Pentair 9302C-HM2C, 9302C-HMIC, 9303C-HMIC, 9302CT-GM1, 9302C-HM4C Installation, Operation, Repair And Parts Manual

...Page 1

Series 9300 Hydraulically-Driven

Centrifugal Pumps

Installation, Operation, Repair and Parts Manual

Description

Form L-1526

(12/12, Rev. B)

Hypro centrifugal pumps are designed for agricultural and

industrial spraying and transfer of a variety of fluids: water,

insecticides, herbicides, wettable powders, emulsives, liquid

fertilizers, etc. Polypropylene centrifugal pumps may also be

used to pump acid fertilizer, calcium chloride and other highly

corrosive liquids such as sulfuric and phosphoric acids.

SERIES 9302C & 9302S

Cast Iron & Stainless Steel

Centrifugal Pumps

Max. Flow Rate: .............. 100 gpm

Max. Pressure: ...................120 psi

Ports: ....................1-1/4” NPT Inlet

.................................. 1” NPT Outlet

Hydraulic Ports: ...... 1/2” NPT Inlet

.................................3/4” NPT Tank

SERIES 9303C & 9303S

Cast Iron & Stainless Steel

Centrifugal Pumps

Max. Flow Rate: .............. 147 gpm

Max. Pressure: ...................145 psi

Ports: ....................1-1/2” NPT Inlet

............................ 1-1/4” NPT Outlet

Hydraulic Ports: ...... 1/2” NPT Inlet

.................................3/4” NPT Tank

Hypro Series 9300 hydraulic motor-driven centrifugal pumps

provide smooth performance. They can be conveniently

mounted on the tractor or sprayer, becoming part of the vehicle’s hydraulic system and freeing the PTO for other uses.

The Hypro “close-coupled” design reduces the mounting

space required, eliminating long shafts and couplers between the pump and motor.

SERIES 9303P

Polypropylene

Centrifugal Pumps

Max. Flow Rate: .............. 113 gpm

Max. Pressure: ...................125 psi

Ports: ....................1-1/2” NPT Inlet

............................ 1-1/4” NPT Outlet

Hydraulic Ports: ..... 1/2” NPT Inlet

.................................3/4” NPT Tank

SERIES 9303C-SP

Cast Iron Centrifugal Pumps

Max. Flow Rate: .............. 122 gpm

Max. Pressure: ...................140 psi

Ports: ....................1-1/2” NPT Inlet

............................ 1-1/4” NPT Outlet

Hydraulic Ports: ...... 1/2” NPT Inlet

.................................3/4” NPT Tank

SERIES 9305C-HM3C

Cast Iron Centrifugal Pumps

Max. Flow Rate: .............. 190 gpm

Max. Pressure: ...................180 psi

Ports: .......................... 2” NPT Inlet

............................ 1-1/2” NPT Outlet

Hydraulic Ports: ...... 1/2” NPT Inlet

.................................3/4” NPT Tank

SERIES 9305C-

HM3C-SP, -BSP

Cast Iron Centrifugal Pumps

Max. Flow Rate: .............. 178 gpm

Max. Pressure: ...................154 psi

Ports: ..............2” NPT or BSP Inlet

......................2” NPT or BSP Outlet

Hydraulic Ports: ...... 1/2” NPT Inlet

.................................3/4” NPT Tank

SERIES 9306C & 9306S

Cast Iron & Stainless Steel

Centrifugal Pumps

Max. Flow Rate: .............. 214 gpm

Max. Pressure: ...................150 psi

Ports: .......................... 2” NPT Inlet

............................ 1-1/2” NPT Outlet

Hydraulic Ports: ..... 1/2” NPT Inlet

.................................3/4” NPT Tank

Page 2

General Safety Information

California Proposition 65 Warning -- This product

and related accessories contain chemicals known to the

State of California to cause cancer, birth defects or other

reproductive harm.

Notes are used to notify of installation, operation, or

maintenance information that is important but not safety

related.

Caution is used to indicate the presence of a hazard,

which will or may cause minor injury or property damage

if the notice is ignored.

Warning denotes that a potential hazard exists and

indicates procedures that must be followed exactly to

either eliminate or reduce the hazard, and to avoid serious

personal injury, or prevent future safety problems with

the product.

Danger is used to indicate the presence of a hazard

that will result in severe personal injury, death, or

property damage if the notice is ignored.

Do not pump flammable or explosive fluids such as

gasoline, fuel oil, kerosene, etc. Do not use in explosive

atmospheres. Components not rated for use with

Anhydrous Ammonia. The pump should be used only

with liquids compatible with the pump component

materials. Failure to follow this notice may result in

severe personal injury and/or property damage and will

void the product warranty.

1. Do not pump at pressures higher than the maximum

recommended pressure.

o

2. Maximum liquid temperature is 140

centrifugal pumps.

3. Disconnect power before servicing.

4. Release all pressure within the system before

servicing any component.

5. Drain all liquids from the system before servicing

any component. Flush with water.

6. Secure the outlet lines before starting the pump. An

unsecured line may whip, causing personal injury

and/or property damage.

7. Check hose for weak or worn condition before each

use. Make certain that all connections are tightly

secured.

8. Periodically inspect the pump and the system

components. Perform routine maintenance as

required (See Repair Instructions).

9. Use only pipe, hose and fittings rated for the

maximum psi rating of the pump.

10. Do not use these pumps for pumping water or other

liquids for human or animal consumption.

F for Series 9300

Hazardous Substance Alert

1. Always drain and flush pump before servicing or disassembling for any reason.

2. Always drain and flush pumps prior to returning unit

for repair.

3. Never store pumps containing hazardous chemicals.

4. Before returning pump for service/repair, drain out

all liquids and flush unit with neutralizing liquid.

Then, drain the pump. Attach tag or include written

notice certifying that this has been done. It is illegal

to ship or transport any hazardous chemicals without United States Environmental Protection Agency

Licensing.

L-1526 (12/12, Rev. B)

Never use your hand to check the condition of hydraulic

lines or hoses. If hydraulic fluid penetrates the skin, get

medical help immediately. Failure to get proper medical

help may result in loss of limb or life. The safest way to

check hydraulic lines or hoses is by holding a piece of

cardboard next to the hydraulic line or hose.

The sound pressure level of the pump is 80dBA. Observe

all safety precautions when operating the pump within

close proximity for extended periods of time by wearing hearing protectors. Extended exposure to elevated

sound levels will result in permanent loss of hearing

acuteness, tinnitus, tiredness, stress, and other effects

such as loss of balance and awareness.

-2-

Page 3

Hydraulic Pumps

General Information—Hydraulic Systems

Hydraulic pumps come in two basic types:

• Constant displacement - which will continue to put

out its rated flow regardless of pressure, until the relief valve bypasses the flow.

• Variable displacement - which will produce only the

flow needed by the implement until the total pump

output is reached. If less than the full pump output

is required, an automatic stroke control mechanism

decreases the pump output to maintain a constant

pressure and flow. The output varies according to

demand.

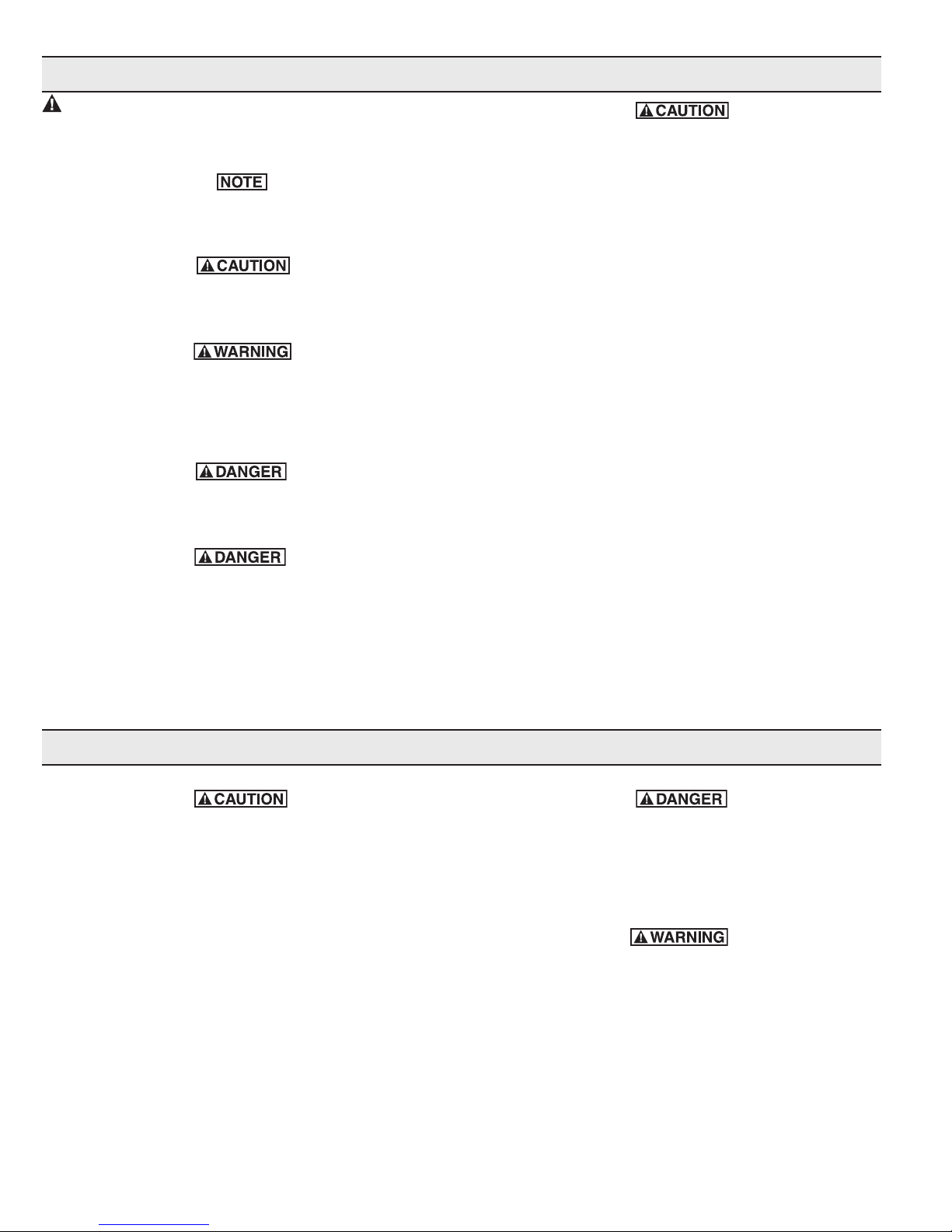

Open Center

Spool Valve

In Neutral

Position

Figure 1

Spool Valves

There are two basic types of spool valves used in conjunction

with these pumps — Open and Closed Center. In the Open

Center Valve (See Figure 1), the flow goes straight through

the valve when in the neutral position. This type is used for

constant displacement pumps where the flow should never

be shut off.

Closed Center

Spool Valve

In Neutral

Position

Gerotor-Type

Hydraulic Motor

Figure 3

Three Systems

Fitting these components together and installing a motor,

we have one of the three types of systems: Open Center,

Closed Center (pressure compensated) and Closed Center

Load Sensing (flow and pressure compensated).

Open Center Systems

In an Open Center System, the hydraulic pump puts out a

constant flow. If the pump puts out more oil than the motor can use, a portion of the oil must be bypassed around

the motor. When the oil is bypassed around a loop and does

no work, the energy put into it by the pump turns into heat.

Therefore, the amount of oil bypassed should be kept to a

minimum. Use the largest motor possible.

Closed Center (Pressure-Compensated) Systems

The Closed Center Pressure-Compensated system has a

variable displacement pump which will deliver flow at the

necessary rate to maintain a specified pressure. It is desirable to equip implements with a motor of a low flow range

that will cause the pump to operate between 1800 and 2100

psi [124 and 145 BAR]. A motor that requires a large volume to obtain the correct implement speed usually causes

the hydraulic pump in a closed center system to operate at

a lower pressure than desirable. This low pressure results in

unnecessary flow and the generation of heat that lowers the

lubricating quality of the oil and may damage transmission

parts. Use the smallest motor possible.

Figure 2

The Closed Center Valve (See Figure 2) is used with variable

displacement pumps. The flow is completely shut off in the

neutral position, causing the pump stroke to adjust to zero

flow. The flow stops, but the pump maintains a static pressure up to the valve.

Hydraulic Motors

Figure 3 shows an internal gear motor (Gerotor) where pressure causes the cavities between the gears to expand on one

side, developing torque. The Gerotor type of hydraulic motor

is used on Hypro pumps for its superior performance characteristics, including cooler running and higher rpm capabilities.

Closed Center Load Sensing Systems

(Flow and Pressure-Compensating)

The Closed Center Flow-Compensated System is a variation

of the pressure-compensated system, designed primarily for

more efficient operation and the generation of less heat. It

works on the principle of maintaining a constant pressure

drop from the pump to the work port of the selector valve. Any

variation in demand at the motor will cause a change in flow.

The system senses this change in flow due to the change

in pressure drop across the valve and causes the pump to

compensate by varying the pump flow. No restrictor is used

in the pressure line and no oil is bypassed.

-3-

L-1526 (12/12, Rev. B)

Page 4

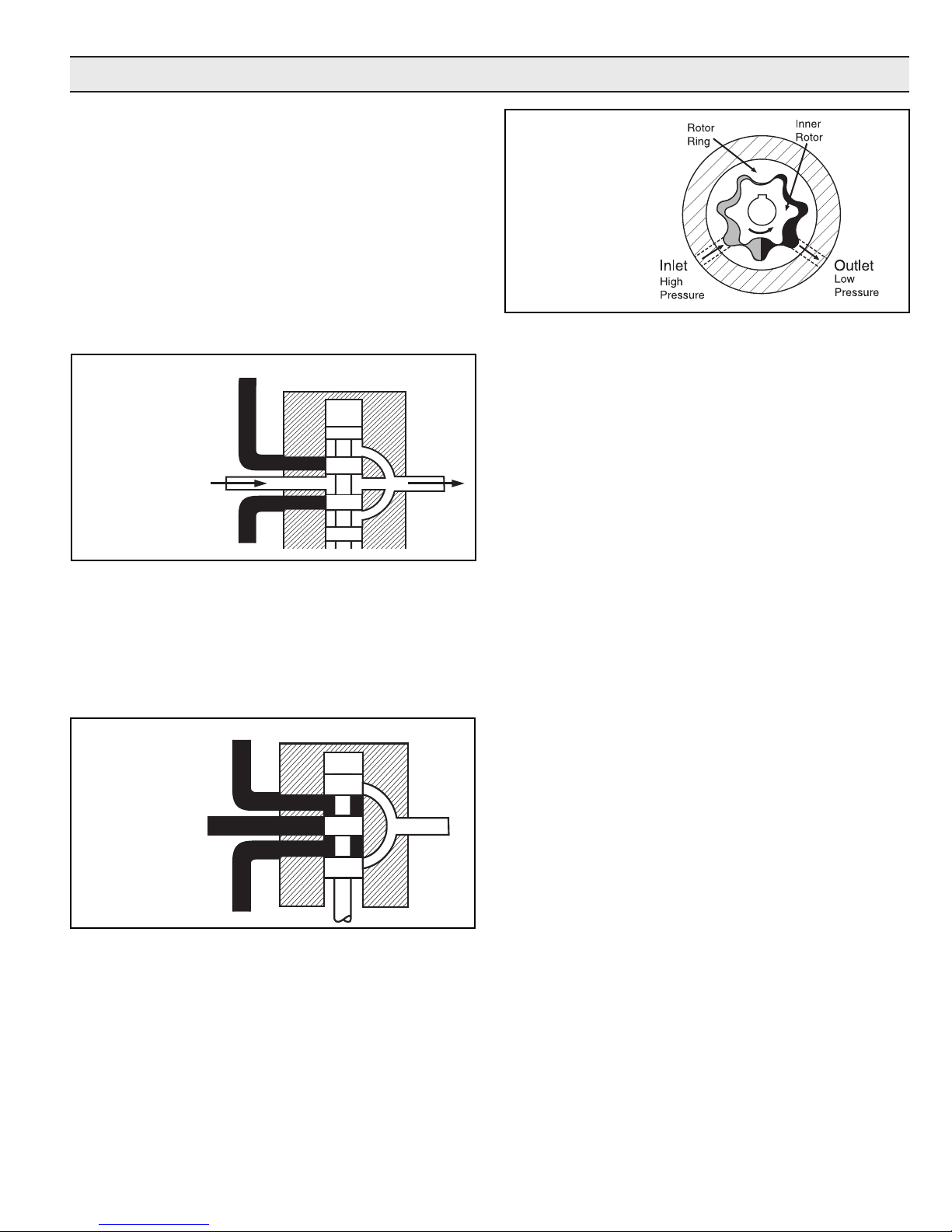

Plumbing Installation

7

6

Centrifugal Plumbing Hook-up

REF. DESCRIPTION

NO.

1 Tank Lid

2 Vent Line #3430-0456

3 Jet Agitator

4 Shut-off Ball Valves

5 Centrifugal Pump

6 Spray Control Console

7 Centrifugal Pump Control

8 Manifold Boom Valve

9 Electromagnetic Flowmeter

10 Compact Jet Turret Nozzle Body

L-1526 (12/12, Rev. B)

-4-

Page 5

Installation Instructions

All Models — Open Center Systems

Models include Tank Port Adapter with built-in Check Valve

Assembly and Pressure Port Adapter.

HM2C and HM4C Models Only — Closed Center and

Small Open Center Systems.

Models include Tank Port Adapter with built-in Check Valve

Assembly and Pressure Port Adapter with three different

size metering orifices for HM4C models. The orifices are not

required for use with closed center systems with flow control,

such as John Deere closed center systems. Also, do not

use for small open center systems with a maximum flow of

8 gpm [30.28 lpm] for HM2C model; 10 gpm [37.85 lpm] for

HM4C model. If necessary, the pressure port adapter may be

used without a metering orifice installed in any closed center

system. For best results, the pressure differential across the

motor should be less than 2500 psi (170 bar).

Preliminary to Mounting

Consult the owners manual to determine the type and

capacity of the hydraulic system. Make sure the hydraulic

system is recommended to operate with a continuous load.

Refer to the Pump Selection Guide to confirm you have the

proper pump for your hydraulic system.

Check to see that the pump impeller can be turned by hand.

(Turn the shaft clockwise using a deep socket wrench on the

impeller nut.) If it cannot be turned, open the pump casing to

look for obstructions. Clean out any corrosion build up where

the casing fits over the eye of the impeller.

Pump Inlet Line

To achieve full capacity from the pump, the inlet line should

be at least the same size as the inlet port on the pump.

Reducing this line size will restrict the capabilities of the

pump. The line must also be free of air leaks. Check all

fittings and connections in the suction line for tightness.

The introduction of air may affect the priming and pumping

capabilities of the pump. Use good quality suction hose that

will not be collapsed by suction.

For non self-priming models, the centrifugal pump should

be mounted below the liquid level and as near to the liquid

source as possible to allow for the shortest suction line

practical. To achieve optimal performance, the suction line

should slope down into the pump. Avoid rises and humps

that could trap air in the line to the pump. The suction line

and pump should be filled with liquid prior to starting the

pump, and all discharge lines should be open.

Pump Outlet Line

The recommended orientation for the outlet port is pointing

straight up. This allows liquid to stay in the pump while it

is priming. The outlet line should be the same size as the

pressure port on the pump to give the optimal flow. The line

should have as few restrictions and elbows as possible to

optimize the pump performance and reduce pressure drop

from the pump to the spray tips.

Priming the Pump

The pump must not be run dry.

Before starting the pump, the inlet line and pump must be

filled with liquid and all discharge lines must be open. On selfpriming models, only the pump chamber needs to be filled

with liquid. The pump must not be run unless it is completely

filled with liquid because there is a danger of damaging

the mechanical seal, which depends on the liquid for its

lubrication.

Non-self-priming models should be mounted below the level

of the liquid. The suction line should slope down to the pump

and be free of dips and bends. If this cannot be done, a foot

valve should be installed in the end of the inlet line so that

the line can be completely filled with liquid before starting the

pump.

For best priming results, the top vent plug should be

removed from the pump casing. A vent line (1/4” [6.35

mm] tubing is sufficient) should be installed running

back to the top of the tank. This line prevents air lock and

allows the pump to prime itself by bleeding off trapped air. The

small stream of liquid that returns to the tank during operation

is negligible. The discharge from this line should be positioned

in the tank above the high liquid level. Self-priming models

can be primed by removing the top vent plug and filling the

priming chamber. The priming chamber will fill to the level

of the inlet port. After use, the priming chamber should be

flushed and drained to avoid chemical corrosion and damage

from freezing. Drain by removing the lower drain plug.

Controlling the Pump Flow

The best way to control the flow is by incorporating two

control valves in a pipe tee immediately after the strainer

in the discharge line. This permits controlling agitation flow

independently of nozzle flow.

In any centrifugal pump, it is the large volume of liquid which

puts load on the drive. Use only the flow needed to develop

the pressure required at the boom and to maintain adequate

agitation. Hydraulic motor-driven centrifugal pumps are

easily adjusted to the exact flow required, as explained in the

Operating Instructions of this manual.

Centrifugal Pump Control

Hypro now offers many different components for spraying

systems. The Hypro centrifugal pump control incorporates

the electric flow control valve, a self-cleaning line strainer, a

visual pressure gauge and a manual agitation control valve.

Flow Control Valve

A high-flow electric proportional valve allows for maximum

flow control to the boom valves. It provides smooth, rapid

control that can be controlled from either an electronic rate

controller or switch box.

Strainers

The recommended placement of the strainer for a centrifugal

pump is in the pump outlet line. This will eliminate any

possible restriction that the strainer could create if it were

installed in the inlet line. Ensure that the proper strainer

size and screen mesh are used to limit the pressure drop

-5-

L-1526 (12/12, Rev. B)

Page 6

Plumbing Installation

and achieve the best filtration. Line strainers can also be

installed in the tank fill line to filter liquid as it is loaded into

the tank as well as in the boom lines to further filter the

solution prior to the spray tips. Tank baskets can also be

used to filter material added through the tank lid.

Agitation

The centrifugal pump control contains a manual agitation

control valve that can be adjusted to provide the right

amount of flow to the jet agitators in the tank to ensure

proper mixing within the tank.

Flowmeter

To eliminate the mechanical problems of a turbine flowmeter,

we recommend that an electromagnetic flowmeter be used.

These flowmeters have no moving parts to wear out and will

provide a more consistent and accurate flow reading. They

can be input into just about any electronic rate controller or

switch box.

Boom Section Valves

For rapid response and reliability, we recommend electric

plunger valves be used for boom control. The valves should

be sized accordingly to minimize the pressure drop and

maximize the flow rate. The boom tubing or hose should

be sized accordingly to ensure that a pressure drop in the

lines does not occur, causing inconsistent pressures at the

nozzles.

Nozzle Bodies

Nozzle bodies with shut-off check valves are recommended

to eliminate dripping from the spray tips when the boom

valves are shut down.

Hooking Up the Hydraulic Motor to the

Tractor Hydraulic System

Hypro Series 9300HMC hydraulic motor-driven pumps can

be mounted on either the tractor or sprayer. When hooking

up, make sure that no dirt or liquid gets into the hydraulic

motor. Keep all hydraulic connections clean. Be sure

to connect the hydraulic motor into the system correctly by

putting the pressure line to the Pressure Port Adapter and

return line to the Tank Port Adapter. The adapters on the

hydraulic motor are sized to accommodate 1/2” NPT fittings

on the pressure port and 3/4” NPT on the tank port. For

maximum performance, the hydraulic lines should also be at

least 1/2” [12.7 mm] in size for the pressure line and 3/4”

[19.05 mm] for the tank line.

The tank (OUT) port adapter with a built-in check valve

assembly will guard against reverse operation — allowing you

to reverse oil flow to operate other equipment. This adapter

must not be removed. On HM2C and HM4C model pumps,

the pressure (IN) port adapter is a two-piece assembly

consisting of an open (unrestricted) adapter with three orifices

packed loose with the pump. (See the Operations Section.)

When using the HM2C or HM4C unit on any flow- compensated

(load sensing) closed center system, or any small open center

system with a maximum flow of 8 gpm [30.28 lpm] for HM2C

or 10 gpm [37.85 lpm] for HM4C, the metering orifice should

be removed from the pressure port adapter. When using these

units on flow-compensated systems, connect to the motor

priority circuit if your tractor has one.

Standard spool valves, which are found on all tractor

hydraulic systems, may cause potentially damaging high

peak pressures in the hydraulic system when closed because

of abrupt shut-off of oil flow in both the supply and return

lines. When shutting off the pump, move the selector to the

FLOAT position to allow the centrifugal pump to come to a

stop gradually.

For further information

regarding Hypro products,

contact your local dealer or

Hypro directly at

www.hypropumps.com or by

calling 1-800-424-9776.

Open Center Systems— All Models

Adjusting Centrifugal Pump Output

HM1C, HM3C & HM5C motors have bypass screw fully

closed from the factory. HM2C & HM4C motors have bypass

screw set at 1-1/2 turns from fully closed from the factory.

1. Open the bypass adjustment screw 2-1/2 turns from fully

closed. Turn the bypass screw in to achieve the flow for

the desired gpm and psi.

2. Start the tractor. Leave the directional valve in the

neutral position and allow hydraulic oil to circulate for

approximately 10 to 15 minutes or until adequately

warmed.

L-1526 (12/12, Rev. B)

Operation

3. Prime the centrifugal pump with all valves open (See

the Installation Instructions and System Configuration

Diagram).

4. Close the agitation line valve and keep the control

valve and the boom shut-off valve open. Note the spray

pressure.

5. Open the agitation line valve until you have desired

circulation in the tank. Recheck the spray pressure. If it

is too low, close down the agitation line valve until the

desired spray pressure is reached. If the spray pressure

is too high, throttle the centrifugal pump by closing down

the control valve.

-6-

Page 7

Closed Center (Pressure-Compensated) —

HM2C and HM4C Models Only

On a pressure-compensated system, the amount of oil that

is allowed to flow through the hydraulic motor is regulated

by a metering orifice in the pressure port adapter. Three

different sizes of orifices are supplied with the HM2C and

HM4C model pumps to allow flexibility in the flow required for

individual sprayer needs.

The smaller the orifice, the less hydraulic oil goes through

the motor, so the pump will run slower and the flow of liquid

pumped and the spray pressure will also be less. As the

hydraulic oil flow is increased (by installing a larger orifice),

the amount of liquid being pumped and the spray pressure is

also increased.

Installing and Removing Metering Orifice

1. Shut off the hydraulic system.

2. Disconnect the line to the pressure port of the hydraulic

motor.

3. Remove the adapter from the motor using a 1-1/16’’

wrench. Make sure the o-ring is on the metering orifice

before installing into port adapter.

4. The orifice is removed or installed in the port adapter by

tapping either in or out of the adapter.

A. To remove — tap the orifice out from the small end

of the adapter.

B. To install — tap the orifice in from the large end of

the adapter. The orifice is seated when a snap sound

is heard.

Adjusting Centrifugal Pump Output

1. Open the bypass adjusting screw in the hydraulic motor

three (3) turns.

2. Start the tractor and allow the hydraulic oil to circulate

for approximately 10 to 15 minutes or until adequately

warmed.

3. Close and lock down the bypass adjusting screw in the

hydraulic motor.

4. Prime the centrifugal pump with all valves open (See

Installation Instructions and System Configuration

Diagram).

5. Close the agitation line valve and the control valve; open

the boom shut-off valve.

6. With the pump running, open the control valve until the

pressure gauge indicates the desired spraying pressure.

7. Open the agitation line valve until sufficient agitation is

observed. Then, if spray pressure drops, readjust the

control valve to restore to the desired pressure.

8. If a sufficient boom pressure cannot be attained, install

the #2 size orifice and repeat Steps 5 through 7.

9. If a sufficient boom pressure still cannot be attained with

the #2 size orifice, install the #3 size orifice and repeat

Steps 5 through 7.

10. If a sufficient boom pressure still cannot be attained

with the #3 size orifice, remove the orifice and repeat

Steps 5 through 7.

Closed Center (Load Sensing) — All Models

Many tractors are being introduced with load sensing

systems (also referred to as flow and pressure- compensated

systems) which simplify system setup and eliminate many

of the problems associated with using the wrong size pump

motors on a given hydraulic system. Usually, any of Hypro’s

9300HMC models may be used on this type of system,

provided the hydraulic system produces sufficient oil flow for

the hydraulic motor being used (Refer to the Pump Selection

Guide).

This system maintains a constant flow of hydraulic oil for a

given pressure drop. The flow is adjustable with a flow control

valve installed in the hydraulic system (such as the Tortoise/

Hare control on John Deere tractors). Because this system

has adjustable flow, there is no need to bypass hydraulic oil

as in an open center system, or to restrict the flow with orifices

as in a closed center pressure- compensated system.

Adjusting Centrifugal Pump Output

1. Make sure the orifice from the pressure port adapter

of the hydraulic motor has been removed (HM2C and

HM4C models only).

2. Close and lock down the bypass adjusting screw in the

hydraulic motor.

3. Set the tractor hydraulic flow control valve for minimum

hydraulic oil flow to the remote outlet (Tortoise position).

4. Start the tractor and allow the hydraulic oil to circulate

for approximately 10 to 15 minutes or until adequately

warmed.

5. Prime the centrifugal pump with all valves open (See

the Installation Instructions and System Configuration

Diagram).

6. Close the agitation line valve and open the control valve

and the boom shut-off valve.

7. Slowly adjust the tractor hydraulic flow control valve until

the desired boom pressure is attained.

8. Open the agitation line valve until sufficient agitation is

observed. If spray pressure drops, readjust the tractor

hydraulic flow control valve to restore it to the desired

pressure.

Flush Pump After Use

One of the most common causes for faulty pump performance

is gumming or corrosion inside the pump. Flush the pump

and entire system with a solution that will chemically

neutralize the liquid pumped. Mix this solution according to

the manufacturer’s directions. This will dissolve most residue

remaining in the pump, leaving the inside of the pump clean

for the next use.

To Prevent Corrosion

After cleaning the pump as directed above, flush it with a

permanent-type automobile antifreeze (Prestone®, Zerex®,

etc.) containing a rust inhibitor. Use a 50% solution, half

antifreeze and half water. A protective coating will remain on

the inner pump surfaces. Save the excess antifreeze for the

next application. Plug the ports to keep out air during storage.

For short periods of idleness, noncorrosive liquids may be left

in the pump, but air must be kept out. Plug the ports or the

seal port connections.

-7-

L-1526 (12/12, Rev. B)

Page 8

Repair Instructions

Hypro Repair Tools:

ToolBoxNo.3010-0168•1/4”AllenWrenchNo.3020-0008

SupportBars(2)No.3010-0064•PortBrushNo.3010-0066

1/16”AllenWrenchNo.3020-0009•BrushHolderNo.3010-0067•

LargeRetainingRingPliersNo. 3010-0084 • Small RetainingRing

Pliers No. 3010-0167

NOTE:

Shop Tools Needed:

BenchVice•ArborPress•AirorHandDrill•SmallKnife

Metal Pipe - 1” dia. x 4” high (Bearing Seating Tool)

PVC Pipe - 3/4” dia. x 4” - 6” high (Seal Seating Tool)

12”CrescentWrench•TwoFlatScrewdrivers(approx.10”long)

1/2’’,9/16”,5/8”and7/8”sockets•HammerorRubberMallet

SmallScrewdriver(recommended)•LargeFile(optional)

1/2”and9/16”BoxEndWrench•LubricatingSpray(WD-40orLPS)

SmallamountHydraulicOil•CleaningSolventTank(recommended)

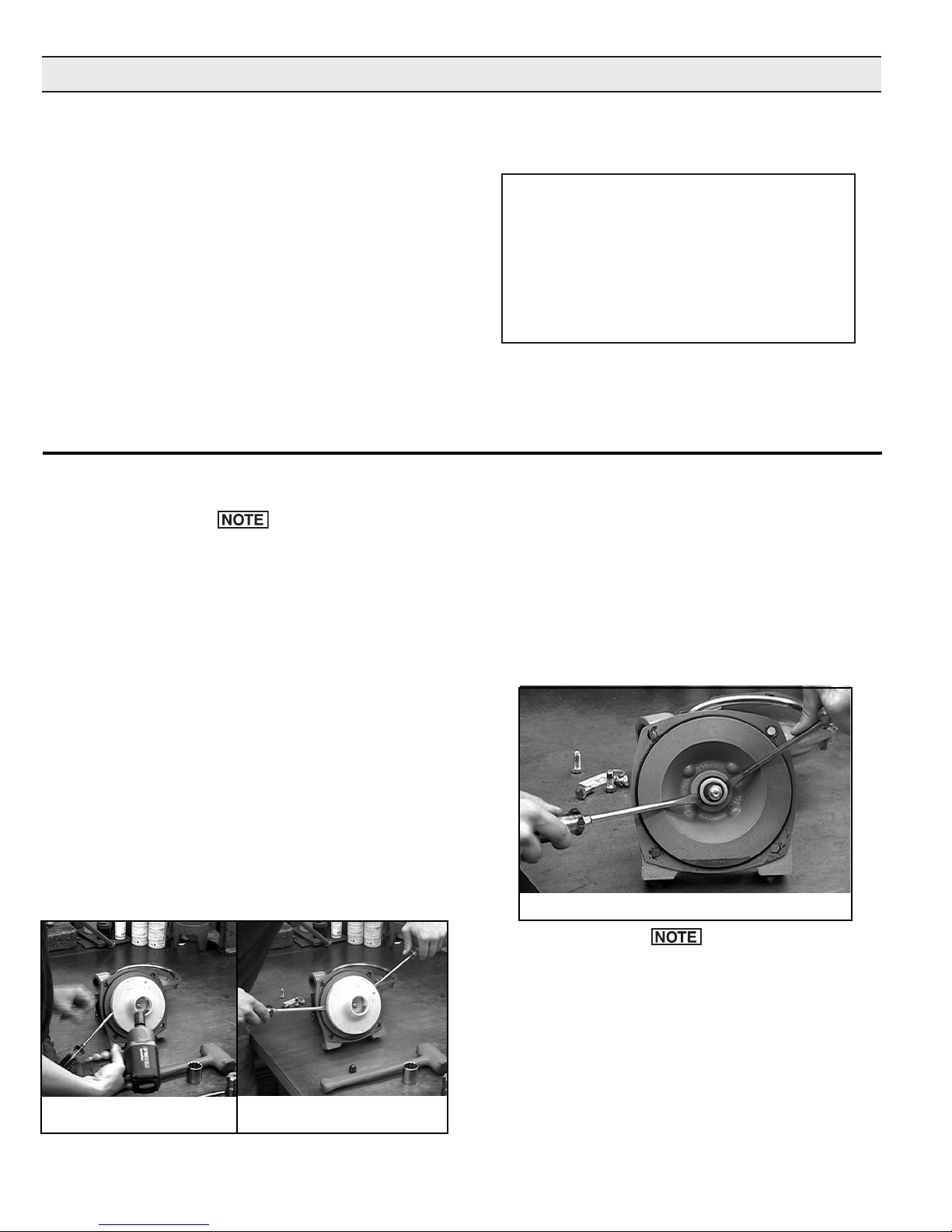

Pump Housing Disassembly

Instructions in italics describe procedures for the Series

9300P Polypropylene Centrifugal Pumps, when different

than the cast iron pumps.

1. Using a 9/16” box end wrench, remove the four Hex

Head Bolts holding the Pump Casing to the Mounting

Flange. (If necessary, tap Pump Casing Outlet Port with

rubber mallet or hammer to separate.) [Using a 1/2”

wrench, remove the six bolts from the front. For the two

bottom bolts securing the base, you will need to hold the

two nuts with another 1/2” wrench. Also remove the 5/16”

screw from the rear, near the outlet port.]

Visit our website at

www.hypropumps.com

for video repair procedures,

under the Tools section.

3. Once nut [and washer] is removed, place a screwdriver

on each side behind the Impeller and pry away from

the Mounting Flange (See Figure 7). Remove Woodruff

KeyfromtheShaft.RemoveO-ringfromthe Mounting

Flange.

Pump Seal Removal

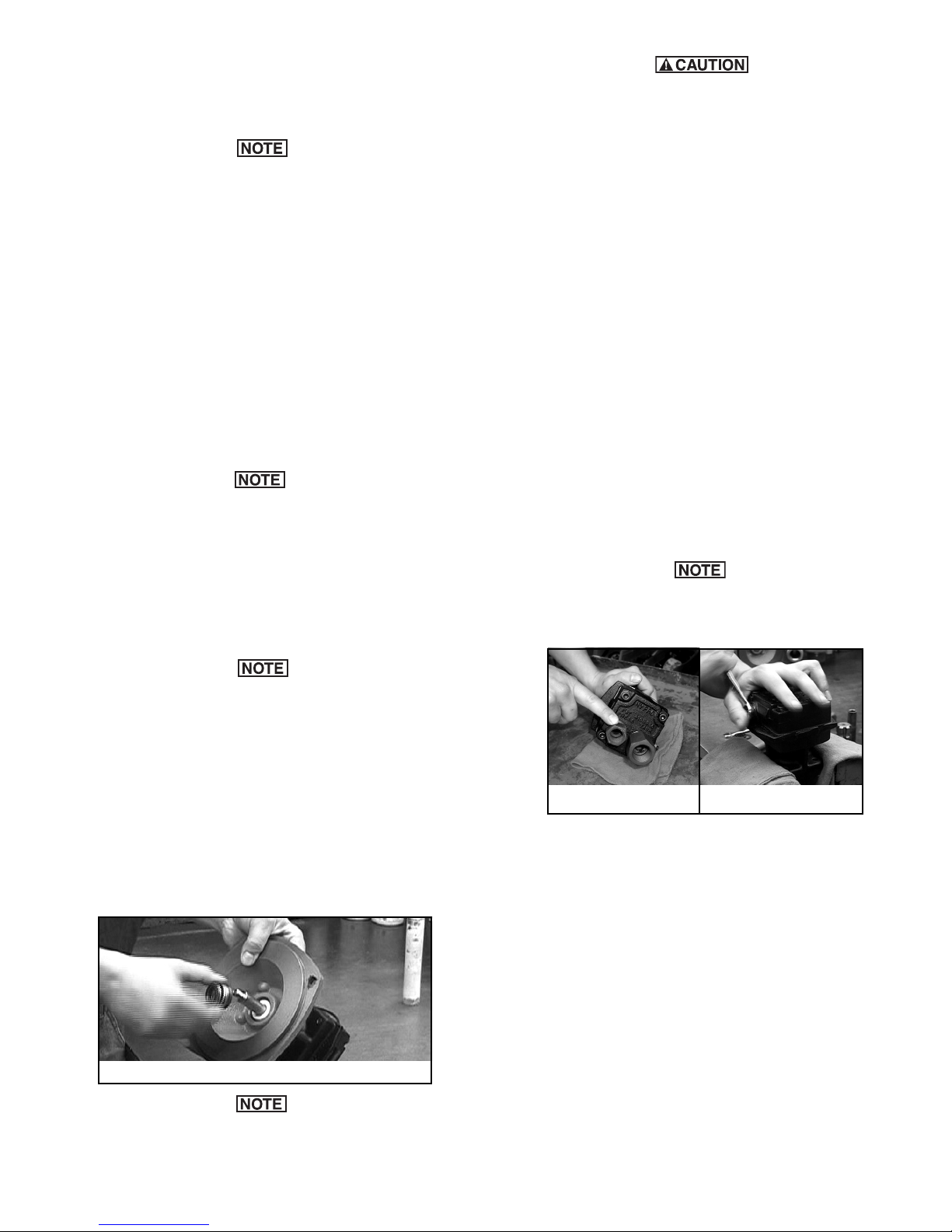

1. Lightly lubricate the Shaft for easier removal of the Seal.

Using two screwdrivers positioned opposite each other,

pry the rotary portion of the Seal from the Shaft (See

Figure 8).

2. To remove the Impeller Nut, insert a large screwdriver

or file (at least 10” [254 mm] long) into Impeller Vanes to

prevent Impeller from turning when loosening nut. Use a

5/8” socket wrench to remove the Impeller Nut by turning

it counterclockwise (See Figure 6). [Use 7/8” deep

socket wrench to remove Plastic Seal Nut, then 9/16”

deep socket to remove Metal Jam Nut and Washer.]

Figure 6

L-1526 (12/12, Rev. B)

Figure 7

Figure 8

In the case of a severe pump seal leak, inspect the

Shaft/Bearing Assembly in the hydraulic motor for

possible contamination.

2. Using a 1/2’’ box end wrench, remove the four bolts

holding the Motor to the Mounting Flange. Remove

Motor. [Remove the Plastic Back Cover flange. Knock

the Seal out from back with a hammer and screwdriver.

Use a 1/2’’ socket wrench and 1/2’’ box end wrench to

remove the Mounting Flange from the Hydraulic Motor.]

-8-

Page 9

3. Using a screwdriver and hammer, tap out the stationary

portion of the Mechanical Seal from the motor side of the

Mounting Flange. (If the motor is not removed, the seal

can be pried out with a small screwdriver.)

The seal will be damaged by removal in this manner. A

new seal must be used when pump is reassembled.

Clean-Up Of Pump Housing

1. Using a circular bottle-type wire brush with air or hand

drill, clean the Outlet Port, Inlet Port and the sealing

areas of the o-ring on the Pump Casing and Mounting

Flange. Using the port brush, clean the seal cavity in the

Mounting Flange. [The last step should not be performed

on the 9300P.]

2. After wire brush cleaning, it is recommended that the

Pump Casing and Mounting Flange be further cleaned in

a solvent tank to remove rust and corrosion particles.

The threads of the Plastic Seal Nut are fine and can

be easily cross threaded. To prevent cross threading,

turn the Plastic Seal Nut counterclockwise until area

of thread engagement is detected; then turn the Plastic

Seal Nut clockwise until it is secure. Do not over tighten

the Plastic Seal Nut.

6. InsertaWoodruffKeyintotheShaftkeyslot;thenplace

theImpellerontheShaftandalignitwiththeKey and

press against the Mechanical Seal Assembly. Apply a

blue thread locking compound to the Impeller Nut, and

using a 5/8’’ socket wrench and using a screwdriver to hold

the Impeller, install the Impeller Nut. [On polypropylene

models, insert the Woodruff Key into the Shaft key slot.

Place the Impeller on the Shaft and align it with the Key;

then press against the Mechanical Seal Assembly. Place

the Metal Seal Washer on the Shaft. Apply a drop of blue

thread locking compound on the Impeller Nut and secure

the Impeller to the Shaft as described previously.]

Seal Replacement/Pump Housing Reassembly

If the hydraulic motor requires repair, proceed to

Disassembly and Repair of the Hydraulic Motor in the

next column.

1. Lubricate the seal cavity in the Mounting Flange with

®

WD-40

, LPS or equivalent. Do not lubricate the shaft.

2. Install the stationary portion of the Mechanical Seal by

sliding over the Shaft with the ceramic side out.

Make sure both the seal cavity and seal are clean and

lubricated.

3. To seat the seal in the seal cavity, use a piece of 3/4”

PVC pipe 4” to 6” [101.6 to 152.4 mm] in length. Lubricate

sealing surface on seal after it is seated. Do not lubricate

the shaft.

4. To install the rotary portion of the mechanical seal, place

it over the shaft with the carbon side facing in, and press

against the stationary portion (See Figure 9).

5. Install rubber gasket 1700-0100 over shaft against rotary

portion of seal.

7. Install the o-ring on the mounting flange. Replace the

o-ring if worn or damaged.

8. Place the pump casing on the mounting flange, insert

and tighten the bolts.

Disassembly and Repair of the Hydraulic Motor

The work area and motor should be as clean as

possible to prevent contamination of parts.

Figure 10

Figure 10a

1. Remove the Mounting Flange from the motor body and

place Hydraulic Motor in vise.

2. Remove Tank Port Adapter and Pressure Port Adapter

with large crescent wrench or 1-1/16” and 1-3/8” box end

wrench (See Figure 10).

Figure 9

On Models 9305C-HM3C-SP, 9505C-HM3C-BS and

9305C-HM3C, install the washer on the shaft prior to

installing the impeller nut.

3. Using a 9/16” box end wrench, loosen the nut on the Bypass Adjusting Screw (See Figure 10a).

4. Using a small screwdriver, remove the Bypass Adjusting

Screw from the Motor. (This will remove the Screw, Nut,

Washer and Thread-Seal Gasket.)

5. Using a 1/4” Allen wrench, remove the Socket Head Cap

Screws from the Motor End Plate (See Figure 10).

6. If Motor End Plate will not lift off easily, use a small screwdriver to carefully pry apart the boss portion of the End

Plate and Gerotor Housing until free (See Figure 11). If

Gerotor Housing will not lift off easily, carefully pry apart

-9-

L-1526 (12/12, Rev. B)

Page 10

the boss area between the Gerotor Housing and the Motor Body. (It may be necessary to alternate sides when

prying apart Motor sections.)

Figure 11

7. Remove both parts of the Gerotor.

8. OnHM3C models, remove theWoodruffKey from the

Shaft. On HM1C, HM2C and HM4C models, remove the

Roll Pin from the Shaft.

9. Remove the o-ring from the Motor End Plate and Body

with a flat instrument such as a knife blade.

10. Inspect Motor End Plate, Body and Gerotor Housing for

wear and/or gouging. If gouging has occurred in both the

Motor End Plate and Body, the motor is not repairable.

If gouging has occurred in the Motor End Plate, Body or

Gerotor Housing, the part that is worn must be replaced.

If Gerotor Housing is damaged, Gerotor parts must also

be replaced.

Hydraulic Motor Shaft Disassembly and Repair

1. Remove Large Retaining Ring from Shaft with a screwdriver. Remove Thrust Bearing Assembly from Shaft (includes the Thrust Bearing and two Thrust Bearing Races) and the Seal Spacer.

2. Remove the Small Retaining Ring next to the Shaft Ball

Bearing.

3. To remove the Bearing from the shaft, place the shaft

(threaded end up) in the arbor press fixture. Place the two

support bars provided in the repair kit opposite each other and between the seal on the shaft and the arbor press

fixture. Using an arbor press, press the shaft through the

Bearing, Seal Spacer and Seal (See Figure 13).

4. Inspect the sealing area of the shaft for wear. Inspect

other Shaft Assembly Components for wear and replace

if necessary.

Figure 13

5. While motor is completely disassembled, clean all parts

in a solvent bath.

Build Shaft Sub-Assembly

To Remove the Shaft Assembly from the Motor Body

1. Remove the Slinger Ring from the Motor Shaft.

Special attention should be exercised when working with

retaining rings. Always wear safety goggles when working with spring or tension loaded fasteners or devices.

2. Using the large retaining ring pliers, remove the Retaining

Ring next to the Ball Bearing in the Motor Body.

If bearing is binding against the retaining ring so that it

cannot easily be removed, place the motor body (threaded portion of the shaft up) on arbor press. Using a piece

of un-threaded metal pipe (1” dia. x 4” high [254. mm x

101.6 mm high]), slide over the shaft and gently press

down with the arbor press just enough to relieve the

pressure on the retaining ring.

1. To assemble the seal cartridge, remove the old

seal from the cartridge by pressing it out. The cartridge is reused by assembling the new seal into cartridge, ensuring the new seal is pressed in with the lip

seal on the opposite side as shown in Fig.A.

Press

Seal Spacer

Seal

Cartridge

Fig. A

Important: To prevent damage to the seal lip extending out,

use seal spacer as shown to guard lip during assembly.

2. Install the large retaining ring onto large diameter end of

shaft.

3. From the small, threaded end of the shaft, install the

following parts in this order: thrust bearing race, thrust

bearing, 2nd thrust bearing race.

Note: The thrust bearing and races should not be reused if

they are showing any signs of wear.

Figure 12

3. Place body in position on arbor press. Threaded portion

of the Shaft should be inside the fixture. Press out shaft

assembly with arbor press (See Figure 12).

L-1526 (12/12, Rev. B)

4. Install new type seal spacer (looks like a thick washer,

approx .130 inch thick).

5. Before installing the new seal, its lip must be expanded to

fit on the shaft. With the seal lip facing out, slide the seal

over the threaded end of the shaft and gently push the seal

onto the raised area of the shaft. Do not push the seal past

the large retaining ring groove on the shaft.

-10-

Page 11

6. Once the seal has been expanded, remove the seal from

the shaft.

7. Install seal cartridge assembly: With seal lip facing the

large end of the shaft, slide the seal cartridge assembly

over the threaded end of the shaft and gently push into the

raised area of the shaft. Align the seal lip to enter

the center diameter of the seal spacer and push until seal

body touches seal spacer.

Important: If the seal lip is longer than the seal spacer’s

width, please stop the assembly and review parts being used.

8. Assemble two o-rings on the outside body of the new seal

cartridge assembly as shown in Fig B. Install o-rings one at

a time and do not roll over each other.

(2) O-rings

Fig. B

Shaft

9. Finished shaft sub-assembly should look like this:

Figure 15

3. Turn the motor body assembly over (threaded shaft end

down) on the arbor press. Press the shaft down into

its “final position” until the small retaining ring can be

installed in the shaft next to the ball bearing.

4. Install small retaining ring on shaft.

5. Check shaft rotation at this point. It should rotate

smoothly with only slight resistance from the seal lip

pressure on the shaft. If you feel any gritty or sticking movement, return assembly to the arbor press

and lightly press on the threaded end of the shaft to

relieve press fit compression on the thrust bearing. Note: Don’t over do this press. The objective is

to move the small outer retaining ring installed in the

previous step back to ”touching only” the ball bearing

inner race.

10. Do not press, but place the shaft sub-assembly into the

motor body with threaded end of shaft up. Lubricate the

two o-rings with hydraulic or mineral oil before assembling.

Figure 14

Install Shaft Sub-Assembly Into Motor Body

Important: Make sure the surface edge of the arbor press

fixture is smooth and clean. An unthreaded piece of

pipe (1” x 4” high) is needed to support the outer race of

the seal cartridge sub-assembly and outer race of the

ball bearing during assembly. Place this pipe over the

shaft threaded end for assembly of the following steps.

1. Place the body on a support fixture in the arbor press.

Using an unthreaded piece of pipe (1” dia. x 4” high),

press the shaft subassembly down into the body until it

bottoms out. This is a light press fit and should be done

slow and easy.

2. Install the new ball bearing onto the threaded end of

the shaft. Press down using the 1” x 4” pipe until the

retaining ring can be installed in its groove in the bearing core of the motor body. Install the retaining

ring.

Important:

If gritty or sticky movement persists, it’s likely

due to re-used parts or the body needle bearing is in

need of replacement.

Reassembly of Remaining Hydraulic Motor Parts

1. Place Motor Body in a vise with large end of shaft facing

up.

2. Install the o-ring in the body.

3. Install the Roll Pin on the shaft. Place the Inner Gear of

the Gerotor onto the shaft making sure Gerotor slot lines

up with the key in the shaft.

The Roll Pin can slide up behind the inner gear of the

gerotor when the gear is installed. Make sure the key is

visible in the slot after the gear is in place.

4. Install the outer portion of the Gerotor, making sure the

Gerotor is centered within the o-ring groove on the body.

5. Install the Gerotor Housing, making sure the pins in the

Gerotor Housing line up with their respective holes in the

body.

6. Lightly lubricate the area between the Inner and Outer

Gerotor, the Outer Gerotor, and Gerotor Housing with

hydraulic oil or mineral oil.

Special attention should be exercised when working with

retaining rings. Always wear safety goggles when working with spring or tension-loaded fasteners or devices.

7. Install o-ring on the motor end plate.

8. Place end plate on gerotor housing, making sure holes in

end plate line up with pins in the gerotor housing.

-11-

L-1526 (12/12, Rev. B)

Page 12

9. Install four Socket Head Cap Screws in Motor End Plate,

and using a 1/4” Allen wrench, tighten Cap Screws alternately and evenly in a crisscross pattern to approximately 15 foot pounds [ 20 Nm] of torque.

10. Install the Thread Seal Gasket on the Bypass Adjusting

Screw. Put the Gasket on from the slotted end and turn

until four threads on the screw are showing. Install the

Washer and the Nut. Install Bypass Adjusting Screw in

the motor end plate.

A. For closed center hydraulic systems, turn the By-

pass Adjusting Screw in until it bottoms out in the

End Plate. Tighten nut down with 9/16” box end

wrench.

B. For open center hydraulic systems, turn the Bypass

Adjusting Screw in until it bottoms out in the End

Plate; then turn back out 1

1

⁄2 full turns. Holding the

Bypass Adjusting Screw with a screwdriver, tighten

Nut. (Motor will then have to be readjusted to tractor

system.)

Troubleshooting

11. Replace o-ring on both port adapters.

12. Install Pressure Port Adapter and Tank Port Adapter

back onto the motor. (For ease of installation, tighten the

Pressure Port Adapter first, then the Tank Port Adapter.)

13. Remove Hydraulic Motor from the vise. Turn shaft by

hand to check for binding.

14. Install Slinger Ring over Motor Shaft.

15. Install Motor into Pump Mounting Flange. Insert four Hex

Head Bolts; then alternately and evenly tighten them.

[For polypropylene models, secure the Hydraulic Motor

to the Mounting Flange with four Hex Head Cap Screws

and Nuts. The nuts should be visible when the assembly

is complete.]

If the proper Hydraulic Pump Unit has been selected according

to Hypro recommendations, and the unit has been correctly

draulic system heat is excessive etc., check the following trou-

bleshooting guide for possible problems and solutions.

plumbed into the hydraulic system, operation should be quite

satisfactory. If spraying performance is unsatisfactoryor hy-

Troubleshooting Guide

Symptom Probable Cause(s) Corrective Action(s)

Low discharge Pump not primed. — Remove top most vent plug from face of pump and run

pump to expel trapped air (see Installation Instructions).

Air leaks in inlet line. — Check and reseal inlet fittings.

Blocked or clogged line strainer. — Inspect strainer and clear any debris from screen.

Impeller plugged. — Inspect and clear obstruction.

Undersize inlet line or — Suction line should be the same diameter as inlet port of pump or larger.

collapsed hose.

Improperly sized hydraulic motor. — Refer to Pump Selection Guide to determine proper size

hydraulic motor for your hydraulic system.

Bypass Adjustment Screw not — Adjust bypass screw on side of hydraulic motor

set properly. in until the desired output is attained.

Eye of impeller rubbing on volute. — Remove volute (front cover) and inspect the impeller.

If wear detected, sand the impeller eye O.D. with emery cloth.

Hydraulic system Improper hydraulic motor size. — Refer to Pump Selection Guide on our website to determine proper size

overheating for your hydraulic system.

Bypass Adjustment Screw — Close adjustment screw on side of hydraulic motor

set to bypass too much oil. to lessen the amount of oil being bypassed.

Improper metering orifice — Install proper size orifice. Refer to Installation section for proper sizing.

installed in pressure port.

Insufficient hydraulic hose size. — Check hydraulic hose size. Hose should be at least 1/2” [12.7 mm]

on the pressure port and 3/4” [19.05mm] on the tank port.

NOTE: See Hydraulic Test Kit 3430-0650 and our Operation Manual No. L-1503

for further guidance and troubleshooting.

L-1526 (12/12, Rev. B)

-12-

Page 13

Performance Graphs

GPM

9303C-HM1C-SP Performance at 11 GPM

GRAPHS FOR HYDRAULICALLY-DRIVEN CENTRIFUGALS

9302

9302

9303

9302CT-GM1 & 9302ST-GM1

-13-

050 100 150 200 250 300 350 400 450

100

90

80

70

P

60

S

50

I

40

30

20

10

0

020406080 100 120

L/min

1-1/2˝ Inlet Hose

Feet of lift = 15 10

50

L-1526 (12/12, Rev. B)

6

5

B

4

A

R

3

2

1

0

Page 14

Performance Graphs

P

S

9303C-HM1C-SP Performance at 13 GPM

05

P

S

9303C-HM2C-SP Performance at 4 GPM

P

S

9303C-HM2C-SP Performance at 6 GPM

9303C-HM1C-SP Performance at 12 GPM

9303 9303

050 100 150 200 250 300 350 400 450

120

100

80

P

S

60

I

L/min

1-1/2˝ Inlet Hose

050 100 150 200 250 300

8

7

6

B

5

A

4

R

40

30

20

I

L/min

1-1/2˝ Inlet Hose

2.5

2

1.5

B

A

R

40

20

0

020406080 100 120

Feet of lift = 15 10

50

GPM

050 100 150 200 250 300 350 400 450

140

120

100

80

L/min

1-1/2˝ Inlet Hose

I

60

40

20

0

020406080 100 120

Feet of lift = 15 10

50

GPM

3

2

1

0

10

0

01

Feet of Lift = 15

5

10

060708030 4020

1

0.5

0

0

GPM

9

8

7

6

B

A

5

R

4

3

2

1

0

L-1526 (12/12, Rev. B)

-14-

050 100 150 200 250 300 350 400 450

80

70

60

50

40

I

30

20

10

0

06080 100 1204020

Feet of Lift = 15

1-1/2˝ Inlet Hose

10

0

5

GPM

L/min

5

4

B

3

A

R

2

1

0

Page 15

Performance Graphs

08

9303C-HM3C-SP Performance at 15 GPM

08

9303C-HM3C-SP Performance at 18 GPM

08

9303C-HM3C-SP Performance at 20 GPM

9303 9303

050 100 150 200 250 300 350 450 450

90

80

70

L/min

1-1/2˝ Inlet Hose

6

5

050 100 150 200 250 300 350

50

40

P

30

1-1/2˝ Inlet Hose

S

I

L/min

20

10

0

02

Feet of Lift = 15

10

GPM

60

P

50

S

I

40

30

20

10

0

02

Feet of Lift = 15

10

5

0

0 100 1206040

4

B

A

R

3

2

1

0

GPM

3

2.5

B

2

A

R

1.5

1

0.5

5

0

0 1006040

0

050 100 150 200 250 300 350 450 450

80

70

60

50

P

S

40

I

30

20

10

0

02

Feet of Lift = 15

1-1/2˝ Inlet Hose

10

GPM

L/min

5

4

B

A

3

R

2

1

5

0

0 100 1206040

0

-15-

L-1526 (12/12, Rev. B)

Page 16

Performance Graphs

08

P

S

08

9303C-HM5C-SP Performance at 15 GPM

P

S

9303P-HM2C

GPM

9303P-HM1C

9303P-HM3C

08

9303C-HM5C-SP Performance at 13 GPM

9303 9303

050 100 150 200 250 300 350 400 450

90

80

70

60

1-1/2˝ Inlet Hose

P

L/min

50

S

I

40

30

20

10

0

02

Feet of Lift = 15 10 50

060 10040 120

GPM

9303C-HM5C-SP Performance at 14 GPM

L/min

050 100 150 200 250 300 350 400 450

120

100

80

60

I

40

20

0

02

1-1/2˝ Inlet Hose

Feet of Lift = 15 10 50

060 10040 120

GPM

6

5

4

B

A

3

R

2

1

0

8

7

6

B

5

A

4

R

3

2

1

0

050 100 150 200 250 300 350 400 450

140

13GPM

120

12GPM

100

11GPM

P

80

S

I

60

40

20

0

020406080 100 120

050 100 150 200 250 300

100

90

7GPM

80

6GPM

70

60

5GPM

50

I

40

30

20

10

0

02010 4030 50 60 70 80 90

L/min

L/min

GPM

9

8

7

6

B

A

5

R

4

3

2

1

0

6

5

B

4

A

R

3

2

1

0

050 100 150 200 250 300 350 400 450

L/min

120

100

80

P

S

60

I

40

20

0

02

L-1526 (12/12, Rev. B)

1-1/2˝ Inlet Hose

Feet of Lift = 15 10 50

GPM

060 10040 120

050 100 150 200 250 300 350

L/min

-16-

100

90

20 GPM

80

18 GPM

70

P

60

S

15 GPM

50

I

40

30

20

10

0

0204060 10060 120

GPM

6

5

B

4

A

R

3

2

1

0

8

7

6

B

5

A

4

R

3

2

1

0

Page 17

Performance Graphs

08

P

S

9303P-HM4C

9303P-HM5C

9305C-HM3C-SP, BSP Performance at 18 GPM

9305C-HM3C-SP, BSP Performance at 19 GPM

B

A

R

9303

050 100 150 200 250 300

90

80

7GPM

70

60

6GPM

50

I

40

5GPM

30

20

10

0

020406

050 100 150 200 250 300 350 400 450

120

15 GPM

14 GPM

100

13 GPM

80

12 GPM

P

S

60

I

40

20

0

020406080 100 120

L/min

GPM

L/min

GPM

070503010 90

9305

9305C-HM3C-SP, BSP Performance at 17 GPM

L/min

0 100 200 300 400 500 600

6

5

4

B

A

R

3

2

1

0

120

100

80

P

S

60

I

40

20

0

020 100 120 140 16060 8040

2˝ Inlet Hose

Feet of Lift = 15

10

8

7

6

5

4

3

2

1

5

0

0

GPM

L/min

0 100 200 300 400 500 600

8

7

6

5

B

A

4

R

3

2

1

0

140

120

100

P

80

S

I

60

40

20

0

020 100 120 140 16060 8040

2˝ Inlet Hose

Feet of Lift = 15

9

8

7

6

B

A

5

R

4

3

2

10

1

5

0

0

GPM

9305

0 100 200

160

140

120

P

100

18 GPM

17 GPM

9305C-HM3C

L/min

300 400 500 600 700

19 GPM

S

80

I

60

40

20

0

0 20 40 60 80 100 120 140 160 180 200

GPM

11

10

9

8

7

B

6

A

R

5

4

3

2

1

0

-17-

0 100 200 300 400 500 600

160

140

120

100

P

2˝ Inlet Hose

S

80

I

60

40

20

0

020 100 120 140 16060 8040

Feet of Lift = 15

GPM

10

L-1526 (12/12, Rev. B)

10

8

B

A

6

R

4

2

5

0

0

L/min

Page 18

Performance Graphs

9306

9306C-HM1C-3U & 9306S-HM1C-3U

9306C-HM3C-3U & 9306S-HM3C-3U

L-1526 (12/12, Rev. B)

9306C-HM5C-3U & 9306S-HM5C-3U

-18-

Page 19

Repair Parts Kit No. 3430-0332

Contains: One o-ring (Ref. 5),

one rubber gasket (Ref. 6), and

one mechanical seal (Ref. 7).

9302C and 9302S Series Pumps

Silicon Seal Kit No. 3430-0589

Contains one each:

1720-0083 o-ring (Ref. 5)

and mechanical seal (silicon carbide) (Ref.7).

Adapter Kit No. 3430-0187

(HM2 and HM4 Models Only):

Contains one each:

No. 3360-0021 Pressure Port Adapter

No. 3373-0020 (Size #1)

No. 3373-0021 (Size #2)

No. 3373-0022 (Size #3)

No. 1720-0108 Adapter O-ring and

No. 1720-0105 Orifice O-ring (Qty. 3)

NOTE: When ordering parts, give

QUANTITY, PART NUMBER,

DESCRIPTION, and COMPLETE

MODEL NUMBER. Reference

numbers are used ONLY to identify parts in the drawing and are

NOT to be used as order numbers.

Parts Kit No. 3430-0748

Contains: One each ball bearing

(Ref. 13), motor shaft seal (Ref.

16), thread seal gasket (Ref. 35),

two cartridge o-rings (Ref. 15) and

washer (Ref. 36); two each motor

housing o-rings (Ref. 22), and port

adapter o-rings (Ref. 30 & 32).

Hydraulic Motor Part Nos.

2500-0081C (HM1C Models)

2500-0082C (HM2C Models)

2500-0084C (HM4C Models)

Ref. Qty.

No. Req’d. Part No. Description

1 4 2406-0007 Drain/Vent Plug (9302C)

1 4 2406-0016 Drain/Vent Plug (9302S)

2 1 0150-9200C Pump Casing (Model 9302C)

2A 1 0156-9200S Pump Casing (Model 9302S)

3 1 2253-0002 Impeller Nut (9302C)

3 1 2253-0006 Impeller Nut (9302S)

4 1 0401-9100P Impeller (Nylon Std. 9302C)

4 1 0402-9100P Impeller (Polypropylene Optional) (Std 9302S)

5 1 1720-0083 O-ring

6 1 1700-0100 Gasket

7 1 2120-0009 Mechanical Seal (Viton/Ceramic) (Std 9302C)

7 1 3430-0589 Mechanical Seal (Silicon Carbide) (Std 9302S)

8 1 0750-9300C Mounting Flange (9302C)

8 1 0756-9300S Mounting Flange (9302S)

9 4 2210-0020 Hex Head Cap Screw (9302C)

9 4 2210-0125 Hex Head Cap Screw (9302S)

10 1 1410-0056 Slinger Ring

11 1 1810-0014 Snap Ring

12 1 1820-0013 Retaining Ring

13 1 2000-0010 Ball Bearing

14 1 1410-0131 Cartridge, Front

15 2 1720-0268 O-ring

16 1 2104-0010 Lip Seal

17 1 1410-0130 Seal Spacer

18 1 2029-0014 Thrust Bearing Assembly

19 1 0531-2500 Shaft (HM2C/HM4C)

19 1 0533-2500 Shaft (HM1C)

20 1 0150-2500C Motor Body (includes needle bearing)

21 4 2210-0005 Hex Head Cap Screw

Ref. Qty.

No. Req’d. Part No. Description

22 2 1720-0110 O-ring

23 1 1600-0045 Dowel Pin (HM2C / HM4C)

23 1 1600-0044 Dowel Pin (HM1C)

24 1 1600-0042 Dowel Pin (HM2C / HM4C)

24 1 1600-0037 Dowel Pin (HM1C)

25 1 3900-0022 Gerotor (HM1C)

25 1 3900-0023 Gerotor (HM2C)

25 1 3900-0025 Gerotor (HM4C)

26 1 0701-2500C1 Gerotor Housing (HM2C Models) 1/4” wide

26 1 0700-2500C1 Gerotor Housing (HM1C Models) 1/2” wide

26 1 0703-2500C1 Gerotor Housing (HM4C Models) 5/16” wide

27 1 0254-2500C2 Motor End Plate (includes needle bearing)

28 4 2270-0039 Washer

29 4 2220-0045 Cap Screw (HM2C / HM4C Models)

29 4 2220-0021 Cap Screw (HM1C Models)

30 1 1720-0108 O-ring

31 1 3360-0021A Pressure Port Adapter (includes o-ring)

32 1 1720-0262 O-ring

33 1 3320-0051A Tank Port Adapter (includes o-ring)

34 1 3220-0029 Bypass Adjusting Screw

35 1 1700-0047 Gasket

36 1 2270-0027 Washer

37 1 2250-0038 Lock Nut

38 1 1610-0032 Roll Pin (HM2C / HM4C)

38 1 1610-0031 Roll Pin (HM1C)

39 1 1810-0026 Snap Ring

40 1 1610-0012 Woodruff Key (9302C)

40 1 04432 Woodruff Key (9302S)

-19-

L-1526 (12/12, Rev. B)

Page 20

13

12

Models 9302CT-GM1 & 9302ST-GM1

8

11

9

16

19

17

14

15

10

Note 1: Mechanical Seal Ref. 9 is not avail-

able outside of the kit form. For replacement

seal,orderKit#3430-0332orKit#3430-0589

forModel9302CT-GM1andKit#3430-0589for

Model 9302ST-GM1.

7

4

2

2

5

6

3

7

1

Note: When ordering parts, give

QUANTITY, PART NUMBER,

DESCRIPTION and COMPLETE

MODEL NUMBER. Reference

numbers are used ONLY to identify

parts in the drawing and are NOT

to be used as order numbers.

18

HydraulicMotorSealKitNo.3430-0649

Ref.

No. Qty. Part No. Description

1 1 0701-9300C Bearing Housing

2 2 2008-0001 Bearing

3 1 1410-0108 Bearing Spacer

4 1 1410-0110 Motor Pilot Ring

5 1 0517-2500 Shaft Assembly

6 2 1810-0013 Retainer Ring

7 1 2500-0033 Hydraulic Gear Motor

8 1 0750-9300C2 Mounting Flange

8* 1 0756-9300S Mounting Flange

9 1 See Note 1 Mechanical Seal

9* 1 See Note 1 Mechanical Seal

10 1 1610-0012 Key

10* 1 04432 Key

* Denotes part for 9302ST-GM1.

L-1526 (12/12, Rev. B)

Ref.

No. Qty. Part No. Description

11 1 1720-0083 O-Ring

12 1 0401-9100P Impeller (Nylaglass)

12* 1 0402-9100P Impeller (Polypropylene)

13 1 2253-0006 Acorn Nut

14 1 0150-9200C2 Pump Casing

14* 1 0156-9200S1 Pump Casing

15 4 2406-0007 Pipe Plug

15* 4 2406-0016 Pipe Plug

16 4 2210-0020 Hex Head Cap Screw

16* 4 2210-0125 Hex Head Cap Screw

17 4 2210-0130 Threaded Stud

18 4 2260-0002 Lockwasher

19 4 2250-0008 Nut

-20-

Page 21

All 9303C and 9303S Series Pumps

Repair Parts Kit No. 3430-0332

Contains: One o-ring (Ref. 5),

one rubber gasket (Ref. 6),

and one mechanical seal (Ref. 7).

Ref. Qty.

No. Req’d. Part No. Description

1 4 2406-0007 Drain/Vent Plug (9303C)

1 4 2406-0016 Drain/Vent Plug (9303S)

2 1 0150-9000C Pump Casing (Model 9303C)

2 1 0150-9000S Pump Casing (Model 9303S)

2A 1 0153-9000C Pump Casing (Universal Flange Model C-U)

2A 1 0153-9000S Pump Casing (Universal Flange Model S-U)

3 1 2253-0002 Impeller Nut (9303C)

3 1 2253-0006 Impeller Nut (9303S)

4 1 0401-9100P Impeller (Nylon Std. 9303C)

4 1 0402-9100P Impeller (Polypropylene Optional) (Std 9303S)

5 1 1720-0083 O-ring

6 1 1700-0100 Gasket

7 1 2120-0009 Mechanical Seal (Viton/Ceramic) (Std 9303C)

7 1 3430-0589 Mechanical Seal (Silicon Carbide) (Std 9303S)

8 1 0750-9300C Mounting Flange (9303C)

8 1 0756-9300S Mounting Flange (9303S)

9 4 2210-0020 Hex Head Cap Screw (9303C)

9 4 2210-0125 Hex Head Cap Screw (9303S)

10 1 1410-0056 Slinger Ring

11 1 1810-0014 Snap Ring

12 1 1820-0013 Retaining Ring

13 1 2000-0010 Ball Bearing

14 1 1410-0131 Cartridge, Front

15 2 1720-0268 O-ring

16 1 2104-0010 Lip Seal

17 1 1410-0130 Seal Spacer

18 1 2029-0014 Thrust Bearing Assembly

19 1 0531-2500 Shaft (HM2C/HM4C)

19 1 0533-2500 Shaft (HM1C/HM5C)

19 1 0536-2500 Shaft (HM3C)

20 1 0150-2500C Motor Body (includes needle bearing)

21 4 2210-0005 Hex Head Cap Screw

22 2 1720-0110 O-ring

23 1 1600-0045 Dowel Pin (HM2C / HM4C)

23 1 1600-0044 Dowel Pin (HM1C/HM5C)

Silicon Seal Kit No. 3430-0589

Contains one each:

1720-0083 o-ring (Ref. 5)

and one mechanical seal (silicon

carbide) (Ref.7).

NOTE: When ordering parts, give

QUANTITY, PART NUMBER,

DESCRIPTION, and COMPLETE

MODEL NUMBER. Reference

numbers are used ONLY to identify parts in the drawing and are

NOT to be used as order numbers.

Parts Kit No. 3430-0748

Contains: One each ball bearing

(Ref. 13), motor shaft seal (Ref. 16),

thread seal gasket (Ref. 35), two

Adapter Kit No. 3430-0187

(HM2 and HM4 Models Only):

Contains one each:

No. 3360-0021 Pressure Port Adapter

No. 3373-0020 (Size #1)

No. 3373-0021 (Size #2)

No. 3373-0022 (Size #3).

No. 1720-0108 Adapter O-ring and

No. 1720-0105 Orifice O-ring (Qty 3).

cartridge o-rings (Ref. 15) and washer

(Ref. 36); two each motor housing

o-rings (Ref. 22), and port adapter

o-rings (Ref. 30 & 32).

Hydraulic Motor Part Nos.

2500-0081C (HM1C Models)

2500-0082C (HM2C Models)

2500-0083C (HM3C Models)

2500-0084C (HM4C Models)

2500-0085C (HM5C Models)

Ref. Qty.

No. Req’d. Part No. Description

23 1 1600-0052 Dowel Pin (HM3C)

24 1 1600-0042 Dowel Pin (HM2C / HM4C)

24 1 1600-0037 Dowel Pin (HM1C/HM5C)

24 1 1600-0068 Dowel Pin (HM3C)

25 1 3900-0022 Gerotor (HM1C)

25 1 3900-0023 Gerotor (HM2C)

25 1 3900-0024 Gerotor (HM3C)

25 1 3900-0025 Gerotor (HM4C)

25 1 3900-0048 Gerotor (HM5C)

26 1 0701-2500C1 Gerotor Housing (HM2C Models) 1/4” wide

26 1 0700-2500C1 Gerotor Housing (HM1C Models) 1/2” wide

26 1 0703-2500C1 Gerotor Housing (HM4C Models) 5/16” wide

26 1 0702-2500C1 Gerotor Housing (HM3C Models) 1” wide

26 1 0704-2500C1 Gerotor Housing (HM5C Models) 5/8” wide

27 1 0254-2500C2 Motor End Plate (includes needle bearing)

28 4 2270-0039 Washer

29 4 2220-0045 Cap Screw (HM2C / HM4C Models)

29 4 2220-0021 Cap Screw (HM1C Models)

29 4 2220-0044 Cap Screw (HM3C Models)

29 4 2220-0032 Cap Screw (HM5C Models)

30 1 1720-0108 O-ring

31 1 3360-0021A Pressure Port Adapter (includes o-ring)

32 1 1720-0262 O-ring

33 1 3320-0051A Tank Port Adapter (includes o-ring)

34 1 3220-0029 Bypass Adjusting Screw

35 1 1700-0047 Gasket

36 1 2270-0027 Washer

37 1 2250-0038 Lock Nut

38 1 1610-0032 Roll Pin (HM2C / HM4C)

38 1 1610-0031 Roll Pin (HM1C / HM5C)

38 1 1610-0055 Roll Pin (HM3C)

39 1 1810-0026 Snap Ring

40 1 1610-0012 Woodruff Key (9303C)

40 1 04432 Woodruff Key (9303S)

-21-

L-1526 (12/12, Rev. B)

Page 22

Repair Parts Kit No. 3430-0332

Contains: One o-ring (Ref. 5),

one rubber gasket (Ref. 6),

and one mechanical seal (Ref 7).

All 9303 Self-Priming Series Pumps

Silicon Seal Kit No. 3430-0589

Contains one each:

1720-0083 o-ring (Ref. 5)

and mechanical seal (silicon

carbide) (Ref. 7).

SP Chamber Kit No. 3430-0480SP

Contains: One chamber with wear

ring, (Ref. 2), one o-ring (Ref. 5),

one drain/vent plug (Ref. 1) and one

vent plug (Ref.1A).

Hydraulic Motor Part Nos.

2500-0081C (HM1C Models)

2500-0082C (HM2C Models)

2500-0083C (HM3C Models)

2500-0084C (HM4C Models)

2500-0085C (HM5C Models)

NOTE: When ordering parts, give

QUANTITY, PART NUMBER,

DESCRIPTION, and COMPLETE

MODEL NUMBER. Reference

numbers are used ONLY to identify parts in the drawing and are

NOT to be used as order numbers.

Parts Kit No. 3430-0748

Contains: One each ball bearing

(Ref. 13), motor shaft seal (Ref. 16),

thread seal gasket (Ref. 35), two

cartridge o-rings (Ref. 15) and washer (Ref. 36 ); two each motor housing

o-rings (Ref. 22), and port adapter

o-rings (Ref. 30 & 32).

Adapter Kit No. 3430-0187

(HM2 and HM4 Models Only):

Contains one each:

No. 3360-0021 Pressure Port Adapter

No. 3373-0020 (Size #1)

No. 3373-0021 (Size #2)

No. 3373-0022 (Size #3)

No. 1720-0108 Adapter O-ring and

No. 1720-0105 Orifice O-ring (Qty. 3).

Ref. Qty.

No. Req’d. Part No. Description

1 1 2406-0007 Drain/Vent Plug (9303C-SP)

1 1 2406-0016 Drain/Vent Plug (9303S-SP)

1A 1 2406-0001 Vent Plug (9303C-SP)

1A 1 7SP34 Vent Plug (9303S-SP)

2 1 3430-0480SP Pump Casing (9303C-SP)

2 1 0150-9070S Pump Casing (9303S-SP)

3 1 2253-0002 Impeller Nut (9303C-SP)

3 1 2253-0006 Impeller Nut (9303S-SP)

4 1 0401-9100P Impeller (Nylon Std. 9303C-SP)

4 1 0402-9100P Impeller (Polypropylene Optional) (Std 9303S-SP)

5 1 1720-0083 O-ring

6 1 1700-0100 Gasket

7 1 2120-0009 Mechanical Seal (Viton/Ceramic) (Std 9303C-SP)

7 1 3430-0589 Mechanical Seal (Silicon Carbide) (Std 9303S-SP)

8 1 0750-9300C Mounting Flange (9303C-SP)

8 1 0756-9300S Mounting Flange (9303S-SP)

9 4 2210-0020 Hex Head Cap Screw (9303C-SP)

9 4 2210-0125 Hex Head Cap Screw (9303S-SP)

10 1 1410-0056 Slinger Ring

11 1 1810-0014 Snap Ring

12 1 1820-0013 Retaining Ring

13 1 2000-0010 Ball Bearing

14 1 1410-0131 Cartridge, Front

15 2 1720-0268 O-ring

16 1 2104-0010 Lip Seal

17 1 1410-0130 Seal Spacer

18 1 2029-0014 Thrust Bearing Assembly

19 1 0531-2500 Shaft (HM2C/HM4C)

19 1 0533-2500 Shaft (HM1C/HM5C)

19 1 0536-2500 Shaft (HM3C)

20 1 0150-2500C Motor Body (includes needle bearing)

21 4 2210-0005 Hex Head Cap Screw

22 2 1720-0110 O-ring

23 1 1600-0045 Dowel Pin (HM2C/HM4C)

L-1526 (12/12, Rev. B)

Ref. Qty.

No. Req’d. Part No. Description

23 1 1600-0044 Dowel Pin (HM1C/HM5C)

23 1 1600-0052 Dowel Pin (HM3C)

24 1 1600-0042 Dowel Pin (HM2C/HM4C)

24 1 1600-0037 Dowel Pin (HM1C/HM5C)

24 1 1600-0068 Dowel Pin (HM3C)

25 1 3900-0022 Gerotor (HM1C)

25 1 3900-0023 Gerotor (HM2C)

25 1 3900-0024 Gerotor (HM3C)

25 1 3900-0025 Gerotor (HM4C)

25 1 3900-0048 Gerotor (HM5C)

26 1 0701-2500C1 Gerotor Housing (HM2C Models) 1/4” wide

26 1 0700-2500C1 Gerotor Housing (HM1C Models) 1/2” wide

26 1 0703-2500C1 Gerotor Housing (HM4C Models) 5/16” wide

26 1 0702-2500C1 Gerotor Housing (HM3C Models) 1” wide

26 1 0704-2500C1 Gerotor Housing (HM5C Models) 5/8” wide

27 1 0254-2500C2 Motor End Plate (includes needle bearing)

28 4 2270-0039 Washer

29 4 2220-0045 Cap Screw (HM2C/HM4C Models)

29 4 2220-0021 Cap Screw (HM1C Models)

29 4 2220-0044 Cap Screw (HM3C Models)

29 4 2220-0032 Cap Screw (HM5C Models)

30 1 1720-0108 O-ring

31 1 3360-0021A Pressure Port Adapter (includes o-ring)

32 1 1720-0262 O-ring

33 1 3320-0051A Tank Port Adapter (includes o-ring)

34 1 3220-0029 Bypass Adjusting Screw

35 1 1700-0047 Gasket

36 1 2270-0027 Washer

37 1 2250-0038 Lock Nut

38 1 1610-0032 Roll Pin (HM2C/HM4C)

38 1 1610-0031 Roll Pin (HM1C/HM5C)

38 1 1610-0055 Roll Pin (HM3C)

39 1 1810-0026 Snap Ring

40 1 1610-0012 Woodruff Key (9303C-SP)

40 1 04432 Woodruff Key (9303S-SP)

-22-

Page 23

All 9300 Polypropylene Series Pumps

Repair Parts Kit No. 3430-0445

Contains: One o-ring (Ref. 13),

one rubber gasket (Ref. 11), one mechanical

seal (Ref. 12), one gasket (Ref. 8) and one

washer (Ref. 9).

Ref. Qty.

No. Req’d. Part No. Description

1 4 2210-0087 Hex Head Cap Screw

2 2 2210-0016 Hex Head Cap Screw (Base Only)

3 6 2270-0041 Washer

4 4 2406-0020 Pipe Plug

5 1 0700-9000P Pump Casing

6 1 2250-0052 Impeller Nut

7 1 2250-0051 Jam Nut

8 1 1700-0097 Gasket (Viton)

9 1 2270-0057 Washer

10 1 0402-9100P Impeller

11 1 1700-0100 Rubber Gasket

12 1 2120-0009 Mechanical Seal (Viton/Ceramic) (Std 9303P)

12 1 3430-0593 Mechanical Seal (Silicon Carbide) (Optional)

13 1 1721-0083 O-ring

14 1 0750-9300P Cover

15 1 2210-0088 Screw

16 1 0750-9006C Intermediate Flange

17 1 1510-0063 Base Plate

18 2 2250-0008 Hex Nut

19 1 1410-0056 Slinger Ring

20 1 1810-0014 Snap Ring

21 1 1820-0013 Retaining Ring

22 1 2000-0010 Ball Bearing

23 1 1410-0131 Cartridge, Front

24 2 1720-0268 O-ring

25 1 2104-0010 Lip Seal

26 1 1410-0130 Seal Spacer

27 1 2029-0014 Thrust Bearing Assembly

28 1 1610-0042 Woodruff Key (9303P all except HM3C)

28A 1 1610-0053 Square Key (9303P-HM3C Only)

29 1 0534-2500 Shaft (HM2C/HM4C)

29 1 0535-2500 Shaft (HM1C/HM5C)

29 1 0537-2500 Shaft (HM3C)

30 1 1810-0026 Snap Ring

Silicon Seal Parts Kit # 3430-0593

Contains one each:

mechanical seal (Ref. 12) and o-ring (Ref. 13).

Ref. Qty.

No. Req’d. Part No. Description

31 1 1610-0055 Roll Pin (HM3C)

32 1 0150-2500C Motor Body (includes needle bearing)

33 4 2210-0021 Hex Head Cap Screw

34 2 1720-0110 O-ring

35 1 1600-0045 Dowel Pin (HM2C / HM4C)

35 1 1600-0044 Dowel Pin (HM1C/HM5C)

35 1 1600-0052 Dowel Pin (HM3C)

36 1 1600-0042 Dowel Pin (HM2C/ HM4C)

36 1 1600-0037 Dowel Pin (HM1C/HM5C)

36 1 1600-0068 Dowel Pin (HM3C)

37 1 3900-0022 Gerotor (HM1C)

37 1 3900-0023 Gerotor (HM2C)

37 1 3900-0024 Gerotor (HM3C)

37 1 3900-0025 Gerotor (HM4C)

37 1 3900-0048 Gerotor (HM5C)

38 1 0701-2500C1 Gerotor Housing (HM2C Models) 1/4” wide

38 1 0700-2500C1 Gerotor Housing (HM1C Models) 1/2” wide

38 1 0703-2500C1 Gerotor Housing (HM4C Models) 5/16” wide

38 1 0702-2500C1 Gerotor Housing (HM3C Models) 1” wide

38 1 0704-2500C1 Gerotor Housing (HM5C Models) 5/8” wide

39 1 0254-2500C2 Motor End Plate (includes needle bearing)

40 4 2270-0039 Washer

41 4 2220-0045 Cap Screw (HM2C / HM4C Models)

41 4 2220-0021 Cap Screw (HM1C Models)

41 4 2220-0044 Cap Screw (HM3C Models)

41 4 2220-0032 Cap Screw (HM5C Models)

42 1 1720-0108 O-ring

43 1 3360-0021A Pressure Port Adapter (includes o-ring)

44 1 3320-0051A Tank Port Adapter (includes o-ring)

45 1 1720-0262 O-ring

46 1 3220-0029 Bypass Adjusting Screw

47 1 1700-0047 Gasket

48 1 2270-0027 Washer

49 1 2250-0038 Lock Nut

31 1 1610-0032 Roll Pin (HM2C / HM4C)

31 1 1610-0031 Roll Pin (HM1C / HM5C)

-23-

Adapter Kit No. 3430-0187

(HM2 and HM4 Models Only):

Contains one each:

No. 3360-0021 Pressure Port Adapter

No. 3373-0020 (Size #1)

No. 3373-0021 (Size #2)

No. 3373-0022 (Size #3)

No. 1720-0108 Adapter O-ring and

No. 1720-0105 Orifice O-ring (Qty. 3).

NOTE: When ordering parts, give

QUANTITY, PART NUMBER,

DESCRIPTION, and COMPLETE

MODEL NUMBER. Reference

numbers are used ONLY to identify

parts in the drawing and are NOT to

be used as order numbers.

Parts Kit No. 3430-0748

Contains: One each ball bearing

(Ref. 22), motor shaft seal (Ref.

25), thread seal gasket (Ref.

47), two cartridge o-rings (Ref.

24) and washer (Ref. 48); two

each motor housing o-rings (Ref.

34), and port adapter o-rings

(Ref. 42 & 45).

Hydraulic Motor Part Nos.

2500-0181C (HM1C Models)

2500-0182C (HM2C Models)

2500-0183C (HM3C Models)

2500-0184C (HM4C Models)

2500-0185C (HM5C Models)

L-1526 (12/12, Rev. B)

Page 24

Models 9305C-HM3C-SP and 9305C-HM3C-BSP

NOTE: When ordering parts, give

QUANTITY, PART NUMBER,

DESCRIPTION, and COMPLETE

MODEL NUMBER. Reference

numbers are used ONLY to identify parts in the drawing and are

NOT to be used as order numbers.

Silicon Seal Kit No 3430-0601

Contains one each: mechanical

seal (Ref. 8) and o-ring (Ref. 9).

Repair Parts Kit No. 3430-0500

Contains one each: mechanical seal

Hydraulic Motor Part No.

2500-0083C

Ref. Qty.

No. Req’d. Part No. Description

1 1 2406-0002 1/2” NPT Drain Plug

2 1 3430-0481SP Self Priming Chamber (SP model only)

Includes a stainless wear ring, plugs, & o-ring

2 1 3430-0481BSP Self Priming Chamber (BSP model only)

Includes a stainless wear ring, plugs, & o-ring

3 1 2406-0034 1” NPT Prime Port Plug (SP model only)

3 1 2406-0036 1” BSP Prime Port Plug (BSP model only)

4 1 2253-0002 Impeller Nut

5 1 2270-0071 Washer

6 1 0403-9200P1 Impeller

7 1 1700-0100 Rubber Gasket

8 1 2120-0009 Mechanical Seal (Viton/Ceramic) (Std 9305C)

8 1 3430-0601 Mechanical Seal (Silicon Carbide) (Optional)

9 1 1720-0180 O-ring

10 1 0752-9200C Mounting Flange

11 6 2210-0086 Hex Head Cap Screw

12 1 1410-0056 Slinger Ring

13 1 1810-0014 Snap Ring

14 1 1820-0013 Retaining Ring

15 1 2000-0010 Ball Bearing

16 1 1410-0131 Cartridge, Front

17 2 1720-0268 O-ring

18 1 2104-0010 Lip Seal

(Ref. 8), o-ring (Ref. 9), and rubber