Pentair Goyen Precision PS-L, Goyen Precision PS CA, Goyen Precision P2, Goyen Precision PS-LA, Goyen Precision P-CTX Installation And Operating Instructions Manual

...Page 1

PENTAIR CLEAN AIR SYSTEMS

FILTER CLEANING

SYSTEM CONTROLS

PRECISION

®

INSTALLATION AND OPERATING INSTRUCTIONS

Page 2

02 INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

PRECISION

FILTER CLEANING SYSTEM CONTROLS

TABLE OF CONTENTS

Warning .......................................................................................................................................................................................

3

Precision Program Commissioning Log ..................................................................................................................................... 3

Product Description .................................................................................................................................................................... 3

Identifying the Parts ................................................................................................................................................................... 4

Installation – General ................................................................................................................................................................. 6

Mechanical ................................................................................................................................................................................... 6

Electrical Installation ................................................................................................................................................................... 6

Installation – Optional Accessories ............................................................................................................................................ 12

P-CTX: I/O Card ............................................................................................................................................................................ 12

P-MOD: Modbus Communications Card .................................................................................................................................... 13

Operation .................................................................................................................................................................................... 14

Powering Up the System ............................................................................................................................................................. 14

The Display and Interface ............................................................................................................................................................ 14

Manual Activation of Solenoid Outputs ....................................................................................................................................... 14

Programming and Advanced Features ....................................................................................................................................... 15

P1 – Continuous Control .............................................................................................................................................................. 15

P2 – Enhanced Demand Control ................................................................................................................................................. 16

Messages and Alarms ................................................................................................................................................................ 18

Messages ...................................................................................................................................................................................... 18

Troubleshooting .......................................................................................................................................................................... 20

General/Startup ............................................................................................................................................................................ 20

Operational ................................................................................................................................................................................... 21

P-MOD Modbus Communications .............................................................................................................................................. 21

Precision System Specifications ................................................................................................................................................ 22

Installation and Operating Instructions

Owner's Records for P1, P2, PS-L, PS-C, PS-LA, PS_CA, P-CTX and P-MOD

Deine-007

© Copyright by Pentair International Ltd. 2014

This manual is provided as an aid to owners of a Pentair Clean Air Systems instrument and contains information proprietary to Pentair Clean Air Systems.

This manual may not, in whole or part, be copied, or reproduced without the express written consent of Pentair Clean Air Systems.

Goyen Controls Co Pty Ltd reserve the right to change product designs and specifications without notice.

Rev02 – November 2014

Page 3

03INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

WARNING

To avoid product malfunction or electrical shock, do not expose Precision circuit boards to rain or moisture. Installation must be

performed using qualified technicians.

CAUTION

Use of controls or adjustments or performance or procedures other than those specified in this manual may result in product

failure, or poor product performance. You are cautioned that any changes or modifications to the product not expressly approved

in this manual could void your product warranty.

Note

The P1, P2, PS-L, PS-C, P-CTX and P-MOD have been tested and found to comply with EN55024:1998, EN61000-4-2, EN610004-4, EN61000-4-5 and EN61000-4-11 for immunity to ESD, immunity to EFT and bursts, immunity to surges and immunity to

voltage dips and interruptions. This equipment did not become dangerous or unsafe as a result of the application of the tests

defined in EN55024:1998.

PRECISION PROGRAM COMMISSIONING LOG

Use this log during system commissioning to keep a permanent record of controller settings.

PARAMETER DEFAULT

Language English

On time (ms) 100

Off time (s) 50

Display units* kPa

Demand cleaning*

(by limits; default)

High dP

Low dP

1.0 kPa

0.5 kPa

Demand cleaning*

(by bandwidth)

High dP

% band

1.0 kPa

40

Alarm delay(s) * 0

High dP alarm* 2.0 kPa

Precoating* None

Pattern cleaning* Off

Blowdown cycles None

Remote stop* Hardwired

Tube cleaner CTX Off

Maximum Interval* (s) Off

Network MOD Off

* Only with P2 controllers.

CTX Available on the AC/AC baseboard, otherwise only when P-CTX fitted.

MOD Only when P-MOD fitted.

PRODUCT DESCRIPTION

The Precision (or controller) is an advanced filter cleaning control system for reverse-pulse jet dust collectors. This system

may be specified with a selection of control interfaces and signal output options. The controller may be easily upgraded from

simple sequential mode control (P1 interface) to Enhanced Demand Mode (P2 interface). An RS-485 Modbus RTU compliant

communications card (P-MOD) provides full networking and remote programming for DCS and SCADA systems. An I/O card

(P-CTX) provides voltage-free contacts for alarms, 4–20 mA output (for dP reporting, P2 only), and basic remote control. The

solenoid outputs can be expanded up to 200 outputs through the use of the PS-L or PS-C expansion cards (or slave cards) with

the AC/DC baseboard (AC voltage input, DC voltage output) or DC/DC baseboard (DC input and output) and PS-LA or PS-CA

expansion cards on the AC/AC baseboard (AC input and output).

Page 4

04 INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

Your system may have some or all of these components. Note that terminal headers are supplied for all push-in contacts.

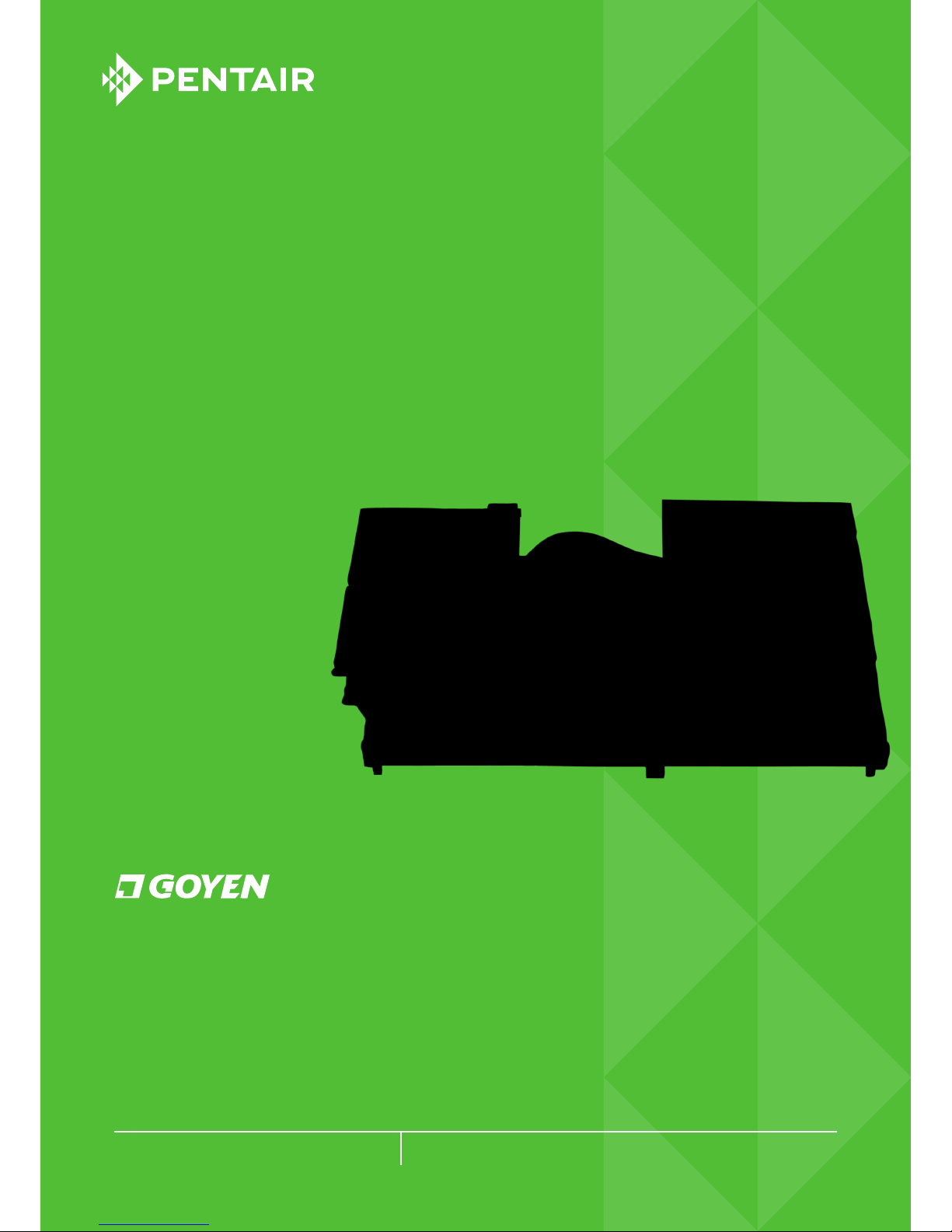

Figure 1:

P1 Interface and Controller, Top View

4

5

3

22

6

1278

9

23

4

5

Figure 2: Controller, Front View

71211 2010

DIRTY

CLEAN

21

Note: Controller assemblies in

Figures 1 and 2 include (left to right)

P-CTX, P-MOD and P2 interface, all

mounted on the AC/AC baseboard.

Figure 3:

PS-C, DC Output Compact Terminal Expansion Card

17

16

18

1514

13

IDENTIFYING THE PARTS

Page 5

05INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

Figure 4: PS-L, DC Output Large Terminal Expansion Card

19

14

15

17

18

16

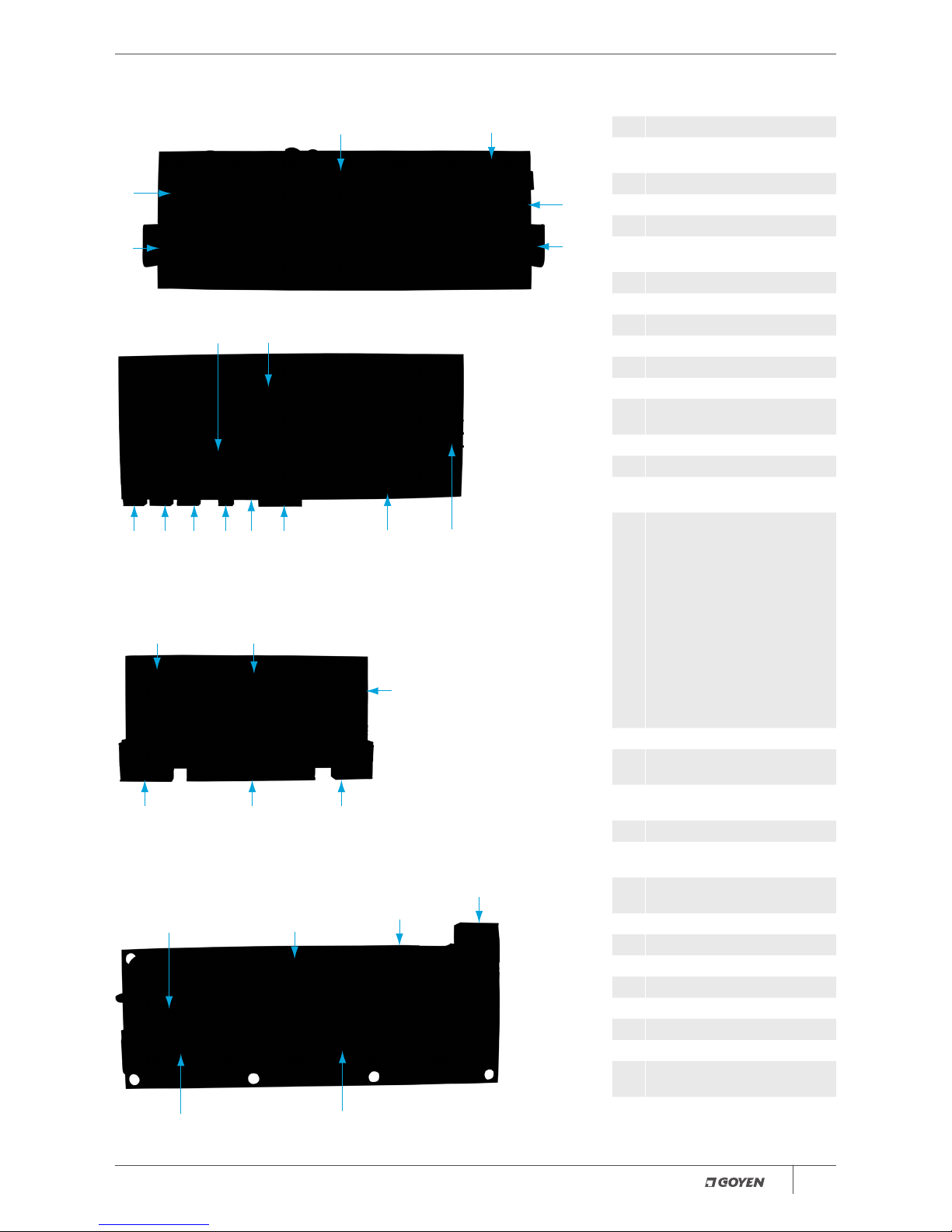

Figure 5: AC/AC Baseboard Top View

27

24

287

10 30 31 29 20 12

Note: AC/AC baseboard comes with the tube cleaner mounted on the baseboard.

For the AC/DC and DC/DC baseboards it comes separately on the P-CTX card.

Figure 6:

PS-CA AC output Compact Terminal Expansion Card

27

24

30

3115

17

Note: No LEDs for AC output Compact Terminal Expansion Card.

Figure 7:

PS-LA AC output Large Terminal Expansion Card

30

31

15

17

27

26

Note: All AC output products (Figures 5–7) have no manual solenoid triggers.

Key to Figures 1 to 7

1 Precision motherboard (10 output)

2 P2 Enhanced Demand Mode

interface

3 P1 Sequential Mode interface

4 Power-on switch

5 Power LED

6 Motherboard manual solenoid

triggers and LEDs.

7 Motherboard solenoid terminals

8 P-MOD, Modbus card (optional)

9 P-CTX, I/O card (optional)

10 Power in

11 Expansion card connection

12 Fan contacts

13 PS-C, compact expansion card (10

output)

14 Expansion card contacts

15 Solenoid terminals and LEDs

16 Expansion card manual solenoid

triggers and LEDs

17 Expansion card terminating

resistor and addressing switches –

Switch No.1:

Turns on terminating resistor*

Addresses 1 to 9:

Turn DIP switch No. 2 to ‘OFF’

position and use Rotary switch to

select address

Addresses 10 to 19:

Turn DIP switch No. 2 to ‘ON’

position and use Rotary switch to

select address

* Terminating resistor is turned to

‘ON’ position on last slave card.

18 Expansion card fuse

19 PS-L, large expansion card (10

output)

20 Motherboard terminating resistor

(DIP switch No. 1)

21 Pressure Transducer

22

24 V Rail Fuse – 250 V 4 A (located

on motherboard)

23

Mains Fuse – 250 V 2 A (located on

motherboard)

24 AC/AC Baseboard

25 PS-CA Compact expansion card

26 PS-LA Large expansion card

27

T3A 250 V slow-blow fuse 20 mm

28 Isolate and Purge contacts

29

24 V DC additional voltage in

30 Power to expansion cards

31 Communications with expansion

cards and baseboard

Page 6

06 INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

MECHANICAL

The Precision may be supplied as PCB only, in 316 stainless steel IP65 (Nema 4) enclosures, or in painted steel IP65 (Nema 4)

enclosures.

General

• Install Precision in areas of minimal vibration.

• Install in an area free from high electrical noise or interference.

• Install in an area where there is low risk of impact to the Precision.

• The Precision will operate in ambient temperatures of 70°C (158°F). At temperatures higher than this the display may become

difficult to read and the high temperature alarm will activate. Cooling should be provided if the Precision is to be installed in

conditions with ambient temperatures of 70°C (158°F) or higher.

P2 Enhanced Demand Mode

• Ensure pneumatic sensing lines are kept as short as possible to minimise pressure losses.

• Ensure pneumatic sensing lines are free from blockages, kinks or leaks.

Installations where PCB only has been supplied

• Ensure that installation is made into enclosures chosen with due consideration of the nature of the location, and that the

boards are protected from moisture, heat above 70°C (158°F), dust, and chemical attack.

• Ensure a common earth connection is present for all conductive material within immediate proximity to the device being

powered, e.g. a common earth connection between the baseboard and mounting bracket, enclosure, etc. Please follow all

local electrical standards.

ELECTRICAL INSTALLATION

Warnings:

• Electrical installation to be undertaken by suitably qualified technicians.

• Ensure that mains power has been isolated before conducting any work on the Precision.

Connecting power to the Precision

Applying power to the AC/DC and AC/AC Precision motherboard (AC Voltage models):

• Ensure input voltage is 110 or 240 V AC (+/− 10%), 50/60 Hz.

• Ensure power supply is not affected by high load or noisy electrical machinery such as fans, which may cause unreliable

system operation.

• Connect Earth, Active and Neutral supply to their respective terminals (ref. Figures 2 and 5, item 10).

Applying power to the DC/DC Precision motherboard (DC Voltage models):

• Ensure input voltage is 24 to 48 V DC (+/− 10%).

• Ensure power supply is not affected by high load or noisy electrical machinery such as fans, which may cause unreliable

system operation.

• Connect Earth, Positive and Negative supply to their respective terminals (ref. Figure 2, item 10).

Surge Protection and Earthing

• Goyen Controls recommends the use of a Metal Oxide Varistor (MOV)-based surge protection device between the supply

voltage and the Precision. Clamping voltage =

275 V RMS (approx.), Energy Absorption = 175 joules (approx.).

• Ensure that when using a metal enclosure, both lid and box are connected to the supply earth.

Connection of solenoid valves and expansion cards to Precision outputs

Please refer to the system wiring diagrams (Figures 8–11) on pages 8–11.

INSTALLATION

GENERAL

Page 7

07INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

• The Precision baseboard has ten outputs. A further 190 outputs may be added in increments of 10 by serial connection

(19 maximum expansion cards per baseboard) by either PS-C and PS-L terminal expansion boards connected to AC/DC

or DC/DC baseboards, and PS-CA and PS-LA connected to AC/AC baseboards.

• PS-C, PS-L expansion cards, AC/DC and DC/DC baseboards have 24 V DC output at each terminal, each capable of powering

three 24 V DC, 20 W solenoids simultaneously to a maximum of 2.5 A at each DC output terminal. With a maximum of

19 expansion cards connected to the baseboard (200 outputs), the controller can pulse 600 solenoids.

• PS-CA and PS-LA expansion boards and AC/AC baseboards have 110 V AC or 240 V AC output (depending on mains input

power) at each terminal, each capable of powering ten 110 V AC, 22 W or 240 V AC, 25 W solenoids simultaneously to a

maximum of 2.4 A at each AC output terminal. With a maximum of 19 expansion cards connected to the AC/AC baseboard

(200 outputs) the controller can pulse 2000 solenoids.

• Terminal expansion board types may be mixed between compact and large expansion cards but not between AC and DC

output voltage.

• DC expansion cards are connected to the baseboard in series via terminals 11 and 14 in Figures 2, 3, and 4. AC expansion

cards are connected via terminals 30 and 31 in Figures 5, 6 and 7. Please refer also to the system wiring diagram in Figures 8,

9 and 10 for connecting details.

• Communication between baseboard and DC output expansion cards is via a multi-drop RTU two-wire RS485 connection.

Four-core shielded mains-flex cable is recommended for the connection of expansion cards. Suggested wire gauge is

11/0.2 × 4-core plus shield (drain) such as a Belden 8723NH data cable or equivalent. Two cores are used for communication

between baseboard and expansion cards; the remaining two cores are required for power supply to the solenoids, plus drain.

Note that solenoid power is provided by this connection; no additional external power is required.

• Communication between baseboard and AC output expansion cards is via an isolated multi-drop RTU two-wire RS485

connection (7/0.2) plus drain cable. Power is supplied via 2-core plus earth (1.5 mm2) cable. Note that solenoid power is

provided through this connection; no additional external power is required. Please follow any local standards for segregation

of power and communications cables.

• Ensure each expansion card is given a sequential address by using the rotary switch and DIP switch No. 2 (see item 17,

Figures 3, 4, 6 and 7). Do not assign an address of zero on expansion cards; zero is reserved for the baseboard.

• For solenoid connections, connect up to 2.5 mm

2

stranded cable from the output terminal to the relevant valve solenoid.

Link the common terminal of all solenoids and return to the common on the baseboard or on the expansion cards.

• When connecting expansion cards, set DIP switch 1 (Figures 2 and 5, item 20) to the ‘ON’ position. This enables the 120 ohm

terminating resistor. No separate resistor is required. Repeat this process on the last expansion card on the Modbus network.

Note: The precision automatically detects all expansion cards and solenoids connected to the system.

Fan contact connections

These contacts (Figures 2 and 5, item 12) are used to trigger blowdown cycles; if the blowdown cleaning cycles are selected, this

feature is triggered through electrical contacts. Optionally, blowdown cycles may be triggered by the dP of the collector (this is a

feature of the P2 interface). Please refer to the system wiring diagrams in Figure 8.

• These are voltage-free contacts

• Connect the normally open voltage-free contacts on the dust collector fan motor to the ‘Fan’ and ‘GND’ contacts on the

baseboard (refer Figures 2 and 5, item 12). When the system fan is turned off, the motor contacts close and the ‘Fan’ and

‘GND’ contacts are bridged on the Precision baseboard. This triggers the blowdown cycles to commence for the programmed

number of cycles.

Page 8

08 INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

Figure 8: Wiring Diagram for the AC/DC and DC/DC Baseboard with P-CTX (CTX Card), P-MOD (Modbus), Expansion Cards

and Tube Cleaner

Page 9

09INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

Figure 9:

Wiring Diagram for the AC/AC Baseboard with P-CTX (CTX Card), (P-MOD) Modbus, P1 and P2 Option

Page 10

10 INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

Figure 10:

Wiring Diagram for Compact Expansion Cards on the AC/AC Baseboard

Page 11

11INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

Figure 11:

Wiring Diagram for Large Expansion Cards on the AC/AC Baseboard

Page 12

12 INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

P-CTX: I/O CARD

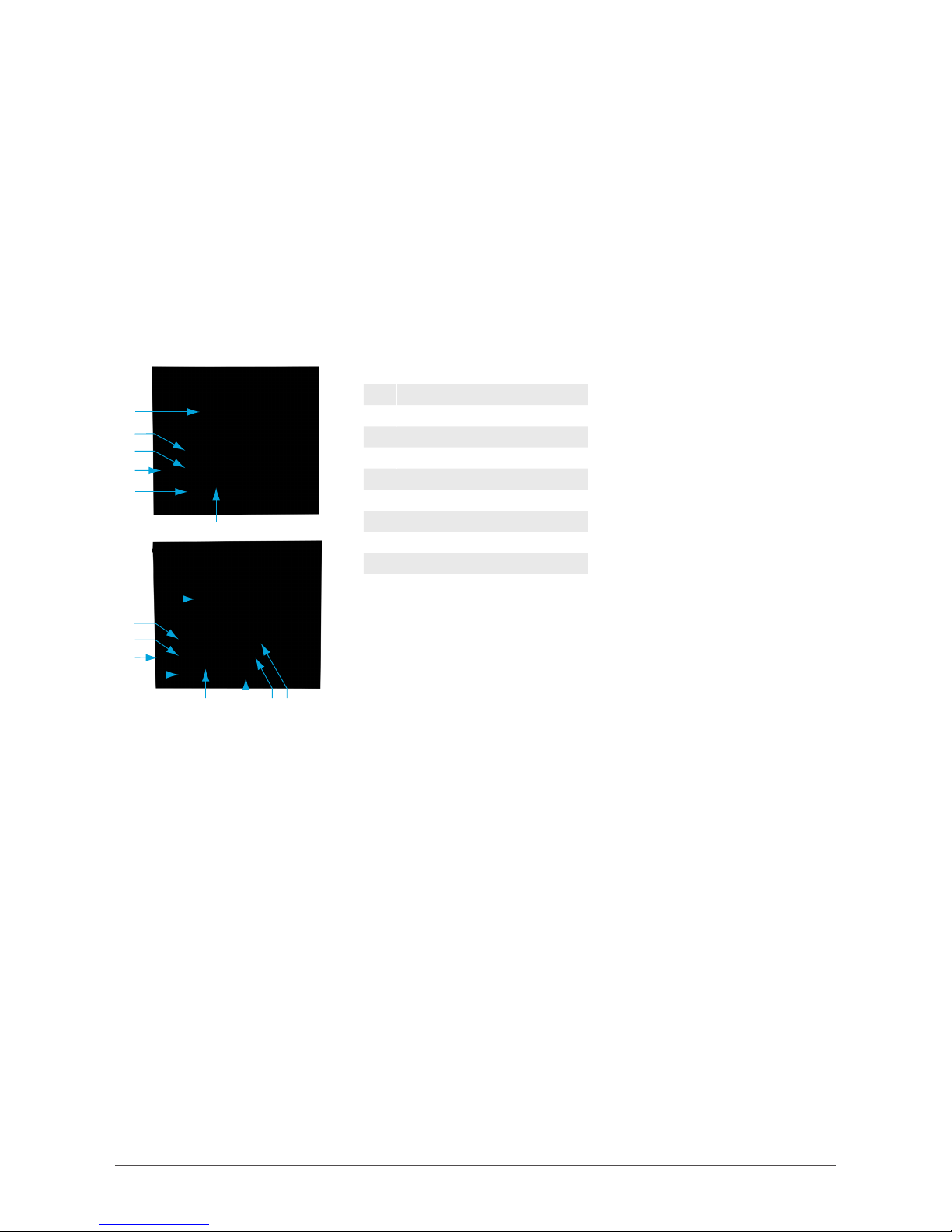

Figure 12: P-CTX

Key to Figure 12

DESCRIPTION TYPE DETAILS

1 Fuse

2

4–20 mA differential pressure output GND

+

-

Output

Output

Output

Ground

24 VDC

0 VDC

3 Cycling

Remote indication of when a valve is being actuated.

Output

Common

Voltage free

Voltage free

4 Watchdog alarm

Indicates failure of microprocessor.

Output

Common

Voltage free

Voltage free

5 High dP alarm

Indicates that dP has reached the programmed alarm trigger.

Output

Common

Voltage free

Voltage free

6 Service alarm

Indicates that either 100K, 500K, or 950K cycles have been completed.

Output

Common

Voltage free

Voltage free

7 Coil failure alarm

Indicates solenoid failure on the system.

Output

Common

Voltage free

Voltage free

8 Auxiliary alarm

Indicates the alarm state of an auxiliary input device (see 14).

Output

Common

Voltage free

Voltage free

9 Power OK signal

Indicates system power is OK.

Output

Common

Voltage free

Voltage free

10 Isolate valve (for optional tube-cleaner function only)* Output

Common

24 V DC**

11 Purge valve (for optional tube-cleaner function only)* Output

Common

24 V DC**

12 Demand/Continuous switch

Allows remote switching between continuous and demand control modes (when P2 interface

is fitted).

Input

Common

Voltage free

Voltage free

13 Manual cycle

Forces a full cleaning cycle.

Input

Common

Voltage free

Voltage free

14 Auxiliary input

Allows the connection of an auxiliary device (e.g. pressure switch, broken bag detector, etc.).

Input

Common

Voltage free

Voltage free

15 Low header (tank pressure) alarm

Indicates low tank pessure, when connected to an appropriate pressure switch (not supplied).

Input

Common

Voltage free

Voltage free

16 Reset service alarm

Resets the service alarm signal.

Input

Common

Voltage free

Voltage free

17 Reset general alarm

Resets all alarms, with the exception of the service alarm.

Input

Common

Voltage free

Voltage free

Note:

The 4–20 mA output (2) is internally powered from the control system. No additional power supply is required.

* The Isolate and Purge functions are disabled on the P-CTX card when attached to the AC/AC baseboard only.

** Isolate and Purge contacts on the AC/AC baseboard have an output voltage equal to mains input voltage (110 V AC or 240 V AC).

INSTALLATION

OPTIONAL ACCESSORIES

2 3 4 5 6 7 8 9

1

10 11 12 13 14 15 16 17

Page 13

13INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

BASIC INFORMATION

The P-CTX card provides voltage-free contacts for alarm outputs, basic remote control inputs and a 4–20 mA output for differential

pressure reporting (P2 only). Figure 2 shows the P-CTX mounted correctly on the left side of the baseboard. The table on page

12 provides a description of each I/O point, which may be connected to remote push-buttons, lights, sirens, data-loggers, control

panels and programmable logic controllers.

Voltage-free Outputs

The P-CTX provides a number of voltage-free output contacts that can be used for alarm reporting. Each alarm output consists

of an output terminal and a common terminal. Any voltage applied to the common terminal will be present on the output

terminal when the alarm is raised.

Voltage-free Inputs

The P-CTX provides a number of voltage-free input contacts that can be used for basic remote control of the P1 or P2. Each

input consists of an input terminal and a common terminal; bridging these two contacts triggers the corresponding function.

4–20 mA Output

The P-CTX features a 4–20 mA output that can be used for differential pressure reporting. The output consists of a ground terminal,

24 V DC terminal and 0 V DC. An output current of 4 mA corresponds to a dP = 0 kPa and 20 mA corresponds to a dP = 2.5 kPa.

The table over the page provides a description and details of each output terminal on the P-CTX.

P-MOD: MODBUS COMMUNICATIONS CARD

Figure 13:

P-MOD

1

2

3 4 5

Key to Figure 13

1 Switch for terminating resistor (DIP switch No.1)

2 Communications LED

3 Bus A (RS485+)

4 Bus B (RS485−)

5 GND (Ground/Drain)

BASIC INFORMATION

The P-MOD card is a network card which operates using the Modbus RTU communication protocol. Via the P-MOD the

controller can be connected to a DCS or SCADA system, allowing remote programming and monitoring of all menu items,

alarms and system details.

RS485 Modbus system specification is:

ITEM DETAIL

Protocol Modbus RTU

Hardware layer 2-wire, half-duplex RS485

Communications speed 9600 BPS

Stop bits 1

Data bits 8

Parity None

If the P-MOD is the last device connecting the Modbus RTU network, ensure DIP 1 of the terminating resistor switch (Figure 13,

item 1) is set to ‘ON’. This enables the 120 ohm resistor on the P-MOD; no separate resistor is required.

Page 14

14 INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

POWERING UP THE SYSTEM

See Figure 1 (items 4 and 5). Moving the power switch into the on position will power up the Precision. The Power LED will light,

and the backlit interface display will light up.

The Precision performs a self-diagnostic routine, confirming all attached modules and reporting automatically all attached

solenoids and expansion cards. The Precision will then operate according to its programmed modes.

Note that the Precision automatically identifies all connected expansion cards, modules and solenoids. No programming is

required.

THE DISPLAY AND INTERFACE

Figure 14:

P1 and P2 Interfaces

4

1

2

6

5

3

7 8 9

4

1

2

6

5

3

Key to Figure 14

1 Backlit LCD

2 Previous menu item

3 Next menu item

4 Increment

5 Decrement

6 Enter

7 Alarm reset

8 Demand/Continuous mode toggle

9 Manual Cleaning Cycle

P1 – Continuous Control Interface

The P1 interface provides sequential and continuous pulse cleaning control. While in RUN mode, the two-line LCD will show:

Line 1: Scrolling display of system settings and alarms

Line 2: Time to next pulse (seconds)/Output ID of next pulse

P2 – Enhanced Demand Interface

The P2 interface provides cleaning on demand basis (i.e. in accordance with the differential pressure across the filters),

minimising air consumption and valve wear, and maximising filter life. The P2 also provides enhanced pulse-control functions,

including Pattern Cleaning and Maximum Interval between cleaning cycles.

While in RUN mode, the four-line LCD will show:

Line 1: Scrolling display of system settings and alarms

Line 2: Differential pressure and units (Pa, kPa, InWG, mm H2O, or mm Hg)

Line 3: Pulsing status (cycling, paused, stopped)

Line 4: Time to next pulse (seconds)/Output ID of next pulse

MANUAL ACTIVATION OF SOLENOID OUTPUTS

See Figure 1 (item 6) and Figures 3 and 4 (item 16).

Pushing the manual output triggers will power their corresponding output for 100 ms if there is a solenoid connected.

Simultaneously the output LED will light. Note that this function has been removed for all AC output boards to comply with

safety standards. Alternatively, pressing the manual cycle button on the P2 interface (Figure 14, item 9) will force a single

complete pulsing sequence for all baseboards, AC and DC output. This feature can be used for confirming valve operation

and diagnosing filter cleaning problems.

OPERATION

Page 15

15INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

To enter programming mode, press Enter (Figure 14, item 6), followed by:

+ − − + Enter

UP (Figure 14, item 2), scroll to previous menu item; DOWN (Figure 14, item 3), scroll to next menu item.

P1 – CONTINUOUS CONTROL

Menu Structure

LEVEL 1 ENTRY LEVEL 2 MENU ITEM LEVEL 3 OPTIONS

1 Code

2

2a

2b

2c

2d

2e

Language

English

Italian

Spanish

German

French

3 Reset Factory Defaults

4 On Time

5 Off Time

6 Blowdown Cycles

7 Hour Counter

8 Number of Slaves

9 Total Cycles

10

10a

10b

Tube Cleaner*

Period

Duration

11 Network**

12 Run

* Available on the AC/AC baseboard, otherwise only when P-CTX is fitted.

** Only when P-MOD is fitted.

DESCRIPTION OF MENU ITEMS

Language

Precision may be run in one of five languages, as listed above.

Reset Factory Defaults

Puts all settings back to defaults (set at time of manufacture).

On Time

Sets electrical output duration between 30 and 500 ms.

Off Time

Sets pause between pulses between 1 s and 999 s.

Blowdown Cycles

Sets the number of off-line cleaning cycles to be executed after the dust collector fan is shut down. Off to 10 cycles. This only

operates when the fan contacts (Figure 2, item 12) are closed.

Hour Counter

Displays the total hours that the controller has been running for. Pressing [Enter] allows the hour counter to be reset.

Number of slaves

Displays the number of expansion cards connected to the system.

Total Cycles

Displays the total number of cycles completed. This will trigger a service alarm at 100 K, 500 K, and 950 K cycles. Pressing

[Enter] allows the cycle counter to be reset. 0 to 1 000 000 cycles.

PROGRAMMING AND

ADVANCED FEATURES

Page 16

16 INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

Tube Cleaner

Available on the AC/AC baseboard, otherwise only when P-CTX is fitted. This allows the tube-cleaning parameters to be

specified: Select ON or OFF, then:

Period: The frequency of the tube-cleaning pulse. 1 to 999 minutes.

Duration: The duration of the tube-cleaning pulse. 1 to 60 seconds. This feature is used to control the pulse cleaning of the

differential pressure-sensing lines. In the case of the P1 with P-CTX, these may be used to clear the pressure lines of third-party

pressure gauges installed on the dust collector.

Network

Allows the network address to be set for controllers running on a DCS. Values 0 to 255, and OFF. Setting to OFF takes the

Precision off the network.

Run

Returns the controller to operating mode.

P2 – ENHANCED DEMAND CONTROL

Menu Structure

LEVEL 1 ENTRY LEVEL 2 MENU ITEM LEVEL 3 SUB-MENU OPTIONS LEVEL 4 OPTIONS

1 Code

2

2a

2b

2c

2d

2e

Language

1

English

Italian

Spanish

German

French

3 Factory Defaults

1

4 On Time

1

5 Off Time

1

6

6a

6b

6c

6d

6e

Display Units

kPa

Pa

in WG

mm H20

mm Hg

7

7a

7ai

7aii

7b

7bi

7bii

Demand Cleaning

Limits

Bandwidth

Low dP

High dP

High dP

Bandwidth %

8 Alarm Delay

9 High dP Alarm

10 Precoating

11 Pattern Cleaning

12 Blowdown Cycles

1

13

13a

13b

Remote Stop

Hardwired

Automatic

14

14a

14b

Tube Cleaner

1

*

Period

Duration

15 Maximum Interval

16 Hour Counter

1

17 Number of Slaves

1

18 Total Cycles

1

19 Network1**

20 Run

1

1

As described for the P1 interface.

* Available on the AC/AC baseboard, otherwise only when P-CTX is fitted.

** Only when P-MOD is fitted.

Page 17

17INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

DESCRIPTION OF MENU ITEMS (P2 SPECIFIC)

Display Units

Allows the display units for pressure to be set to one of five commonly used measures. See table above. The selected units will

then be used for all differential pressure-related settings, and network reporting via P-MOD.

Demand Cleaning

Allows the parameters associated with demand cleaning control to be specified.

Limits

High dP – The differential pressure at which pulse cleaning is to start.

Low dP – The differential pressure at which pulse cleaning is to stop. Alternatively:

Bandwidth

High dP – The differential pressure at which cleaning is to start. (up to 10″ WG or 2.49 kPA) Bandwidth % – The % range in which

the differential pressure is to be maintained (5 to 50%).

Alarm Delay

Used in conjunction with High dP Alarm, this allows the specification of a delay before an alarm is triggered. This can be used to

eliminate false alarms caused by spikes in the pressure readings. 255 seconds maximum delay.

High dP Alarm

Assigns the differential pressure at which a high dP alarm is to be triggered. Maximum value is 10″ WG or 2.49 kPa.

Precoating

Allows filter seeding/precoating before the controller moves into its regular cleaning program mode. This is specified by a

differential pressure value at which the regular cleaning program is to activate. Maximum value is 10

″ WG or 2.49 kPA.

Pattern Cleaning

This allows the selection of a pulse-cleaning pattern to minimise dust re-entrainment. Selecting a cleaning pattern allows

solenoids to be wired in a sequential manner to the controller outputs, while pulsing in a non-sequential manner. Three options

are available: OFF, SKIP 1, SKIP 2.

With baseboard outputs only, valves fire in the following sequence:

OFF 1, 2, 3, 4, 5, 6, 7, 8, 9, 10

SKIP 1 1, 3, 5, 7, 9, 2, 4, 6, 8, 10

SKIP 2 1, 4, 7, 10, 2, 5, 8, 3, 6, 9

Where expansion cards are connected (example below shows 2 cards connected):

OFF 1 … 10, 1C1 … 10C1, 1C2 … 10C2

SKIP 1 1M, 1C1, 1C2, 3M, 3C1, 3C2, 5M, 5C1, 5C2, 7M, 7C1, 7C2, 9M, 9C1, 9C2, 2M, 2C1, 2C2, 4M, 4C1, 4C2, …

SKIP 2 1M, 1C1, 1C2, 4M, 4C1, 4C2, 7M, 7C1, 7C2, 10M, 10C1, 10C2, 2M, 2C1, 2C2, 5M, 5C1, 5C2, 8M, 8C1, 8C2, …

M refers to baseboard output; C1 refers to expansion card 1; C2 refers to expansion card 2.

Remote Stop

Used in conjunction with Blowdown Cycles. This allows the blowdown cycles trigger to be selected from either:

Hardwired – blowdown cycles are started when the fan contacts are closed (Figure 2, item 12).

Automatic – blowdown cycles are started when differential pressure drops to a set value (0.1 to 2.0 kPa or 0.4 to 8.0″ Wg).

No electrical connections to the dust collector fan are required. If the dP rises above the set value, normal operation resumes

regardless of the number of blowdown cycles completed.

Maximum Interval

Only functions when the P2 is in Demand cleaning mode. This specifies a maximum pause duration between pulsing cycles

when in Demand mode. This may be set to OFF, or from 1 minute to 999 minutes. When the cycle is triggered on the basis of

Maximum Interval, one complete cleaning cycle is executed. This mode can act as a backup cleaning mode when differential

pressures do not rise to the preset level for cleaning to commence, or when there is a blockage or leak in the differential

pressure-sensing lines.

Page 18

18 INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

MESSAGES

Scrolling Display

DISPLAY DESCRIPTION

Model xx.xx Software version number

Continuous Mode

P2

Controller is in Continuous Mode

Demand Mode

P2

Controller is in Demand Mode

On Time = xxx ms Electrical On Time of Solenoid

Off Time = xxx sec Electrical Off Time of Solenoid

Slaves = xxxx Number of Slaves connected to Controller

Blowdown cycles = xxxx Number of complete cleaning cycles the controller performs after the fan has been switched off

Remote Stop = Hardwired

P2

Remote Stop is hardwired to the fan or circuit breaker

Remote Stop = Automatic

P2

Remote Stop is dependent on dP of system

Hour Counter = xxHrs Number of hours the controller has been operational

Total Cycles = xxxxxx Number of complete cleaning cycles the controller has performed

Max. Interval = xxx

P2

The maximum time that can elapse before a cleaning operation takes place (only in use when in

Demand Mode)

Pattern Cleaning = xxx

P2

Allows the controller to ‘Off’, ‘Skip 1’ or ‘Skip 2’ outputs (refer to cleaning patterns)

Alarm Delay = xxx sec

P2

Delays high dP and Auxiliary Alarm for this amount of time to avoid false alarms due to system spikes,

etc.

Tube Cleaner = xxxx ‘Off’, ‘Tube Cleaner Duration’ and ‘Tube Cleaner Period’

Units = xxx

P2

Current units being used for display of dP

P2

Only for the P2 interface.

General Messages

DISPLAY DESCRIPTION

dP = xxxx (units)

P2

Current dP

Stopped (dP)

P2

Remote Stop due to Automatic Blowdown dP measurement

Stopped (Fan) Remote Stop due to Hardwired Blowdown

Manual Cycle

P2

Either the Manual Cycle button or contact (P-CTX) has been activated. The controller is now performing

one complete cleaning cycle with the programmed On and Off Time.

Cycling – Paused

P2

Controller waiting for dP to exceed High dP Limit value

Cycling –(Precoating)

P2

Controller waiting for dP to exceed Precoating value

xxx sec Countdown to next solenoid operation

xx:xx Next SLAVE# : OUTPUT# to operate

Tube Cleaner xx sec Controller is performing a Tube Clean operation with xx sec remaining

P2

Only for the P2 interface.

MESSAGES AND ALARMS

Page 19

19INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

Alarm Messages

DISPLAY DESCRIPTION

Coil OC Fail – xx:yy* Coil yy on Slave xx has failed Open Circuit – Replace coil.

Coil CC Fail – xx.yy* Coil yy on Slave xx has failed Closed Circuit – Replace coil.

Low Coil Voltage – xx.yy Voltage outside the recommended voltage is being delivered to the coil yy on Slave xx or to the

baseboard – check connections.

Slave Removed – xx Slave xx has been lost since power-up – Check connections.

Over Temperature – Slowed Power Supply is warm. Off Time has been increased to allow the Power Supply to return to normal.

Over Temperature – Stopped Power Supply is hot. Controller has ceased to function to allow the Power Supply to return to normal

temperature. The controller will then automatically operate.

Power Supply Low Power Supply voltage is below the minimum voltage. Once voltage is within operating range, the

controller will automatically operate normally.

Stop (Over Temp) Power Supply is hot. Controller has ceased to function to allow the Power Supply to return to normal

temperature. The controller will then automatically operate.

Bad MOD board xx A faulty ‘plug-in’ board has been identified as number xx where xx is:

3. P-CTX

4. P-MOD

Contact Goyen for replacement board.

Unknown Fault xx Firmware Error – Contact Goyen.

Exception # xx Contact Goyen with Exception category # and Exception number xx – Contact Goyen.

1. P2 interface Board requires calibration

2. Could not communicate to baseboard slave (may indicate problem with external slave bus, but most

likely a problem with the micro or the RS485 comms on the baseboard; other options are a fault on

the micro on the P1/2 interface or possibly the 50-way cable).

3. 3.3 V rail is low (< 3 V) – this message indicates a fault in the 3V3 supply on the baseboard.

Aux. Alarm Auxiliary Alarm is present (P-CTX must be present).

Low Header P Insufficient compressed-air pressure exists in header. Solenoid operation is ceased until pressure is at

acceptable levels once again (P-CTX must be fitted).

Service Alarm 100 000 cycles 100 000 complete cleaning cycles have been completed – Check control system parameters.

Service Alarm 500 000 cycles 500 000 complete cleaning cycles have been completed – Check condition of filter elements.

Service Alarm 950 000 cycles 950 000 complete cleaning cycles have been completed – Replace kits in valves.

* In the case of solenoid failure, all other solenoids will continue to operate. Alarm will be automatically cancelled on connection of a good

solenoid to the output in question.

Page 20

20 INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

The Precision is programmed with system self-diagnostics. Most issues can be resolved by reference to the system messages

and alarms present on the interface and listed in the previous section, ‘Messages and Alarms’. For issues which cannot be

resolved in this way, refer to the table below or contact your system supplier.

General/Startup

SYMPTOM CAUSE RESOLUTION

System does not power up. Power LED

remains off.

Power is not connected to the baseboard.

Power wiring is incorrect.

Power supplied is below the minimum

required to operate the controller.

Ribbon cable to P1 or P2 interface is loose.

Blown fuse.

Defective on-board power supply or interface.

Check connection.

Check wiring to socket is in accordance with

this manual.

Check power supply is within tolerance.

Check and ensure fit to interface and

baseboard is secure.

Replace fuse.

Contact your supplier.

Some or all expansion cards are not detected

on startup.

Cabling between expansion cards and the

baseboard is incorrect.

Broken cabling between expansion cards and

the baseboard.

Damaged fuse on expansion card or

baseboard.

Check connections are in accordance with

this manual.

Replace cable.

Replace fuse.

Some or all connected solenoids are not

detected on startup.

Cabling between expansion cards and the

baseboard is incorrect.

Broken cabling between expansion cards and

the baseboard.

The common terminals between each bank

of solenoids (or between solenoids) are not

linked or returned to the common terminal

on the relevant baseboard or expansion card.

The solenoid active terminal is not properly

linked to its relevant system output terminal.

Damaged fuse on expansion card or

baseboard.

Check connections are in accordance with

this manual.

Replace the cable.

Ensure commons are linked.

Check connections and repair if necessary.

Replace fuse.

TROUBLESHOOTING

Page 21

21INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

Operational

SYMPTOM CAUSE RESOLUTION

P2 does not go into cleaning mode on

startup. Display shows: ‘Precoating’.

Valves do not pulse.

P2 is waiting for differential pressure to rise

above the factory preset Precoating value

(1.5 kPa, 6″ WG) or the user set value.

Enter the menu and set Precoating to off, or

wait for differential pressure to rise.

P2 does not go into cleaning mode on

startup. Display shows: ‘Stopped (dP)’. Valves

do not fire.

P2 is waiting for differential pressure to

rise above the factory preset Remote Stop

trigger value (0.5 kPa or 2″

WG) to commence

operation.

Enter the menu and set remote stop dP to

the preferred value or to ‘Hardwired’, or wait

for the dP to rise.

P2 does not go into cleaning mode on

startup. Display shows: ‘Stopped (FAN)’.

Valves do not pulse.

Fan contacts are closed on the baseboard. Check wiring to fan contacts; if the fan or

another circuit breaker is not connected

to the Precision, the fan contact terminals

should be open.

If the fan is connected to the baseboard,

check that the contacts at the fan are

normally open type, and check the wiring.

Valves on multiple expansion boards

are firing simultaneously. The outputs

correspond to each other.

Two or more expansion cards are set with the

same address.

Check each output is assigned a unique

address.

Expansion cards are not pulsing sequentially

(Pattern cleaning mode is off).

Expansion card addresses have not been

assigned in sequential order.

Re-assign expansion card addresses in

numerical order.

P-MOD Modbus Communications

SYMPTOM CAUSE RESOLUTION

System is not recognised on the DCS or

plant SCADA system. P-Mod is recognised

by Precision on startup.

Modbus communications is turned OFF in the

menu. Diagnostics on startup will indicate

Network is OFF.

Network address of controller is incompatible

with address assigned at DCS level.

Enter the menu, and at the network menu

item ensure the network is given an address,

rather than set to off.

Check address setting on the Precision

matches the DCS.

Page 22

22 INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

ELEMENT DETAILS

P2 on-board pressure transducer Operating Pressure Range: 0 to 2.5 kPa (0 to 10″ WG)

Accuracy: +/−2.5% FSS

Burst pressure: 20 kPa (83″ WG)

Vibration resistance: to 10 G at 20–2000 Hz

Response time: 8 ms

Temperature-compensated ASIC signal conditioning

DC/DC baseboard

Input voltage: 24 to 48 V DC (+/−10%)

Input current: 3 A maximum

Permissible transients: 60 V maximum

AC/AC baseboard Input voltage: 110 or 240 V AC (+/−10%) 50/60Hz

Input current: 3 A maximum

Permissible transients: 300 V maximum

AC/DC baseboard Input voltage: 110 to 240 V AC (+/−10%) 50/60Hz

Input current: 2 A maximum

Permissible transients: 300 V maximum

DC Output terminals Voltage: 24 V DC

Output current: 2.5 A maximum

10 on baseboard, 10 on each expansion card

AC Output terminals Voltage: Equal to input voltage

Output current: 2.4 A

10 on baseboard, 10 on each expansion card

Maximum number of expansion 19 giving 200 outputs total cards connected

Maximum distance between 100m expansion cards

Tube cleaner output (P-CTX) AC/DC or DC/DC baseboard

Voltage: 24 V DC

Output current: 2.5 A maximum

Tube cleaner output (P-CTX) on AC/AC baseboard Voltage: Equal to input voltage

Output current: 2.4 A

Analogue output (P-CTX) Type: Internally powered 4–20 mA

Voltage: 24 V DC

Output current: 20 mA maximum

Digital I/O (P-CTX) Type: Voltage-free (dry) contacts

Maximum applied voltage: 300 V AC

FAN & GND contacts (baseboard) Type: Voltage-free (dry) contacts

Maximum applied voltage: 300 V AC

RS485 contacts (P-MOD) Type: Data

Maximum applied voltage: 24 V DC

Modbus implementation Layer: 2-wire, half-duplex, RS485 serial

Protocol: Modbus RTU

Baud Rate: 9600

Data bits: 8

Stop Bits: 1

Parity: None

Address range: 0–255

System safe operating temperature 0 to 70°C (32 to 158°F)

System humidity allowance Non-condensing to 85%

PRECISION SYSTEM

SPECIFICATIONS

Page 23

23INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

REGISTER DEFINITIONS P-MOD (MODBUS)

Page 24

24 INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

REGISTER DEFINITIONS P-MOD (MODBUS)

Page 25

25INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

REGISTER DEFINITIONS P-MOD (MODBUS)

Page 26

26 INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

REGISTER DEFINITIONS P-MOD (MODBUS)

Page 27

27INSTALLATION AND OPERATING INSTRUCTIONS PRECISION® FILTER CLEANING SYSTEM CONTROLS

REGISTER DEFINITIONS P-MOD (MODBUS)

Page 28

Goyen Precision Inst-Ops Manual Rev02 11/14

CLEANAIRSYSTEMS.COM

© 2014 Pentair Clean Air Systems reserves the right to change product designs and specifications without notice.

Loading...

Loading...