Page 1

EN Instruction Manual

B 27977-3.1-1404

www.pts-jung.co.uk

PUMP TECHNICAL SERVICES LTD/JUNG PUMPEN

BAUFIX 5

0

1

Pump Technical Servcices Ltd/Jung Pumpen - Pump House - Unit 12 - Bilton Road

Industrial Estate - Erith - Kent - DA8 2AN - United Kingdom

Tel. +44 1322 357 080 - Fax +44 1322 341 341 - eMail: sales@pts-jung.co.uk

Page 2

2

Page 3

ENGLISH

You have purchased a product made by JUNG

PUMPEN and with it, therefore, also excellent quality and service. Secure this service

by carrying out the installation works in accordance with the instructions, so that our

product can perform its task to your complete

satisfaction. Please remember that damage

caused by incorrect installation or handling

will adversely affect the guarantee.

Therefore please adhere to the instructions in

this manual!

As with all electrical devices, this product

can also fail to operate due to an interruption

in the electricity supply or due to a technical defect. If this could result in damage, a

mains-independent alarm system must be

installed. Depending on the application, you

may also wish to install an emergency power

generator, or a second system as a back-up.

SAFETY

INSTRUCTIONS

This instruction manual contains essential

information that must be observed during

installation, operation and servicing. It is

therefore important that the installer and

the responsible technician/operator read this

instruction manual before the equipment is

installed and put into operation. The manual

must always be available at the location

where the pump or the plant is installed.

Failure to observe the safety instructions can

lead to the loss of all indemnity.

In this instruction manual, safety information

is distinctly labelled with particular symbols.

Disregarding this information can be dangerous.

General danger to people

Warning of electrical voltage

ATTENTION!

Danger to equipment and operation

Qualification and training of

personnel

All personnel involved with the operation,

servicing, inspection and installation of the

equipment must be suitably qualified for this

work and must have studied the instruction

manual in depth to ensure that they are sufficiently conversant with its contents. The supervision, competence and areas of responsibility of the personnel must be precisely

regulated by the operator. If the personnel do

not have the necessary skills, they must be

instructed and trained accordingly.

Safety-conscious working

The safety instructions in this instruction

manual, the existing national regulations

regarding accident prevention, and any internal working, operating and safety regulations

must be adhered to.

Safety instructions for the

operator/user

All legal regulations, local directives and

safety regulations must be adhered to.

The possibility of danger due to electrical energy must be prevented.

Leakages of dangerous (e.g. explosive, toxic,

hot) substances must be discharged such

that no danger to people or the environment

occurs. Legal regulations must be observed.

Safety instructions for installation, inspection and maintenance works

As a basic principle, works may only be carried out to the equipment when it is shut

down. Pumps or plant that convey harmful

substances must be decontaminated.

All safety and protection components must

be re-fitted and/or made operational immediately after the works have been completed.

Their effectiveness must be checked before

restarting, taking into account the current

regulations and stipulations.

Unauthorised modifications,

manufacture of spare parts

The equipment may only be modified or altered in agreement with the manufacturer.

The use of original spare parts and accessories approved by the manufacturer is important for safety reasons. The use of other

parts can result in liability for consequential

damage being rescinded.

Unauthorised operating

methods

The operational safety of the supplied equipment is only guaranteed if the equipment is

used for its intended purpose. The limiting

values given in the "Technical Data" section may not be exceeded under any circumstances.

Instructions regarding accident prevention

Before commencing servicing or maintenance

works, cordon off the working area and check

that the lifting gear is in perfect condition.

Never work alone. Always wear a hard hat,

safety glasses and safety shoes and, if necessary, a suitable safety belt.

Before carrying out welding works or using

electrical devices, check to ensure there is

no danger of explosion.

People working in wastewater systems must

be vaccinated against the pathogens that

may be found there. For the sake of your

health, be sure to pay meticulous attention to

cleanliness wherever you are working.

Make sure that there are no toxic gases in the

working area.

Observe the health and safety at work regulations and make sure that a first-aid kit is to

hand.

In some cases, the pump and the pumping

medium may be hot and could cause burns.

For installations in areas subject to explosion

hazards, special regulations apply!

This appliance can be used by children aged

8 years or over and by persons with limited

physical, sensory or intellectual capabilities,

or with limited experience and knowledge,

provided that they are supervised or have

been instructed in the safe use of the appliance and are aware of the dangers involved.

Children must not be allowed to play with the

appliance. Cleaning and user maintenance

must not be carried out by children unless

they are supervised.

3

Page 4

ENGLISH

USE

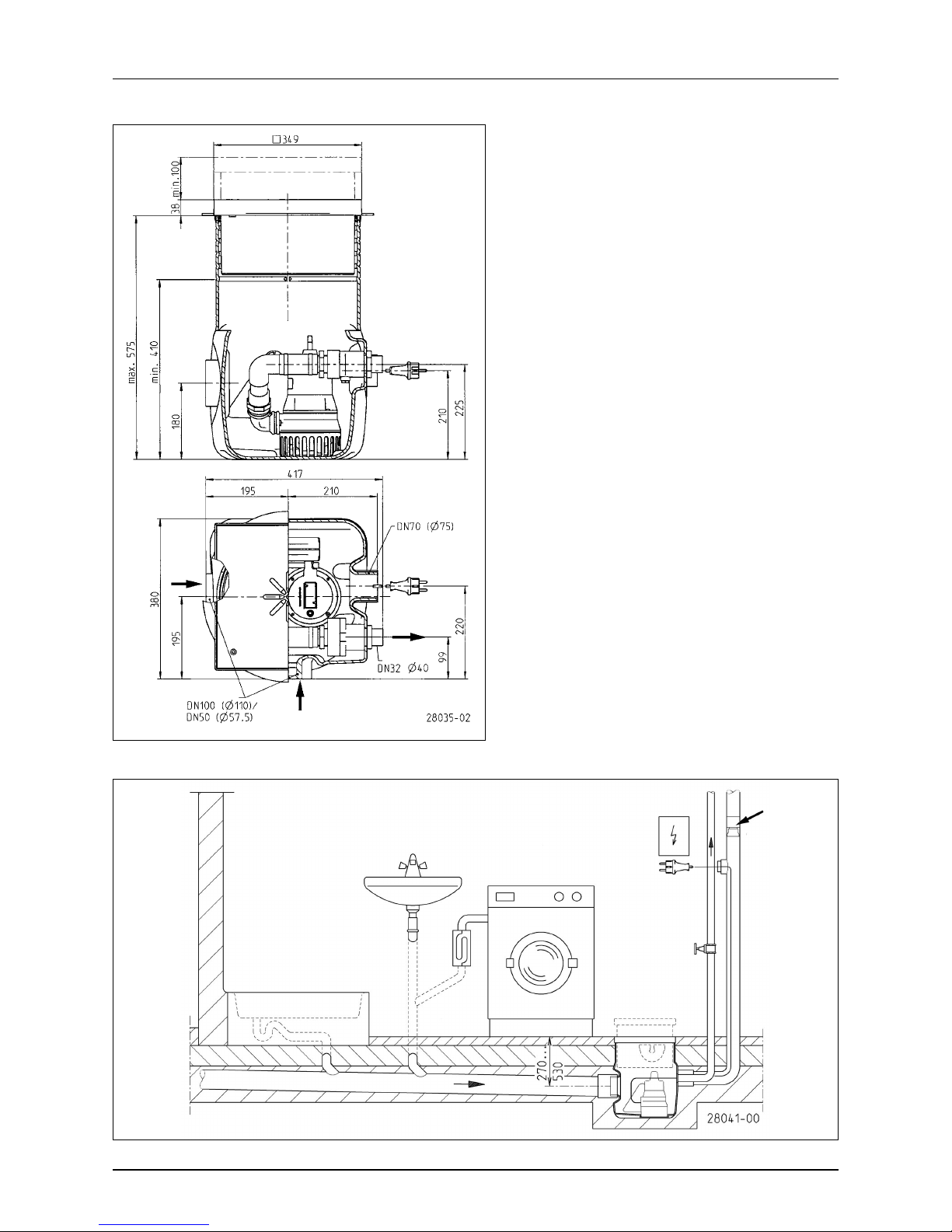

The sump is a conventional effluent collecting pit in conjunction with a separately orderd U3 KS or U3 KS special.

ATTENTION! Due to the space saving

tank design the U3 KS or the U3 KS can

only be operated with the low level float

which is part of the extent of delivery

ATTENTION! The connection between

the sump and the concrete can not be

sealed against pressing water. Do not

install the sump in areas with high

groundwater levels!

ATTENTION! In some countries it must

not be used for pumping sewage water

from lavatories.

The allowed temperature of the pumped

medium is 35 °C, short time period

60°C.

The screwed cover is smell-tight and

level compensating. The integrated and

smell-tight floor drain can be opend on

request.

The PE-tank has two collateral inlet

sockets DN 100, offset by 90 °, one discharge socket for Ø 40 mm PVC pipe

and a vent socket DN70. The tank neck

with its adjustable and rotatable cover

allows an optimized level compensation

at the building site.

Extent of delivery

Underground sump Baufix 50 pre-assembled with male threaded pressure

outlet, non-return valve 1 ¼", nipple

40-1¼", cover frame with seal, lid with

sealing plug usable as a grommet, pipework, low level float, hose clamp with

snap buckle; profiled seal, hose clamp

1½" DN 40; siphon, elastic connection

and plug-in seals

ELECTRICAL

CONNECTION

Please refer to the relevant instructions

in the manual for the pump.

MOUNTING

The pressure tube must be taken in a

loop over the local backpressure level

and secured with a reflux valve. (EN

12056) The reflux valve is already installed in the BAUFIX 50.

Tank installation

1. Take the parts out of the tank. Do

not dismantle the pre-assembled

pipework or the reflux valve, because

they are already sealed.

2. Saw off the tank neck in the required

height along the marked grooves.

3. Push the profile packing with its

clamping groove on the edge of

the tank opening. The lips of the

seal must be directed to the inside.

Grease the seal and push the frame

a little bit declined into the opening.

Then adjust it und push the frame

into the opening completely, up to the

desired position (final floor height).

The air will escape audible out of the

seal. If the seal is rolled up, the installation must be repeated.

4. Open the required sockets for the inlet and the ventilation at the marked

positions with a saw or a knife and

remove the burr. Connect the inlet

and the ventilation pipes with PVCsleeves and O-rings (not included).

The pressure pipe must be glued

with a PVC sleeve onto the pressure

outlet.

5. After connection of all pipes, the

BAUFIX 50 must be levelled and

washed in. Do not remove the cover

during the installation to keep the

tank clean.

6. At concreting the base, the tank can be

secured against buoyancy by reinforcing steel at the welded wire mash.

.

7. Do not embed the frame in concrete.

It should stay adjustable to compensate floor pavements or tiles up to

100 mm.

8. Before carrying out the flooring

works adjust the frame in the planed

position and fasten it.

Pump installation

1. Seal the pump quarter elbow with

Teflon strap and screw it on the discharge branch.

2. Seal the thread of the pre-assembled

pipework with Teflon strap, screw it

in the quarter elbow of the pump and

adjust it as shown below.

3. Unscrew the standard float at the

control shaft, replace it by the low

level float and fasten it again with the

sheet metal screw.

4. Push the elastic connector up to the

end on the pipework and fasten it

with a hose clamp.

5. Push the hose clamp with the snap

buckle on the flexible connector. Insert the pump in the tank and push

the flexible connector on the reflux

valve. Fasten it with the hose clamp.

ATTENTION! Ensure the stable position of the pump as well as the free

movement of the float switch!

6. Pull the cable up to the T-piece

through the vent pipe. Enough cable has to be in the tank to allow the

pump to be pulled out of the tank for

servicing. The T-piece can then be

sealed with the slotted plug.

Installation of floor drain

1. Take out the 2 screws of the cover

plate and remove it.

2. Take the plug out of the cover connection piece with a screwdriver.

3. Screw the siphon with the union nut,

the packing and the expanding ring

on the connection piece.

4. The outlet of the siphon must not be

positioned directly above the pump.

5. At using the stainless steel frame,

grease the screws and screw down

the cover plate again.

4

Page 5

ENGLISH

Accessory alarm device

The alarm device signals an excessive

high water level. It can be installed subsequently. The cable is pulled through

the vent pipe and sealed in the same

way as the pump cable. The alarm unit

should be connected to a separate electric circuit, to ensure the operation in

case of a pump fault. Alternatively it can

be equiped with our 9V-rechargeable

battery for off the line operation.

Accessory special ventilation

If the ventilation over the roof level is not

possible, alternatively the special ventilation consisting of a ventilation screen

and 3 activated carbon filters can be installed with a T-piece in the cable pipe.

MAINTENANCE

The tank, the float switches and the foot

strainer of the pump should be inspected regularly and cleaned if necessary.

To service the pump, please refer to the

separate operating instruction.

ATTENTION! Always grease the screws

before using them to close the cover

plate and ensure the correct position of

the profiled seal.

5

Page 6

JUNG PUMPEN GmbH - Industriestr. 4-6 - 33803 Steinhagen - Deutschland

Tel. +49 5204 170 - Fax +49 5204 80368 - eMail kd@jung-pumpen.de

6

Pump Technical Services Ltd/Jung Pumpen - Pump House - Unit 12 - Bilton Road

Industrial Estate - Erith - Kent - DA8 2AN - United Kingdom

+44 1322 357 080 - Fax +44 1322 341 341 - eMail: sales@pts-jung.co.uk

Loading...

Loading...