Pentair Anderson Greenwood 93 Series Installation And Maintenance Instructions Manual

ANDERSON GREENWOOD SERIES 93 POSITIVE PRESSURE POSRV

InstallatIon and MaIntenance InstructIons

Before installation these instructions must be fully read and understood

TABLE OF CONTENTS

1. General valve description and start-up ....... 1

2. Main valve maintenance ............................... 2

3. Pilot maintenance ......................................... 4

4. Pilot adjustment ............................................ 6

5. Accessory repair ............................................ 8

6. Leak testing assembly .................................. 9

7. Pilot set pressure field test procedure ........ 9

8. Soft goods repair kits .................................. 10

Installation and maintenance instructions for

Series 93 Positive Pressure Pilot Operated

Safety Relief Valves (POSRV).

The intent of these instructions is to acquaint

the user with the storage, installation and

operation of this product. Please read these

instructions carefully before installation.

WARNING

Removal of the seal wires in an attempt to adjust

and/or repair this product by unauthorized or

unqualified persons voids the product warranty

and may cause damage to equipment and serious

injury or death to persons.

The product is a safety related component

intended for use in critical applications. The

improper application, installation or maintenance

of the product or the use of parts or components

not manufactured by Anderson Greenwood may

result in a failure of the product.

Any installation, maintenance, adjustment, test,

etc. performed on the product must be done

in accordance with the requirements of all

applicable Anderson Greenwood procedures and

instructions as well as applicable National and

International Codes and Standards.

SAFETY PRECAUTIONS

When the pressure relief valve is under pressure

never place any part of your body nearthe pilot

exhaust nor the outlet of themainvalve.

The main valve outlet should be piped or vented

to a safe location.

Always wear proper safety gear to protect

head, eyes, ears, etc. anytime you are near

pressurized valves.

Never attempt to remove the pressure relief

valve from a system that is pressurized.

Never make adjustments to or perform

maintenance on the pressure relief valve while

in service unless the valve is isolated from

the system pressure. If not properly isolated

from the system pressure, the pressure relief

valve may inadvertently open resulting in

seriousinjury.

Remove the pressure relief valve prior to

performing any pressure testing of the system.

The safety of lives and property often depends

on the proper operation of the pressure relief

valve. The valve must be maintained according

to appropriate instructions and must be

periodically tested and reconditioned to ensure

correct function.

STORAGE AND HANDLING

Pressure relief valve performance may be

adversely affected if the valve is stored for an

extended period without proper protection.

Rough handling and dirt may damage, deform,

or cause misalignment of valve parts and may

alter the pressure setting and adversely affect

valve performance and seat tightness.

It is recommended that the valve be stored in

the original shipping container in a warehouse

or as a minimum on a dry surface with a

protective covering until installation. Inlet and

outlet protectors should remain in place until

the valve is ready to be installed in the system.

1 GENERAL VALVE DESCRIPTION AND

START-UP

1.1 Operation

The Anderson Greenwood Pilot Operated Safety

Relief Valves utilize the principle of backloading the top of a differential area diaphragm

with line pressure to hold the diaphragm

closed up to set pressure. At set pressure the

pilot valve relieves, partially evacuating the

dome (volume above the diaphragm) and the

seat assembly lifts permitting discharge from

the main valve. When the pilot reseats, line

pressure is diverted to the dome closing the

main valve.

Engineering Doc. #05.9040.081 Rev. J

www.pentair.com/valves VCIOM-03092-EN 15/09© 2014 Pentair plc. All Rights Reserved.

ANDERSON GREENWOOD SERIES 93 POSITIVE PRESSURE POSRV

InstallatIon and MaIntenance InstructIons

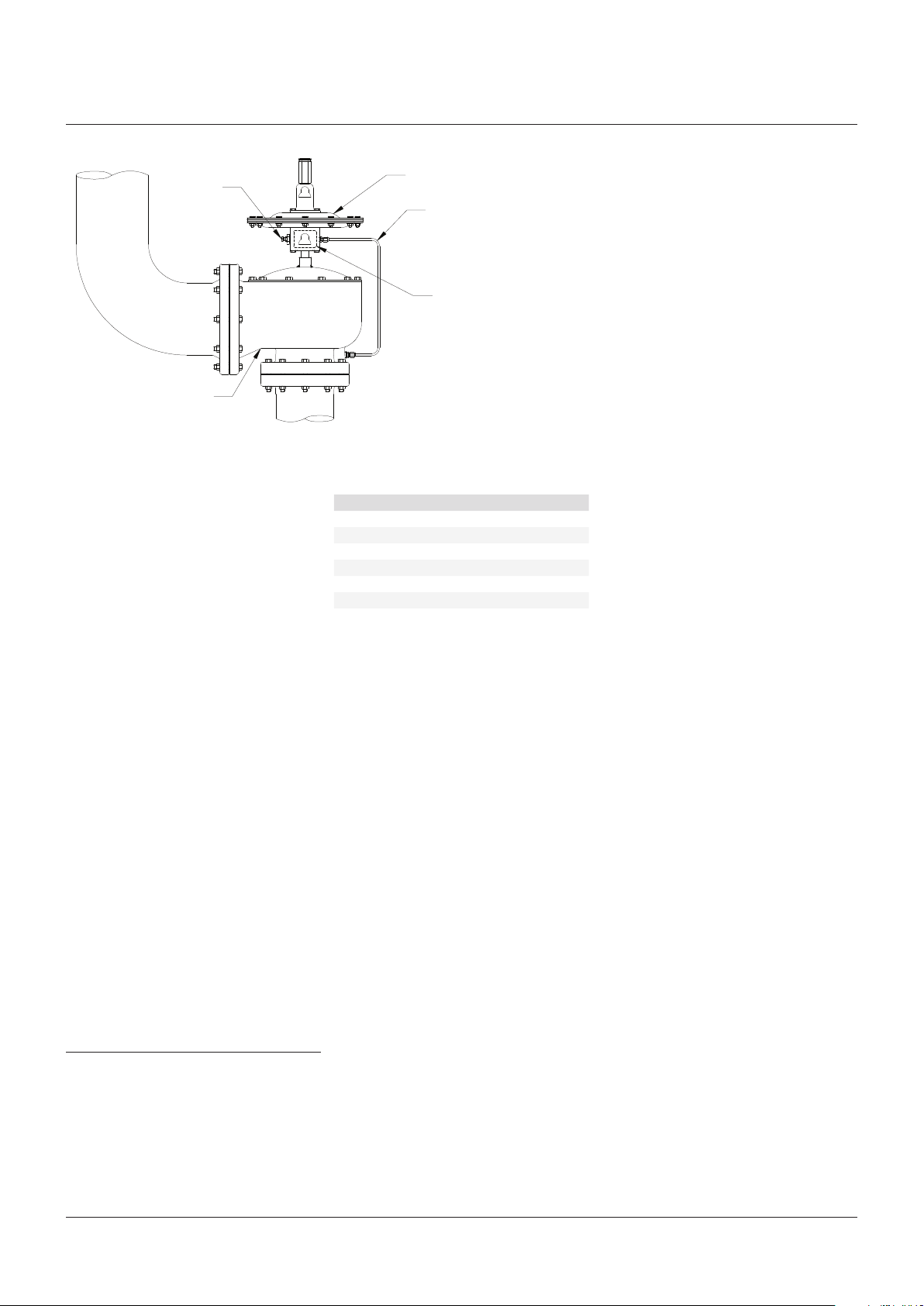

External

blowdown

Outlet

adjustment

Main valve

(typical)

Inlet

FIGURE 1

1.2 Installation

Both inlet and outlet may be standard ANSI or

DIN flange connections and are to be installed

in accordance with accepted piping practices.

The installed position of the safety valve should

be in the upright position as shown in Figure 1.

When remote pressure pick-up is used the pilot

supply tube is connected to a remote location

rather than to the inlet neck of the valve. If a

block valve is used in the remote pilot supply

line, be sure it is opened before pressurizing

the system.

Note: remote pressure pick-up piping must

have the equivalent flow area of ½” tubing for

lengths up to 20 feet. For lengths greater than

20 feet, larger tubing or pipe should be used.

1.3 Start-up

There must be pressure at the valve inlet

to establish a differential in force across

the diaphragm and “load” it in the closed

position. Pressure must pass through the pilot

supply tube and pilot and exert force on the

diaphragm. On normal start-up the valve loads

itself without incident as pressure increases.

Block valves are often used under safety valves

in order to isolate them when maintenance

is required. When putting the safety valve in

service be sure the block valve is fully opened.

If the block valve is opened after system startup, the safety valve may briefly vent to the

atmosphere before the dome gets pressurized.

It will then close.

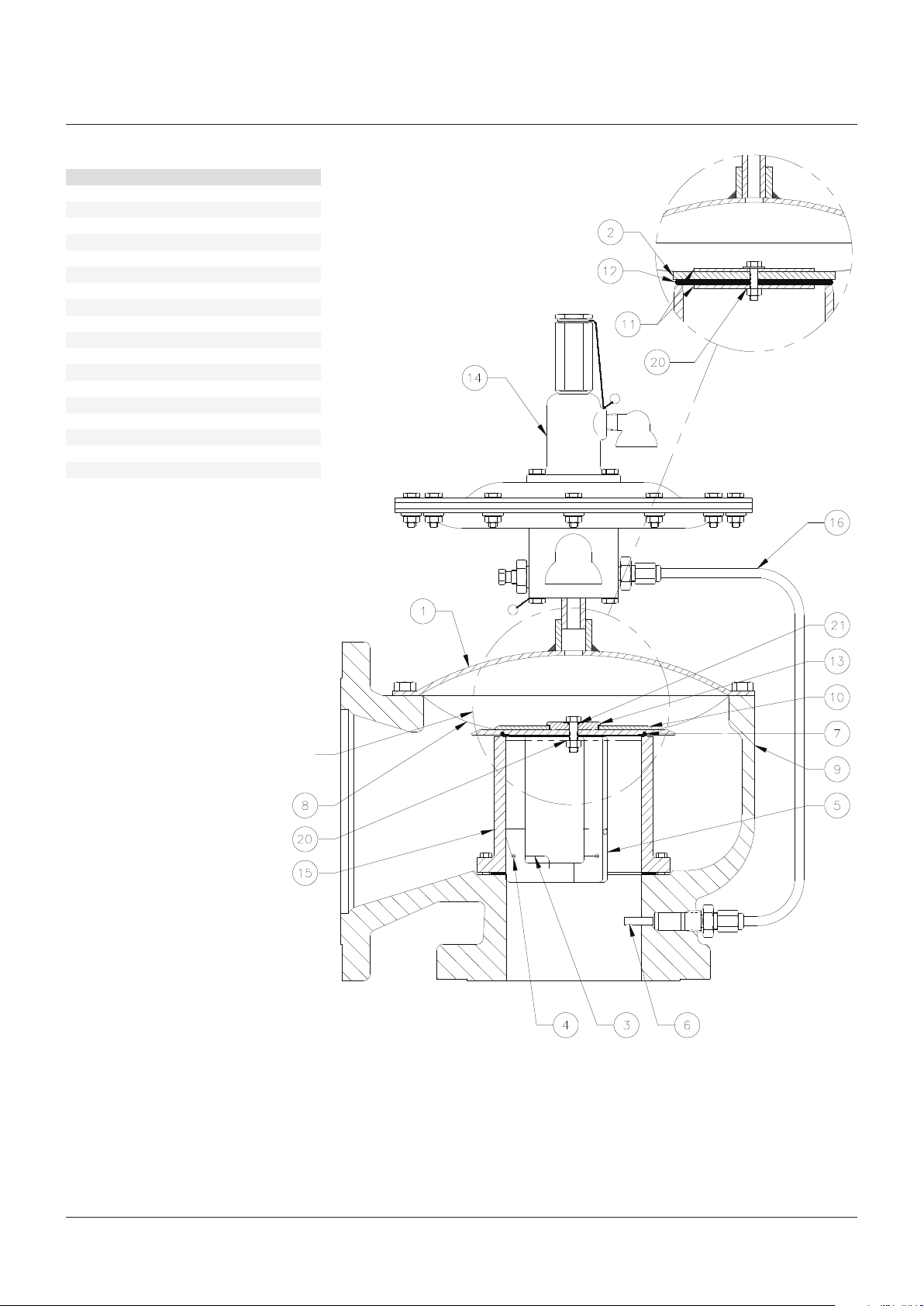

2 MAIN VALVE MAINTENANCE (REFER TO

FIGURES 2 AND 2A)

2.1 Valve configuration

Two different valve internals are used in the

main valve, depending on set pressure. The

sponge seat is used for the set pressures

shown below. The O-ring seat with guide is

used for all pressures above these values. For

some applications, a guide may be used in

place of Item 11 with a sponge seat.

Pilot valve

Supply tube

Nameplate

SET PRESSURES WHERE SPONGE SEAT

ISUSED

Valve size Set pressure (psig)

2 x 3 Below 2.5 psig

3 x 4 Below 1.5 psig

4 x 6 Below 1.0 psig

6 x 8 Below 1.0 psig

8 x10 Below 1.0 psig

10 x12 Below 1.0 psig

12 x16 Below 1.0 psig

2.2 Disassembly

Disconnect the supply tube from the pilot,

remove the cap bolts, lift the cap from the valve

body and lift the diaphragm, seat and guide

(where used) from the valve. Remove the seat

bolt(s) to separate the diaphragm from the

seat, guide, and retainer plates.

2.3 Repair

Inspect the nozzle seating area for nicks or

scratches. If they cannot be removed with

crocus cloth or fine sandpaper, the nozzle must

be remachined. On steel valves the nozzle

may be removed from the body. Machining of

the nozzles should be limited to .06” material

removal.

2.4 Assembly

Reassemble the diaphragm, seat guide,

and pilot supply tube in the reverse order of

disassembly. Apply a light film of lubricant to

all threaded parts. Care should be taken to

adequately tighten the seat bolt(s) on those

valves with guides to prevent the diaphragm

from pulling away from the bolt under

pressure.

On valves with sponge seats (no guide), the

seat bolt need not be tightened as much since

these valves are used at lower pressures and

excessive tightening will distort the seat.

Carefully insert the guide (where used) squarely

into the nozzle and lower the diaphragm

assembly into place. Align the holes on the

diaphragm O.D. with those on the body.

The guide spring, Item 3, is used to create

frictional drag to prevent valve chatter caused

by excessive inlet piping pressure losses. The

tension of these springs is correct when the

diaphragm/guide assembly slowly free falls to

the closed position. If the assembly will not do

this, adjust the spring tension by bending the

tail or lower half of the spring.

Refer to paragraph 8 for Soft goods repair kits

2

ANDERSON GREENWOOD SERIES 93 POSITIVE PRESSURE POSRV

InstallatIon and MaIntenance InstructIons

PARTS LIST

Item Description

1 Cap

2 Retainer plate

3 Guide spring

4 Spring pin

5 Guide

6 Dipper tube

7 O-ring, seat*

8 Diaphragm*

9 Body

10 Retainer, diaphragm

11 Seat retainer

12 Seat, sponge

13 Top plate

14 Pilot valve

15 Nozzle

16 Supply

20 Seal, thread**

21 O-ring*

1. Used in 8" and larger valves only

* Recommended spare parts for repair

** Used with elastomer diaphragms only

[1]

Sponge seat

(no guide)

See PTFE diaphragm

deflector detail next page

FIGURE 2

3