Page 1

MODEL D65-20AVD

INDUSTRIAL PUMPS

INSTRUCTIONS AND SERVICE MANUAL

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Part # 13800A917 | © 2012 Pentair Ltd. | 12/05/12

Page 2

SPECIFICATIONS

BELT DRIVE SEWER CLEANERS

Type Triplex - Single Acting

*Rated Capacity

Gear Reduction Ratio

*Discharge Capacity

Rated Pressure

Temperature Rating

Cylinder Bore & Stroke

Suction Size

Discharge Size

Cylinder Body Mtl.

Cylinder Mtl.

Piston Packing Mtl.

Piston Assembly Mtls.

Valve Mtl.

Valve Seat Mtl.

Pump Drive End

Pinion Shaft Speed

at Rated Capacity

Pinion Shaft Exten. Dia.

Keyway

Pinion and Crankshaft

Main Bearings

Crankshaft Journ. Bearings

Crosshead Pin Bearing

Recommended Regulator

Cylinder Removal Tool Kit

Valve Seat Removal Tool Kit

Allen Wrench for

Packing Capscrew

*Based on 100% Volumetric Efficiency – Allow 5 to 7% for Valve Slippage.

69.7 GPM @ 456

Strokes/Minute*

3.95

3.87 GPM per 100

Pinion RPM*

2000 PSI Max.

160°F Max.

2" x 3-3/4"

3" NPT

1-1/4" NPT

Ductile Iron

Ceramic

Coated Stainless Steel

Molded Composition

V-Rings

Stainless Steel

Delrin

Stainless Steel, Hardened

Helical Gear Single

Reduction

1800 RPM Max.

1-5/8"

3/8" x 3/16" Straight

Tapered Roller

Steel/Babbit Inserts

Bronze Bushing

15696C5

17539B1

19555B

8574A11

GENERAL INSTRUCTIONS

CAUTION: Positive Displacement Pumps must have a

proper size and operable type of pressure regulating

valve or pressure relief valve piped into the discharge

line. This is mandatory to prevent damage to pump

and piping or possible injury to personnel. Do not

install any valves or shutoff devices in the by-pass

line from pressure regulator to tank or supply.

CAUTION: All pumps should be installed level.

For mobile applications the maximum angle of

intermittent operation should be no more than

5 degrees in any one direction.

CALIFORNIA PROPOSITION 65 WARNING:

This product and related accessories

contain chemicals known to the State of California

to cause cancer, birth defects or other reproductive

harm.

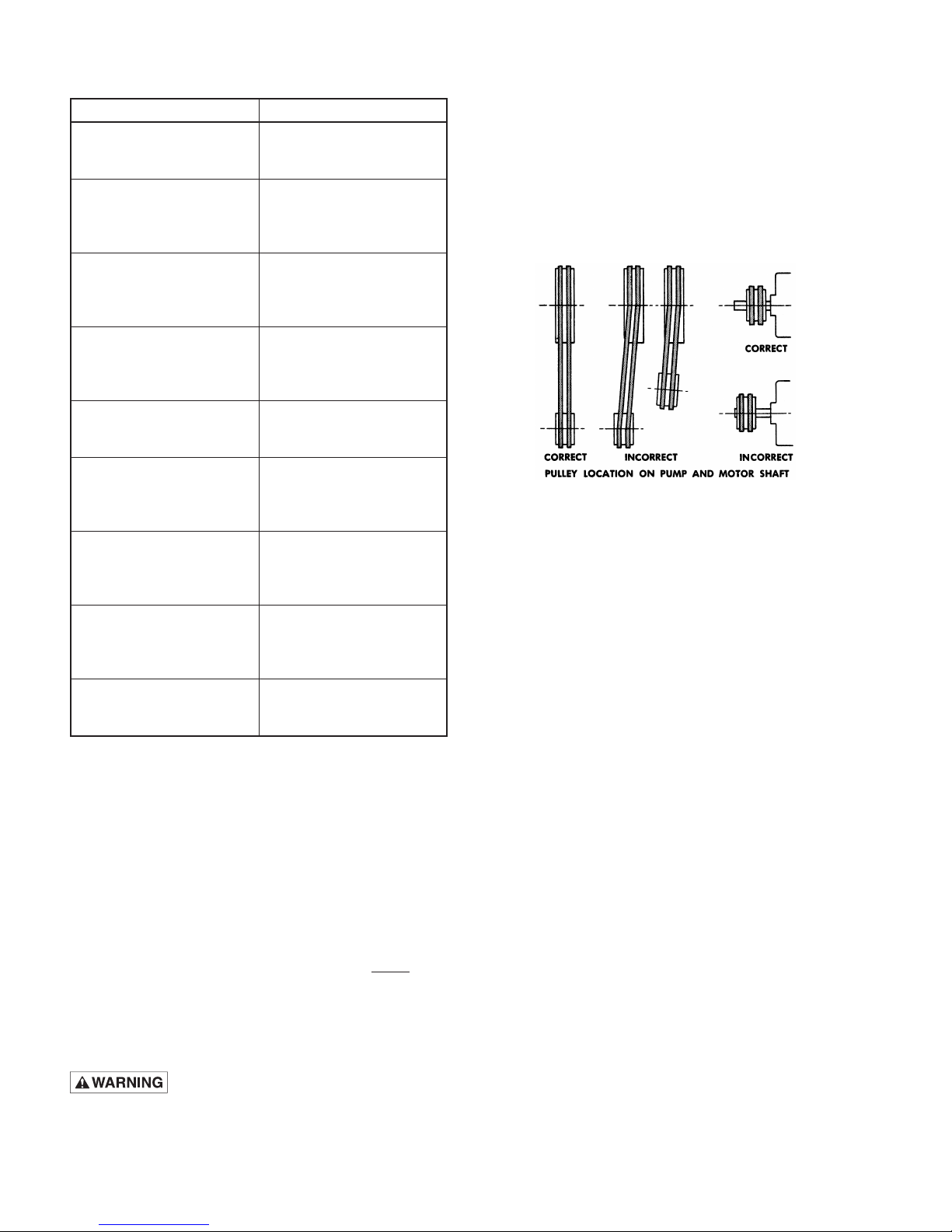

With belt drives, pulley on both engine and pump should

be located as closely as possible to bearing to reduce

bearing and shaft bending loads.

NOTE: See Maintenance Chart for Belt Tension

Specifications in Sewer Cleaner “Operator’s Manual”.

Make sure that all bolts, nuts, set screws, and keys are

properly tightened.

STARTING PUMP

A. Before starting:

1. Read all instructions carefully.

2. Fill pump crankcase with recommended oil to level

mark on oil saber. Oil recommendations are covered

in lubrication section of pump instructions.

3. Replace all drain plugs in pump and piping.

4. Inspect tank to be sure that no foreign material is in

tank or suction line.

5. Fill tank at least half full or connect suction to

water supply. Open valve (if present) in suction line.

Avoid prolonged dry operation which may cause

excessive wear on cylinders and piston packing.

Be sure that an operating pressure gauge is

located in discharge line.

6. Make sure all valves,including spray gun or nozzles,

are open in discharge line. Spray gun may be

anchored to discharge back into tank.

7. Completely back off pressure adjusting screw on

pressure regulating valve.

B. Starting the Unit:

1. After starting, close discharge valve or spray gun

slowly while watching pressure gauge to make sure

relief valve or unloader is operating properly.

2. Adjust relief valve or unloader to desired pressure.

See regulator instructions.

3. Cycle nozzles or gun on and off to be sure that

pressure adjustment and regulator operation is

satisfactory.

NOTE: Nozzle capacity should not exceed 90% of pump

capacity for satisfactory regulator operation. AVOID

FREEZING by draining all water from pump and system

in cold weather.

13800A917 12/05/12

2

Page 3

3

13800A917 12/05/12

Page 4

13800A917 12/05/12

4

Page 5

5

13800A917 12/05/12

Page 6

13800A917 12/05/12

6

Page 7

7

13800A917 12/05/12

Page 8

13800A917 12/05/12

8

Page 9

9

13800A917 12/05/12

Page 10

13800A917 12/05/12

10

Page 11

11

13800A917 12/05/12

Page 12

STANDARD LIMITED WARRANTY

CENTRIFUGAL & RECIPROCATING PUMPS

Pentair Myers® warrants its products against defects in material and workmanship for a period of 12 months from

the date of shipment from Pentair Myers or 18 months from the manufacturing date, whichever occurs first – provided

that such products are used in compliance with the requirements of the Pentair Myers catalog and technical manuals.

During the warranty period and subject to the conditions set forth, Pentair Myers, at its discretion, will repair or

replace to the original user, the parts that prove defective in materials and workmanship. Pentair Myers reserves the

right to change or improve its products or any portions thereof without being obligated to provide such a change or

improvement for prior sold and/or shipped units.

Seals, piston cups, packing, plungers, liners and valves used for handling clear, fresh, nonaerated water at a

temperature not exceeding 120ºF are warranted for ninety days from date of shipment. All other applications are

subject to a thirty day warranty. Accessories such as motors, engines and auxiliary equipment are warranted by

the respective manufacturer and are excluded in this standard warranty. Under no circumstance will Pentair Myers

be responsible for the cost of field labor, travel expenses, rented equipment, removal/reinstallation costs or freight

expenses to and from the factory or an authorized Pentair Myers service facility.

This limited warranty will not apply: (a) to defects or malfunctions resulting from failure to properly install, operate

or maintain the unit in accordance with the printed instructions provided; (b) to failures resulting from abuse, accident

or negligence; (c) to normal maintenance services and parts used in connection with such service; (d) to units that

are not installed in accordance with applicable local codes, ordinances and good trade practices; (e) if the unit is

moved from its original installation location; (f) if unit is used for purposes other than for what it is designed and

manufactured; (g) to any unit that has been repaired or altered by anyone other than Pentair Myers or an authorized

Pentair Myers service provider; (h) to any unit that has been repaired using non factory specified/OEM parts.

Warranty Exclusions: PENTAIR MYERS MAKES NO EXPRESS OR IMPLIED WARRANTIES THAT EXTEND BEYOND THE

DESCRIPTION ON THE FACE HEREOF. PENTAIR MYERS SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE.

Liability Limitation: IN NO EVENT SHALL PENTAIR MYERS BE LIABLE OR RESPONSIBLE FOR CONSEQUENTIAL,

INCIDENTAL OR SPECIAL DAMAGES RESULTING FROM OR RELATED IN ANY MANNER TO ANY PENTAIR MYERS

PRODUCT OR PARTS THEREOF. PERSONAL INJURY AND/OR PROPERTY DAMAGE MAY RESULT FROM IMPROPER

INSTALLATION. PENTAIR MYERS DISCLAIMS ALL LIABILITY, INCLUDING LIABILITY UNDER THIS WARRANTY, FOR

IMPROPER INSTALLATION. PENTAIR MYERS RECOMMENDS INSTALLATION BY PROFESSIONALS.

Some states do not permit some or all of the above warranty limitations or the exclusion or limitation of incidental or

consequential damages and therefore such limitations may not apply to you. No warranties or representations at any

time made by any representatives of Pentair Myers shall vary or expand the provision hereof.

1101 MYERS PARKWAY

ASHLAND, OHIO, USA 44805

419-289-1144

WWW.FEMYERS.COM

Warranty Rev. 12/13

Loading...

Loading...