV Terms of guarantee 103

Appendix V EC Declaration of conformity RPU 352 / 353 105

Appendix VI EC Declaration of conformity RPC 50 107

Appendix VII EC Declaration of conformity RPC 80 109

Appendix VIII Spare parts 111

Page 8 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 9

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

1 TECHNICAL SPECIFICATIONS

Storing data

Max No. of fields

Recording timer setting

Recording interval setting

Only for RPU-352:

Only for PRU-353:

Recording

inputs

Number of input channels 2 1

Nominal range

Resolution 0.02 ºC 0.002 bar

* The display can show results in alternative units if required.

Measuring

accuracy

Temperature

Only for PRU-353:

Operating

conditions

Only for PRU-353:

Max No. of files 4 * (a file is a single recording run)

15860 (a field is one channel

record)

4 hours * (the maximum recording

run)

10 seconds (user can select from 2

s to 60 s)

* Other values available to special order. Recording both channels at 10 second intervals a total of 22

hours recording can be stored.

* Other values available to special order. Recording all 3 channels at 10 second intervals a total of 14.6

hours recording can be stored.

Temperature

Only for PRU-353:

Pressure

-5 to +105 ºC * -0.5 to +18.0 bar

gauge*

Worst case, all errors, including sensors

± 0.25 ºC (sensor in range 40 to 80

ºC)

± 0.4 ºC (over rest of range)

Pressure

(after setting zero)

± 0.08 bar (sensor in range 0 to 8

bar gauge and 40 to 80 ºC)

± 0.2 bar (all other conditions)

All sensors are interchangeable within the accuracy specification

Operation outside these limits may cause permanent damage

Instrument

Temperature sensor -30 to +150

-10 to +85 ºC

ºC

Pressure sensor

up to +20 bar gauge

RPU 352, RPU 353, RPC 80, RPC 50 Page 9 of 112

Page 10

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Battery life

Dimensions

Weight

Materials

Calculation of pasteurisation units (PU) can take place in the RPU-352, PRU-353

* Note that a temperature measurement error of ± 0.25 ºC represents ± 8% error in PU value.

From a fully charged battery

Example (a) 2 maximum runs Record 4 hours, display (with

backlight) 20 minutes

Example (b) 15 typical runs Record 40 minutes, display (with

backlight) 5 minutes

Assumes final recording is completed within one week of the first

(Length x Width x Height)

In frame

9.25 kg Including

380 x 175 x 230 mm

frame

Dimensions and weight are inclusive of carrying frame, can holder and can pressure fitting

Stainless steel, toughened glass and PET-P plastic.

Accuracy Better than ± 0.001% for calculation

alone *

Range 0 to 9999.9

PU

Resolution

0.1 PU

Page 10 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 11

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

2 SAFETY

2.1 SYMBOLS

Attention, warning and danger symbols used in this manual have the following significance.

Attention!

Warning

Information for correct or effective use of the equipment.

Incorrect or careless use can cause serious damage to the

equipment.

Failure to observe this information can result in major

personal injury or loss of life.

2.2 PRECAUTIONS AND SAFETY INSTRUCTIONS

Always follow basic safety precautions when using this equipment to reduce risk of injury.

Before using the equipment, read and understand the operating instructions in this manual.

This equipment is intended to monitor the pasteurisation process in tunnel pasteurisers. It

should not be used for any other purpose.

The equipment should only be connected to other equipment intended for the purpose and

manufactured by Redpost Electronic Products Ltd. Suitable battery chargers are RPC-50 and

RPC-80. Battery chargers from other manufacturers should not be used, they may result in

danger.

The equipment may remain hot for some time after being taken from the pasteuriser. Wear

protective gloves when carrying.

Always place the equipment on a level, stable surface. Do not place on shelves above eye

level.

RPU 352, RPU 353, RPC 80, RPC 50 Page 11 of 112

Page 12

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 12 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 13

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

3 INSTALLATION

3.1 UNPACKING

This manual was written for the RPU-352 and PRU-353. You will find all the information in this

manual. When there is specific information for one product, it is written with the specific item.

Before despatch the RPU-352, PRU-353 was checked and tested by Haffmans B.V. Make sure

that the content of the delivery is complete and undamaged.

If the delivery is incomplete or damaged, please contact Haffmans B.V. or the

representative/agent designated by Haffmans B.V, immediately (appendix III). Always include the

serial number, order number or invoice number (given by Haffmans B.V.) of the RPU-352, PRU353 in the correspondence.

The delivery for the RPU-352 contains: The delivery for the PRU-353 contains:

1 PE-Monitor Type RPU-352 1 PE-Monitor Type PRU-353 for bottles and cans

1 Can/bottle holder PRU-353

1 Quick change facility 1 Quick change facility

1 Spray water temperature probe 1 Spray water temperature probe

1 Test plug 60°C 1 Test plug 60°C

1 Dummy temperature probe 1 Dummy temperature probe

1 Connector grease 1 Connector grease

1 Set of operating magnets (pkg 2) 1 Set of operating magnets (pkg 2)

1 Temperature probe, Lg 150 mm with set

of distance tubes (8 pieces)

1 Plate with bottle holder, Ø 55-68 mm 1 Plate with bottle holder, Ø 55-68 mm

1 K-plug 1 K-plug

1 Manual RPU-352 and PRU-353 1 Manual RPU-352 and PRU-353

Optional: Optional:

Temperature probe Temperature probe

1 Lg 110 mm* 1 Lg 110 mm*

1 Lg 190 mm* 1 Lg 190 mm*

1 Lg 230 mm* Plate with bottle holder

1 Lg 270 mm* 1 Ø 45-55 mm*

1 Lg 310 mm* 1 Ø 68-80 mm*

1 Lg 350 mm* 1 Ø 80-90 mm*

1 Lg 390 mm* 1 Ø 90-100 mm*

Plate with bottle holder 1 Play Back Unit, Type RPC-50

1 Ø 45-55 mm* 1 Play Back Unit, Type RPC-80

1 Ø 68-80 mm*

1 Ø 80-90 mm*

1 Ø 90-100 mm*

1 Play Back Unit, Type RPC-50

1 Play Back Unit, Type RPC-80

*Depending on the item(s) ordered.

1 Temperature probe, Lg 150 mm with set of

distance tubes (8 pieces)

RPU 352, RPU 353, RPC 80, RPC 50 Page 13 of 112

Page 14

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 14 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 15

2

I/O

4 OPERATION

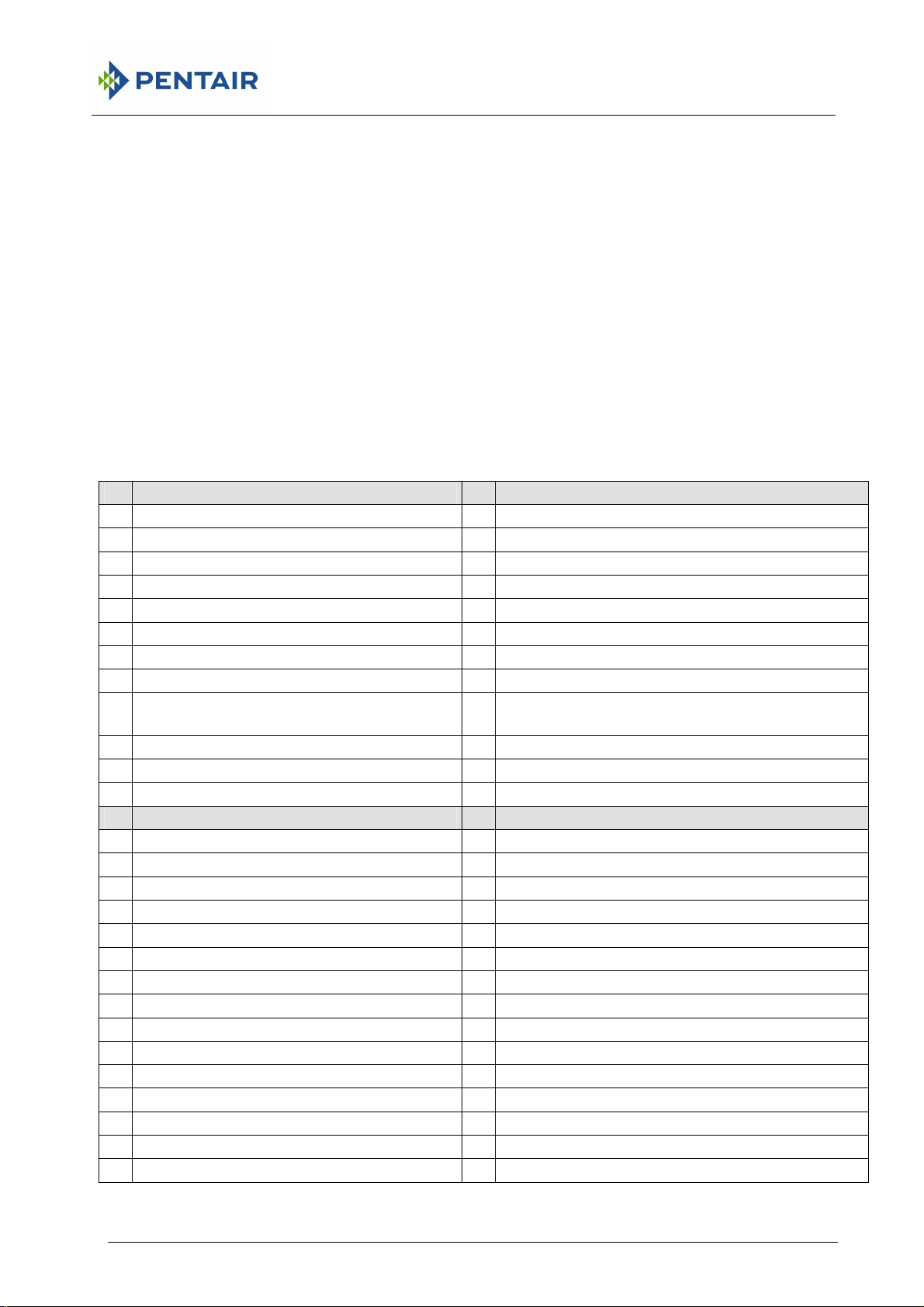

4.1 CONTROLS

Flashing

“ON” indicator

There are four control switches arranged around the display screen. Operate the

switches by touching one end of the actuator onto the glass in the marked area.

Keep the actuator in position until you see a change in the display or the flashing

indicator.

The two top switches are used for the main control functions. They take a few

seconds to operate so that there is less chance of any accidental actions.

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

Icon relates to

this switch

Display

DISPLAY

4.2 I/O SWITCH

The top left switch is the I/O (on/off) switch. Switch the instrument on by

activating this switch. Switch the instrument off by activating and holding this

switch for at least ten seconds. The display shows you what is happening.

Remove the actuator after the instrument switches off.

If there are any recorded files they will be saved during the time the instrument is

switched off.

You cannot switch the instrument off when the battery is charging from a Redpost

printer/charger unit or a Redpost battery charger.

4.3 INDICATOR

The small green lamp on the panel flashes once per second to show that the

instrument is operating. This lamp also flashes quickly five times to acknowledge

the action of either of the two top switches.

RPU 352, RPU 353, RPC 80, RPC 50 Page 15 of 112

Page 16

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

4.4 DISPLAY ILLUMINATION

The I/O (on/off) switch also turns on the backlight that lights up the display.

When any switch is operated or there is any other activity, such as connecting a

probe, the backlight will turn on. It will turn off again after a short time to save

battery power. Activate the I/O switch (for about half a second) to turn on the

backlight without causing any other action.

If there is very little charge in the battery then the backlight will not turn on. This

saves unnecessary battery drain.

4.5 SWITCH FUNCTIONS AND ICONS

The I/O (on/off) switch always keeps the same function but for the other three

switches the display will show a small “icon” to indicate the function of each

switch. The icon is in the same corner as the switch it relates to. The switch icon

becomes inverted (black for white) when the switch is operated. If a switch has

no icon then it has no function at that time.

4.6 AUTO POWER ON

The instrument will automatically switch on when it is connected to a Redpost

printer/charger or a Redpost battery charger. This allows the battery charging to

be controlled and the charging information to be displayed.

The I/O (on/off) switch will not turn the instrument off while it is connected to a

charger but it can still be used to turn on the display backlight.

4.7 AUTO POWER OFF

The instrument uses several methods to reduce battery power consumption. The

automatic control of the display backlight is described above.

If the instrument is idle and waiting to record a file it will automatically switch off

after ten minutes. The instrument is idle if no switches are activated, no data

communication is taking place and it is not connected to an active battery

charger.

If the instrument is idle and displaying the results of a recorded file it will

automatically switch off after twenty minutes.

When the instrument switches off automatically any recorded files are saved.

To resume normal operation activate the I/O (on/off) switch or connect the

instrument to a Redpost battery charger.

Page 16 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 17

2

4.8 LOW BATTERY CONDITION

If recording is taking place when the battery charge level falls below 15%

then recording will stop and the file will be saved. This ensures that

recordings cannot be corrupted by low battery condition. The results

screen will show the reason for stopping.

If there is less than 15% charge in the battery then the backlight cannot be

switched on. This helps to ensure that the battery lasts for as long as

possible. The backlight increases the battery drain by about four times.

At an even lower level of charge (below 5%) the whole instrument will turn

off. Any recorded files will be saved. If you switch the instrument on again

in this state it will stay on for only a few seconds. Connect the instrument

to a Redpost battery charger as soon as possible.

The instrument continuously monitors its own battery use and battery

charging to gauge the amount of charge that remains in the battery. If the

battery voltage falls to a low level unexpectedly it may indicate that the

battery is not correctly holding its charge. This can happen after several

years of use. If this problem occurs the display will warn you that the

battery may need to be replaced. More information can be found in the

“Maintenance” section.

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

RPU 352, RPU 353, RPC 80, RPC 50 Page 17 of 112

Page 18

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 18 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 19

2

5 STARTING

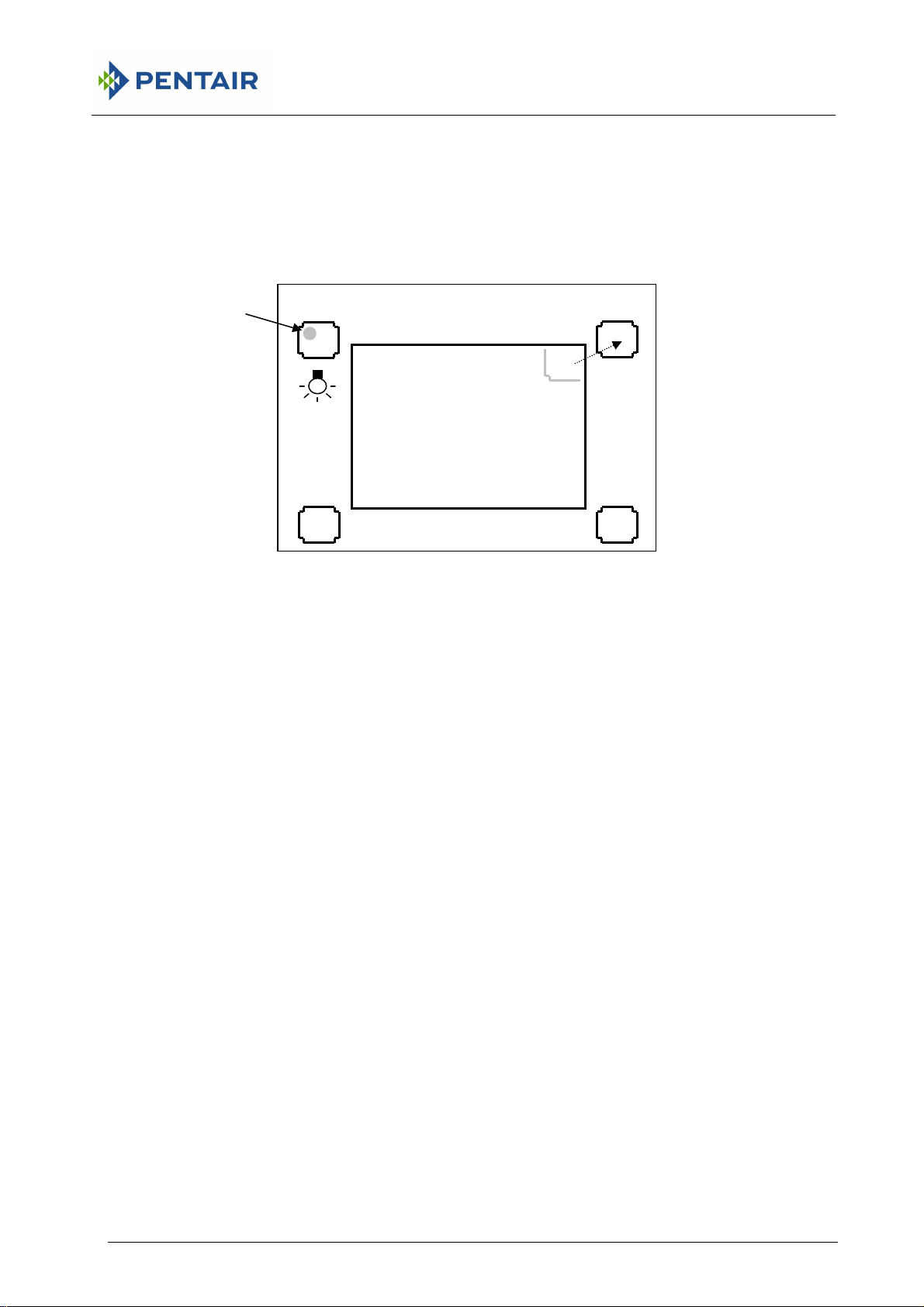

Temperature of

probe (channel 2)

Only for PRU-353:

Pressure

(channel 3)

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

Temperature of

probe (channel 1)

Start

recording

Set pressure

zero

5.1 PREPARING THE INSTRUMENT

Switch on the instrument. If there are any problems, such as insufficient charge in the battery,

the display will give the information you need. Before the temperature probes are connected

the location and numbering of the sockets is shown on the display.

Set up the bottle or can in the correct size holder and fit the correct length temperature probe.

Connect this probe into the channel 1 socket. Channel 1 is to the right of the display. When

calculating the results channel 1 is given most importance and is assumed to show the product

temperature.

Select the spray probe or second container temperature probe and connect it to channel 2.

Channel 2 is to the left of the display.

Both sockets must always be occupied. To run without one of the probes you can connect a

dummy temperature probe. (A special plug marked with a ‘T’.) You can also configure a

channel to be permanently inactive: see the section “Key Plug”. An inactive channel is shown

by an X on the screen.

RPU 352, RPU 353, RPC 80, RPC 50 Page 19 of 112

Page 20

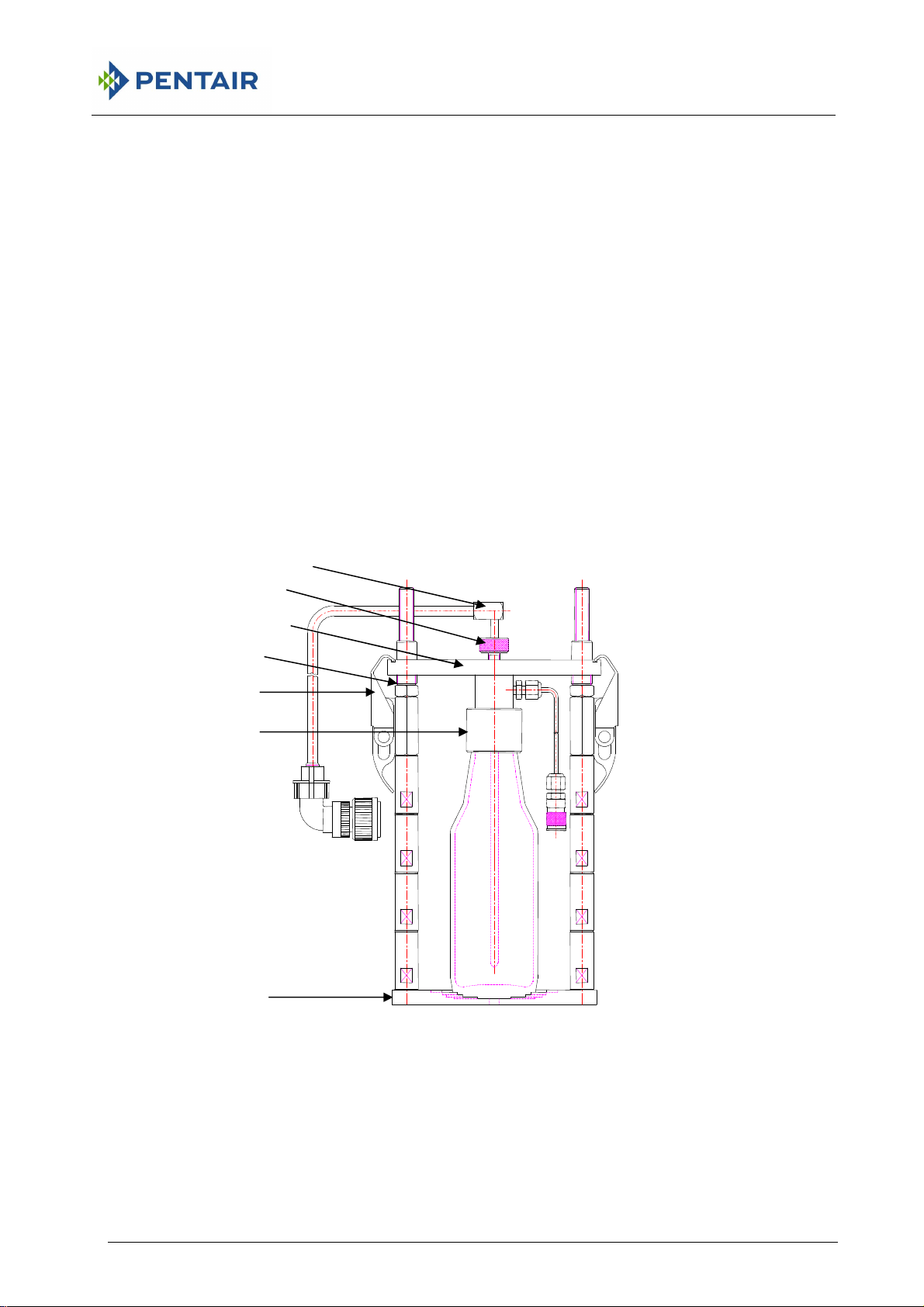

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

1

3

7

2

Only for RPU-353:

In order to make a record run the pressure sensor can be connected in the same bottle as the

temperature sensor.

Preparation for measurement in bottles and cans. For bottles an additional centre ring (1) is

needed to centre the bottle. Preparations are:

1. Adjust the Piercing mechanism (2) by placing a sufficient amount of distance tubes

Bottle length = 80 (base ring) + n x 40 (distance ring) + n x 5 (distance ring)

2. Tighten nut (3).

3. Place bottleor can on the base (4)

4. Lower the plate with pressure adapter and temperature sensor (5).

5. Close the piercing mechanism (2)

6. Optional snifting. By pushing the levers (2) up and down quickly, the pressure in the

bottle or can gets down to the atmospheric pressure

7. Push the temperature sensor (6) down into the bottle and adjust the sensor with the

screw (7). This process is described in the section “Appendix 1: Background Information”

6

5

2

4

Page 20 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 21

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

5.2 PRESSURE ZERO SETTING

Only for PRU-353

Before you connect the pressure fitting to the PRU-353 you should set the zero

point of the pressure channel (channel 3). This setting should be made before

each recording run and compensates for changes in atmospheric pressure. With

the pressure port open to the atmosphere activate the bottom right switch (0).

After the zero has been set you can connect the pressure fitting to the port and

then pierce the container to let the pressure reach the sensor. The pressure port

(channel 3) is on the back edge of the instrument to the left of the display.

5.3 THERMOMETER

When the instrument is ready to record, the temperature of the probes is shown

on the display, updated every second.* In this form the instrument can be used

as a highly accurate thermometer.

5.4 STARTING THE RECORDING

When you are ready to put the instrument into the pasteuriser, start recording by

activating the top right switch ().

*

The illustration shows the English language version in °C and bar. The text changes according to the language and

units selected for the display.

RPU 352, RPU 353, RPC 80, RPC 50 Page 21 of 112

Page 22

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 22 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 23

2

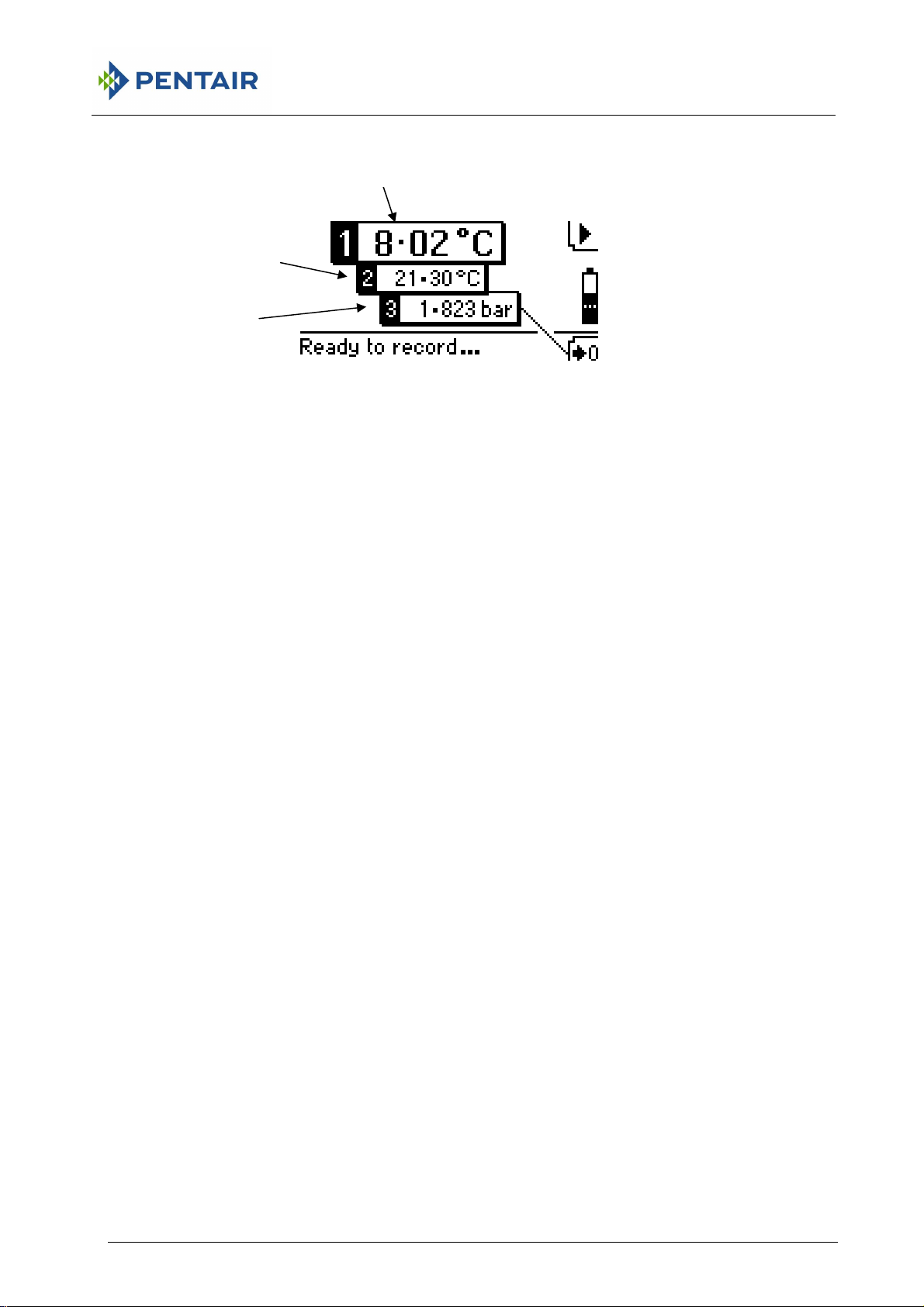

6 RECORDING

Only for PRU-353:

The temperature of the probes, the pressure sensor reading and the elapsed

recording time are shown on the display throughout the recording run.*

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

Stop

recording

Animated

Elapsed

6.1 STOPPING THE RECORDING

When the instrument exits from the pasteuriser you can stop the recording by

activating the top right switch () or by unplugging either probe. Recording will

also stop after the maximum time (4 hours) or if the charge in the battery

becomes too low.

As soon as recording stops the results are displayed.

You can record again without erasing the previous file. Use the top right switch

to access the main menu and then select “Record Again”. (See “Results”

section.)

6.2 SCREEN TEMPERATURE

The display screen will switch off if the instrument is too hot (above 70°C). This

avoids damage to the screen. Recording will continue normally under these

conditions and the flashing green indicator lamp shows that the instrument is

operating. Normal display operation will resume as soon as the instrument has

cooled.

Warning

The instrument should never be operated at temperatures above

the maximum ambient temperature shown in the specifications

.

.

*

The illustration shows the English language version in °C and bar. The text changes according to the language and

units selected for the display.

RPU 352, RPU 353, RPC 80, RPC 50 Page 23 of 112

Page 24

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 24 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 25

2

7 RESULTS

The calculated results are displayed as soon as recording stops. It is also

possible to select different representations of the results.

7.1 RESULTS DISPLAYS

There are three different results displays and they can be selected from the main

menu. The right hand switch above all the results screens gives access to this

menu. Later in this manual the “Menus” section explains the operation of the

menus in detail.

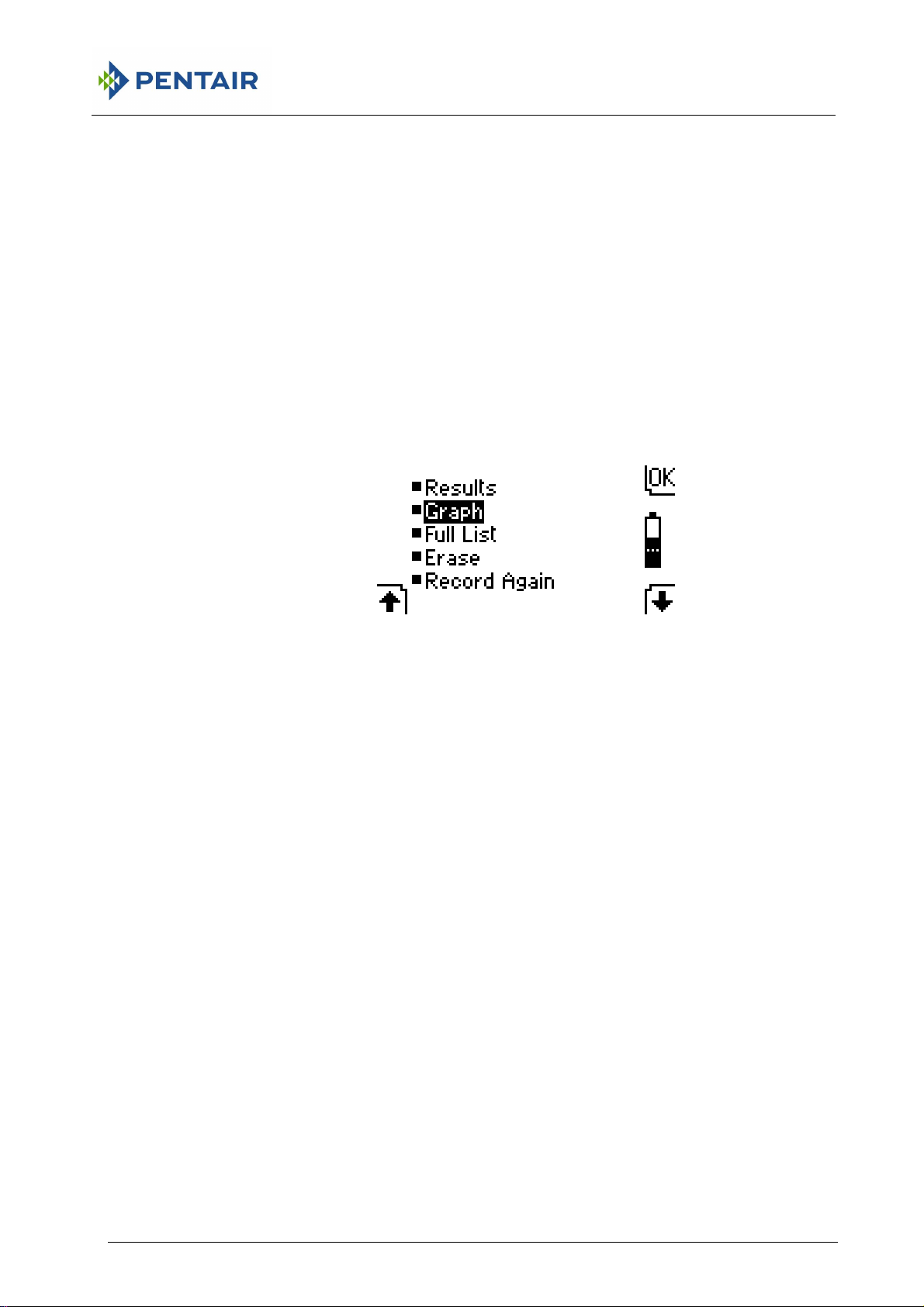

7.2 MAIN MENU

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

• The calculated Results such as the total PU achieved.

• The Graph of the file with a movable cursor that allows you to select one

record to be shown in detail.

• The Full list of all the records in the file in detail.

• Erase the recorded file(s). See more details below. You should print out

important files or copy them to a PC before you erase them.

• Record again without erasing the previous file(s). Up to four files can be

saved in the instrument at any one time. When the memory is too full to save

any more files, or when the battery is being charged, this item is not shown.

Files that have been printed using the RPC-80 printer/charger unit must be

erased before you can record any more files.

If more than one file has been recorded you will be asked to choose the file you

wish to show.

7.3 CALCULATED RESULTS

The results are set out on five “pages” with up to 3 items on each page. The right

hand switch below the screen () is used to move to the next page and then

from the final page back to the first ().

On the screen the channel number relating to each result is shown at the left

hand side of each line as a white figure on black. Channel 1 is given most

importance and is assumed to show the product temperature.

RPU 352, RPU 353, RPC 80, RPC 50 Page 25 of 112

Page 26

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

• The total PU value achieved (channel 1)

• The unique ID number of the file

• The total recording time (and optional date & time †)

• The maximum temperature recorded (channel 1)

• The total time during which the temperature was within 2°C of the maximum

• The temperature at the exit from the pasteuriser (channel 1)

• The total PU value achieved (channel 2)

• The maximum temperature recorded (channel 2)

• The total time during which the temperature was within 2°C of the maximum

• The PU cut-off temperature (applies to both temperature channels)

• The total time accumulating PU’s: i.e. while temperature was at or above the

• The total time accumulating PU’s (channel 2)

• The maximum pressure recorded (channel 3)

• The total time during which the recorded pressure was within 0.2 bar of the

• The reason for stopping recording

All these results are calculated wherever possible. If the file contains any offscale records (outside the recording range of the instrument) then some results

may be invalid. A warning is shown if this is the case and some items may be

shown as “unknown”. Off-scale records can be caused by a faulty temperature

probe.

† If the instrument’s clock has been set then the date and time at the start of

the recording is shown alternating with the total recording time. See section

“Key Plug” for clock setting.

(channel 1) *

(channel 2) *

PU cut-off temperature (channel 1)

maximum (channel 3) *

7.4 ERASING A FILE

When files are no longer required you can remove them by selecting the Erase

option from the main menu. The “Menus” section explains the operation of the

menu in detail.

Move the menu highlight to Erase and hold the actuator on the top right (OK)

switch for ten seconds. The display shows you what is happening. All recorded

files are erased together. After the files have been erased you can release the

switch and the instrument will be ready to record again.

When you use the RPU-352, PRU-353with the RPC-80 printer/charger unit you

can erase the files, after they have been printed, by using the control panel of the

RPC-80. Files that have been printed using the RPC-80 must be erased before

you can record any more files.

*

The limits for this result vary according to the display units selected.

Page 26 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 27

2

8 CALCULATED RESULTS

Shows the data in the recorded file reduced to the most important details.

8.1 TOTAL PU ACHIEVED

The total number of Pasteurisation Units accumulated during the recording run.

This is calculated using your chosen definition of PU and cut-off temperature.

You can change the PU calculation by using the key plug. More details of the

calculation are given in the “Key Plug” section and in appendix I Background

information.

Your packaging specification will normally set the PU definition and a target PU

value for each product to ensure sufficient pasteurisation.

8.2 UNIQUE ID NUMBER

This file identity number is a combination of the instrument serial number and a

running number that advances for each recording. It is therefore unique to the

file.

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

8.3 TOTAL RECORDING TIME

The total elapsed time from the moment you start recording by activating the

switch until recording stops. Recording may be stopped in a variety of ways either

under your control or automatically. (The reason for stopping is given as the final

result.)

If the instrument’s internal clock has been set then the date and time the

recording started is also shown. These extra items show alternately with the total

recording time.

8.4 MAXIMUM TEMPERATURE

The maximum recorded temperature.

Your packaging specification may call for a certain maximum product

temperature and exceeding it could produce unacceptable flavour changes.

8.5 TIME NEAR MAXIMUM TEMPERATURE

The total time during which the temperature was within 2°C of the maximum.

This gives an approximate value for the time the product was within the

pasteuriser holding zone. The limit for this result changes to 4°F when

temperature is displayed in Fahrenheit.

RPU 352, RPU 353, RPC 80, RPC 50 Page 27 of 112

Page 28

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

8.6 TEMPERATURE AT PASTEURISER EXIT

The moment that the instrument leaves the pasteuriser is judged by a rise in light

level from the relatively dark interior. Inspection lights inside the pasteuriser may

prevent this result from being calculated. The light sensor can be seen on the

front panel between the two left hand control switches, don’t cover this area with

tape or adhesive labels.

Your packaging specification may call for a maximum product exit temperature. If

the product leaves the pasteuriser at too high a temperature the flavour may be

impaired.

This result is shown for channel 1 only because that channel is assumed to show

the product temperature.

8.7 PU CUT-OFF TEMPERATURE

At or above this temperature PU’s are accumulated. Below this temperature they

are not. The cut-off temperature can be adjusted by using the key plug. More

details of the cut-off and the PU calculation are given in the “Key Plug” section.

Your packaging specification may call for a particular PU cut-off temperature to

ensure that pasteurising conditions are correct.

8.8 TIME ADDING PU’S

The total time during which the product temperature was high enough for PU’s to

be achieved and added to the total. The product temperature was at or above

the cut-off temperature for this length of time.

8.9 MAXIMUM PRESSURE

Only for PRU-353

The maximum recorded gauge pressure.

Attention!

Your container specification will show a maximum acceptable

internal pressure and exceeding it could lead to leakage or container

damage.

8.10 TIME NEAR MAXIMUM PRESSURE

The total time during which the gauge pressure was within 0.2 bar of the

maximum. The limit for this result changes to 4 psi or 0.2 kg/cm2 when pressure

is displayed in alternative units.

Only for PRU-353

8.11 REASON FOR STOPPING

You can stop recording by activating the switch or by unplugging either probe.

Recording will also stop after the maximum time (4 hours) or if the charge in the

battery becomes too low.

Page 28 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 29

2

menu screen

cursor

Channel 1

Channel 2

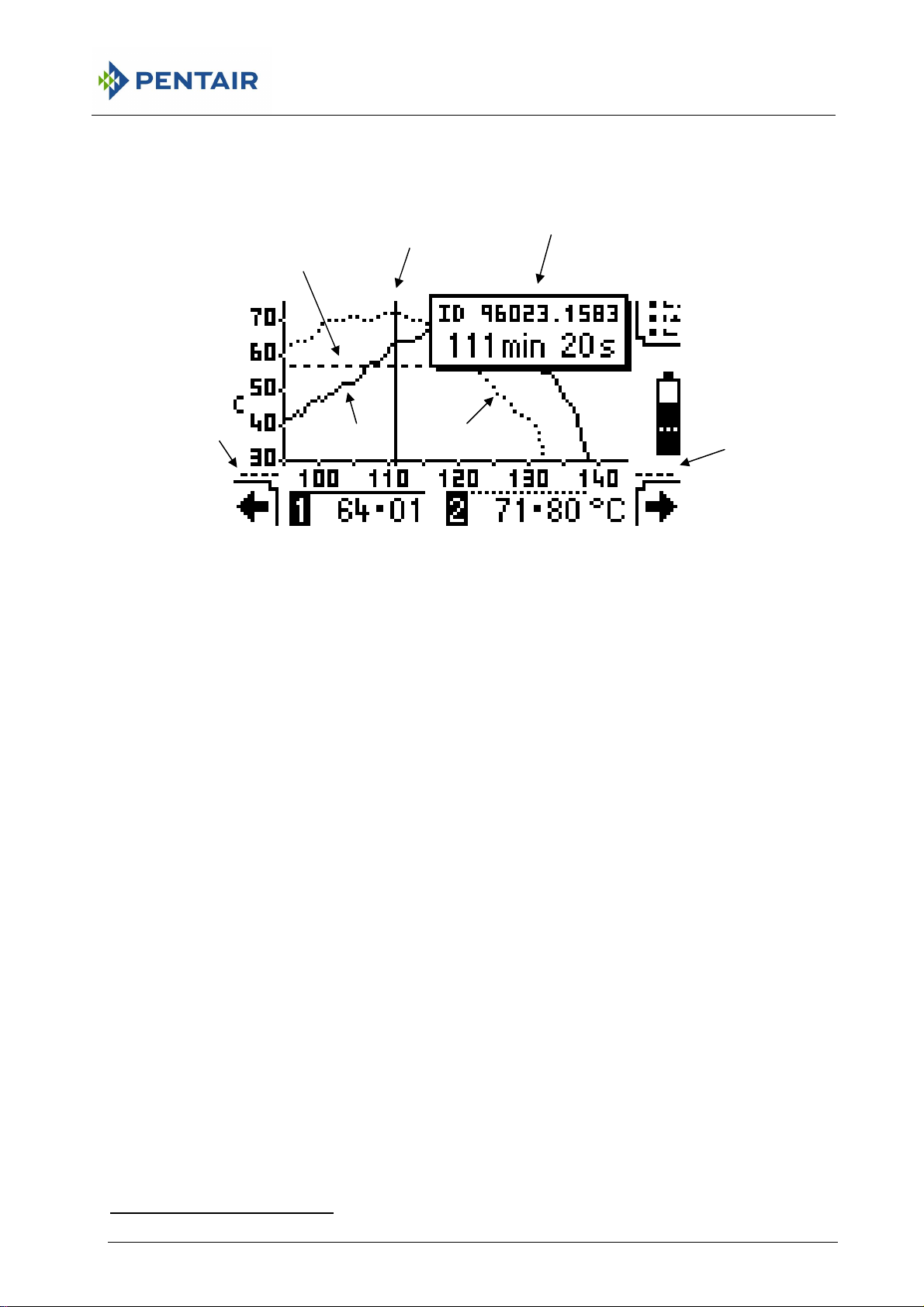

9 GRAPH

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

Indicates that

graph extends

PU cut-off temperature

to left

Move cursor

to left

Shows the data in the recorded file as a graph. The temperature (in the selected

display units) runs up the vertical axis and elapsed time (in minutes) runs along

the horizontal. *

This panel appears

Flashing

Full details of record under cursor

when cursor moves

Return to

Indicates that graph

extends to right

Move

cursor to

right

9.1 CURSOR MOVEMENT

The record under the cursor is shown in detail below the graph. The two switches

below the screen are used to move the cursor. Moving the cursor to the right

moves it towards the end of the file.

The cursor moves by one record as soon as you operate the switch. If you hold

the switch for a short time then the cursor starts to move continuously, slowly at

first and then faster, for as long as the switch is held. When the cursor reaches

the last record in the file the switch outline becomes dim and it no longer has any

effect.

Moving the cursor to the left (towards the start of the file) works in a similar way.

Whenever the cursor is moving, the elapsed time of the record under the cursor

is shown in a panel at the top right of the screen. The ID number of the file is

also shown here.

*

The illustration shows the graph in °C. The details change according to the units selected for the display.

RPU 352, RPU 353, RPC 80, RPC 50 Page 29 of 112

Page 30

2

9.2 GRAPH LINES

Channel 1 shows as a solid line on the graph while channel 2 shows as a dotted

line. The position of the PU cut-off temperature is shown as a dashed line. The

horizontal lines above each channel in the detailed record show the style of the

line for that channel.

ONLY FOR PRU-353

The pressure channel (channel 3) is not shown as a line on the graph but if the

pressure channel is active then the gauge pressure is shown in the detailed

record area alternating with the temperature records.

An inactive channel is not shown on the graph and is shown with an X in the

detailed record.

The vertical temperature scale adjusts automatically so that the maximum

reading of the highest channel is always on the graph. A record that is below the

scale leaves a gap in the graph.

If the whole graph is wider than will fit on a single screen then the cursor causes

the graph to scroll from side to side so that the required portion is visible. Small

dashed lines at the left or right of the time axis indicate that the graph extends

further in that direction.

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

:

9.3 OFF-SCALE RECORDS

Off-scale records are too high or too low to fit within the available recording range

of the instrument. The available recording range is shown in the “Specification”

section. Off-scale records can be caused by a faulty probe.

Any record that is too high or too low for the recording range does not show on

the graph and leaves a gap in the graph. In the detailed record area, records

above the top of the recording range show as a row of ‘+’ signs. Similarly a row

of ‘-’ signs indicates a record that is too low for the recording range.

Display backlight

You can use the top left switch at any time to turn on the display backlight.

Page 30 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 31

2

Channel details

10 FULL LIST

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

Elapsed time from

start of file

Move line

to left

“Time line”

shows position in file

Shows a list of all the data in the recorded file. *

10.1 TIME LINE MOVEMENT

Four records from a file can be shown in detail on the screen. The “time line”

shows the position of these records in relation to the whole file. The two switches

below the screen are used to move the time line. Moving the line to the right

shows records nearer to the end of the file.

The line moves by one record as soon as you operate the switch. If you hold the

switch for a short time then the line starts to move continuously, slowly at first and

then faster, for as long as the switch is held. When the line reaches the last

record in the file the switch outline becomes dim and it no longer has any effect.

Moving the line to the left (towards the start of the file) works in a similar way.

The time line is not shown for very short files (under 1 minute).

An inactive channel gives a blank column with an X in the header.

Display backlight

You can use the top left switch at any time to turn on the display backlight.

File ID number

ONLY FOR

PRU-353

Return to

Move line

to right

*

The illustration shows the list in °C and bar. The details change according to the display units selected.

RPU 352, RPU 353, RPC 80, RPC 50 Page 31 of 112

Page 32

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 32 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 33

2

condition

11 BATTERY CHARGING

The battery in the instrument can be re-charged by the Redpost RPC-80

printer/charger or the Redpost RPC-50 battery charger. You can connect the

charger to either socket. If you connect to the charger before recording a file you

see the complete charging information on the screen.*

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

Warning

Do not leave the battery on charge continuously for more than 24

hours.

Battery

condition*

11.1 BATTERY INFORMATION

All the other display screens show the battery condition using just the small

battery image from the complete diagram. This shows when the battery is being

charged by an arrow head that moves up the battery image. The speed of

movement shows the charge rate. The dotted line shows the minimum level of

charge needed to start recording.

Moves faster for

higher charge rate

Instrument type and serial number

Software

Level of black filling

shows battery

Charge

rate*

version

Indicates that charger

Charge above here

before recording

11.2 BATTERY TEMPERATURE

The charge rate is controlled by several factors including battery temperature.

The battery will not charge if it is too hot and in that case the arrow head in the

battery diagram will be stationary. Charging will resume as soon as the battery

has cooled.

*

The illustration shows the English language version. The text changes according to the language selected for the

display.

RPU 352, RPU 353, RPC 80, RPC 50 Page 33 of 112

Page 34

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 34 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 35

2

item

down

12 MENUS

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

Move highlight

up

There are stages in the operation and configuration of the instrument when you

need to choose an action etc. from a menu list. A menu shows all the possible

choices or items in a vertical list. The method of operation is the same in every

case although there can be as few as 2 and as many as 6 items in the menu list.

12.1 MOVING THE HIGHLIGHT

The two switches below the screen are used to move the highlight over the item

in the list that you wish to select.

The highlight moves down by one item as soon as you operate the right hand

switch. If you hold the switch for a short time then the highlight starts to move

down continuously for as long as the switch is held. When the highlight reaches

the bottom item the switch outline becomes dim and it no longer has any effect.

Moving the highlight up with the left switch works in a similar way.

Highlighted

item

Select highlighted

Move highlight

12.2 SELECTING AN ITEM

Operate the top right (OK) switch to select the item you have highlighted.

Example

RPU 352, RPU 353, RPC 80, RPC 50 Page 35 of 112

Select French

language

Page 36

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 36 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 37

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

13 KEY PLUG (CONFIGURATION)

The key plug is a special plug marked with a ‘K’ which can be inserted into either

probe socket and puts the instrument into configuration mode. This allows you to

change the way the instrument operates. The key plug restricts access to this

mode so that changes are not made unintentionally. You can use the key plug

only when there are no recorded files in the instrument and it is not connected to

an active battery charger.

The parameters you can change are presented on a series of screens. Each

screen shows the symbol of a key at the bottom. The screen first shows you the

present setting or value, if that is correct you can activate the top right (OK)

switch to move to the next screen.

Activate the lower control switches if you need to change the present value.

Sometimes you choose from a menu, sometimes change the value directly.

When the value is correct you should always activate the top right (OK) switch.

Changes you make on a screen are only saved when you activate the OK switch

for that screen.

13.1 OUTPUT TO OTHER EQUIPMENT

The settings you make with the key plug will decide how the results are shown on

the display of the RPU-352 OR PRU-353.

When used with other equipment the final output device dictates all settings.

Therefore when you use the RPU-352, PRU-353with the RPC-80 printer/charger

the settings you make on the RPC-80 and the clock in the RPC-80 will take

priority when results are calculated for printing. Similarly when connecting to a

PC the settings and clock in the PC take priority when results are displayed or

printed by the PC.

13.2 LANGUAGE

You can select the language used for the text on the display. The decimal point

symbol used for numerical output is also changed according to the language you

select. English will use the point, other languages the comma.

13.3 DISPLAY CONTRAST

You can adjust the appearance of the display to give the best contrast. This is

set during manufacture and will seldom need changing. Adjust so that the

background “off” dots become just visible compared to the clear glass at the

edges of the screen. Adjusting for the darkest “on” dots will not give the best

contrast.

The changes you can make are intentionally kept quite small. You can however

set the maximum + or – value, save it with the OK switch and then repeat the

adjustment for greater changes. See “Leaving configuration” below.

RPU 352, RPU 353, RPC 80, RPC 50 Page 37 of 112

Page 38

2

13.4 CLOCK

You can set the current date and time. Setting the clock in this way is optional. If

recorded files are printed and then erased using the RPC-80 printer/charger then

the clock settings of the RPC-80 will be automatically copied into the RPC-353. If

set, the clock will be used when results are shown on the display.

The screen first shows the present setting for the date. If you wish to make any

changes then activate the lower right (+/-) switch otherwise move on by activating

the OK switch.

You change the year, month and day by using the lower switches. A flashing

indicator appears under the item you are changing. When the first item is correct

use the top right () switch to move to the next item and so on.

If you make a mistake you cannot move the cursor backwards but you can start

the date entry process again as described in the next paragraph.

When you have moved past the last item the screen changes and you have the

chance to make more changes by activating the (+/-) switch again. If the date is

now correct you must save the changes you have made by activating the OK

switch.

The screen then changes to show the present setting for the time on a 24 hour

clock system. If you wish to make any changes then activate the lower right (+/-)

switch otherwise move on by activating the OK switch.

You change the hours and minutes by using the lower switches in the way

described above for the date. The seconds cannot be changed and will always be

set to zero. You must end by saving the changes you have made by activating

the OK switch.

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

13.5 DISPLAY UNITS

You can choose to display all temperatures in either Celsius (°C) or Fahrenheit

(°F).

Whenever you change the temperature display units the PU calculation is also

changed to the default values for those units (See below).

ONLY FOR PRU-353:

You can choose to display gauge pressures in bar, psi or kg/cm2.

Page 38 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 39

2

13.6 ACTIVE CHANNELS

You can make the channels active or inactive using this screen. Inactive

channels do not use up any storage memory and so longer recordings can be

made if required.

If you make a channel inactive in this way it will remain inactive for all recordings

until you change the setting again using the key plug. To make a temperature

channel temporarily inactive you can also use a dummy plug. (A special plug

marked with a ‘T’.) All temperature probe sockets must be occupied before you

start a recording run, even for inactive channels.

If you wish to change the active state of one of the channels then activate the

lower right (+/-) switch otherwise move on by activating the OK switch. On this

screen a tick () represents an active channel and a cross (X) an inactive one.

A flashing indicator appears under the channel you are changing. When the first

channel is correct use the top right () switch to move to the next. You can

leave a channel as it is by moving straight to the next one.

When you have moved past the third channel position the screen changes and

you have the chance to make more changes by activating the (+/-) switch again.

If the channel states are now correct you must save the changes you have made

by activating the OK switch.

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

13.7 PU CUT-OFF TEMPERATURE

You can change the cut-off temperature in steps of 0.1°C.

13.8 PU CALCULATION – BASE

You can select a Base value of 60, 70 or 80°C.

13.9 PU CALCULATION – Z

You can select a Z value of 6.94*, 7 or 10°C.

If you set a PU definition other than the standard for beer (i.e. other than Base =

60°C and Z = 7°C) the results display will show the calculation you have chosen.

*Note that 6.94°C is equivalent to a value of 12.5°F: often used in American textbooks.

13.10 PU CALCULATION – FAHRENHEIT

If you have selected to display in °F then the default PU definition will be Base =

140°F and Z = 12.5°F. The cut-off can be changed i n steps of 0.1°F. You can

select a Base value of 140, 160 or 180°F and a Z value of 12.5 or 18°F.

RPU 352, RPU 353, RPC 80, RPC 50 Page 39 of 112

Page 40

2

13.11 RECORDING INTERVAL

This screen allows you to select the time interval between recordings. You can

choose any value between 2 and 60 seconds. The factory setting is 10 seconds.

13.12 EQUIPMENT NUMBER

This screen allows you to set your own equipment number or identification for the

instrument. This can consist of up to 15 letters or numbers and will be printed

with the results by the Redpost RPC-80 printer/charger. This identification may

be required for ISO9000 schemes. Only upper case Roman script letters without

accents can be used with numerals, space, period (.) and forward slash (/).

The screen first shows the present equipment number or a series of blank spaces

if nothing has been set yet. If you wish to change or add to the equipment

number then activate the lower right (+/-) switch otherwise move on by activating

the OK switch.

You change the first character position of the equipment number using the lower

switches. A flashing indicator appears under the character you are changing.

When the first character is correct use the top right () switch to move to the next

character position and so on. You can leave a character blank by moving straight

to the next position.

If you make a mistake you cannot move the cursor backwards but you can start

the whole entry process again (see below). After entering all the characters you

want you can move quickly through any remaining blank spaces by holding the

top right () switch for a few seconds.

When you have moved past the last character position the screen changes and

you have the chance to make more changes by activating the (+/-) switch again.

If the equipment number is now correct you must save the changes you have

made by activating the OK switch.

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

13.13 MAINS FREQUENCY

Choose 50 or 60 Hz according to the nominal frequency of your local mains

supply. This setting helps the instrument to reject interference.

After you activate the OK switch for this screen you have finished the

configuration cycle.

13.14 LEAVING CONFIGURATION

Remove the key plug if you have made all the changes you need. You can

continue through another configuration cycle if you need to make more changes.

You can remove the key plug at any time or switch the instrument off using the

I/O (on/off) switch but remember that any changes you make on a screen are

only saved when you activate the OK switch for that screen.

The configuration cycle will be interrupted if you connect the instrument to a

battery charger.

Page 40 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 41

2

14 OUTPUT

The RPU-352, PRU-353instrument can be used as a stand-alone PU & pressure

monitor or it can be connected to a variety of other equipment so that the

recorded files can be permanently saved and/or printed.

14.1 STAND ALONE OPERATION

With its detailed display of calculated results, graph and full list of all records it is

possible to obtain all the information about a file directly from the display of the

instrument. The only other equipment required is a Redpost RPC-50 battery

charger.

14.2 CONNECTION TO RPC-80

The instrument connects to the Redpost RPC-80 printer/charger. Printed results

are available and a status report for the instrument can be obtained. Connection

to a PC is possible using the serial port on the RPC-80.

The settings you make on the RPC-80 will take priority over the settings in the

RPU-352, PRU-353 when results are calculated for printing. File start time will be

calculated using the clock in the RPC-80 as a reference.

When files are erased using the control button on the RPC-80 the clock settings

are automatically copied into the RPU-352, PRU-353. This applies to RPC-80

software version ‘p’ or later.

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

14.3 CONNECTION TO PC

It is possible to connect the instrument to a PC using the Redpost RPC-50

battery charger. The same connection is also possible using the serial port on

the RPC-80 (See manuals for RPC-50 or RPC-80).

Recorded files can also be copied and carried to a remote PC using an optional

hand-held infrared data transfer unit (Future product.)

The settings you make on the PC will take priority over the settings in the RPU352, PRU-353 when results are calculated for display or printing. File start time

will be calculated using the clock in the PC as a reference. The software

currently offered for the PC does not alter the clock settings in the RPU-352,

PRU-353.

RPU 352, RPU 353, RPC 80, RPC 50 Page 41 of 112

Page 42

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 42 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 43

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

15

MAINTENANCE

General

To maintain the accuracy and reliability of the equipment we recommend that it is

serviced and re-calibrated (with the probes) at regular intervals. Under light

conditions of use this should be carried out at least every 1500 recording runs.

When the equipment is heavily used, particularly where high pasteuriser

temperatures are involved as with fruit juices, then the service and re-calibration

should take place every year.

If this work is done by the manufacturers or an approved agent then the

calibration and service details can be recorded in the equipment and are

available via the status report.

The regular service will replace both temperature probe sockets and the battery

(see below) and so ensure reliable operation.

Dessicant

The dessicant in the electronics housing needs to be replaced annually.

Probe sockets

The probe sockets should be lubricated after every 50 recording runs using the

contact treatment grease supplied. This protects the sockets from corrosion and

greatly extends their service life. A lubrication reminder is shown on the display

at the correct times.

If you leave a probe or dummy plug permanently connected to one of the

channels it is important to unplug it occasionally and lubricate the socket before

replacing it. The lubrication reminder applies to all sockets.

If the equipment has not been returned for servicing as recommended above

then after about a year of heavy use (or two years of light use) then the exchange

unit should be replaced as a precaution. The exchange unit includes both

temperature probe sockets and the battery. Full fitting instructions are enclosed

with the new part.

Probes

The probes do not require routine maintenance. Handle them with care. When

re-calibrating the equipment always re-calibrate all the probes at the same time.

Only for PRU-353:

Pressure port

The pressure port should be occasionally cleaned. Remove the instrument from

its frame and stand it in a tray of hot water about 25 mm deep. The water should

just cover the pressure port. Never insert anything into the port or attempt to

remove the pressure connector.

RPU 352, RPU 353, RPC 80, RPC 50 Page 43 of 112

Page 44

2

Battery

60ºC Test Plug

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

Always switch the instrument off when it is not in use. If the instrument is left idle

it will switch off automatically.

Do not leave the battery on charge continuously for more than 24 hours.

If the equipment has not been returned for servicing as recommended above

then as the battery ages it will not hold as much charge as it did when new. The

instrument can detect this and when the problem becomes severe it may give a

warning on the display that the battery should be replaced. After about a year of

heavy use (or two years of light use) the exchange unit should be replaced as a

precaution. The exchange unit includes both temperature probe sockets and the

battery. Full fitting instructions are enclosed with the new part.

If you unplug the exchange unit and then reconnect it the instrument will assume

you have fitted a new battery. Never unplug the exchange unit unless you

intend to replace it with a new one.

If you plan to store the instrument unused for more than 6 months you should first

fully re-charge the battery. When the instrument is left unused, even though it is

switched off, the battery gradually loses charge by a process known as “self

discharge”. If possible give the battery a few hours charge every 3 months

during storage.

The supplied 60ºC Test Plug can be used as a diagnostics tool for the RPU

monitor. It can be connected to the main unit to verify the unit’s measuring

functionality. To use the 60ºC Test Plug, connect it to one of the unit’s channels.

When the unit measures a temperature between 59,8ºC and 60,2ºC with the Test

Plug connected, the unit functions correctly. When different temperatures are

measured with the Test Plug connected, the unit needs to be serviced.

Page 44 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 45

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

16 FREQUENTLY ASKED QUESTIONS

Battery

1) Sometimes the battery charge indicator doesn’t move even though the instrument is

connected to the charger. What’s wrong?

2) When I switch the instrument on it often has less charge in it than when I switched it off.

Why?

3) How long should I leave the instrument connected to the charger?

4) How long will the battery last?

5) How is battery charging controlled?

6) The display tells me that a new battery has been installed. I haven’t fitted a new battery,

what’s going on?

7) The charge rate shown on the RPC-80 is not the same as that shown on the PU monitor.

Which is correct?

Controls

8) Which switches control the display backlight?

ONLY FOR PRU-353:

9) Why can’t I zero the pressure channel? The message tells me that “error is too great”.

Results

10) If the product temperature is exactly equal to the cut-off temperature will any PU’s be

achieved?

11) The PU value displayed by the RPU-352, PRU-353is not the same as that printed for the

same run by the RPC-80. Why?

ONLY FOR PRU-353:

12) The maximum pressure value displayed by the PRU-353 is lower than that printed for

the same run by the RPC-80. Why?

13) Why is the file start time shown on the display of the RPU-352, PRU-353almost an hour

different from the start time in the results printed by my PC?

14) Why is the exit temperature sometimes not included in the results?

15) Why doesn’t the date and time of my file appear on the display of the PU monitor? It

appears correctly on the printed results from my PC.

16.1 BATTERY AND BATTERY CHARGING

1) Sometimes the battery charge indicator doesn’t move even though the instrument is

connected to the charger. What’s wrong?

Nothing’s wrong. When the battery is too hot to charge more quickly the charge rate is lowered

to the “trickle” charge rate which has to be set to a low level so that charging conditions are

safe. If the instrument is very hot then no charging is possible. When the instrument has cooled

down the charge rate will increase and refill the battery. The heat may have come from outside,

for example from the pasteuriser or from inside from the process of charging the battery itself.

When the battery is full it will also stop charging although the instrument will occasionally

increase the charge rate to “trickle” to make up for any gradual losses. The battery is quickly

refilled and charging stops again. This cycle repeats as long as the instrument is connected to

the charger. Do not leave the battery on charge continuously for more than 24 hours.

If there are no recorded files then the main battery display will show all the charging information

including the reason why the battery is not charging.

RPU 352, RPU 353, RPC 80, RPC 50 Page 45 of 112

Page 46

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

2) When I switch the instrument on it often has less charge in it than when I switched it off.

Why?

When the instrument is switched off and left unused the battery gradually loses charge by a

process known as “self discharge”. When it is next switched on the instrument estimates how

much charge has been lost in this way and compensates by reducing the charge percentage.

3) How long should I leave the instrument connected to the charger?

There is no need to leave the instrument on the charger after the battery shows 100% which is

full charge. You should not leave the charger connected for more than 24 hours.

4) How long will the battery last?

The specification shows examples of the instrument running time that can be expected from a

fully charged battery.

The service life of a battery will depend on the conditions of use. Giving an exact life time is

difficult. Heavy use at high pasteurising temperatures such as used for fruit juices will reduce

the life. Under such conditions a battery might be expected to last for about a year. With light

use and at beer pasteurising temperatures the battery might last for 2 years.

5) How is battery charging controlled?

The instrument continuously monitors its own battery use and any battery charging to gauge the

amount of charge that remains in the battery. This allows the percentage charge to be

displayed either as a number or as the black fill level on the battery information diagram.

Whenever the charger is connected the charge rate is controlled by the instrument taking into

account the state of charge and temperature of the battery and the total charging time.

Charging can be fastest when the battery is empty and cool but must be slower when the

battery is nearly full or is hot. The aim is to replace the charge as quickly as possible without

overcharging or overheating the battery. This ensures a long service life for the battery.

6) The display tells me that a new battery has been installed. I haven’t fitted a new battery,

what’s going on?

If you unplug the exchange unit (which includes the battery) and then reconnect it the

instrument will assume you have fitted a new battery. NEVER UNPLUG THE EXCHANGE

UNIT unless you intend to replace it with a new one. See the “Maintenance” section of the

operating manual.

If the battery voltage falls to a low level and then recovers it may appear as though the battery

was removed and replaced by a new battery. This can happen if the battery is failing to hold its

charge after a year or two of use. It might also happen if the instrument has been switched off

and left unused for a long period (six months or more).

A new battery must be charged to a certain level before use and so the instrument must be

connected to the charger for several hours. The instrument display gives information about this

commissioning process.

Page 46 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 47

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

In your case the instrument has wrongly sensed a battery change. You should follow the

instructions on the display and charge the battery as if it were new. The internal clock settings

and any saved files will have been lost. If the same problem occurs again within a short time

then the battery is beginning to fail and you should fit a new exchange unit.

7) The charge rate shown on the RPC-80 is not the same as that shown on the PU monitor.

Which is correct?

The RPC-80 is compatible with the RPU-352, PRU-353PU & pressure monitor but it was

designed for use with equipment that has a different battery type. The definitions of the charge

rates are not exactly equivalent but charging will take place correctly. Refer to the display on

the PU monitor for the correct charging information.

16.2 CONTROLS

8) Which switches control the display backlight?

The display backlight is switched on by any of the following actions: activating any switch (even

those that have no other function at the time), plugging or unplugging anything into either socket

or starting any communications activity that causes a message to be displayed. The backlight

will switch off again after one minute unless another action keeps it on.

If you only wish to switch on the backlight you should use the I/O (on/off) switch because then

there is no chance of the switch causing any other unwanted operation (unless you hold it for

more than 10 seconds!).

ONLY FOR PRU-353:

9) Why can’t I zero the pressure channel? The message tells me that “error is too great”.

You should set the zero for the pressure channel before each recording run to compensate for

changes in atmospheric pressure. Therefore, the pressure port must be open to the

atmosphere and so you should set the zero before you connect up to the pressure fitting on the

container. The pressure must be within ±0.5 bar of standard atmospheric pressure otherwise

the zero correction cannot be made.

If the port is open to the atmosphere and you still get the message “Can’t set zero - the error is

too great” then the pressure port may be blocked. This is most likely to be a problem when

pasteurising soft drinks with high sugar content. Clean the port as directed in the “Maintenance”

section of the operating manual. If the problem persists then there may be a fault in the

pressure sensor.

RPU 352, RPU 353, RPC 80, RPC 50 Page 47 of 112

Page 48

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

16.3 RESULTS

10) If the product temperature is exactly equal to the cut-off temperature will any PU’s be

achieved?

Yes, PU’s will be achieved and added to the total. The precise definition of the PU cut-off (see

“Results” section of the operating manual) is as follows: “At or above this temperature PU’s are

accumulated. Below this temperature they are not.”

This definition also applies to the timing result displayed as “Adding PU’s” but often printed as

“Time above cut-off”. The definition of the result has always been the same but in printed

results the headings used in the past were not always so precise.

11) The PU value displayed by the RPU-352, PRU-353 is not the same as that printed for the

same run by the RPC-80. Why?

Remember that the final output device dictates all settings for PU calculation, date and time.

The RPC-80 recalculates the results from the raw data based on values you choose when

setting up the RPC-80. The clock in the RPC-80 is also used as a reference for the file timing.

These features make it easy to maintain a plant-wide standard for PU calculations and the date

& time and to change those standards without making modifications to all the monitors. When

using the RPU-352, PRU-353 with the RPC-80 you must be aware that different standards for

PU calculation (including PU cut-off temperature) may apply to the displayed and printed

results.

The same applies when connecting the PU monitor to a PC. The settings you make in the

program running on the PC will take priority over the settings in the RPU-352, PRU-353 when

results are calculated for display or printing. File start time will be calculated using the clock in

the PC as a reference.

ONLY FOR PRU-353:

12) The maximum pressure value displayed by the PRU-353 is lower than that printed for the

same run by the RPC-80. Why?

The final output device dictates all settings for PU calculation, date, time, etc. and this also

extends to the pressure results. The previous answer gives more details.

The RPC-80 can be set to make a correction for errors introduced by the older pressure fittings

where the head space in the can is very small. These errors are very small for the more recent

pressure fittings and so these corrections are not made in the PRU-353. We recommend that

the head space correction in the RPC-80 is turned off. See the RPC-80 configuration manual.

13) Why is the file start time shown on the display of the RPU-352, PRU-353 almost an hour

different from the start time in the results printed by my PC?

The final output device dictates all settings for PU calculation, date and time. The previous

answers give more details. In this case the clock in the PC was probably adjusted automatically

for Summer Time (Daylight Saving) but you have not changed the clock in the RPC-353.

If the PU monitor is used with the RPC-80 printer/charger then the clock will be automatically

Page 48 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 49

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

updated every time files are printed out and then erased. (The software in the RPC-80 must be

version ‘p’ or later.) This makes it easy to maintain a plant-wide standard for date & time

without making modifications to all the monitors. The software used in the PC does not

currently offer this facility.

14) Why is the exit temperature sometimes not included in the results?

The moment that the instrument leaves the pasteuriser is judged by a rise in ambient light level

from the relatively dark interior. If there are inspection lights inside the pasteuriser or if for any

other reason the light level is too high inside the pasteuriser or too low outside it (where the

instrument exits) then the result may not be calculated. It may be necessary to improve the

lighting at the exit end of the pasteuriser particularly during night shifts.

The sensing sequence is triggered by the channel 1 temperature first rising above the PU cutoff temperature and then falling below it again before the exit from the pasteuriser. If this does

not happen then the result is not calculated. (Channel 1 is assumed to read the temperature of

the product.)

The light sensor can be seen on the left of the instrument’s front panel between the two left

hand control switches, don’t cover this area with tape or adhesive labels.

15) Why doesn’t the date and time of my file appear on the display of the PU monitor? It

appears correctly on the printed results from my PC.

The date and time when the file recording started is shown on the first page of results only if the

instrument’s internal clock has been set. These extra items are shown alternately with the total

recording time. When the PC is used to print the results the clock in the PC is used as a

reference for the file timing.

If you wish to see the file start date and time on the display then you must set up the internal

clock.* See “Key Plug” section of the operating manual. As supplied the instrument’s clock is

not usually set. When a new exchange unit is fitted (which includes the battery) the internal

clock settings are lost.

* If the PU monitor is used with the RPC-80 printer/charger then the clock will be automatically

set or updated every time files are printed out and then erased. (The software in the RPC-80

must be version ‘p’ or later.) This makes it easy to maintain a plant-wide standard for date &

time without making modifications to all the monitors. The software used in the PC does not

currently offer this facility.

RPU 352, RPU 353, RPC 80, RPC 50 Page 49 of 112

Page 50

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 50 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 51

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

INSTRUCTION MANUAL

RPC-80

PRINTER/CHARGER

Essential reading!

Page 52

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 53

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

17 TECHNICAL SPECIFICATIONS

Voltage : 82-275V, 50/60Hz

Dimensions (LxWxH) 310x240x150 mm

Weight 4,5 kg

Charging time 6 hours for full charge (300 serie)

Display LCD, back illuminated, 2 lines, 24 characters

Outputs USB for printing

RS-232

RPU 352, RPU 353, RPC 80, RPC 50 Page 53 of 112

Page 54

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 54 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 55

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

18 INTRODUCTION

The RPC-80 converts the data from the RPU.-351, RPU-352 and RPU-353 into an easy to

understand tabulated result that is printed on a separate printer by just pressing one button.

Furthermore the data can be passed on to a computer. The instrument has a menu driven

operation programme which enables adaptation of the instrument to any pasteurisation process.

Adjustable are among others:

• P.U.-calculation formula (base-value and Z-value).

• Lower cut-off temperature.

• Graph format.

• Units of temperature and pressure.

• Language.

• Calibration check timing (for ISO 9000 certification).

• Furthermore 8 templates can be stored so that a recording run can be simply qualified.

A limited number of adjustments apply to the combination with the RPU.-120 monitor.

RPU 352, RPU 353, RPC 80, RPC 50 Page 55 of 112

Page 56

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 56 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 57

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

19 UNPACKING

Before despatch the PRU-352 / RPU-353 was checked and tested by Haffmans BV. Make sure

that the content of the delivery is complete and undamaged.

If the delivery is incomplete or damaged, please contact Haffmans BV or the representative/agent

designated by Haffmans BV, immediately (appendix IV). Always include the serial number, order

number or invoice number (given by Haffmans BV) of the PRU-352 / RPU-353 in the

correspondence.

The delivery contains:

• Play back unit type RPC-80.

• Connecting cable.

• USB printer cable.

• Mains cable (depending on the destination; Euro, CH, I, GB, USA, Aus).

• Cd-rom Redlink-II.

• Instruction manual PRU-352 / RPU-353, RPC 80, RPC-50.

• Instruction Manual Redlink-II.

RPU 352, RPU 353, RPC 80, RPC 50 Page 57 of 112

Page 58

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

•

Page 58 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 59

2

20 CONTROL PANEL

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

Warning

Haffmans

-REDPOST RPC-80

Fig. 20.1 Control panel

Before using the RPC-80 first carefully read this chapter

2 Line display

3 Switches

RPU 352, RPU 353, RPC 80, RPC 50 Page 59 of 112

Page 60

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

Page 60 of 112 RPU 352, RPU 353, RPC 80, RPC 50

Page 61

2

Link to

21 USE

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

Warning

Read this chapter carefully before using the RPC-80. The RPC-80 is not

waterproof.

21.1 SWITCHING ON

Switch on the mains switch of the RPC-80. The display will light up and briefly show time and

date. The Canon printer must be switched on, don't try to start printing until the "on line" lamp is

lit steadily. Always check that there is enough paper in the Canon printer before starting to use

the RPC-80.

21.2 CONNECTING THE MONITOR

The RPC-80 will now be showing

Connect a monitor that has some files recorded in it, use the same lead to connect to the new

2OO series and the older 100 series monitors. For connections see fig 5.1.

ATTENTION

!

If the P.U. monitor has two sockets, use socket number 1.

"TRYING TO COMMUNICATE WITH MONITOR..."

monitor

Mains Power In

On /OFF

Data to printer

DC power to

printer

Haffmans-REDPOST RPC-80

Fig 21.1 RPC-80 connections

RPU 352, RPU 353, RPC 80, RPC 50 Page 61 of 112

Page 62

2

21.3 PRINTING RECORDED FILES

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

ATTENTION

When a monitor has been connected the display changes to

serial number and the word

show its function. Press this button. The display changes to

recorded files are printed out. All the pages of the printed graphs, results and listed data for one

recording run are identified by the same unique file number (200 series monitors) or print run

number (100 series monitors).

!

Do not switch the P.U. Monitor off until all printing has been completed.

Leave the P.U. monitor connected to the printer charger until the

required charging time is over.

PRINT

"FOUND...",

appears on the bottom line over the left hand button to

"PRINTING..."

and the monitor

and all the

21.4 AFTER PRINTING

After the printing is finished the print run can be started again.