Page 1

™

INTELLIZONE

COMMERCIAL OZONE GENERATOR

Models CD-15G, CD-25G - All Models

INTELLIZONE

COMMERCIAL OZONE SYSTEM

ADVANCED SANITATION S OLUTIONS

TM

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

INSTALLATION AND

USER'S GUIDE

Page 2

TABLE OF CONTENTS

SECTION 1 General Information

Description .....................................................................1

Specifications .................................................................1

SECTION 2 Installation

Location ..........................................................................1

Mounting .........................................................................1

Electrical .........................................................................2

Plumbing .........................................................................2

SECTION 3 Operation

Initial System Start-Up ....................................................3

Normal Operation ...........................................................3

System Shut-Down .........................................................3

IMPORTANT SAFETY INSTRUCTIONS

SECTION 4 Maintenance & Service

System Electro-Mechanical Overview ........................... 3

PM Schedule ................................................................. 7

Troubleshooting ............................................................. 7

Contact Information ....................................................... 7

SECTION 5 Replacement Parts & Order Info

Ordering Information...................................................... 7

Warranty ..................................................................... 8

Appendix

Appendix A (Troubleshooting Guide) ............................ 8

Warranty .................................................................... 12

Appendix B (Safety) ................................................... 13

READ AND FOLLOW ALL INSTRUCTIONS.

• Read this manual completely before attempting installation.

• Risk of Electric Shock. Install the ozone unit and any metallic plumbing associated with the unit at least

5 ft from the inside wall of tub or pool.

• Risk of Electric Shock. Connect this ozone generator in accordance with the installation instructions.

Do not install within an enclosure that would restict ventilation.

• (Applicable to cord/plug connected units only) Risk of electric shock. Connect only to a properly grounded,

grounding type receptacle.

• Do not bury cord.

• Warning – To reduce the risk of electric shock, replace damaged cord immediately.

• Follow all applicable electrical codes.

• Electric shock hazard. Be sure to turn power OFF at power source before any service work is performed.

Failure to do so could result in serious injury or death.

• Warning – Short term inhalation of high concentrations of ozone and long term inhalation of low

concentrations of ozone can cause serious harmful physiological effects. DO NOT inhale ozone gas

produced by this device.

• For your safety, do not store or use gasoline, chemicals or other flammable liquids or vapors near this

or any other appliance.

• A spontaneous and violent ignition may occur if oil, grease or greasy substances come in

contact with oxygen under pressure. These substances must be kept away from oxygen

regulators, cylinder valves tubing and connections, and all other oxygen equipment.

SAVE THESE INSTRUCTIONS!

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 3

1

SECTION 1 General Information

Description

The IntelliZone™ Commercial Ozone Gererator (Models

CD-15G and CD-25G (521659, 521660, 521761 and

521762) described in this manual is designed to provide

the benefits of ozonated water in an environmentally

safe and effective manner. The high quality, specially

engineered components ensure efficient ozone output

and reliable performance.

Thos ozone generator is safe and harmless

to your equipment if installed properly.

24.1 613

A

31112.3

24.4 620

A

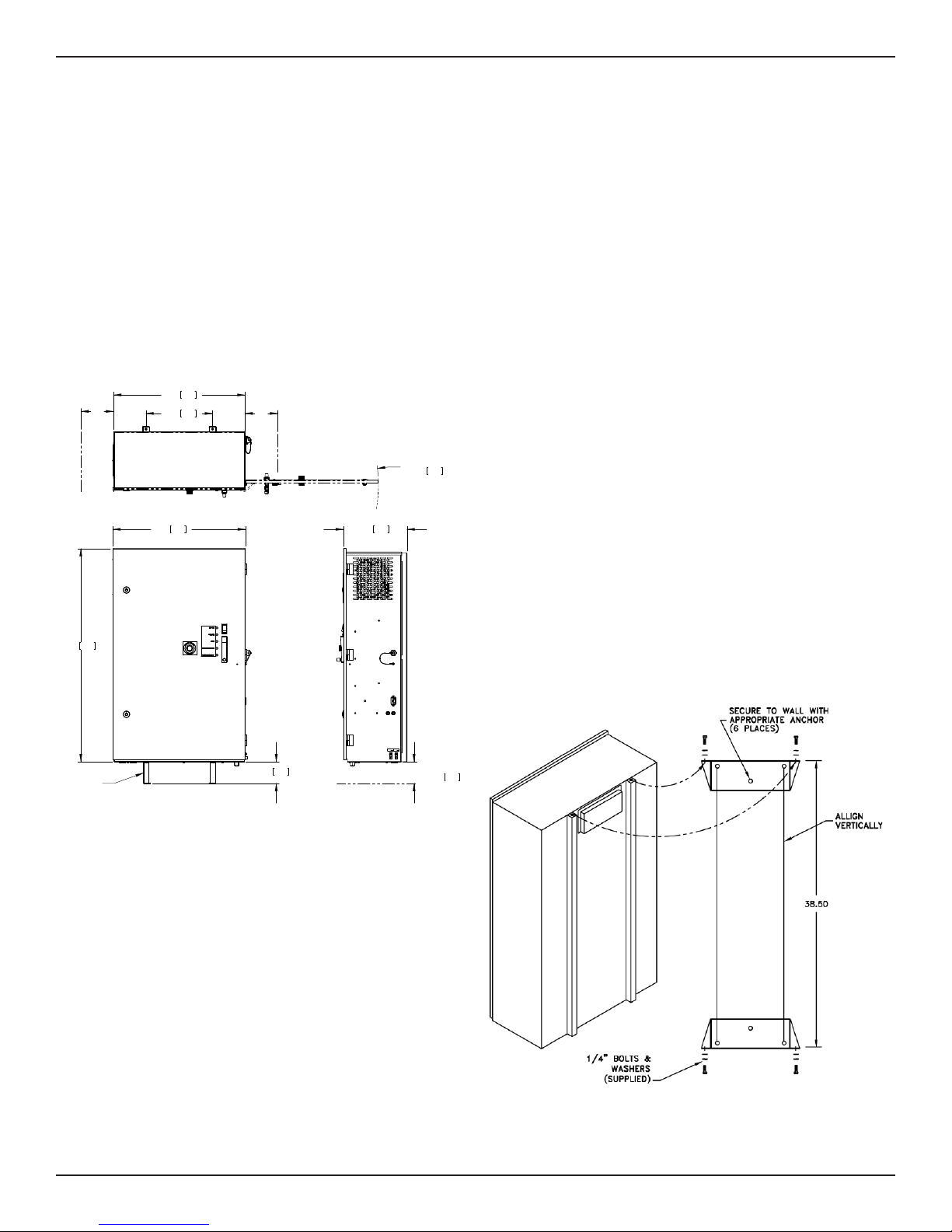

DIM "A" = 6 [152] MIN CLEARANCE

11.7 297

DOOR SWING

621R24.5

SECTION 2 Installation

Location

The ozone generator is designed for either floor or wall

mounting in a clean, protected area, either indoors or

outdoors. Locate generator out of reach of sprinklers or

drainage spouts. Allow sufficient access for maintenance

and all tubing and electrical wires. The generator must

not be placed in locations where ambient ozone levels

exceed 0.01 PPM.

Mounting

NOTE: Do not remove compressor packing

material until unit has been mounted.

Wall Mount Option

1. Attach two mounting brackets to wall using

anchors appropriate for mounting surface.

See Figure 2.

2. Using 1/4"-20 bolts (with washers as shown)

secure generator to mounts.

Floor Mount Option

1. Use the four 1/4"-20 bolts with washers to

secure feet to bottom of cabinet.

2. Stand upright and securely fasten to concrete

slab using appropriate anchors and bolts.

39.2 995

MOUNTING

BRACKETS (2)

1024.0

MIN. CLEARANCE

(IF WALL MOUNTED) 4.0 102

Figure 1

Specifications

For detailed specifications refer to the ozone

generator specification label located on the inside

of the door on the unit.

Location Requirements*:

Mounting: Floor or wall mount in a clean, protected

area using supplied brackets.

Ventilation: Room should provide 6 air changes

per hour

Ambient Temp.: 40–100˚F (5–38˚C)

* Protection from weather elements must be provided

for outdoor installations. Operating outside of the

recommended temp. ranges may result in damage

not covered under the manufacturer’s warranty.

Figure 2: Wall Mount

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 4

2

Electrical

Refer to the units specification label and local

electrical codes for information on proper electrical

connection.

120V Models

Main power circuit: Unit is supplied with a

standard power cord. Plug cord into standard

120V grounded, gounding type receptacle only.

230V Models

Main power circuit: 230V models are supplied

with an IEC 6032 C-14 Type power receptacle.

A power cord, having at least a 10AMP rating, with

a IEC 60320 C-13 Type plug and a country specific

plug is required to power generator.

Figure 3: Country Specific Plug

(Australia shown for reference only)

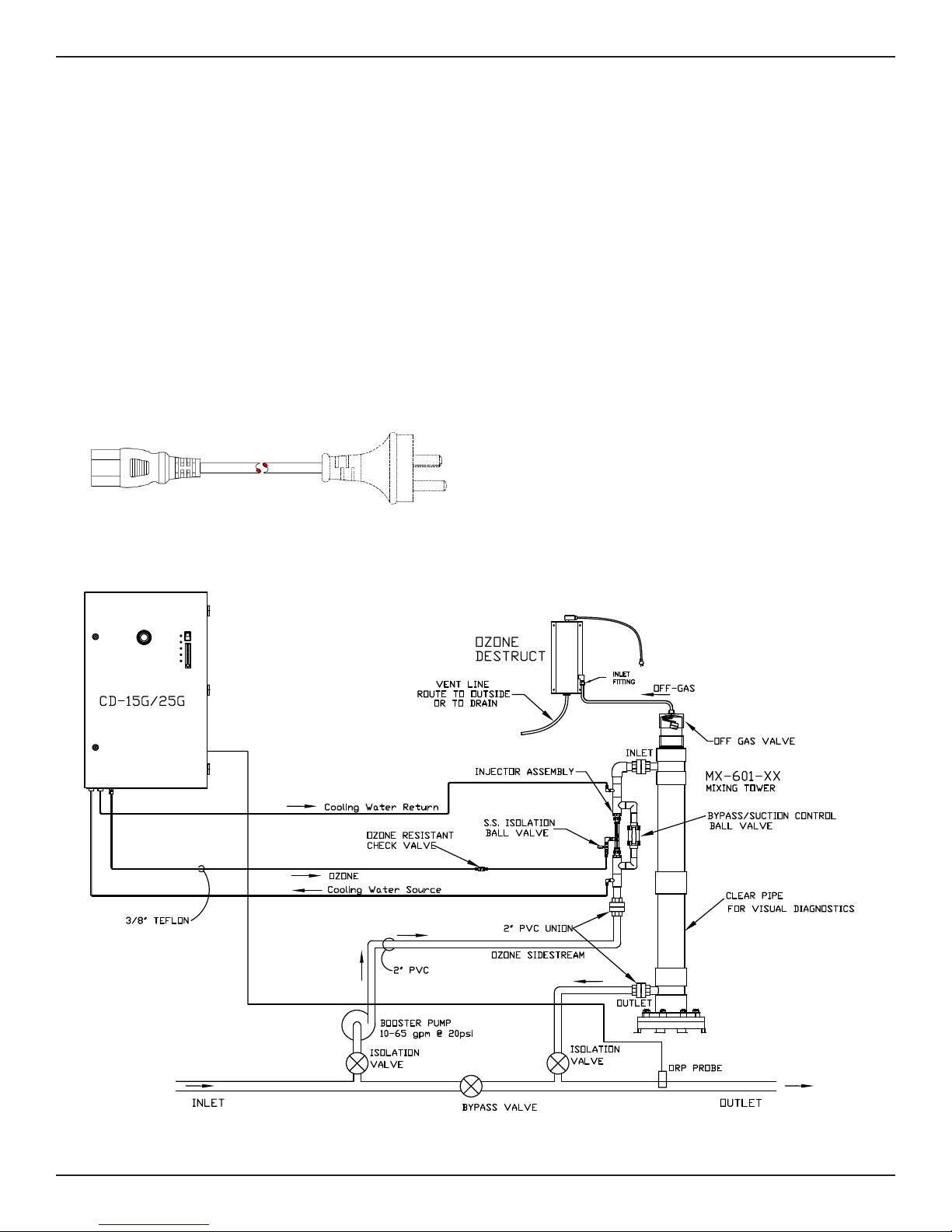

Plumbing

Ozone gas is introduced to the circulation line using

a venturi in-line injector. Suction developed by the

venturi injector allows the generator to operate

safely under vacuum. See installation manual

for Model 521683 or 521684 for proper venturi

installation.

Ozone Gas Line

1. Connect ozone tubing to generator outlet fitting.

(3/8" stainless steel compression fitting.)

2. Connect opposite end of ozone tubing to injector

suction port. (Suction port fitting: 3/8" stainless

steel compression fitting.) See Figure 4.

NOTE: The ozone gas supply line must be

made of PTFE or stainless steel and have a

back flow prevention device (such as a check

valve) installed between the ozone generator

cabinet and the point of injection to prevent

water from backing up into the generator

system. An ozone supply check valve is

included with the Model 521683 or 521684

system.

Figure 4: Plumbing Schematic - Example of Swimming Pool Application

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 5

3

Cooling Water

Cooling Water Flow: .1 Gpm (.4 Lpm)

Colling water Pressure: 15–40 psi (103–275 kPa)

Cooling Water Temp.: 5–90˚F (10–32˚C)

1/4" FPT connections are supplied on the

generator. See Figure 4, 5a, 6a. Be sure that

the tubing is appropriately matched with the marked

inlet and outlet ports. Carefully match and connect

to water plumbing as shown in Figure 4. Alternate

method using connections at injector may be used.

SECTION 3 Operation

Initial System Start-Up

Upon completing all of the generator system

connections, you are ready to begin start-up

procedures.

1. Check electrical fittings.

2. Check for proper voltage.

3. Turn on circulation pump.

4. Check for leaks.

5. With the ozone isolation valve closed, adjust the

injector bypass valve and/or filtration sidestream

valve to flow water through the injector.

6. Check cooling water.

7. Open the ozone isolation valve.

8. Turn main power switch to "ON" position.

9. Adjust injector by-pass to attain required vacuum.

(Red "Vacuum" light will go out.) Gas flow

(as indicated by the flow meter on the door of

the unit) should correspond with the rating listed

for the specific model on the specification label.

Normal Operation

With the power switch on, the system’s

compressors and cooling fans will start-up, the

oxygen concentrator will begin operating, and

the output solenoid valve will open. With the

injector adjusted to attain the correct gas flow,

the ozone generator should be producing ozone

and injecting it into the process line.

Both (2) green indicator lights should be lit. If

an optional ORP Controller is installed, it should

be displaying a reading from the sensor probe

and will automatically cycle the generator on and

off as needed to maintain water quality. Residual

ORP levels will vary per application.

However, the system will not start under any of

the following conditions:

1. The system will not start-up if the door is not

secured. A door interlock switch is incorporated

into the system enclosure.

2. If the optional ORP/DO3 controller is installed the

system will not produce ozone if the measured

level is already above the setpoint of the controller.

3. The system will not produce ozone if there is not

enough vacuum being generated by water flow

through injector. The red "Vacuum" light will go

out when proper vacuum is attained.

If you experience complications, see APPENDIX

A, TROUBLESHOOTING GUIDE or call

800.831.7133 for assistance.

System Shut-Down

The ozone generator is a specialized water

cooled device that must be properly protected

during shut-down/storage periods. The

following sequence of steps must be used for

servicing or for storage.

1. Toggle the main system power switch to the

“OFF” position to shut-down generator.

2. Close the ozone isolation valve to prevent water

back flow.

3. After the generator has been shut-down, the

process water circulation pump may be turned

off.

4. If the system is going to be shut-down and

stored during freezing weather, it is very

important that the cooling water be drained to

protect it from rupture or damage.

NOTE: Process water flow must not be shut-

down when the ozone generator is operating.

Doing so may cause water to backflow into

the system and damage the generator cells.

SECTION 4 Maintenance & Service

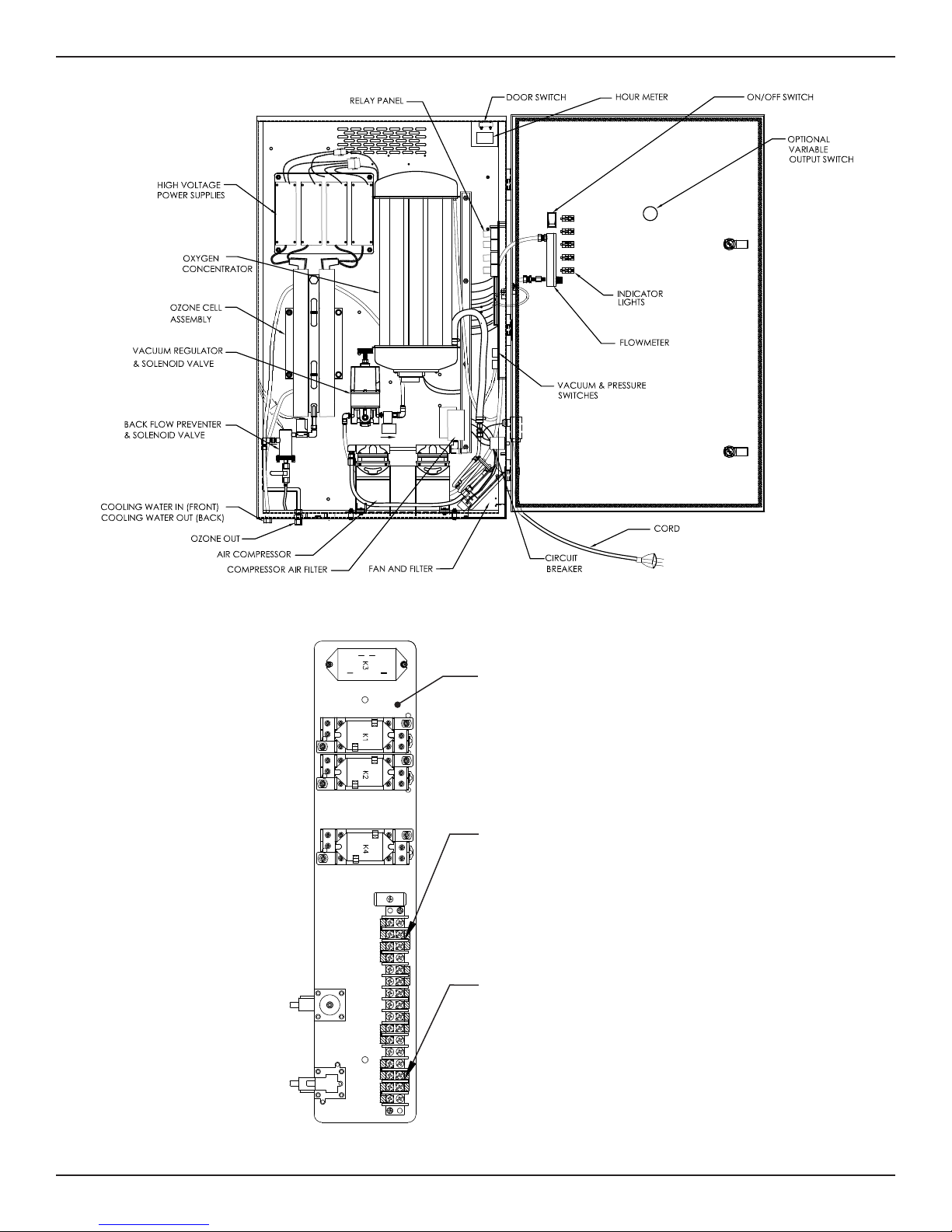

System Electro-Mechanical Overview

Refer to Figure 5a and 6a for component locations.

Indicator Lights

1. Main Power: Green light indicates that power is

being supplied to the ozone generator.

2. Ozone Power: Green light indicates that power

is being supplied to the high voltage Corona

Discharge circuits and that ozone is being

produced.

3. Vacuum: Red light indicates a low vacuum fault

condition. (Refer to APPENDIX A

TROUBLESHOOTING).

4. High Coolant Temperature: Red light indicates

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 6

4

cell temperature is over 110F - resulting from

loss of cooling water flow. (Refer to APPENDIX

"B", TROUBLESHOOTING GUIDE.)

5. Water Backflow Detected: Red light indicates

water backflow from injector into generator.

(Refer to APPENDIX "B", TROUBLESHOOTING

GUIDE.)

External Components

1. Main Power Switch: Power switch is used for

system start-up and shut-down. Switch activates

the control system allowing the generator to

start up.

2. Flowmeter: Flowmeter controls and indicates

the oxygen flow through the system.

3. Circuit Breaker: Circuit breaker protects the

generator from over current conditions. Push

the breaker button to reset.

Internal Components

1. Variable Output Switch (optional): Adjusts

high voltage power supplied to the ozone

generator module controlling ozone output

concentration. Located on the outside of the

enclosure door.

External Devices that Control Ozone Production

The devices turn ozone production on or off

based on programmed level set points. Refer

to Figure 5b and 6b for connection details.

1. ORP Controller (optional): The ORP controller

receives a millivolt (mV) signal from the ORP

sensor mounted in the process water line. ORP

(Oxidation-Reduction Potential) is a measure

of the relative oxidation strength of the water.

As ozone is added to the water system the ORP

level will rise. As ozone is used up in the water

system the ORP level will drop. The ORP

controller continuously analyzes the sensor

signal, compares it to the setpoint that has

been programmed, indicates the ORP level on

the digital display, and relays the signal to the

ozone generator.

2. Dissolved Ozone Monitor (optional):

Monitoring system designed for the continuous

measurement of ozone gas in solution. The

operating range of the system may be selected

by the user from 0-2.00 PPM or from 0-20.00

PPM. The basic sensing element used is

polarographic membraned sensor which

measures ozone directly.

External Devices that Control System

Power

The devices turn power to the ozone generator

on or off. Examples of such devices would be an

ambient ozone monitor or flow switch. Refer to

Figure 5b and 6b for connection details.

Internal Components

1. Ozone Cell Assembly: Cells are made of two

aluminum halves. Enclosed in the aluminum

halves are a ceramic tube, coil type high voltage

electrode and a PTFE rod.

2. High Voltage Supply(s): Power supplies raise

incoming line voltage and frequency to deliver it

to the cells. Each power supply is rated at 100W.

3. Air Compressors: Compressors produce and

supply compressed air to oxygen concentrator.

4. Oxygen Concentrator: Supplies concentrated,

dry, oxygen feed gas to the ozone generator.

5. Low Limit Vacuum Switch: If the vacuum in the

ozone output supply line falls below 1.5 in. Hg

the switch will open causing the system to shut

down.

6. Vacuum Regulator: Regulates the oxygen

flow into the generator cell based on a vacuum

setpoint (factory set to 3-5 in. Hg). When the

sufficient suction is being developed by the

injectors downstream the regulator will allow full

flow to pass. As suction is reduced, flow is

restricted proportionally to maintain the vacuum

set point. If suction is lost completely, flow is

cut off.

7. Water Backflow: The backflow detector senses

water present in ozone tubing in generator. If

water is detected, system will close solenoid

valve to prevent additional water backflow from

occuring. Water in the generator will cause

severe damage to the high voltage electrodes.

8. Ventilation Fan: Cooling fan operates when

main power switch is “ON”.

9. Air Filter: Filter cleans ventilation air entering

the enclosure.

10. Door Interlock Switch: Interlock switch will

shut down entire system if door is opened.

Securing the door will bring the system back

into operation.

11. Relay Panel: Contains control relays for system

interlocks, indicator lights and main power

control.

12. Hour Meter: Indicates total system operating

time in hours.

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 7

5

Figure 5a: Component Locations (ALL MODELS EXCEPT 521761 and 521762)

Relay Panel

Remove jumper if ORP controller or dissolved

ozone monitor is used. Connect dry contact

leads from controller/monitor or leave open

if 5 pin external interface connector is used.

Remove jumper and connect dry contact leads

if external device is used. (ambient ozone, flow

switch, etc.)

Figure 5b: Connection Details for External Control Devices (ALL MODELS EXCEPT 521761 and 521762)

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 8

6

AIR COMPRESSOR

FANS

HIGH VOLTAGE

POWER SUPPLIES

OXYGEN

CONCENTRATOR

VACUUM REGULATOR

& SOLENOID VALVE

OZONE CELL

ASSEMBLY

COOLING WATER OUT

COOLING WATER IN

COMPRESSOR

AIR FILTER

DOOR SWITCH

OZONE OUT

AIR INTAKE SCREENS (3)

HOUR METER

INDICATOR

LIGHTS

FLOW METER

VACUUM & PRESSURE

SWITCHES

BACK FLOW PREVENTER

& SOLENOID VALVE

RELAY PANEL

ON/OFF SWITCH

OPTIONAL

VARIABLE

OUTPUT SWITCH

5 PIN EXTERNAL

INTERFACE

CONNECTOR

RECEPTACLE

IEC 60320 C-14

CIRCUIT

BREAKERS (2)

Figure 6a: Component Locations

K3

Relay Panel

K5

K1

K2

K4

Remove jumper if ORP controller or dissolved

ozone monitor is used. Connect dry contact

leads from controller/monitor or leave open

if 5 pin external interface connector is used.

Remove jumper and connect dry contact leads

if external device is used. (ambient ozone, flow

switch, etc.)

Figure 6b: Connection Details for External Control Devices

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 9

7

Preventative Maintenance Schedule

Regular maintenance should be performed to avoid

damage to the system, more costly repairs and

to keep the warranty active. For instance, the

compressor should be rebuilt every 8,750 hours

to prevent the reduction in air-pressure and flow.

If the compressor is not rebuilt, oxygen concentrator

sieve beds will become plugged and unusable,

creating more costly problems. If the generator

cells are not cleaned or replaced annually, a lower

ozone output will result.

DAILY:

Check ozone generator for proper operation.

- Make sure no red indicator lights are lit.

- Make sure flow meter is indicating proper

air flow.

MONTHLY:

1. Inspect compressor air filter.

- Replace quarterly

2. Remove and clean air filter or intake screens

See Figure 7.

- Remove filter cover plate to access filter.

- Rinse filter in warm, soapy water and blow dry.

- Replace filter.

- For models 521761 and 521762, remove and

clean intake screens.

3. Perform general cleaning of cabinet interior.

Troubleshooting

See APPENDIX A TROUBLESHOOTING.

NOTE: Knowledge of electrical applications is

required for trouble shooting. Contact a certified

electrician if you are unsure of your ability to

service the equipment. If any condition persists,

call 800.831.7133 for technical assistance.

Contact Information

For Technical assistance:

Call: 800.831.7133

Visit: www.pentaircommercial.com

www.pentairpool.com

SECTION 5 Replacement Parts &

Order Information

Ordering information

For replacement parts call 800.831.7133

Be prepared with the following information:

• Customer Name

• Customer Address

• Model Number

• Serial Number

EVERY 8,750 HOURS:

1. Rebuild compressor. Kit Avaiable. See Section 5

for ordering information.

2. Replace/Service Check Valve(s) and Solenoid

Valves.

3. Replace ozone cell O-rings and inspect ozone

cells.

IN TAKE SC RE EN

BO TTO M OF

CD CA BI NE T

Figure 7: Filter or Intake Screen Removal for Cleaning

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 10

8

APPENDIX A

TROUBLESHOOTING

TROUBLESHOOTING

FOR CD-15G & 25G SERIES

OZONE GENERATORS

The following information can help resolve problems that might arise in operation of the CD-15G & 25G

Series ozone generators. It contains three main sections that when used together provide a basic overview

of the ozone generator layout, troubleshooting table for common problems, and electrical, pneumatic, and

hydraulic order diagrams. If you still need help, call 800.831.7133.

.

Note: Always disconnect the ozone generator from the power source before attempting service or repair.

Image 1: Ozone Generator Component Locations (CD-25GV model shown)

12

15

2

22

3

11

21

19

10

26

20

29

30

18

8

17

9

24

5

6

14

31

25

7

1

28

27

23

16

13

4

32

1. 5-Pin connector (not shown) 12. Door switch 23. Power switch

2. 12VDC power supply (optional) 13. Flowmeter 24. Pressure relief valve

3. Backflow prevention device (BFPD) hctiws erusserP .52 esuF .41

emruoH .51 ecifiro ssarB .4 ter 26. S.S. check valve

gil rotacidnI .61 naf tenibaC .5 hts 27. Terminal block 1 (TB1)

6. Cabinet filter (not shown) 17. Oxygen concentrator 28. Terminal block 4 (TB4)

dionelos negyxO .81 rekaerb tiucriC .7 valve 29. Thermal switch (not shown)

rotaluger muucaV .03 sllec enozO .91 rosserpmoC .8

9. Compressor air filter 20. Ozone output fitting 31. Vacuum switch

10. Cooling block assembly 21. Ozone power supplies

11. Cooling water in & out fittings 22. Ozone solenoid valve

32. Variable ozone output control

(optional)

TSG CD-15G & 25G 1 of 4 4-1529-01_Rev.A

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 11

Table 1: Troubleshooting (for best results follow the table order)

Problem (Indication) Possible Cause Corrective Action

1. Unit does not start

(main power light is off and no

sound is coming from the unit)

2. Unit is in vacuum fault

(vacuum light is on)

3. Unit is in high temperature fault

(high coolant temperature light is

on)

4. Unit is in backflow fault

(water backflow detected light is on)

5. Unit does not flow gas

(flowmeter at bottom of scale)

6. Unit ozone production does not

start

(both

ozone power and vacuum

lights are off)

7. Unit does not provide effective

sanitation

(both

main power and ozone power

lights are on)

a. Unit is not supplied power

b. Unit door switch is open Close unit door

c. Unit power switch is in off position Turn power switch on

d. Unit circuit breaker is tripped Reset circuit breaker

a. Inadequate vacuum is supplied to

unit

b. Unit S.S. check valve has failed Clean or replace S.S. check valve

c. Unit vacuum switch has failed Replace vacuum switch

d. Unit vacuum regulator requires

adjustment or has failed

a. Unit thermal switch has tripped

b. Unit thermal switch has failed Replace thermal switch

a. Water has returned from injection

point and triggered unit back flow

float switch

a. Unit flowmeter valve is closed Adjust flowmeter valve open

b. Unit jumper(s) at TB1 are removed

(optional system control hookup, e.g.

flow switch and/or ambient O3)

c. Unit fuse is blown Replace fuse

d. Unit pressure switch is not active

e. Unit orifice is plugged Clean or replace orifice

f. Unit solenoid valve(s) has failed Clean or replace solenoid valve(s)

g. Unit flowmeter ball is stuck on

bottom of sight tube

h. Unit vacuum regulator requires

adjustment or has failed

a. Unit jumper at TB4 is removed

(optional external ozone control

hookup, e.g. ORP or dissolved O3,

directly wired or through 5-Pin)

a. Unit variable ozone output control

setting is too low (optional feature)

b. Leak in plumbing that dilutes

applied ozone dose

c. Low gas flow and/or low oxygen

concentration

d. Unit ozone cell has reached

service life or failed

e. Unit ozone power supply has failed Replace power supply

Connect unit to power source

Turn power source breaker on

Reset power source G.F.C.I.

Verify power source voltage is

within unit specification

Connect unit to vacuum source

(injector)

Adjust injector to provide more

vacuum

Fix leak or obstruction in plumbing

between injector and unit

Call service department for

assistance

Reduce supplied cooling water

temperature and/or increase flow

rate

Obstruction or scaling in cooling

block assembly (clean or replace)

Disconnect ozone line between

injector and unit at ozone output

fitting, drain BFPD vessel, and

replace SS check valve

Re-install jumper(s) and/or verify

system control(s) are operational

Verify unit plumbing between

oxygen concentrator and pressure

switch is securely connected

Replace compressor air filter

Rebuild compressor

Replace oxygen concentrator

Repair or replace flowmeter

Call service department for

assistance

Re-install jumper and/or verify

external ozone control is

operational

If so equipped, increase ozone

output setting

Fix leak in plumbing (inside unit

and/or between unit and injector)

Replace unit compressor air filter

Clean or replace unit orifice

Clean or replace unit check valve

Rebuild unit compressor

Replace unit oxygen concentrator

Replace ozone cell

9

TSG CD-15G & 25G 2 of 4 4-1529-01_Rev.A

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 12

10

TSG CD-15G & 25G 3 of 4 4-1529-01_Rev.A

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 13

11

TSG CD-15G & 25G 4 of 4 4-1529-01_Rev.A

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 14

12

LIMITED WARRANTY

Pentair Aquatic Systems warrants the IntelliZone

521761 and 521762) as follows:

Limited Warranty: Pentair warrants the (Models CD-15G and CD-25G (521659, 521660, 521761 and 521762) to be free from defects in

material and/or workmanship for a period of two (2) years from the original date of installation.

Exceptions that shall result in Pentair’s denial of a warranty claim:

1. Damage caused by careless handling, improper repackaging, or shipping.

2. Damage due to misapplication, misuse, abuse or failure to operate equipment as specified in the (Models CD-15G and

CD-25G (521659, 521660, 521761 and 521762) Installation and User’s Guide.

3. Damage caused by failure to install products as specified in the (Models CD-15G and CD-25G (521659, 521660, 521761

and 521762) Installation and User’s Guide.

4. Damage due to unauthorized product modifications or alterations, or failure to use Pentair original replacement parts.

5. Damage caused by negligence, or failure to properly maintain products as specified in the (Models CD-15G and CD-25G

(521659, 521660, 521761 and 521762) Installation and User’s Guide.

6. Damage caused by failure to maintain water chemistry in conformity with the standards set forth in the (Models CD-15G and

CD-25G (521659, 521660, 521761 and 521762) Installation and User’s Guide.

7. Damage caused by water scaling, freezing or any conditions causing inadequate water circulation.

8. Accidental damage, fire, acts of God, or other circumstances outside the control of Pentair.

• This warranty extends to the original retail owner (Customer) only, beginning on the date of installation and is not enforceable

by any other party. Proof of purchase and/or date of installation will be required for all warranty claims. Customer agrees to pay

all shipping charges to Pentair.

• Warranties by others: Some products incorporate components manufactured by other manufacturers. Some of these provide

warranties in addition to the warranty provided herein. In all such cases a copy of that warranty will be provided with the product

To the extent protection provided under any such third party warranty exceeds the Limited Warranty provided herein, the

Customer must look only to that other manufacturer for the additional warranty protection.

Warranty Obligations of Pentair: Should a defect in workmanship and/or material in any item covered by this warranty

become evident during the term of the warranty, then upon the Customer following the procedures set forth below, Pentair will, at

its option, repair or replace such item or part at its own cost and expense. Pentair’s maximum obligation under this warranty is

limited to the repair and replacement of the (Models CD-15G and CD-25G (521659, 521660, 521761 and 521762). Pentair

disclaims all other expressed or implied warranty obligations.

™

Commercial Ozone Gererator (Models CD-15G and CD-25G (521659, 521660,

Pentair is not, however, responsible under this warranty for any cost of shipping or transportation of the equipment or parts thereof to or

from Pentair’s Technical Service Department. Also, Pentair is not liable for any loss of time, inconvenience, incidental expenses such

as telephone calls, labor or material charges incurred in connection with the removal or replacement of the equipment, or any other

incidental or consequential damages, including but not limited to damage to pool equipment or any surface in or around the pool in

which the (Models CD-15G and CD-25G (521659, 521660, 521761 and 521762) is installed.

PLEASE NOTE: Some states do not allow the exclusion or limitation of incidental, or consequential damages, so the above limitation or

exclusion may not apply to you.

No Other Warranties: TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, PENTAIR DISCLAIMS ALL OTHER

WARRANTIES, WHETHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Procedure for Obtaining Performance: In order to obtain the benefits of this warranty, the Customer who made the original retail

purchase must contact the Pentair Technical Service Department upon discovery of the defect, but in no event later than the expiration

date of the warranty period provided in this warranty. Upon receipt of this communication, Pentair will promptly notify the Customer

of the address to which the defective item may be shipped. The Customer shall then ship the item, freight prepaid, to the address

indicated, together with a "RETURN GOODS AUTHORIZATION" form obtained from Pentair Technical Service and a brief description of

the problems encountered. Unauthorized returns will not be accepted. Freight must be prepaid by customer.

Warranties or Representations by Others: No dealer or other third party entity has any authority to make any warranties or

representations concerning Pentair or its products. Accordingly, Pentair is not responsible for any such warranties or representations.

Other Rights: This warranty gives you specific legal rights and you may also have other rights, which vary from state to state. This

warranty supersedes all previous publications.

Pentair Aquatic Systems.

1620 Hawkins Ave. Sanford, NC 27330 - 10951 W. Los Angeles Ave. Moorpark, CA 93021 - Phone 800-831-7133 - Fax 800-284-4151

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 15

APPENDIX - SAFETY

OZONE Material Safety Data Sheet

SECTION I: MATERIAL IDENTIFICATION

IDENTITY: OZONE (Gaseous) ISSUED: February, 1992

FORMULA: O3 REVISED: April 3, 2012

Description (origin/uses): Occurs in atmosphere from UV light action on oxygen at high altitude. Commercially obtained by

passing air between electrodes carrying a high voltage alternating current. Also found as a by-product in welding areas, high

voltage equipment, or UV radiation.

Ozone is used as an oxidizing agent in air and water disinfection: for bleaching textiles, oils, and waxes; organic synthesis as in

processing certain perfumes, vanillin, camphor; for mold and bacteria control in cold storage

Cautions: A powerful oxidizing agent, ozone generally exists as a gas and is highly chemically reactive. Inhalation produces

various degrees of respiratory effects from irritation to pulmonary edema (fluid in lungs) as well as affecting the eyes, blood, and

central nervous system.

Manufacturer/Supplier: On-site generation, equipment available from various suppliers, including:

DEL Ozone

3580 Sueldo Street

Phone: (805) 541-1601

FAX: (805) 541-8459

San Luis Obispo, CA 93401

SECTION II: INGREDIENTS AND HAZARDS

.

13

Ozone, CAS No. 10028-15-6: NIOSH RTECS No. RS8225000

1991 OSHA PELs

8-hr TWA: 0.1 ppm vol. (0.2 mg/m

15-min STEL: 0.3 ppm vol (0.6 mg/m

1990 IDLH

10 ppm

1990 NIOSH REL

Ceiling: 0.1 ppm vol. (0.2 mg/m

3

)

3

)

3

)

1991-1992 ACGIH TLV

Ceiling: 0.1 ppm (0.2 mg/m

1990 DFG (Germany) MAK

TWA: 0.1 ppm (0.2 mg/m

Category 1: Local Irritant

Peak Exposure Limit: 0.2 ppm

5 min momentary value, 8 per shift

3

)

3

)

Other Designations: Triatomic oxygen: CAS No. 10028-15-6, NIOSH RTECS No. RS8225000

SECTION III: PHYSICAL DATA

Boiling Point: . . . . . . .

Vapor Pressure: . . . . .

Vapor Density (

Solubility in Water: . . .

AIR = 1):

-169 F

>1 ATM

1.6

0.49 ml @ 32 F (0 C),

3 ppm @ 20 C

Appearance and Odor: Colorless to blue gas (greater than -169 F): characteristic odor often associated with electrical sparks or

lightning in concentrations of less than 2 ppm and becomes disagreeable above 1-2 ppm. CAUTION: Olfactory fatigue develops

rapidly, so do not use odor as a preventative warning device.

Melting Point: . . . . . . . .

% Volatile by Volume: . .

Molecular Weight: . . . . .

pH: . . . . . . . . . . . . . . . .

Critical Temperature: . .

-315.4 F (-193 C)

100%

48 Grams/Mole

Not Listed

10.22 F (-12.1 C)

SECTION IV: FIRE AND EXPLOSION HAZARD DATA

Flash Point: . . . . . . . .

Extinguishing Media: .

Special Fire Fighting Procedures: Wear a self contained breathing apparatus with full face pieces operated in a pressure-

demand or other positive-pressure mode.

Unusual Fire/Explosion Hazards: Decomposition of ozone into oxygen gas, (O

Nonflammable

Use large amounts of water spray or fog to put out fires involving ozone. Use appropriate fire-fighting

techniques to deal with surrounding material.

), can increase strength of fire.

2

SECTION V: REACTIVITY DATA

Stability: Ozone is not stable. Hazardous polymerization cannot occur.

Chemical Incompatibilities: Ozone is chemically incompatible with all oxidizable materials, both organic and inorganic.

Conditions to Avoid: Ozone is unstable at room temperatures and spontaneously decomposes to oxygen gas. Avoid ignition

sources such as heat, sparks, and open flame. Keep away from strong reducing agents and combustible materials such as

grease, oils, and fats.

Products of Hazardous Decomposition: Ozone spontaneously decomposes to oxygen gas, even at room temperatures.

4-0697_ Rev.C

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 16

14

SECTION VI: HEALTH HAZARD DATA

Carcinogenicity: Ozone is not listed as a carcinogen by the NTP, IARC, or OSHA.

Primary Entry: Inhalation

Target Organs: Respiratory system, eyes, blood.

Summary of Risks: There is no true threshold limit and so no exposure (regardless of how small) is theoretically without effect

from ozone’s strong oxidative ability. Ozone passes straight to the smallest bronchioles and alveoli and is not absorbed by

mucous membranes along the way. Initial small exposure may reduce cell sensitivity and/or increase mucous thickness

producing a resistance to low ozone levels. Short exposure to 1-2 ppm concentrations causes headache as well as irritation to

the respiratory tract. but symptoms subside when exposure ends. High concentrations of ozone produce severe irritation of the

eyes and respiratory tract. Exposure above the ACGIH/OSHA limits produce nausea, chest pain, coughing, fatigue, reduced

visual acuity, and pulmonary edema. Symptoms of edema from excessive exposure can be delayed one or more hours.

Inhalation of >20 ppm for an hour or more (>50 ppm for 1/2 hour) can be fatal.

Acute Effects: Acute damage from ozone appears to be mainly from its oxidizing effect on contact with tissue.

Chronic Effects: Respiratory disease. Deleterious effects on lungs and acceleration of tumors have been reported.

Medical Conditions Generally Aggravated by Long-Term Exposure: History of respiratory or heart disorders.

First Aid: Remove from ozone containing air, get prompt medical help*, administer oxygen if necessary.

Eye Contact - Gently lift eyelids and flush eyes continuously with flooding amounts of water for 15 minutes or until transported to a

medical facility*.

Inhalation - Remove exposed person to fresh air, support breathing, administer humidified oxygen as needed, get medical help*.

Ingestion - Highly unlikely since ozone is a gas until -169 F,

* GET MEDICAL ASSISTANCE = APPROPRIATE IN-PLANT, PARAMEDIC, or COMMUNITY. Get prompt medical assistance for

further treatment, observation, and support after first aid.

SECTION VII: PRECAUTIONS FOR SAFE HANDLING AND USE

Steps to be Taken in Case of Spill/Leak:

1. Discontinue production

2. Isolate and vent area

3. Immediately notify personnel

4. Deny entry

5. Follow applicable OSHA regulations

Disposal: Provide ventilation to dilute and disperse small amounts of ozone (below OSHA PELs) to outside atmosphere. Follow

federal, state, and local regulations.

Handling/Storage Precautions: Ensure proper personnel training and establish emergency procedures.

SECTION VIII: CONTROL MEASURES

Respiratory Protection: High Level (>10 ppm) - Self Contained Breathing Apparatus: MISH/NIOSH approved.

Low Level (0.3 - 10 ppm) - Canister Type (carbon) respirator may be used.

Eye Protection: Wear chemical safety goggles if necessary to work in high ozone (>10 ppm).

Skin Protection: Effects of ozone on skin are minimal to non-existent.

Ventilation: Provide general and local exhaust ventilation to dilute & disperse small amounts of ozone into outside atmosphere.

SECTION IX: SPECIAL PRECAUTIONS AND COMMENTS

Storage Segregation: Prevent ozone from coming into direct physical contact with strong acids or bases or with strong

oxidizing/reducing agents.

Engineering Controls: Install ventilation systems capable of maintaining ozone to concentrations below the ACGIH/OSHA

exposure limits (see sect. II). Install ambient ozone monitor(s) configured to shut down ozone equipment and turn high speed

ventilation on.

4-0697_ Rev.C

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 17

Page 1 of 3

15

Material Safety Data Sheet

This MSDS complies with OSHA’s Hazardous Communication

Standard 29 CFR 1910.1200 and OSHA form 174.

DEL Ozone

3580 Sueldo Street

San Luis Obispo, CA 93401

Product Information 805-541-1601

Product Name

AQUEOUS OZONE SOLUTION

4 = Extreme

3 = High

2 = Moderate

1 = Slight

0 = Insignificant

NFPA 704 Designation

Hazard Rating

Chemical Name DISSOLVED OZONE GAS IN WATER 0 TO 2 PPM

Product Description AQUEOUS SOLUTION OF OZONE DISSOLVED IN POTABLE WATER

D.O.T. Shipping

Classification

NON REGULATED

I PHYSICAL DATA

Boiling Point 212 F Freezing Point 32 F

Specific Gravity 1.0 Solubility in Water COMPLETE

Evaporation Rate APPROX 1 Physical Form LIQUID

Appearance & Odor COLORLESS (CLEAR) WATER WITH FRESH, ASEPTIC ODOR

II HAZARDOUS INGREDIENTS

MATERIAL HAZARD CAS # % BY WT ACGIH TLV OSHA PEL

None

III FIRE AND EXPLOSION HAZARD DATA

Flash Point NA Method NA Auto Ign. Temp. NA

Flammable Limits in

Air

Extinguishing Media

Unusual Fire &

Explosion Hazards

Special Fire Fighting

Procedures

NON APPLICABLE Lower NA Upper NA

NON APPLICABLE

NONE

NONE

4-1444-01_Rev.C

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 18

16

Page 2 of 3

Material Safety Data Sheet Cont.

Product Name AQUEOUS OZONE SOLUTION

IV HEALTH HAZARD DATA

Threshold Limit Value NOT DETERMINED

Route of Exposure Inhalation Ingestion Skin Eye Not Hazardous

Eye Contact Hazard

Ingestion Hazard

Inhalation Hazard

Skin Contact Hazard

Skin Absorption Hazard

Effects of Acute

Exposure

Effects of Chronic

Exposure

If exposure to water containing aqueous solution of ozone causes irritation to eyes, flush eyes with

Eye Contact

Skin Contact

Inhalation

plenty of clean, ozone free, running water for at least 15 minutes, lifting the upper and lower lids

occasionally. Remove contact lenses if worn. Seek medical attention if irritation persists.

Not likely to become irritated unless repeatedly exposed to large volumes of material. If irritation

develops, rinse affected area with ozone free potable water. If irritation continues seek medical

advice.

Inhalation of mists could lead to irritation of lungs. If symptoms develop, move individual away from

exposure and into fresh air. If symptoms persist, seek medical attention.

Exposure may cause mild eye irritation, but is not expected.

Not Hazardous

Inhalation is not likely to be a primary route of exposure but could become irritating if

aerosols are exposed to individual for extended period of time.

No skin irritation is expected from short term exposure.

No published data indicates this product is absorbed through the skin.

Mild skin or eye irritation.

Repeated exposure of the skin to concentrated product should be avoided to prevent

irritation and drying of the skin.

V EMERGENCY AND FIRST AID PROCEDURES

Ingestion

Incompatibility

(Materials to Avoid)

Conditions

to Avoid

Hazardous

Decomposition

Stability STABLE UNSTABLE Hazardous Polymerization MAY OCCUR WILL NOT OCCUR

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

NA

Natural rubber (may degrade, or “dry”, rubber components over extended periods of exposure)

NONE KNOWN

NONE

VI REACTIVITY DATA

4-1444-01_Rev.C

Page 19

Material Safety Data Sheet Cont.

Product Name AQUEOUS OZONE SOLUTION

VII SPILL OR LEAK PROCEDURES

Steps To Be Taken

If Material Is Released

Or Spilled

NONE

17

Page 3 of 3

Waste Disposal

Method

DISPOSE OF THE SAME AS POTABLE RINSE WATER

VIII SPECIAL PROTECTIVE INFORMATION

Respiratory Protection

(Specify Type)

Local

Ventilation

Exhaust

Mechanical

(general)

Protective Gloves NOT REQUIRED

Eye Protection NOT REQUIRED

Other Protective

Equipment

Precautionary

Labeling

NOT REQUIRED FOR NORMAL USE OF THIS PRODUCT

PREFERABLE Special NA

OK Other NA

NOT REQUIRED

Certified testing of DEL Ozone systems by NSF (National Sanitation Foundation) has shown that

under normal conditions of use, aqueous solutions containing low levels of ozone gas dissolved in

potable water do not present a safety hazard when contact to the individual is incidental. When

used in a room with normal ventilation, levels of ozone gas being released into the air have been

shown by NSF to be well below the periodic exposure levels established by OSHA for worker

safety through the use of DEL’s ozone management technology.

IX SPECIAL PRECAUTIONS

Precautions To Be

Taken In Handling

This material safety data sheet is provided as an information resource only. It should not be taken as a warranty or representation for which the preparer

assumes legal responsibility. While we believe the information contained herein is accurate and compiled from sources believed to be reliable, it is the

responsibility of the user to investigate and verify its validity. The buyer assumes all responsibility of using and handling the product in accordance with

applicable federal, state, and local regulations.

Aqueous solutions of ozone in potable water should not be sprayed as an aerosol (i.e. >20psi) to

avoid releasing higher levels of ozone gas into the work area. The decay rate of ozone gas is a

function of temperature and exposure to organic material. Certified testing has shown that when

ozone gas has been properly dissolved in ambient temperature (or colder (33 – 70 °F)) potable

water at a level not exceeding 2 mg/l (ppm) using DEL’s ozone management technology, the rate

at which ozone is released from the water as ozone gas is below the PEL established for gaseous

ozone.

Rev. Date 03/26/12

4-1444-01_Rev.C

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 20

18

Notes

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 21

Notes

19

INTELLIZONE™ COMMERCIAL OZONE GENERATOR Installation and User's Guide

Page 22

© 2012 Pentair Aquatic Systems. All rights reserved.

This document is subject to change without notice.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

All Pentair trademarks and logos are owned by Pentair, Inc. Pentair Aquatic Systems™ and IntelliZone™ are

trademarks and/or registered trademarks of Pentair Water Pool and Spa, Inc. and/or its affiliated companies in the

United States and/ or other countries. Unless expressly noted, names and brands of third parties that may be used in

this document are not used to indicate an affiliation or endorsement between the owners of these names and brands

and Pentair Water Pool and Spa, Inc. Those names and brands may be the trademarks or registered trademarks of

those third parties. Because we are continuously improving our products and services, Pentair reserves the right to

change specifications without prior notice. Pentair is an equal opportunity employer.

*521810*

P/N 521810 Rev A - 6/4/12

Loading...

Loading...