PENTAIR ENVIRONMENTAL SYSTEMS

Version 1.1

Thank you for purchasing the Greenspan Pressure Sensor Model PS7000. This manual provides a guide to the

configuration, operation and maintenance of these sensors to provide long term reliable and accurate monitoring.

The Greenspan PS7000 is fully submersible Pressure Measurement Sensor designed for remote applications. It

utilises a sophisticated capacitive ceramic pressure sensitive diaphragm. Its special features include high overload

protection (up to 60 times nominal pressure) corrosion resistance and long term stability. The change in the

capacitive element varies with applied pressure. This variation is measured by an electronic circuit and converted

into an analogue output. The sensor can be supplied in a variety of standard ranges.

The PS7000 has a standard, 2-wire, loop powered, 4-20mAoutput with an option for 0-2.5Vdc suitable for a wide

range of Data Loggers, Process Controllers and other third party devices. New features include the ability to rerange the sensor as well as adjust the fluid density and gravity to suit specific applications.

The instrument is packaged in a small, robust, stainless steel housing fully sealed against moisture penetration and

is hardwired to either vented or non-vented cable supplied by Greenspan.

The sensors are suitable for applications in harsh remote applications including groundwater, streams and rivers,

water storage bodies including stratification studies, hydrological run off studies and industrial process

monitoring.

Along with this manual, there are several other documents that may assist in the successful configuration and

operation of the Greenspan PS7000 Sensor. These should be maintained on file as a permanent reference as to

the features, applications and use of the PS7000.

Greenspan PS7000 – Specifications Brochure

Greenspan PS7000 – Certificate of Conformance

Greenspan PS7000 – Quick Start Guide

The PS7000 sensors are assembled and tested in accordance with Greenspan’s ISO 9001 Quality

Certified System. Following calibration the sensors undergo a range of additional control processes to ensure that

all specifications are consistent and documented.

The instrument is visually inspected, marked and labelled.

The complete sensor calibration record is archived for reference, and batch number information is kept

on file for statistical analysis.

An individual Certificate of Conformance is issued to the customer.

All Greenspan Sensors are made to order and are individually calibrated and inspected. This ensures that they

leave the factory in a working condition. On receipt, the customer should inspect the packaging and contents for

any signs of damage during transportation. The customer should also check that all items on the delivery note

have been received.

Please contact the factory in case anything has been damaged or missing. A full set of documentation including

Certificate of Conformance, Quick Start Guide, and User Manual will be provided with all equipment – either in

hard copy format or in electronic format on the USB shipped with the goods.

The 316 Stainless Steel, PS7000 sensor should only be used in relatively low EC situations. Stainless steel has

excellent anti-corrosion properties but care should be taken against possible corrosion in high Chloride or Ferric

solutions, water with high iron or sulphate reducing bacteria, or low dissolved oxygen. Greenspan offer a PS1000

Sensor fitted with an Acetal body which provides superior corrosion protection in a wide range of chemically

active waters.

Because an individual sensor may be used in a variety of locations, media compatibility should be checked before

installing and advice sought from Greenspan if any doubt exists.

Checking the Model Number and Range

Before installing your Greenspan PS7000 sensor check the information on the label is correct to confirm you have

received the instrument you have ordered. The label will look similar to this.

MODEL PS7000

RANGE 0 – xx m

S/N 012345

The customer is advised to keep a record of the serial numbers in case the sensor is lost or the label damage.

Greenspan keeps records of all sensors sold including a calibration history.

Greenspan warrants all new Greenspan products against defects in materials and workmanship for 12 months from

the date of invoice. Products that prove to be defective during the warranty period will be repaired or replaced at the

discretion of Greenspan.

Under Greenspan warranty conditions; it is the responsibility of the customer to cover shipping charges back to the

factory. Upon repair/replacement Greenspan will cover the return shipping charges to the customer.

This warranty does not apply to products or parts thereof which have been altered or repaired outside of the

Greenspan factory or other authorised service centre; or products damaged by improper installation or application, or

subjected to misuse, abuse neglect or accident. This warranty also excludes items such as reference electrodes and

Dissolved Oxygen membranes that may degrade during normal use.

Greenspan will not be liable for any incidental or consequential damage or expense incurred by the user due to partial

or incomplete operability of its products for any reason whatsoever or due to inaccurate information generated by its

products.

All Warranty service will be completed as soon possible. If delays are unavoidable customers will be contacted

immediately.

Any sensor should not be dismantled unless under instruction from Greenspan Technical Service staff. Incorrect

handling will void the warranty.

The correct choice of sensor and assistance with field installation can be provided by Greenspan and their sales

offices. A correct choice of equipment, together with technical advice and field experience should result in long term

success in the field. Greenspan Technical Services is dedicated to customer support and provides assistance in the

selection, installation, deployment and commissioning of sensors with a full range of consulting services. All

Greenspan products are designed, developed and manufactured in Australia and can be supplied at short notice.

If for some reason sensors are required to be returned to our factory or your sales representative, please note the

model and serial number, Describe the problem, including how and under what conditions the instrument was being

used at the time of malfunction. Clean the product and cable. Decontaminate thoroughly if used in toxic or hazardous

environment. Carefully pack product in original packaging if possible & include a statement certifying product and

cable have been decontaminated with supporting information. Products returned for repair must be accompanied by

a completed GRA (Goods Return Advice) form. All sensors returned for service and repair work must be properly

decontaminated prior to return. A cleaning charge may be applied to sensors that require further decontamination.

Service work will not commence until the quotation has been accepted by the customer. A purchase order for all

repair and service work will be required before work is carried out.

The PS7000 Pressure Sensor utilizes a ceramic-based, capacitive element as the transducer. This is designed to be of

rugged construction and incorporates active electronics as an integral part of the transducer substrate to enhance

reliability and accuracy. Force applied to the ceramic element, due to the pressure, deforms its shape. This

deformation causes a change in capacitance which can be measured by the electronics. The inherently stability and

toughness of the ceramic ensures the repeatability and long term accuracy of the readings are maintained under the

harshest field conditions.

The on board microprocessor converts the transducer output voltage to a digital signal and also measures the

transducer temperature. This information is used to temperature compensate the sensor over the range 0 - 50°C. The

result is converted to an analogue output of typically 4-20mA.

Benefits of the Ceramic Capacitance Sensors over other types of sensors are:

Extremely high overload limit (typically up to 10 X overload protection)

Absolute resistant to wear

High temperature stability

Excellent Long term stability

Excellent Repeatability and linearity

No hysteresis effects normally associated with Strain Type Sensors

Corrosion resistant – Other sensors require contact of stainless steel face

Not subject to mechanical fatigue that may affect strain gauge type sensors

Low power consumption suitable for remote monitoring & control units

When pressure sensors are used for depth readings of any fluid, the density becomes an important parameter. In

Australia a standard describes the relationship between force and water depth:

Australian Standard AS1376-1996 *

1kPa = 102.15 mm of pure water. @20degC

There is typically a 3% difference in the density between pure water and seawater. This difference should be

considered when particular measurement accuracy’s are required.

Another factor affecting calibration accuracy is gravity. The departure from standard gravity in Warwick, Qld is –

0.17%. at latitude 27.973 deg, height 458m above sea level.

The PS7000 has a feature to adjust the fluid density and gravity to suit specific applications.

*For conditions, see Clause 1.3.8.3 Australian Standard AS1376

Applications in which the Greenspan PS7000 can be used include:

Monitoring of streams and rivers.

Monitoring of water storage bodies including stratification studies.

Hydrological run off studies.

Ground and bore water analysis.

Industrial process monitoring.

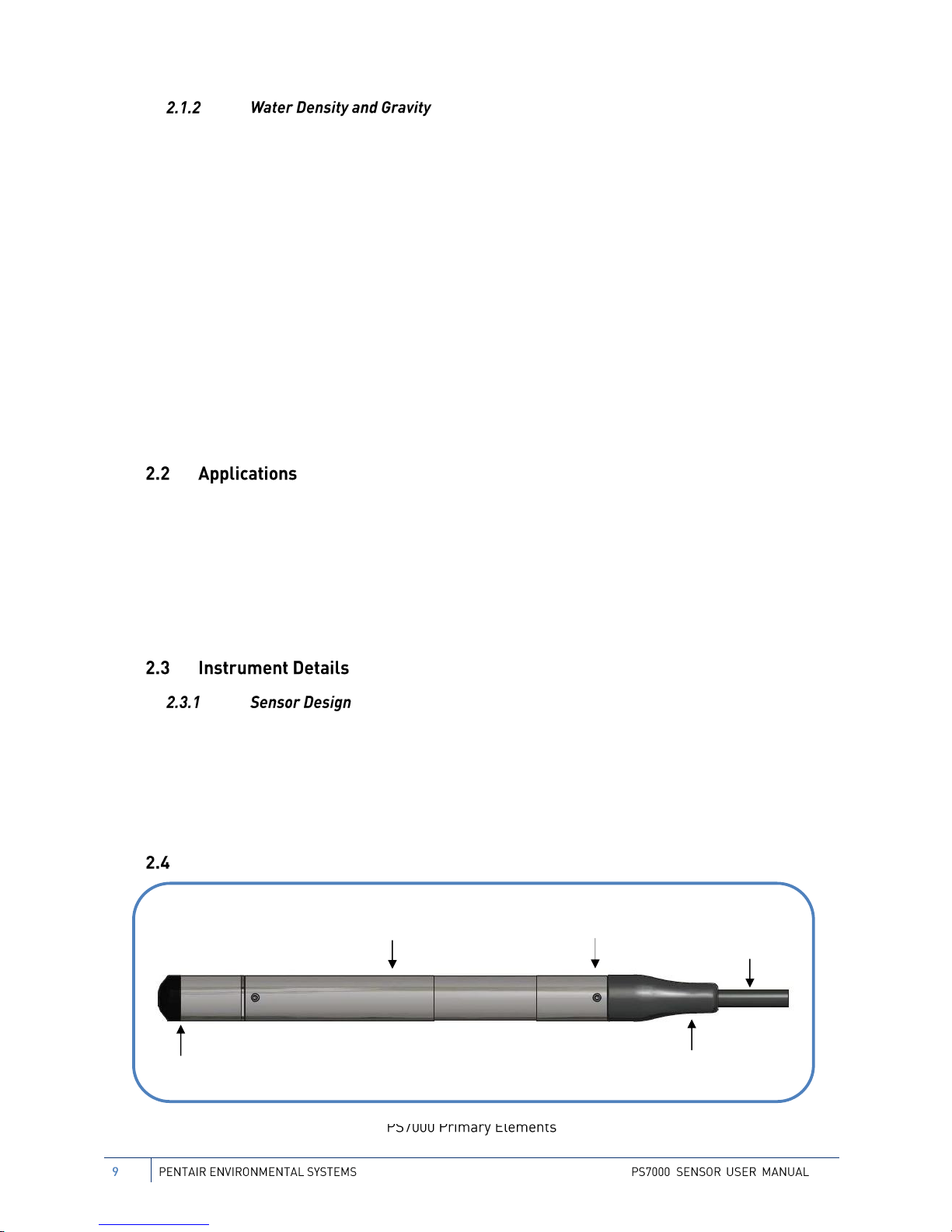

The Greenspan PS7000 consists of the following primary elements:

Ceramic capacitance transducer with Acetal protective nose cone

22.5mm outer diameter

Stainless steel body material

Moulded cable entry

Power and

Data Cable

Moulded Cable Entry

22.5mm OD 316SS Body

Double O Ring connections

Ceramic capacitance

transducer Acetal

protective nose cone

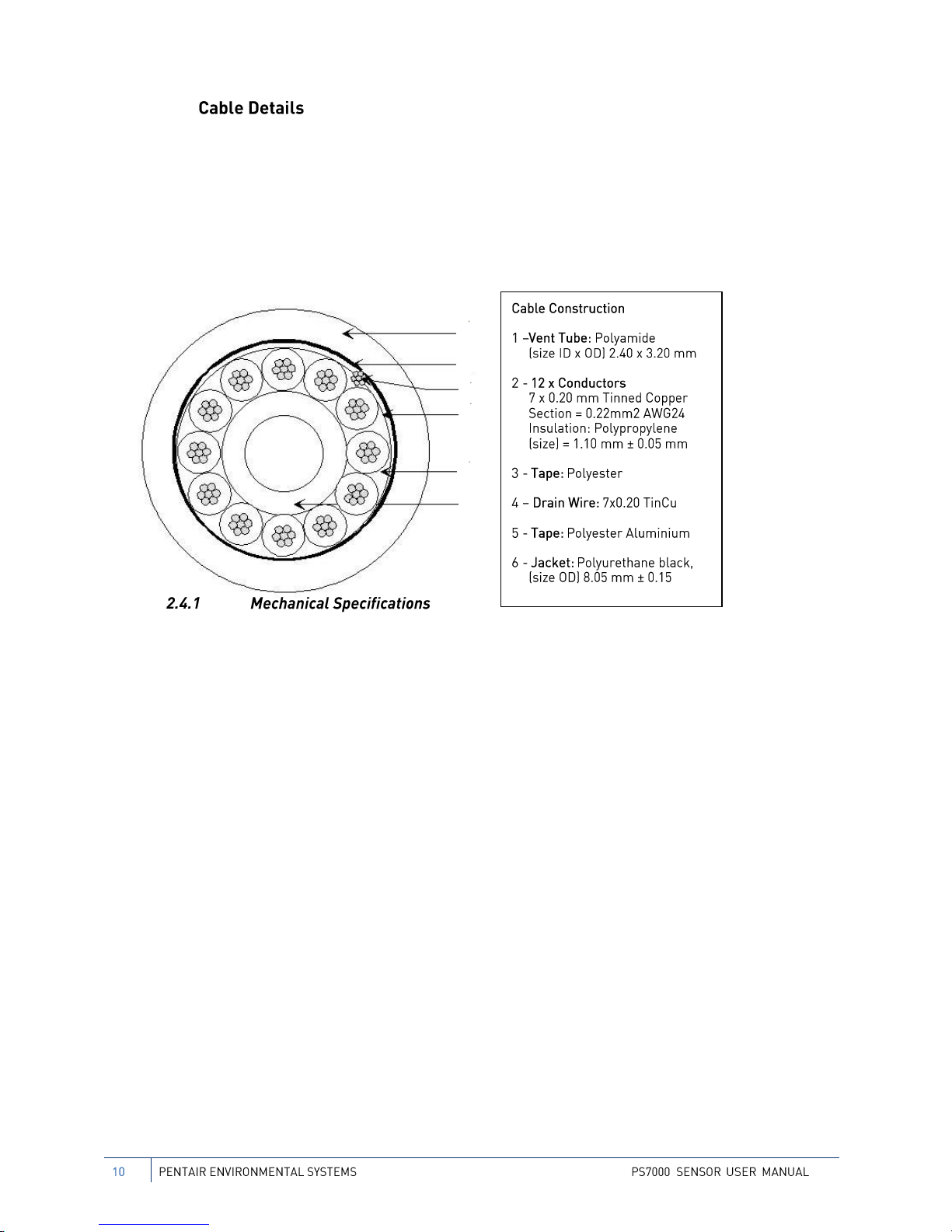

All Greenspan Sensors utilise a specially designed Polyurethane Cable. The cable contains 12 x conductors, 1 x drain

wire, and an internal vent tube. The outer jacket is made from UV stabilized Polyurethane and is suitable for all

external, underwater or harsh environment applications. This common cable construction is utilized for vented and

non-vented sensors and all Greenspan Water Quality Sensors. Cables are generally factory fitted at time of

manufacture in specified lengths. Cables can be joined or repaired in the field providing a waterproof connection can

be maintained. Alternatively, cables can be terminated in waterproof junction boxes where cabling to other devices

or longer cable runs are required.

Specially Manufactured Greenspan Cable with 12 cores and Internal Vent

High chemical resilience and abrasive resistance

Conductor cross section : AWG 24,

Electrical Resistance 9 ohm per 100m (per conductor)

Operating temperature: 85°C (max.),

Bending radius (static) : 6 ,

Bending radius (dynamic) 12.

Max Operating voltage : 250V

Jacket Printing (white colour each meter)

Conductor colour codes : green, yellow, white, black, brown,

turquoise, violet, pink, red, blue, grey

Tensile Strength is sufficient to self-suspend the Greenspan Sensor to depths of 300m.

Long term creep due to temperature effects or tensile loading is negligible.

The moulded cable is fitted to the sensor using a double o ring seal and located using 2 x grub screws. The length of

the cable is not critical to the long term calibration and operation of the sensor (provided the electrical requirements

such as minimum supply voltage are maintained).

6

4

5

6

3

2

1

Loading...

Loading...