Pentair freshpoint GRO-350B, freshpoint GRO-350M, freshpoint GRO-475B, freshpoint GRO-475M, freshpoint GRO-575B Installation And Operating Instructions Manual

...Page 1

GRO350B / GRO350M

REVERSE OSMOSIS WATER FILTRATION SYSTEM

INSTALLATION AND OPERATION MANUAL

FDF1-RCFDF1-RC GRO50-RC

F1GC-RC

FDF1-RCFDF1-RC GRO50-RC

F1GC-RC

©2017 Pentair Residential Filtration, LLC waterpurification.pentair.com

Page 2

FreshPoint GRO-350B, GRO-350M

Filtration System

INSTALLATION INSTRUCTIONS

English ................................Pages 3-17

Repair Parts ...........................Pages 15-16

FDF1-RCFDF1-RC GRO50-RC

F1GC-RC

FDF1-RCFDF1-RC GRO50-RC

F1GC-RC

FreshPoint GRO-350B, GRO-350M

Sistema de filtración

INSTRUCCIONES DE INSTALACIÓN

Español ............................. Páginas 18-32

Piezas de repuesto ................... Páginas 30-31

FreshPoint GRO-350B, GRO-350M

Système de filtration

DIRECTIVES D'INSTALLATION

Français .............................. Pages 33-47

Piéces de Rechange ....................Pages 45-46

Page 3

IMPORTANT: Before installing this reverse osmosis system,

WARNING:

make certain your water supply complies with the following

operating specifications. Failure to do so may reduce the

effectiveness of the system and will void the warranty.

SPECIFICATIONS

Pressure Range: 40 to 100 psi (2.75–6.89 bar)

Temperature Range: 40–100°F (4.4–37.8°C)

TDS: <2000 ppm

Maximum Hardness

Sulfide, Iron and Manganese

Chlorine in Water Supply: <2 ppm

pH Limits: 3–11

Overall Dimensions: 11.32"W x 5.46"D x 12.54"H

(288mm x 139mm x 319mm)

Weight: 7.1 lbs (3.2 kg)

Tank Dimensions: 8.94"DIA x 13.83"H

(227mm DIA x 351mm)

Tank Capacity Max: 2.1 gal (7.9 L)

Tank Air Pressure Empty: 5-7 psi (0.34-0.48 bar)

Tank Weight (Full): 19.50 lb (8.8 kg)

†

If the hardness of your water is above 10 gpg (171 mg/L), lime

scale will build up rapidly on the membrane. Scale buildup will

plug the membrane and make the system ineffective. We do not

recommend these reverse osmosis systems to be used with

water in excess of 10 gpg (171 mg/L) hardness.

‡

A maximum total level of approximately 0.01 ppm sulfide, iron

or manganese is permissible. See your local dealer to reduce

these substances in your water.

†

: <10 gpg (170 mg/L)

‡

: <0.1 ppm

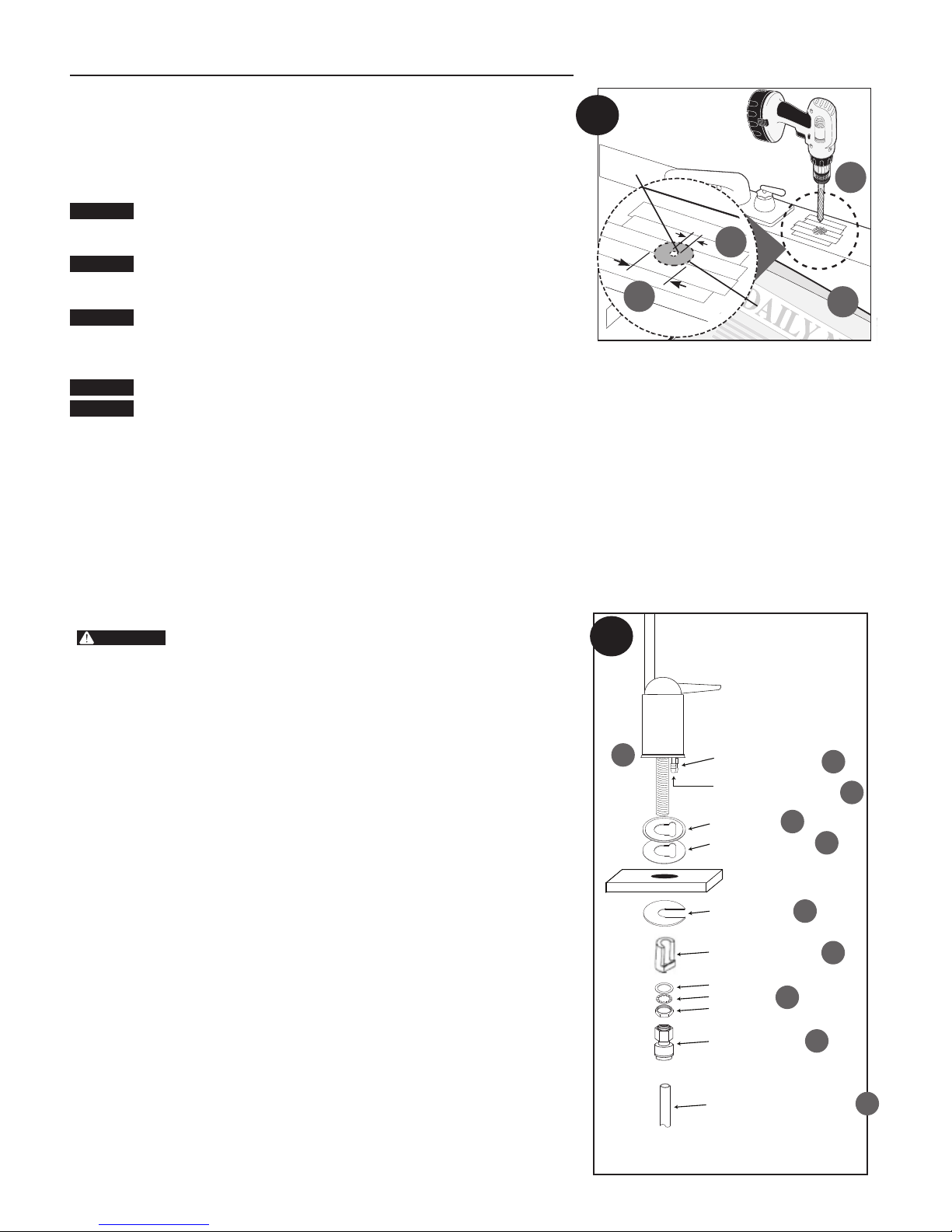

Tools and Materials Required

• Hand or electric drill (cordless preferred)

• (2) Adjustable wrenches

• Slotted and Phillips screwdrivers

• File

• Safety glasses

• Drill bits: 1/8", 3/16", 1/4", 3/8"

• Tube cutter or utility knife

• Pencil

• Towel

• Bucket

• Screwdriver bits: 1/8", 3/16", 1/4", 3/8"

If sink does not have hole for separate faucet:

• Center punch

• 3⁄4" hole saw or drill bit

• Safety mask

NOTE: All tools may not be necessary for installation. Read

installation procedures before starting to determine

what tools are necessary.

PARTS INCLUDED:

• System with cartridges

• Storage Tank

• Installation Hardware Kit

• Lead-free drinking water faucet with air gap

CALIFORNIA PROPOSITION 65 WARNING

This product contains chemicals known to the

State of California to cause cancer or birth

defects or other reproductive harm.

FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual • 3

Page 4

WARNING:

CAUTION

PRECAUTIONS

GENERAL

Do not use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system.

Systems certified for cyst reduction* may be

used on disinfected waters that may contain

filterable cysts.

*NSF/ANSI Standard 58 certified to reduce cysts such as

Cryptosporidium and Giardia by mechanical means.

RO System must be protected against freezing,

which can cause cracking of the RO components

and water leakage.

NOTE:

• Your water must be within required limits for satisfactory

operation. If not, your membrane life may be shortened and

your warranty will be voided (see Specifications on page 3).

• This reverse osmosis system will not protect against

disease-causing bacteria or remove naturally-occurring

harmless bacteria.

• Install on cold water line only.

• Make certain that installation complies with all state and

local laws and regulations.

• The replacement cartridges and reverse osmosis element

included with this system have limited service lives. Changes

in taste, odor, and color of the water being filtered indicate

that the cartridge should be replaced.

• After prolonged periods of non-use (such as during a

vacation) it is recommended that the system be flushed for 5

minutes before it is used.

• A drinking water cartridge may contain carbon fines (very

fine black powder). After installation, flush the system for 5

minutes to remove the carbon fines before using the water.

• It is recommended that you run the tap at least 20 seconds

prior to using water for drinking or cooking purposes.

• The contaminants or other substances removed or reduced

by this water treatment device are not necessarily present in

your water.

HOW REVERSE OSMOSIS WORKS

The GRO-350B/GRO-350M Reverse Osmosis (RO) System uses

a semi-permeable membrane to reduce dissolved salts and

minerals, improving the taste and odor of your water. The RO

membrane is made of layers of micron-thin film wound around

a hollow center core. Water molecules can pass through the

membrane, but dissolved salts and minerals are rejected.

The GRO-350B/GRO-350M Reverse Osmosis System features

3-stage filter action. Your water supply is pre-filtered to

reduce dirt and chlorine that may foul the membrane. The RO

membrane separates this pre-filtered water into PRODUCT

WATER and DRAIN or REJECT WATER. Incoming water

pressure forces the product water through the membrane and

into the storage tank. Dissolved solids and other contaminants

cannot pass through the membrane and are sent to the drain

as reject water. When you open the drinking water faucet,

product water is drawn from the storage tank through an

activated carbon post-filter, providing you with cleaner, greattasting water.

For each gallon of water produced, several gallons are

discharged as reject water. The storage tank can hold up to

2.1 gallons (7.9 L) of water at a time, for drinking and cooking

needs. When used under the Specifications on page 3 of the

manual, your Reverse Osmosis membranes should last 12-24

months.

4 • FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual

Page 5

1

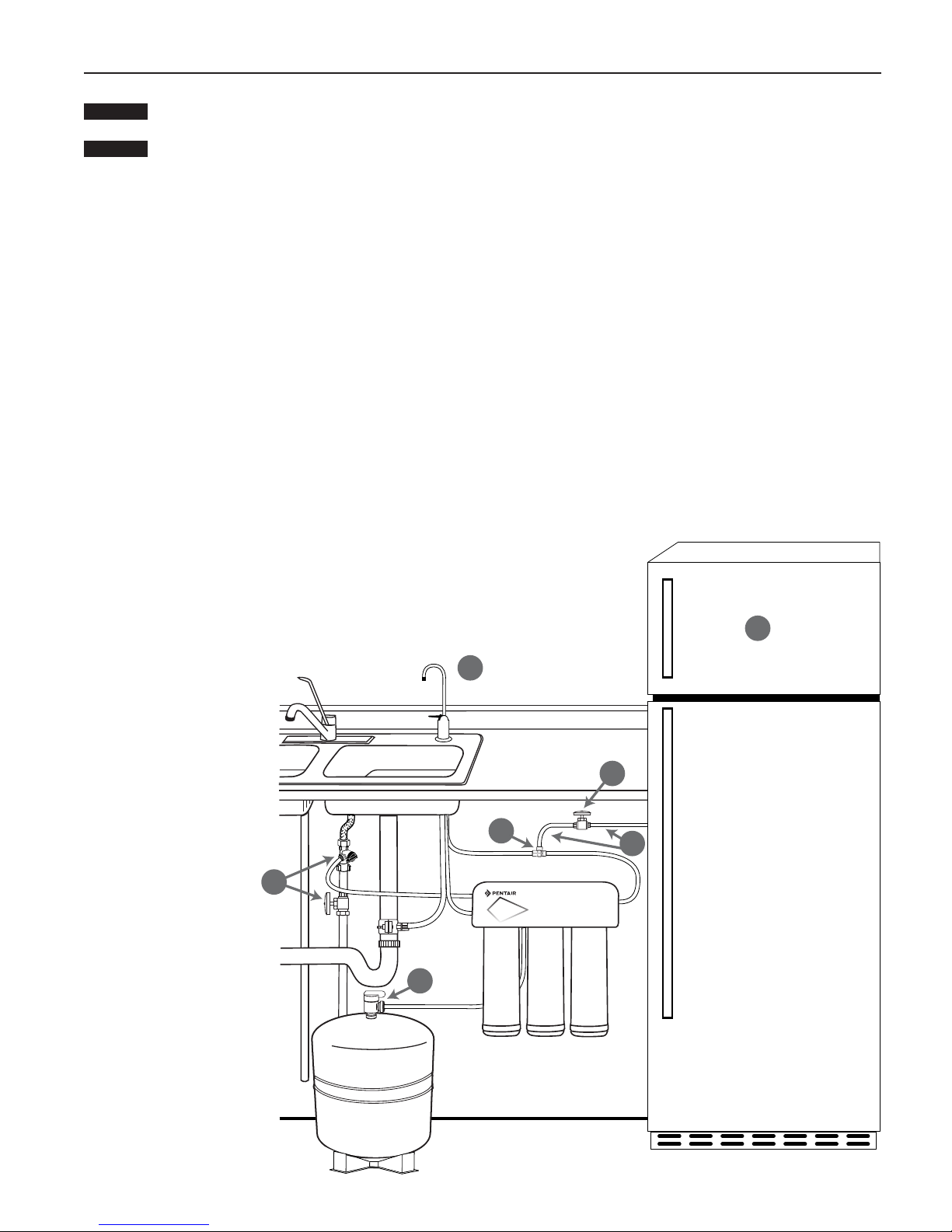

INSTALLATION

• Please read all instructions and precautions before installing and using

your GRO-350B/GRO-350M.

• For standard, under-sink installation on 3/8" (9.52 mm) steel, brass, or

copper cold water line.

• When selecting a mounting location of the system and tank, take into

consideration the length of tubing required for connections between existing

plumbing and system components. Some installation sites may require

more tubing than provided in the kit.

• Numbered diagrams correspond with numbered steps.

1. Installing the Water Supply Adapter

The supply adapter fits 1/2"-14 NPS supply threads or

3/8" x 3/8" compression. If local codes permit, it may be used to connect the

system to the cold water supply line. If local codes do not permit the use of the

supply adapter, alternate connectors can be obtained from your local supplier.

Directions:

(A) Turn off cold water supply line. If cold water line does not have a shut-off

valve under the sink, you should install one.

(B) Turn on the cold water faucet and allow all water to drain from line.

(C) Disconnect riser cold water supply valve.

(D) Ensure the sealing gasket is fully seated into the feed adapter valve female

thread.

(E) Install feed adapter valve onto supply valve as desired. The feed adapter valve

may be installed at the bottom of the supply hose or the top of the cold water

line. Hand tighten only.

(F) Connect the riser to the feed adapter valve.

NOTE: Be careful not to cross-thread.

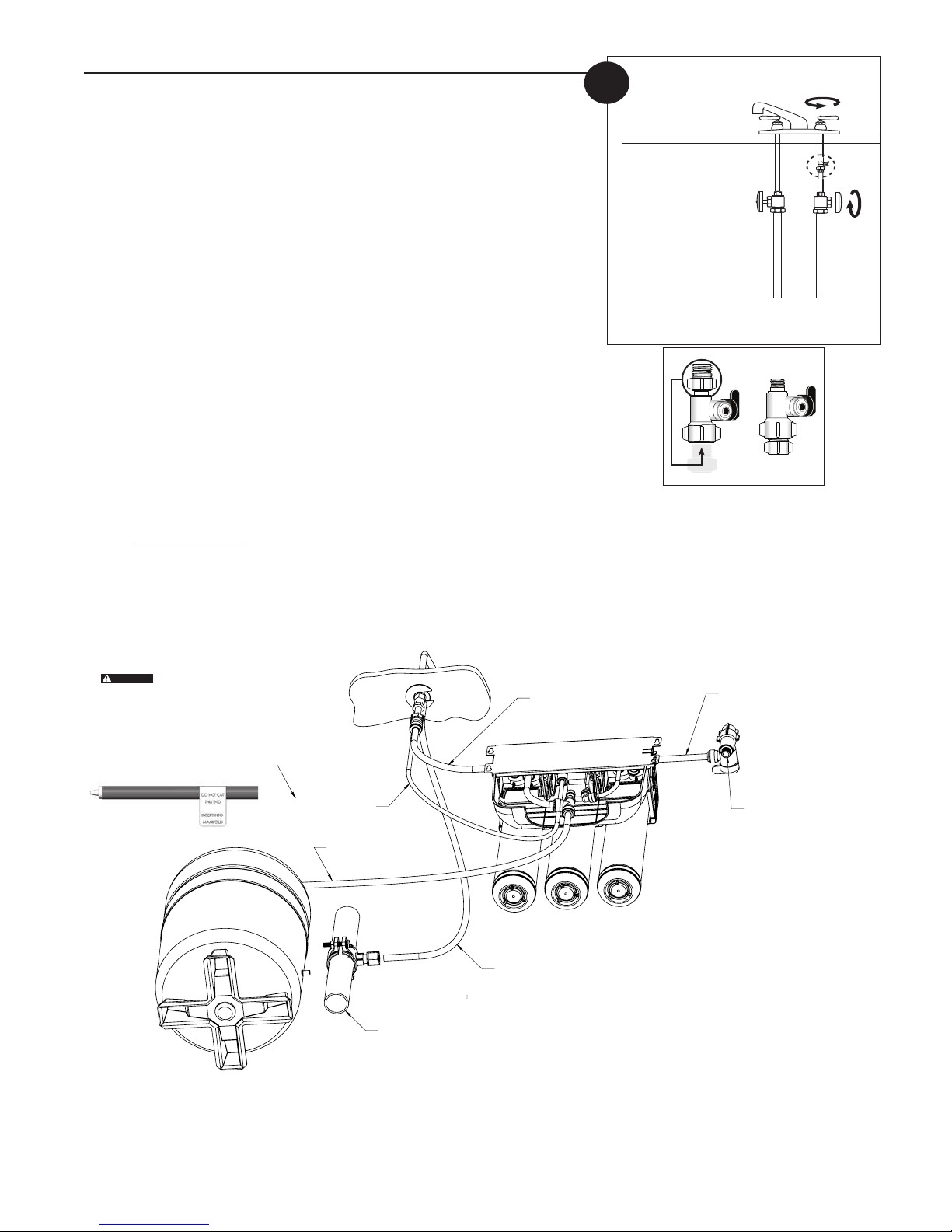

The 1/4" red drain tubing includes a

WARNING:

ow controller installed in one end of

the tubing. The end of the tubing

with the ow restrictor must be

installed into the RO system before

attaching to the faucet.

DO NOT cut o the ow restrictor.

RO DRAIN LINE (1/4" RED)

RO LINE TO TANK (3/8” BLUE)

DRAIN PIPE

RO OUTLET LINE (3/8” BLUE)

FAUCET DRAIN LINE (3/8" RED)

RO INLET LINE (3/8” WHITE)

CONNECT TO WATER SUPPLY LINE

FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual • 5

Page 6

INSTALLATION CONTINUED . . .

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING:

2. Selecting the Faucet Location

The drinking water faucet should be positioned with function, convenience, and

appearance in mind. An adequate flat area is required to allow faucet base to rest

securely. The faucet fits through a 3/4" hole. Most sinks have pre-drilled 1-3⁄8" or

1-1⁄2" diameter holes that may be used for faucet installation. If these pre-drilled

holes cannot be used or are in an inconvenient location, it will be necessary to

drill a 3/4" hole in the sink to accommodate the faucet.

This procedure may generate dusts which can cause severe irritation if

inhaled or come in contact with the eyes. The use of safety glasses and

safety mask for this procedure is recommended.

DO NOT ATTEMPT TO DRILL THROUGH AN ALL-PORCELAIN SINK. If

you have an all-porcelain sink, mount the faucet in pre-drilled sprayer

hole or drill through countertop next to sink.

When drilling through a countertop, make sure the area below the

drilled area is free of wiring and piping. Make certain that you have

ample room to make the proper connections to the bottom of the

faucet.

Do not drill through a countertop that is more than 1" thick.

Do not attempt to drill through a tiled, marble, granite or similar

countertop. Consult a plumber or the countertop manufacturer for

advice or assistance.

The following instructions apply to stainless steel sinks ONLY.

(A) Line bottom of sink with newspaper to prevent shavings, parts or tools from

falling down the drain.

(B) Place masking tape over the area to be drilled to help prevent scratches if

drill bit slips.

(C) Mark point with center punch. Use a 1/4" drill bit to drill a pilot hole through

sink.

1

(D) Use a 1-

⁄4" hole saw to enlarge hole. Smooth rough edges with a file.

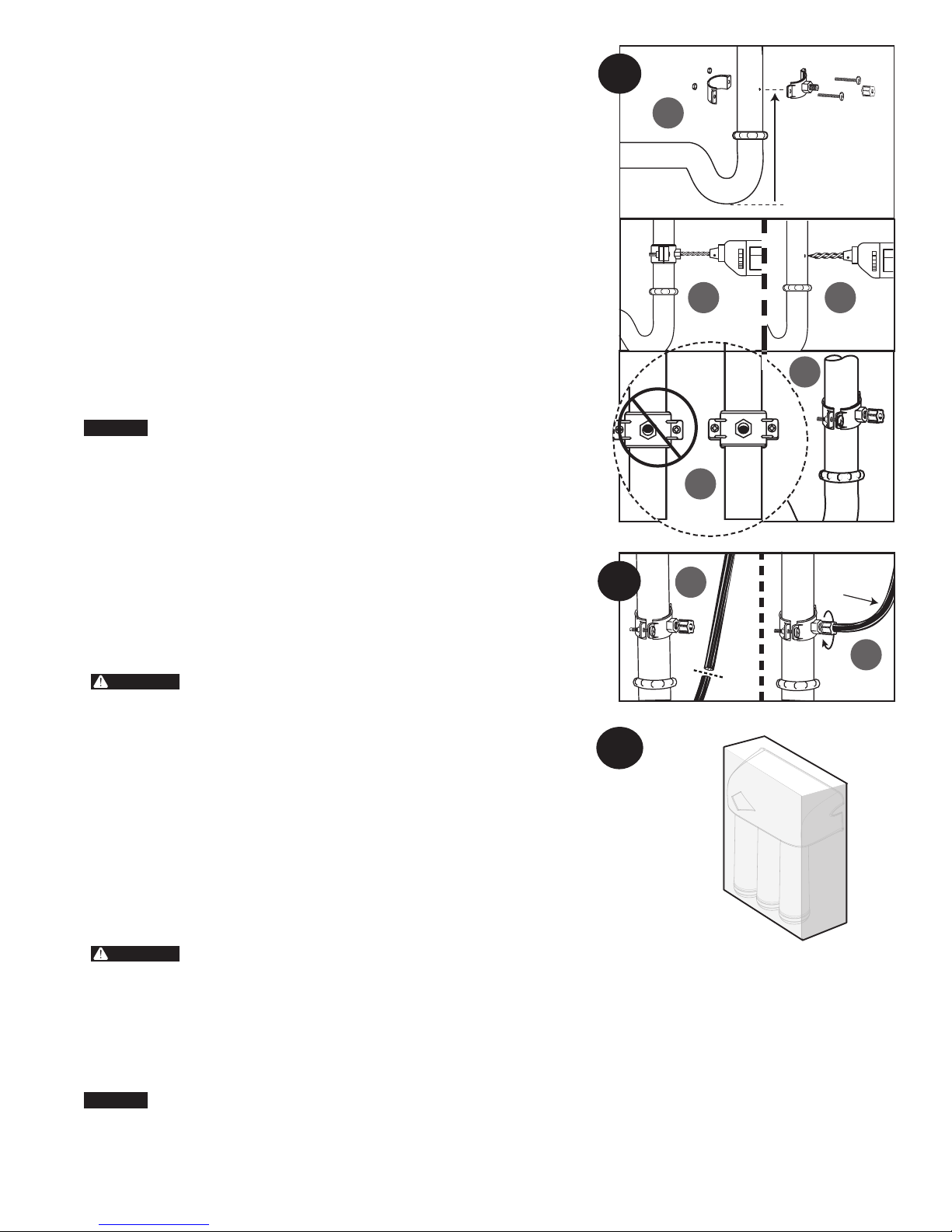

3. Mounting the Faucet

Due to variance in installation sites, it is highly recommended to

install the 1/4" red drain tubing to the RO system manifold before

fully mounting the faucet. Make note of the 1/4" red drain tubing

length required to reach from the RO system manifold to the

faucet connection and plan accordingly in relation to mounting

location of system components. Furthermore, the 1/4" red drain

tubing includes a flow controller installed in one end of the

tubing. The end of the tubing with the flow restrictor must be

securely installed into the RO system manifold before attaching to

the faucet. DO NOT cut off the flow restrictor.

NOTE: Not all parts provided with the faucet may be needed for installation.

(A) Slide chrome plate and black rubber washer onto faucet by threading both

drain tubes through the holes on the plate and washer.

(B) Attach large diameter red 3/8" drain tube to barb fitting at the faucet base.

This tube should be long enough to reach the drain clamp in Step 4.

(C) Locate the small diameter red 1/4" drain tube connected to the drain port

of the GRO element. Route the tubing to the faucet and cut off the excessive

length of tubing.

(D) Slide white extension spacer onto long threaded section of faucet. Open end

of extension should come in contact with base of faucet.

(E) Screw washer, lockwasher, and locking nut onto end of faucet threads

(F) Screw quick connector onto end of facuet threads.

(G) Wet end of 3/8" blue tube. Push into bottom of quick connector. Tug gently to

be sure connection is complete.

NOTE: To remove the tube, push on the fittings' collar and pull the tube out.

(H) Holding the faucet, feed the three tubes through the hole in the sink. Position

the faucet handle at a desired location

(I) Center the faucet and slip slotted disc between the white extension spacer

and the bottom of the counter or sink. Tighten the locking nut with a wrench

until it is tight.

2

Pilot Hole

D

3

B

C

1/4"

1

4”

⁄

C

1

⁄4"

1

11⁄4”

D

Mounting

Hole

H

BARB FITTING

(1/4” RED RO DRAIN LINE)

BARB FITTING

(3/8” RED FAUCET DRAIN LINE)

CHROME PLATE

BLACK RUBBER WASHER

COUNTER TOP

SLIP SLOTTED DISC

WHITE EXTENSION SPACER

WASHER

LOCKWASHER

LOCKING NUT

QUICK CONNECTOR

TUBING (3/8” BLUE RO OUTLET LINE)

A

E

A

C

B

A

I

D

F

G

6 • FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual

Page 7

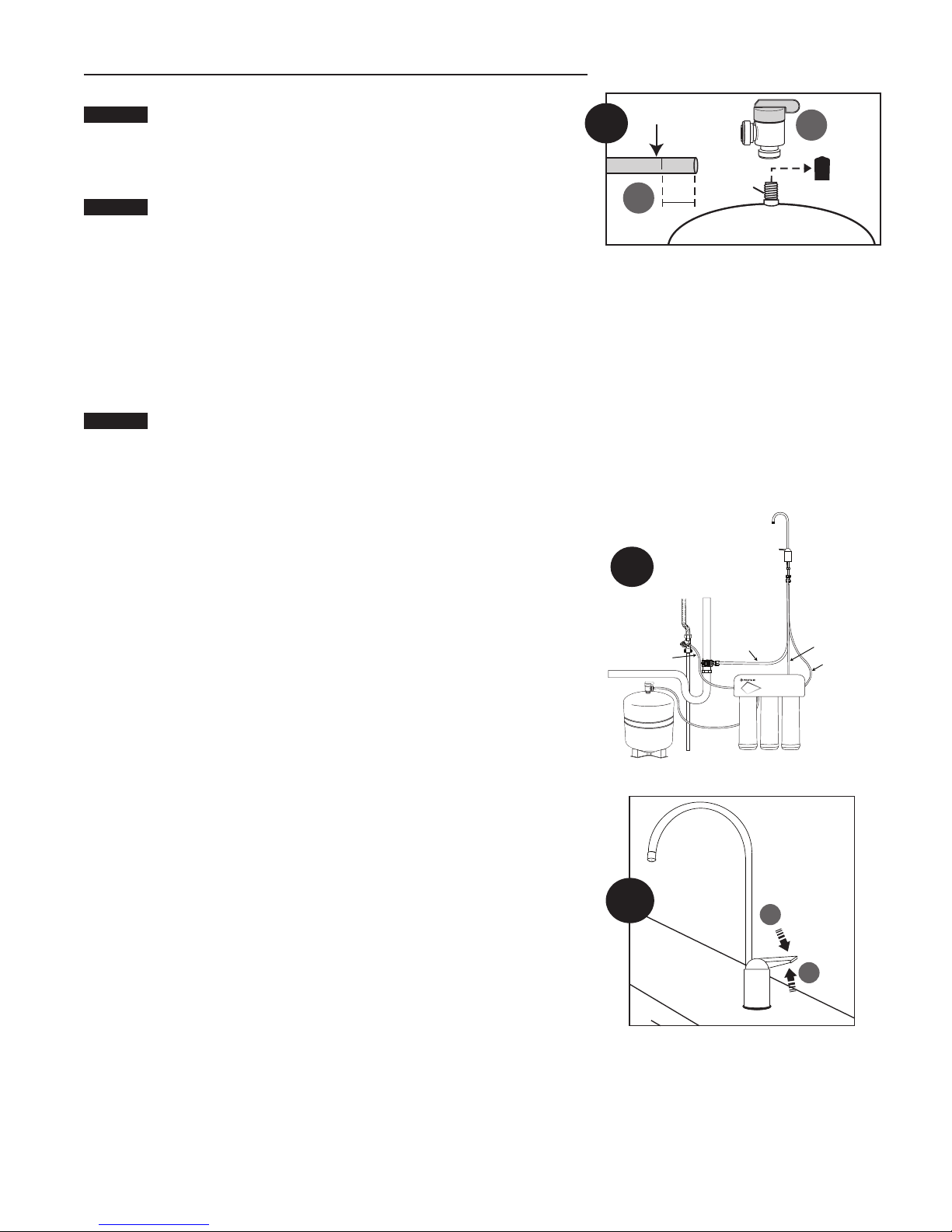

4. Installing the Drain Clamp

CAUTION

WARNING:

WARNING:

CAUTION

5

6

NOTE: If you have a single-basin sink with a disposal unit, call Technical Support

for options.

NOTE: Before installing the drain clamp, check the drainpipes under the sink

for corrosion. Corroded pipes should be replaced before continuing with

installation.

(A) Attach the drain clamp to a vertical section of the drainpipe, about 6" above

the trap. Make sure the opening on the drain clamp is facing towards the

drinking water faucet.

(B) Using the fitting hole of the drain clamp as a guide, drill a 1/4" hole through

one side of the drainpipe.

(C) Remove the drain clamp from the drainpipe and enlarge the hole with a

3/8" drill bit. Use a file to remove rough edges from the drilled hole.

(D) Make sure the black rubber gasket is adhered to the inside of the drain clamp

and place the drain clamp assembly over the drilled hole. Look through the

hole and position the clamp so that the center of the clamp hole is slightly

higher (about 1/16") than the center of the drilled hole. Tighten the clamp

securely.

(E) Screw the plastic compression nut onto the drain clamp until hand-tight.

5. Connecting the Faucet to the Drain

This is a gravity drain line. Any loops, kinks or sharp bends must be

eliminated before proceeding. Failure to create a straight line to the

drain may result in reject water leaking through the air gap in the

faucet onto the countertop and below the faucet.

(A) Align the larger reject 3/8" red tubing from the faucet with the compression

nut on the drain clamp. Create as straight and smooth a path as possible with

the tubing. Do not kink tube. Cut the tubing squarely and remove any internal

and external burrs. Insert inner tube insert (white cone) into end of 3/8" red

tubing. Remove compression nut from the drain clamp. Place compression

nut on end of 3/8" red tubing.

(B) Insert the tubing into the drain port until it stops. Tighten the compression nut

with fingers, then tighten 1 to 2 turns with a wrench to secure tubing to drain

port.

6. Mounting the System

When selecting a mounting location of the system and tank, take

into consideration the length of tubing required for connection

between components. Some installation sites may require more

tubing than provided in the kit.

(A) Select a location under the sink, or other suitable area where the system will

be installed.

NOTE: The system carton can be used to determine the operational footprint

required for installation of the system and replacement cartridges.

(Figure 6)

(B) Mount the system vertically. Ensure mounting is level. Remove filter

cartridges for easier access to bracket mounting holes. Place a pencil mark

in the upper slots of the bracket mounting holes. (Figure 4b). Alternate

mounting option: If mounting the system near the floor, place the pencil

marks above each of the mounting holes on the bracket to ensure enough

space resides below the cartridge and the floor for cartridge replacement

(Figure 4c). Use the 3/32" drill bit to create pilot holes for mounting.

The system should be mounted to a firm, solid surface that is

able to support the weight of the system.

4

6

A

B C

D

A

7” (178 mm)

16.25”

(413 mm)

14”

(356 mm)

6"

E

3/8" Tube

B

7. Connecting the Faucet to the System

(A) Determine the length of plastic blue tubing needed to connect to the outlet

(right) side of the filter from the faucet. Be sure to allow enough tubing to

prevent kinking and cut the tubing squarely. Use a marker to mark one end of

the tubing 5/8" from the end. Wet the end of the 3/8" tube and push into the

outlet (right) connection of the system up to the mark.

Do not bend or crimp tube while inserting.

(B) Gently pull back on the tube to ensure it is connected properly.

FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual • 7

Page 8

7

RO INLET LINE (3/8” WHITE)

RO DRAIN LINE

RO LINE TO TANK

(3/8” BLUE)

(3/8" RED)

FAUCET DRAIN LINE (1/4” RED)

RO OUTLET LINE (3/8” BLUE)

8 • FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual

Page 9

INSTALLATION CONTINUED . . .

CAUTION

CAUTION

CAUTION

10

8. Connecting the Storage Tank to the System

When tank is full, it weighs approximately 19.50 lbs. (8.8 kg.) Provide

ample support under the tank.

(A) To prevent leaks, apply 3 or more wraps of plumber tape to threads on tank.

Thread the tank valve onto the top of the tank opening. Turn tank so handle is

in line with tubing.

The tank/valve connection will leak if not properly sealed. Plumber

tape will normally seal the threaded connection.

(B) Locate the 3/8" blue tubing. Place a mark on the tubing 5/8" from one end.

Moisten the marked end of the tubing with water and insert with a twisting

motion into the port of the tank valve until the 5/8" mark is flush with the

quick connect fitting. Then locate the tank near the system's installation

area.

(C) Cut the tubing to correct length. Install free end of tubing into white

quick-connect fitting on the system. Ensure the tubing does not kink. Retain

remaining blue tubing for use in connecting system to water supply adapter.

Some installation sites may require additional tubing not provided in kit.

(D) Place entire system over mounting screws on wall and slide down.

Make certain system is firmly attached to wall to prevent it from falling

and possibly becoming damaged.

NOTE: Use caution not to bend or pinch the tubing behind the system while

attaching to mounting screws.

9. Connecting the System to the Water Supply Adapter

(A) Locate remaining length of 3/8" plastic blue tubing.

(B) Place a mark on the tubing 5/8" from the end. Moisten the end of the tubing

with water and insert with a twisting motion push into white quick connect

fitting on the left side of system. Depending on the installation, the system

may need to be removed from the mounting surface to access the left side of

the system.

(C) Cut the tube to a length that will allow connection to the Water Supply

Adapter. Ensure the tubing does not kink. Place a mark on the tubing

5/8" from the end. Moisten the end of the tubing with water and insert with a

twisting motion push into quick connect fitting on the Water Supply Adapter.

8

RO INLET LINE (3/8” WHITE)

3/8" Tube

B

9

5/8"

Apply

plumber

tape

RO DRAIN LINE

(3/8" RED)

A

FAUCET DRAIN LINE (1/4” RED)

RO OUTLET LINE (3/8” BLUE)

10. Faucet Operation

(A) For controlled water flow, push the handle down.

(B) For constant water flow, lift the faucet handle to lock it in the open position.

RO LINE TO TANK

(3/8” BLUE)

A

Push Down

B

Push Up

FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual • 9

Page 10

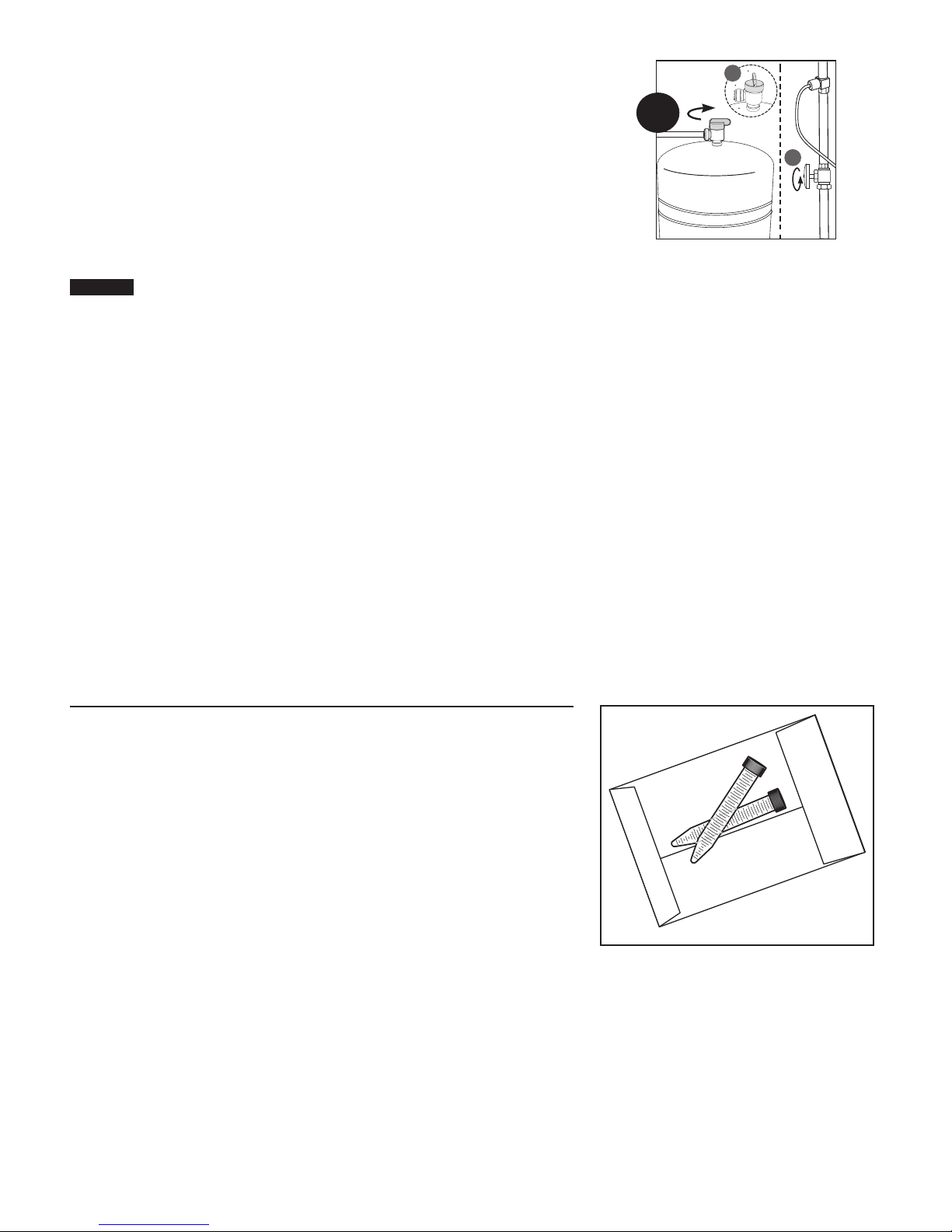

11. System Start-up

CAUTION

NOTE: The reverse osmosis membrane is treated with a food grade sanitizing

agent that may cause an undesirable taste. Although it is not harmful, it

should be flushed from the system.

NOTE: The post-polishing filter may contain fine black carbon particles. These

fines are harmless, but may make the water appear gray in color. The

carbon fines are flushed from the system with the first tank full of water.

NOTE: The RO system does not produce a high volume of water on demand as an

ordinary filter does. Water is produced at a slow, drop-by-drop rate. The

system requires about 2 to 4 hours to fill the storage tank. As water is

taken from the tank, the system automatically starts the cycle of replacing

the water and then stops water production when the tank is full.

Visually check the entire system for leaks.

Troubleshooting on page 14.

(A) Turn off valve at top of storage tank.

(B) Turn on the cold water supply slightly, and ensure the supply adapter valve is

open.

(C) Lift the faucet handle to lock it in the open position and let it drip for 30 min.

(D) Completely open the cold water supply until it comes to a stop. Allow water

to drip from the faucet for 12 more hours. Then close the faucet and open the

valve on the storage tank. The tank valve is open when the handle lines up

with the tubing connection.

(E) Allow 3 hours for the tank to fill. Continue to periodically check the

installation for leaks. After the storage tank is filled, open the faucet to flush

the post-filter cartridge. Allow 4 to 5 minutes for all of the water to drain from

the tank. Close faucet and allow tank to fill.

(F) Repeat step E four times.

NOTE: Initially, the water may appear cloudy. This is a result of air trapped in

the post-polishing filter. It is not harmful and will disappear in a matter

of minutes. It may take up to a week after installing a new post-polishing

filter for the trapped air to dissipate.

The system is ready for operation. You can now enjoy quality water from your

Reverse Osmosis System.

If a leak is present, see

11

Closed Tank Valve

A

Open

Tank Valve

B

Counterclockwise

TESTING YOUR REVERSE OSMOSIS SYSTEM

(NON-MONITORED SYSTEMS ONLY)

Model GRO-350B Reverse Osmosis System

Total Dissolved Solids (TDS) Test

NOTE: It is highly recommended that you (the consumer) have your water

tested at least every 6 months to verify that your system is performing

satisfactorily.

SAMPLING INSTRUCTIONS:

Sampling instructions are included with the Total Dissolved Solids (TDS) Test Kit.

Total Dissolved

Solids Test Kit

10 • FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual

Page 11

OPTIONAL INSTALLATION

CAUTION

CAUTION

Connecting your Reverse Osmosis System to Refrigerator Icemaker / Water Dispenser

If you are connecting this unit to your refrigerator/icemaker with initial RO installation, wait to turn on the icemaker

until the post-polishing filter has been flushed according to Step 11.

Use plastic tubing and fittings. Do not use copper tubing or brass fittings.

For optimum performance, it is recommended that the distance between the RO system and the refrigerator icemaker/water

NOTE:

dispenser be no greater than 10 feet (3 m). At distances greater than 10 feet, the water pressure from the system may not be

adequate to deliver water to the refrigerator.

MATERIALS REQUIRED(available from your local hardware store):

• 3/8" x 3/8" x 3/8" (0.952 mm x 0.952 mm x 0.952 mm) compression or quick-connect tee

• 10 feet (3 m) of 3/8" (0.952 mm) polyethylene tubing

• Shut-off valve

1. Turn off refrigerator water supply and icemaker (consult manufacturer’s guidelines).

2. Close tank valve (on top of storage tank).

3. Turn off water to RO system at the cold water supply, or at the feed water supply adapter.

4. Open drinking water faucet to relieve pressure.

5.

Locate tubing (permeate) leading to your drinking water faucet. Cut and insert the

3/8"

x

3/8"

x

3/8"

compression or quick-connect tee into the permeate tubing.

Consult manufacturer’s guidelines before installing the supply adapter.

NOTE: When cutting the permeate tubing, you may experience some water leakage.

6. Using a length of 3/8" polyethylene tubing, connect the

icemaker/dispenser line with the free port on the compression tee.

7. The shut-off valve should be installed as close to this port of the tee

as possible. Shut-off valve should be installed in the OFF position

Consult manufacturer’s guidelines before installing the shut-off valve.

8. Completely open cold water supply.

9. Open tank valve.

10. Turn off the drinking water faucet.

11. Turn on water to RO system at cold water supply.

12. Turn on icemaker and open shut-off valve.

Consult manufacturer’s instructions.

13. Check for leaks and tighten connections if necessary.

4

1

3

7

5

6

2

FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual • 11

Page 12

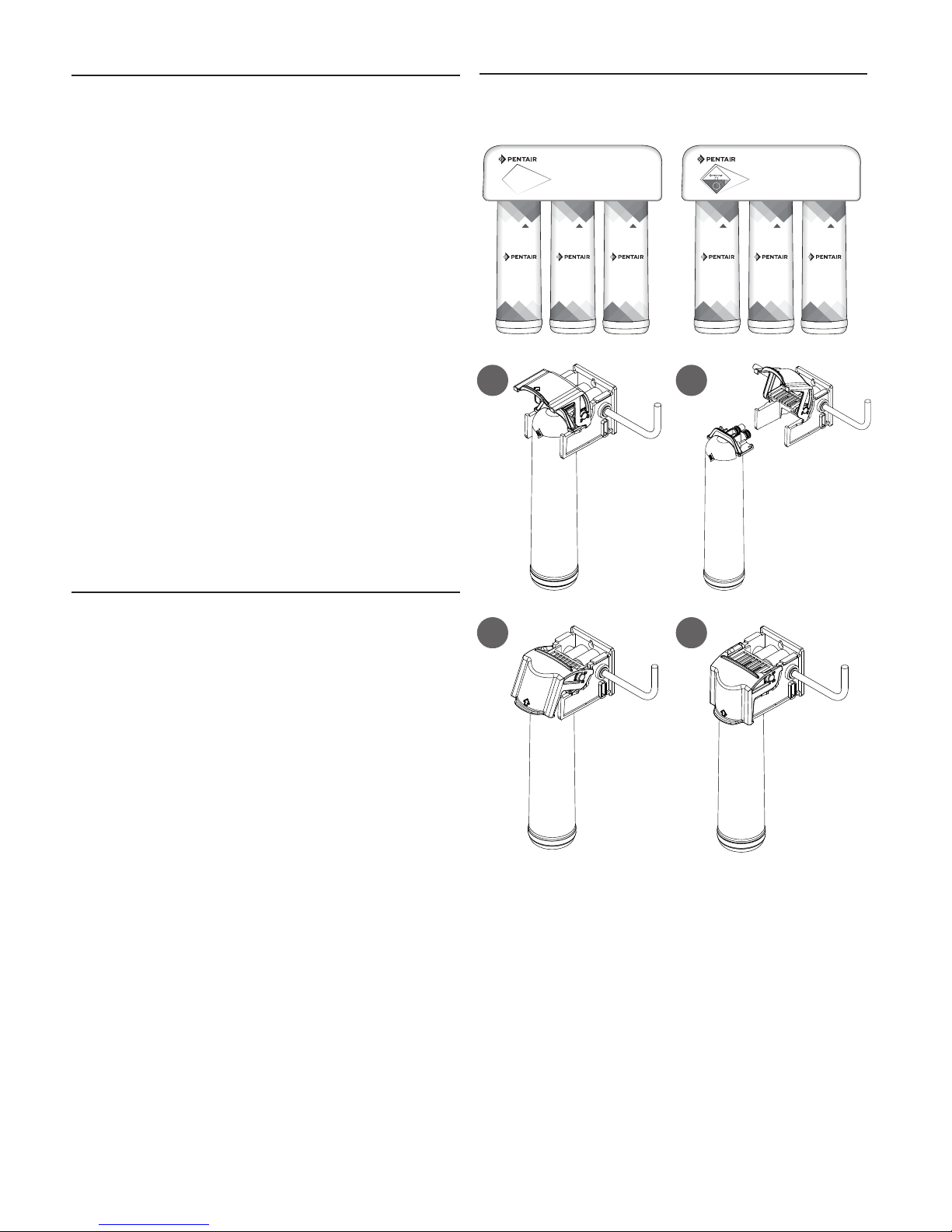

Filter Cartridge Replacement

NOTE: The life of the filter cartridges depends on water

volume used and the quality of the feed water. It is

recommended that the filter cartridges be replaced

every 6-12 months, or when there is a noticeable

change in taste, odor, or flow of filtered water.

Ensure the correct cartridge is purchased for the

system.

Model GRO-350B/GRO-350M uses FDF1-RC, GRO50-RC, and

F1GC-RC Replacement Cartridges

1. Cartridge Replacement

A. Relieve pressure by turning off the water supply to the

system and opening a faucet until water flow stops (wait 5

to 10 minutes after water stops to relieve pressure in RO

membrane). Place a bucket or towel under the system to

catch any water drips.

B. Lift the locking bar upward until the filter cartridge

disengages from the filter head assembly (Figure A).

C. Pull the cartridge away from the filter head assembly and

ensure the locking bar remains in the fully up position

(Figure B).

D. Align the posts on the filter cartridge with the ports in the

filter head assembly. Slide the cartridge filter into the filter

head assembly (engaging with the locking bar causing it to

drop forward and down). (Figure C).

E. Pull down the locking bar until it snaps into place

(Figure D).

Cartridge Sequence

GRO-350B GRO-350M

FDF1-RCFDF1-RC GRO50-RC

A

F1GC-RC

FDF1-RCFDF1-RC GRO50-RC

B

F1GC-RC

Troubleshooting

Leaks between filter head assembly and filter

cartridge

1. Relieve pressure by turning off the water supply to the

system and opening faucet until water flow stops. Place a

bucket or towel under the system to catch any water drips.

2. Remove cartridge and inspect O-rings to make sure they

are seated and clean.

3. Install filter cartridge. Place system into operation and

check for leaks. If leaks persist, turn off the water supply

and contact Technical Support at 1-800-279-9404.

Leaks from tubing fittings

1. Relieve pressure by turning off the water supply to the

system and opening faucet until water flow stops. Place a

bucket or towel under the system to catch any water drips.

2. Depress collet on system or inlet supply adapter tubing

fittings and pull tubing from fitting. Inspect surface of

tubing for scratches or debris. Clean or cut back tubing to

access clean surface.

3. Wet the end of the inlet tubing and press into the inlet

fitting of the system. Ensure the tubing is fully pushed past

the fitting O-rings. Place system into operation and check

for leaks. If leaks persist, turn off the water supply and

contact Technical Support at 1-800-279-9404.

C

D

12 • FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual

Page 13

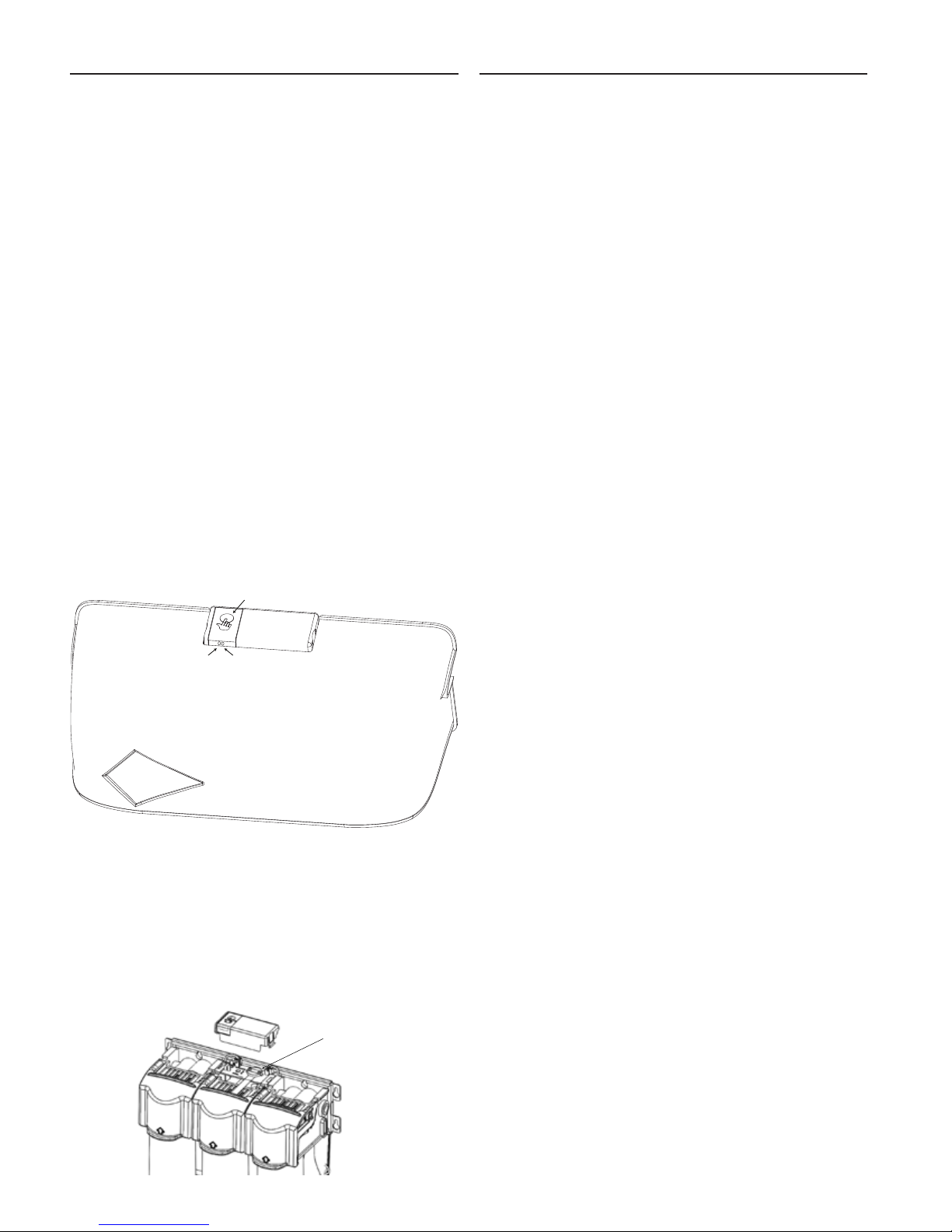

Cartridge Timer Procedure

Metal

Blinks red 1x after 11 months

Blinks red 3x after 12 months

FILTER CARTRIDGE TIMER

(MONITORED SYSTEMS ONLY)

The filter cartridge timer can be installed to the systems

decorative cover by peeling away the adhesive backing on the

metal plate included with the cartridge timer. The timer can

also be attached to a metal magnetic surface using the magnet

that is factory installed on cartridge timer.

INSTALLATION AND ACTIVATION

Once the installation location has been selected, activate the

timer by pulling the plastic tab out from the side of the timer.

Press and release the key to verify the battery is operational.

The light will blink green three times. (Figure A)

NOTE: The timer operates on 12 month schedule. The timer

uses a coin cell type 2023 battery.

The Filter Cartridge Timer is Operational

Operation

1. The timer will begin to blink red once every three minutes

after 11 months, and will blink red three times every three

minutes after 12 months. (Figure B)

NOTE: Timer status of the cartridge life can also be

viewed immediately by pressing and releasing the

key.

Reset Timer

1. To reset the timer after filter cartridge replacement, press

the key and hold for 5 seconds. The timer is now reset to 12

months. (Figure C)

Battery Replacement

1. Replace the battery every 12 months. To replace the battery,

locate the slot on the side of the timer body and carefully

remove the front of the timer. The battery is now accessible.

(Figure D)

2. Slide the new battery under the battery retention bracket

with the positive + side of the battery facing up towards the

battery retention bracket. Align the tab on the timer back

to the slot on the timer front and press and snap both timer

halves together. Battery replacement will not reset the 12

month timer. If reset is required, press and hold key for 5

seconds.

Magnet

A

Blinks

Greeen 3x

Key

B

C

Press and hold for 5 seconds

D

FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual • 13

Page 14

(MONITORED SYSTEMS ONLY)

The GRO-350M is equipped with a TDS monitor that checks the

Total Dissolved Solids (TDS) the system is reducing from the

water. The TDS Monitor allows the user to test the quality of

the water produced by the system. Test the unit if a noticeable

change occurs in the taste of the drinking water.

The TDS Monitor will display the following colors when

pressing the test button:

Red Light (Left): Water Quality Test Required, proceed to

following steps

1. Draw 1 gallon of water from the unit to purge standing

water from the TDS monitor probes.

2. Push button to test again. If the light is still red, open the

faucet and allow water to run until the storage tank is

empty. Flow from faucet will noticeably decrease indicating

the storage tank is empty.

3. Close faucet and allow system to fill storage tank, 2-3

hours

4. Push button to test. If the light is still red, replace the

membrane cartridge.

Green Light (Right): System Operational

Red and Green Light: Verify inlet and outlet conductivity probes

dry, no water to system

No Lights: The battery needs to be changed. Replace battery

every 12 months.

NOTE: The TDS monitor is activated during initial installation

by pulling the plastic tab out from the TDS monitor.

TDS MONITOR TEST BUTTON

RED LED

GREEN LED

TROUBLESHOOTING GUIDETDS MONITOR

Leaks on tank valve assembly

1. Open drinking water faucet to drain storage tank. Let

drinking water faucet run until it drips. Turn off cold water

supply.

2. Push in on white collar of tank valve fitting and pull out

tubing. Unscrew the tank valve from the storage tank.

Rewrap threads on top of the tank with plumber tape. Screw

tank valve back onto tank. Trim 1/2" from end of tubing and

reinsert 5/8" into tank valve fitting.

3. Open the cold water supply and shut off the reverse osmosis

faucet. Let the system pressurize for several hours and

check for leaks. Check again after tank is fully pressurized.

Leaks on quick-connect fittings

1. Close the cold water supply and tank valve.

2. Depress plastic collar and pull out tubing.

3. Cut off 1" of tubing and place a mark 5/8" from end of

tubing. Tubing should be cut squarely. The internal and

external burrs should be removed.

4. Push tubing 5/8" into fitting.

5. Open the cold water supply and tank valve. If leaks persist,

call Technical Support.

High TDS in Product Water

If high levels of TDS (Total Dissolved Solids) are detected in

your product water as determined by the TDS Monitor or by the

TDS test kit, the cartridge membrane may need to be replaced

or the reject flow control may be clogged. See your dealer or

plumber to check product water TDS.

Reduced production

Slow or no product water flow usually indicates a clogged

cartridge.

Gradual return of taste and odor

Gradual return of unpleasant taste and odor over a period of

time may indicate that your cartridges need to be replaced.

Sudden return of taste and odor

If shortly after complete servicing noticeable taste and odors

return, contact Technical Support.

No water pressure from the drinking water faucet

or low volume in storage tank

1. Close the cold water supply to system.

Replacing the Battery

1. Replace the battery every 12 months. To replace the

battery, remove the TDS Monitor Cover and remove the

battery from retainer.

2. Slide the new battery under the battery retention bracket

with the positive + side of the battery facing up towards the

battery retention bracket.

3. Install TDS Cover and press button to verify operation.

BATTERY

REPLACEMENT

14 • FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual

2. Lift storage tank to see if it is empty. If not, open the

drinking water faucet to empty water from tank.

NOTE: It may be necessary to pump a small amount of air into

the tank with a bicycle pump to remove all the water

from the tank.

3. When tank is empty, use a pressure gauge to check

tank pressure. An empty tank should contain 5 to 7 psi

pressure. Increase or decrease the air pressure in the tank

accordingly.

4. Open cold water supply. Let system run for 3 hours to fill

tank, then check system performance. If performance has

not improved, call Technical Support.

Page 15

GRO350B PARTS GUIDE

1

2

4

1/4" NPT

6

5

7

8

3

9

ITEM NO. PART NO. DESCRIPTION QTY

1 4005008 ASSY, RO 3-STAGE 1

2 4004917 ASSY, 3 STAGE COVER, MAGNET 1

3 4003597 KIT, RO SYSTEMS 50 GPD 1

4 244820 FAUCET AIR-GAP 1

5 244833 TANK, RO 1/4" NPT 1

6 655123-96 FDF1-RC Cartridge Filter 1

7 655121-96 GRO50-RC Cartridge Membrane 1

8 655117-96 F1GC-RC Cartridge Filter 1

9 4003280 SHROUD, ASO 1

For replacement parts, contact your nearest Water Filter dealer or call 800.279.9404

FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual • 15

Page 16

GRO350M PARTS GUIDE

1

2

4

1/4" NPT

6

5

7

8

3

9

10

ITEM NO. PART NO. DESCRIPTION QTY

1 4005011 RO HEAD, MODEL GRO-350M 1

2 4004919 ASSY, 3 STAGE COVER, MAGNET 1

3 4003597 KIT, RO SYSTEMS 50 GPD 1

4 244820 FAUCET AIR-GAP 1

5 244833 TANK, RO (STL 3.2 GAL) 1/4" NPT 1

6 655123-96 FDF1-RC CARTRIDGE FILTER 1

7 655121-96 GRO50-RC CARTRIDGE MEMBRANE 1

8 655117-96 F1GC-RC CARTRIDGE FILTER 1

9 4003280 SHROUD, ASO 1

10 4003641 TIMER, FILTER CARTRIDGE 1

16 • FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual

Page 17

WARNING:

PERFORMANCE DATA

IMPORTANT:

Read this performance data and compare the capabilities of

this system with your actual water treatment needs.

It is recommended that before installing a water treatment

system, you have your water supply tested to determine your

actual water treatment needs.

This system has been tested according to NSF/ANSI 58 for the

reduction of substances listed below. The concentration of the

indicated substances in water enteringthe sysem was reduced

to a concentration less than or equal to the permissible limit

for water leaving the system as specified in NSF/ANSI 58.

The GRO-350B/GRO-350M shall only be used for arsenic

reduction on chlorinated water supplies containing detectable

residual free chlorine at the system inlet. Water systems using

an in-line chlorinator should provide a one-minute chlorine

contact time before the RO system.

Do not use with water that is microbiologically

unsafe or of unknown quality without adequate disinfection

before or after the system. Systems certified for cyst reduction

may be used on disinfected waters that may contain filterable

cysts.

NOTE: Substances reduced are not necessarily in your water.

Filter must be maintained according to manufacturer’s

instructions, including replacement of filter cartridges.

The tested efficiency rating for these systems is 22.05%.

Efficiency rating means the percentage of the influent water

to the system that is available to the user as reverse osmosis

treated water under operating conditions that approximate

typical daily usage.

The tested recovery rating is 38.65%. Recovery rating means

the percentage of the influent water to the membrane portion

of the system that is available to the user as reverse osmosis

treated water when the system is operated without a storage

tank or when the storage tank is bypassed.

The GRO-350B/GRO-350M has been tested for the treatment

of water containing pentavalent arsenic [also known as As(V),

As(+5), or arsenate] at concentrations of 0.050 mg/L or less.

This system reduces pentavalent arsenic, but may not remove

other forms of arsenic. This system is to be used on water

supplies containing a detectable free chlorine residual or on

water supplies that have been demonstrated to contain only

pentavalent arsenic. Treatment with chloramine (combined

chlorine) is not sufficient to ensure complete conversion

of trivalent arsenic to pentavalent arsenic. Please see the

Arsenic Facts section of the Performance Data Sheet for

further information.

EPA # 082989-CHN-001

System Production Rate: 14.96 gpd (56.63 Lpd)

Recovery Rating: 38.65%

Efficiency Rating: 22.05%

TDS Rejection: 96.9%

C US

System Tested and Certified by NSF International

against NSF/ANSI Standard 42, 58, and CSA B483.1

for the reduction of the claims specified on the

Performance Data Sheet.

GRO-350B/GRO-350M SYSTEM INSTALLED

WITH FDF1-RC, GRO50-RC, F1GC-RC

FILTER CARTRIDGES

Model GRO-350B / GRO-350M

Substance

Standard 42

Chlorine

Taste and Order

Standard 58

Total Dissolved Solids 750 ± 40 mg/L 187 mg/L 96.9%

Pentavalent Arsenic 0.050 mg/L ± 10% 0.010 mg/L 88.0%

Fluoride 8.0 mg/L ± 10% 1.5 mg/L 93.6%

Cysts* Minimum 50,000/mL 99.95% >99.99%

Turbidity 11 mg/L ± 1 NTU 0.5 NTU >99.1%

Lead 0.15 mg/L ± 10% 0.010 mg/L 98.6%

Selenium 0.10 mg/L ± 10% 0.05 mg/L 97.9%

Copper 3.0 mg/L ± 10% 1.3 mg/L 98.5%

Cadmium 0.03 mg/L ± 10% 0.005 mg/L 99.1%

Hexavalant Chromium 0.3 mg/L ± 10% 0.1 mg/L 96.4%

Trivalent Chromium 0.3 mg/L ± 10% 0.1 mg/L 98.2%

Radium 226/228 25 pCi/L ± 10% 5 pCi/L 80.0%

Barium 10.0 mg/L ± 10% 2.0 mg/L 96.3%

*NSF/ANSI Standard 58 certified to reduce cysts such as Cryptosporidium and Giardia by mechanical

means.

Influent Challenge

Concentration

2.0 mg/L ± 10% ≥50% 95.9%

Arsenic Fact Sheet

Arsenic (abbreviated As) is found naturally in some well

water. Arsenic in water has no color, taste or odor. It must

be measured by a lab test. Public water utilities must have

their water tested for arsenic. You can get the results from

your water utility. If you have your own well, you can have

the water tested. The local health department or state

environmental health agency can provide a list of certified

labs. There are two forms of arsenic: pentavalent arsenic [also

called As(V), As(+5), and arsenate] and trivalent arsenic [also

called As(III), As(+3) and arsenite]. In well water, arsenic may

be pentavalent, trivalent, or a combination of both. Special

sampling procedures are needed for a lab to determine what

type and how much of each type of arsenic is in the water.

Check with the labs in your area to see if they can provide

this type of service. Reverse osmosis (RO) water treatment

systems do not remove trivalent arsenic from water very well.

RO systems are very effective at removing pentavalent arsenic.

A free chlorine residual will rapidly convert trivalent arsenic to

pentavalent arsenic. Other water treatment chemicals such as

ozone and potassium permanganate will also change trivalent

arsenic to pentavalent arsenic. A combined chlorine residual

(also called chloramine) may not convert all the trivalent

arsenic. If you get your water from a public water utility,

contact the utility to find out if free chlorine or combined

chlorine is used in the water system. The GRO-350B/GRO350M system is designed to remove pentavalent arsenic.

It will not convert trivalent arsenic to pentavalent arsenic.

The system was tested in a lab. Under those conditions, the

system reduced 0.050 mg/L (ppm) pentavalent arsenic to

0.010 mg/L (ppm)(the USEPA standard for drinking water)

or less. The performance of the system may be different at

your installation. Have the treated water tested for arsenic to

check if the system is working properly. The RO component

of the GRO-350B/GRO-350M system must be replaced every

12-24 months to ensure the system will continue to remove

pentavalent arsenic. The component identification and

locations where you can purchase the component are listed in

the installation/operation manual.

Max Permissible

Product Water

Concentration

Reduction

Requirements

Average

Reduction

FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual • 17

Page 18

IMPORTANTE: Antes de instalar este sistema de ósmosis

ADVERTENCIA:

inversa, asegúrese de que el suministro de agua cumpla con las

siguientes especificaciones de funcionamiento. No cumplir con las

especificaciones puede reducir la efectividad del sistema y anulará la

garantía.

ESPECIFICACIONES

Gama de presión: 40 a 100 psi (2.75–6.89 bares)

Gama de Temperatura: 40-100 °F (4.4-37.8 °C)

Sólidos disueltos totales: <2000ppm

†

Dureza máxima

Sulfuro, hierro y manganeso

Cloro en el suministro de agua: <2ppm

Límites de pH: 3-11

Dimensiones totales: 11.32” ancho x 5.46” prof. x 12.54” alto

(288 mm x 139 mm x 319 mm)

Peso: 7.1 lbs (3.2 kg)

Dimensiones del tanque: 8.94” diám x 13.83” alto

(227mm diám x 351 mm alto)

Capacidad máxima del tanque: 2.1 gal (7.9 L)

Presión de aire del tanque

vacío: 5-7 psi (0.34-0.48 bares)

Peso del tanque (lleno): 19.50 lb (8.8 kg)

†

Si la dureza del agua sobrepasa los 10 gpg (171 mg/L), se acumulará

sarro rápidamente en la membrana. La acumulación del sarro tapará

la membrana y hará que el sistema sea ineficaz. No se recomienda

el uso de estos sistemas de ósmosis inversa en aguas con dureza

superior a 10 gpg (171 mg/L).

‡

Se permite un nivel máximo total de aproximadamente 0.01ppm de

sulfuro, hierro o manganeso. Consulte con su representante local para

reducir estas sustancias en el agua.

: <10 gpg (170 mg/L)

‡

: <0.1ppm

Herramientas y materiales requeridos

• Taladro de mano o eléctrico (se prefiere inalámbrico)

• (2) llaves inglesas

• Destornilladores planos y Phillips

• Lima

• Gafas de seguridad

• Brocas: 1/8", 3/16", 1/4", 3/8"

• Cortatubos o navaja multiuso

• Lápiz

• Toalla

• Cubeta

• Puntas de destornillador: 1/8", 3/16", 1/4", 3/8"

Si el fregadero no tiene orificio para una llave separada:

• Punzón

• Broca común o broca hueca cilíndrica de 3/4''

• Máscara de seguridad

NOTA: Es posible que no necesite todas las herramientas para la

instalación. Lea los procedimientos de instalación antes

de comenzar para determinar qué herramientas son

necesarias.

PIEZAS INCLUIDAS:

• Sistema con cartuchos

• Tanque de almacenamiento

• Kit de tornillería de instalación

• Llave de agua potable sin plomo con espacio de aire

ADVERTENCIA RELACIONADA CON LA

PROPUESTA 65 DE CALIFORNIA

18 • FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual

Este producto contiene productos químicos de los

cuales el estado de California sabe causan cáncer o

anomalías congénitas u otros daños reproductivos.

Page 19

ADVERTENCIA:

PRECAUCIÓN:

PRECAUCIONES

GENERAL

No se debe utilizar con agua microbiológicamente

insegura o de calidad desconocida sin la

desinfección adecuada previa o posterior al paso

por el sistema. Los sistemas certificados para la

reducción de quistes* pueden usarse en aguas

desinfectadas que pudieran contener quistes

filtrables.

*Con certificado de la Norma 58 de NSF/ANSI para reducir los quistes

como Cryptosporidium y Giardia por medios mecánicos

Se debe proteger el sistema de ósmosis inversa contra el

congelamiento para evitar la rotura de los componentes

de ósmosis inversa y fugas de agua.

NOTA:

• El agua debe estar dentro de los limites requeridos para

un funcionamiento satisfactorio. De lo contrario, la vida

de la membrana se acortará y se anulará su garantía (ver

Especificaciones en la página 18).

• Este sistema de ósmosis inversa no protege de bacterias causantes

de enfermedades ni remueve bacterias inofensivas que están

presentes en forma natural.

• Instale solo en la línea de agua fría.

• Asegúrese de que la instalación cumpla con todas las leyes y

normas estatales y locales.

• Los cartuchos de repuesto y el elemento de ósmosis inversa

incluidos en este sistema tienen una vida útil limitada. Los cambios

en el sabor, olor o color del agua filtrada indican que el cartucho de

filtro debe ser reemplazado.

• Luego de períodos prolongados sin uso, como por ejemplo durante

las vacaciones, se recomienda enjuagar el sistema durante

5minutos antes de ser usado.

• Un cartucho para agua potable puede contener finos de carbono

(polvo negro muy fino). Después de la instalación, enjuague el

sistema durante5 minutos para eliminar los finos de carbón antes

de utilizar el agua.

• Se recomienda dejar correr el agua durante al menos 20segundos

antes de utilizar el agua para beber o cocinar.

• Las sustancias contaminantes que este dispositivo de tratamiento

de agua elimina o reduce no están necesariamente presentes en el

agua que usted consume.

CÓMO FUNCIONA LA ÓSMOSIS INVERSA

El sistema de ósmosis inversa (RO) GRO-350B/GRO-350M utiliza una

membrana semipermeable para reducir las sales y los minerales

disueltos, y así mejorar el gusto y olor de su agua. La membrana RO

está hecha con una película micro delgada bobinada alrededor de un

núcleo central hueco. Las moléculas de agua pueden pasar a través

de la membrana, pero se rechazan las sales y minerales disueltos.

El sistema de ósmosis inversa GRO-350B/GRO-350M cuenta con una

acción de filtro de 3etapas. Su suministro de agua se prefiltra para

reducir la suciedad y el cloro que pueden contaminar la membrana.

La membrana de ósmosis inversa separa esta agua prefiltrada en

AGUA DE PRODUCTO y AGUA RECHAZADA o DE DESAGÜE. La presión

del suministro de agua provoca que el agua de producto pase a través

de la membrana y entre al tanque de almacenamiento. Los sólidos

disueltos y otros contaminantes no pueden pasar a través de la

membrana y son enviados al desagüe como agua rechazada. Cuando

abre la llave de agua potable, el agua de producto se extrae del tanque

de almacenamiento a través de un posfiltro de carbón activado,

brindando así agua más limpia y con mejor sabor.

Por cada litro de agua producida, varios litros se desechan como

agua rechazada. El tanque de almacenamiento puede almacenar

hasta 2.1 galones (7.9 litros) por vez, para beber y cocinar. Cuando

se usan según las Especificaciones de la página 18 del manual, las

membranas de ósmosis inversa deberían durar de 12 a 24 meses.

FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual • 19

Page 20

1

INSTALACIÓN

• Lea todas las instrucciones y precauciones antes de instalar y usar su GRO-350B/

GRO-350M.

• Para una instalación normal bajo el fregadero en tuberías de agua fría de acero, latón

o cobre de 3/8".

• Al seleccionar una ubicación de montaje del sistema y tanque, tenga en cuenta la

longitud de la tubería necesaria para las conexiones entre la plomería existente y

los componentes del sistema. Algunos sitios de instalación podrían necesitar más

tubería que la que se suministra en el kit.

• Los diagramas numerados corresponden a los pasos numerados.

1. Cómo instalar el adaptador de suministro de agua

El adaptador de suministro es para roscas 1/2"-14 NPS

o de compresión de 3/8" x 3/8". Si los códigos locales lo permiten, puede utilizarse para

conectar el sistema a la tubería de agua fría. Si los códigos locales no permiten el uso

del adaptador de suministro, sus proveedores locales pueden facilitarle conectores

alternativos.

Instrucciones:

(A) Cierre la tubería de suministro de agua fría. Si la tubería de agua fría no tiene una

válvula de cierre bajo el fregadero, deberá instalar una.

(B) Abra la llave de agua fría y permita que se desagüe toda el agua de la tubería.

(C) Desconecte la válvula de suministro de agua fría del tubo vertical.

(D) Asegúrese de que la junta selladora esté completamente asentada en la rosca hembra

de la válvula del adaptador de alimentación.

(E) Instale la válvula del adaptador de alimentación sobre la válvula de suministro en la

forma deseada. La válvula del adaptador de alimentación se puede instalar en la parte

inferior de la manguera de suministro o en la parte superior de la tubería de agua fría.

Apriete a mano exclusivamente.

(F) Conecte el tubo vertical a la válvula del adaptador de alimentación.

NOTA: Tenga cuidado de no trasroscar.

ADVERTENCIA:

La tubería de desagüe roja de 1/4"

incluye un controlador de ujo instalado

en un extremo de la tubería. El extremo

de la tubería con el limitador de ujo se

debe instalar en el sistema de ósmosis

inversa antes de unirlo a la llave. NO

corte el limitador de ujo.

NO CORTE

ESTE EXTREMO

LÍNEA DE DESAGÜE DE ÓSMOSIS

INSERTE EN EL

COLECTOR

INVERSA (1/4" ROJA)

LÍNEA DE ÓSMOSIS INVERSA

AL TANQUE (3/8” AZUL)

LÍNEA DE DESAGÜE

LÍNEA DE SALIDA DE ÓSMOSIS

INVERSA (3/8" AZUL)

LÍNEA DE DESAGÜE DE LLAVE (3/8" ROJA)

LÍNEA DE ENTRADA DE

ÓSMOSIS INVERSA

(3/8" BLANCA)

CONECTAR A LA LÍNEA

DE SUMINISTRO DE AGUA

20 • FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual

Page 21

INSTALACIÓN CONTINUACIÓN . . .

PRECAUCIÓN:

PRECAUCIÓN:

PRECAUCIÓN:

ADVERTENCIA:

2. Selección de la ubicación de la llave de agua

Se debe prever la funcionalidad, la conveniencia y el aspecto de la llave de agua potable antes

de su colocación. Se necesita una superficie plana adecuada de modo que la base de la llave

de agua se asiente firmemente. La llave calza a través de un orificio de 3/4''. La mayoría de

los fregaderos tienen orificios de 1-3⁄8'' o 1-1/2'' de diámetro previamente perforados que

se pueden utilizar para instalar la llave de agua. Si no se pueden usar estos orificios o están

en una ubicación inconveniente, será necesario perforar un orificio de 3/4'' de diámetro en el

fregadero para acomodar la llave de agua.

Este procedimiento puede producir polvos que pueden causar una irritación grave

si se aspiran o entran en contacto con los ojos. Se recomienda llevar anteojos de

seguridad y una máscara de seguridad durante este procedimiento.

PRECAUCIÓN:

PRECAUCIÓN:

Las siguientes instrucciones se aplican ÚNICAMENTE a los fregaderos de acero inoxidable.

(A) Cubra el fondo del fregadero con papel de periódico para impedir que caigan al drenaje

(B) Coloque cinta de enmascarar sobre el área que se va a perforar para ayudar a evitar

(C) Marque el punto con un punzón de marcar. Use una broca de 1/4" para hacer un orificio de

(D) Use un sacabocados de 1

NO TRATE DE PERFORAR UN FREGADERO HECHO TOTALMENTE DE

PORCELANA. Si tiene un fregadero hecho totalmente de porcelana, monte la llave

de agua en el orificio previamente perforado para el rociador o perfore un orificio

en la cubierta adyacente al fregadero.

Cuando perfore a través de la cubierta asegúrese de que no haya cables ni

tuberías debajo del área donde se hará la perforación. Asegúrese de que haya

un amplio espacio para hacer las conexiones adecuadas en la parte inferior de la

llave de agua.

No perfore a través de una cubierta de un espesor mayor a 1".

No trate de perforar a través de una cubierta de azulejo, mármol, granito o

materiales similares. Consulte con un plomero o con el fabricante de la cubierta

para obtener consejos o asistencia.

virutas, piezas o herramientas.

rayones si la broca del taladro se resbala.

guía a través del fregadero.

lima.

1

⁄4" para ensanchar el orificio. Alise los bordes ásperos con una

3. Colocación de la llave de agua

Debido a la variación en los sitios de instalación, se recomienda

especialmente que instale la tubería de desagüe roja de 1/4" en el colector

del sistema de ósmosis inversa antes de montar la llave por completo.

Anote la longitud de tubería de desagüe roja de 1/4" necesaria para llegar

del colector del sistema de ósmosis inversa hasta la conexión de la llave

y planear en consecuencia en relación con la ubicación de montaje de los

componentes del sistema. Además, la tubería de desagüe roja de 1/4"

incluye un controlador de flujo instalado en un extremo de la tubería. El

extremo de la tubería con el limitador de flujo se debe instalar de manera

segura en el colector del sistema de ósmosis inversa antes de unirlo a la

llave. NO corte el limitador de flujo.

NOTA: Es posible que no se necesiten para la instalación todas las piezas proporcionadas con

la llave.

(A) Enrosque ambas tuberías de desagüe a través de los orificios en la placa y la arandela

para deslizar la placa cromada y la arandela de caucho negro sobre la llave.

(B) Una la tubería de desagüe de 3/8" roja de diámetro grande a la conexión de espiga

en la base de la llave. Esta tubería debe ser lo suficientemente larga para alcanzar la

abrazadera de drenaje del Paso 4.

(C) Ubique la tubería de desagüe de 1/4" roja de diámetro pequeño conectada al puerto de

desagüe del elemento GRO. Tienda la tubería hasta la llave y corte el exceso de tubería.

(D) Deslice el espaciador de extensión blanco sobre la sección roscada larga de la llave. El

extremo abierto de la extensión deberá estar en contacto con la base de la llave.

(E) Atornille la arandela, arandela de seguridad y contratuerca en el extremo de las roscas

de la llave.

(F) Atornille el conector rápido en el extremo de las roscas de la llave.

(G) Moje el extremo del tubo azul de 3/8". Empuje a la parte inferior del conector rápido. Jale

suavemente para asegurarse de que la conexión esté completa.

NOTA: Para retirar el tubo, empuje el collarín de la conexión y jale el tubo.

(H) Sosteniendo la llave, pase los tres tubos a través del orificio en el fregadero. Ponga la

empuñadura de la llave en la ubicación deseada.

(I) Centre la llave y deslice el disco ranurado entre el espaciador blanco y el fondo de la

cubierta o el fregadero. Apriete la contratuerca con una llave hasta que quede apretada.

2

Orificio de guía

C

D

1

⁄4"

1

11⁄4”

D

3

H

1/4"

1

4”

⁄

C

Orificio de

CONEXIÓN DE ESPIGA

(LÍNEA DE DESAGÜE DE

ÓSMOSIS INVERSA 1/4”

ROJA)

CONEXIÓN DE ESPIGA

(LÍNEA DE DESAGÜE DE

LLAVE 3/8” ROJA)

PLACA CROMADA

ARANDELA DE GOMA

NEGRA

CUBIERTA

DISCO RANURADO

ESPACIADOR DE

EXTENSIÓN BLANCO

ARANDELA

ARANDELA DE PRESIÓN

CONTRATUERCA

CONECTOR RÁPIDO

TUBERÍA (LÍNEA DE

SALIDA DE ÓSMOSIS

INVERSA 3/8” AZUL)

B

A

montaje

C

B

A

A

I

D

E

F

G

FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual • 21

Page 22

4. Instalación de la abrazadera de drenaje

PRECAUCIÓN:

ADVERTENCIA:

ADVERTENCIA:

PRECAUCIÓN:

5

6

NOTA: Si tiene un fregadero de una sola tina con un triturador, llame a Asistencia Técnica

para obtener más opciones.

NOTA: Antes de instalar la abrazadera de drenaje, revise si los tubos de desagüe bajo el

fregadero tienen corrosión. Las tuberías con corrosión deben ser reemplazadas

antes de continuar con la instalación.

(A) Coloque la abrazadera de desagüe en una sección vertical de la tubería de desagüe,

alrededor de 6'' sobre el sifón. Asegúrese de que la abertura de la abrazadera de

desagüe esté viendo hacia la llave de agua potable.

(B) Con el orificio del acoplamiento de la abrazadera de desagüe como guía, perfore un

orificio de 1/4'' a un lado de la tubería de desagüe.

(C) Quite la abrazadera de desagüe de la tubería de desagüe y ensanche el orificio con una

broca de 3/8''. Utilice una lima para quitar los bordes ásperos del orificio perforado.

(D) Asegúrese de que la junta de goma negra esté adherida al interior de la abrazadera de

desagüe y coloque el conjunto de la abrazadera de desagüe sobre el orificio perforado.

Mire a través del orificio y posicione la abrazadera para que el centro del orificio de

la abrazadera sea apenas más alto (alrededor de 1/16'') que el centro del orificio

perforado. Apriete la abrazadera firmemente.

(E) Atornille la tuerca de compresión plástica a la abrazadera de desagüe hasta que no

pueda apretar más con la mano.

5. Conexión de la llave de agua al desagüe

Este es un desagüe de gravedad. Cualquier bucle, doblez o curvas peligrosas

se debe eliminar antes de continuar. No crear una línea recta al desagüe puede

provocar que el agua rechazada se fugue a través del espacio de aire en la llave

de agua hacia la cubierta y debajo de la llave de agua.

(A) Alinee la tubería más grande de rechazo roja de 3/8'' de la llave de agua con la tuerca

de compresión en la abrazadera de desagüe. Cree un pasaje lo más recto y liso posible

con la tubería. No retuerza la tubería. Corte la tubería en ángulo recto y retire las

rebabas internas y externas. Inserte el inserto del tubo interior (cono blanco) en el

extremo de la tubería roja de 3/8". Retire la tuerca de compresión de la abrazadera de

desagüe. Ponga la tuerca de compresión en el extremo de la tubería roja de 3/8".

(B) Inserte la tubería dentro del puerto de desagüe hasta que se detenga. Apriete la tuerca

de compresión con los dedos, luego apriete 1 a 2 vueltas con una llave para asegurar la

tubería al puerto de desagüe.

4

A

B C

D

A

6"

E

Tubo de

3/8''

6. Cómo montar el sistema

Al seleccionar una ubicación de montaje del sistema y tanque, tenga

en cuenta la longitud de la tubería necesaria para la conexión entre los

componentes. Algunos sitios de instalación podrían necesitar más tubería

que la que se suministra en el kit.

(A) Seleccione una ubicación bajo el fregadero, u otra área adecuada en la que se instalará

el sistema.

NOTA: Se puede usar el cartón del sistema para determinar la huella de operación que se

requiere para la instalación del sistema y los cartuchos de repuesto. (Figura 6)

(B) Monte el sistema verticalmente. Asegúrese de que la montura esté al ras. Retire los

cartuchos de filtro para facilitar el acceso a los orificios del soporte de montaje. Ponga

una marca con lápiz en las ranuras superiores de los orificios de los soportes de

montaje (Figura 4b). Opción de montaje alternativa: Si está montando el sistema cerca

del piso, ponga las marcas con lápiz encima de cada uno de los orificios de montaje en

el soporte para asegurar que haya suficiente espacio debajo del cartucho y el piso para

el reemplazo del cartucho (Figura 4c). Use la broca de 3/32'' para crear orificios de

guía para el montaje.

El sistema se deberá montar en una superficie sólida y firme que pueda

apoyar el peso del sistema.

7. Conexión de la llave de agua al sistema

(A) Determine la longitud de la tubería azul de plástico que se necesita para conectar al

lado de la salida (derecho) del filtro desde la llave. Asegúrese de dejar suficiente

tubería pare evitar retorcimientos y corte el tubo en ángulo recto. Use un marcador

para marcar un extremo de la tubería a 5/8" del extremo. Moje el extremo del tubo de

3/8" y empújelo a la conexión de salida (derecha) del sistema hasta la marca.

No doble ni engarce el tubo que está insertando.

(B) Jale levemente del tubo para corroborar que esté correctamente conectado.

B

7” (178 mm)

6

16.25”

(413 mm)

14”

(356 mm)

22 • FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual

Page 23

7

LÍNEA DE ENTRADA DE

ÓSMOSIS INVERSA

(3/8" BLANCA)

LÍNEA DE DESAGÜE DE

ÓSMOSIS INVERSA

(3/8" ROJA)

LÍNEA DE ÓSMOSIS

INVERSA AL TANQUE

(3/8” AZUL)

LÍNEA DE DESAGÜE DE LLAVE

(1/4" ROJA)

LÍNEA DE SALIDA DE

ÓSMOSIS INVERSA

(3/8" AZUL)

FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual • 23

Page 24

INSTALACIÓN CONTINUACIÓN . . .

PRECAUCIÓN:

10

8. Conexión del tanque de almacenamiento al sistema

Cuando el tanque está lleno, pesa aproximadamente 19.50 libras (8.8 kg.).

Coloque un soporte amplio debajo del tanque.

(A) Para prevenir las fugas, aplique 3 vueltas o más de cinta de teflón a las roscas del

tanque. Enrosque la válvula del tanque sobre la parte superior de la abertura del

tanque. Gire el tanque de modo que la manivela quede alineada con la tubería.

PRECAUCIÓN:

(B) Ubique la tubería azul de 3/8". Haga una marca en el tubo de 5/8'' desde un extremo.

(C) Corte la tubería a la distancia correcta. Instale el extremo libre de la tubería dentro

(D) Coloque el sistema completo sobre los tornillos de montaje en la pared y deslícelo

PRECAUCIÓN:

NOTA: Tenga cuidado de no doblar ni pinchar la tubería detrás del sistema mientras coloca

La conexión tanque/válvula goteará si no se sella correctamente.

Normalmente, la cinta de teflón sellará la conexión roscada.

Humedezca un extremo marcado de la tubería con agua e insértela con un movimiento

giratorio dentro del puerto de la válvula del tanque hasta que la marca de 5/8'' quede

alineada con el cople de conexión rápida. Luego coloque el tanque cerca de la zona de

instalación del sistema.

del cople de conexión rápida blanco en el sistema. Asegúrese de que la tubería no

se doble. Retenga la tubería azul restante para usarla para conectar el sistema al

adaptador de suministro de agua. Algunos sitios de instalación podrían necesitar

tubería adicional que no se incluye en el kit.

hacia abajo.

Asegúrese de que el sistema esté conectado firmemente a la pared para

prevenir que se caiga y posiblemente se dañe.

los tornillos de montaje.

8

Tubo de 3/8''

5/8"

B

A

Aplique

cinta de

teflón

9. Cómo conectar el sistema al adaptador de suministro de agua

(A) Ubique el tramo restante de la tubería azul de plástico de 3/8''.

(B) Haga una marca en el tubo a 5/8'' del extremo. Humedezca el extremo de la tubería

con agua e inserte con un movimiento giratorio dentro del cople de conexión rápida

blanco en el lado izquierdo del sistema. Dependiendo de la instalación, puede ser

necesario retirar el sistema de la superficie de montaje para tener acceso al lado

izquierdo del sistema.

(C) Corte el tubo a una longitud que permita la conexión con el adaptador de suministro

de agua. Asegúrese de que la tubería no se doble. Haga una marca en el tubo a

5/8'' del extremo. Humedezca el extremo de la tubería con agua e inserte con

un movimiento giratorio dentro del cople de conexión rápida en el adaptador de

suministro de agua.

10. Funcionamiento de la llave de agua

(A) Para tener un flujo de agua controlado, empuje la empuñadura hacia abajo.

(B) Para tener un flujo de agua constante, levante la empuñadura de la llave para fijarla

en la posición abierta.

9

LÍNEA DE ENTRADA DE

ÓSMOSIS INVERSA

(3/8" BLANCA)

LÍNEA DE DESAGÜE DE

LÍNEA DE ÓSMOSIS

INVERSA AL TANQUE

(3/8” AZUL)

ÓSMOSIS INVERSA

(3/8" ROJA)

Empujar hacia abajo

A

B

Empujar hacia

LÍNEA DE DESAGÜE DE LLAVE

(1/4" ROJA)

LÍNEA DE SALIDA DE

ÓSMOSIS INVERSA

(3/8" AZUL)

arriba

24 • FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual

Page 25

11. Inicio del sistema

PRECAUCIÓN:

NOTA: La membrana de ósmosis inversa está tratada con un agente sanitizante de grado

alimenticio que puede causar un gusto indeseable. Aunque no es dañino, debe ser

expulsado del sistema.

NOTA: El filtro pospulidor puede contener partículas finas de carbón negras. Estos finos

son inofensivos, pero pueden hacer que el agua luzca gris. Los finos de carbón se

eliminan del sistema con el primer tanque lleno de agua.

NOTA: El sistema de ósmosis inversa no produce altos volúmenes de agua a pedido como lo

hace un filtro común. El agua se produce a un ritmo lento, gota por gota. El sistema

necesita alrededor de 2 a 4horas para llenar el tanque de almacenamiento. A

medida que se saca agua del tanque, el sistema comienza el ciclo automáticamente

para reemplazar el agua y luego frena la producción de agua cuando el tanque está

lleno.

Revise visualmente todo el sistema para encontrar fugas.

consulte la sección Resolución de problemas en la página 29.

(A) Cierre la válvula de la parte superior del tanque de almacenamiento.

(B) Abra el suministro de agua fría ligeramente, y asegúrese de que la válvula del

adaptador de suministro esté abierta.

(C) Levante la empuñadura de la llave de agua para trabarla en la posición abierta y deje

gotear durante30 minutos.

(D) Abra el suministro de agua fría completamente hasta que se detenga. Deje gotear el

agua de la llave de agua durante otras 12horas. Luego cierre la llave de agua y abra la

válvula del tanque de almacenamiento. La válvula del tanque está abierta cuando las

líneas de la manivela se alinean con la conexión de la tubería.

(E) Espere 3 horas para que el tanque se llene. Siga revisando la instalación

periódicamente para encontrar fugas. Una vez que el tanque de almacenamiento está

lleno, abra la llave de agua para dejar correr el agua a través del cartucho postfiltro.

Espere de 4 a 5minutos para que el tanque se vacíe completamente. Cierre la llave de

agua y deje que se llene el tanque.

(F) Repita el paso E cuatro veces.

NOTA: En un primer momento, el agua puede parecer turbia. Esto es debido al aire

atrapado en el filtro pospulidor. No es dañino y desaparecerá en cuestión de

minutos. Puede tomar hasta una semana luego de instalar el filtro pospulidor nuevo

para que el aire atrapado se disipe.

El sistema está listo para funcionar. Ahora puede disfrutar agua de calidad del sistema de

ósmosis inversa.

Si existe una fuga,

11

Válvula del tanque

cerrada

A

Válvula del

tanque abierta

B

En sentido

antihorario

PRUEBA DEL SISTEMA DE ÓSMOSIS INVERSA

(SOLO SISTEMAS QUE NO ESTÁN MONITOREADOS)

Prueba de sólidos disueltos totales (TDS) para sistema de

ósmosis inversa modelo GRO-350B

NOTA: Se recomienda enfáticamente que usted (el consumidor) haga analizar el agua cada

6meses para verificar que el sistema esté funcionando satisfactoriamente.

INSTRUCCIONES DE MUESTREO:

Las instrucciones de muestreo se incluyen en el kit de prueba de sólidos disueltos totales

(TDS).

Kit de prueba de sólidos

disueltos totales

FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual • 25

Page 26

INSTALACIÓN OPCIONAL

Cómo conectar su sistema de ósmosis inversa al dispensador de hielo/agua del refrigerador

PRECAUCIÓN:

PRECAUCIÓN:

NOTA:

MATERIALES NECESARIOS (disponibles en su ferretería local):

• "T" de compresión o de conexión rápida de 3/8" x 3/8" x 3/8" (0.952 mm x 0.952 mm x 0.952 mm)

• 10 pies (3 m) de tubería de polietileno de 3/8" (0.952 mm)

• Válvula de cierre

1. Cierre el suministro de agua y el dispensador de hielo del refrigerador (consulte las pautas del fabricante).

2. Cierre la válvula del tanque (sobre el tanque de almacenamiento).

3. Cierre el paso de agua al sistema de ósmosis inversa en el suministro de agua fría, o en el adaptador de suministro de agua de entrada.

4. Abra la llave de agua potable para aliviar la presión.

Ubique la tubería (permeable) que conduce a la llave de agua potable. Corte e inserte la "T" de compresión o conexión rápida de

5.

NOTA: Cuando corte la tubería permeable, puede experimentar un poco de goteo.

6. Use un tramo de 3/8'' de tubería de polietileno para conectar la línea del dispensador de hielo con el puerto libre de la "T" de compresión.

7. La válvula de cierre debe instalarse lo más cerca posible de este puerto de la "T". La válvula de cierre se deberá instalar en la posición

8. Abra el suministro de agua fría completamente.

9. Abra la válvula del tanque.

10. Cierre la llave de agua potable.

11. Abra el paso de agua al sistema RO desde el suministro de agua fría.

12. Encienda el dispensador de hielo y abra la llave de paso.

13. Compruebe que no haya fugas y apriete las conexiones si es necesario.

Si va a conectar esta unidad al dispensador de hielo del refrigerador con la instalación inicial de ósmosis inversa, espere a que el

filtro pospulidor se descargue de acuerdo al Paso 11.

Utilice mangueras y conexiones de plástico. No utilice mangueras de cobre ni acoplamiento de bronce.

Para un rendimiento óptimo, se recomienda que la distancia entre el sistema de ósmosis inversa y el dispensador de hielo/agua del refrigerador

no sea mayor a 10 pies (3metros). En distancias mayores de 10 pies, es posible que la presión de agua del sistema no sea adecuada para

proporcionar agua al refrigerador.

3/8"

x

3/8"

x

3/8"

dentro de la tubería permeable. Consulte las guías del fabricante antes de instalar el adaptador de suministro.

CERRADA. Consulte las pautas del fabricante antes de instalar la válvula de cierre.

Consulte las instrucciones del fabricante.

1

4

7

5

6

3

2

26 • FRESHPOINT GRO-350B/GRO-350M Installation and Operation Manual

Page 27

Reemplazo del cartucho de filtro

NOTA: La vida útil de los cartuchos de filtro depende del volumen

de agua usado y la calidad del agua de alimentación. Se

recomienda que los cartuchos de filtro se reemplacen cada

6 a 12 meses, o cuando haya un cambio apreciable en sabor,

olor o flujo del agua filtrada.

Asegúrese de comprar el cartucho correcto para el

sistema.

El modelo GRO-350B/GRO-350M usa cartuchos de repuesto FDF1-RC,

GRO50-RC y F1GC-RC

3. Reemplazo del cartucho

A. Desfogue la presión al cortar el suministro de agua del sistema

y abrir una llave hasta que cese el flujo de agua (espere de 5 a

10 minutos después de que se detenga el agua para desfogar la

presión en la membrana de ósmosis inversa). Ponga una cubeta

o una toalla bajo el sistema para captar el goteo de agua que

pudiera haber.

B. Levante la barra de bloqueo hasta que el cartucho de filtro se

separe del conjunto de la cabeza del filtro (Figura A).

C. Jale el cartucho del conjunto de la cabeza del filtro y asegúrese de

que la barra de bloqueo continúe en la posición completamente

hacia arriba (Figura B).

D. Alinee los postes en el cartucho de filtro con los puertos en el

conjunto de la cabeza del filtro. Deslice el filtro de cartucho al

interior del conjunto de la cabeza del filtro y engarce con la barra

de bloqueo haciendo que caiga hacia adelante y hacia abajo

(Figura C).

E. Jale la barra de bloqueo hacia abajo hasta que se inserte en su

lugar (Figura D).

Secuencia de cartucho

GRO-350B GRO-350M

FDF1-RCFDF1-RC GRO50-RC

A

F1GC-RC

FDF1-RCFDF1-RC GRO50-RC

B

F1GC-RC

Resolución de problemas

Fugas entre el conjunto de la cabeza del filtro y el

cartucho de filtro

1. Desfogue la presión al girar el suministro de agua al sistema y

abrir la llave hasta que cese el flujo de agua. Ponga una cubeta

o una toalla bajo el sistema para captar el goteo de agua que

pudiera haber.

2. Retire el cartucho e inspeccione las juntas tóricas para asegurarse

de que estén asentadas y limpias.

3. Instale el cartucho de filtro. Ponga el sistema en funcionamiento y

revise si hay fugas. Si las fugas persisten, cierre el suministro de

agua y comuníquese con Asistencia Técnica al 1-800-279-9404.

Fugas de conexiones de tubería

1. Desfogue la presión al girar el suministro de agua al sistema y

abrir la llave hasta que cese el flujo de agua. Ponga una cubeta

o una toalla bajo el sistema para captar el goteo de agua que

pudiera haber.

2. Oprima la presilla en el sistema o las conexiones de tubería