Pentair AUTOTROL 460i, AUTOTROL 460TC Installation And Operation Instructions Manual

AUTOTROL 460i AND 460TC CONTROL SYSTEM

INSTALLATION AND OPERATION INSTRUCTIONS

www.pentairaqua.com

CONTENTS

WARNING:

460I ELECTRONIC DEMAND SYSTEM ................................. 2

SPECIAL FEATURES 460I .................................................... 2

PROGRAMMING THE 460I ...................................................3

CONTROL FEATURES 460I ..................................................3

PROGRAMMING THE 460TC ................................................4

ADJUSTMENT OF BRINE CONTROL 460I/460TC ................5

TROUBLESHOOTING ...........................................................6

460i ELECTRONIC DEMAND SYSTEM

The 460i electronic demand system is available as an option

on automatic controls for water conditioning equipment.

Retrofitting of existing water treatment installations is easily

accomplished, and the cost is amortized over a short period of

time by the home owner in salt and water savings.

The two key components of the 460i electronic demand system

are the microprocessor, a miniature computer located on the

circuit board, and a water meter located at the valve outlet.

The flow of conditioned water through the meter generates

electrical impulses that tell the computer the amount of water

being used.

Every day, at 2:00 a.m., the past seven days’ water usage is

statistically averaged to anticipate the amount of water to be

used the next day. The computer then determines if the water

conditioner has enough remaining capacity to supply the next

day’s needs. If not, the unit will regenerate.

If the water usage pattern changes, the computer

automatically compensates for the change and regenerates

only when needed. This results in higher operating efficiency

and lower salt usage than a conventional conditioner operating

on a fixed regeneration schedule.

SPECIAL FEATURES 460i

Memory Retention

During a power outage, all of the data in the microprocessor’s

memory is stored in a special electronic chip called NOVRAM,

Nonvolatile Random Access Memory. This data includes the

time of day, water usage amounts, and the number of days

since the last regeneration. The NOVRAM will maintain the

data in its memory. When power is restored, the NOVRAM

returns the data to the microprocessor and operation resumes

as if an outage never occurred.

The time of day will be late by the length of the power

outage. Most power outages are less than one minute in

duration. Therefore, it may be months or years before the

time display would require resetting. If an outage of one or

more hours occurs, the time of day should be reset. No other

reprogramming is necessary.

Self-Adjusting Reserve

“Reserve” refers to the amount of soft water that may be

needed for the next 24 hours. The microprocessor calculates

how much soft water was used and adjusts the reserve

capacity accordingly at the end of each day. As a result, the

reserve is kept at a minimum for optimum economy. The

reserve amount is calculated by multiplying the average past

seven days’ usage by 1.20. Regeneration decisions are based

on the calculated reserve.

In the event of unusually high water usage (twice or more than

the current daily average), the high usage amount will be used

as the reserve when the computer performs its regeneration

computation at 2:00 a.m. This is done in anticipation of a

second day of very high usage.

High Water Usage

The 460i is programmed to react to a sudden increase in

water usage. If a day’s usage is more than double the current

average, the computer anticipates that a second day of high

usage is likely to occur. The high usage amount will be used as

the reserve when the 460i performs its

regeneration computation.

Low or No Water Usage

The 460i is programmed to recognize a day of very little or no

water usage as an abnormality. It will not use data from such

a day to compute the average usage. For example, if the family

is on vacation for a week, the prior average will be maintained.

When household activity resumes, the 460i will operate as if

the vacation had not occurred.

Design Reliability

Solid-state electronics assure many years of trouble-free

performance. And, the metering system has only one moving

part, that is the rotating turbine that measures water usage

and creates magnetic pulses that are continually counted by

the microprocessor to determine the need to regenerate.

CALIFORNIA PROPOSITION 65 WARNING

This product contains chemicals known to the

State of California to cause cancer or birth

defects or other reproductive harm.

2 • AUTOTROL 460i and 460TC Control System Installation and Operation Instructions

PROGRAMMING THE 460i

Plug the wall mount transformer into a functioning electrical

outlet that is not controlled by a switch. Plug the transformer

plug into the transformer plug receptacle on the timer.

NOTE: If the included transformer cord is not long enough,

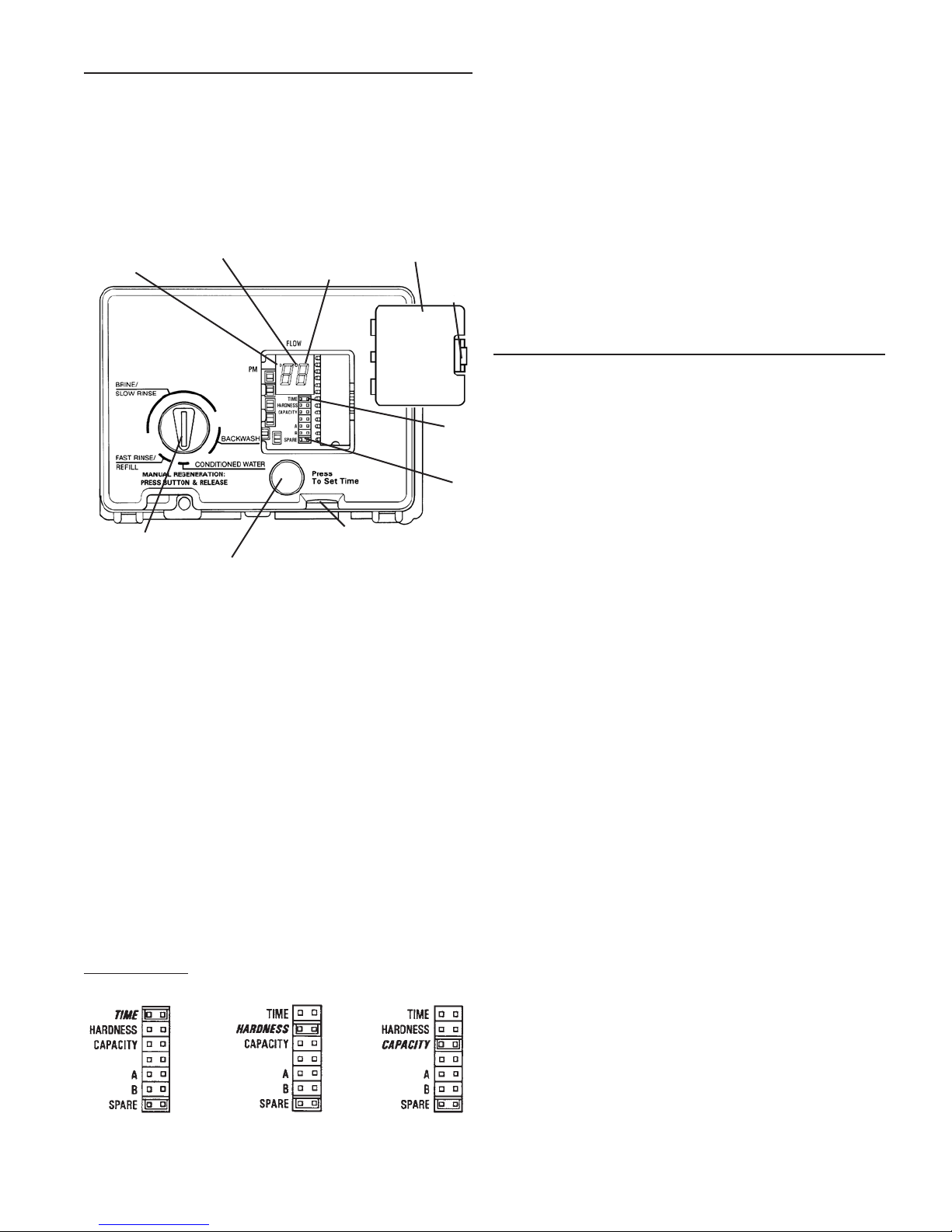

Open the access door by pushing the raised tab on the door

toward the left while pulling the tab out (Figure 1).

Time of Day Setting

With the jumper on the set of pins next to the word TIME

(Figure 2), set the time of day to the closest hour by pressing

the black TIME SET button. PM hours are indicated by a light

next to the letters PM on the display window.

NOTE: The use of a small needle nose pliers or tweezers

NOTE: The unit is factory set to regenerate at 2:00 a.m.

If you prefer to have the unit regenerate at an earlier or later

time, simply set the current time of day accordingly. To have

the unit regenerate at 4:00 a.m., two hours later, set the clock

two hours earlier than the actual current time.

a 15 foot (4.6 m) extension is available or reference

page 5 for splicing directions.

Water Flow

PM Indicator

Indicator

Knob

will aid in moving the jumper.

Indicator

Time Set Button

Hour Time Display

Transformer Plug

Receptacle

Figure 1

Access Door

Raised

Tab

Jumper

Spare

Jumper

Capacity Setting

Move the upper jumper to the set of pins next to the word

CAPACITY (Figure 4). Press the black TIME SET Button until

the correct capacity value is displayed. The capacity range is 1

to 99 kilograins. Refer to the salt setting chart (Table 1).

Return the jumper to the top set of pins next to the word TIME

and replace the access door. The next three sets of pins are

used for factory testing and are not used in normal operation.

The jumper must NOT be left on any pins other than the top

pair next to the word TIME. Otherwise, the unit may

not function.

NOTE: A spare jumper is located on the bottom set of pins.

In the event that the hardness or capacity setting must be

changed, simply follow the appropriate steps described above.

CONTROL FEATURES 460i

Time Display

The time of day to the nearest hour will continually appear

in the time display during normal conditioning operation. To

change the hour display, press the TIME SET BUTTON until the

present hour appears. The PM light will be on when the time

is between 12:00 noon and midnight. The light is off during the

AM hours.

Flow Indicator

The water flow indicator on the time display flashes whenever

service water is flowing through the valve. This allows an easy

determination of proper meter operation.

Hardness and Capacity Settings

Once the hardness and capacity settings have been set,

the information cannot be lost due to a power outage;

reprogramming is not necessary.

Guest Cycle

An extra regeneration can be achieved at any time by pressing

the pointer knob. It will take a few minutes for the regeneration

to start and the unit will return to conditioned water in two

hours. This feature is beneficial when you expect to use more

than the normal amount of water, for example: guest visits,

extra heavy laundry days, etc.

Hardness Setting

Move the upper jumper to the set of pins next to the word

HARDNESS (Figure 3). Press the black TIME SET button until

the correct hardness is displayed. The hardness range is from

1 to 99 grains per gallon.

To change water hardness stated in parts per million (PPM) to

grains per gallon (GPG), use this formula.

Parts per million = grains per gallon

17.1

Figure 2 Figure 3 Figure 4

AUTOTROL 460i and 460TC Control System Installation and Operation Instructions • 3

Loading...

Loading...