Pentair AUTOTROL LOGIX 740, AUTOTROL Performa 267, AUTOTROL Performa 265, AUTOTROL LOGIX 741, AUTOTROL LOGIX 742 Installer Manual

...

AUTOTROL

Performa 263-268

LOGIX 740-760

INSTALLER

MANUAL

WATER PURIFICATION

Installer Manual Performa 263-268 / LOGIX 740-760 - Table of content

Table of content

1. Generalities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1. Scope of the documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2. Release management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3. Manufacturer identifier, product . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4. Abbreviations used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5. Norms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5.1. Applicable norms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5.2. Available certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6. Procedure for technical support . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.7. Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.8. Limitation of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1. Safety pictograms definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2. Safety tags location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3. Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.1. Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.2. Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4. Hygiene and sanitization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.1. Sanitary issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.2. Hygiene measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1. Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.1. Performance flow rate characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2. Outline drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3. Description and components location . . . . . . . . . . . . . . . . . . . . . . . 12

3.4. Options available on the valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4.1. Chlorine generator (check salt light) . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4.2. Blending valve kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5. System regeneration cycle (8-cycles operation) . . . . . . . . . . . . . . . 15

3.6. Filter cycle (4-cycles operation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4. System sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1. Softener configuration (Performa 268) . . . . . . . . . . . . . . . . . . . . . . 19

4.1.1. Injector/DLFC/Refill flow controller-Valve configuration . . . . . . . . . . . 19

4.2. Filter configuration (Performa 263) . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3. Cycle time calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4. Injector flow rates (tables) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5. Salt amount definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2 / 64 Ref. MKT-IM-011 / A - 15.06.2017

Installer Manual Performa 263-268 / LOGIX 740-760 - Table of content

5. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.1. Safety notices for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2. Installation environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2.1. General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2.2. Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.3. Mechanical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.4. Outdoor Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3. Integration constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4. Block diagram and configuration example . . . . . . . . . . . . . . . . . . 24

5.5. Valve connection to piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5.1. Top-mounted valve installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.6. Connections (electrical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.7. Bypassing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.8. Drain line connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.9. Overflow line connection (Performa 268 - Softener

configuration only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.10. Brine line connection (Performa 268 - Softener

configuration only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6. Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.1. Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2. Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3. Basic programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3.1. Program system size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3.2. Time setting and winter time - summer time change . . . . . . . . . . . . . 33

6.3.3. Day of week . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3.4. Regeneration time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.5. Days to regenerate (740 time-clock controller only) . . . . . . . . . . . . . . 34

6.3.6. Calendar override (760 on-demand controller only) . . . . . . . . . . . . . . 34

6.3.7. Amount of brine used per regeneration . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.8. Estimated capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3.9. Hardness (760 on-demand controller only) . . . . . . . . . . . . . . . . . . . . . 35

6.4. Advanced programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4.1. Cycle time programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4.2. Diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.4.3. Resetting the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7. Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

7.1. Water filling, draining and waterproofness inspection . . . . . . . . . 38

7.1.1. Activating the softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.1.2. Additional tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.2. Sanitization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.2.1. Disinfection of water softeners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Ref. MKT-IM-011 / A - 15.06.2017 3 / 64

Installer Manual Performa 263-268 / LOGIX 740-760 - Table of content

7.2.2. Sodium or calcium hypochlorite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.2.3. Electro chlorination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.1. Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.2. Manual regeneration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.3. To advance regeneration cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

8.4. To cancel a regeneration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1. Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1.1. Use original spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1.2. Use original approved lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1.3. Maintenance instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.2. Cleaning and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.2.1. Cleaning and maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.2.2. Cleaning the injector valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2.3. Cleaning the refill controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2.4. Cleaning the injector screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.2.5. Cleaning the backwash controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.2.6. Disassembling valve cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2.7. Motor and camshaft replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.2.8. Optical sensor and controller replacement . . . . . . . . . . . . . . . . . . . . . . 49

9.2.9. Turbine cleaning or replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.2.10. Top plate, flapper spring and flappers replacement. . . . . . . . . . . . . . . 51

10. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.1. Logix controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.2. Performa Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

11. Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

11.1. Valve parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

11.2. 740 / 760 / 742 / 762 Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

11.3. 1265 Bypass & Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

11.4. 268 Valve installation kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

11.5. 263 Valve installation kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

12. Scrapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4 / 64 Ref. MKT-IM-011 / A - 15.06.2017

Installer Manual Performa 263-268 / LOGIX 740-760 - Generalities

1. Generalities

1.1. Scope of the documentation

The documentation provides the necessary information for appropriate use of the product. It informs

the user to ensure efficient execution of the installation, operation or maintenance procedures.

The content of this document is based on the information available at the time of publication. The

original version of the document was written in English.

For safety and environmental protection reasons, the safety instructions given in this documentation

must be strictly followed.

This manual is a reference and will not include every system installation situation. The person

installing this equipment should have:

• Training in the 700 Logix series controllers and water softener installation;

• Knowledge of water conditioning and how to determine proper controller settings;

• Basic plumbing skills.

This document is available in other languages on https://www.pentairaquaeurope.com/productfinder/product-type/control-valves

1.2. Release management

Revision Date Author Description

A 15.06.2017 STF First edition

1.3. Manufacturer identifier, product

Manufacturer: Pentair Manufacturing Italy Srl

Via Masaccio, 13

56010 Lugnano di Vicopisano (PI) – Italy

Product: Performa 263-268 / LOGIX 740-760

Ref. MKT-IM-011 / A - 15.06.2017 5 / 64

Installer Manual Performa 263-268 / LOGIX 740-760 - Generalities

1.4. Abbreviations used

DF............................................................ Down Flow

UF............................................................ Up Flow

Inj ............................................................ Injector

DLFC ....................................................... Drain Line Flow Controller

BLFC / Refill Flow Controller................. Brine Line Flow Controller

Regen...................................................... Regeneration

SBV.......................................................... Safety Brine Valve

TC ............................................................ Time Clock

1.5. Norms

1.5.1. Applicable norms

Comply with the following guidelines:

• DM174: "Regulation of materials and objects that can be used in stationary collection, treatment,

supply and distribution of water intended for human consumption"

• Attestation de Conformité Sanitaire (ACS): "Test and Certification valid for France performed by

independent laboratories for the evaluation of materials and components that are in contact with

drinking water."

• 2006/42/EC: Machinery Directive

• 2014/35/UE: Low Voltage Directive;

• 2014/30/UE: Electromagnetic compatibility;

• 2011/65/EC: Restriction of use of certain hazardous substances in electrical and electronic

equipment (RoHS);

Meets the following technical standards:

• IEC/EN 60335-1

• IEC 61010-1

• EN 55014-1

• EN 55014-2

• EN 61000-3-2: 2006 + A1: 2009 + A2: 2009

• EN 61000-3-3: 2008

• EN 61000-6-2: 2005

• EN 61000-6-3: 2007 + A1: 2011

• EN 61326-1

6 / 64 Ref. MKT-IM-011 / A - 15.06.2017

Installer Manual Performa 263-268 / LOGIX 740-760 - Generalities

1.5.2. Available certificates

•CE •ACS

•DM174

Access to all certifications:

1.6. Procedure for technical support

Procedure to follow for any technical support request:

A Collect the required information for a technical assistance request.

→ Product identification (see 2.2. Safety tags location, page 8 and 9.1. Recommendations,

page 44);

→ Problem description of the device.

B Please refer to the "Troubleshooting" chapter, page 52. If the problem persists contact your

supplier.

1.7. Copyright

© 2017 Pentair International Sàrl All rights reserved.

1.8. Limitation of liability

Pentair Quality System EMEA products benefit, under specific conditions, from a manufacturer

warranty that may be invoked by Pentair’s direct customers. Users should contact the vendor of this

product for applicable conditions and in case of a potential warranty claim.

Any warranty provided by Pentair regarding the product will become invalid in case of:

• Improper installation, improper programming, improper use, improper operation and/or

maintenance leading to any kind of product damages;

• Improper or unauthorized intervention on the controller or components;

• Incorrect, improper or wrong connection/assembly of systems or products with this product and

vice versa;

• Use of a non-compatible lubricant, grease or chemicals of any type and not listed by the

manufacturer as compatible for the product;

• Failure due to wrong configuration and/or sizing.

Pentair accepts no liability for equipment installed by the user upstream or downstream of Pentair

products, as well as for process/production processes which are installed and connected around or

even related to the installation. Disturbances, failures, direct or indirect damages that are caused by

such equipment or processes are also excluded from the warranty. Pentair shall not accept any

liability for any loss or damage of profits, revenues, use, production, or contracts, or for any indirect,

special or consequential loss or damage whatsoever. Please refer to the Pentair List Price to know

more about terms and conditions applicable to this product.

Ref. MKT-IM-011 / A - 15.06.2017 7 / 64

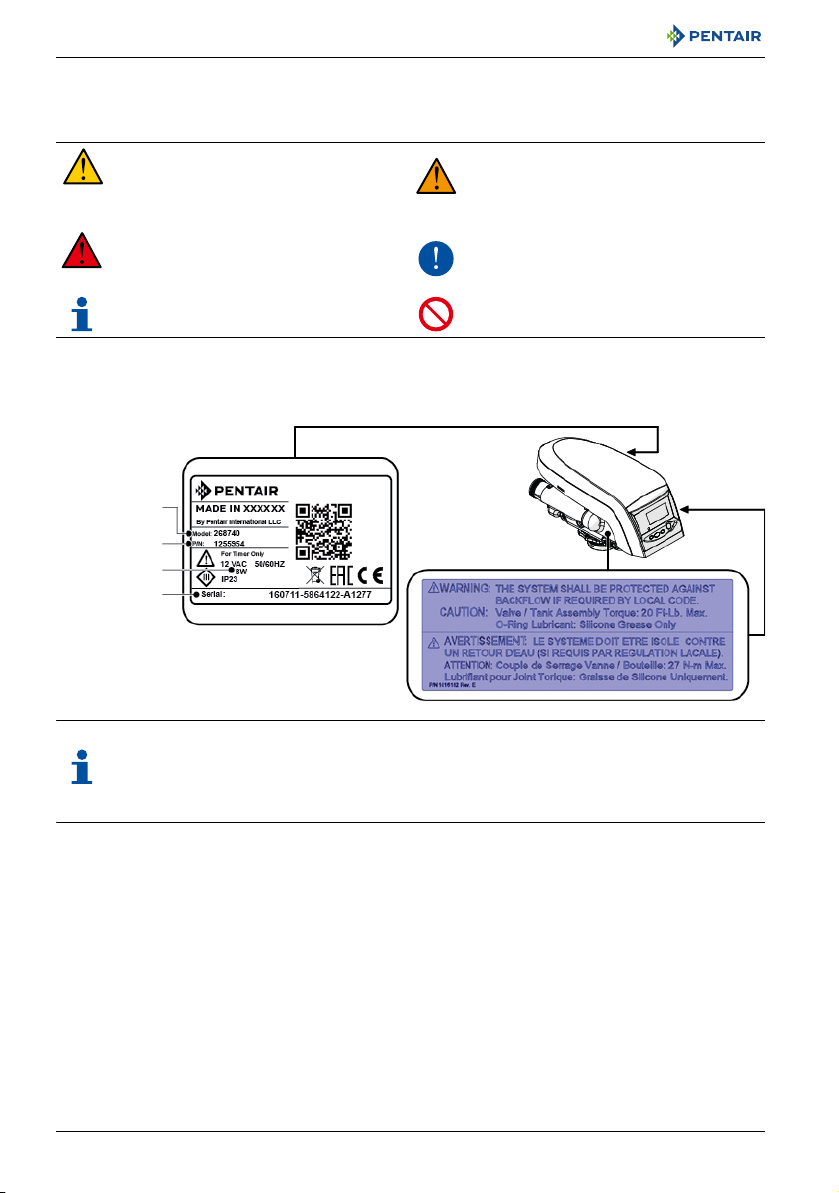

Installer Manual Performa 263-268 / LOGIX 740-760 - Safety

A

A

A

Electrical

ratings

Serial number

Serial label

QR code (access

to installer

manual)

Installation warning

Part number

Model

A

2. Safety

2.1. Safety pictograms definition

Caution

Warns of a risk of minor injury or major

material damage to the device or

environment.

Danger

Warns against serious personal injury or

death.

Note

Comment

2.2. Safety tags location

A

Warning

Warns against serious personal injury

and damage to health.

A

Mandatory

Standard or measure to apply.

A

Prohibition

Restriction to be observed.

Note

Ensure that the safety tags on the device are completely legible and clean. If necessary,

replace them with new tags and put them in the same places.

2.3. Hazards

All the safety and protection instructions contained in this document must be observed in order to

avoid temporary or permanent injury, damage to property or environmental pollution.

At the same time, any other legal regulations, accident prevention and environmental protection

measures, as well as any recognized technical regulations relating to appropriate and risk-free

methods of working which apply in the country and place of use of the device must be adhered to.

Any non-observation of the safety and protection rules, as well as any existing legal and technical

regulations, will result in a risk of temporary or permanent injury, damage to property or

environmental pollution.

8 / 64 Ref. MKT-IM-011 / A - 15.06.2017

Installer Manual Performa 263-268 / LOGIX 740-760 - Safety

A

A

2.3.1. Personnel

Only qualified and professional personnel, based on their training, experience and instruction as well

as their knowledge of the regulations, the safety rules and operations performed, are authorized to

carry out necessary work.

2.3.2. Material

The following points must be observed to ensure proper operation of the system and the safety of

user:

• Be careful of high voltages present on the transformer (230V).

• Do not put your fingers in the system (risk of injuries with moving parts and shock due to electric

voltage).

2.4. Hygiene and sanitization

2.4.1. Sanitary issues

Preliminary checks and storage

• Check the integrity of the packaging. Check that there is no damage and no signs of contact with

liquid to make sure that no external contamination occurred.

• The packaging has a protective function and must be removed just before installation. For

transportation and storage appropriate measures should be adopted to prevent the

contamination of materials or objects themselves.

Assembly

• Assemble only with components which are in accordance with drinking water standards.

• After installation and before use, perform one or more manual regenerations in order to clean

the media bed. During such operations, do not use the water for human consumption. Perform a

disinfection of the system in the case of installations for treatment of drinking water for human

use.

Note

This operation must be repeated in the case of ordinary and extraordinary maintenance. It

should also be repeated whenever the system remains idle for a significant time.

Note

Valid only for Italy

: In case of equipment used in accordance with the DM25, apply all the

signs and obligations arising from the DM25.

2.4.2. Hygiene measures

Disinfection

• The materials used for the construction of our products meet the standards for use with potable

water; the manufacturing processes are also geared to preserving these criteria. However, the

process of production, distribution, assembly and installation, may create conditions of bacterial

proliferation, which may lead to odor problems and water contamination.

• It is therefore strongly recommended to sanitize the products. See 7.2. Sanitization, page 40.

• Maximum cleanliness is recommended during the assembly and installation.

• For disinfection, use Sodium or Calcium Hypochlorite and perform a manual regeneration.

Ref. MKT-IM-011 / A - 15.06.2017 9 / 64

Installer Manual Performa 263-268 / LOGIX 740-760 - Description

3. Description

3.1. Technical specifications

Design specifications/ratings

Valve body ............................................... Glass-filled Noryl

Rubber components ............................... Compounded for cold water - NSF listed material

Valve material certification .................... WQA Gold Seal Certified to ORD 0902, NSF/ANSI 44, CE, ACS

Weight (valve with controller) ................ 2.42 kg

Recommended operating pressure ....... 1.38 - 8.27 bar

Hydrostatic test pressure....................... 20.69 bar

Water temperature................................. 2 - 38°C

Ambient temperature............................. 2 - 48.9°C

®

- NSF listed material

Flow rates (valve only)

Service at 1.03 bar drop.......................... 5.7 m

Backwash at 1.72 bar drop..................... 4.5 m

Service .................................................... Kv = 5.6 m

Backwash................................................ Kv = 3.5 m

3

/h

3

/h

3

/h (Cv = 6.50 gpm)

3

/h (Cv = 4.00 gpm)

Valve connections

Tank thread............................................. 2½" - 8 NPSM, male

Inlet/Outlet threads ................................ 1¾" - 12 UNC - 2A male

Drain line ................................................ ¾" NPT, male

Brine line ................................................ ⅜" NPT, male

Distributor tube [Ø]................................. 27 mm (1.050")

Distributor tube [length]......................... 13 mm ± 3 mm (½ ± ⅛") above top of tank

Electrical

Controller Operating Voltage ................. 12 VAC (requires use of Pentair Water supplied transformer)

Input Supply Frequency.......................... 50 or 60 Hz (controller configuration dependent)

Motor Input Voltage ................................ 12 VAC

Controller Power Consumption ............. 3 W average

Protection rating..................................... IP23

10 / 64 Ref. MKT-IM-011 / A - 15.06.2017

Installer Manual Performa 263-268 / LOGIX 740-760 - Description

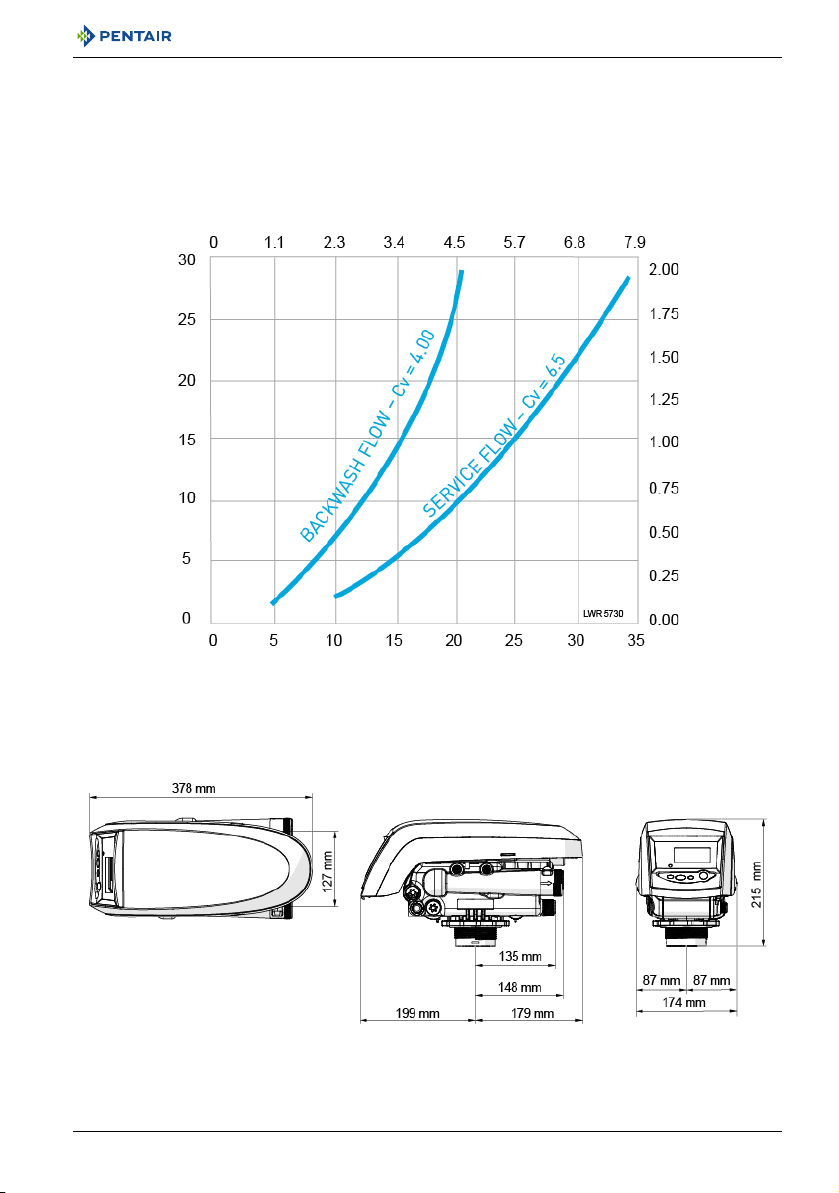

Flow rate (m3/h)

Flow rate in gallons per minute

Pressure drop (bar)

Pressure drop in psi

3.1.1. Performance flow rate characteristics

The graph shows the pressure drop created by the valve itself at different flow rates. It makes it

possible to predetermine the maximum flow rate going through the valve depending on the system

settings (inlet pressure etc). It also makes it possible to determine the valve pressure drop at a given

flow rate, and therefore to evaluate the system pressure drop vs flow rate.

3.2. Outline drawing

Ref. MKT-IM-011 / A - 15.06.2017 11 / 64

Installer Manual Performa 263-268 / LOGIX 740-760 - Description

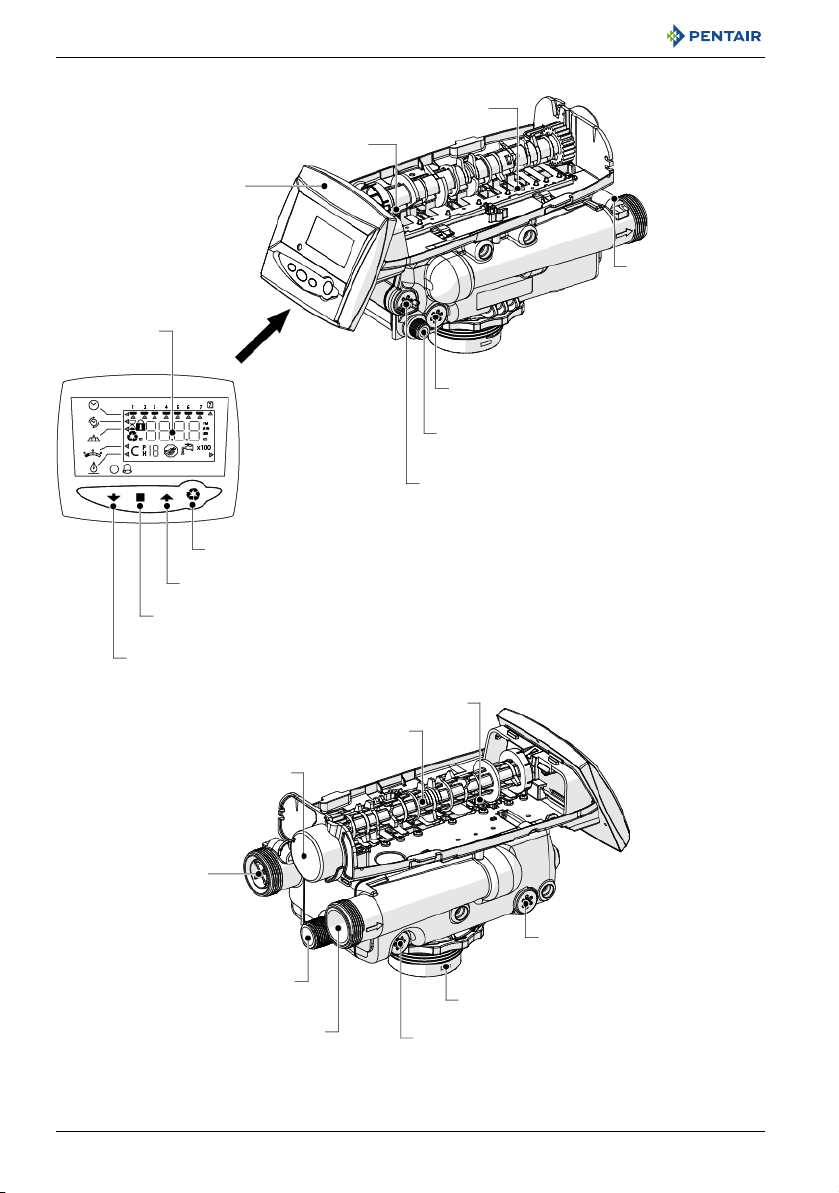

LCD display

DOWN button

SET button

UP button

Manual REGEN button

Control module mount

BLFC / Refill controller

Injector and cap

Brine tank tube connection

Tank thread

One-piece valve disc spring

Valve discs

Optical sensor

Camshaft

Motor

Drain

Inlet

Backwash flow drain controller

Injector screen

Outlet

Turbine cable

connection

3.3. Description and components location

12 / 64 Ref. MKT-IM-011 / A - 15.06.2017

Installer Manual Performa 263-268 / LOGIX 740-760 - Description

Chlorine generator

(check salt light)

A

3.4. Options available on the valve

3.4.1. Chlorine generator (check salt light)

The Logix 740 and 760 controllers have the capability to produce a low level of chlorine to chlorinate

the resin bed during regeneration. A check salt light will indicate when the user needs to add salt to

the brine tank. Potassium chloride or sodium chloride may be used.

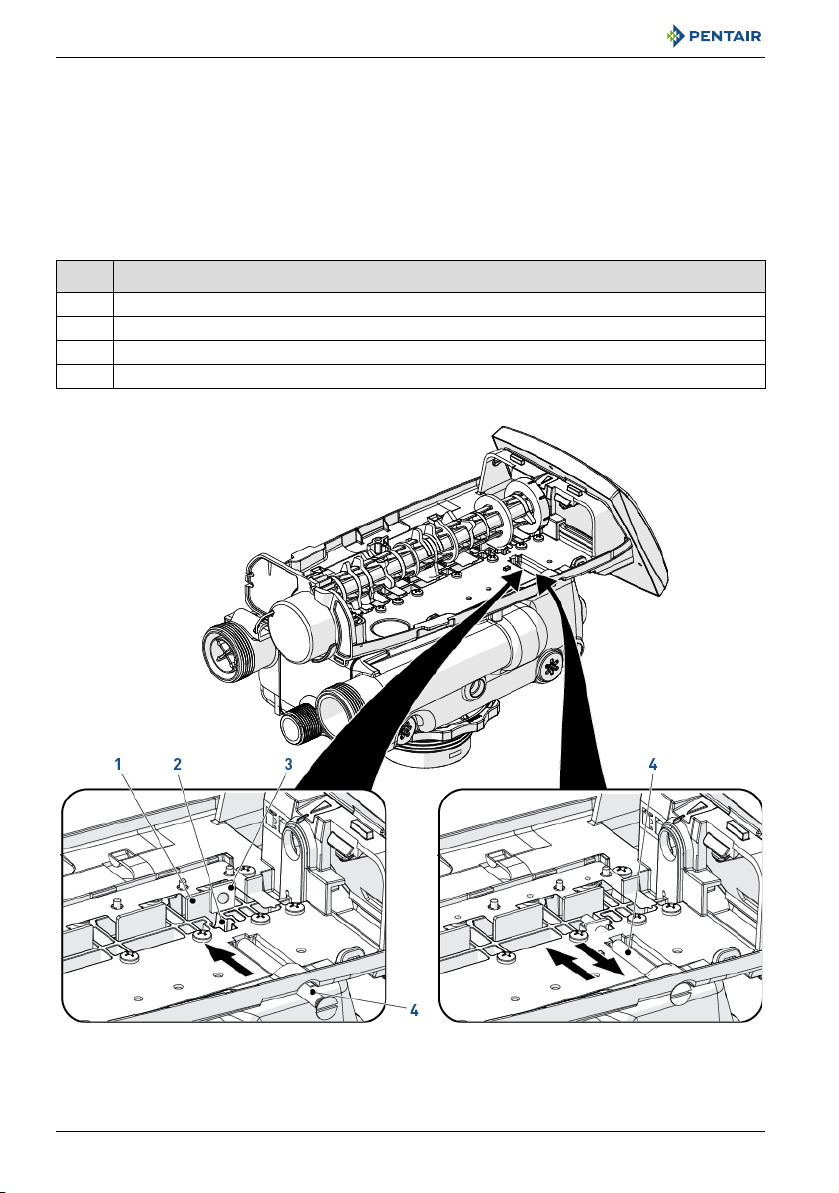

No. Operation

A Unplug the wall-mounted transformer.

B Shut off water supply or put bypass valve(s) into bypass position.

C Relieve system pressure before performing any operations.

D Unlock the cover (2) from the slide clips (1) (one on each side of the valve).

E Remove the controller (3) by pressing on (4).

F Connect the small chlorine generator connector to the back of the controller (5).

Remove the existing refill controller (6) with the ball (7) from the valve and replace it with

G

the one provided in the kit.

Connect the other end of the cable to the refill controller previously installed.

H

Connect firmly to ensure a good contact.

I Reverse above procedure steps to rebuild.

Note

No programming is necessary for the chlorine generator to work properly on the controller.

The system will be automatically functional after the chlorine generation senses brine for

the first time. There is a check salt light on the front of the controller that will illuminate

when there is no brine present during the brine draw.

Ref. MKT-IM-011 / A - 15.06.2017 13 / 64

Installer Manual Performa 263-268 / LOGIX 740-760 - Description

3.4.2. Blending valve kit

Tightening the adjusting screw provided by the kit will force the bypass flapper open. The open flapper

will allow untreated (hard) water to blend with the treated water supply. As the adjusting screw is

turned in, the hardness of the outlet water increases.

Loosening the adjusting screw will allow the bypass flapper to close. The closing action will blend less

untreated water into the outlet flow.

To blend a specific amount of hardness into outflow, adjust the screw and test the water. Repeat the

following procedure as needed until the desired harness level is reached.

No. Operation

A Insert the nut (3) into the blending valve orifice (2).

B Insert the adjusting screw (4) through the top plate and then through the nut.

C Tighten the adjusting screw (4) until it touches the bypass flapper (1).

D Adjust the position of the screw (4) until the desired hardness level of water is reached.

14 / 64 Ref. MKT-IM-011 / A - 15.06.2017

Installer Manual Performa 263-268 / LOGIX 740-760 - Description

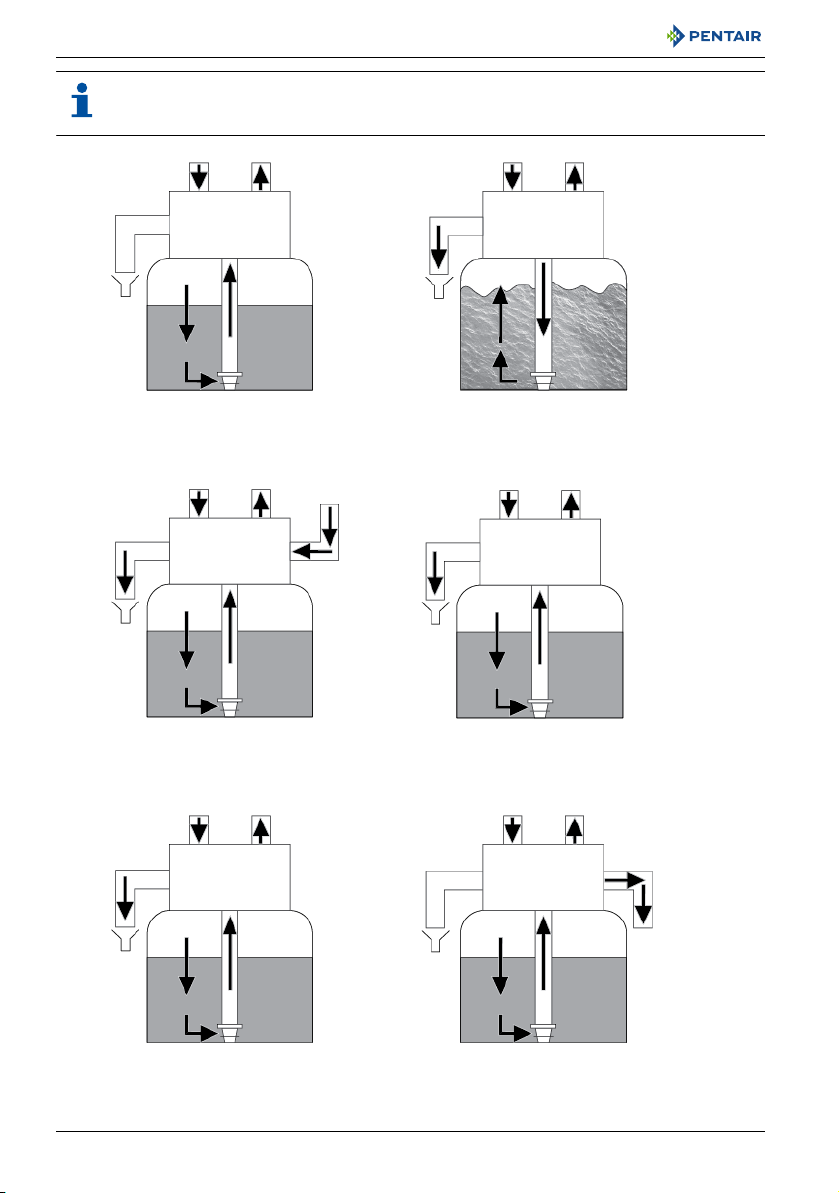

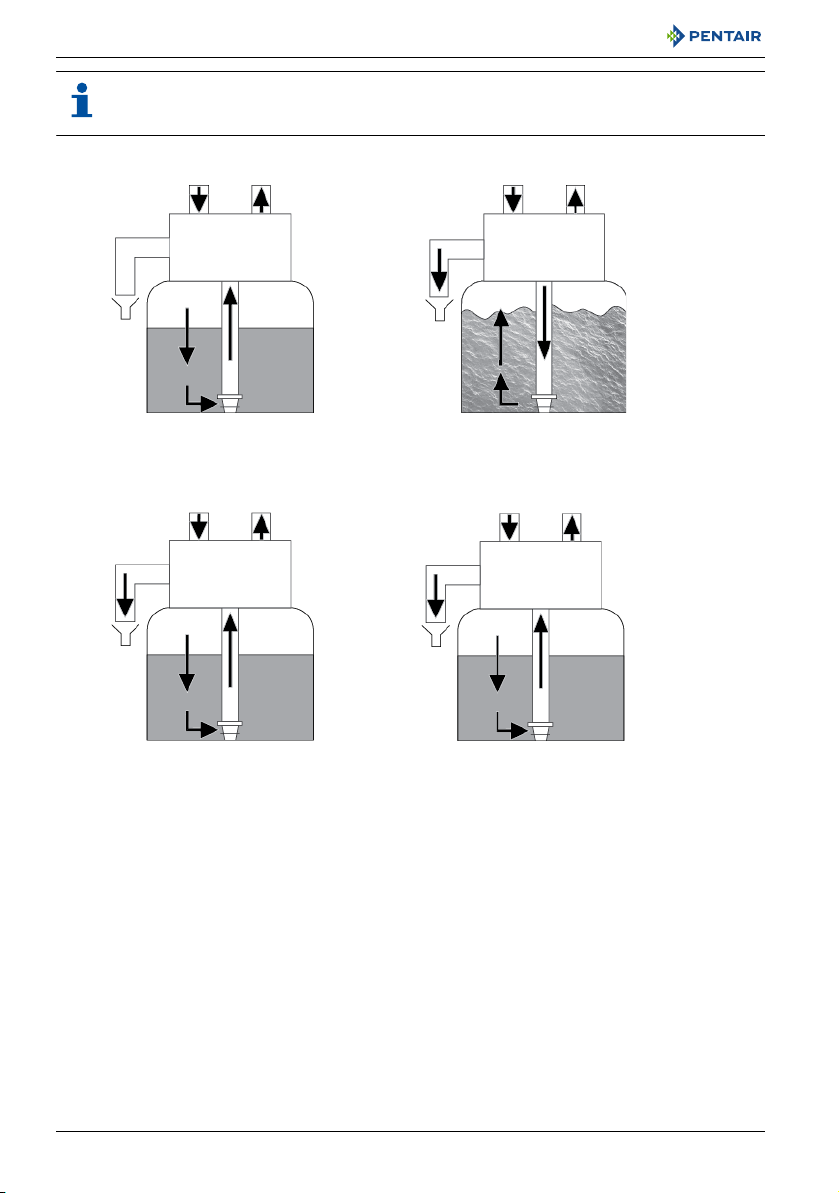

3.5. System regeneration cycle (8-cycles operation)

Service (downflow) — cycle C0

Untreated water is directed down through the resin bed and up through the riser tube. The hardness

ions attach themselves to the resin and are removed from the raw water being exchanged on the resin

beads against sodium ions. The water is conditioned as it passes through the resin bed.

Backwash (upflow) — cycle C1

The flow of water is reversed by the valve and directed down the riser tube and up through the resin

bed. During the backwash cycle, the bed is expanded and debris is flushed to the drain, while the

media bed is remixed.

Brine (downflow) — cycle C2

The controller directs water through the brine injector and brine is drawn from the brine tank. The

brine is then directed down through the resin bed and up through the riser tube to the drain. The

hardness ions are displaced by sodium ions and are sent to the drain. The resin is regenerated during

the brine cycle. When the air check valve closes brine drawing finishes, and then the slow rinse phase

starts.

Slow rinse (downflow) — cycle C3

Repressurize cycle (hard water bypass flapper open) — cycle C4

This cycle allows the air and water to hydraulically balance in the valve before continuing the

regeneration.

Fast rinse (downflow) — cycle C5

The controller value directs water down through the resin bed and up through the riser tube to the

drain. Any residual brine is rinsed from the resin bed, while the media bed is re-compacted.

2nd Backwash (upflow) — cycle C6

2nd Fast rinse (downflow) — cycle C7

Brine refill — cycle C8

Water is directed to the brine tank at a rate controlled by the refill controller, to create brine for the

next regeneration. During brine refill, treated water is already available at the valve outlet.

Ref. MKT-IM-011 / A - 15.06.2017 15 / 64

Installer Manual Performa 263-268 / LOGIX 740-760 - Description

A

From brine tank

BRINE/SLOW RINSE

C2 and C3

BACKWASH

C1 and C6

SERVICE

C0

FAST RINSE

C5 and C7

BRINE REFILL

C8

Valve

Valve

Valve

Valve Valve

Valve

REPRESSURIZE

C4

To brine tank

Note

For illustration purpose only. Always verify inlet and outlet marking on the valve.

16 / 64 Ref. MKT-IM-011 / A - 15.06.2017

Installer Manual Performa 263-268 / LOGIX 740-760 - Description

3.6. Filter cycle (4-cycles operation)

Service — cycle C0

Unfiltered water is directed down through the media and up through the riser tube. The water is

filtered as it passes through the media.

Backwash — cycle C1

The flow of water is reversed by the valve and directed down through the riser tube and up through

the media. During the backwash cycle, the media is expanded and debris is flushed to the drain.

Repressurize cycle (hard water bypass flapper open) — cycle C4

This cycle allows the air and water to hydraulically balance in the valve before continuing the

regeneration.

Fast rinse — cycle C5

The valve directs water down through the media and up through the riser tube to the drain while the

media is re-compacted.

Ref. MKT-IM-011 / A - 15.06.2017 17 / 64

Installer Manual Performa 263-268 / LOGIX 740-760 - Description

A

REPRESSURIZE

C4

BACKWASH

C1

SERVICE

C0

Valve Valve

Valve Valve

FAST RINSE

C5

Note

For illustration purpose only. Always verify inlet and outlet marking on the valve.

18 / 64 Ref. MKT-IM-011 / A - 15.06.2017

Installer Manual Performa 263-268 / LOGIX 740-760 - System sizing

4. System sizing

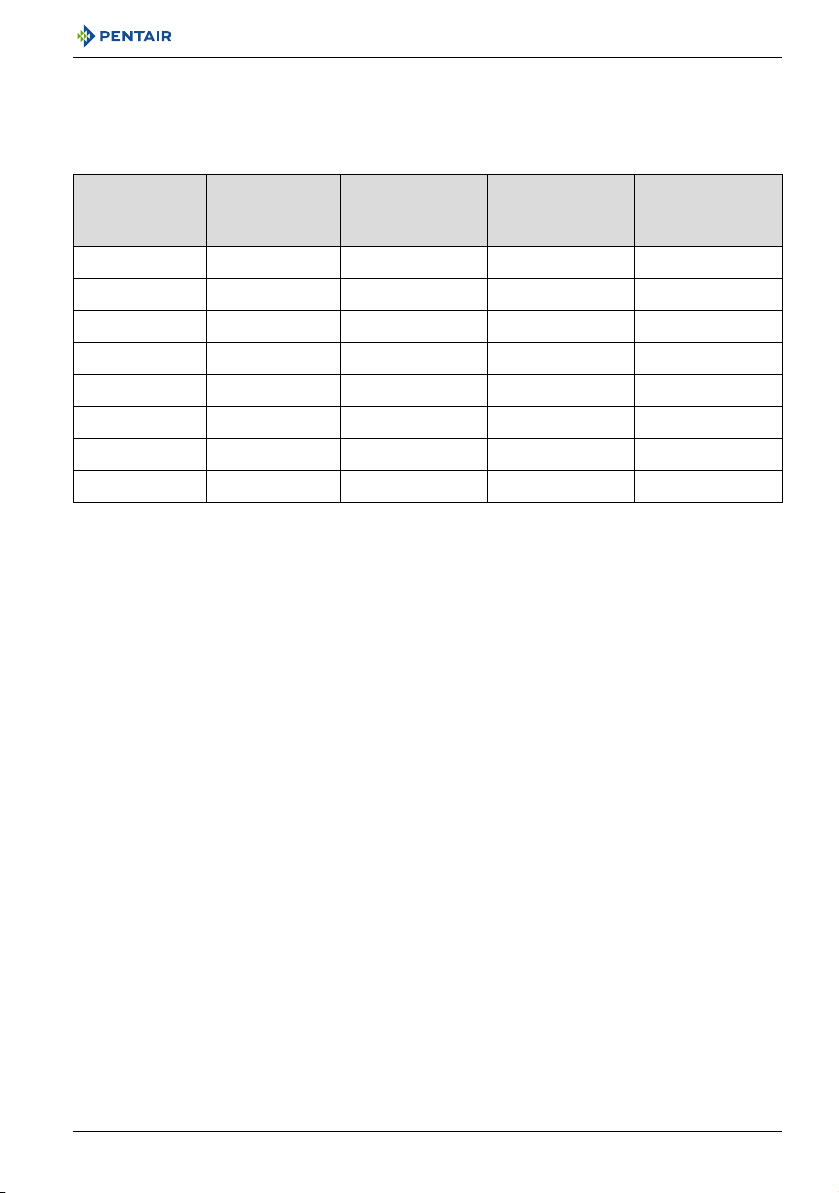

4.1. Softener configuration (Performa 268)

4.1.1. Injector/DLFC/Refill flow controller-Valve configuration

Vessel diameter

[In]

6 5 / 10 E [yellow] 0.33 0.9

7 15 F [peach] 0.33 1.2

8 20 G [tan] 0.33 1.6

9 30 H [lt purple] 0.33 2.0

10 35 J [lt blue] 0.33 2.5

12 40 K [pink] 0.33 3.5

13 50 L [orange] 0.33 4.1

14 80 L [orange] 0.33 4.8

Media volume

[L]

Injector Flow

control

Refill flow control

[gpm]

4.2. Filter configuration (Performa 263)

In filter configuration, the valve body, the camshaft and the controller are identical to the one used for

softening. The only difference is related to the valve configuration.

In filter mode, the injector size installed in the valve does not matter, it is only required to allow intern

pressure balancing during cleaning cycles. Refill flow controller is plugged.

The DLFC used is now related to the tank size and media type.

Backwash flow

control

[gpm]

4.3. Cycle time calculation

All the Logix controller range automatically calculates the unit capacity as well as the cycle time.

No calculations are therefore required.

Ref. MKT-IM-011 / A - 15.06.2017 19 / 64

Installer Manual Performa 263-268 / LOGIX 740-760 - System sizing

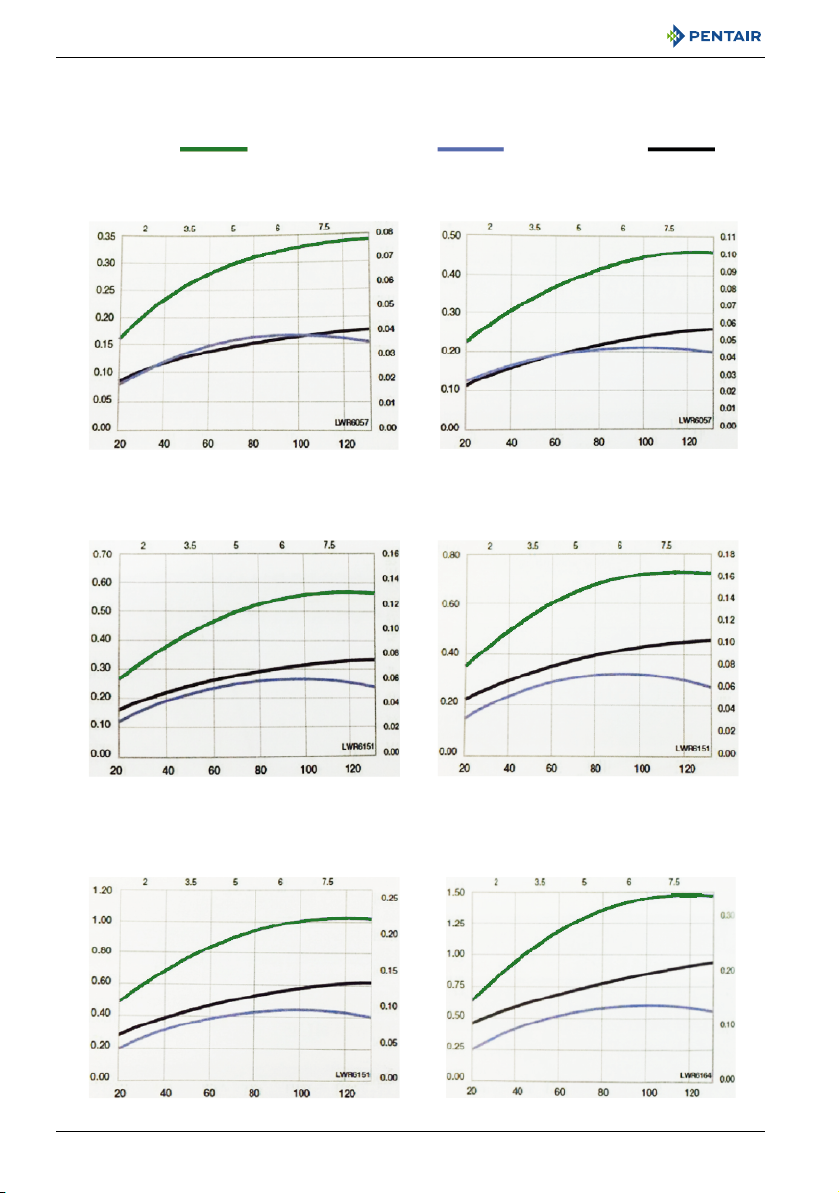

TOTAL BRINE DRAW

psi

Injector "F" (Peach)

For 7" Tanks

Injector "G" (Tan)

For 8" Tanks

Injector "H" (Light Purple)

For 9" Tanks

Injector "J" (Light Blue)

For 10" Tanks

Injector "K" (Pink)

For 12" Tanks

Injector "L" (Orange)

For 13 " and 14" Tanks

gpm

psi

psi psi

psi psi

bar bar

bar bar

barbar

gpmgpm

gpm gpm gpm

m

3

/h

m

3

/h

m

3

/h

m

3

/h

m

3

/h

m

3

/h

RINSE

4.4. Injector flow rates (tables)

The following tables represent the injectors flow rate as a function of the inlet pressure for the

different injector sizes.

20 / 64 Ref. MKT-IM-011 / A - 15.06.2017

Loading...

Loading...