Page 1

ACU-TROL® CHEMICAL CONTROLLER

FOR POOL AND SPA

MODEL AK110

Certied to

NS F/ANSI Standa rd 50

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

INSTALLATION AND

USER’S GUIDE

Page 2

CUSTOMER SERVICE / TECHNICAL SUPPORT

If you have questions about ordering Pentair Aquatic Systems replacement parts, and pool products, please contact:

Customer Service and Technical Support, USA

(8 A.M. to 4:30 P.M. — Eastern/Pacific Times)

Phone: (800) 831-7133

Fax: (800) 284-4151

Web site

Visit www.pentairpool.com or www.staritepool.com

Sanford, North Carolina (8 A.M. to 4:30 P.M. ET)

Phone: (919) 566-8000

Fax: (919) 566-8920

Moorpark, California (8 A.M. to 5 P.M. PT)

Phone: (805) 553-5000 (Ext. 5591)

Fax: (805) 553-5515

2

Page 3

CONTENTS

SECTION 1 INFORMATION

IMPORTANT WARNING AND SAFETY INSTRUCTIONS ..............................................................5-6

CONTROLLER OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

SECTION 2 INSTALLATION

INSTALLATION PREPARATION .................................................................................8

INSTALLATION SUMMARY .................................................................................8

MOUNTING INSTRUCTIONS ................................................................................9

ELECTRICAL SPECIFICATIONS .................................................................................10

INPUT VOLTAGE SELECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

CONNECTING POWER .......................................................................................10

ELECTRICAL LOADS .......................................................................................11

RELAY BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

CHEMICAL FEED PUMP LOCATION ...........................................................................13

HEATER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

PLUMBING INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

SECTION 3 HARDWARE

MODULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

SENSOR MODULES .......................................................................................16

COMMUNICATION MODULES ...............................................................................16

RELAY MODULES .........................................................................................16

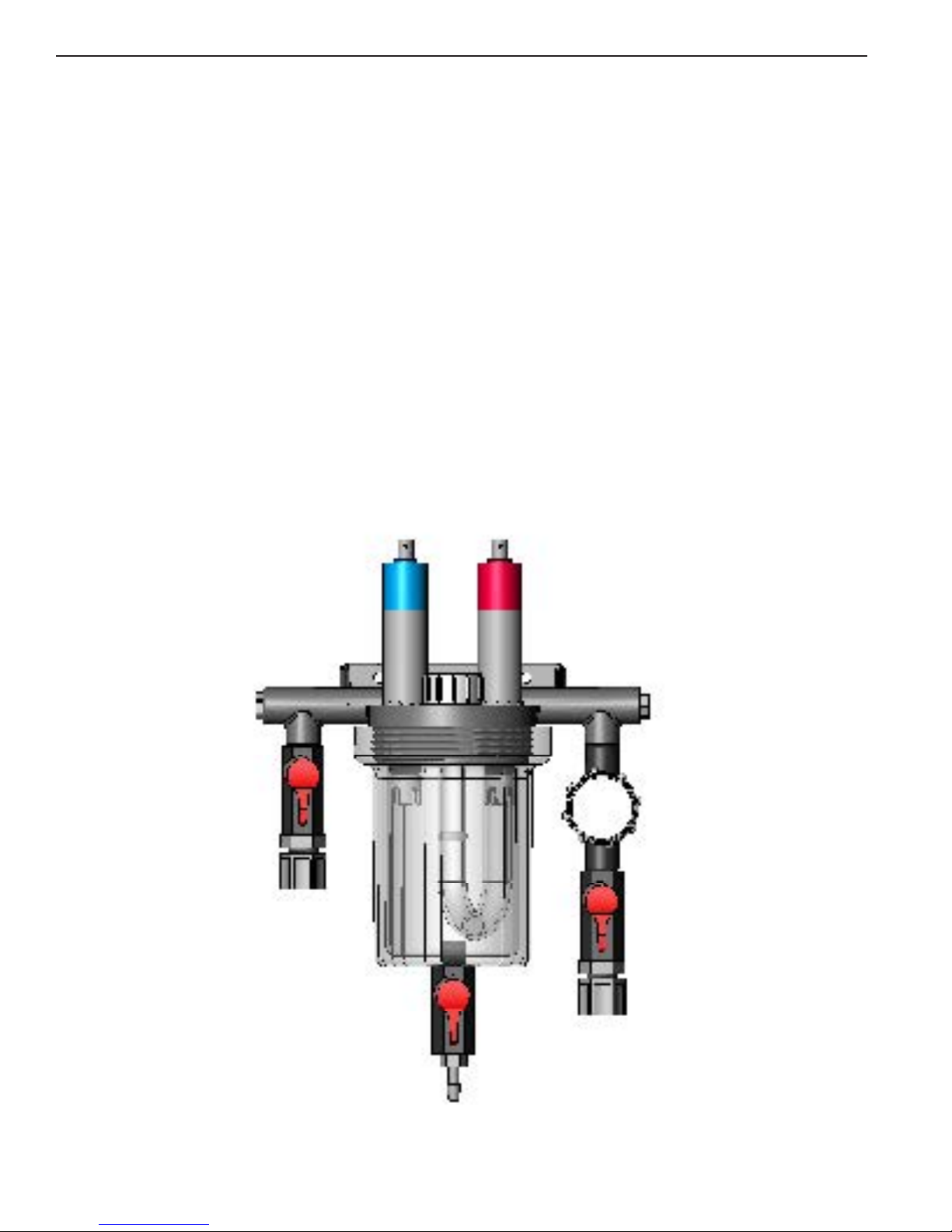

SECTION 4 AK1200 FLOW CELL

AK1200 FLOW CELL .........................................................................................18

FLOW CELL ASSEMBLY ....................................................................................19

FLOW CELL MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

INLET AND EXIT LINES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

SENSORS ...............................................................................................19

SECTION 5 SENSORS

pH AND ORP SENSORS ......................................................................................21

CALCULATED PPM ..........................................................................................22

AKCOLOR PPM .............................................................................................22

TEMPERATURE SENSOR ......................................................................................22

FLOW SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

SENSOR CARE .............................................................................................23

FINISHING AND TESTING THE INSTALLATION ....................................................................23

SECTION 6 OPERATIONS

CONTROLLER WINDOW NAVIGATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SELECTING ITEMS IN THE WINDOWS ........................................................................25

MAKING CHANGES .......................................................................................25

START UP .................................................................................................26

INITIALIZING THE CONTROLLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

POWER UP SCREEN .........................................................................................26

DISPLAY SCREEN ...........................................................................................27

THE DISPLAY SCREEN .......................................................................................27

CALIBRATING TEMPERATURE ...............................................................................27

CALIBRATING pH .........................................................................................28

CALIBRATING ORP ........................................................................................28

CALIBRATING CALCULATED PPM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

MANUAL RELAY CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

RELAY TIME DISPLAY ......................................................................................30

SET UP FLOW ............................................................................................30

CONFIGURATION MENU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

NAME ..................................................................................................32

SYSTEM ................................................................................................32

3

Page 4

CONTENTS (Continued)

PROGRAMMING .........................................................................................33

SERVICE ................................................................................................35

DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

COMMUNICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

PAGER SETUP SCREENS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

EMAIL SETUP ............................................................................................37

SECURITY ...............................................................................................37

WIZARDS ...............................................................................................38

SECTION 7 TROUBLESHOOTING

COMMON PROBLEMS .......................................................................................39

REAL TIME CLOCK ..........................................................................................39

ORP TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

USING THE TEST STRIP ......................................................................................40

AKCOLOR PPM TROUBLESHOOTING ............................................................................41

pH TROUBLESHOOTING ......................................................................................41

SECTION 8 APPENDIXES

UTILITY PASSWORDS 9000-9020 ..............................................................................42

SET-UP DIGITAL FLOW .......................................................................................42

PROPORTIONAL FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

SECTION 9 WIRING DIAGRAMS

RELAY WIRING DIAGRAMS ...................................................................................43

SENSOR WIRING DIAGRAMS .................................................................................44

SECTION 10 MENUS

SCREEN NAVIGATION KEYS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

MAIN STATUS SCREEN NAVIGATIONS ..........................................................................46

RELAY AND ALARM TIMER SCREEN NAVIGATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

CONFIGURATION MENU SCREEN NAVIGATION ...................................................................52

CONTROLLER NAME SCREEN NAVIGATION ......................................................................54

SYSTEM SETUP SCREEN NAVIGATION ..........................................................................56

PROGRAMMING SCREEN NAVIGATION , pH MIX TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

PROGRAMMING SCREEN NAVIGATION, pH CYCLE TIME. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

PROGRAMMING SCREEN NAVIGATION, ORP MIX TIME ............................................................62

PROGRAMMING SCREEN NAVIGATION, ORP CYCLE TIME ..........................................................66

PROGRAMMING SCREEN NAVIGATION, ORP CAL HYPO ............................................................70

PROGRAMMING SCREEN NAVIGATION, PPM CYCLE TIME ..........................................................74

PROGRAMMING SCREEN NAVIGATION, PMM MIX TIME ...........................................................78

PROGRAMMING SCREEN NAVIGATION, PROBE CLEAN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

PROGRAMMING SCREEN NAVIGATION, HEATER ..................................................................84

PROGRAMMING SCREEN NAVIGATION, ALARM OUT ..............................................................96

PROGRAMMING SCREEN NAVIGATION, AUX. MAKE-UP (AUTO-FILL) ..................................................90

PROGRAMMING SCREEN NAVIGATION, DAILY EVENT .............................................................92

PROGRAMMING SCREEN NAVIGATION, WEEKLY EVENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

PROGRAMMING SCREEN NAVIGATION, FRONT PANEL ALARM ......................................................96

PROGRAMMING SCREEN NAVIGATION, PAGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

PROGRAMMING SCREEN NAVIGATION, EMAIL ..................................................................104

WIZARDS SETUP SCREEN NAVIGATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

DATA SCREEN NAVIGATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

COMMUNICATIONS SCREEN DIAL-UP ..........................................................................114

COMMUNICATIONS SCREEN INTERNET MODEMS ................................................................118

SECURITY SETUP SCREEN NAVIGATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

AKCOLOR SCREEN NAVIGATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

SERVICE SCREEN NAVIGATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

AK110 CHEMICAL CONTROLLER ILLUSTRATED PARTS LIST ..................................................130

4

Page 5

IMPORTANT WARNING AND SAFETY INSTRUCTIONS

SERIOUS BODILY INJURY OR DEATH CAN RESULT IF THIS PRODUCT IS NOT INSTALLED

AND USED CORRECTLY.

INSTALLERS, POOL OPERATORS AND POOL OWNERS MUST READ THESE WARNINGS AND

ALL INSTRUCTIONS BEFORE USING THIS PRODUCT.

Most states and local codes regulate the construction, installation, and operation of

public pools and spas, and the construction of residential pools and spas. It is important

to comply with these codes, many of which directly regulate the installation and use

of this product. Consult your local building and health codes for more information.

IMPORTANT NOTICE - Attention Installer: This Installation and User’s Guide

(“Guide”) contains important information about the installation, operation and safe use

of this product. This Guide should be given to the owner and/or operator of this product.

DO NOT INSTALL THE AK110 CHEMICAL CONTROLLER WHERE IT CAN BE READILY

ACCESSIBLE T O THE PUBLIC.

Before installing this product, read and follow all warning notices and instructions in this

Guide. Failure to follow warnings and instructions can result in severe injury, death, or

property damage. Call (800) 831-7133 for additional free copies of these instructions.

RISK OF ELECTRICAL SHOCK OR ELECTROCUTION:

BEFORE WORKING ON THE AK110 CHEMICAL CONTROLLER: Always disconnect power to the

AK110 controller at the circuit breaker before servicing. Failure to do so could

result in death or serious injury to service person, pool users or others due to electric

shock.

BE SURE TO DISCONNECT ALL SUPPLY CONNECTIONS BEFORE SERVICING.

This product must be installed by a licensed or certified electrician or a qualified pool professional in accordance

with the National Electrical Code (NEC), NFPA 70 or the Canadian Electrical Code (CEC), CSA C22.2. All

applicable local installation codes and ordinances must also be adhered to. Improper installation will create an

electrical hazard which could result in death or serious injury to pool users, installers or others due to electrical

shock, and may also cause damage to property.

BEFORE USING YOUR POOL, SPA OR HOT TUB, CHECK THE

pH AND SANITIZER LEVELS OF THE WATER

.

Do not permit children to operate this equipment.

When mixing acid with water, ALWAYS ADD ACID TO WATER. NEVER ADD WATER TO ACID.

When adding any chemical to the pool/spa, be sure to follow the manufacturer’s instructions

thoroughly.

DO NOT MIX SODIUM HYPOCHLORITE AND MURATIC ACID

Risk of electrical shock. Connect AK110 Chemical Controller to a ground-fault interrupter-circuit

(GFCI). Contact a qualified electrician if you cannot verify that the receptacle is protected by a

GFCI.

IF “CLEAR OVERFEED LIMIT” SETTING IS SET TO 24 HOURS, DO NOT SET “FEED TIME”

GREATER THAN 20 HOURS AS THIS WILL VOID NSF CERTIFICATION.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

5

Page 6

IMPORTANT WARNING AND SAFETY INSTRUCTIONS

WARNING CHEMICAL BURN HAZARD: Make sure all pumps are switched off at the main circuit

breakers at the house before drilling into any pipes. Securely fasten all electrical, water and

chemical lines. Locate chemical feed pumps and chemical storage tanks in a safe and secure

area.

Strictly follow the acid manuf acturers safety and handling protocols including hand, body and eye protection

when transferring or handling acid. Safety precautions should be used when handling Muriatic acid to

control pH water lev els. Muriatic acid can cause serious body injury and damage pool equipment. Extra

care must be taken when installing, maintaining and operating acid pump feed systems. Acid is dangerous to

handle and should be properly contained, transported, poured, stored, and dispensed.

Check the pH and sanitizer levels of the water before use.

Periodically use an independent pH and Chlorine test kit to verify that pH and chlorine is at a

safe level. If the pH and Oxidation Reduction Potential (ORP) or Flow Cell sensors are broken,

depleted or dirty with oils, lotions, or other contaminants, they can report inaccurate results to the

system causing incorrect water chemistry, which could harm people or equipment.

Check the main status display each day to ensure there are no Alarm messages.

See “Troubleshooting” section for more information.installing, maintaining and operating acid

pump feed systems. Acid is dangerous to handle and should be properly contained, transported,

poured, stored, and dispensed.

GENERAL WARNINGS AND SAFETY PRECATIONS

PLEASE READ THIS USER MANUAL completely before installing or operating the equipment. The Controller Pool and Spa Chemical Controller is a Class 1 product for protection against electric shock and a Type 1 product with regards to disconnection of the control circuits.

Be sure to observe the following safety precautions:

• Donotpermitanyoneuntrainedorundertheageof18tousethisproduct.

• Unitmustbeproperlygrounded.

• Frontpanelmustbeclosedbeforepowerisapplied.

• AlwaysturnOFFmaincircuitbreakertounitandallequipmentbeforeservicing.

• Touchingthecontroller’sinternalpartscouldresultininjuryandordamagetothecontroller.Incaseofa

malfunction, only a qualified technician should repair the controller.

• RiskofElectricShock.Connectonlytoagroundingtypereceptacleprotectedbyaground-faultcircuitinterrupter(GFCI).

• Donotburycord.Routecordtoeliminateexternaldamage.

• Becarefulnottodamageanyoftheinsulationonwiresorthepowercord.Shouldthecordbedamaged,returnittoyourdealerfor

a replacement. Continued use could result in fire or electric shock.

• Toreducetheriskofelectricshock,donotuseanextensioncordtoconnectunittoelectricsupply,providea

properly located GFCI.

• Neverremoveorinstallanycablesonthecircuitcardswhenpowerisapplied,damagetothecomponentsmay

occur.

!

WARNING

CHEMICAL BURN HAZARD

Make sure pumps are OFF before drilling into pipes.

Securely fasten all electrical, water and chemical lines. Locate chemical feed

pumps and chemical storage tanks in a safe and secure area.

CHEMICAL HAZARD CONDITION

DO NOT TURN CHEMICAL FEED PUMPS ON WHEN BOTH FLOW

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

6

!

WARNING

CELL VALVES ARE CLOSED.

Page 7

AK110 Pool and Spa Chemical Controller Overview

The AK110PS Pool and Spa Chemical Controller ("Controller") is a microprocessor based modular automation system

capable of continuous local or remote monitoring and control of water chemistry for pool and spa applications. The

Controller will maintain the pH and sanitizer levels of your water system automatically. Customized applications are

possiblewiththeadditionofoptionalexpansionmodules.

MODULAR: The Controller is designed to grow with the needs of the customer. There are optional modules that can

be installed as the need arises without having to remove the Controller from the wall.

INTERFACE: The Controller uses a built-in keypad with 16 buttons, and an easy to read 80 character liquid crystal

display.Thedisplay’sinternalback-lightprovidesviewinginlowlightconditions.Theback-lightilluminationtimecanbe

adjustedtosuittheoperator.

MENUS:

The Controller features easy to use display menus for on screen navigation.

MEMORY:

In case of power loss, all set-points and programming are retained in nonvolatile memory. These values will

be protected for a minimum ten (10) years without having power applied.

DATA RECORDING: The Controller has the ability to record data at 2 hour time intervals. Over 1 month of data can be

recorded before filling up the memory. When the memory is full the new data will overwrite the oldest data.

RELAYS: The Controller can control up to three (3) relays. There are various types of relay configurations available to

different types of load requirements.

DISPLAYS: The Controller can display measurements, relay ON/OFF states, length of time that relays have been on

and the alarm status.

SENSORS: The Controller can measure readings and control based on inputs from the following sensors: temperature,

digital flow,

pH, ORP, and AKColor PPM.

VOLTAGE: The Controller includes a switch to select the input voltage of 110 or 220 VAC (single or dual phase).

HEALTH: The Controller can be configured to maintain the bacteriological and physiological requirements of state and

local health departments. In addition, the Controller has the capability to be configured such that equipment can be

protected from the effects of improper water balance.

REMOTE MONITORING:TheControllercanbeeasilyconguredforremote,fullduplexcommunicationusingan

internal 56K modem and a phone line, or a wireless modem and an internet connection. This feature allows a user

remote access to Controller operations using an MS Windows Based PC and the Acu-Com Software. The Acu-Com

Software is a full featured software package that allows the operator to download recorded data, monitor system

inputs in real time and provides a graphing option that allows for detailed analysis of water system parameters and

performance. In addition, AcuManage II, an online database management system will display data from any internet

enabled Controller.

REMOTE PAGING: With the optional modem installed, the Controller can be programmed to dial out to electronic

paging systems for notifying operators of an alarm condition.

REMOTE EMAILING: With the optional wireless modem installed, the Controller can be programmed to send an email

notifying operators of an alarm condition.

SECURITY: The Controller provides two level security protection based on passwords for both local and remote

interaction.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

7

Page 8

SECTION 2

INSTALLATION

Installation Preparation

Inspection: Upon receiving the Controller check the carton carefully.

Reportanyshippingdamagetoshippingcompany.Examinetheenclosedshippinglistandverifythatallitemsare

present. Contact Customer Support (800) 831.7133 if any items are missing or have been damaged. Use care when

unpacking equipment to avoid damage or loss of small parts. Verify that the fuses are the correct values and that the

voltage select switch is in the proper position.

Installation Summary

The following steps are required to install the Controller:

1. Identifynewandexistingequipmenttobeconnected.

2. Decide if the sensors will be in-line, in a separate by-pass line, or if the AK1200 flow cell will be used.

Caution:IftheAK1200owcellisused,theinputwatermaximumpressureis25PSI.

3. Determine the supply voltage, 110 VAC or 220 VAC, and set the supply voltage switch as necessary.

4. Determine if the control to the equipment uses the same voltage as the supply voltage.

All controlled equipment must be compatible.

5. Determine the water-tap points for the flow cell bypass inlet and outlet.

6. Mount the Controller away from direct sunlight and on a flat vertical surface.

7. Connect the supply voltage with main breaker off. (Must be a separate dedicated circuit GFCI).

8. If using an AK1200 flow cell install the bypass now.

9. Connect the sensors.

10. Test the plumbing for leaks.

11. Turn on the Controller for the first time.

12. Test the equipment, using the Controller manual relay mode.

13. Calibrate the probes, then re-calibrate as the probes acclimate to the system.

Acclimation can take as little as two hours or as long as 24 hours.

14. Program the Controller.

15. Callorvisitthecontrolleroverthenextfewdaystoinsurethesystemisbalancedandincontrol.

Fine-tune the setup if necessary.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

8

Page 9

Mounting Instructions

!

!

Select a location for mounting the Controller, meeting the following recommendations:

1. Mount at least ten (10) feet from open water.

2. Mount close enough for the supplied power cord to reach the supply voltage. The Controller will not operate

properly without a solid earth ground connection.

WARNING

Proper and safe operation requires an earth ground connection.

3. Supply power must be routed to the Controller in accordance with the applicable codes in the area; the

supplied power cord is not code in some areas.

4. The installation surface must be solid and vertical. Do not mount the Controller in a horizontal position.

WARNING

Keep the Controller out of direct sunlight, inside a room if possible.

Direct sunlight on the Controller will result in inaccurate readings.

A shade screen should be used for outdoor installations.

5. Maintain adequate clearance for opening the front panel enclosure.

6. Theenvironmentshouldbefreeofchemicalfumesandexcessiveheat.

Themaximumroomtemperatureisshouldnotexceed110ºF.

7. Mount as far as possible from sources of electrical interference.

8. Install the four mounting feet as desired to the Controller back and prepare the hole to the mounting

surface as desired.

9. Hold the Controller against the mounting surface with a closed lid and mark the location of the mounting

bracketlocatedonthetopoftheControllernexttothewall.Prepareholesasnecessaryandsecure

Controller using hardware provided.

10. Mountonaatsurface.Controllerboxwilldistortifmountedonanunevensurface.

11. Pre-install screws with ¼ left out on bottom so that the Controller can slide into them. Install the remaining

side screws and tighten.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

9

Page 10

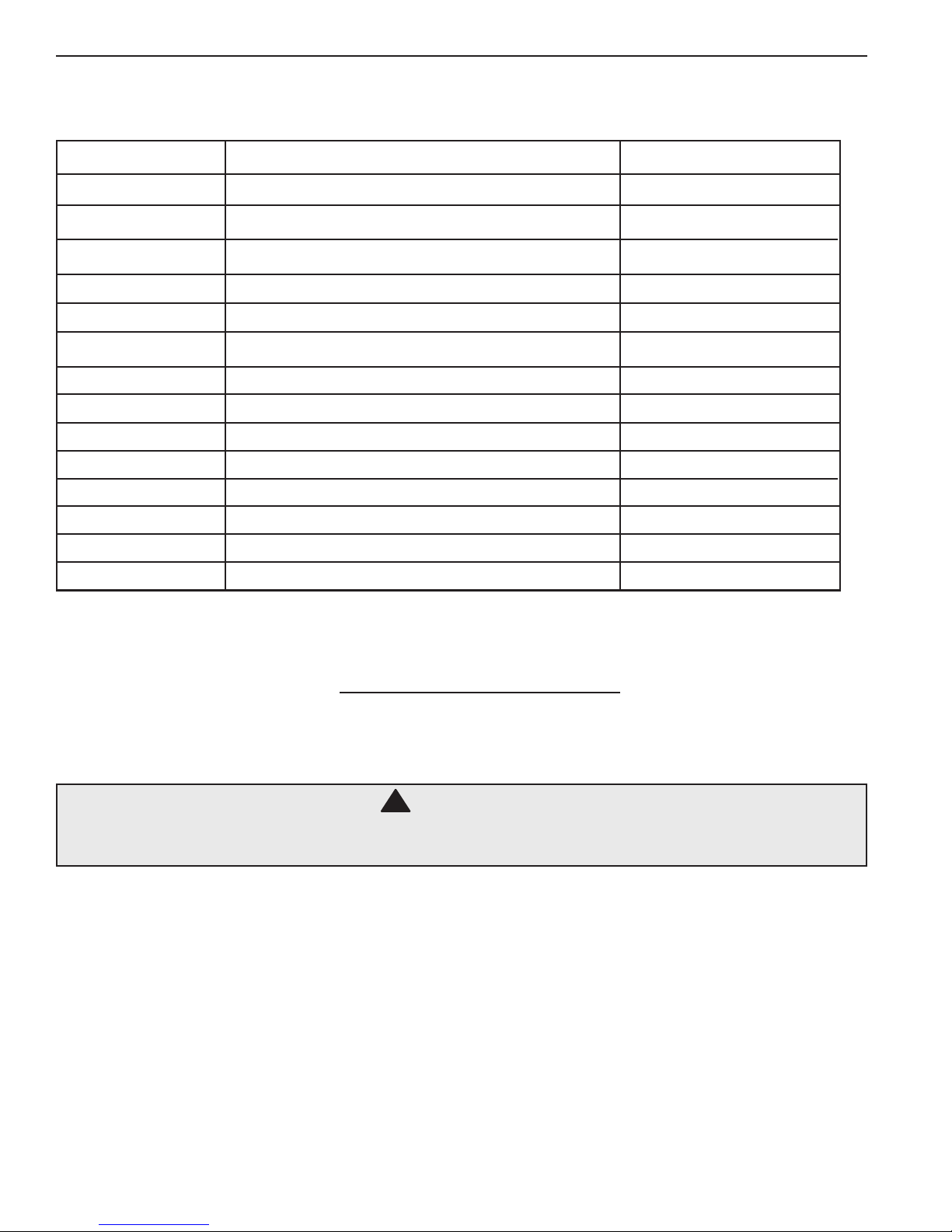

Electrical Specications

!

Thefollowingelectricalspecicationsinthetablebelowmustnotbeexceeded.

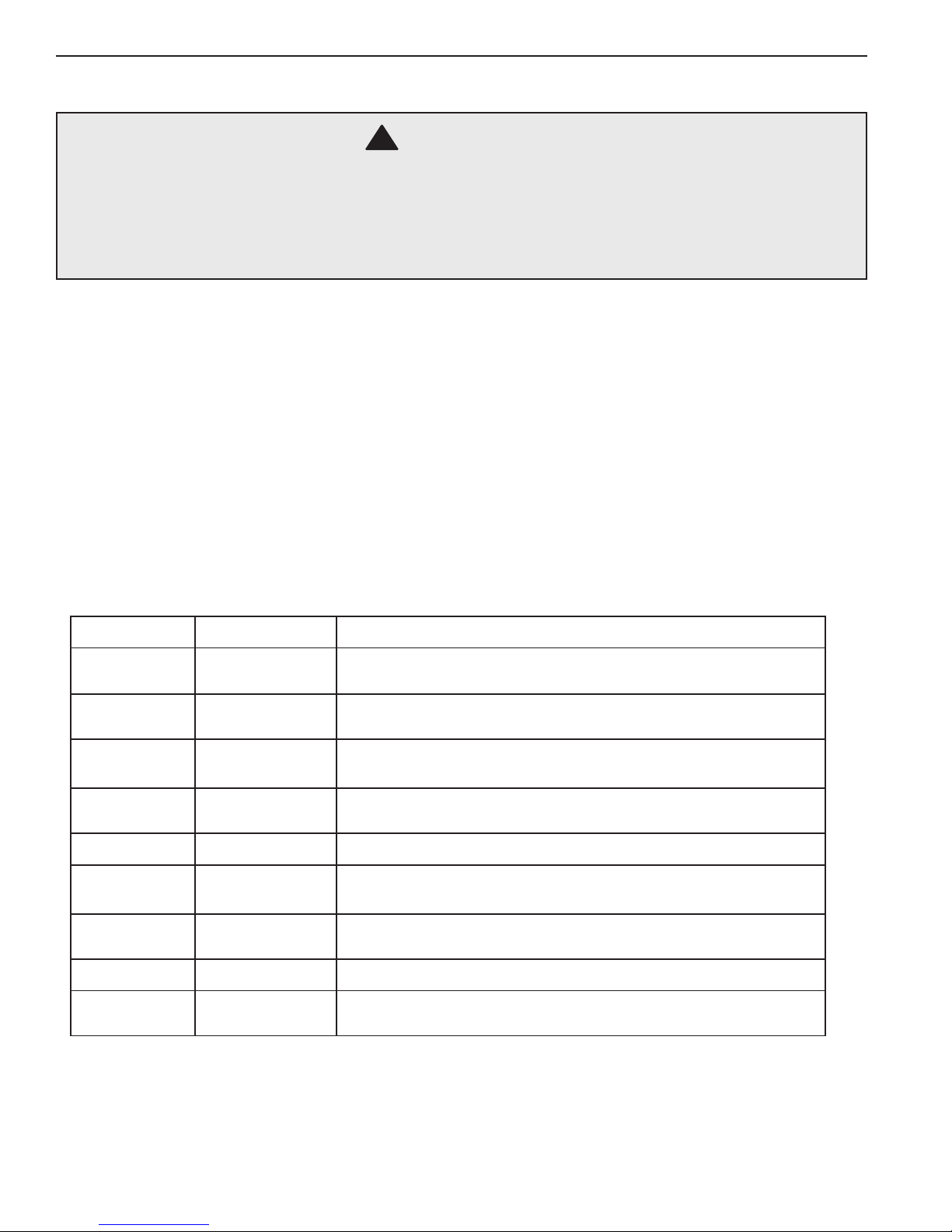

ITEM DESCRIPTION LIMIT

Input Voltage Maximum Input AC Voltage 250 VAC

Input Current Maximum Input Current 5 Amps (AC)

Output Current Maximum Current for 3 Relays 110V 5 Amps (AC)

Maximum Combined Current 3 Relays 24V Dry 1 Amp

Temperature Min./Max. Operating Temperature 30° - 110° F

Standby Current Current with all Relays OFF, LED ON 50mA (AC) Typical

Current with all Relays OFF, LED OFF 30mA (AC) Typical

Sensor Range pH 4.22 - 9.78

ORP 0 - 999mV

Temperature 32 - 212° F

PPM 0 - 8 PPM

Digital Flow 0 - 9999 GPM

Volume 0 - 65,535 Gallons

Flow Open or Closed

Input Voltage Selection

The Controller will operate on input voltages of 110 VAC or 220 VAC.

Thefactoryjumpersettingisfor110VAC.

The supply power is commonly used to power the feed pumps and

otherexternalloads.Ifalltheloadsare110VACthenuse110VACoriftheloadsare220VACthenuse220VAC

as the input voltage.

WARNING

If the Controller is connected to 220 VAC the voltage selection switch must be changed

to 220 VAC before connecting power to the unit or damage will occur.

Note: It is not possible to power the AK110 Chemical Controller with 110 VAC,

and control 220 VAC loads or vise versa.

Connecting Power

For cord connected installations wait to plug the cord in as the last step in the installation. For hard-wired installations

make sure the circuit breaker is off and turn it on as the last step in the installation. Have a licensed electrician perform

the installation to ensure the local codes are met.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

10

Page 11

Electrical Loads

!

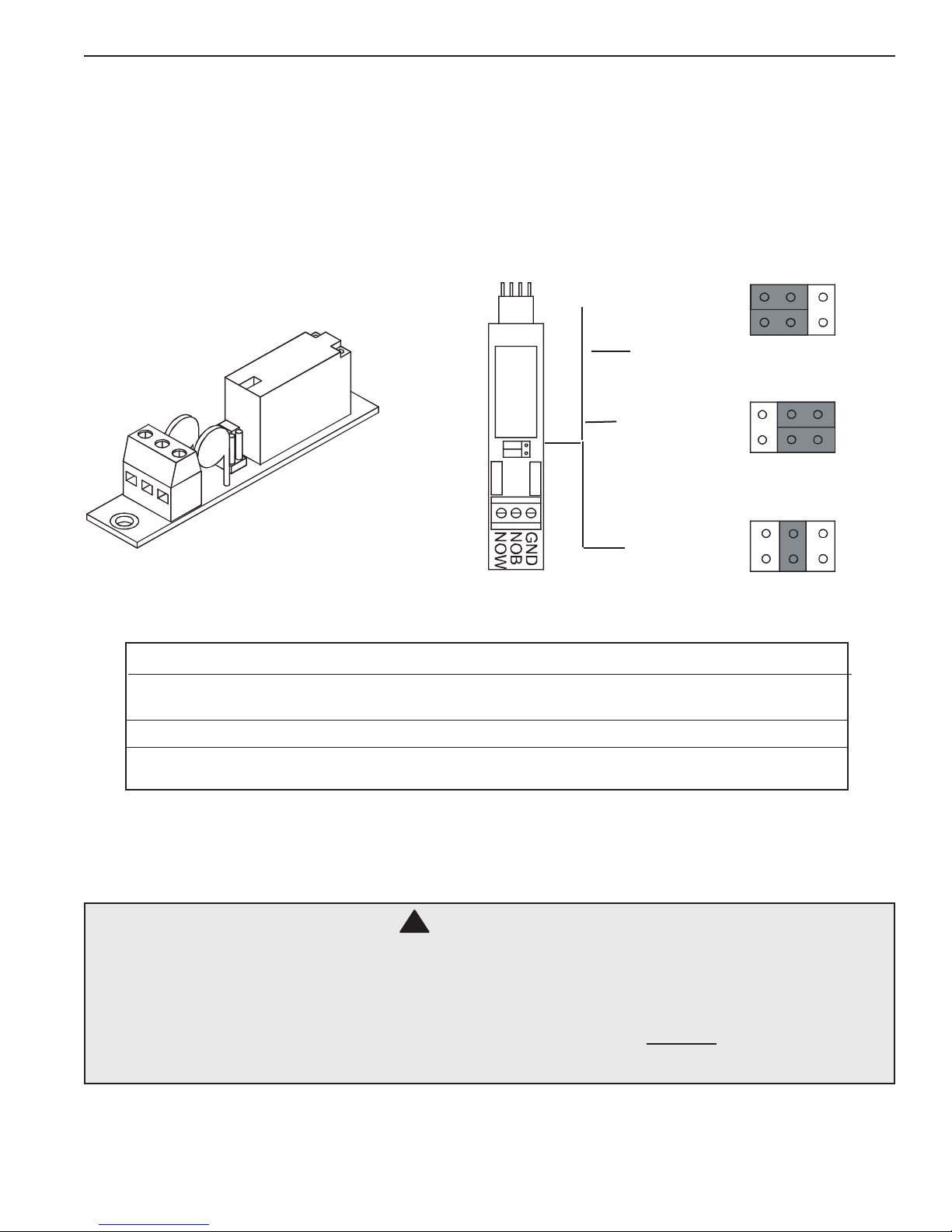

The Controller with revision F and greater relay board has the capability of utilizing up to three (3) modular relay boards

that can be purchased in a number of configurations. The Controller is shipped from the factory with three (3) 110 VAC

Normally Open modules installed (Part# 724000050). Listed below are the different types of relay modules that can

be purchased and their function. The correct ones must be ordered based on the load requirements. Check with your

distributor for the proper relay modules for your application.

Factory Setting

for input power

115 VAC

Setting for input

power 24VAC

Dry (Switch)

White = No Jumper

Grey = Jumper

Relay Modules

Part # FUNCTION

724000050 For control of 110 VAC Normally Open Circuits

(most applications will use this model).

724000060 For control of 110 VAC Normally Closed Circuits.

724000440 For control of 110 VAC Single Pole, Double Throw

Circuits, with common white and no ground.

The wiring on each board may be different depending on the model that you purchase. Look on the board, check with

your distributor or call Pentair Customer Support at 800-831-7133 with any questions.

WARNING

Do not change relay modules when power is applied.

This type of damage is not covered in the warranty.

Do not connect any load not rated for the supply voltage to any of these relays.

TOTAL COMBINED LOADS MUST BE LESS THAN FIVE (5) AMPS

FOR ALL THREE RELAYS.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

11

Page 12

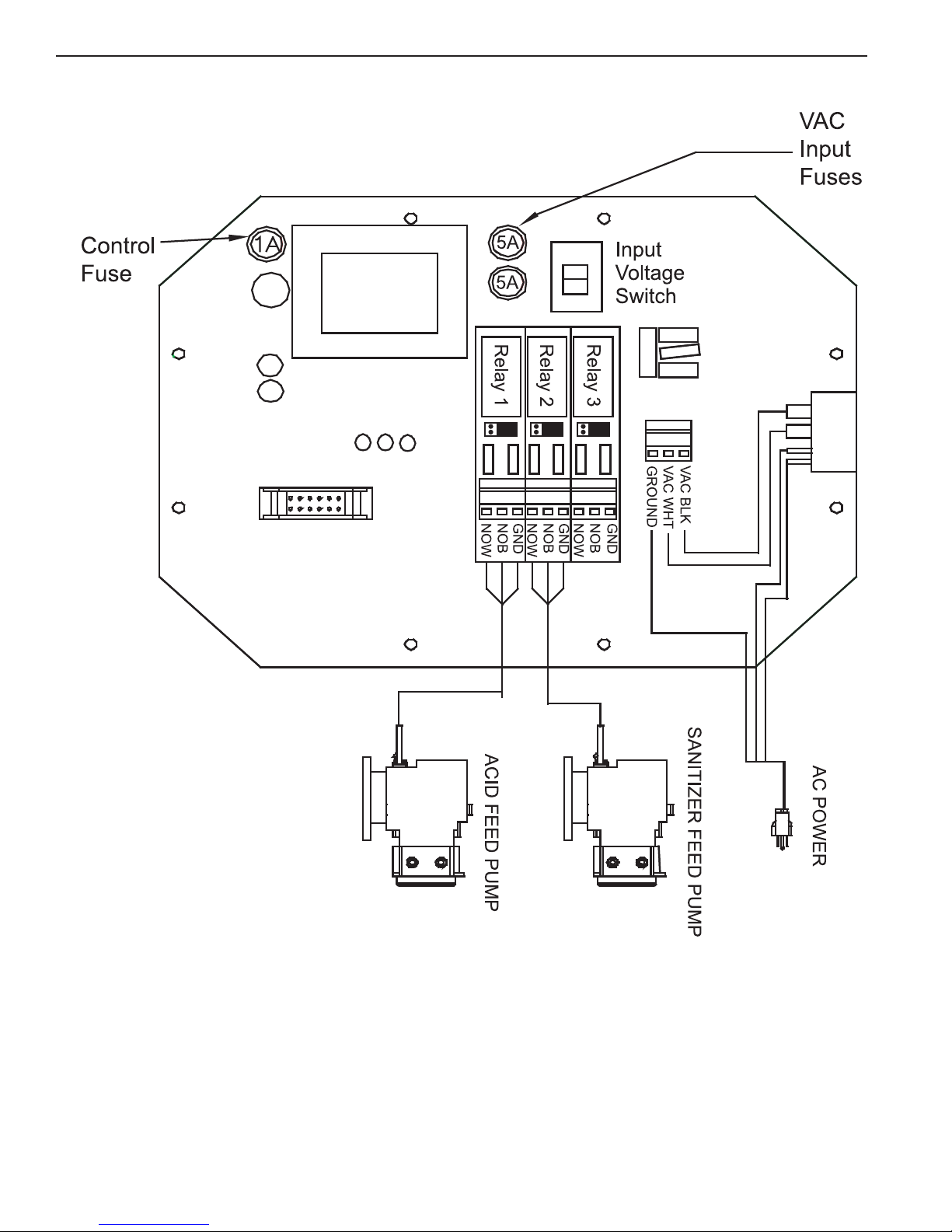

RELAY BOARD

115

Relay 1: Configured for pH control.

Relay 2: Configured for ORP control.

Relay 3: User configured.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

12

Page 13

Chemical Feed Pump Location

If unit has not been previously installed, follow the instructions included with the chemical feed pump. Some loads

include power cords already connected to the load and are ready to plug in. If “pigtails” have been ordered with the

Controller simply plug the power cord into the appropriate "pigtail". If "pigtails" are not installed the power cord from

the pump will need to be modified. The list below provides installation recommendations:

1. Mount at least 10 feet from open water.

2. Install the pump below the level of the Controller and away from any other equipment or systems.

This is to reduce any damage to other equipment should the pump leak.

3. Install close enough to the Controller for the feed pump power cords to reach.

4. If "pigtails" are included simply plug in the pumps to the appropriate "pigtail". If pigtails are not installed,

cut the electric plugs from the feed pumps and strip and ferrule the ends.

5. Route the power cords to the Controller through the lower fittings and attach to the appropriate relay

terminals on the relay circuit board. If the wire ends were striped and not ferruled make sure that no frays

of wire are out of the connector as this may lead to a short.

6. Conduitorexternalplugscanalsobeused(accordingtothecodesinthelocalarea).

7. When installing metal conduit into the Controller, a ground LUG should be used to connect the conduit to

the relay board ground.

Heater Installation

The Controller third relay can control a heater, turning it on and off based on the temperature settings you have

programmed in to the Controller. The heater control portion of the Controller can be used to maintain a constant

temperature or maintain a temperature during operating hours. Even though the Controller is a very accurate and

reliable device, for safety, always use the over-temp device on your heater to prevent overheating.

1. Always install any heater according to the manufacturer's instructions.

2. Mount the Controller at least 10 feet from open water.

3. Install close enough to the Controller for the wiring connections to reach.

4. DO NOT attempt to power the heater with the Controller controller.

5. A heater unit must always be independently powered, either through a separate cord, or through an

externalrelayliketheAcu-TrolHAR1relaymodule.(Part#735000060)

6. Always use the over-temp device on the heater to prevent overheating.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

13

Page 14

Plumbing Installation

!

WARNING

Be sure to have a licensed plumber perform all plumbing; this is important, as they will

be familiar with all of the codes in the local area.

Follow the instructions that came with the AK1200 flow cell. This section gives the basic principles to be applied for any

specific installation, which are listed as follows:

1. Turn OFF all equipment including the filtration system.

2. Determine a suitable location for the flow cell. Which should be located where water spillage will not

damage surroundings.

3. Securely mount the flow cell.

4. Install the supply and return lines for each flow cell. Drillandtap¼”holesforthe½”exibletubingorhard

plumb the flow cell.

A. Locate where the water will be supplied from and returned for each flow cell. The most common

location for the water inlet to the flow cell is after the main filter and the outlet after the heater.

B. If there is no suitable location the cell inlet can be after the main pump and the outlet before the main

pump. This method may cause a suction in the flow cell and damage to the sensors. If any chemicals

areinjectedintothecelltheymaycausetemporaryinvalidreadings.

5. Locatethechemicalinjectionpoints.

6. Prepareandinstallthechemicalinjectorttings.

7. Install the chemical storage containers.

8. Install the sensors.

9. Turn ON the main circulation pump.

10. Check for leaks and verify the flow sensor indicates flow.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

14

Page 15

Plumbing Installation

!

WARNING

Do not inject acid directly in to the AK1200 ow cell.

Injecting acid in this way may damage the existing pool equipment.

Pool

Pump

Water

Return

Sample

Test

Supply

Preferred Plumbing Routes

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

15

Page 16

SECTION 3

HARDWARE

Modules

Modules are the electronic controls and components that make up the Controller.

Each module has a specific function or functions that tell the Controller what information to accept and what

information to display. The modular design of the Controller enables it to interface with many types of modules

including Sensor, Communication, and Relay modules.

Sensor Modules

Sensor modules determine the types of sensors signals the control can recieve. There are three sensor modules

currently available for the Controller.

AK111: pH, ORP, temp and heater control. Calculated PPM can also be displayed (Part# 724000010).

AK112: pH, AKColor(PPM), heater control (Part# 724000380)

AK113SC: pH AKColor(PPM) ORP, Temp (Part # 725000390)

Communication Modules

The Controller has the ability to work with several types of communication modules. The Controller can communicate

with a PC through an RS232 cable, a standard modem, or a wireless modem.

Controller Modem: High-speed modem. (Part # 725000010)

Wireless Modem: The wireless modem allows the Controller to be accessed over the internet from any PC.

Wireless modems are a perfect solution for installations without phone lines. Please note that the wireless

modem and the standard modem can not be installed in the same Controller.

Relay Modules

The Controller is able to automate nearly any device in your pump room. The Controller uses a relay module to turn

electricity to the device on and off. Each Controller can control up to 3 relay modules. Each relay module can control

one device. Relay modules are available in seven different models. The type of relay module used depends on the

load requirements of the device that is controlled with the relay module. To determine the load requirements, please

consult the instruction manual or the device manufacturer. Any combination of the seven models of relay modules can

beinstalledinthethreeavailableslotsonarelayboard,aslongasthecombinationdoesnotexceedthecombined

maximumcurrentfortherelayboard.Thecombinedmaximumcurrentforanyindividualrelayboardis5amps.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

16

Page 17

Themaximumrelaycurrentfortherelayboardis5ampswhenswitching115VACor220VACand1ampswhen

switching 24 VAC.DRY

CONTACTS: These relays act as a dry contact switch only and have no connection to the input VAC. The relay ratings

are 5A and 250 VAC.

115 VAC Normally Closed: These relays supply the input voltage to the load when the relay is in the “OFF” mode.

Note that both VAC inputs are controlled by the relay. The relay ratings are 5A and 250 VAC.

115 VAC Normally Open: These relays supply the input voltage to the load when the relay is in the “ON” mode. Note

that both VAC inputs are controlled by the relay. The relay ratings are 5A and 250 VAC.

115 VAC SPDT: These relays are hard-wired selectable to be either NO (Normally Open) or NC (Normally Closed)

switching of the input voltage. They are always powered, and the wiring will dictate whether the power flows in the on

or off position. The relay ratings are 5A and 250 VAC. The neutral is common for both NO and NC.

24 VAC Normally Closed: These relays supply 24 VAC to the load when the relay is in the “OFF” mode. Note that both

VAC inputs are controlled by the relay. The relay ratings are 1A and 250 VAC.

24 VAC Normally Open: These relays supply 24 VAC to the load when the relay is in the “ON” mode. Note that both

VAC inputs are controlled by the relay. The relay ratings are 1A and 250 VAC.

24 VAC SPDT: These relays are hard-wired selectable to be either NO (Normally Open) or NC (Normally Closed)

switching of the 24 VAC. They are always powered, and the wiring will dictate whether the power flows in the on or off

position. The relay ratings are 1A and 250 VAC. The neutral is common for both NO and NC.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

17

Page 18

SECTION 4

AK1200 FLOW CELL

AK1200 Flow Cell

Remove flow cell from shipping carton and make sure all parts are included with AK1200 flow cell.

•1–AK1200Lid •1–AK1200JarwithO-Ring

•1–Flowswitchmagnet •3-¼”Valves.

•1-Samplebarbtting •4-¼”NPTby½”exttings.

•1-FilterassemblywithO-Ring •2-¼”plugs.

•1-FlowswitchwithO-Ring,2’ •1-¼”CloseNipple

and10’wirelengthsavailable. •1-Threaded Seal Tape

•2-Mountingscrews

Notethat½”exibletubingisnotincludedandissuppliedbytheinstallerormaybeorderedfromAcu-Trol.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

18

Page 19

Flow Cell Assembly

1. Wrapallfourexttingswiththreaded seal tape.

2. Installtwoexttingsintotwoballvalves.

3. Wrap barb fitting with threaded seal tape. Install barb into remaining ball valve.

4. Wrap both ends of the close-nipple with threaded seal tape. Install into the filter assembly using (either end OK).

Hand-tighten only.

5. Install one ball valve into the filter.

6. Install the filter and remaining ball valves as shown in the figure.

7. Verify that the flow switch magnet is in the flow cell tube with the large or hat end pointing down.

NOTE: Wrap fittings only twice around with threaded seal tape.

Flow Cell Mounting

Select a suitable location for the flow cell meeting the following recommendations:

1. Sensors wires will connect to within ten (10) feet.

2. Do not mount in direct sunlight. SUNLIGHT WILL CAUSE INACCURATE READINGS.

3. Water leaks will cause damage! Mount where water does not leak and damage other compentents.

4. Mount flow cell vertically with provided screws.

5. Securely fasten all electrical, water and chemical lines.

6. Locate chemical feed pumps and chemical storage tanks in a safe and secure area.

7. Maximumoperatingpressure=25psi

8. Extremepressurevariancesmayaffectreadingsandcancausedamagetothesensors.

9. Avoid installing the outlet before the main pump as the vacuum may damage the chemical sensors.

10. OnlyinjectchemicalsontheoutletsideoftheAK1200FlowCell

11. Do not over tighten fitting on flow cell top.

1. It is essential that the supply line be at a higher pressure than the discharge line so the water will flow through

the cell at a steady rate in the right direction. Installing a ball valve in the main circulation line may be required

if the pressure is too low.

2. Inlet should be installed after filter and before heater.

3. Exitshouldbeinstalledafterheaterandasfarawayfromanyequipmentaspossible.

4. Drill and tap at above locations with 7/16” drill and 1/4” NPT tap. Choose a location on a fitting where the

pipeenterssoyouaredrillingthroughboththepipeandttingtogetmaximumdepthofthread.

5. Install¼”NPTby½”exttingsthenrouteinletandexitlines.

Inlet and Exit Lines

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

19

Page 20

Sensors

!

!

1. pH and ORP sensors must remain wet at all times. Install the sensors into the flow cell,

HAND-TIGHTEN ONLY and save caps for future use and fill flow cell with water.

2. Route the flow switch wires into the Controller through the strain relief and connect to the Controller.

Wire one (either one) to ground and one to the appropriate input switch.

3. Route the chemical sensors into the Controller through the strain relief and connect to the Controller.

The sensor wires are labeled and the PLUS AND MINUS POLARITY MUST BE OBSERVED.

4. Turn the main pump on and open the valves to test for leaks and the free movement of magnet.

Magnet must be all the way up in order to close the flow switch. 1/4 GPM will push the magnet all the

way up.

CAUTION

The ow switch is a dry contact only (no current).

Use with any other brand Controller VOIDS WARRANTY.

WARNING:

Make sure all pumps are OFF before drilling into pipes.

Never turn chemical feed pumps ON when both

ow cell valves are closed.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

20

Page 21

SECTION 5

!

SENSORS

The Controller can accept readings from a wide variety of sensors. The sensors the Controller can read depends on

the sensor module installed in the Controller. Each sensor has its own unique circuitry that is connected directly to the

micro-Controller for measurement. Isolation of each sensor ensures more accurate measurements.

The Controller measures the following sensor measurements with the listed characteristics:

pH - Range: 4.22 to 9.78

ORP - Range: 0 to 999 mV

Temperature - Range: 32 to 212 °F

Flow Switch: This input measures if a switch is open or closed.

WARNING

Sensors are shipped with a protective cap covering the electrode tip to protect

the sensing element. Sensors should be kept in the protective cap until ready for

installation, if the sponge in the boot becomes dry, wet it with pool water.

Before using the sensor remove the cap.

pH and ORP Sensors

pH electrodes sense the acidity of the water and work with any acid or base. The blue bands on the cables identify the

pH sensors. The red bands on the cables identify ORP sensors. Each sensor is also identified on the sensor body. ORP

electrodesareusedtomonitortheOxidationReductionPotential(ORPissanitizationqualityofthewater)ofagiven

solution. The sensing element of the ORP electrode is made of a precious metal such as platinum or gold.

THE POLARITY (+ AND -) OF THE pH AND ORP SENSORS MUST BE OBSERVED. The ORP sensor (+) copper and the pH

sensor(+)copper,andthegreenleadsare(-)polaritylabeled.LeaveexcesswireoutsidetheControllerenclosure.Ifthe

cable is longer than needed, it should be coiled neatly and attached under the Controller enclosure.

DO NOT CUT THE SENSOR WIRES.

Do not stuff excess wire inside the controller as this may cause excess strain

on sensor and relay connections.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

21

Page 22

Calculated PPM

If you have an ORP sensor module you can choose to operate the AK110 in Calculated PPM (Parts Per Million) mode.

When in Calculated PPM mode, the Controller uses a special formula to convert the ORP reading from the sensor in to

PPMunits.ToactivatetheCalculatedPPMmode,select"PPM,MixTime"or"PPM,CycleTime"inthewizardsection.

Note when you are in Calculated PPM mode ORP will not be displayed on any screens. See page 78 for PPM Cycle time

menu tree.

AKColor PPM Sensor

TheAKCOLORisacolorimetricmethodchlorineanalyzerdesignedtoworkinconjunctionwithmostAcu-Trol®

Controllers. The AKColor is capable of measuring the amount of free chlorine present in a body of water. The colormetric

method of measuring PPM is superior to other methods because it is much less sensitive to varying water conditions,

including pH and salinity. The information gathered by the AK Color can be used to control chemical feed pumps and

signal alarm conditions. For more information on the AKColor please see Navigation Screen on page 128 or consult your

AKCOLOR installation manual.

Temperature Sensor

The AK10K sensor can be installed to measure/display temperature. The sensor should be installed as close as possible

to where the water comes from the pool. If a temperature probe is installed in the AK1200 flow cell there will be a

temperature variation due to the long tubes and the temperature in the pump room. A common place to install it is in the

small plugged hole in the bottom of the main pump strainer basket.

The sensor uses a special ¼” NPT fitting to hold the stainless steel sensor. A hole should be drilled (7/16”) and tapped

(1/4”) where the water enters the pump room through a fitting to get double the depth to hold the sensor. If installed

outdoors make sure to keep it out of direct sunlight. Route the wires into the Controller through a strain relief and

connect to the temperature input. The red wire goes to T and the black wire to GND.

Flow Sensors

The Controller has the capability of measuring two flow switches in which one or both can be a digital flow sensor.

These inputs are general purpose and can measure any dry contact switch state. This can include flow, pressure,

temperature, digital flow rate and so on.

The typical uses for the flow switches are:

Switch

1: Typically used to indicate flow through the flow cell and it is OK to feed chemicals. If a digital sensor is

used the actual flow rate can be measured and displayed in gallons/liters per hour.

Switch 2: Can be used to measure water level for automatic level control. If a digital sensor is used the actual

flow can be measured and displayed in gallons / liters per hour.

NOTE:

To obtain liters per minute the scale factor must be changed to pulses per liter.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

22

Page 23

Sensor Care

!

Contamination of the sensing elements often results in slow response and inaccurate readings. Clean the elements by

the following procedures:

pH and ORP Sensors

1. Wash electrode tip in a liquid detergent and water. Carefully use a soft bristled toothbrush to wash the

electrode tip and white sensing ring.

2. Rinse after cleaning. To install, place in flow cell according to the diagram and hand tighten.

3. Make sure the O-ring is installed on sensor.

4. If the cable is longer than needed, it should be coiled neatly and attached under the cabinet.

pH Sensors Only

5. Attempt to clean the sensor with liquid detergent first.

6. If this is not successful, swirl the tip of the sensor in a 5 parts water and 1 part muriatic acid solution

for 10 - 20 seconds.

7. Rinse again and reinstall.

WARNING

Do not rub hard the glass element in the sensor or use sand paper or

other polishing material to clean.

HANDLE ELECTRODE CAREFULLY

Sensors contain external and internal glass elements. Do not drop or otherwise

subject the sensor to vibration, physical impact, or freezing conditions.

ANY TYPE OF BREAKAGE IS NOT COVERED UNDER WARRANTY.

Finishing and Testing the Installation

OncetheControllersystemhasbeeninstalledwithapplicablesensorsandexpansionmodulesthefollowingstepsare

required for final system finishing and testing.

1. After all wire connections are complete close the panel and tighten the enclosure.

2. Plug in the Controller and turn on the main breaker. Switch the ON/Off switch to ON.

Up is ON and down is OFF.

3. Verify that the display is active and displays various introduction/initialization screens.

4. SENSORS: The first screen displays the sensor readings, verify that they are connected properly.

Example: pH is within 0.5. This is to verify that the pH is connected to the pH input and

the ORP is connected to the ORP input.

5. FLOW: Verify that the flow switch indicates on (S1ON) and the green flow LED is on. Close the valve

in the flow cell to stop the flow and verify that the Controller indicates no flow (S1OFF) and the flow

LED is off.

6. LOADS: Leave the valve closed (S1OFF) for this part of the test so that the relay programs will keep

relays "automatically" off. Press the Right button 1 time to R1 (ph) OFF and press ENTER to "manually"

turn on the load, verify that the correct load turns on and press enter to turn it off.

Pressthedownarrowtoselectthenextrelayandrepeatfortheothertworelays.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

23

Page 24

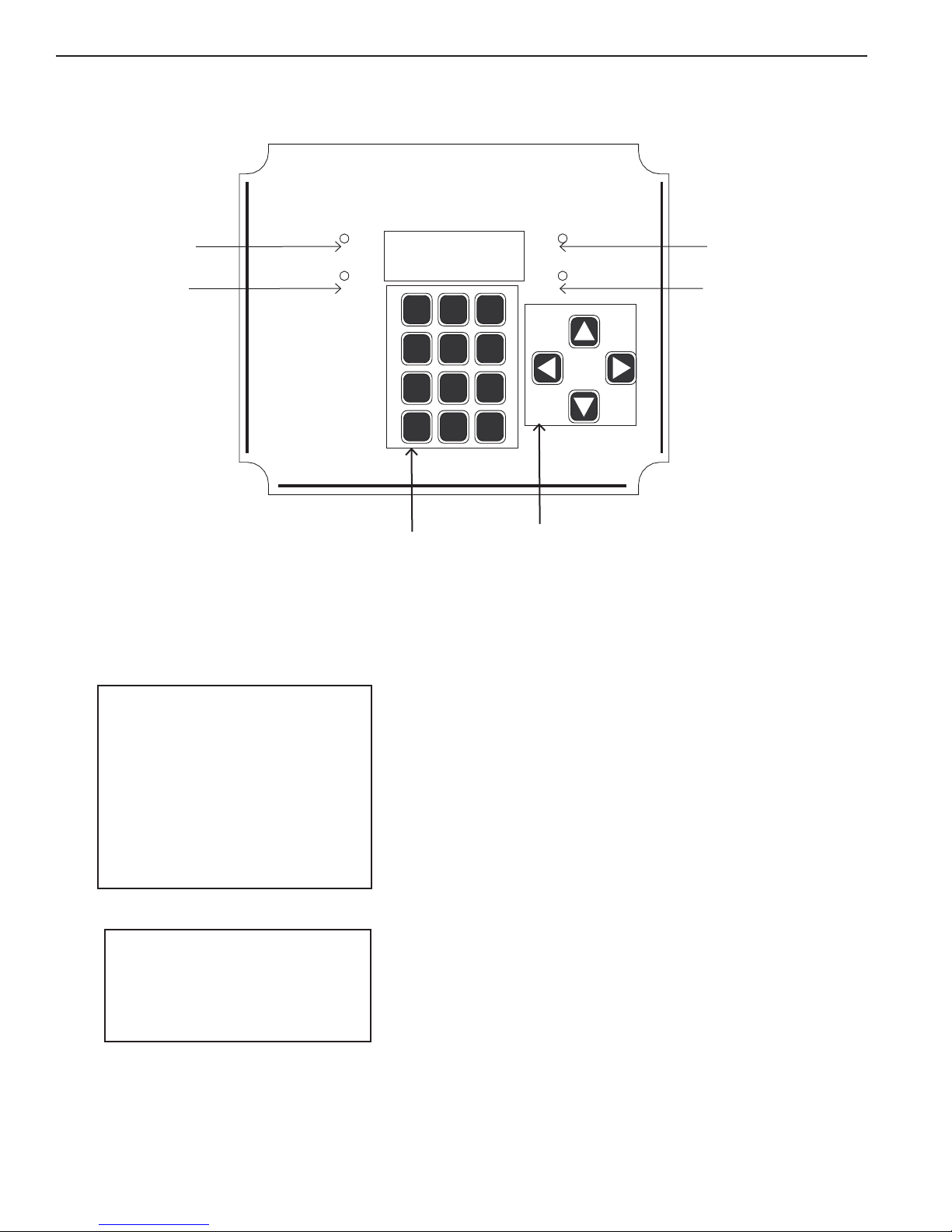

SECTION 6

FLOW

ALARM

POWER

SECURITY

Made in USA

110/220 VAC. 5A Disconnect Power Source Before Servicing Unit

AK110

87 9

54 6

21 3

Back

0

Enter

OPERATION

FLOW

INDICATOR LIGHTS

Flow is on when light

is lit.

Alarm

Indicator Lights

Light is lit when a

warning or alarm

condition occurs.

ALPHANUMERIC KEYPAD

Used to enter numeric parameter settings, alphabetic charac-

ters, and special shortcuts for commonly used menus.

POWER

INDICATOR LIGHT

Power is on when light is lit.

SECURITY

INDICATOR LIGHT

Light is lit when password

protection is active

ARROW BUTTONS

Up/ Down/ Left/ Right arrow buttons move you

through the AK110's menus.

.

Conguration Menu Screen

>Name:Main Pool

System

Programming

Service

Data ( 8:441 )

Communications

Security Setup

Wizards

Serial # 123456

Main Status, cursor at pH value

pH > 7.67-OFF 7.50s

ORP 490 -OFF 700s

_____

69.0f SW1OFFSW2OFF

Window Navigation

This section introduces window navigating and how to

edit and modify the Controller settings and programs

usingguidelinesandexamplesforselectingandchanging

items.

The Controller provides two main screens for user

operations:

1. Display Screen: for monitoring measurements,

calibrating and manually turning on relays. This is the list

that displays at startup.

2. Menu List: for editing and setup of parameters.

24

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

Page 25

Selecting Items in the Windows

!

The 16-button touch pad is used to access and modify the different Controller functions:

•PressingtheBACKbuttononthetouchpadwillmovebackonewindow.

•PressingtheBACKbuttonwilltogglebetweenDISPLAYSCREENandMENULIST.Ifthe"REDsecuritylight"is

on a password must be entered to access MENU LIST.

•Pressingthearrowbuttonswillrepositionthecursoronthescreen.TheUPorDOWNarrowbuttonswillscroll

up or down the screens and the RIGHT and LEFT will move arrows to the RIGHT and LEFT on the screen

See page 48 for more detailed navigation instructions.

WARNING

Press 16 Button touch pad with nger pads only. A sharp object such as a

pen or tool will damage button pads.

MAKING CHANGES

To change a parameter move the cursor to the parameter and press the ENTER key. The Controller will then open the

value entry screen for that parameter. The Controller navigation system uses the following considerations:

1. Use the right and left arrows to change to a different digit to enter.

2. Press a number on the keypad to change a digit.

3. Press the left button to add a digit and make the number bigger.

4. Press the ENTER button to save the change.

NOTE

Changes must be saved by pressing the nal ENTER.

If ENTER is not pressed as the last step the changes with not be saved.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

25

Page 26

Start Up

The following steps need to be performed to properly setup the Controller:

1. Perform any required calibrations.

2. Decidetousemixingtimecontrolorcycletimecontrol.

3. Set up the timing parameters based on the size of the water and chemical feeding system.

4. If the AKRTC (Real Time Clock) module is installed set the time, date and weekday. (Part # 724000280)

5. Set the overfeed time limits in programming.

6. Return as needed to recalibrate any changes to the settings

7. If the AK540 modem (Part# 725000010) is installed, then set the number

of rings to answer on and setup the paging conditions.

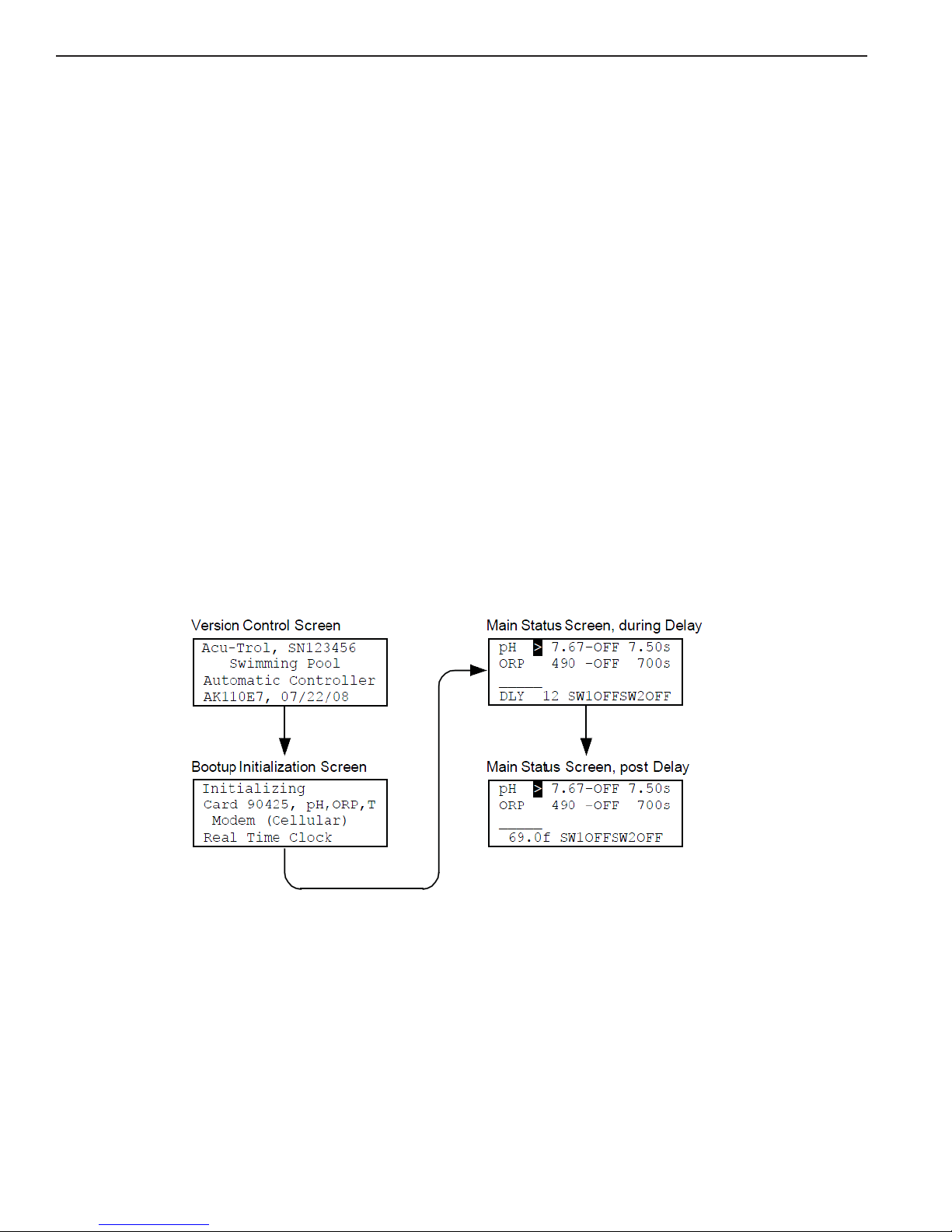

Initializing the AK110PS Pool and Spa Chemical Controller

During power-up the Controller will display the Power Up Screens for a few seconds before defaulting to the Display

Screen. During this Power On Self Test mode, the Controller will perform a brief check of its internal systems and

initializetheinternal(RAM)memoryforControlleroperation.NexttheControllerwillautodetectforthevarious

installed modules and indicate which ones are detected. The opening screen includes the software version number and

will be required when requesting support. When turning on a number will be displayed in the lower left corner of the

display screen indicating how many seconds until control will actually start. This is to allow time for the sensor readings

to stabilize.

Power Up Screens

Display Screen

Display Screen: Displays measurements of connected sensors and also relay status. To the right of the Sensor readings are also displayed the set point values. To change set points you will need to go to programming and change them

there. Pressing the Up Arrow key when the curser is at the top of the readings screen will move you back to the opening

screen.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

26

Page 27

The Display Screen

The DISPLAY SCREEN shows all the current measurements, as well as the

user programmed set points. It allows access to specific types of information

including the current measurements. Press the arrows on the touch pad to

scroll up or down or left or right as indicated by moving the > Cursor on the

screen.

Calibration: Position the cursor to the left of any of the three measurements

and press ENTER to calibrate that sensor. A value entry screen will then be

opened. Enter the calibrated value with the numeric key pad. To save your

changeandexitthevalueentryscreen,presstheenterbutton.Tocleara

specific calibration press "0" on the touch pad when the cursor is in front of

the value (The reading may not go to a zero reading but it will default to the

sensors uncalibrated reading).

Manually turn on relays: The relays in the Controller are represented on the

displayscreennexttoitscorrespondingsensorreading.Positionthecursor

to the left of the status word (either OFF or ON) and press ENTER to toggle

therelayonandoff.Thelengthoftimetherelayisonisadjustableinthe

programming. When the relay is toggled to off the relay

immediately goes back to automatic control and in some cases may turn back

on immediately.

Main Status, cursor

at pH Relay

pH 7.67>OFF 7.50s

ORP 490 -OFF 700s

_____

69.0f SW1OFFSW2OFF

Calibrating Temperature

The temperature sensor is very accurate and should not require calibration. If the calibration is more than a couple

degrees off there may be an installation problem. The most common problems with temperature sensors are listed

below:

1. The most common temperature problem is the temperature is not the same at the sensor as it is in the main

body of water. It is also possible the temperature error is different depending on the time of day. Make sure the sensor

is not in direct sunlight, and is installed as far into the fitting and as close as possible to the body of water. Evaluate

where the sensor is installed.

2. The sensor may be damaged. If the sensor is put in a room of 76°F the resistance should be 10,000 OHM's

that can be measured with a standard voltmeter. To calibrate the temperature sensor move the cursor in front of the

temperature reading and press ENTER. Enter the measured value. Press ENTER again to save the calibration change.

Calibrating pH

Measure the pH using a standard test kit by taking several readings and averaging the results. To calibrate the pH

sensor move the cursor to pH and press ENTER. Enter the value obtained from the test kit in to the value entry screen.

Press ENTER again to save your changes.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

27

Page 28

Calibrating ORP

!

WARNING

Always make sure the pH is at the set point before calibrating ORP. Always control

at PPM levels greater than 1.0 PPM when using ORP sensors.

IMPORTANT:

For best results the ORP should be at the ORP set point when calibrating.

For best results the PPM should be at the desired level when calibrating ORP.

Measure the current PPM

using a standard test kit. Calibrating ORP is intuitive and takes a little practice. The following

table can be used to improve the accuracy of the calibration. Follow the recommendations in the table and within a few

days the PPM should be on track. The values of interest are:

Measured PPM: The hand measurement.

Desired PPM: The actual PPM that is desired in the pool.

ORP: The value of ORP that is displayed on the screen.

ORP Set point: The value of ORP that the Controller is trying to achieve.

Hand PPM ORP Display Action

Low

Perfect

Above hand

check

At hand check

Below hand

check

Above hand

check

Calibrate to hand check measurement: 10mV per each

PPM Low

Review Setpoints: May need to increase chemical feed

times

Calibrate to hand check measurement: 10mV per each

PPM Low

May need to decrease chemical feed times & calibrate to

hand check

At hand check No changes

Below hand

check

High

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

28

Above hand

check

At hand check Lower the set point

Below hand

check

Calibrate to the hand check

May need to decrease chemical feed times & calibrate to

hand check

Calibrate to hand check measurement: 10mV per each

PPM High

Page 29

Calibrating ORP

!

EXAMPLE 1: The default set point is 700, the PPM

hand measurement is 1.0 (2.0 PPM desired), and the current

display shows a measurement of 690 mV. From the above table the hand PPM is low and the ORP is below the set

point. The chemical feed times are not high enough for the ORP to reach the set point and should be increased.

EXAMPLE2:Fromexample1changethehandmeasurementto4.0PPMwithORPreading700mV.Fromtheabove

table the hand PPM is high and the ORPisbelowthesetpoint.TheORPshouldbecalibratedto700+(4.0–2.0)*10=

720.To compare ORP measurements to PPM measurements per actual pH readings refer to the calculated PPM chart on

page 131.

Calibrating Calculated PPM

If you have an ORP sensor module and Calculated PPM mode selected. You can calibrate the Calculated PPM in the

following manner. Measure the PPM using a standard test kit. To calibrate the PPM, move the cursor to PPM and press

ENTER. Enter the value obtained from the test kit in the value entry screen. Press ENTER again to save your changes.

NOTE

You can enter the password 9003 to see the ORP and adjusted ORP being

used for calculated PPM. These ORP values will only be displayed for four

(4) seconds.

WARNING

Always make sure the pH is at the pH setpoint and PPM is greater than

1.5 PPM before calibrating calculated PPM.

Always control at PPM levels greater than 1.0 PPM when using

ORP sensors.

MANUAL RELAY CONTROL

Display Screens

Position the cursor to the left of the status word and press

ENTER

to toggle the relay on and off. The length of time the

relaystaysonisadjustableintheprogramming.Whenthe

relay is toggled to OFF the relay immediately goes back to

automatic control and in some cases may immediately turn

ON.

back

Main Status, cursor

at pH Relay

pH 7.67>OFF 7.50s

ORP 490 -OFF 700s

_____

69.0f SW1OFFSW2OFF

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

29

Page 30

RELAY TIMER DISPLAY

The Relay Timer display indicates the present status of the 8 timers

used in the Controller. The most common use for this screen is to

perform diagnostics on a specific relay or to see how long a relay

has been on. From the DISPLAY SCREEN press the right arrow button

twice. Press the left arrow button to return to readings screen.

Timer Screen, Relay 1 (pH)

pH, Mix TMR00:00:00

>TD00:00:00

CNT: 0 S 00:00:00

STS:OFF TOT 0:00

Note: To reset the relay timers to zero use the right button to scroll the cursor beside the information that you want to

reset and then press the ENTER button.

• TMR:Displaysrelaytimer.Showstimeremainingforrelayontime.

This timer will be counting with off and on cycles. Counting down when ON cycle, counting up when OFF cycle.

• TD:DisplaysthetimetheMPShasbeenONforthecurrentday(ToDay).

• CNT:Totalnumberofrelaycyclessincelastreset.

• S:Setoverfeedtimer,lengthofrelayontimewithoutreachingsetpoint.

• STS:StatusofrelayON,OFF,SetPointOverfeed(SOV),Overfeed(OVF),andDisable(DIS).

• TOT:DisplaysthetotaltimetheMPShasbeenONsincelastresetinhours:minutes.

SETUP FLOW

To use a switch as a digital flow switch you must first set it up. To enter the setup screen from the DISPLAY SCREEN

move the cursor to the switch "SW_" to be setup and press ENTER. You can enter the number of pulses per gallon from

1 to 999.9. This second method should only be used for flow meters that generate less than one pulse per gallon.

The highest volume that can be accumulated from the flow rate is 65,535 gallons.

Flow can also be displayed in g/pul and Piezo.

NOTE: Switch 1 is the default ow switch for relay control and should not be used for digital ow if switch 2 is

available.

Flow Switch 2 Setup

Flow Switch #2

SW2 K => 8.5 pul/g

g/m = 35

Total = 256 Clear

NOTE: If k = 0 than g/m = and Total = will not be displayed on the screen.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

30

Page 31

To clear the Total, for any switch place the cursor on Clear

and press ENTER.

When entering pulses per gallon the Controller will only

update this measurement once every 10 seconds.

Conguration Menu

The Configuration Menu consists of the following:

Flow Switch 2 Setup, Clear Counter

Flow Switch #2

SW2 K => 8.5 pul/g

g/m = 35

Total = 0 >Clear

Note:

• Name:Setsupthenameofyouraquaticsystemforeasy

identification during communication and on the wireless

data management system. See pages 56 for Controller

Name Navigation Menu Tree.

Conguration Menu Screen

>Name:Main Pool

System

Programming

Service

Data ( 8:441 )

• System:Setsuptime,date,weekday,andunitdisplay

(English or Metric). See pages 58 or System Set-up Screen

Navigation.

• Programming:RelayprogrammingforRelays1,2,3,Alarm,andPagers.SeeProgramming

Section for details. See pages 52-109 for Programming Set-up Menus.

• Service:Clearcalibrations,data,orrelaytimersaspartofnormalserviceoperations.

• Data:Sensorreadingsarerecordedatadefault2hoursintodata.Atotalof441linesofdatacanbe

stored. Press the down arrow key to view data. See page 114 for Data Screen Navigation.

• Communications:Setupmodems,pagernumbersandoremailaddresses.Seepages102-105for

Programming Screen Navigation Pager 1. See page 116 for Communications Screen for Dail-up and

Internet Modems. See pages 106 for Programming Screen Navigation Email.

Communications

Security Setup

Wizards

Serial # 123456

• SecuritySetup:Setsuppasswords,clearspasswords,andresetsallsettingstofactorydefaults.

See pages 126 for Security Setup Screen Naviagtions.

• Wizards:Selectpre-writtenprogramsforcommonControllerapplications.

See pages 110 for Wizards Setup Screen Navigation.

• Serial#:Viewtheserialnumberhere.Theserialnumberisrequiredwhenrequestingsupport.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

31

Page 32

Name

The Name Setup submenu allows the system controlled by the Controller to be specifically identified on the Controller

and in its communication with other devices. The name of the Controller is particularly useful when using remote

communication devices such as the standard and wireless modem. Naming each aquatic system, pool, or spa will make

it easier to identify each Controller and verify its location before making modifications to the system.

The alphanumeric characters that make up the system name are entered using the touch-pad. You have a full range of

letters, numbers and symbols available to aid you in uniquely identifying each system under your control.

System

Opens a menu where time, date and day can be changed.

• Time:Timeofday;placecursornexttoTIMEselectENTER to set time in hours, minutes, seconds.

• Date:OptionalwithRealTimeClockModule.(Part#724000280)

Date must be set when Real Time Clock is installed. If not installed date with default to 00:00:00.

• Day:OptionalwithRealTimeClockModule.DaymustbesetwhenRealTimeClockisinstalled.

If not installed day with default to 00:00:00.

• Units:SelecttotogglebetweenMetricandEnglishunits.Whenmetricisselectedthedateisdd/mm/yy,

when English is selected the date format is mm/dd/yy.

• Sanitizer:Selectbetween“Cl”(chlorine)and“Br”(bromine).

• OnDelay:PressingEnteronthislineincrements(by15)thenumberofsecondstherelayswillbeoffon

power up.

• BacklightTime:SelecttheamountoftimetheControllerscreenbacklightwillbeoneachtimethecontrol

panel is activated.

• TempDisplay:Displayswatertemperatureinfarnihietdegrees.Toturntemperaturesensoroff,toggleon/off

and select enter.

• ResettoDefault:ReturnsControllertooriginalfactorydefaultsettings.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

32

Page 33

Programming

The Programming menu provides sub-menus used to

configure and view the three output relays, alarm,

and 4 pagers as appropriate. To edit a program use

the up and down arrows to position curser and press

ENTER.

Below are the edit option screens for pH. Use the up

and down arrow to position the curser in front of the

option to be edited.

Edit Settings: Place the cursor to the desired location to

edit the values. Setting a value equal to zero will disable

thatcommand.Forexample,theOffifSwOffcommandis

disabled in the program below. To enable this command

change the "No" to "Yes".

Manual Time: The amount of time the relay will turn on during

a manual cycle. This will occur each time the manual cycle is

activated.

Proportional: The percentage of the set point where the

Controller will begin automatically shortening the length of

the feed cycle to prevent the Controller from over shooting

the set point. To turn off the proportional feed function, enter

"0" as the proportional feed percentage.

Programming Setup Screen

>>1:pH, Mix Time

2:ORP, Mix Time

3:Not Used

A:Alarm

P:Pager1

P:Pager2

P:Pager3

P:Pager4

pH Mix Time Programming Screen

ManualTime 00:02:00<

Proportional% 10

On If pH> 7.50

On If pH< 0.00

Off if RLY On 2

On DELAY 00:00:20

On Time 00:01:00

MinTimeOff 00:05:00

Off if Sw1 Off-YES

Off if Sw2 On -NO

SetOvrfeed 00:00:00

Overfeed 01:00:00

Example:5isenteredastheproportionalfeed%.Thismeans

that the Controller will automatically shorten the length of

thefeedcycleoncethemeasuredreadingiswithin5%ofthe

set point. If the pH set point is set at 7.50, the proportional

feed will begin to limit the feed cycle at 7.87 and continue

to shorten the feed cycle each time it feeds until set point is

reached. For best results, the proportional feed percentage

should be kept between 0 and 5 percent.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

33

Page 34

Programming

On If pH>: Acid Feed: the set point value at which the Controller will begin to feed acid or other pH chemicals to the water

source. Set this value to zero if not using acid to control the pH.

On If pH<: Base Feed: the set point value at which the Controller will begin to feed base or other pH chemicals to the water

source. Set this value to zero if not using base to control the pH.

Off if RLy on(#): Number of relay (1 or 2) will display. Depending on which relay is on the other relay will remain off. Prevents

bothrelaysfromcomingonatthesametimeandmixingChlorineandMuriaticAcid.

OnDelay:ThisisabuiltintimerwhichpreventstheControllerfromprematurelymixingchemicalsstillinthesystemorwhen

suctionsidechemicalfeedingisused.Thispreventstherelayfromturningonwhilechemicalsaremixinginthesystem.

OnTime:MaximumamountoftimethattheControllerwilldispensechemicals.

Min Time Off: Minimum amount of time that the Controller will be off before it will dispense any more chemicals, regardless

of the set point reading.

Off if Sw_Off: Tells the Controller not to dispense any chemicals if this switch number is in an OFF condition. This prevents a

large amount of chemicals from being added into the water line as flow of water returns.

Set Point Overfeed: If a relay output is "ON"accumulativeforlongerthanthesetpointoverfeed'smaximumtimeallowedthe

reading screen will display a “SOV” (Set Point Overfeed) on relay display. (This is to keep the Controller from continuously

feeding chemicals in case the sensor has a problem or if there is a clog in the feed tubes or you run out of chemicals). This

control condition will automatically reset itself if the sensors set point value is reached.

Overfeed:Thisvalueshouldbesetforthemaximumaccumulated“ON” time that the Controller will be allowed to feed each

chemical in a 24 hour period. If the Controller's “ON”timeexceedsthetotalallowed"ON" time within a 24-hour period the

Controller will disable the associated feed relay, and not feed any more of that chemical until the overfeed timers are cleared

manually, or until the Controller automatically resets the overfeed timers at the end of its 24 hour day. Each relay output used

tocontrolafeedsystemwillhaveitsownoverfeedsettings.Exceedingtheoverfeedtimerscanbesettocauseanalarm

condition. If the overfeed time alarm condition persists over a few days you may need to check the chemical container levels,

Controller feeder problems or you may need to increase the overfeed time to a level that will allow the Controller to maintain

the water quality levels within your specified limits. If the system does go into an overfeed condition along with the alarm LED

coming on, it will also display an "OVR" statement in the display screen, for the relay output that was in an overfeed condition.

Overfeed for 01:15:00 or 01:30:00, in case there was a problem with the feeder, chemicals or the sensor that are in overfeed

condition, the Controller would disable feed and alert a problem.

NOTE: The Controller's Overfeed feature is equivalent to the amount of time the chemical feeders will feed during

an alarm condition.

OPR Indicating

Overfeed Condition

Timer Screen, Clear

Overfeed

pH 7.67>OFF 7.50s

ORP 490 -OVR 700s

_____

69.0f SW1OFFSW2OFF

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

34

ORP, Mix TMR00:00:00

>TD01:30:00

CNT: 0 S 00:00:00

STS:OVR TOT 0:00

Page 35

Programming

To manually reset the Overfeed Timer be sure that the cursor is

beside the TD Reading and press the ENTER button.

This will reset the timer to zero.

Service

All Off 10 min (NO) Press the Enter button to turn all three relays off for 10 minutes. This feature is useful when calibrating. After selecting the display will change to (YES) selecting the line again will remove the "All OFF" condition.

•ClearCalibrations:Clearsallpreviouslyenteredcalibrations

•ClearData:Erasesalloftheexistingdata.

•ClearRelayTimers:Resetsalltimerstozeroforallrelays.

Data

Sensor readings are recorded every 2 hours into the data log. Up to 12 lines of data can be recorded a day. The

Controller will save up to 441 lines of data in its data log. When the data log is full the oldest records will be over

written.

The default data log includes the day of operation, the hour sequence, and the sensor readings. When used in

conjuctionwitharealtimeclock,dataincludesdateandhourandsensorreadings.Pressingthedownarrowkeyto

view subsequence data.

When downloading the data with a PC the following information will also be displayed:

Title=MPBPF123:Modem,PCRS232, Front Button pressed, Password entered, Flow S1 on, and relays 1-3 status.

ACU-TROL® AK110 Chemical Controller Installation and User's Guide

35

Page 36

Communications

The followings are only available if the modem is purchased and installed.

Modem: Sets up the number of rings to answer on and the long hang up time. If you enter the password 9000 you can