Page 1

Instruction Manual

Electronic Control Pump

ISO 9001 Certified

AQ Series

Page 2

~ 1 ~

EC Declaration of Conformity

Pentair Southern Cross declares that the machinery described:

Name : Water Pump

Model : AQ Series

Conform to the following directive:

2006/42/EC—Machinery directive

2006/95/EC—Low voltage directive

2004/108/EC—EMC (Electromagnetic compatibility) directive

Refer to the following standards:

EN ISO 12100-1:2003 EN ISO 12100-2:2003

ISO14121-1:2007

EN60335-1:2001 EN 809:1998

EN60335-2-41:2001

EN61000-6-2 EN61000-6-3

Page 3

Please read all instructions carefully before

installing your new systems, as failures caused by

incorrect installation or operation are not covered

by the warranty.

1. Introduction

1.1 Applications:

The AQ series pumps are designed for water supply

and pressure boosting in residential, commercial

and light industrial applications where low or

inadequate water pressure exists. It is suitable for

boosting pressure from underground or surface

water supplies.

1.2 Product Features:

1.2.1 Consisting of pump, motor, and electronic

controller. The built-in electronic controller

provides constant pressure which ensures

that the pump starts automatically when

water is consumed and operates continuously

until water is not required.

1.2.2 Compact design and quiet operation make the

AQ suitable for many applications.

1.2.3 The AQ is constructed from the top quality

corrosion resistant materials.

1.2.4 The motor has built-in thermal overload to

protect against high operating temperatures

and over current.

1.2.5 No pressure tank design

Easy to install and saving space.

1.2.6 Dry-run protection:

automatic reset function.

1.3 Controller instruction

When the pump starts to deliver water, the pressure

switch will sense system pressure and compare it

with the preset pressure. It will automatically start

the pump if system pressure is lower than the

preset pressure.

1.4 Operation Conditions:

1. Ambient temperature: Max. +40°C

2. Liquid temperature: +4°C ~ +40°C

3. System Pressure : Max. 8.5 kg/cm²

4. Relative humidity: Max. 85% (RH)

5. Under normal operation, it is not necessary to

adjust the pressure unless the cut in pressure is

higher than preset activation point (refer to

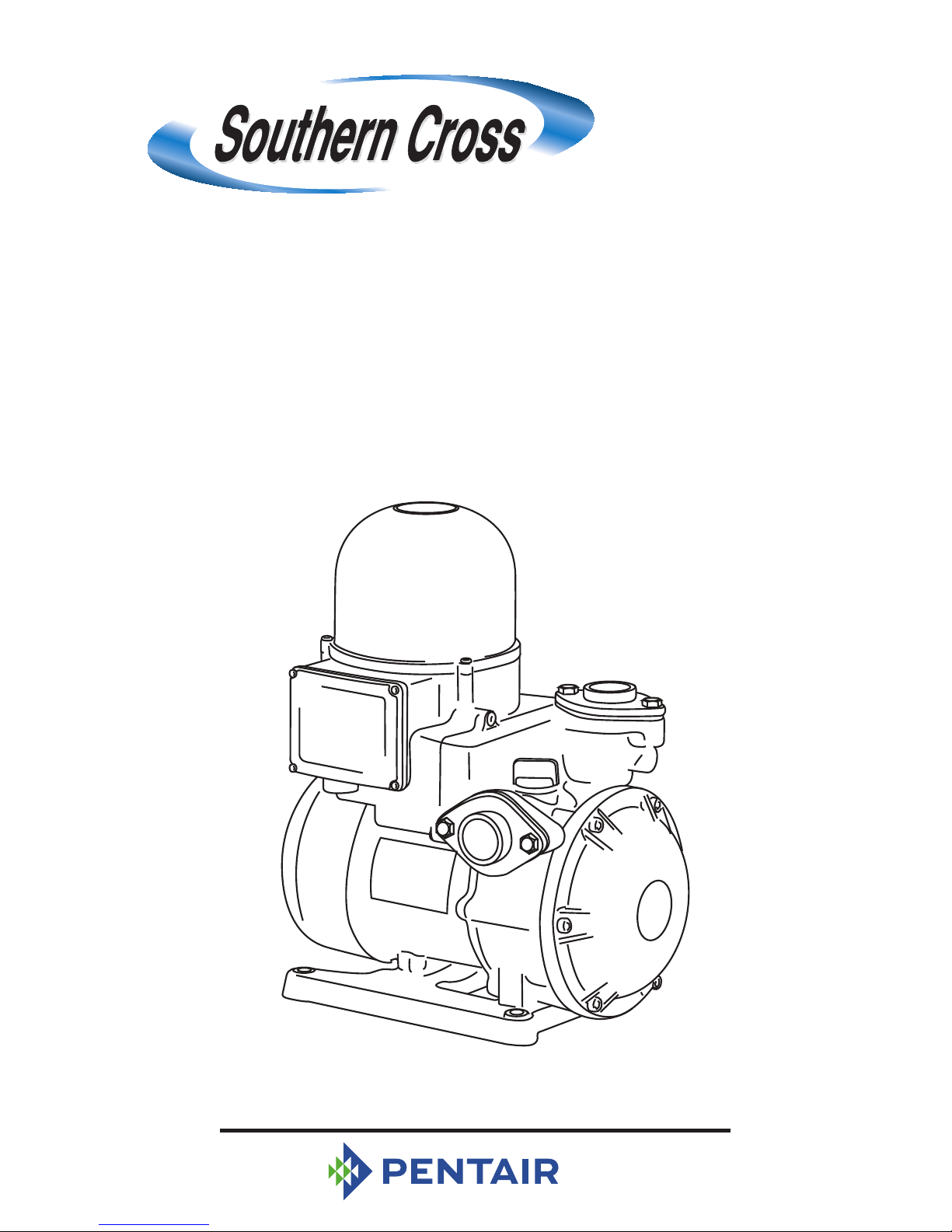

2. Automatic Pump Control

2.1 Power

Status indicator Tension LED

2.2 Failure

Faulty alarm LED

2.3 On

Light include: Pump-working LED

2.4 Reset

Manual reset switch

3. Installation

1. Choose a site with sold foundation, dry and good

ventilation. Please provide accessible space

around the pump and leave at least 30cm

clearance between your motor end to the wall.

2. Indoor: TO avoid water, do not install the pump

on ceiling, carpet or any place close to electrical

appliances. Make sure to provide a drain hole to

waste.

~ 2 ~

R

e

s

e

t

Power

Failure

On

AQ200

AQ200

ELECTRONIC CONTROL PUMP

Drain hole

When all taps are turned o there will be no ow

through the Reed switch and teh pump will

automatically shut o.

Page 4

3. Outdoor: When the pump is installed outside,

please provide a suitable cover to protect it from

all weather conditions. Please do not allow

any foreign objects fall into the motor fan cover.

base.

5. Please install the pump as close to water source

as possible. The long suction pipes may cause

pressure loss.

6. Ensure all connections are completely sealed

using thread tape only. An air leak on the suction

may cause your pump to run without a discharge

7. Make sure the environment of your pump site

free from abrasive liquid, PVC, metal chips or

anything else that will damage your pump.

8. The pump outlet has a built-in check valve.

9. For best performance, use pipes at least the same

diameter as the pump's inlet and delivery outlet

openings. It is recommended to use metal hose

for outlet piping.

4. Electrical connection

This mark is located outside of the

connection box and is a warning of an

electrical hazard.

1. Ensure the mains voltage is the same as the value

shown on the motor plate and that the pump is

safely connected to ground/earth.

2. The single phase models are supplied with plug

and lead and can be connected directly to the

mains supply.

5. Wiring diagram

WARNING:

Risk of Electric Shock - This pump is supplied with

a grounding conductor and grounding-type

attachment plug. To reduce the risk of electric

shock, be certain that it is connected only to a

properly grounded, electrical supply outlet.

Before operation, please ensure the voltage is

correct and the circuit breaker and grounding

connectors are all connected in accordance with

local regulations.

6. Operation

Do not start the pump until the system has been

Fig. 5 to start up the operation.

1. Remove the water plug and pour water into the

pump and suction piping , then secure the priming

plug.

2. When the pump inlet is lower than the water

repeated as many times as necessary till the air is

completely released from system. Then, replace

Input power

Grounding

Motor

M

1~

L1

U

V

N

FIG.5

~ 3 ~

supply level, please remove the priming plug to

let water ow into the pump chamber. It can be

Page 5

4. Connect the power cable to the electricity supply,

turn faucet ON and OFF the pump will start

immediately. If not, please refer to 13. for

troubleshooting.

5. If pump does not start, please switch it OFF. Prime

the pump as shown in Fig. 5. Or when suction is

lower than water supply level, follow instructions

in 6.2 before you start the pump.

6. After successful start up of your pump, please

turn your faucet ON and OFF several times to

the faucet, the pump should stop in 7-9 seconds

and the LED “Power” is still illuminated). Please

refer to troubleshooting check if you have any

problem.

7. When the pump is running normally, please

measure the running current with a multimeter. If

it exceeds the rated value on nameplate, please

check if your power supply voltage is within

±10%. Please contact your pump supplier if you

are not sure how to correct it.

7. Precautions

1. The pump should be shut down and the trouble

corrected if the pump is running at speed and

found to have any of the following problems:

- No liquid discharged - Not enough liquid

discharged

- Excessive vibration - Motor runs hot

2. Do not allow the pump to continually start and

stop (cycling) as this will reduce the motor life.

3. Cycling can occur on pressure units where there is

a leak in the discharge plumbing.

Fig. 6

Fig. 7

8. Pressure switch

Adjust the pressure switch setting as shown in Fig 7.

Make sure the system is primed.

The pump is supplied with a preset pressure in the

pressure switch. For most applications, it will be

required. This can be achieved by following the

instructions below. However, it is highly recommended

that the adjustment is only done by the professional

personnel.

Instructions for pressure adjustment (Fig. 7):

1. If pump does not start when tap is on, adjust

counter clockwise ("+") till it starts.

2. If pump does not stop when all taps are turned

o, adjust clockwise (”-”) till it stops.

9. Adjustments and Reset procedures

For most applications AQ pumps need no

adjustment to operate under normal conditions. It

is only necessary when the inlet pressure is higher

than the factory preset range. It is highly

recommended that the adjustment is performed by

the professional personnel.

+

-

+

-

~ 4 ~

3. For intitial startup or after long periods of

inactivity, place a screwdrive against the shaft at

the motor end and turn clockwise to see if rotor

spins freely (Fig. 6) If it does , you are free to run

the pump.

several times to make sure it operates normally.

Page 6

10. Frequently asked questions:

1. What is the maximum pressure switch activation

point?

Adjust the pressure only when the cut in pressure

is higher than the preset activation point. Do not

adjust the pressure to exceed the maximum

pressure range (refer to specication) because the

pump will not stop if teh pressure is above the

maximum pump pressure.

2

. How is the dry-run condition determined and the

protection provided?

When the pump is run dry for 2 minutes, it will

attempts to restart. When all 3 attempts are

failed, the pump will rest for 1 hour and then

attempts to restart. This protection mode will be

repeated until the water supply is back to normal.

system, air loss in the pressure tank or leak in the

pipeline, the protection is provided:

The pump will run for 8 seconds and stop for

about 3 seconds. When the cycling mode repeat

for 15 times consecutively, the pump will be rest

for 1 hour. Then it will start over the protection

mode until the problem is corrected.

Note: Above unusual pump shutdown, Press

“Reset” button to reset the pump or users may

remove power plug for more than 6 seconds and

reconnect again to restart, if it is necessary.

11. Dimensions: (mm)

~ 5 ~

Model

AQ200

AQ400

AQ800

Power

( w )

180

370

750

Voltage

( V )

200-240

110 220

200-240

110 220

200-240

110 220

Phase

( Ø )

1

1

1

Outlet

( in. )

1"

1"

1"

P max.

2.3

2.2

2.7

2.6

3.5

4.2

Q max.

( L/min )

55

60

70

60

90

80

Amp's

( A )

1.8

4.0 2.0

3

6.0 3.0

4.4

11 5.5

Inlet

( in. )

1"

1"

1"

Preset

activation

point

1.2

1.4

1.8

1.8

2.0

3.0

N.W.

(kg)

7.8

9.6

11.4

175 B

A

130

101 50

85

78

C

192

345

205 160

58

Model

AQ200

AQ400

AQ800

A

297

273

305

279

351

351

Hz

50

60

50

60

50

60

B

90

66

99

73

99

99

C

95

71

104

78

104

104

Outlet

Inlet

Cycle

( Hz )

50

60

50

60

50

60

Page 7

13. Troubleshooting

Problem

1. Pump doesn't

stop:

2. Pump doesn't

start:

3. The pump

starts and stops

frequently.

4. Pump runs

normal but with

very low

Cause

a. Water leakage higher than 3 lpm.

b. Manual start switch (RESET) is

blocked.

c. Failure of the electronic circuit

board.

a. Not enough water supply, and the

LED light (FAILURE) is illuminated.

b. Pump is blocked: LED (FAILURE)

light is illuminated and by pressing

the manual start switch (RESET),

the LED (ON) is illuminated; but the

pump doesn't work.

c. Failure of the electronic circuit

board.

d. No electrical supply.

e. Pump pressure is too low and the

LED light (FAILURE) is illuminated.

f. Air Pocket in the system, and

LED(FAILURE) is illuminated.

a. Leakage in the system.

a. Poor water supply

Remedy

Check the system,the tap,etc, and

1. Press it for several times.

2. Consult your dealer if the problem

persists.

Replace it.

Check the water supply and restart

the pump by pressing the reset

switch(RESET).

Consult your dealer.

seconds and turn it on again. If the

pump doesn't start immediately, it

needs to replace the circuit board.

Check the electrical supply.

The LED light (POWER) should be

illuminated.

Check if the pump max pressure is at

the starting pressure of the

controller.

Check if all pipe joints are tightened.

Reprime the pump to force the air

out of the system.

Stop the leak.

check if water supply is adequate

and if the suction pipe is blocked.

Before starting troubleshooting the pump, make sure that the power has been

~ 6 ~

Switch o power supply, wait 6

Page 8

Phone: 131 PUMP Web: www.southerncross.pentair.com

A division of Pentair Flow Control Pacific Pty Ltd

A.B.N. 83 000 922 690

Loading...

Loading...