Page 1

®

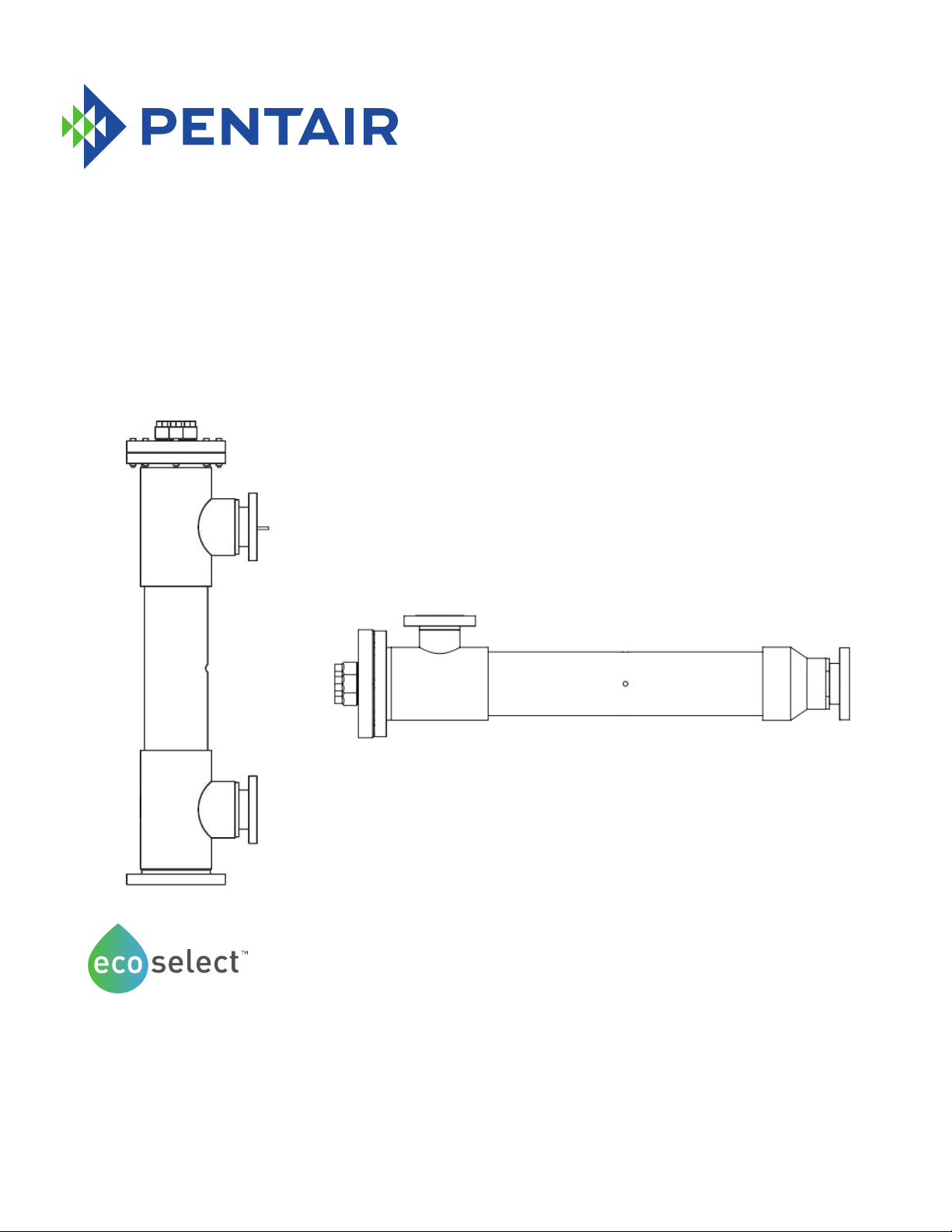

BIOSHIELD

COMMERCIAL UV STERILIZER

INSTALLATION AND

USER'S GUIDE

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Page 2

2

CUSTOMER SERVICE / TECHNICAL SUPPORT

If you have questions about ordering Pentair Aquatics Systems replacement parts and products,

please contact:

CUSTOMER SERVICE

8AM to 7PM—Eastern and Pacic Times

Toll Free: 800.831.7133

Fax: 919.566.8920

WEB SITE

Visit Pentair.com

©2019 Pentair Water Pool and Spa, Inc. All rights reserved.

This document is subject to change without notice.

1620 HAWKINS AVE., SANFORD, NC 27330 • (919) 566-8000

10951 WEST LOS ANGELES AVE., MOORPARK, CA 93021 • (805) 553-5000

WWW.PENTAIR.COM

All Pentair trademarks and logos are owned by Pentair or one of its global aliates. Pentair Commercial Aquatics™

and Bioshield® are trademarks and/ or registered trademarks of Pentair Water Pool and Spa, Inc. and/or its aliated

companies in the United States and/ or other countries. Unless expressly noted, names and brands of third parties

that may be used in this document are not used to indicate an aliation or endorsement between the owners of these

names and brands and Pentair Water Pool and Spa, Inc. Those names and brands may be the trademarks or registered

trademarks of those third parties. Because we are continuously improving our products and services, Pentair reserves

the right to change specications without prior notice. Pentair is an equal opportunity employer.

P/N 960064 Rev. D 7/23/2019

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 3

TABLE OF CONTENTS

3

Section 1: Introduction ............................................. 4

General Information ............................................. 4

Glossary ............................................................... 4

Section 2: Health and Safety Precautions ............. 5

Safety Symbols .................................................... 5

Safety Instructions .............................................. 5

Hazardous Situations and

Appropriate Actions ............................................ 5

Section 3: Installation ............................................... 7

Pre-Installation Inspection .................................. 7

UV Vessel Installation .......................................... 8

Quartz Sleeve Installation ................................. 10

Power Supply Installation ................................. 12

Temperature and UV Intensity

Sensor Installation ............................................. 13

Section 4: Mandatory Water Test .......................... 14

Section 5: UV Lamp Installation ............................ 15

Lamp Field Safety Cover Installation ............... 17

Section 6: Commissioning ..................................... 18

Start-Up.............................................................. 18

Section 7: Operation ............................................... 19

Programmable Logic Control (PLC) .................19

PLC Enclosure ...................................................19

PLC Descriptions ............................................... 19

PLC Touch Screen Display ................................ 20

Section 8: Maintenance .........................................23

Routine Inspection ............................................ 23

UV Lamp Replacement ..................................... 23

UV Lamp Removal ............................................. 23

UV Lamp Recycling ...........................................24

UV Lamp Installation ......................................... 24

Quartz Sleeve .................................................... 24

Quartz Sleeve Removal ..................................... 24

Quartz Sleeve Cleaning ..................................... 25

Quartz Sleeve Installation ................................. 26

UV Vessel Cleaning ............................................26

UV Vessel Disassembly ..................................... 27

Cooling Fan and Filter Mat ................................ 29

Cooling Fan Filter Removal ............................... 29

Cooling Fan Filter Cleaning ............................... 29

Cooling Fan Filter Installation ........................... 29

Section 9: Replacement Parts ...............................30

Replacement Parts ............................................ 31

Section 10: Troubleshooting ..................................32

Section 11: System Specications ........................34

Vertical Series ....................................................34

CLP Series .........................................................36

Sizing Chart .......................................................39

Section 12: Product Warranty ...............................40

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 4

4

SECTION 1: INTRODUCTION

General Information

In this manual you will nd user information for

your Bioshield® Commercial UV Sterilizer. It is an

important document for safety guidance, installation,

operation and maintenance. Read and understand all

sections of this Manual before starting the installation

or operation of this UV system. Strictly follow this

Manual and all safety notes, they are for your own

safety.

Custom-made, project specic modications of the

UV system and/or additionally integrated components

may result in non-conformity of the system and void

the warranty.

The information contained in this manual represents

our most recent experiences and technical

knowledge. This information does not hold a

legally binding promise of certain characteristics or

suitability for a specic application. The user of the

UV system will be required to perform verications

and safety measures.

Pentair Water Pool and Spa, Inc. (Pentair) accepts no

responsibility for any problems arising from incorrect

installation, lack of routine maintenance as specied

in this manual or modications of the UV system.

Important Note: This unit has demonstrated an ability

to provide three log inactivation of Enterococcus

Faecium [ATCC #6569] and Pseudomonas Aeruginosa

[ATCC #27313]. This unit has not demonstrated

an ability to provide three log kill or inactivation

of Cryptosporidium. This product is designed for

supplementary disinfection and is intended for use

with appropriate residual levels of EPA registered

disinfecting chemicals. Specic residual levels of EPA

registered disinfecting chemicals may be required by

the regulatory agency having authority.

Glossary

TERM DESCRIPTION

Disinfection The inactivation of harmful microorganisms

End of Useful Lamp Life Recommended time to replace a UV lamp

Fouling Buildup of scale in the vessel, sensor or quartz sleeve

J/m2 Joule per square meter A Unit of UV Dose 10 J/m2 = 1 mJ/cm2 = 1,000 uWs/cm

Minimum UV Intensity Required value at end of lamp life (alarm threshold value) to maintain the

minimum UV dose at a given ow rate and a given UV transmission.

nm Nanometer – Light wavelength measurement

Personal Protective

Equipment

Power Supply Enclosure NEMA Type-12 cabinet housing electrical hardware, instruments and PLC

Text Display Screen used to view PLC Controller/Monitor data

UV-C Specic UV area of the light spectrum (200 – 280 nm) UV Dose Indicates amount

UV Intensity Indicates the strength of UV light

UV Output Amount of UV light emitted from a UV lamp

UVT Ultraviolet Transmissibility how far UV-C light travels through water

UV Sensor Sensing-probe installed on the UV vessel to measure UV intensity-UV light

UV System Entire UV System that includes the Power Supply Enclosure and UV Vessel

UV Vessel Wet portion of the UV System consists of: quartz sleeve(s), UV lamp(s), vessel,

Hard Hat, Safety Glasses, Rubber Gloves, Safety Shoes

control/monitor

of UV light

wavelength 254nm

and valve(s)

2

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 5

SECTION 2: HEALTH AND SAFETY PRECAUTIONS

Safety Symbols

5

Caution

Warning

High Voltage

Chemical (Corrosive)

Sharp Object

Protective Eye wear (UV Light)

SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS PLEASE READ PRIOR

TO INSTALLATION AND OPERATION

Strictly follow the instructions within this manual to ensure the health

and safety of both, yourself and the UV system. The installation,

operation and maintenance of the Bioshield® Commercial UV

Sterilizer can only be carried out after reading and understanding the

information contained in this manual.

The installation of the UV system must be carried out in accordance

with local regulations and codes.

WA RNING : Water and electricity can be a dangerous

combination. Help us ensure your safety. READ AND FOLLOW ALL

SAFETY INSTRUCTIONS.

DANG ER: UV lamps and quartz sleeves are fragile and if

broken and handled incorrectly may cause serious injury.

IMPORTANT: READ AND OBSERVE ALL IMPORTANT

NOTICES AND LABELS ON THE UNIT. REMOVAL OF PRODUCT

LABEL W ILL VOID WARRANTY!

Recycle

DANGE R: If the unit shows any sign of water leakage,

immediately unplug it from the power source.

DANGER : DO NOT operate this unit if it has a damaged cord

or plug, if it is malfunctioning, or if it has been dropped or damaged in

any manner.

IMPORTANT: Close supervision is necessary when any

appliance is used by or near children ; this UV system is no exception.

IMPORTANT: Always unplug the unit from the electrical

outlet when it’s not in use, before servicing, cleaning or removing

parts. Never yank the cord to pull the plug from the outlet. Grasp the

plug and pull to disconnect.

IMPORTANT: Each UV system is designed for a specific

water-pressure. DO NOT use the UV system for any application other

than its intended use. The use of attachments not recommended or

sold by Pentair Aquatic Eco-Systems may cause unsafe conditions

and possibly void any warranty.

IMPORTANT: For your safety the quartz sleeve and /or

the UV lamp in this product may have been broken or damaged

during shipping. It is ESSENTIAL that the unit be CAREFULLY

INSPECTED BEFORE CONNECTING TO ELECTRIC POWER.

WARNING: DO NOT exceed listed pressure rating for unit.

DANGER : To avoid possible electric shock special care

should be taken since water is emp loyed in the use of the UV System.

For each of the following situations, do not attempt repairs yourself.

Call Pentair customer service department at ( 800) 831-7133.

DANGER: If the unit falls into the water, DO NOT REACH

FOR IT ! First unplug it and then retrieve it. If the internal electrical

components of the unit get wet, unplug the unit immediately.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

IMPORTANT: Only (3) three wire grounded cables suitable

for outdoor use should be used to connect this unit. If joining cables

for outdoor use, a suitable watertight cable connector must be used.

Care should be taken to arrange the cord so that it will not be tripped

over or pulled. If in doubt consult a qualified electrician.

IMPORTANT: Only operate the UV system when it is

properly maintained and in good working order.

IMPORTANT: DO NOT modify the UV system without

authorization from Pentair Aquatic Eco-Systems.

DANGER : BLUE-LIGHT HAZARD Ultraviolet light will

cause serious damage to your eyes an d skin! DO NOT handle or stare

at an operating UV lamp. UV lamps become hot during operation, DO

NOT handle them during operation.

Page 6

6

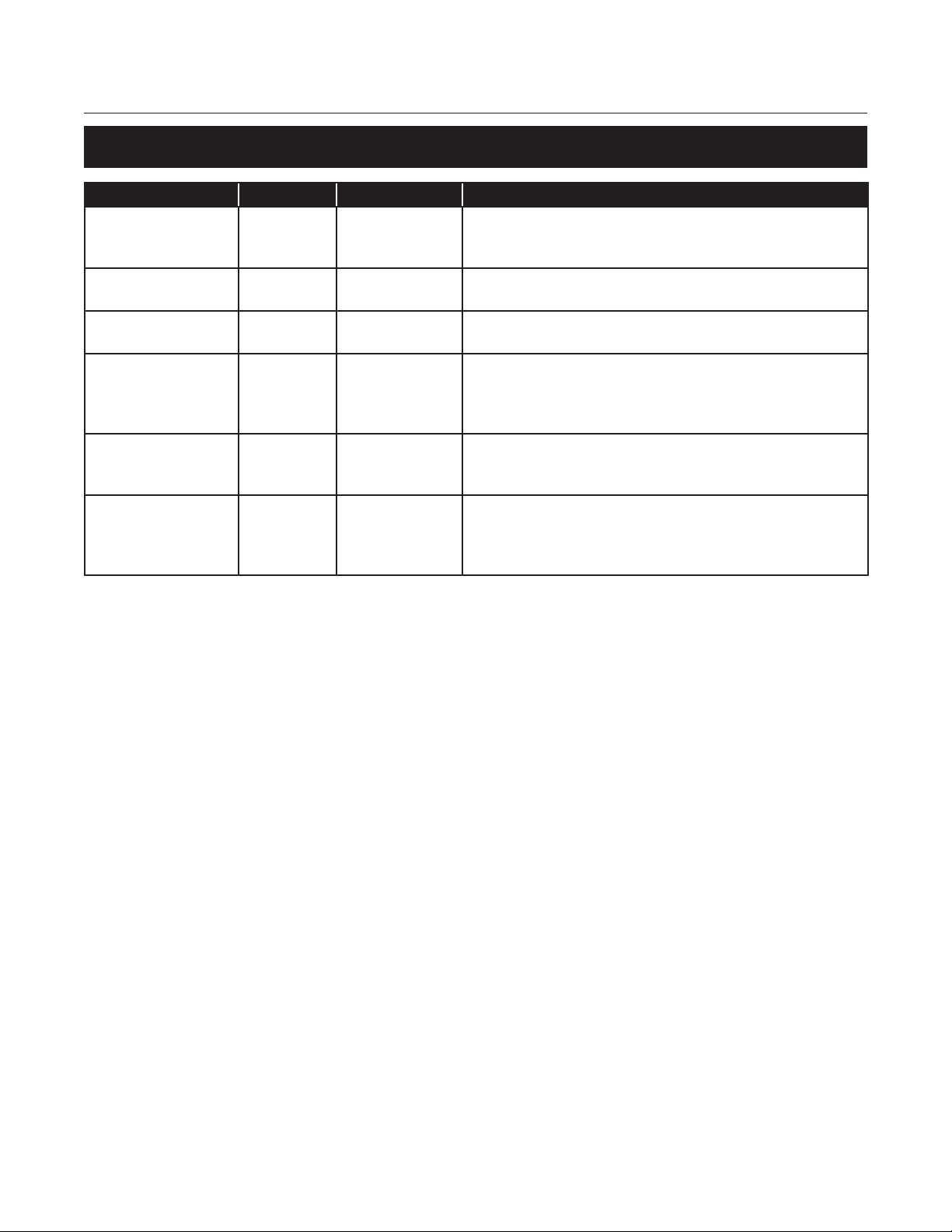

SECTION 2: HEALTH AND SAFETY PRECAUTIONS

HAZARDOUS SITUATIONS & APPROPRIATE ACTIONS

SITUATION LOCATION HAZARD ACTIONS

Lamp or Quartz

Sleeve Removal

Broken Quartz

Sleeves/ UV Lamps

UV Lamp

Replacement

Drain UV Vessel UV Vessel Pressure

Vessel Cleaning UV Vessel

Electrical Work UV System

UV Vessel Burn

UV Vessel Sharp Object

UV Vessel

Blue-Light

Hazard

Corrosive/

Chemical

Electrical

Shock

Isolate UV system from water source, shutdown

system using external On/ O switch and lock-out

disconnect from input power source.

Handle quartz sleeves and UV lamps with extreme

care, wear clean cotton gloves.

DO NOT operate UV lamps outside the UV vessel,

wear protective eye wear against ultraviolet light.

Isolate UV system from water source and shutdown

system using external On/O switch and lock-out/

disconnect from input power source. Open valves

carefully to relieve pressure and drain the UV Vessel.

Isolate the UV vessel and secure against unauthorized

operation. Wear appropriate protection equipment. No

smoking or food allowed.

Shutdown system using the UV system’s external On/

O switch and lock-out/disconnect from input power

source. All electrical work should be carried out by

authorized and qualied personnel only.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 7

SECTION 3: INSTALLATION

7

Pre-Installation Inspection

Purpose

To familiarize the installer/operator with the UV

Systems™ Commercial Lines’ components, to assure

proper delivery of all the system’s components and

to inspect each component for shipping damages.

Frequency

To be conducted prior to installation.

Parts and Required Equipment

• Adjustable Wrench or 1.5” Socket

• Box Cutter

• Hammer/Nail Remover

• Flashlight

During pre-installation there is a general risk

due to load.

The UV System consists of:

• Quartz Sleeve Module (QSM) Faceplate (assembled

on Vessel)

• QSM Faceplate Gasket (assembled on Vessel)

• UV Intensity Sensor (PLC models only)

• Temperature Sensor

• Quartz Sleeve Retainer Nut (one for each quartz

sleeve)

• Quartz Sleeve Gasket (one for each quartz sleeve

retainer nut)

• Drain Valve Assembly

• Quartz Sleeve (one for each UV Lamp)

• UV Lamp(s)

• Vessel

• Bolt(s) (assembled on Vessel)

• Nut(s) (assembled on Vessel)

Quartz Sleeves and UV Lamps are fragile and

potentially dangerous if broken. Handle with care.

Procedure

NOTE: Vessel diameters up to 8” are shipped with

their quartz sleeves assembled. Vessel

diameters 10” and larger are shipped with

their quartz sleeves packaged separately.

NOTE: UV Lamp(s) are shipped in a separate package

either inside the vessel crate or separately.

1. Unpack and inspect vessel for shipping damage. A

box cutter or hammer/nail remover may be needed

to unpack the UV System.

2. Conduct an internal, visual inspection of models

shipped with their quartz sleeves assembled. A

ashlight will help with the internal inspection.

• Washer(s) (assembled on Vessel)

• 4-Pin Connector(s) (attached to lamp cables)

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 8

8

SECTION 3: INSTALLATION

UV Vessel Installation

Purpose

Proper installation of the UV Vessel achieves expected

results and ensures safe operation.

Frequency

Required with new construction, retro-t or

replacement of outdated equipment.

Parts and Required Equipment

• Socket Wrenches

• Adjustable Wrenches

• Set of Slotted and Phillips Head Screwdrivers

• Lifting Equipment with Slings

• Vessel Mounting Brackets

• Required Isolation Valves

• Plumbing Components

3. Install UV vessel mounting brackets if required (to

be supplied by others).

NOTE: A 46” clearance for both Vertical Series and

CLP4 Series models is required for lamp and

quartz sleeve removal.

A 76” clearance for CLP6 Series models is

required for lamp and quartz sleeve removal.

Horizontal Installation

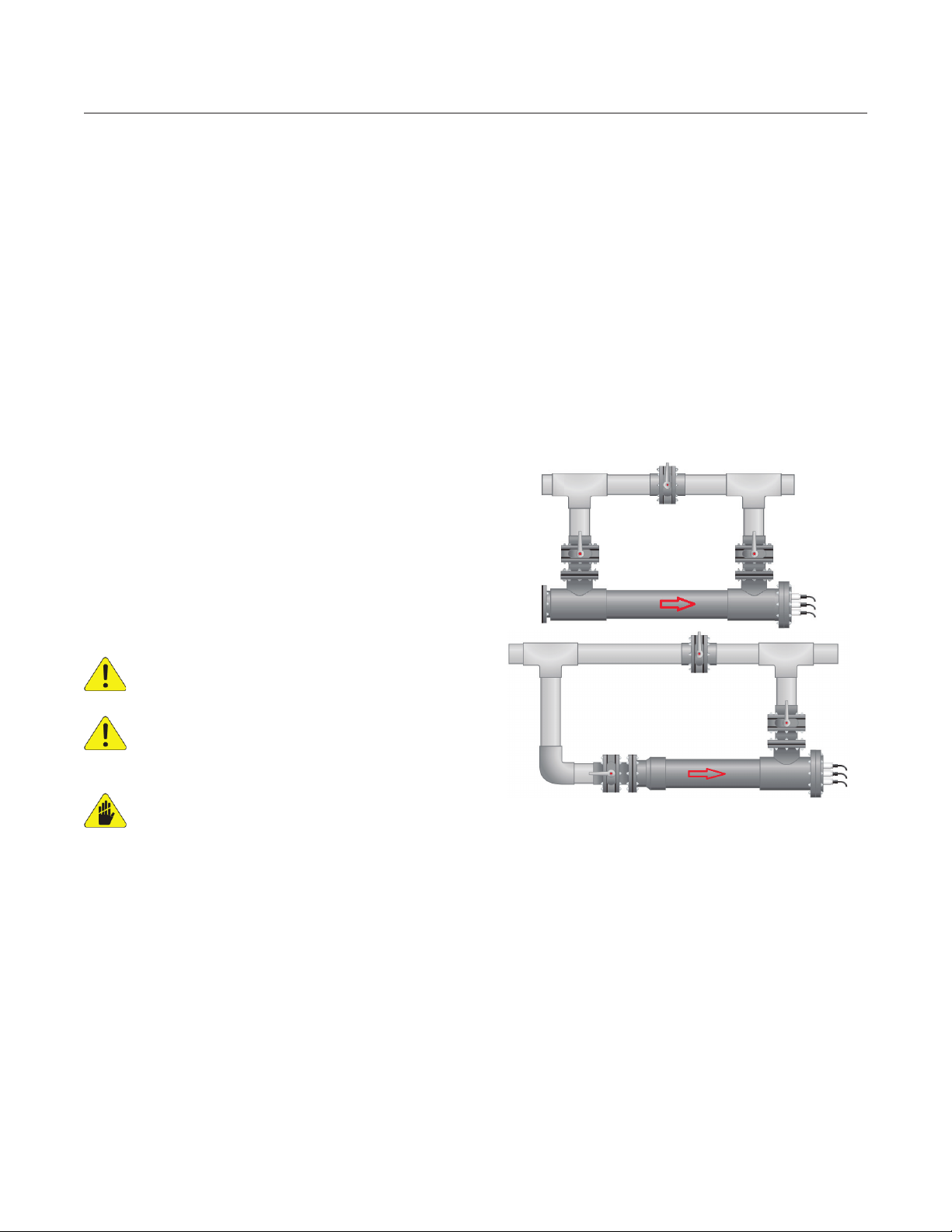

Horizontal installation requires the vessel outlet port

to face upwards, allowing trapped air to escape. If

installed on a “by-pass lter loop” or isolated using

valves, an automatic air bleed system is required.

Failure to remove trapped air can result in rupture

or heat damage to the vessel.

• Personal Safety Equipment

General risk due to load.

General risk due to pressurized piping or UV

Vessel.

Quartz Sleeves are fragile and potentially

dangerous if broken. Handle with care.

Procedure

IMPORTANT: The installation of the UV system must

be carried out in accordance with local

regulations and codes.

1. Install the UV system after the mechanical ltration.

This eliminates debris from entering the vessel and

diminishing the unit’s eectiveness, as well as

potentially damaging the quartz sleeves and UV

lamps.

2. Install inlet and outlet isolation valves (to be

supplied by others).

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 9

SECTION 3: INSTALLATION

9

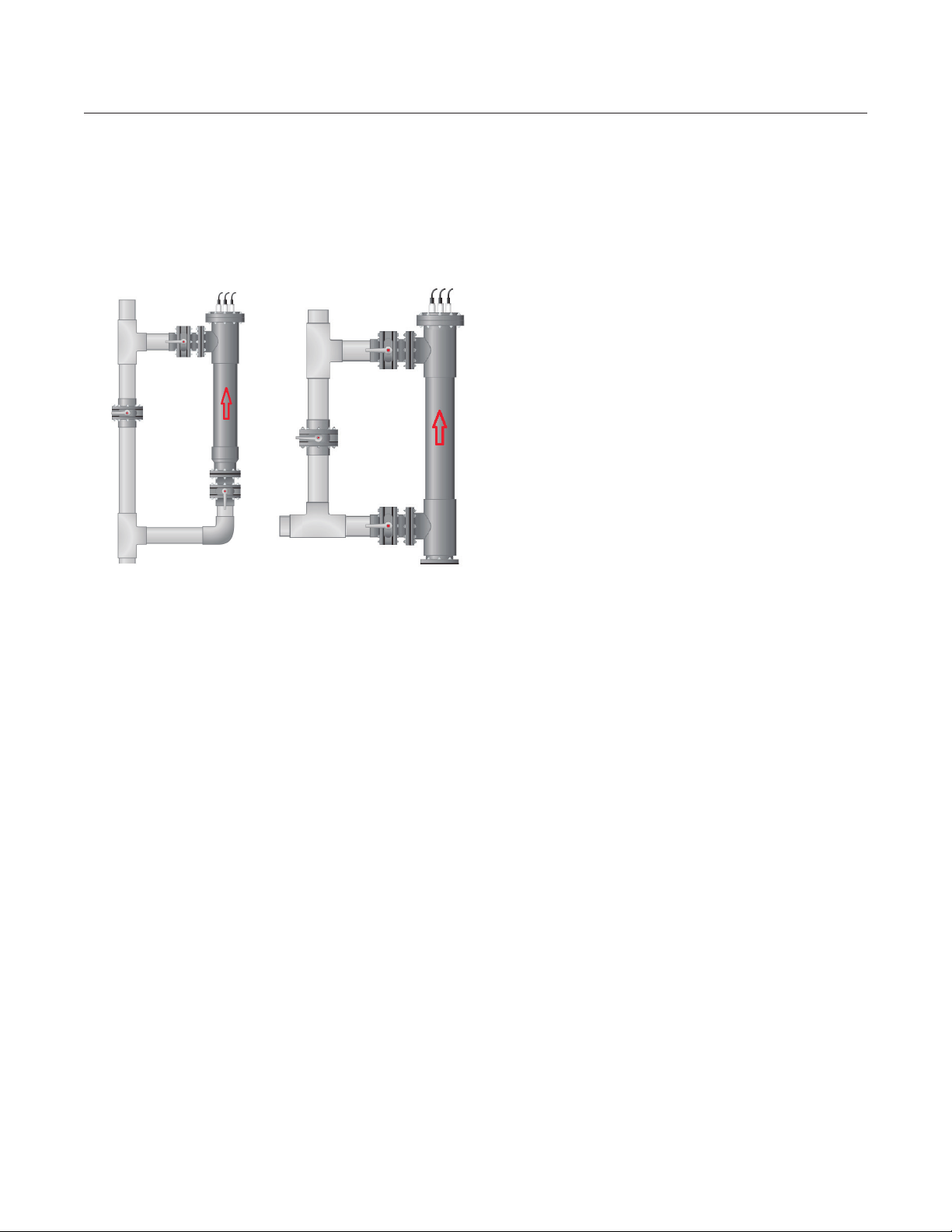

Vertical Installation

Vertical installation requires the bottom port to be

used as the vessel’s inlet and the port closest to

the electrical end to be used as the outlet; allowing

trapped air to escape. If installed on a “by-pass lter

loop” or isolated using valves, an automatic air bleed

system is required. Failure to remove trapped air

can result in rupture or heat damage to the vessel.

5. The UV System (models w/ diameters of 10” and

larger) may have been shipped without their quartz

sleeves installed in the vessel, please install now.

6. The vessel is equipped with a 0.5” female threaded

drain port for installation of the Drain Valve

Assembly. Use thread tape on the threads when

installing the drain valve assembly.

7. The vessel is equipped with various sensor ports

(UV Intensity and Water Temperature Sensors);

additional sensor ports may be included depending

on the model or options purchased with the UV

System. All sensor ports will be labeled on the

vessel based on their respective function. Use

thread tape on the threads to create a reliable seal

with all sensors. Sensors must be threaded into

their respective vessel ports prior to connection

to the power supply enclosure to avoid sensor

damage from cable twisting.

4. Isolation Valves are necessary for vessel removal and

chemical cleaning procedure. It is recommended

to install the isolation valves in conjunction with a

separate set of, matching size & type, water port

connections to the inlet/outlet ports of the vessel.

Adding the “double connection” will enable the

UV sterilizer to be removed from the ltration loop

without shutting the total ltration system down.

If this installation arrangement is not possible,

install the unit in a way that chemical cleaners or

freshwater rinse can be drained completely from

the vessel without contaminating the process

water.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 10

10

SECTION 3: INSTALLATION

Quartz Sleeve Installation

Purpose

To thermally protect the UV lamp and isolate it from

water.

Frequency

Quartz Sleeve(s) are installed after being inspected/

cleaned or damaged. Water quality conditions may

warrant more frequent inspection/cleaning. Fouled

quartz sleeves absorb UV light and therefore may

reduce the UV intensity.

Replace broken quartz sleeve(s).

Parts and Required Equipment

• Quartz Sleeve(s)

• Quartz Sleeve Retaining Nut Gasket

• Adjustable Wrench

• Cotton or Silicon Gloves

• Personal Safety Equipment

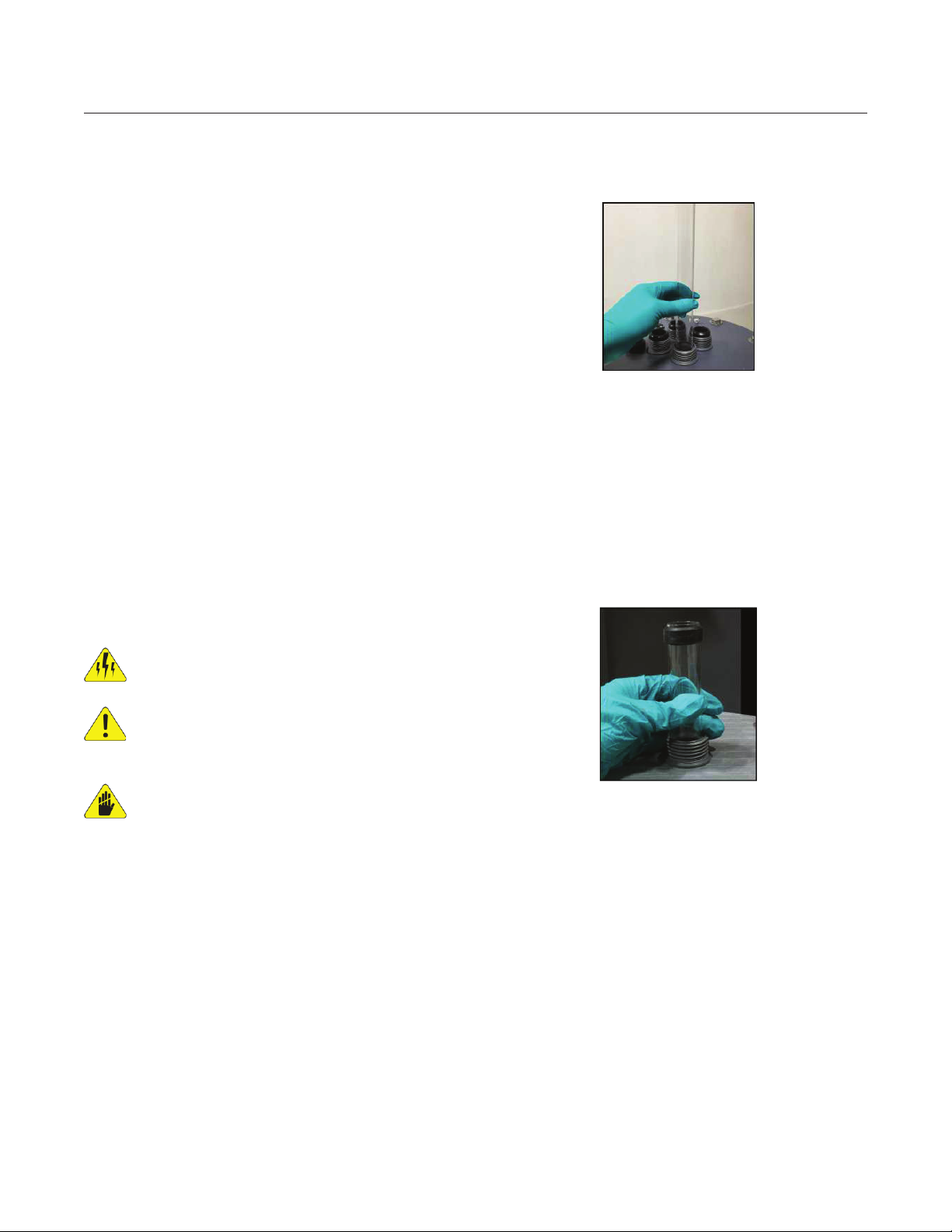

2. Carefully slide the quartz sleeve(s) into the Quartz

Sleeve Faceplate’s “Quartz Sleeve Module” (QSM)

allowing approximately 12” of the quartz sleeve to

remain outside the UV vessel.

3. With 12” of the quartz sleeve exposed outside the

vessel, carefully place the Quartz Sleeve Rubber

Gasket Seal onto the open-end of the quartz

sleeve.

Apply water or a small amount of water soluble

lubricant onto the end of the quartz sleeve, this will

act as a lubricant and will allow you to easily slide

the Rubber Gasket onto the quartz sleeve.

The rubber gasket should be ush with the end of

the quartz sleeve.

General risk due to electricity.

General risk due to pressurized piping or UV

Vessel.

Quartz Sleeves are fragile and potentially

dangerous if broken. Handle with care.

Procedure

NOTE: Use clean cotton or silicon gloves when

handling the quartz sleeve(s). Skin oils absorb

ultraviolet light and reduce UV intensity.

1. Apply water (wet) or a small amount of water

soluble lubricant to the domed-end of the quartz

sleeve. Lubricating will aid in inserting the domedend of the quartz sleeve into the vessel’s internal

quartz sleeve coupler.

4. As you push the quartz sleeve into the vessel

(through the Quartz Sleeve Module) elevate the

domed-end of the quartz sleeve by gently pushing

down on the open-end approximately 1/2”. This will

help guide the domed-end of the quartz sleeve into

its correct Internal Quartz Sleeve Coupler “Port”.

5. Finish sliding the remainder of the quartz sleeve

into the vessel until the gasket makes contact with

the Quartz Sleeve Module.

As you thread and tighten the Quartz Sleeve

Retaining Nut onto the Quartz Sleeve Module

the Quartz Sleeve Retaining Nut’s internal lip will

automatically set the quartz sleeve in its proper

position.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 11

SECTION 3: INSTALLATION

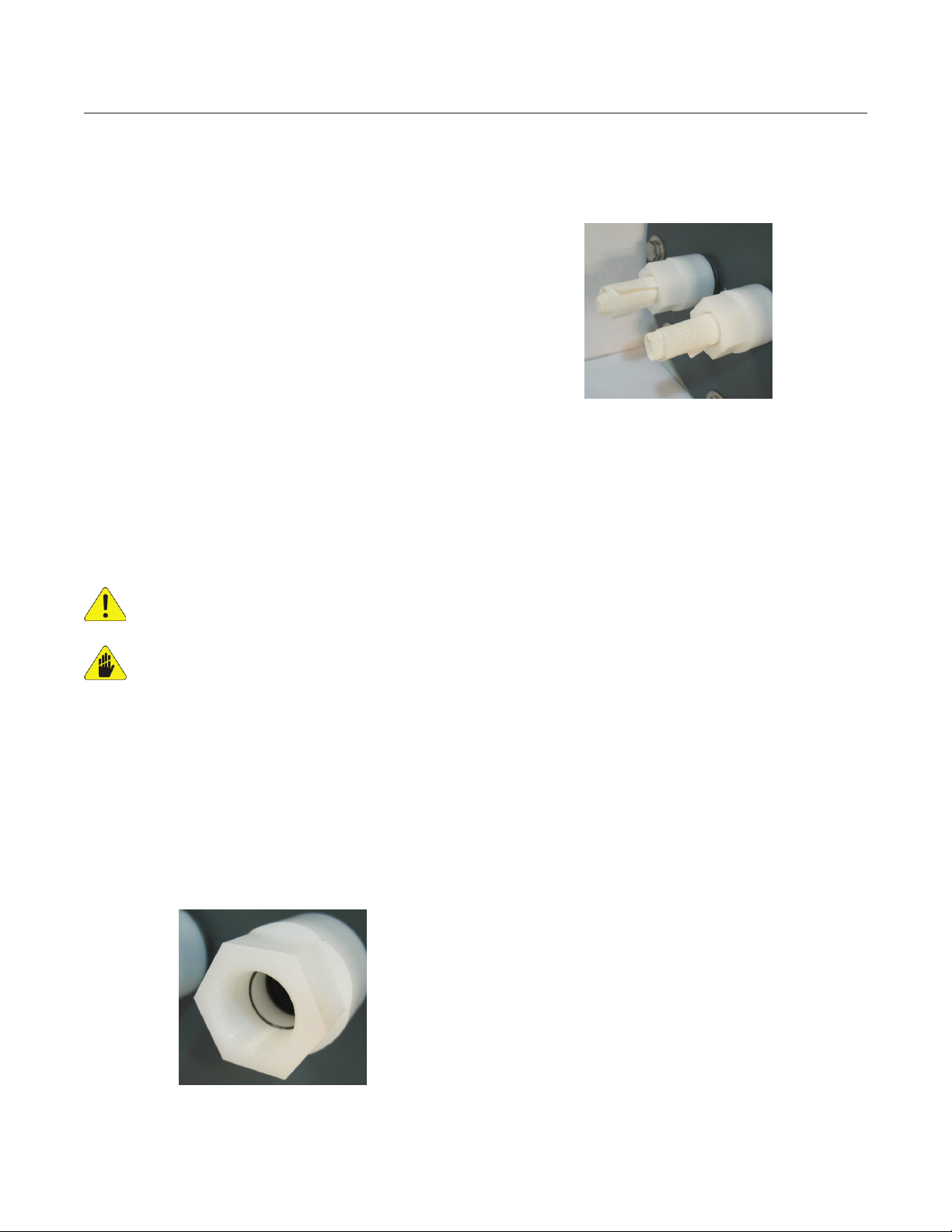

6. Using the white retaining nut tightening tool

included with the UV system or a 1.5” socket or

an adjustable wrench, tighten the Quartz Sleeve

Retaining Nut until snug (5 ft. • lb.). Over-tightening

can break the Quartz Sleeve Module on the

faceplate or the quartz sleeve inside the UV vessel.

7. The quartz sleeve is now properly assembled; you

are now ready to perform a Water Test See Page

14.

11

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 12

12

SECTION 3: INSTALLATION

Power Supply Installation

Purpose

Power Supply Enclosure is part of the complete

Bioshield UV Systems™ Series.

Frequency

Required with new construction, retro-t or

replacement of outdated equipment.

Parts and Required Equipment

• Set of Slot and Phillips Head Screwdrivers

• Adjustable Wrench

• Pliers

• Wall Struts or Braces

• Supplied Enclosure Mounting Hardware

• Personal Safety Equipment

4. The Power Supply Enclosure should be located in

a place that provides sucient weather protection,

in the case of outdoor installation. Sucient space

near the cooling fan’s intake and exhaust must be

provided.

5. The Power Supply Enclosure must be supplied

with the correct operating voltage (120/230 VAC).

Failure to supply the UV System with the correct

operating voltage can damage the ballasts and

other electrical hardware. Use only a well- ground

electrical circuit.

6. The UV System is equipped with an equipmentgrounding conductor and a grounding plug. The

grounding plug must be installed and grounded in

accordance with all local codes and ordinances.

Improper connection of the equipment- grounding

conductor can result in electrocution. Check

with a qualied electrician or service personnel if

you question whether the equipment is properly

grounded.

7. Input power to the Power Supply Enclosure is

switched on and o using the enclosure’s External

On/O switch or Remote On/O control.

General risk due to suspended load.

General risk due to electricity.

General risk due to pressurized piping or UV

Vessel.

Procedure

1. Use the supplied enclosure mounting feet if the

Power Supply Enclosure is going to be mounted

on a wall.

2. Mount the Power Supply Enclosure close to the

UV Vessel so that the lamp cables reach between

the Power Supply Enclosure and the UV Vessel.

The power supply lamp and sensor cables are

approximately 20’ long to provide an adequate

routing length from the power supply enclosure to

the UV vessel.

3. The Power Supply Enclosure should be mounted so

that the PLC is visible to the operator. The location

used for mounting the Power Supply Enclosure

should be as dry and cool as possible.

NOTE: All UV control enclosures that utilize our PLC

should be mounted with considerations to

other devices that emit, or are suspected of

emitting, any EMI & RFI noise and that any

sensors used in conjunction with our PLC

should use industry standard procedures to

avoid EMI & RFI noise issues.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 13

SECTION 3: INSTALLATION

13

Temperature & UV Intensity Sensor

Installation

Purpose

To instruct the operator how to properly install the

Temperature and UV Intensity Sensors.

Frequency

Required with new installation or when servicing the

unit during general maintenance.

Parts and Required Equipment

• Flare-Nut Wrenches

• Thread Tape

• Personal Safety Equipment

General risk due to electricity.

3. Once the sensors have been installed into the

vessel you can attach cables to their respective

connection points located on the bottom of the

Power Supply Enclosure.

WARNING: Sensor-cables should be isolated from

other electrical devices, preventing

electrical interference. UV intensity

sensor-cables must also be separated

from UV lamp cables to minimize

electrical interference.

NOTE: The Temperature Sensor must be installed

in the vessel with its water tight connector

properly connected to its respective port

located on the power supply enclosure.

A Temperature Sensor Cable connection

interruption will automatically shut down the

system.

General risk due to pressurized piping and UV

vessel.

General risk due to suspended load.

Procedure

1. Install the Temperature and UV Intensity Sensors

into their respective port locations as labeled on

the vessel using Thread Tape to properly seal the

sensor threads in the vessel. To avoid possible

sensor damage from cable twisting, DO NOT

connect the sensor cables to the power supply

until after they are installed into the vessel. Leave

the sensor cables coiled up close to the sensor

during the installation process to allow the cable

to rotate as the sensor is being screwed into the

vessel. If the cable becomes twisted during the

installation process, untwist it before proceeding.

2. Use a are-nut wrench to carefully tighten the UV

sensor and temperature sensor. These components

are made of soft polytetrauoroethylene (PTFE)

and can be easily damaged. Leave the sensor

cables coiled up close to the sensor during the

installation.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 14

14

SECTION 4: MANDATORY WATER TEST

Mandatory Water Test

Purpose

The Mandatory Water Test identies a potential

quartz sleeve assembly seal failure. During normal

UV system operation, a quartz sleeve assembly

failure can result in extensive damage to the UV lamp,

quartz sleeve and ballast.

Frequency

The Mandatory Water Test must be performed after

a quartz sleeve/retaining nut gasket inspection/

replacement. Quartz

Sleeve inspection/retaining nut gasket replacement

must be carried out annually, at minimum.

Parts and Required Equipment

• Paper Towels

• Personal Safety Equipment

General risk due

UV Lamps are fragile and potentially dangerous

if broken. Handle with care.

Procedure

IMPORTANT: Failure to perform a water test could

lead to unsafe conditions and may void

your product’s warranties.

3. Place rolled-up paper towels into the Quartz Sleeve

Retaining Nuts. During the water test, the paper

towels may absorb moisture. The presence of any

moisture identies that a quartz sleeve seal failure

(leak) has occurred.

4. Inspect all piping connections to the UV Vessel

and conrm that valves are in their correct position

prior to start-up.

5. With satisfactory piping and valve inspection,

operate the UV system. Allow water to ow through

the UV Vessel for no less then fteen minutes.

6. After fteen minutes of owing water through the

UV vessel, remove the paper towel from each

Quartz Sleeve Retaining Nut and inspect closely

for ANY sign of moisture. If leaks are detected,

shut the system down and re-install any quartz

sleeve with an inadequate seal. For quartz sleeve

removal/installation See Page 24 and 7.

7. If no leaks were detected you are now ready to

install the UV Lamp(s). See Page 15.

1. With the quartz sleeves installed inside the UV

vessel, before installation of the UV lamps, perform

a water test as explained below. For quartz sleeve

removal See Page 24. For installation See Page 7.

2. Thread all sensors into their respective ports on

the UV vessel.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 15

SECTION 5: UV LAMP INSTALLATION

15

Purpose

To instruct the operator how to properly install the UV

lamp(s).

Frequency

Lamp installation in new unit or lamp replacement

change-out (after every 12,000 hours of continual

operation).

Parts and Required Equipment

• UV Lamp(s)

• Wire Cutters

• Adjustable Wrenches

• Cotton or Silicon Gloves

• Personal Safety Equipment

General risk due to electricity.

1. Gently slide the UV Lamp into the Quartz Sleeve

Retaining Nut leaving 6” of the UV lamp exposed.

IMPORTANT: INSTALL LAMPS WITH AMALGAM

SPOT IN DOWN POSITION!

NOTE: Lower wattage amalgam lamps contain a

single mass of amalgam while higher wattage

amalgam lamps contain multiple masses of

amalgam.

UV Lamps are fragile and potentially dangerous

if broken. Handle with care.

Procedure

IMPORTANT: Before installing the UV Lamp(s) a

MANDATORY WATER TEST must be

performed. See Page 14.

NOTE: Use clean cotton or silicon gloves when

handling the UV lamp(s). Skin oils absorb

ultraviolet light and reduce UV intensity. Skin

oils may also lead to premature lamp failure.

NOTE: When installing the lamp into the quartz sleeve

position that is monitored by the UV Intensity

Sensor, it is important to make sure the lamp

wires that run the length of the lamp are not

facing the sensor. See diagram at right for the

proper lamp placement

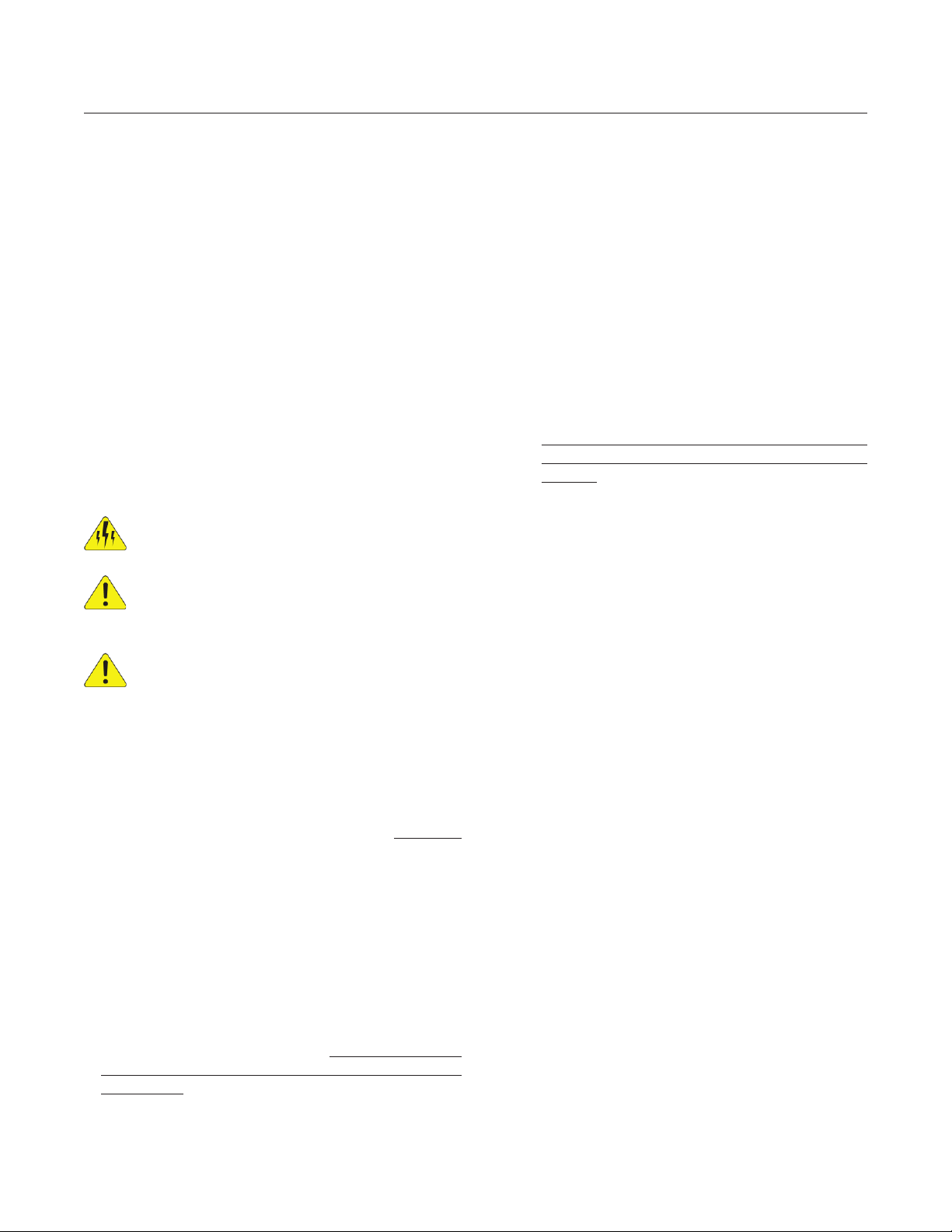

NOTE: Each Lamp cable (1) is equipped with a Water

Tight Connector (2). This cable adapter is

made up of three components: Nut (3), Rubber

Gasket (4) and Male-Threaded Body (5).

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 16

16

SECTION 5: UV LAMP INSTALLATION

2. Loosen (not remove) the lamp Water Tight

Connector nut (3) to release tension on the lamp

cable allowing the cable to slide freely through the

adapter. This will allow the male-threaded body

(5) portion of the lamp Water Tight Connector to

be threaded into the white quartz sleeve retaining

nut without twisting the lamp cable (after lamp

installation).

3. With the UV lamp installed inside the quartz sleeve

and six inches exposed, attached the lamp cable’s

stepped 4-Pin Connector on to the four pins of the

UV lamp.

4. With the lamp cable/lamp connection complete

gently slide the remainder of the lamp w/ cable

through the Quartz Sleeve Retaining Nut and into

the quartz sleeve. With the lamp now inside the

quartz sleeve, gently continue to push the lamp (w/

connected lamp cable) into the quartz sleeve until

it stops, then pull out 1/2” of the lamp cable. This

will position the lamp properly inside the quartz

sleeve avoiding heat damage to the Quartz Sleeve

Module Faceplate and Quartz Sleeve Module.

6. With the “black” Water Tight Connector threaded

into the Quartz Sleeve Retaining Nut, tighten the

Cable Adapter Nut (3) to create a watertight seal on

the lamp’s cable. Take care not to bend or damage

the Water Tight Connector’s “gasket prongs”

during this process.

7. The UV lamp is now properly installed.

5. With the UV lamp in its correct position inside the

quartz sleeve, thread the water tight connector

into the Quartz Sleeve Retaining Nut.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 17

SECTION 5: UV LAMP INSTALLATION

17

Lamp Field Safety Cover Installation

Purpose

To instruct the operator how to properly install the

Lamp Field Safety Cover.

Frequency

Required anytime the lamp eld is accessed.

Parts and Required Equipment

• Lamp Field Safety Cover

• Pliers

• Personal Safety Equipment

General risk due to electricity.

Procedure

1. With the UV lamps and lamp cables installed hand

loosen the four Safety Cover Retaining Screws from

the QSM Faceplate so they have approximately

3/8” of clearance between the head of the screw

and the QSM Faceplate.

3. Once the cover is in place, tighten the four

Retaining Screws down until the cover is snugly

held in place.

4. With the cover installed on the vessel, connect the

Lamp Field Safety Cover cable that is attached to

the power supply to the connector that is located

on the end of the Safety Cover.

NOTE: The Lamp Field Safety Cover must be installed

onto the vessel with its respective cable,

located on the Power Supply Enclosure,

properly connected to its respective port on

the Safety Cover. Removing the Lamp Field

Safety Cover or the cable connection will

automatically shut o the UV system’s lamp

eld and generate an alarm signal.

2. The Lamp Field Safety Cover uses a twist-lock

attachment method that can only be installed one

way. Take the cover assembly with the cable slot

facing downward and align the four slotted keyways

on the cover’s ange face with the retaining screws

on the QSM Faceplate. Then place the cover over

the screws and turn counterclockwise to engage

the retaining screws.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 18

18

SECTION 6: COMMISSIONING

Start-Up

Purpose

This section contains the necessary steps required to

prepare the Bioshield® Commercial UV Sterilizer for

proper operation.

Frequency

Required with new construction, retro-t or

replacement of outdated equipment.

Parts and Required Equipment

• Personal Safety Equipment

General risk due to pressurized piping and UV

Vessel!

General risk due to electricity!

Procedure

1. Conrm that all personnel operating this UV system

have thoroughly reviewed these instructions prior

to operating.

2. Remove all dirt/debris from power supply

enclosure, vessel and installation area resulting

from installation activities.

3. Inspect all plumbing connections and immediate

plumbing network to ensure safe start-up.

4. Inspect the vessel’s Quartz Sleeve Module

Faceplate to ensure proper assembly.

5. Inspect quartz sleeve assemblies (Quartz Sleeve

Retaining Nuts) conrming that they are tight.

6. Inspect Power Supply Enclosure, conrm that it

has been mounted properly and input power is in

accordance with local ordinances and codes.

7. Inspect all sensors ensuring that the probes are

properly installed in the vessel and Water Tight

Connectors are properly connected to their

respective Power Supply Enclosure ports.

Hydraulic shock (water hammer) may occur

as a result of improper use of valve(s) or trapped air

inside the vessel. Hydraulic shock and trapped air

can damage the vessel.

Trapped air or no-ow situations may damage

the vessel and/or the UV lamps due to overheating.

8. Verify that a successful Leak Test has been

completed. See Page 14 for instructions.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 19

SECTION 7: OPERATION

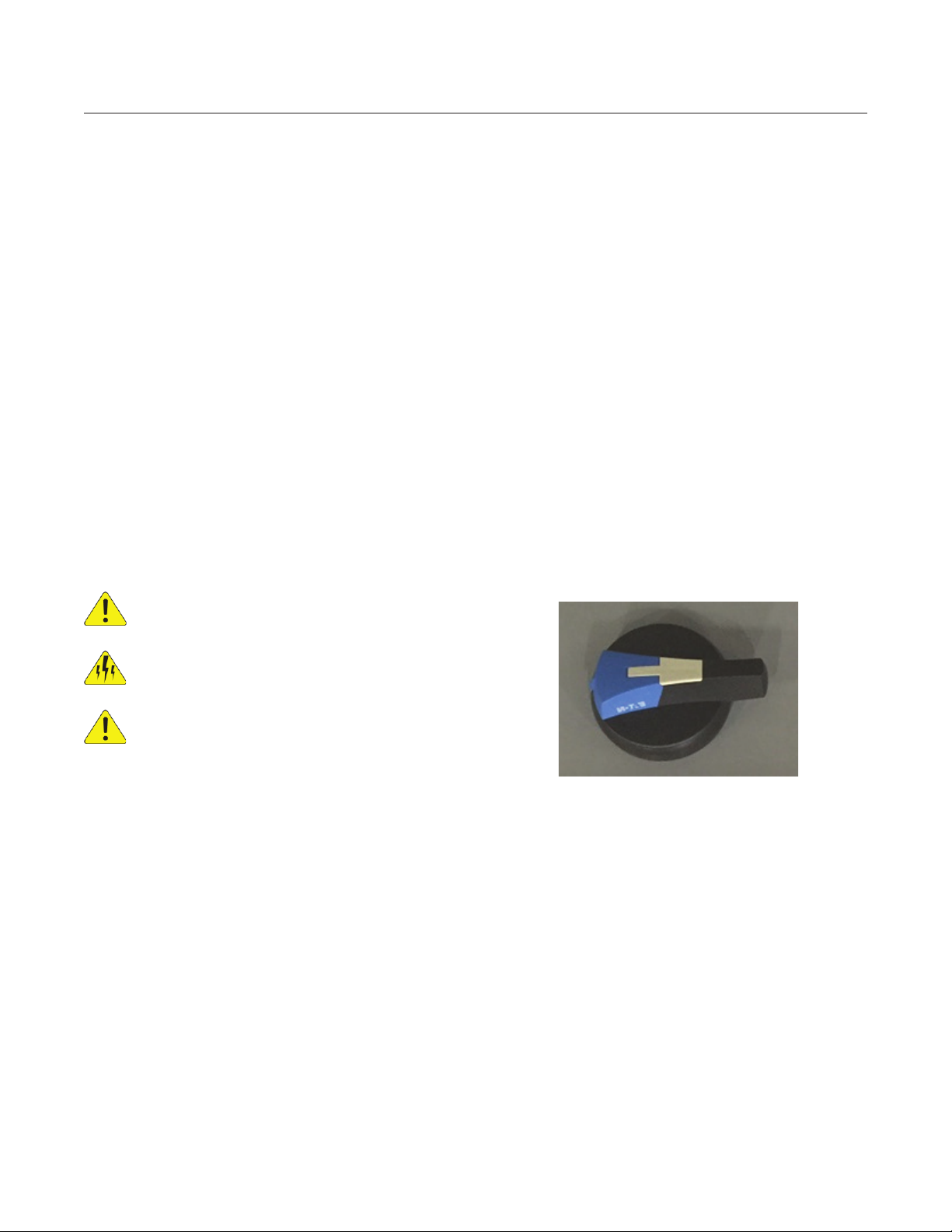

PLC (Programmable Logic Control) Power

Supply

Operation

The operation of the Bioshield® Commercial UV

Sterilizer may only be carried out by authorized

personnel. The personnel responsible for the

operation of this system must read and understand

this Section, Section 2 (Health & Safety Precautions),

and strictly comply with all relevant rules for accident

prevention and local health and safety regulations.

Check all relevant safety measures before you switch

on the UV system.

Operating Modes

Generally, the UV system is operated in “LOCAL’

mode. An optional, discrete input circuit is provided

to allow for either “LOCAL/REMOTE” or “LOCAL’

mode. If this option has been ordered there are two

terminal blocks (brown) located inside the Power

Supply Enclosure. The UV system is supplied with

both the brown terminals jumped together as the

default “ON” setting. To operate the UV system in

the “REMOTE” mode, the “Factory-Installed Jumper”

must be removed. Both the brown terminals need to

be wired to an external switch (not included) capable

of handling 120/230-volt AC @ 1-amp.

PLC

Enclosure

19

PLC Control Descriptions

Total Operating Hours Meter

The measurement is in 1-hour increments and may

be reset by the operator via the Alarms Tab.

Lamp Status & Lamp Life Monitor

An inactive lamp will trigger an alarm which can

be identied in the Alarms Tab. The alarm may be

reset but will continue to activate every twenty-four

(24) hours until the lamp is replaced and the SETUP

individual lamp reset is completed.

Features

1. PLC Power Enclosure

2. 3.5” Color Touch-Screen

3. Shortcut Buttons (only available on Advanced PLC)

4. External On/O Switch

5. Main Power Cable

6. Temperature Sensor

7. UV Intensity Sensor

8. Lamp Field Safety Cover Cable

9. Lamp/Power Cables

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Power Supply Enclosure Temperature

Monitor

The temperature monitor is used to protect the

electronics within the UV system panel from

overheating. The enclosure temperature alarm will

be triggered above 120° F and will shut down the

lamp eld. The PLC must be powered o to reset the

system and to restore lamp eld operation.

UV Vessel Water Temperature Monitor

The UV Vessel Water Temperature Monitor is used

to protect the vessel from overheating due to a no

or low-ow condition. The temperature alarm will be

triggered above 140°F and will shut down the lamp

eld. The PLC must be powered o to reset the

system and to restore lamp eld operation.

Page 20

20

SECTION 7: OPERATION

UV Intensity Sensor

The PLC monitoring system displays the UV intensity

as a function of percent (0%-100%); this UV intensity

measurement is a relative power measurement of the

UV energy inside the vessel and not a measurement

of UV dose. The relative UV intensity (power) must

be calibrated and will be performed once the system

has been in service for 100 hours.

Lamp Field Safety Cover

On all NSF-50 certied units there is a safety cap that

covers the electrical cables to the lamps. Removing

the Lamp Field Safety Cover or a cable connection

interruption will automatically shut o the UV system’s

lamp eld and generate an alarm signal.

Alarm Relays

A discrete output relay(s) circuit is provided to

allow for alarm signal of any of the following

monitored conditions: General Alarm, enclosure over

temperature, low UV intensity, vessel water overtemperature, end of lamp life, and lamp failure.

• Options: Reset Lamp Timers, View UV Intensity

Chart, Set Update Interval for ow and

Change Time and Date.

Status (Main) Display

Lamp Status: Lamps will be displayed with a status

indicator to the right. Green for “Lamp ON” and red

for “Lamp OFF”.

UV Intensity: The status indicator to the right of the

% will turn red once UV Intensity drops below 70%.

Enclosure Temp: The status indicator to the right

will turn red once the internal enclosure temperature

rises above 120°F.

4-20 Milliamp Output

The 4-20 mA Output sends out the UV Intensity

measurement to an external recording device.

Flow Sensor

This input allows for a GF Signet 2551 ow sensor

with pulsed output to be connected and displayed

on the PLC. The diagram below shows the wiring

conguration between a GF Signet 2551 pulsed

output and the UV Panel.

PLC Touch Screen Display

The Touch Screen Display is used to present

information to the operator as well as serving as a

command interface. The microprocessor performs

various functions that include intercepting operator

commands and updating displayed data. In addition,

the software trends UV intensity, lamp operation and

current hours.

Touch Screen Tabs and Functions

• Alarms: Current triggered alarms and acknowledge

button

• Status: Lamp condition and hours

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 21

SECTION 7: OPERATION

21

Options Display

Ballasts/Lamps: The “EOL Timers” button allows

the user to reset the lamps once a lamp exchange is

performed.

Intensity: The button to the right of “Low Int” allows

the user to change the alarm setting. 70% is the

recommended lowest alarm setting.

Chart: The “Chart” button allows the user to view the

Intensity history.

Calibrate: PLC will perform an automatic calibration

after 100 hours of operation.

Time/Date: The button to the right of “Time” allows

the user to change the time of day. The button to the

right of “Date” allows the user to change the month,

day and year.

EOL Timers Display

Reset All: Allows the user to reset all timers for the

lamps.

Reset #: Allows the user to reset individual lamps.

Intensity: The UV Intensity trends every day allowing

the user to proactively determine when a lamp

change out will be required. The UV Intensity trend

can also be saved to an SD card for record keeping.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 22

22

SECTION 7: OPERATION

Alarms

The main display will alert when an alarm is active.

Press the “Alarms” button.

The Alarm menu allows the user to view active alarms

and log past alarms.

“ESC” button will bring the user to the main display.

“Reset” button will clear the alarm but if the alarm is

still active, the alarm will engage again.

Select alarm and press the “Magnier Glass”, to the

right under “Details”.

Press the “Ack” button to reset the alarm.

“Refresh” button will clear the alarms from the screen.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 23

SECTION 8: MAINTENANCE

Routine Inspection

The following are required routine maintenance

actions:

A. Daily inspection of the Bioshield® Commercial UV

Sterilizer’s Power Supply Enclosure control panel

to conrm that the unit is operating satisfactorily

(lamp operation).

23

General risk due to pressurized piping and UV

vessel!

General risk due to electricity!

B. Daily visual inspection of the UV vessel and piping

for leaks.

C. Monthly inspection for damage/corrosion.

D. Annual vessel interior inspection/cleaning.

E. Biannual quartz sleeve inspection/cleaning.

F. Replace the UV Lamp & Retaining Nut Gasket after

12,000 hours of cumulative operation.

G. Clean or replace the Cooling Fan Filter Mat monthly,

or more frequently in dusty environments.

H. When the lamps are replaced, calibrate the UV

Intensity Sensor.

UV Lamp Replacement

Lamp Removal

Purpose

To replace expired UV lamp(s)

Frequency

A complete set of UV lamps must be replaced after

12,000 hours of cumulative use (manufacturer’s

suggested useful lamp life rating) or when the UV

Intensity is lower than the PLC threshold value.

DO NOT operate UV Lamp(s) outside of the

vessel. UV light may cause severe irritation/damage

to eyes and skin.

UV lamp(s) become hot during operation.

Handle with care.

UV Lamps are fragile and potentially dangerous

if broken. Handle with care.

Procedure

Read and understand this chapter prior to performing

lamp change-out

NOTE: Use clean cotton or silicon gloves when

handling the UV lamp(s). Skin oils absorb

ultraviolet light and reduce UV intensity. Skin

oils may also lead to premature lamp failure.

1. Turn o the Power Supply Enclosure with the

External ON/OFF Switch and unplug the UV system

from the electrical outlet.

2. With an adjustable wrench loosen (not remove)

the Lamp Cable Adapter Nut that will allow the

complete Water Tight Connector tting to be

unthreaded from the Quartz Sleeve Retaining Nut

without twisting the lamp cable.

Parts and Equipment Required

• UV Lamp(s)

• Adjustable Wrench

• Wire Cutters

• Clean Cotton or Silicon Gloves

• Personal Safety Equipment

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 24

24

SECTION 8: MAINTENANCE

3. Unthread the Water Tight Connector Fitting from

the Quartz Sleeve Adapter Nut.

4. Carefully slide the lamp cable’s adapter tting and

lamp out of the quartz sleeve (through the Quartz

Sleeve Retaining Nut). With part of the UV lamp

outside of the vessel, disconnect the lamp cable’s

4-Pin Connector from the UV lamp. Use caution

connecting/ disconnecting UV lamps in vessels

mounted vertically. To prevent breakage, be careful

not to drop the UV lamps into the quartz sleeve(s).

UV Lamps may be hot, handle with care.

Quartz Sleeve

Quartz Sleeve Removal

Purpose

To inspect or replace broken quartz sleeve(s) in order

to maintain required/expected UV intensity.

Frequency

Quartz Sleeve(s) should be removed, inspected

and cleaned at least once annually (water quality

conditions may warrant more frequent inspections/

cleaning). Fouled quartz sleeves absorb UV light and

therefore may reduce the UV intensity.

Parts and Equipment Required

• Quartz Sleeve(s)

• Quartz Sleeve Retaining Nut Gasket

• Adjustable Wrench

• Clean Cotton or Silicon Gloves

5. With the lamp disconnected from the 4-Pin

Connector, carefully slide the lamp out of the

quartz sleeve and place in a safe location to avoid

breakage

UV Lamp Recycling

Disposal of uorescent bulbs and other mercurycontaining bulbs are regulated under the Resource

Conservation and Recovery Act, the Universal

Waste Rule and Subtitle C of the hazardous waste

regulations. Refer to http://www3.epa.gov/epawaste/

hazard/wastetypes/universal/lamps/ to learn more

about proper lamp disposal.

Lamp Installation

See Page 15 for UV Lamp installation procedure.

• Personal Safety Equipment

• White Retaining Nut Tightening Tool (provided with

the UV system)

General risk due to pressurized piping and UV

vessel!

General risk due to electricity!

Quartz Sleeves are fragile and potentially

dangerous if broken. Handle with care.

Procedure

1. Turn o the Power Supply Enclosure with the

External ON/OFF Switch and unplug the UV system

from the electrical outlet.

2. Drain the vessel completely.

3. Remove UV lamp(s). See Page 23 for instructions.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 25

SECTION 8: MAINTENANCE

25

4. Using the white retaining nut tightening tool

included with the UV system, unthread the Quartz

Sleeve Retaining Nut from the male-threaded

Quartz Sleeve Module located on the QSM

Faceplate. Once the Quartz Sleeve Retaining Nut

is unthreaded the open-end of the quartz sleeve

will be exposed.

5. Wearing clean cotton or silicon gloves gently slide

the quartz sleeve from the UV vessel. DO NOT use

pliers or any tools that may break the quartz sleeve.

Quartz Sleeve Cleaning

Purpose

To manually check and clean quartz sleeve(s).

Frequency

When required, at least once annually.

Parts and Equipment Required

• Cleaning Solution of Muriatic Acid and Water (1:4

ratio)

• Acid-Proof Bucket

• Clean Cloth

• Acid-Proof Drop Cloth

• Acid-Resistant Gloves

• MSDS Sheet

• Personal Protective Equipment

6. Remove the Quartz Sleeve Gasket and continue

removing the quartz sleeves until all are removed

from the vessel. Place quartz sleeves on a safe,

level surface to avoid breakage.

7. Inspect all quartz sleeves for cracks, chips and

scaling. If required, clean the quartz sleeve(s).

See Page 23 Quartz Sleeve Cleaning. Replace

damaged (cracked, chipped) quartz sleeves.

General risk due to pressurized piping and UV

vessel!

General risk due to caustic cleaning agent!

Quartz Sleeves are fragile and potentially

dangerous if broken. Handle with care.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 26

26

SECTION 8: MAINTENANCE

First Aid Measures:

In case of skin exposure, to cleaning agent, remove

by washing with soap and water immediatel

In case of eye exposure to cleaning agent wash

eyes for several minutes with water and contact a

physician immediately.

In case of ingestion of cleaning agent contact

physician immediately.

Procedure

1. See Page 24 for quartz sleeve removal instructions.

2. Inspect quartz sleeve and clean as needed with a

soft, clean cloth and mild dish detergent.

3. For calcium deposits use muriatic acid to dissolve/

clean deposits. See next page for procedure.

4. Rinse quartz sleeve thoroughly with clean

freshwater.

5. See Page 10 for quartz sleeve installation

instructions.

Frequency

When necessary.

Parts and Equipment Required

• Cleaning Solution of Muriatic Acid and Freshwater

(1:4 ratio)

• Acid-Resistant Transfer Pump

• Acid-Resistant Hose (used to transfer the cleaner

from the container to the UV vessel)

• Fittings to connect to vessel

• Acid-Resistant Bucket

• Clean Cloth

• Acid-Resistant Drop Cloth

• Acid-Resistant Gloves

• MSDS Sheet

• Personal Safety Equipment

Quartz Sleeve Installation

See Page 10 for quartz sleeve installation procedure.

UV Vessel Cleaning

Purpose

Over a period of time, dissolved matter can build

up on the surface of the quartz sleeves and the

interior of the vessel aecting the eciency of the

UV disinfection process. Due to fouling, the available

intensity will decrease continuously until the quartz

sleeves are cleaned.

NOTE: The use of the optional wiping system merely

helps to decrease the frequency of the manual

cleaning cycle.

Please be aware that such a decrease also may be

caused by aging of the UV lamps or changes in the

water quality (UV transmission). Repeat of visual

inspections of the UV Sensor or of some example

quartz sleeves will help to determine the necessary

cleaning intervals needed. The removal of this buildup (calcium, etc.) can be carried out with a cleaning

pump. Pentair recommends the use of muriatic acid

to chemically clean the quartz sleeves. Materials

within the vessel chamber are highly resistant against

this acid.

General risk due to pressurized piping and UV

vessel!

General risk due to caustic cleaning agent!

Quartz Sleeves are fragile and potentially

dangerous if broken. Handle with care.

First Aid Measures:

In case of skin exposure, to cleaning agent remove,

by washing with soap and water immediately.

In case of eye exposure to cleaning agent wash

eyes for several minutes with water and contact a

physician immediately.

In case of ingestion of cleaning agent contact

physician immediately.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 27

SECTION 8: MAINTENANCE

27

Procedure

1. With the quartz sleeves still installed in the UV

vessel, turn o the Power Supply Enclosure with

the External ON/OFF Switch and unplug the UV

system from the electrical outlet.

2. Isolate the UV vessel from the water ow using

the required isolation valves and drain the vessel

completely.

3. Clear the work area and layout protective drop

cloths under the UV vessel.

4. Set up the acid transfer pump and attach the acid

input hose to the vessel’s water drain valve.

5. Attach an acid return/overow hose to the UV

vessel’s upper auxiliary service port and route

it back to the acid- resistant bucket. This will be

used as the Acid Overow Recovery Bucket.

6. Using the acid-resistant bucket as an acid supply

container, create a chemical solution of one part

muriatic acid to four parts water (1:4 acid-to-water

ratios).

UV Vessel Disassembly

Purpose

To disassemble the vessel for internal inspection.

Frequency

UV vessel disassembly is only required if a problem

has taken place, such as, quartz sleeve breakage. It is

recommended that the QSM (Quartz Sleeve Module)

Faceplate only be removed if necessary.

Parts and Equipment Required

• Adjustable and Torque Wrenches

• Socket Wrenches

• Clean Cotton or Silicon Gloves

• Flashlight

• Personal Safety Equipment

IMPORTANT: When creating the chemical solution,

always introduce the acid to the water

and introduce the acid as close to

the waterline as possible. This helps

prevent acid-to-skin contact resulting

from unnecessary splashing.

7. With all of the hoses attached to the UV vessel and

the acid transfer pump attached to the acid supply

container, pump acid into the UV vessel until full.

8. Once the UV vessel has been lled with acid, allow

the acid to remain in the vessel for 30 minutes.

9. Disconnect the acid transfer pump’s vessel feed

hose from the transfer pump and use this hose

to drain the acid from the UV vessel through the

vessel’s drain valve and into an acid-resistant

bucket.

10. After all of the acid has been drained from the

UV vessel and the cleaning procedure completed,

rinse the vessel chamber thoroughly to avoid

process water from coming in contact with the

cleaning agent. The rinse water may be taken

from a water tap with the help of a hose and lled

and drained through the unit’s drain valve port.

11. Neutralize old cleaning agent with bases, e.g.

sodium hydroxide solution, sodium carbonate

solution in compliance with all relevant rules for

accident prevention and local regulations.

General risk due to pressurized piping and UV

vessel!

Quartz Sleeves and UV lamps are fragile and

potentially dangerous if broken. Handle with care.

Procedure

IMPORTANT: DO NOT Attempt to remove the QSM

Faceplate with the quartz sleeves

assembled. ALL lamps and quartz

sleeves MUST be removed before

disassembling the QSM Faceplate

from the UV vessel.

1. Turn o the Power Supply Enclosure with the

External ON/OFF Switch and unplug the UV system

from the electrical outlet.

2. Redirect water ow from the vessel using isolation

valves and drain the vessel completely.

3. Remove UV lamp(s). See Page 23 for removal

instructions.

4. Remove quartz sleeve(s). See Page 24 removal

instructions.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 28

28

SECTION 8: MAINTENANCE

5. With the vessel completely drained and the UV

lamps and quartz sleeves removed, loosen the

QSM Faceplate bolts in a diametric sequence.

Continue until all hardware is removed.

6. With fastening hardware removed, pull the QSM

Faceplate from the UV vessel.

7. Clean out the inside of the UV vessel using a mild

dish detergent and rinse thoroughly with clean

freshwater.

8. Thoroughly clean the mating surfaces of both the

QSM Faceplate and the UV Vessel.

IMPORTANT: Use a new QSM Faceplate Rubber

Gasket when re-assembling the

faceplate to the vessel. For replacement

parts please refer to Replacement

Parts list on Page 31 of this manual.

10. With the QSM Faceplate loosely aligned, push

the QSM Faceplate, with the rubber gasket, in

place onto the vessel. Next, loosely install (nger

tight) the supplied stainless steel hardware (bolts/

washers/nuts).

11. With the hardware loosely installed (nger tight)

ne tune the alignment of the #1 lamp position to

the 3 O’ Clock position. To verify proper alignment

install the #1 quartz sleeve as outlined on Page

10. The sleeve should go into its respective port

on the quartz sleeve coupler on the opposite end

of the unit without diculty. If when installing

the sleeve you nd it dicult to get the sleeve

to engage in its respective port on the quartz

sleeve coupler this is an indication that the #1

lamp position is not aligned properly in the 3 O’

Clock position. If this is the case, rotate the QSM

Faceplate either clockwise or counterclockwise

until the sleeve freely engages its respective port

on the quartz sleeve coupler.

12. Once the #1 lamp position is conrmed to be

properly aligned, establish uniform pressure over

the QSM Faceplate by tightening the bolts in 5

ft. • lb. increments in a diametrically opposed

(180°) sequence until the recommended torque is

obtained. See recommendations below.

9. Fit the QSM Faceplate Rubber Gasket onto the

alignment posts.

IMPORTANT: To properly align the QSM Faceplate,

set the #1 lamp position (as stamped on

the faceplate, next to the quartz sleeve

module) to the 3 O’ Clock position

when looking at the QSM Faceplate.

Flange Bolt Torque Recommendations:

0.5” to 1.5” Flange = 12 ft. • lbs.

2.0” to 4.0” Flange = 25 ft. • lbs

5.0” Flange = 30 ft. • lbs.

6.0” to 8.0” Flange = 40 ft. • lbs

10” Flange = 64 ft. • lbs.

12“ Flange = 95 ft. • lbs.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 29

SECTION 8: MAINTENANCE

29

Cooling Filter

Cooling Fan Filter Removal

Purpose

The Cooling Fan is equipped with a Filter Mat used

to trap airborne particles and dust. This Filter Mat

must be routinely inspected and if required, cleaned.

A clogged Filter Mat reduces air circulation in and

out of the enclosure, potentially allowing electrical

hardware to over-heat. If damaged, worn-out or too

dirty replace the Filter Mat.

Frequency

Minimum every six months, but more routine

inspections may be required due to increased

airborne dirt/dust.

Parts and Equipment Required

• Slotted Screwdriver

Procedure

1. Remove Cooling Fan cover to access Filter Mat.

Parts and Equipment Required

• Compressed Air

• Dish Detergent

Procedure

Read and understand this chapter prior to cleaning

Cooling Fan Filter Mat.

1. Remove dust from mat by blowing it out with

compressed air or washing it out with soap and

water.

2. Dry mat, or use new replacement lter mat.

Cooling Fan Filter Installation

Purpose

To install cleaned or new Cooling Fan Filter Mat.

Frequency

A minimum of every six months, but more routine

inspections may be required due to increased

airborne dirt/dust.

2. Remove Cooling Fan Filter Mat

Cooling Fan Filter Cleaning

Purpose

Maximize air circulation in and out of the enclosure.

If damaged, worn-out or cannot be cleaned replace

the Filter Mat. A dirty Filter Mat may cause electronic

ballast failure.

Frequency

A minimum of every six months, but more routine

inspections may be required due to increased

airborne dirt/dust.

Parts and Equipment Required

• Slotted Screwdriver

Procedure

Read and understand this chapter prior to cleaning

Cooling Fan Filter Mat.

1. Place Cooling Fan Filter Mat into fan.

2. Replace fan cover.

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 30

30

SECTION 9: REPLACEMENT PARTS

Pentair oers several dierent variants of the

Bioshield® Commercial UV Sterilizer. These variants

include several dierent vessel dimensions, port

styles/sizes and controller/monitor options to best

t your individual needs. When contacting us for

replacement parts for your UV system, we suggest

Quartz Sleeve & UV Lamp Matrix

Bioshield models are available with dierent size

ports and use varying lengths of quartz sleeves.

Below we match your unit with the correct quartz

sleeve and UV lamp.

that you have the UV system’s serial number readily

available. The serial number can be found on both

the Power Supply Enclosure and UV vessel labels.

Identifying the serial number allows us to process

your request/order quickly and accurately.

QUARTZ

BIOSHIELD®

VERTICAL SERIES

522904, 522917, 522930 1 FL-3213-PL FL-QZ177-PL 20424-6-PL CLPA-1-6BFN-PL 17-060-PL

522905, 522918, 522931 2 FL-3213-PL FL-QZ177-PL 20424-6-PL CLPA-2-6BFN-PL 17-060-PL

522906, 522919, 522932 3 FL-3213-PL FL-QZ177-PL 20424-6-PL CLPA-3-6BFN-PL 17-060-PL

522907, 522920, 522933 3 FL-3213-PL FL-QZ177-PL 20424-8-10-PL CLPA-3-8BFN-PL 17-080-PL

522908, 522921, 522934 4 FL-3213-PL FL-QZ177-PL 20424-8-10-PL CLPA-4-8BFN-PL 17-080-PL

522909, 522922, 522935 5 FL-3213-PL FL-QZ177-PL 20424-8-10-PL CLPA-5-8BFN-PL 17-080-PL

522910, 522923, 522936 6 FL-3213-PL FL-QZ180-PL 20424-8-10-PL CLPA-6-10BFN-PL 17-100-PL

522911, 522924, 522937 7 FL-3213-PL FL-QZ180-PL 20424-8-10-PL CLPA-7-10BFN-PL 17-100-PL

522912, 522925 7 FL-3213-PL FL-QZ180-PL 20424-12-PL CLPA-7-12BFN-PL 17-120-PL

522913, 522926 8 FL-3213-PL FL-QZ180-PL 20424-12-PL CLPA-8-12BFN-PL 17-120-PL

# of

LAMPS LAMP P/N

QUARTZ

SLEEVE P/N NSF CAP P/N

QUARTZ SLEEVE

FACEPLATE P/N

SLEEVE

FACEPLATE

GASKET P/N

QUARTZ

BIOSHIELD®

CLP SERIES

CLP41A6-XN 1 FL-3213-PL FL-QZ177-PL 20424-6-PL CLPA-1-6BFN-PL 17-060-PL

CLP42A6-XN 2 FL-3213-PL FL-QZ177-PL 20424-6-PL CLPA-2-6BFN-PL 17-060-PL

CLP43A6-XN 3 FL-3213-PL FL-QZ177-PL 20424-6-PL CLPA-3-6BFN-PL 17-060-PL

CLP43A8-XN 3 FL-3213-PL FL-QZ180-PL 20424-8-10-PL CLPA-3-8BFN-PL 17-080-PL

CLP44A8-XN 4 FL-3213-PL FL-QZ180-PL 20424-8-10-PL CLPA-4-8BFN-PL 17-080-PL

CLP45A8-XN 5 FL-3213-PL FL-QZ180-PL 20424-8-10-PL CLPA-5-8BFN-PL 17-080-PL

CLP46A10-XN 6 FL-3213-PL FL-QZ180-PL 20424-8-10-PL CLPA-6-10BFN-PL 17-100-PL

CLP47A10-XN 7 FL-3213-PL FL-QZ180-PL 20424-8-10-PL CLPA-7-10BFN-PL 17-100-PL

CLP61A6-XN 1 FL-2940-PL FL-QZ178-PL 20424-6-PL CLPA-1-6BFN-PL 17-060-PL

CLP62A6-XN 2 FL-2940-PL FL-QZ178-PL 20424-6-PL CLPA-2-6BFN-PL 17-060-PL

CLP63A6-XN 3 FL-2940-PL FL-QZ178-PL 20424-6-PL CLPA-3-6BFN-PL 17-060-PL

CLP63A8-XN 3 FL-2940-PL FL-QZ178-PL 20424-8-10-PL CLPA-3-8BFN-PL 17-080-PL

CLP64A8-XN 4 FL-2940-PL FL-QZ178-PL 20424-8-10-PL CLPA-4-8BFN-PL 17-080-PL

CLP65A8-XN 5 FL-2940-PL FL-QZ178-PL 20424-8-10-PL CLPA-5-8BFN-PL 17-080-PL

CLP66A10-XN 6 FL-2940-PL FL-QZ178-PL 20424-8-10-PL CLPA-6-10BFN-PL 17-100-PL

CLP67A10-XN 7 FL-2940-PL FL-QZ178-PL 20424-8-10-PL CLPA-7-10BFN-PL 17-100-PL

CLP67A12-XN 7 FL-2940-PL FL-QZ178-PL 20424-12-PL CLPA-7-12BFN-PL 17-120-PL

CLP68A12-XN 8 FL-2940-PL FL-QZ178-PL 20424-12-PL CLPA-8-12BFN-PL

CLP69A14-XN 9 FL-2940-PL FL-QZ427-PL 20424-12-PL CLPA-9-14BFN-PL 17-140-PL

CLP610A16-XN 10 FL-2940-PL FL-QZ427-PL 20424-12-PL CLPA-10-16BFN-PL 17-160-PL

# of

LAMPS LAMP P/N

QUARTZ

SLEEVE P/N NSF CAP

QUARTZ SLEEVE

FACEPLATE

SLEEVE

FACEPLATE

GASKET

17-120-PL

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 31

31

SECTION 9: REPLACEMENT PARTS

Replacement Parts List

1. Quartz Sleeve Retainer Nut ...........................................................................................................CL-QSR-28-PL

2. Quartz Sleeve Gasket ............................................................................................................................. 22004-PL

3. Quartz Sleeve Faceplate (Includes 3, 4, 2, 1) ................................................................................. (See page 30)

4. Quartz Sleeve Faceplate Gasket .................................................................................................... (See page 30)

5. Quartz Sleeve .................................................................................................................................. (See page 30)

6. UV Lamp .......................................................................................................................................... (See page 30)

7. Lamp Field Safety Cover ................................................................................................................. (See page 30)

Not Shown Parts

1. UV Sensor ............................................................................................................................................. 960262-PL

a. UV Sensor – white (pre-5/2018) .............................................................................................. 20210-UVS-PL

2. Temperature Sensor ............................................................................................................................. 960261-PL

a. Temperature Sensor – white (pre-5/2018) ....................................................................................... 20217-PL

3.

UV Lamp Cable

..................................................................................................................................

960465-PL

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 32

32

SECTION 10: TROUBLESHOOTING

SITUATION INSPECT FOR

UV system will not function with the

External ON/OFF

Switch in the “On” position

UV Lamp does not light 1. Faulty Contact (four-pin connector/lamp pins)

UV Intensity Low 1. Decreased UV Transmissibility

Enclosure Over-Heating 1. Ambient Temperature above 145° F

Quartz Sleeve Seal Failure 1. Cracked/Broken Quartz Sleeve

1. No Input Voltage Available

2. Temperature Sensor Cable Plug is Interrupted/Defective

3. Input Voltage is lower than the Factory Set Threshold

2. Defective Electronic Ballast

3. Defective UV Lamp

4. Water Damage due to Quartz Sleeve Seal Failure

2. UV Lamp reached “End of Life”

3. Quartz Sleeve Fouled

4. Faulty UV Sensor

2. Defective Thermal Switch

3. Cooling Fan Filter Mat needs to be cleaned

4. Defective Cooling Fan

2. Failed Quartz Sleeve Retaining Nut O-Ring Seal

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 33

33

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 34

34

SECTION 11: SYSTEM SPECIFICATIONS

Vertical Series Dimensional Drawings

(See next page for dimensional data)

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 35

SECTION 11: SYSTEM SPECIFICATIONS

Vertical Series Dimensional Drawings

Dimensional Data

VESSEL DIMENSIONS (in Inches)

A B C D E F

VESSEL

I/O PORT

BODY

MODEL

522904 6 2 61 101 39 11 65/8 61/4

522905 6 2 61 101 39 11 65/8 61/4

522918 6 3 62 102 39 11 71/8 67/8

522919 6 3 62 102 39 11 71/8 67/8

522907 8 3 68 107 373/4 131/2 101/2 97/8

522920 8 4 68 107 373/4 131/2 107/8 97/8

522908 8 3 68 107 373/4 131/2 101/2 97/8

522921 8 4 68 107 373/4 131/2 107/8 97/8

522922 8 4 68 107 373/4 131/2 107/8 97/8

522935 8 6 68 107 373/4 131/2 95/8 97/8

522910 10 4 74 117 417/8 16 117/8 115/8

522923 10 6 74 117 417/8 16 105/8 115/8

522924 10 6 74 117 417/8 16 105/8 115/8

52 2912 12 6 77 120 417/8 19 15 135/8

522913 12 6 77 12 0 417/8 19 15 135/8

SIZE

FLANGE

SIZE

HEIGHT w/

SAFETY

COVER

HEIGHT w/

MAINTENANCE

CLEARANCE

PORT

TO

PORT

MOUNTING

FLANGE

OD

CENTERLINE

TO PORT

FLANGE

FLOOR TO

35

INLET

Electrical/Hydraulic Data

POWER ENCLOSURE

DIMENSIONS (H X W

MODEL INPUT WATTS

522904 130 16" X 14" X 8.4" 2.1/1.0 50/3.4 2 - PSI

522905,522918 260 16" x 14" x 8.4" 3.9/2.0 50/3.4 2 - PSI

522919 390 16" x 14" x 8.4" 5.8/2.9 50/3.4 2 - PSI

522907,522920 390 16" x 14" x 8.4" 5.8/2.9 50/3.4 2 - PSI

522908,522921 520 20.2" x 16.3" x 8.4" 7. 5/3.7 50/3.4 2 - PSI

522922,522935 650 24.6" x 20.2" x 10.6" 9.4/4.7 50/3.4 2 - PSI

522910,522923 780 24.6" x 20.2" x 10.6" 11. 2 /5.6 50/3.4 2 - PSI

522924 910 24.6" x 20.2" x 10.6" 13.3/6.5 50/3.4 2 - PSI

52 2912 910 24.6" x 20.2" x 10.6" 13.3/6.5 50/3.4 2 - PSI

522913 104 0 30.5" x 24.1" x 12.6" 15. 0 / 7. 5 50/3.4 2 - PSI

X D)

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

AMPS MAX

LOAD @

120/230 VAC MAX PSI/BAR

MAX HEAD

LOSS PSI

Page 36

36

SECTION 11: SYSTEM SPECIFICATIONS

CLP Series Dimensional Drawings

(See next page for dimensional data)

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 37

SECTION 11: SYSTEM SPECIFICATIONS

CLP Series Dimensional Drawings

Dimensional Data

VESSEL DIMENSIONS (INCHES)

A B C D E

VESSEL

BODY

SIZE

MODEL

CLP41A6-XN 6” 2", 3" ,4" 53.3 41.6 11.3 7. 6 47

CLP42A6-XN 6” 2", 3", 4" 53.3 41.6 11. 3 7. 6 47

CLP43A6-XN 6” 2", 3", 4" 53.3 41.6 11.3 7. 6 47

CLP43A8-XN 8” 3", 4", 6" 58.3 44.2 13.6 9.6 51

CLP44A8-XN 8” 3", 4", 6" 58.3 44.2 13 .6 9.6 51

CLP45A8 -XN 8” 3", 4", 6" 58.3 44.2 13 .6 9.6 51

CLP46A10 -XN 10” 6", 8" 59.7 43.4 16 15.4 51

CLP47A10 -X N 10” 6", 8" 59.7 43.4 16 15.4 51

CLP47A12-XN 12” 6", 8" 61.7 46.5 19 13.1 51

CLP48A12-XN 12” 6", 8" 61.7 46.5 19 13.1 51

(NPS)

I/O PORT

FLANGE SIZE

(NPS)

HEIGHT w/

SAFETY

COVER

HEIGHT w/

MAINTENANCE

CLEARANCE

PORT

TO

PORT

FLOOR

TO

INLET

CENTERLINE

37

TO PORT

FLANGE

CLP61A6-XN 6” 2", 3", 4" 81.8 70.1 11.3 7. 6 75

CLP62A6-XN 6” 2", 3", 4" 81.8 70 .1 11.3 7.6 75

CLP63A6-XN 6” 2", 3", 4" 81.8 70 .1 11.3 7.6 75

CLP63A8-XN 8” 3", 4", 6" 81.8 70 .1 11.3 7.6 75

CLP64A8-XN 8” 3", 4", 6" 82.5 68.4 13.6 9.6 75

CLP65A8-XN 8” 3", 4", 6" 82.5 68.4 13.6 9.6 75

CLP6 6A10-XN 10” 6", 8" 83.9 6 7. 6 16 15 .4 75

CLP67A10-XN 10” 6", 8" 83.9 6 7. 6 16 15 .4 75

CLP67A12-X N 12” 6", 8" 85.9 70.7 19 13.1 75

CLP68A12-XN 12” 6", 8" 85.9 70.7 19 13.1 75

CLP69 A14-XN 14” 8", 10", 12" 94.4 72.8 21 19.8 80

CLP610A16 -XN 16” 10", 12", 14" 95.7 72.4 23.5 21.7 80

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 38

38

SECTION 11: SYSTEM SPECIFICATIONS

CLP Series Dimensional Drawings

Electrical/Hydraulic Data

AMPS MAX

INPUT

MODEL

CLP41A6-XN 130 16" X 14" X 8.4" 2.1/1.0 50/3.4 2 - PSI

CLP42A6-XN 260 16" x 14" x 8.4" 3.9/2.0 50/3.4 2 - PSI

CLP43A6-XN 390 16" x 14" x 8.4" 5.8/2.9 50/3.4 2 - PSI

CLP43A8-XN 390 16" x 14" x 8.4" 5.8/2.9 50/3.4 2 - PSI

CLP44A8-XN 520 20.2" x 16.3" x 8.4" 7. 5 /3.7 50/3.4 2 - PSI

CLP45A8 -XN 650 24.6" x 20.2" x 10.6" 9.4/4.7 50/3.4 2 - PSI

CLP46A10 -XN 780 24.6" x 20.2" x 10.6" 11. 2 /5.6 50/3.4 2 - PSI

CLP47A10 -X N 910 24.6" x 20.2" x 10.6" 13.3/6.5 50/3.4 2 - PSI

CLP47A12-XN 910 24.6" x 20.2" x 10.6" 13.3/6.5 50/3.4 2 - PSI

CLP48A12-XN 1040 30.5" x 24.1" x 12.6" 15. 0 / 7. 5 50/3.4 2 - PSI

CLP61A6-XN 320 24.6” x 20.2” x 10.6” 3.2/1.6 100 2 - PSI

CLP62A6-XN 640 24.6” x 20.2” x 10.6” 6.0/3.0 100 2 - PSI

CLP63A6-XN 960 24.6” x 20.2” x 10.6” 9.0/4.5 100 2 - PSI

CLP63A8-XN 960 24.6” x 20.2” x 10.6” 9.0/4.5 100 2 - PSI

CLP64A8-XN 1280 24.6” x 20.2” x 10.6” 12.0/6.0 100 2 - PSI

CLP65A8-XN 16 00 24.6” x 20.2” x 10.6” 15 . 0/7.5 100 2 - PSI

CLP6 6A10-XN 1920 30.5” x 24.1” x 12.6” 18.0/9.0 100 2 - PSI

CLP67A10-XN 2240 30.5” x 24.1” x 12.6” 11.0 100 2 - PSI

CLP67A12-X N 2240 30.5” x 24.1” x 12.6” 11.0 75 2 - PSI

CLP68A12-XN 2560 30.5” x 24.1” x 12.6” 13.0 75 2 - PSI

CLP69 A14-XN 2880 40.35" X 32.48" X 12.64" 14.0 50 2 - PSI

CLP610A16 -XN 3200 40.35" X 32.48" X 12.64" 16.0 50 2 - PSI

WATTS

POWER ENCLOSURE

DIMENSIONS (H X W X D)

LOAD @

120/230 VAC

MAX

PSI/

BAR

MAX HEAD

LOSS PSI

BIOSHIELD® Commercial UV Sterilizer Installation and User's Guide

Page 39

SECTION 11: SYSTEM SPECIFICATIONS

Sizing Chart

39

TURNOVER RATE (GPM)

6 Hours

2

@ 60 mJ/cm

2

8 Hours

@ 40 mJ/cm

8 Hours

2

@ 60 mJ/cm

MODEL

MAX FLOW RATE (GPM)

40 mJ/cm

2

60 mJ/cm

2

@ 40 mJ/cm

6 Hours

522904 49 33 17,6 4 0 11,8 8 0 23,520 15,840

522905 90 60 32,400 21,6 00 43,200 28,800

522906 125 83 45,000 29,880 60,000 39,840

522907 167 111 60,120 39,960 80,160 53,280

522908 227 151 81,72 0 54,360 108,960 72,480

522909 272 181 97,9 2 0 65,16 0 130,560 86,880

522910 365 244 131,40 0 8 7, 8 4 0 175,200 117,120

522 911 430 287 15 4, 800 103,320 206,400 13 7,76 0

52 2912 492 328 17 7,120 118,080 236,160 157,44 0

522913 555 369 199,800 132 ,840 266,400 17 7,120

CLP41A6-XN 49 33 17,6 4 0 11,8 8 0 23,520 15,8 40

CLP42A6-XN 90 60 32,400 21,600 43,200 28,800

CLP43A6-XN 125 83 45,000 29,880 60,000 39,840

CLP43A8-XN 167 111 60,120 39,960 80,160 53,280