Page 1

CLEAN AND CLEAR® PLUS

CARTRIDGE FILTER

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Pressurized air can cause the lid to separate from the tank with great force. To reduce the

risk of severe injury or death, relieve pressure by opening air relief valve before opening

filter. Before starting the pump after servicing, ensure that clamp band is correctly fastened.

See Important Warnings and Safety Instructions (page iii) and follow all instructions exactly;

including the Opening the Filter (page 4), Installing the Filter Lid and Clamp Ring (page 5), and

Start-Up Instructions (page 6).

INSTALLATION AND

USER’S GUIDE

Page 2

i

CUSTOMER SERVICE / TECHNICAL SUPPORT

If you have questions about ordering Pentair Aquatic Systems replacement parts, and pool products, please contact:

Customer Service and Technical Support, USA

(8 A.M. to 4:30 P.M. — Eastern/Pacific Times)

Phone: (800) 831-7133

Fax: (800) 284-4151

Web site

Visit www.pentairpool.com or www.staritepool.com for

information about Pentair products.

TABLE OF CONTENTS

For Your Safety .....................................................

Customer Service / Technical Support ..............

Important Warnings and Safety Instructions ....

General Information ............................................

Filter Overview

General Operation Information

Pressure Tests

Installation ............................................................

Filter Location

Filter Plumbing

Installing the Manual Air Relief Valve

Opening, Closing and Start-Up ..........................

Opening the Filter

Installing the Filter Lid and Clamp Ring

Start-Up Instructions

i

ii

iii

1

1

1

1

2

2

2

3

4

4

5

6

Sanford, North Carolina (8 A.M. to 4:30 P.M. ET)

Phone: (919) 566-8000

Fax: (919) 566-8920

Moorpark, California (8 A.M. to 4:30 P.M. PT)

Phone: (805) 553-5000 (Ext. 5591)

Fax: (805) 553-5515

Maintenance .........................................................

Maintaining the Pressure Gauge

Cleaning the Manual Air Relief Valve

When to Clean Your Filter

Cleaning the Filter Cartridges

Acid Soaking the Filter Cartridges

Replacing Filter Cartridges

Troubleshooting ..................................................

Technical Data .....................................................

Flow Rates

Dimensional Drawings

Replacement Parts ..............................................

Illustrated Parts View

Parts List

On-Product Safety Labels

7

7

7

8

8

9

10

11

12

12

12

13

13

14

15

P/N 178558 Rev. P 7/6/17

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 3

IMPORTANT WARNINGS AND SAFETY INSTRUCTIONS

IMPORTANT NOTICE:

This guide provides installation and operation instructions for the Clean and Clear® Plus Cartridge Filter. Consult Pentair

Water Pool and Spa, Inc. with any questions regarding this equipment.

Attention Installer: This guide contains important information about the installation, operation and safe usage of this product. This

information should be given to the owner and/or operator of this equipment after installation.

Attention User: This manual contains important information that will help you in operating and maintaining this filter. Please retain it

for future reference.

This is the safety alert symbol. When you see this symbol on your system or in this manual, look for one of the

following signal words and be alert to the potential for personal injury.

Warns about hazards that can cause death, serious personal injury, or major property damage if ignored.

Warns about hazards that may cause death, serious personal injury, or major property damage if ignored.

Warns about hazards that may or can cause minor personal injury or property damage

if ignored.

NOTE Indicates special instructions not related to hazards.

Carefully read and follow all safety instructions in this manual and on equipment. Keep safety labels in good condition; replace if missing

or damaged.

ii

Consumer Information and Safety

This filter is designed and manufactured to provide many years of safe and reliable service when installed, operated and maintained

according to the information in this manual and the installation codes referred to in later sections. Throughout the manual, safety warnings

and cautions are identified by the “ “ symbol. Be sure to read and comply with all of the warnings and cautions.

Before installing this product, read and follow all warning notices and instructions which are included. Failure to

follow safety warnings and instructions can result in severe injury, death, or property damage. Call (800) 831-7133

for additional free copies of these instructions or replacement safety labels.

Do not operate the filter until you have read and understand clearly all the operating instructions

and warning messages for all equipment that is a part of the pool circulating system. The following instructions are

intended as a guide for initially operating the filter in a general pool installation. Failure to follow all operating instructions and warning

messages can result in property damage or severe personal injury or death.

Due to the potential risk that can be involved it is recommended that the pressure test be kept to the minimum time

required by the local code. Do not allow people to work around the system when the circulation system is under

pressure test. Post appropriate warning signs and establish a barrier around the pressurized equipment. If the

equipment is located in an equipment room, lock the door and post a warning sign.

Never attempt to adjust any closures or lids or attempt to remove or tighten bolts when the system is pressurized.

These actions can cause the filter to separate and could cause severe personal injury or death if they were to

strike a person.

This filter must be installed by a qualified pool serviceman in accordance with all applicable local codes and

ordinances. Improper installation could result in death or serious injury to pool users, installers, or others and may

also cause damage to property.

Always disconnect power to the pool circulating system at the circuit breaker before servicing the filter. Ensure that

the disconnected circuit is locked out or properly tagged so that it cannot be switched on while you are working on

the filter. Failure to do so could result in serious injury or death to serviceman, pool users or others due to electric

shock.

DO NOT permit children to use this product.

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 4

iii

IMPORTANT WARNINGS AND SAFETY INSTRUCTIONS

THIS SYSTEM OPERATES UNDER HIGH PRESSURE

When any part of the circulating system, (e.g., closure, pump, filter, valve(s), etc.), is serviced, air can enter the

system and become pressurized. Pressurized air can cause the top closure to separate which can result in severe

injury, death, or property damage. To avoid this potential hazard, follow these instructions:

1. Let air and pressure out of system before and after servicing.

a. Shut off pump and RELIEVE PRESSURE by opening the manual air/pressure relief valve before

servicing, including before tightening the clamp bolt. Follow the Opening the Filter instructions

exactly (page 4).

b. Follow Start-Up Instructions exactly after completing service (page 6). The air/pressure relief valve

must remain open until water comes out, allowing all air out of the system.

2. Install lid and clamp ring properly.

a. Follow the Installing the Filter Lid and Clamp Ring instructions exactly (page 5). The nut must be

tightened until the spring is compressed when clamp is installed. Tap the clamp with a rubber

mallet or similar tool after clamp installation to ensure proper seating.

3. Maintain circulation system properly to help prevent air entering the system.

a. Replace worn or damaged parts immediately, (e.g., closure, pressure gauge, valve(s), O-rings,

etc.).

b. Maintain proper water level in the pool or spa.

4. Verify that the return line to the pool is unobstructed. Ensure return valves are open and any winterizing

plugs are removed.

AVOID DAMAGING SYSTEM

Never Exceed Maximum Pressure of Components. The maximum working pressure of this filter is 50 psi. Never

subject this filter to higher pressure, even when conducting hydrostatic pressure tests. Pressures above 50 psi can damage your filter.

Be sure the maximum pressure of the filter system does not exceed the maximum pressure of any components within the system

(typically stated on each component), including during hydrostatic or external leak tests. Exceeding the maximum pressure of a

component can result in that component failing. If you do not know the pool or spa system operating pressure, install an ASME

approved automatic Pressure Relief or Pressure Regulator in the circulation system set to the lowest working pressure of any of the

components in the system.

Certain codes may require pressure testing the system. Performing pressure tests increases the risk of

component failure. Due to the potential risk that can be involved, keep the pressure test to the minimum time

required by the local code and take precautions. If pressure testing is necessary, follow these precautions:

1. Keep people away.

a. Do not allow people to work around the system when the circulation system is under pressure test.

Post appropriate warning signs and establish a barrier around the pressurized equipment. If the

equipment is located in an equipment room, lock the door and post a warning sign.

2. Never exceed maximum operating pressure.

a. When performing hydrostatic pressure tests or when testing for external leaks of the completed filtration

and plumbing system, ensure that the Maximum Pressure that the filtration system will be subjected

to does not exceed the maximum working pressure of any of the components contained within the

system.

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 5

1

GENERAL INFORMATION

THIS SYSTEM OPERATES UNDER HIGH PRESSURE.

When any part of the circulating system (e.g., Lock Ring, Pump, Filter, Valves, etc.) is serviced, air can enter the system and become

pressurized. Pressurized air can cause the lid to separate which can result in serious injury, death, or property damage. To avoid this

potential hazard, follow the instructions below.

Filter Overview

• Large filter area designed for increased debris capacity

• NSF Listed

• High Flow™ Manual Air Relief Valve provided

• 1.5" x 2" Bulkhead Unions allows for easy piping

installation

General Operation Information

Read and follow all instructions and warnings before installing

or servicing your filter. Proper installation and operation can

prevent unnecessary repairs and maintenance.

Your filter is a piece of machinery, do not tamper

with it, attempt to disassemble it or otherwise adjust

it unless you fully understand it's operation. Serious

injury or death can occur if the equipment is improperly

handled. Consult a pool service professional for

maintenance and service assistance.

1. The Clean and Clear® Plus Cartridge Filter operates

under pressure and operates in a safe manner if clamped

properly and without air in the circulating system.

2. The maximum working pressure of this filter is 50 psi.

Never subject this filter to pressure in excess of this

amount, even when conducting hydrostatic pressure

tests.

3. Be sure the maximum pressure of the filter system does

not exceed the maximum pressure of any components

within the system during hydrostatic or external leak

tests. Consult the maximum pressure stated on each

component of the system.

4. The pressure gauge is the primary indicator of how the

filter is operating. Maintain your pressure gauge in good

working order.

5. Clean your filter when pressure reads between 8-10

psi higher than the “Original Starting Pressure”, or

when significant reduction in flow is noticed. The

pressure reading increases as it filters dirt from your

pool. This build up of pressure will vary due to different

bathing loads, temperature, environmental conditions,

etc.

Note: When using a variable speed pump the “Original

Starting Pressure” will be dependent on the pump speed

(RPM) when recording the original operating pressure.

Record the “Original Pump RPM” in Table 1.

Pressure Tests

When performing hydrostatic pressure tests or when

testing for external leaks of the completed filtration and

plumbing system, ensure that the Maximum Pressure

that the filtration system will be subjected to DOES NOT

EXCEED THE MAXIMUM WORKING PRESSURE OF ANY OF

THE COMPONENTS CONTAINED WITHIN THE SYSTEM. In

most cases, the maximum pressure will be stated on

each component of the system.

If you do not know the pool or spa system operating

pressure, install an ASME approved automatic

Pressure Relief or Pressure Regulator in the

circulation system set to the lowest working pressure

of any of the components in the system.

Table 1

ORIGINAL STARTING PRESSURE IS: ________ psi.

(pounds per square inch)

SERVICE THE MEDIA AT: __________ psi.

ORIGINAL PUMP RPM: __________ rpm.

(for Variable Speed Pumps Only)

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 6

2

INSTALLATION

This filter must be installed by a qualified pool technician in accordance with all applicable local codes and

ordinances. Improper installation could result in death or serious injury to pool users, installers, servicers, or others

and may also cause damage to property.

For Installation of Electrical Controls at Equipment Pad (ON/OFF Switches, Timers, Control Systems and

Automation) Install all electrical controls at the equipment pad, such as ON/OFF switches, timers, control systems,

etc. to allow the operation (startup, shutdown or servicing) of any pump or filter so the user does not place any

portion of his/her body over or near the pump strainer lid, filter lid or valve closures. This installation should allow

the user enough space to stand clear of the filter and pump strainer lid during system startup, shutdown or servicing

of the system filter.

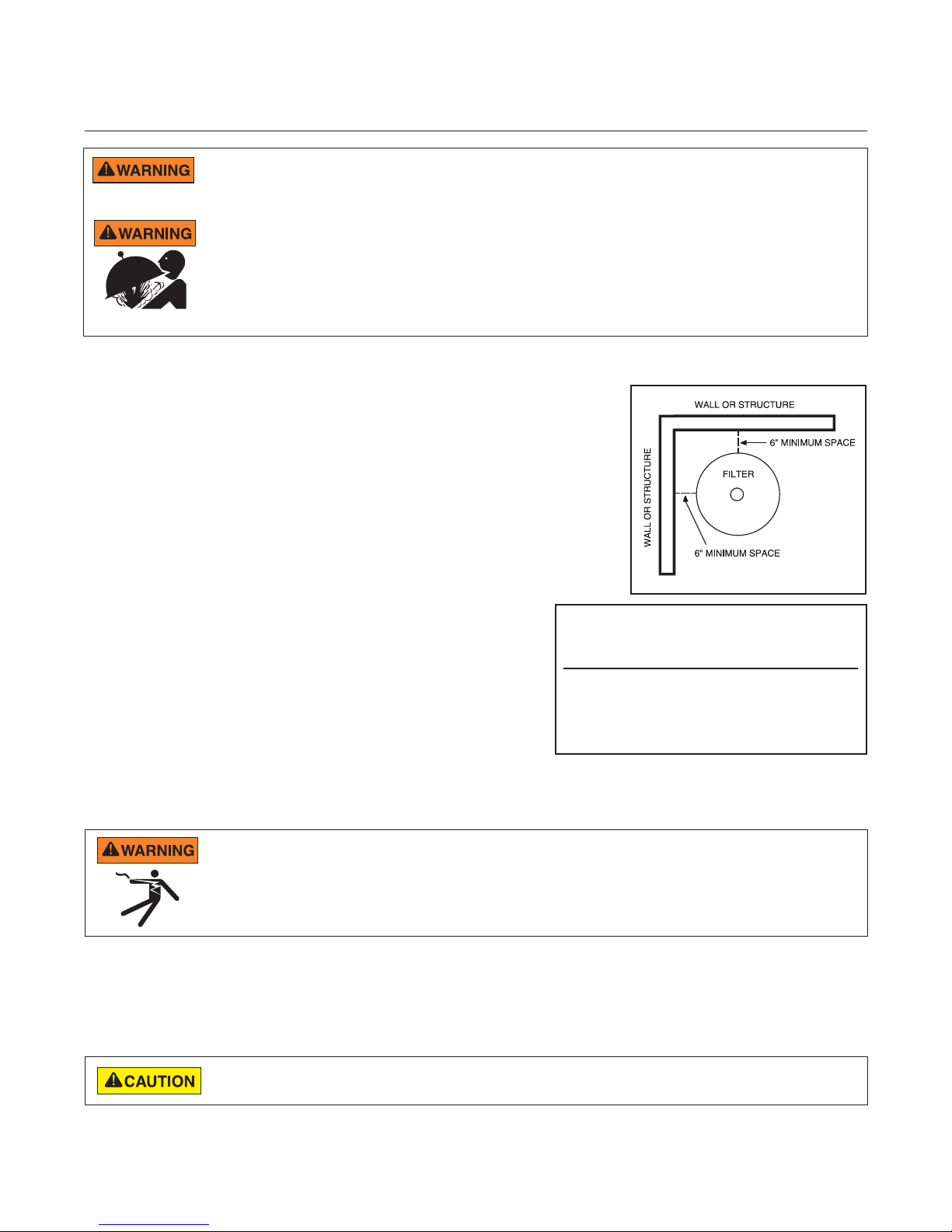

Filter Location

1. The Clean and Clear® Plus Cartridge Filter should be mounted on a

level concrete slab. Position the filter so that instructions, warnings

and the pressure gauge are visible to the operator and readable. It

also should be positioned so that the piping connections, control valve

and waste drain plug are convenient and accessible for servicing and

winterizing.

2. Be certain to install electrical controls (e.g., on/off switches, timers,

control systems, etc.) so that the user is allowed enough space to stand

clear of the filter and pump during startup, shutdown or servicing.

3. Allow sufficient clearance around the filter to permit visual verification

that the clamp is properly installed around the tank flanges,

see Figure 1.

Note: See page 5, Installing the Filter Lid and Clamp Ring.

4. Allow sufficient space above the filter to remove the filter lid for

cleaning and servicing. This distance will vary with the model

of filter you are using. See Table 2 for the required vertical

clearance.

5. Position the filter to safely direct water drainage away from

electrical equipment or anything that might be damaged.

6. Position the High Flow™ Manual Air Relief Valve to safely direct purged air or water (See page 3, Installing

the Manual Air Relief Valve).

Model No. Size Vert. Clearance Req.

(From Ground Level)

CCP240 240 sq. ft. 56in.

CCP320 320 sq. ft. 62in.

CCP420 420 sq. ft. 68in.

CCP520 520 sq. ft. 74in.

Table 2

Figure 1

RISK OF ELECTRICAL SHOCK OR ELECTROCUTION. Water discharged from an improperly positioned filter or

valve can create an electrical hazard that can cause severe personal injury as well as damage property.

Filter Plumbing

Make all plumbing connections in accordance with local plumbing and building codes. Do not use pipe joint compound,

glue or solvent on the bulkhead connections. The provided filter plumbing connections include an O-ring seal.

Use PTFE or silicone based lubricants when lubricating the O-rings on the union and bulkhead couplings. Use of

petroleum based products will damage the equipment.

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 7

3

Installing the Manual Air Relief Valve

Figure 2

The High Flow manual air relief valve and pressure gauge are

included with this filter to help ensure safe operation of the

equipment. Always maintain these components in good working condition.

1. Remove the High Flow™ Manual Air Relief Valve and the

pressure gauge from the accessories package included with your

Clean and Clear® Plus Cartridge Filter.

2. Thread the manual air relief valve into the threaded hole at the top

of the filter tank.

Note: Hand tighten only! Over tightening the valve can cause

damage to the tank or valve connection threads.

3. Verify that the valve is positioned to safely direct purged air or

water away from electrical equipment or anything that might be

damaged.

RISK OF ELECTRICAL SHOCK OR ELECTROCUTION. Water discharged from an improperly positioned

filter or valve can create an electrical hazard that can cause severe personal injury as well as damage

property.

4. Remove the plug from the top of the manual air relief valve with a 9/16" wrench.

5. Wrap the pressure gauge connection threads with thread seal tape (two full wraps of tape will be enough).

6. Thread the pressure gauge into the top of the manual air relief valve. Hand tighten only!

7. Follow Start-up Instructions exactly (page 6).

FILTER

TANK

PRESSURE

GAUGE

VALVE

PLUG

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 8

4

OPENING, CLOSING, AND START-UP

The following information should be read carefully since it outlines the proper manner of care and operation for your filter

system. As a result of following these instructions and taking the necessary preventative care, you can expect maximum

efficiency and life from your filtration system.

Opening the Filter

Follow these instructions exactly to prevent the lid from separating during system start-up, operation or servicing.

This filter operates under high pressure. Air can also enter the system and become pressurized.

If there is air in the system, there will be positive pressure that could cause the lid to separate from the filter when you

release the clamp or during system start-up or operation (see Important Warnings and Safety Instructions, page ii-iii).

If there is no air in the system, there may be negative pressure, which would make the system hard to open.

Follow these instructions exactly - opening the relief valve equalizes the pressure and releases any trapped air within

the system, making it safe and easy to open.

RECOMMENDED EQUIPMENT:

• Ratchet Wrench

• 7/8" Socket

• Socket Extender (if needed)

PROCEDURE:

Clamp Ring

1. Shut off pump and relieve pressure.

a. Turn the pump OFF, shut OFF any automatic

controls (e.g., timers), and disconnect power to

ensure that the system is not inadvertently started

during maintenance.

b. Open the High Flow™ Manual Air Relief Valve by

turning the valve cover assembly counter-clockwise

until it snaps into the full open position.

Clamp Ring,

Closed Position

c. Stand clear of the filter and wait until all pressure is

relieved. Pressure gauge must read zero (0 psi).

2. Open the waste drain plug on the bottom of the Clean

and Clear® Plus Cartridge Filter. Allow all water to drain

from the bottom of the filter tank.

3. Loosen the clamp's barrel nut with a 7/8" wrench,

allowing the spring coils to decompress. See Figure 4.

Remove the barrel nut, spring and two washers from the

Clamp Ring,

Open Position

T-bolt and place them in a safe place where they will not

be lost.

4. Once the spring has fully decompressed the clamp

assembly will rest in the open position. Carefully lift the

filter lid straight up from the lower body of the filter. If

the lid is tightly sealed to the filter body you may have to

gently push the filter lid from side to side in order to separate the lid from the bottom tank manifold.

Figure 3

Sm. Washer

Lrg. Washer

Barrel

Nut

Spring

T-Bolt

Loosen with

7/8" Wrench

Figure 4

DO NOT use the relief valve as a handle or lever since this may damage the valve.

5. Place the tank lid in a safe place where it will not be damaged while performing any maintenance.

NOTE: Attempt to minimize the amount of debris that comes in contact with the tank O-ring while it is exposed. This

will help prolong the life of the O-ring.

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 9

Installing the Filter Lid and Clamp Ring

Follow these instructions exactly to prevent the lid from separating from the filter during system start-up

or operation. (See Important Warnings and Safety Instructions, page ii-iii).

RECOMMENDED EQUIPMENT:

• Ratchet Wrench

• 7/8" Socket

• Socket Extender (if needed)

• Rubber Mallet

PROCEDURE:

1. Be sure the O-ring is clean and in position in the

lower tank half. Press the Clean and Clear® Plus

Cartridge Filter lid onto the lower half so the O-ring

fits in between the tank halves.

2. Hold the ends of the clamp ring apart and place over

both upper and lower tank flanges. Bring the ends of

the filter clamp together.

3. Insert the T-bolt through the other side of the clamp

and hold together.

4. Place the small washer onto the T-bolt.

5. Place the spring, large washer and barrel nut onto

the T -bolt and tighten the nut by hand. Be sure the

clamp ring fits easily on the tank flanges.

6. After tightening by hand:

a. Use a 7/8 in. wrench (ratchet wrench

recommended) to tighten further.

b. Tap around the outside of the clamp ring

with a rubber mallet (or similar tool) multiple

times around the entire clamp to fit the clamp

properly.

c. Continue to tighten until the spring coils touch.

d. Tap around the entire clamp again and verify

the spring coils remain touching. If not, continue

to tighten the nut.

Note: The clamp is installed correctly only when the

spring coils remain touching after tapping the clamp

(See Figure 5).

7. Close the waste drain plug at the bottom of the filter.

8. Follow Start-Up Instructions exactly (see page 6).

Clamp Ring,

Open Position

Clamp Ring,

Closed Position

Spring Coils

Touching

Hand Tighten

onto T-Bolt

Tighten with

7/8" wrench

Figure 5

Note: Check the spring coils at least once a

month to ensure proper tension. If spring coils

do not touch then shut off pump and relieve

pressure and tighten the nut and tap filter clamp

until the coils touch.

5

DO NOT tighten the nut or attempt to adjust the clamp ring or lid while the system is turned on or under

pressure. This could cause the lid to separate from the filter

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 10

6

Start-Up Instructions

Follow these instructions exactly to prevent the lid from separating from the filter during system start-up or

operation. (See Important Warnings and Safety Instructions, page ii-iii).

1. Be sure the spring on the clamp ring is fully compressed, with coils

touching.

2. Open the High Flow™ Manual Air Relief Valve by turning the valve cover

assembly a quarter turn counter-clockwise, until it snaps into the full open

position. See Figure 6.

3. Stand clear of the filter tank, then start the pump.

4. Watch for proper operation. The system is not working properly if:

a. The pressure gauge indicates pressure before water out-flow appears.

b. A solid stream of water does not appear within 30 seconds after the

pump's inlet basket fills with water.

c. Water leaks from where the two halves of the filter come together.

If any of these conditions exist, shut off the pump immediately. Open

the manual air relief valve to relieve pressure and clean the valve (see

Cleaning the Manual Air Relief Valve, page 7). If the problem persists,

call Pentair Technical Service at (800) 831-7133 for assistance.

5. After a steady stream of water appears, close the manual air relief valve

by turning the valve cover assembly a quarter turn clockwise.

6. The first time the system is started up, fill out Table 1 on page 1 and the

corresponding label on the equipment:

a. Record the "Original Starting Pressure"

b. Fill in the pressure at which to clean the filter (8-10 psi higher than

the "Original Starting Pressure").

c. If the system includes a variable speed pump, record "Original

Pump RPM".

Quarter turn counterclockwise to open

Closed Position

Open Position

Figure 6

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 11

MAINTENANCE

Maintaining the Pressure Gauge

The pressure gauge is the primary indicator of how the system is operating, so correct functioning is critical.

Replace the pressure gauge (Pentair P/N 190058) if it does not meet the requirements below:

1. Pressure gauge should go to zero (0) when the system is turned off and pressure is relieved.

2. Pressure gauge should indicate pressure when the system is operating.

3. The pressure gauge should be readable and not damaged in anyway

Cleaning the Manual Air Relief Valve

RECOMMENDED EQUIPMENT:

• 5/16" Drill Bit (to check air passage)

• Silicone-based Lubricant (if needed)

PROCEDURE:

1. Shut off pump and relieve pressure.

a. Turn the pump OFF and shut OFF any automatic controls (e.g., timers)

and disconnect power to ensure that the system is not inadvertently

started during maintenance.

b. Open the manual air relief valve by turning the valve cover assembly a

quarter turn counter-clockwise until it snaps into the full open position.

c. Stand clear of the filter and wait until all pressure is relieved. Pressure

gauge must read zero (0 psi).

2. With the relief valve attached to the Clean and Clear® Plus Cartridge

Filter tank, pull out the locking tabs and unlock the valve stem and cover

assembly from the valve body with a counter-clockwise turn, see Figure 7.

3. Pull the valve stem and cover assembly straight up and away from the valve

body.

4. Clean and check the valve stem and body:

a. Clean off any debris.

b. Verify that the filter tank's air passage is open by inserting a 5/16"

drill bit through the valve body.

c. Verify that the valve stem O-rings are in good condition, properly positioned, and lubricated with a

silicone-base lubricant.

Figure 7

7

If needed, use only a PTFE or silicone-base lubricant on the O-rings. Use of petroleum based

products on O-rings will damage the equipment.

5. Reinstall the valve stem and cover assembly with a downward and clockwise motion until it snaps into

position.

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 12

8

45°

When to Clean Your Filter

Proper operation can prevent avoidable repairs and maintenance.

Use the pressure gauge to determine when to clean your Clean and Clear® Plus Cartridge Filter for proper

operation. The pressure reading increases as dirt is filtered from your pool. This buildup of pressure will vary due to

different bathing loads, temperature, environmental conditions, etc.

Clean your filter when pressure reads between 8-10 psi higher than the “Original Starting Pressure” recorded in

Table 1 (page 1), or when significant reduction in flow is noticed.

Note: When using a variable speed pump the “Original Starting Pressure” will be dependent on the pump speed

(RPM) when recording the original operating pressure.

Cleaning the Filter Cartridges

1. Follow Opening the Filter (page 4) exactly.

2. Remove hair and lint strainer pot lid from the pump and clean

basket. Replace strainer basket and secure strainer pot lid.

3. Remove the compression spring and spring adapter by pulling

them straight up.

4. Separate the top manifold from the filter's cartridges and lay

the manifold to the side. See Figure 8.

5. Carefully remove each cartridge element separately.

6. Using a garden hose with a straight flow nozzle, wash down

the entire filter element. Wash from the top down, holding the

nozzle at a 45-degree angle to the cartridge (See Figure 9).

Pay special attention to the area between pleats.

7. For cartridges used in pools or spas where high levels of

perspiration, suntan lotions and other oils are present:

a. Soak the cartridge for at least one hour (overnight is most

effective) in one of the following:

• A commercial filter cleaner

Heed all manufacturers' instructions and warnings when using

polyhexamethylene biguanide sanitizers or other cartridge filter cleaner

solutions.

Figure 8

Compression Spring

and Spring Adapter

Top Manifold

• One cup trisodium phosphate (TSP) to five gallons of water

• One cup dishwasher detergent to five gallons of water

b. Rinse the cartridge to remove oils and cleaning solution.

Failure to remove all oils and cleaning solutions before acid soaking will result

in permanent restriction of water flow through the filter and will cause premature

cartridge failure.

8. Direct the water spray to wash out the inside of the tank body and bottom manifold.

Water and debris will drain out through the open drain plug.

9. Check gasket around outer lip of bottom plate. Gasket must be firmly and evenly set

around the entirety of the outer lip.

10. Place bottom manifold, four (4) cartridges and top manifold in place. Make sure the

spring and standpipe assembly are retained on the top manifold.

11. Be certain the O-ring is in position in the lower tank half and free of debris.

12. Follow Installing the Filter Lid and Clamp Ring exactly (page 5).

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Figure 9

Page 13

Acid Soaking the Filter Cartridges

After an extended period of operation, it may be necessary to soak the cartridges in an acid solution. Acid soaking

will remove algae, calcium carbonate, iron and other mineral build-ups from the cartridges. If not removed, these

mineral deposits can lead to the restriction of water flow through the Clean and Clear® Plus Cartridge Filter and

can impede efficient operation of the equipment.

Muriatic acid is corrosive and can lead to inflammation or burns to body tissue.

ALWAYS wear rubber gloves, safety glasses and an N-95 dust mask when handling acid to prevent serious bodily

injury.

To prevent degradation of the acid by UV light, store muriatic acid in an opaque container and away from direct

sunlight.

RECOMMENDED EQUIPMENT:

• Large Plastic Container

• Garden Hose with a Straight Flow Nozzle

• Muriatic Acid (stored in opaque container)

• Rubber Gloves

• Safety Glasses

• N-95 Dust Mask

9

PROCEDURE:

1. Remove all oils and cleaning solutions from the cartridges.

Acid soaking without performing this step will result in permanent restriction of water flow through the filter and premature

cartridge failure.

2. Put on protective equipment - rubber gloves, safety glasses

and N-95 dust mask.

Figure 10

3. In a large plastic container, create a solution of one part

muriatic acid to twenty parts water. See Figure 10.

Introduce the muriatic acid as close to the water's

surface as possible. This will minimize splash and

reduce the risk of user contact with the acid.

4. Gently place the bottom of the cartridges into the acid

solution. Allow the cartridges to soak in the solution for 10

minutes, or until bubbling stops.

Muriatic

Acid

5. Turn the cartridges over, placing the top halves into the

solution. Allow the top halves of the cartridges to soak for

10 minutes, or until bubbling stops.

4. Remove the cartridges from the acid solution.

Water

5. Using a garden hose with a straight flow nozzle, thoroughly

wash down the entire filter element. Wash from the top

down, holding the nozzle at a 45-degree angle to the

cartridge. See Figure 9, on page 8.

6. Reinstall the cartridges and dispose of the acid solution in accordance with local regulations.

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 14

10

Replacing Filter Cartridges

Filter cartridge element life will vary with pool conditions such as bather load, wind, dust, etc. You can expect

an average cartridge life of three (3) years under normal conditions.

To replace filter cartridges:

1. Follow Opening the Filter exactly (page 4).

2. Remove the compression spring and spring adapter by pulling them straight up. Once the spring and

spring adapter have been removed, separate the top manifold from the filter cartridges and lay the

manifold to the side. See Figure 6).

2. Carefully remove each cartridge element separately.

3. Check gasket around outer lip of bottom plate. Gasket must be firmly and evenly set around the entirety of

the outer lip.

4. Install the replacement cartridges onto the bottom manifold. Reinstall the top manifold on to the new

cartridges.

Note: Be sure the spring and standpipe assembly are retained on the top manifold.

5. Follow Installing the Filter Lid and Clamp Ring exactly (page 5).

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 15

TROUBLESHOOTING

1. AIR ENTERING THE SYSTEM.

Air entering your Clean and Clear® Plus Cartridge Filter can cause lid separation. Correct any conditions in

your filtration system that allow air to enter the system.

Air entering the system can cause the lid to separate from the filter. If the below symptoms are observed, do not

attempt to remove or tighten the clamping system or perform any other servicing until you have shut off pump

and relieved all air and pressure in accordance with the Opening the Filter instructions (page 4). (See Important

Warnings and Safety Instructions, page ii-iii)

Symptoms:

• Low water level in pool or spa - skimmer starving for water with pump running.

• Air bubbles or low water level in pump hair and lint pot

• Air bubbles coming out of water return lines into pool or spa with pump running

• Air is discharged from the air/pressure relief valve on top of the filter when the valve is opened with the

pump running.

Potential Causes and Solutions:

• Low water level: Add water to pool or spa.

• Clogged skimmer basket: Unclog.

• Damaged or leaking components (e.g., split suction cleaner hose, leak in pump hair and lint pot lid, or

leak in pump suction line): Repair or replace component.

11

2. SHORT FILTER CYCLES BETWEEN CLEANING.

Until the water initially put into the pool has been completely filtered, short filter cycles in between cleanings

are normal. In most cases pool owners are dismayed by the undesirable color and appearance of water in a

newly filled pool. Plaster dust can be responsible for short filter cycles, requiring frequent cleaning.

3. PRESSURE DROP ON GAUGE.

If pressure drops on gauge, check skimmer basket and pump basket first for debris. If the baskets are clean,

there is likely a problem with the pump. Refer to pump manual for pump troubleshooting.

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 16

12

FLOW (gpm)

PRESSURE DROP vs FLOW

PRESSURE DROP (psi)

0

2

4

6

8

10

12

020406080 100 120 140 160

A

7.49”

8.05”

21.45”

22.98”

21.9”

2.4”

R

10.73”

TECHNICAL DATA

Flow Rates

Clean and Clear® Plus Cartridge Filters

Recommended Flow Rate

Model #

Filter Area

(Sq. Ft.)

Vertical

Clearance*

Flow Rate

(GPM)

CCP240 240 56 in. 90 32,400 43,200 64,800

CCP320 320 62 in. 120 43,200 57,600 86,400

CCP420 420 68 in. 150 54,000 72,000 108,000

CCP520 520 74 in. 150 54,000 72,000 108,000

Turnover Capacity (Gallons)

6 Hours 8 Hours 12 Hours

NOTE: Actual system flow will depend on plumbing size and other system components.

* Required Clearance to remove filter elements and lid.

Dimensional Drawings

MODEL DIM "A"

CCP 240 37"

CCP 320 43"

CCP 420 49"

CCP 520 56"

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 17

6

5

4X

3

4

19

1

2

8

22

7

16

21

21

15

20

14

18

17

9

10

11

12

13

Illustrated Parts View

13

REPLACEMENT PARTS

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 18

14

Clean and Clear® Plus Cartridge Filter Parts List

Replacement Parts

Item

No.

1 190058 Pressure Gauge, with Indicator

2 98209800

3 178616 Compression Spring

4 170026 Top Manifold, 240 C&C Plus

4 170027 Top Manifold, 320/420/520 C&C Plus

5 R173572 Cartridge Element, 240 C&C Plus, 4 req.

5 R174573 Cartridge Element, 320 C&C Plus, 4 req.

5 R173576 Cartridge Element, 420 C&C Plus, 4 req.

5 R173578 Cartridge element, 520 C&C Plus, 4 req.

6 170030 Air Bleed Tube Assy., 240 C&C Plus

6 170029 Air Bleed Tube Assy., 320 C&C Plus

6 170028 Air Bleed Tube Assy., 420 C&C Plus

6 178583 Air Bleed Tube Assy., 520 C&C Plus

7 170040 Bottom Manifold

8 39010200 O-ring, Tank Clamp (.470 O.D.)

9 190003 Clamp Band Replacement Kit

10 195610 Clamp Washer, Small I.D.

11 195611 Clamp Washer, Large I.D.

12 194997 Clamp Nut

13 195612 Clamp Spring, 4-Coil

14 190039 Baffle Assy., C&C Plus

15 98960311 Union Kit, Black

15 271096

15 270004

15 274426Z 2 x 2.5" Valve Adapter Kit,

Part

No.

Description

High Flow Manual Air Relief Valve

(HFMARV)

2" Valve Adapter Kit, 1 ½ in. x 2 in. (set),

White

2" Valve Adapter Kit, 1 ½ in. x 2 in. (set),

Black

Item

No.

16 170036 Pipe Assy. Outlet, C&C Plus

17 190143 O-ring, Drain

18 190030 Drain Plug, without O-Ring

19 170023 Tank, Lid Assy., 240 C&C Plus

19 170024 Tank, Lid Assy., 320 C&C Plus

19 178581 Tank, Lid Assy., 420 C&C Plus

19 178582 Tank, Lid Assy., 520 C&C Plus

20 178578

21 86006900 O-ring

22 195339 Ring, Steel Back-up

- 192019 Drain Plug Wrench

- 171013 Label Kit w/ Air Relief, 240 C&C Plus

- 171014

- 190106Z Air Bleed Screen Cap

Part

No.

Description

Tank, Bottom Assy. (Includes Items 7, 14,

16 and 18)

Label Kit w/ Air Relief, 320/420/520 C&C

Plus

(-) Not Shown

CLEAN AND CLEAR® PLUS Cartridge Filter Installation and User’s Guide

Page 19

NOTES

Page 20

1620 HAWKINS AVE., SANFORD, NC 27330 • (919) 566-8000

10951 WEST LOS ANGELES AVE., MOORPARK, CA 93021 • (805) 553-5000

WWW.PENTAIRPOOL.COM

All Pentair trademarks and logos are owned by Pentair or one of its global affiliates. Clean & Clear®, High Flow™ and Eco Select® are trademarks

and/or registered trademarks of Pentair Water Pool and Spa, Inc. and/or its affiliated companies in the United States and/ or other countries. Unless expressly noted, names and brands of third parties that may be used in this document are not used to indicate an affiliation or endorsement

between the owners of these names and brands and Pentair Water Pool and Spa, Inc. Those names and brands may be the trademarks or registered trademarks of those third parties. Because we are continuously improving our products and services, Pentair reserves the right to change

specifications without prior notice. Pentair is an equal opportunity employer.

© 2017 Pentair Water Pool and Spa, Inc. All rights reserved. This document is subject to change without notice.

*178558*

P/N 178558 Rev. P 7/6/17

Loading...

Loading...