Page 1

Warning:

1

MiniMax® 75 & 100

ABOVEGROUND POOL & SPA HEATERS

OPERATION & INSTALLATION MANUAL

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

WARNING

FOR YOUR SAFETY - READ BEFORE OPERATING

If you do not follow these instructions exactly, a fire or explosion may result,

causing property damage, personal injury or loss of life. Call (800) 831-7133

for additional free copies of these instructions.

Consumer

Retain For

Future

Reference

U.S. Patent Numbers

5,201,307 - 4,595,825

WARNING

Warning: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, personal injury or death. Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

For Your

Safety

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

To

Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or other appliances.

Pentair Pool Products

1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

Rev. F 1-22-04 P/N 471105

Page 2

2

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Direct Spark Ignition Lighting/Operation - Natural & Propane . . . . . . . . . . . . . . . . . . . 5

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

To Turn Off Gas to Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Millivolt Lighting/Operation - Natural & Propane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Lighting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

To Turn Off Gas to Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating (Controls) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Heater Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Controls Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Energy Saving Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Spring and Fall Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Winter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chemical Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pool and Spa Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Outdoor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Indoor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Plumbing Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Manual Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Water Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Quick-Flange II Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Gas Line/Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pipe Sizing Chart/Gas Pressure Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Regulated Manifold Pressure Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Gas Pressure Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Outdoor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Indoor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Vent Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Stack Type Indoor Draft Hood Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Indoor Draft Hood Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Transformer Wiring Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Electronic Direct Spark Ignition Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Millivolt Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Trouble Shooting (General). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Parts List & Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21, 22

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

P/N 471105 Rev. F 1-22-04

Page 3

3

Introduction

MiniMax® 75 & 100

ABOVEGROUND POOL AND SPA HEATERS

Congratulations on your purchase of a MiniMax 100 high performance heating system. Proper installation and

service of your new heating system and correct chemical maintenance of the water will ensure years of enjoyment.

The MiniMax 100 is a compact, lightweight and efficient gas fired high performance aboveground pool and spa

heater that can be connected to schedule 40 CPVC or ABS pipe and has a built-in top. Unless noted otherwise, all

instructions refer to both the MiniMax 75 and MiniMax 100 heaters designated collectively as the "MiniMax 100".

The heater features include the following features.

• Reliable direct-spark ignition (DSI) system available in propane or natural gas versions.

• Millivolt standing pilot versions in propane and natural gas, when no convenient line power is present.

• Fuel gas input of 100,000 btu/hr with thermal efficiency in excess of 82%, (74,999 for the 75 Model).

• Quiet and dependable operation from packaged burner system proven reliable in worldwide usage.

• Heat exchanger constructed of premium non-corroding materials including bronze headers standard.

• The controls have been designed to be very easy to troubleshoot and very easy to access and replace in the

rare event of a malfunction-making the MiniMax 100 user friendly.

IMPORTANCE NOTICES FOR THE INSTALLER AND OPERATOR.

The manufacturer’s warranty may be void if, for any reason, the heater is improperly installed and /or operated.

Be sure to follow the instructions set forth in this manual.

These heaters are designed for the heating of swimming pools and spas, and should never be employed for use as

space heating boilers, general purpose water heaters, or for the heating of salt water.

CODES

The installation must conform with local codes or in the absence of local codes with the latest National Fuel Gas

Code, ANSI Z223.1, and the latest edition of the National Electrical Code, NFPA 70.

Installation in Canada to be made in accordance with the latest CAN/CGA-B149.1 or .2 and CSA C22.1

Canadian Electric Code, part 1.

Rev. F 1-22-04 P/N 471105

Page 4

4

This instruction manual provides operating instructions, installation, and service information for the MiniMax 100

high performance heater. The information in this manual applies to the MiniMax 75, and 100, natural gas and

propane, DSI; and MiniMax 100 millivolt standing pilot heater models.

It is very important the owner/installer read and understand the section covering installation and recognize the

local code and state codes before installing the MiniMax 100. History and experience have shown that

most heater damage is caused by improper installation practices.

WARRANTY INFORMATION

The MiniMax 100 pool heater is sold with a limited factory warranty. Specific details are described on the

back cover of this manual and a copy of the warranty and warranty registration card are included with

the product. Return the warranty registration card after filling in the serial number from the rating plate inside the

heater. For ordering parts, you should indicate model and serial numbers of the heater. If the parts are

requested for warranty, you must also indicate the date of installation.

Pentair Pool Products high standards of excellence include a policy of continuous product

improvement resulting in your state-of-the-art heater. We reserve the right to make improvements

which change the specifications of the heater without incurring an obligation to update current heater

equipment.

Operation

SAFETY RULES

1. Spa or hot tub water temperatures should never

exceed 104 °F (40 °C). A temperature of 100 °F

(38 °C) is considered safe for a healthy adult.

Special caution is suggested for young children.

2. Drinking of alcoholic beverages before or

during spa or hot tub use can cause drowsiness

which could lead to unconsciousness and

subsequently result in drowning.

3. Pregnant women beware! Soaking in water

above 102° F. (39° C.) can cause fetal damage

during the first three months of pregnancy

(resulting in the birth of a brain-damaged or

deformed child). Pregnant women should stick

to the 100° F. (38° C.) maximum rule.

4. Before entering the spa or hot tub, the user should

check the water temperature with an accurate

thermometer. Spa or hot tub thermostats may err

in regulating water temperatures by as much as

4° F. (2.2° C.).

5. Persons with medical history of heart disease,

circulatory problems, diabetes or blood pressure

problems should obtain their physician's advice

before using spas or hot tubs.

6. Persons taking medication which induce

drowsiness, such as tranquilizers, antihistamines or

anticoagulants should not use spas or hot tubs.

WARNING

Should overheating occur or the gas supply fail to shut off, turn off the manual gas control valve to the

appliance. Do not use this heater if any part has been under water. Immediately call a qualified service

technician to inspect the heater and to replace any part of control system and gas control which has

been under water.

P/N 471105 Rev. F 1-22-04

Page 5

Operation (contd.)

MINIMAX 100 DIRECT-SPARK IGNITION LIGHTING/OPERATIONNATURAL GAS & PROPANE

FOR YOUR SAFETY: READ BEFORE LIGHTING

WARNING

If you do not follow these instructions exactly, a fire or explosion may result causing personal injury,

loss of life and property damage.

Since propane gas is heavier than air, escaping propane will accumulate and remain at ground level.

Do not attempt to light the heater. If you suspect a propane leak, lighting the heater can result in a fire

or explosion which can cause personal injury, death, and property damage.

5

A. This heater is equipped with an ignition device

which automatically lights the main burner. Do not

try to light the main burner by hand.

B. BEFORE OPERATING smell all around the heater

area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will settle

on the floor.

WHAT TO DO IF YOU SMELL GAS

- Do not try to light any heater.

- Do not touch any electric switch; do not use any

phone in your building.

- Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

- If you cannot reach your gas supplier, call the Fire

Department.

C. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will not

push in or turn by hand, don't try to repair it. Call a

qualified service technician. Forced or attempted

repair may result in a fire or explosion.

D. Do not use this heater if any part has been under

water. Immediately call a qualified service

technician to inspect the heater and to replace any

part of the control system and any gas control

which has been under water.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Set the thermostat to lowest setting, fully counterclockwise.

3. Turn off electric power to the heater.

4. This heater is equipped with an ignition device which automatically lights

the main burner. Do not try to light the main burner by hand.

5. Remove the control access door.

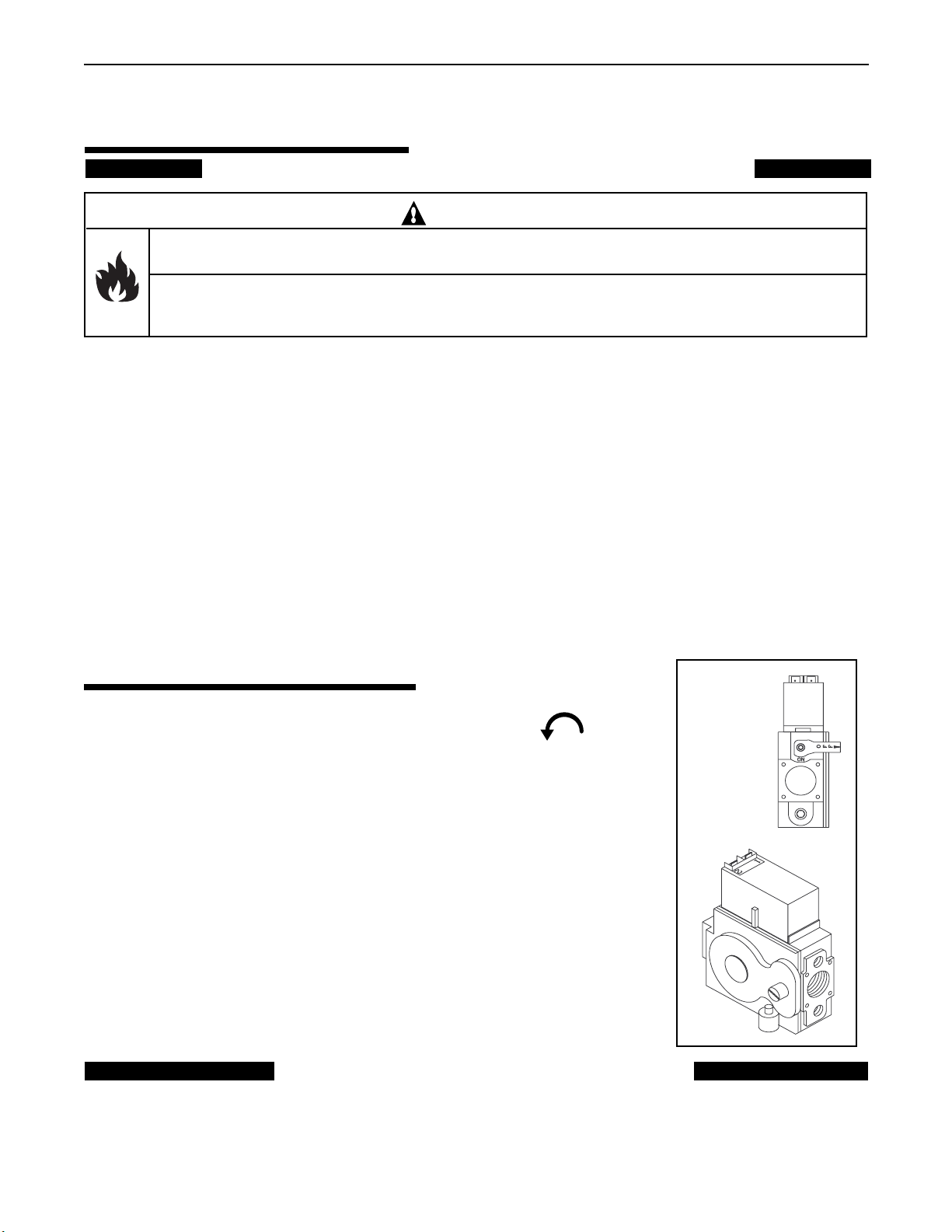

6. Turn the gas control lever horizontally to "OFF"; see Figure 1.

7. Wait five (5) minutes to clear out any gas. If you then smell gas, STOP!

Follow "B" in the safety information above. If you don't smell gas, go to the

next step.

8. Turn the gas control lever vertically to "ON".

9. Replace the control access door.

10. Turn on the electrical power to the heater.

11. Set the thermostat to the desired setting.

12. If the heater will not operate, follow the instructions "To Turn Off Gas To

Heater" and call your service technician or gas supplier.

Figure 1.

TO TURN OFF GAS TO HEATER

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the heater if service

is to be performed.

3. Remove control access door.

Rev. F 1-22-04 P/N 471105

4. Turn gas control lever horizontally to "OFF".

Do not force.

5. Replace control access door.

Page 6

Operation (contd.)

MILLIVOLT LIGHTING/OPERATION- NATURAL GAS & PROPANE

FOR YOUR SAFETY: READ BEFORE LIGHTING

WARNING

If you do not follow these instructions exactly, a fire or explosion may result causing personal injury,

loss of life and property damage.

Since propane gas is heavier than air, escaping propane will accumulate and remain at ground level. Do

not attempt to light the heater. If you suspect a propane leak, lighting the heater can result in a fire or

explosion which can cause personal injury, death, and property damage.

6

A. This heater has a pilot that must be lit manually. When

lighting the pilot follow these instructions exactly.

B. BEFORE LIGHTING smell all around the heater area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

- Do not try to light any heater.

- Do not touch any electric switch; do not use any phone

in your building.

- Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

- If you cannot reach your gas supplier, call the Fire

Department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or

turn by hand, don't try to repair it. Call a qualified service

technician. Forced or attempted repair may result in a

fire or explosion.

D. Do not use this heater if any part has been under water.

Immediately call a qualified service technician to inspect

the heater and to replace any part of the control system

and any gas control which has been under water.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Set the thermostat to the lowest setting.

3. Turn off all electric power to the heater.

4. Remove the control access door.

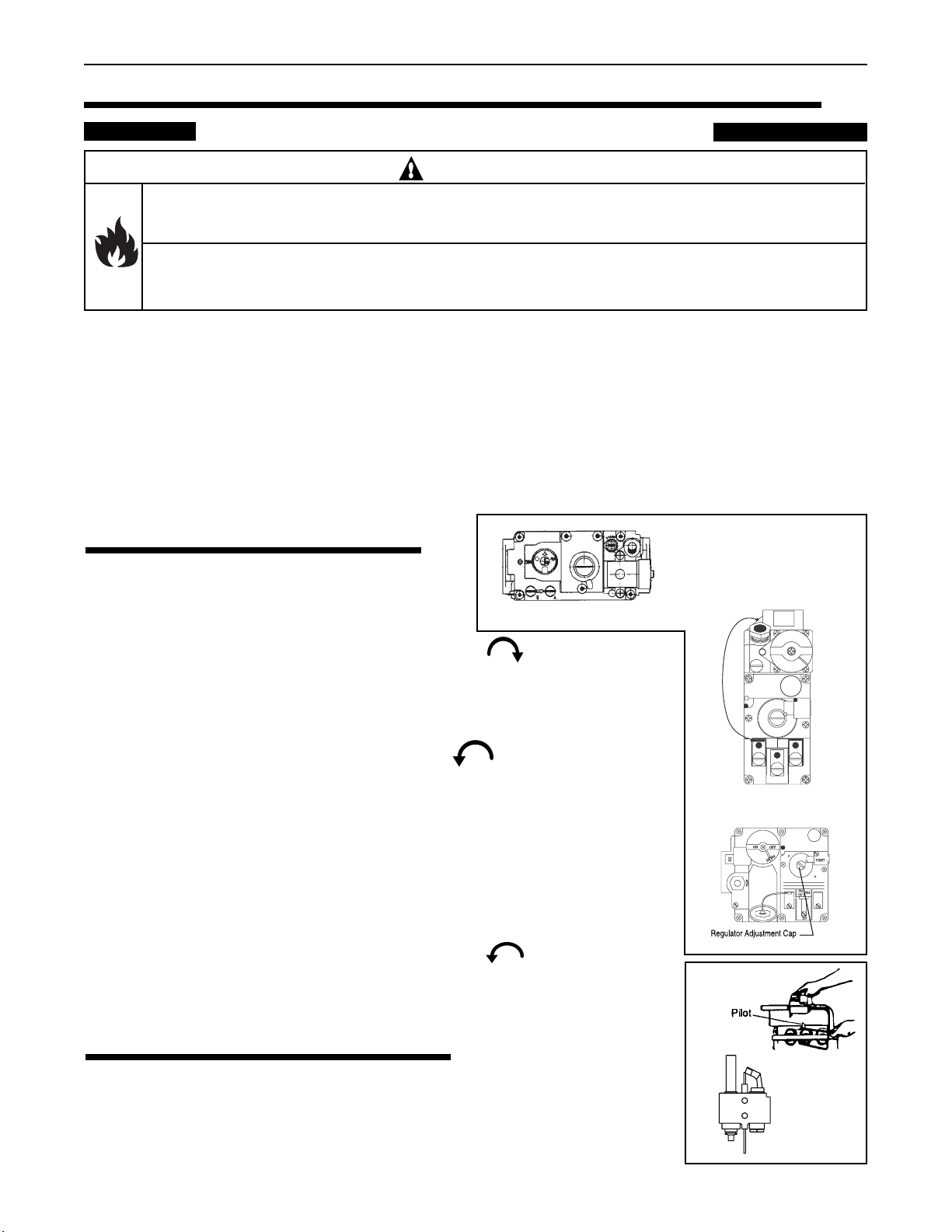

5. Push in the gas control valve slightly and turn clockwise to "OFF"; see Figure 2.

6. The knob cannot be turned from "PILOT" to "OFF" unless the knob is

pushed in slightly. Do not force.

7. Wait five (5) minutes to clear out any gas. If you then smell gas, STOP! Follow "B" in the

safety information above. If you don't smell gas, go to next step.

8. Turn the knob on the gas control to counterclockwise to "PILOT"; see Figure 3.

9. Push the control knob all the way and hold in. Immediately light the pilot with

Presslite matchless ignition system by pressing the red igniter button, (located at

panel next to the gas valve). Continue to hold the control knob in for about (1)

minute after the pilot is lit. Release knob and it will pop back up. Pilot should remain

lit. If it goes out, repeat steps 4 through 7.

10. If the knob does not pop up when released, stop and immediately call your service

technician or gas supplier.

11. If the pilot, see Figure 4, will not stay lit after several tries, turn the gas control knob

to "OFF" and call your service technician or gas supplier.

12. Turn the gas control knob counterclockwise to "ON".

13. Replace the control access door.

14. If the heater will not operate, follow the instructions "To Turn Off Gas To Heater"

and call your service technician or gas supplier.

(SIT valve)

Figure 2.

All Gas knob's shown

in "OFF" position.

IN

PILOT ADJ

ON

OFF

VENT

TH

TH

TP

TP

(Robertshaw valves)

Figure 3.

TO TURN OFF GAS TO HEATER

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the heater if service is to be performed.

3. Remove control access door.

4. Turn gas control lever horizontally to "OFF". Do not force.

5. Replace control access door.

P/N 471105 Rev. F 1-22-04

Figure 4.

Page 7

Operation (contd.)

7

OPERATING (CONTROLS)

DIRECT SPARK ELECTRONIC AND

MILLIVOLT MODELS

For convenience and economy all MiniMax 100

heaters are equipped with a thermostat on the front of

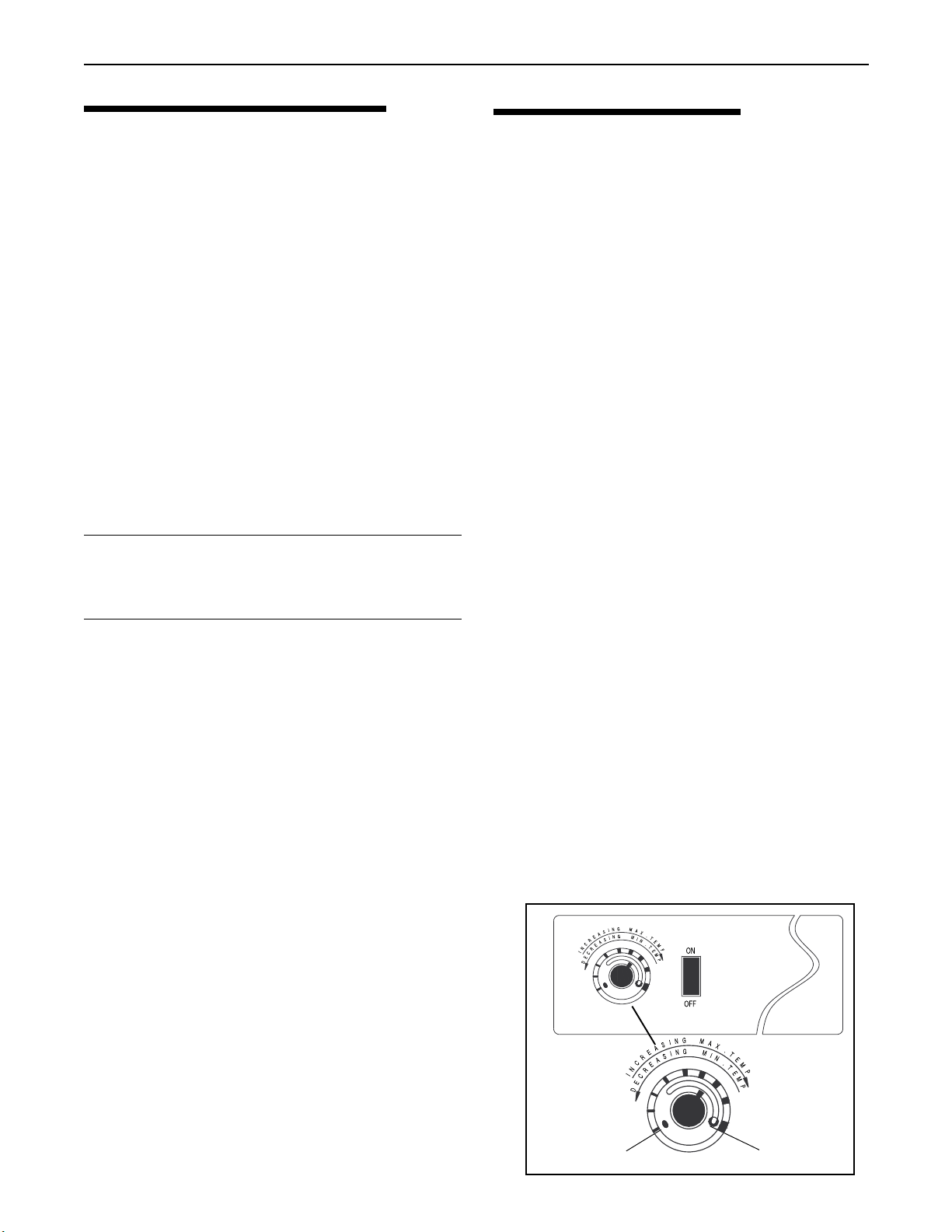

the heater control panel; see Figure 5.

Direct Spark MiniMax 100 heaters are equipped

with an electronic thermostat while Millivolt MiniMax

100 heaters have a mechanical thermostat.

The Pool/Off/Spa switch allows the heater to be turned

off when heating is not desired.

1. "ON" position - Maintains selected pool temperature.

2. "OFF" position - Heater will not come on regardless

of drop in pool temperature.

THERMOSTAT ADJUSTMENT

The knob with locking feature eliminates the need for

constant thermostat adjustments. Set the knob pointer

to the desired spa temperature.

NOTE

To eliminate error due to piping heat losses

measure pool temperature with an accurate

thermometer directly at the pool or spa.

If further adjustment is needed rotate the knob until

the desired temperature is obtained. This knob position

corresponding to your desired maximum pool or spa

temperature may now be preset (locked) by the knob

stopper which prevents the knob from being turned

beyond the maximum temperature you set.

THERMOSTAT KNOB STOPPER

Each thermostat is equipped with a mechanical stop

that can be locked or unlocked with use of a screwdriver to prevent temperatures in excess of that

desired by the user; see Figure 5.

The maximum setting can be adjusted by loosening

the screw "A" and turning the stopper dial to desired

maximum setting. Lock the setting by tightening the

screw. The Mechanical stop is under the knob.

Ensure that the knob is stopping at the correct position when the knob is rotated clockwise from a lower

temperature position.

HEATER OPERATION

GENERAL

The MiniMax 100 DSI employs a microprocessor

based Direct Spark Ignition (DSI) system to light the

main burner and therefore has no pilot. The ignition

circuit operates at 24 VAC and requires that line

voltage 115/230 be supplied to the heater.

The MiniMax 100 MV (Millivolt) requires no external

power source and the control circuit derives all its

power from the energy generated from the standing

pilot/ thermopile-generator combination. Note: Some

states ,including California, have energy conservation

regulations preventing the sale and use of certain

standing pilot (millivolt) equipment.

The MiniMax 100 DSI Control utilizes a

microprocessor to continually and safely monitor,

analyze, and control the proper operation of the gas

burner. The DSI Control features LED diagnostics,

automatic one hour reset, and flame current test pins.

The LED is located on the DSI.

CONTROLS OPERATION (DSI SYSTEM)

Heat Mode

1. When a call for heat is received from the thermostat

supplying 24 volts to TH terminal on control, the

control will reset, perform a self check routine, and

flash the diagnostic LED for up to four seconds.

After a brief delay the gas valve is energized and

the ignition electrode begins to spark for the four

(4) second trial for ignition (TFI) period.

2. When flame is detected during the trial for ignition,

sparking is shut-off immediately and the gas valve

remains energized. The thermostat and main burner

flame are constantly monitored to assure the system

continues to operate properly.

a.When the thermostat is satisfied and the demand

for heat ends, the main valve is de-energized

immediately.

Figure 5.

Knob Stopper

Rev. F 1-22-04 P/N 471105

Screw A

Page 8

Operation - Heater (contd.)

Failure to Light- Lockout

1. Should the main burner fail to light, or flame is not

detected during the trial-for-ignition (TFI) period

the control will go into lockout and the valve will

be turned off immediately.

2. Recovery from lockout requires a manual reset by

resetting the thermostat or turning off the ON/OFF

switch for a minimum period of 5 seconds.

IMPORTANT!

IT IS RECOMMENDED THAT NO MORE THAN

TWO IGNITION ATTEMPTS IN SUCCESSION

BE PERFORMED FOR NATURAL GAS

SYSTEMS . BEFORE FURTHER IGNITION

ATTEMPTS WAIT AT LEAST FIVE MINUTES

FOR GAS TO CLEAR.

FOR PROPANE (LPG) SYSTEMS ALLOW AT

LEAST FIVE (5) MINUTES BETWEEN IGNITION

ATTEMPTS FOR THIS HEAVIER-THAN-AIR

GAS TO SAFELY DISSIPATE. AFTER TWO

UNSUCCESSFUL IGNITION ATTEMPTS WITH

PROPANE OPEN THE BURNER ACCESS

DOOR AND WAIT AT LEAST THIRTY (30)

MINUTES BEFORE REPLACING DOOR TO

ATTEMPT FURTHER IGNITION ATTEMPTS.

8

Control Fault -Diagnostic LED Conditions

Error Mode LED Indication

Internal Control Failure Steady on

Flame Sense Fault 2 flashes

Ignition Lockout 3 flashes

The DSI Ignition Control can be accessed after removing

the heater’s front control panel. The diagnostic LED

located on the top of the DSI control will flash on for 1/4

second, then off for 1/4 second during a fault condition.

The pause between fault codes is 3 seconds.

NOTE

Normally the heater will light in the first or

second attempt. And with the exception of

a new installation or one that has been

shut down for an extended period, where

there is considerable air trapped in the gas

supply line, unsuccessful ignition

indicates other problems with the ignition

system - such as an unclean ignition

electrode impeding flame sensing.

3. If the thermostat is still calling for heat one hour

after a lockout the control will automatically reset

and attempt to ignite the burner again.

Flame Failure-Re-Ignition

1. If the established flame signal is lost while the

burner is operating, the control will respond within

0.8 seconds. The H.V. spark will be energized for a

trial for ignition period in an attempt to relight the

burner.

a. If the burner does not light the control will

de-energize the gas valve, shutting off the gas

flow, and the control will go into lockout as

described above in “Failure to Light-Lockout”.

If flame is re-established, normal operation

resumes.

P/N 471105 Rev. F 1-22-04

Page 9

Operation - Heater (contd.)

9

Proper Electrode Location

Proper location of the ignition electrode assembly is

important for optimum and safe system performance.

The electrode assembly should be located as noted in

Figure 6. The electrode assembly is NOT field

repairable and must be replaced if damaged.

Service Checks

Symptom Cause/Cure

1. Dead A. Miswired

B. Transformer bad

C. Fuse/circuit breaker open

D. Bad control (check LED for steady on)

2. Thermostat on, A. Miswired

no spark B. Bad thermostat no voltage @

terminal TH

3. Valve on, no spark A. Shorted Ign. electrode

B. Open HV Ign cable

C. Miswired

D. Bad DSI control

4. Spark on, no valve A. Valve coil open

B. Open valve wire

C. Bad control (also check voltage

between V1 & V2)

5. Flame okay during A. Bad electrode

TFI, no flame sense B. Bad S1 or HV wire

(after TFI) C. Poor ground at burner

D. Poor flame (check flame sensor

current, which follows)

Flame Sensor Current Check

Flame current is the current which passes through

the flame sensor to ground. The minimum flame

current necessary to keep system from lockout is 0.7

microamperes. To measure flame current, connect

DC microammeter to the FC- FC+ terminals as

shown in Figure 7. The meter should read 0.7

microamperes or higher when the heater is firing.

Figure 7.

Figure 6.

Rev. F 1-22-04 P/N 471105

Page 10

Maintenance

MAINTENANCE INSTRUCTIONS

It is recommended that you check the following items

at least every six months and at the beginning of every

swimming season.

1. Examine the venting system. Make sure there are

no obstructions in the flow of combustion and

ventilation air.

2. Visually inspect the main burner and the pilot

burner flame (on millivolt models). The normal

color of the flame is blue. When flame appears

yellow, burners should be inspected and cleaned;

see Figure 8.

3. Keep the burner area clear and free from combustibles and flammable liquids.

ENERGY SAVING TIPS

1. If possible, keep pool or spa covered when not in

use. This will not only cut heating costs, but also

keep dirt and debris from settling in the pool and

conserve chemicals.

2. Reduce the pool thermostat setting to 78

lower. This is accepted as being the most healthy

temperature for swimming by the American Red

Cross.

3. Use an accurate thermometer.

4. When the proper maximum thermostat settings

have been determined, tighten the thermostat knob

stopper.

5. Set time clock to start circulation system no earlier

than daybreak. The swimming pool loses less heat

at this time.

6. For pools that are only used on the weekends, it is

not necessary to leave the thermostat set at 78

Lower the temperature to a range that can be

achieved easily in one day. Generally, this would

° F. to 15° F., if pool heater is sized properly.

be 10

7. During the winter or while on vacation, turn heater

off.

8. Set up a regular program of preventative

maintenance for the heater each new swimming

season. Check heat exchanger, controls, burners,

operation, etc.

° F. or

°F.

10

Blue Flame

Figure 8.

SPRING AND FALL OPERATION

If the pool is being used occasionally, do not turn the

heater completely off. Set the thermostat down to

° F. This will keep the pool and the surrounding

65

ground warm enough to bring the pool up to a comfortable swimming temperature in a shorter period of

time.

WINTER OPERATION

If the pool won't be used for a month or more, turn

the heater off at the main gas valve. For areas where

there is no danger of water freezing, water should

circulate through the heater all year long, even though

you are not heating your swimming pool. This heater

should not be operated out doors at temperatures

below 32° F. (0° C.). Where freezing is possible, it is

necessary to drain the water from the heater. This

may be done by opening the drain valve located at the

inlet/outlet header allowing all water to drain out of

the heater. It would be a good practice to use

compressed air to blow the water out of the heat

exchanger.

P/N 471105 Rev. F 1-22-04

Page 11

Maintenance (contd.)

11

CHEMICAL BALANCE

POOL AND SPA WATER

Your Pentair Pool Products pool heater was designed

specifically for your spa or pool and will give you many

years of trouble free service provided you keep your

water chemistry in proper condition.

Three major items that can cause problems with your

pool heater are improper pH, disinfectant residual, and

If pH becomes too high (over alkaline), it

has these effects:

1. Greatly lowers the ability of chlorine to destroy

bacteria and algae.

2. Water becomes cloudy.

3. There is more danger of scale formation on the

plaster or in the heat exchanger.

4. Filter elements may become blocked.

total alkalinity. These items, if not kept properly

balanced, can shorten the life of the heater and cause

permanent damage.

WARNING

If pH is too low (over acid) the following

conditions may occur:

1. Excessive eye burn or skin irritation.

2. Etching of the plaster.

Heat exchanger damage resulting from chemical

imbalance is not covered by the warranty.

WHAT A DISINFECTANT DOES

Two pool guests you do not want are algae and

bacteria. To get rid of them and make pool water

sanitary for swimming - as well as to improve the

water's taste, odor and clarity - some sort of

disinfectant must be used.

Chlorine and bromine are universally approved by

health authorities and are accepted disinfecting agents

for bacteria control.

WHAT IS A DISINFECTANT

RESIDUAL?

When you add chlorine or bromine to the pool water, a

portion of the disinfectant will be consumed in the

process of destroying bacteria, algae and other oxidiz-

3. Corrosion of metal fixtures in the filtration and

recirculation system, which may create brown, blue,

green, or sometimes almost black stains on the

plaster.

4. Corrosion of copper in the heater, which may cause

leaks.

5. If you have a sand and gravel filter, the alum used

as a filter aid may dissolve and pass through the

filter.

CAUTION: Do not test for pH when the chlorine

residual is 3.0 ppm or higher, or bromine residual is

6.0 ppm or higher. See your local pool supply store

for help in properly balancing your water chemistry.

RULE: Chemicals that are acid lower pH. Chemicals

that are alkaline raise pH.

ALKALINITY High - Low:

able materials. The disinfectant remaining is called

chlorine residual or bromine residual. You can determine the disinfectant residual of your pool water with a

reliable test kit, available from your local pool supply

store.

You must maintain a disinfectant residual level

adequate enough to assure a continuous kill of bacteria

or virus introduced into pool water by swimmers,

through the air, from dust, rain or other sources.

It is wise to test pool water regularly. Never allow

chlorine residual to drop below 0.6 ppm (parts per

million). The minimum level for effective chlorine or

bromine residual is 1.4 ppm.

pH - The term pH refers to the acid/alkaline balance of

water expressed on a numerical scale from 0 to 14. A test

kit for measuring pH balance of your pool water is

"Total alkalinity" is a measurement of the total amount

of alkaline chemicals in the water, and control pH to a

great degree. (It is not the same as pH which refers

merely to the relative alkalinity/acidity balance.) Your

pool water's total alkalinity should be 100 - 140 ppm to

permit easier pH control.

A total alkalinity test is simple to perform with a reliable

test kit. You will need to test about once a week and make

proper adjustments until alkalinity is in the proper range.

Then, test only once every month or so to be sure it is

being maintained. See your local pool dealer for help in

properly balancing the water chemistry.

Table 1.

Strongly Acid Neutral Strongly Alkaline

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14

pH Chart

available from your local pool supply store; see Table 1.

Muriatic Acid has a pH of about 0. Pure water is 7

Table 2.

(neutral). Weak Lye solution have a pH of 13-14.

RULE: 7.4 to 7.6 is a desirable pH range. It is essential to maintain correct pH, see Table 2.

Rev. F 1-22-04 P/N 471105

Add Soda Ash or

Sodium Bicarbonate

pH Control Chart

7.26.8 7.0 7.4 7.6 7.8

MarginalIdealMarginal

8.0 8.2 8.4

Add Acid

Page 12

12

COLD

POOL TEMP

HOT

OFF

ON

Installation Instructions

SPECIFICATIONS

IMPORTANT NOTICE: These installation instructions are designed for use by qualified personnel only,

trained especially for installation of this type of heating equipment and related components. Some states require

installation and repair by licensed personnel. If this applies in your state, be sure your contractor bears the

appropriate license.

The heater must be installed on a level surface consisting entirely of, or a combination of, noncombustible

materials such as steel, iron, brick, tile, concrete, slate, or plaster. Do not install on carpeting. The heater must be

installed to keep specific clearances on all sides for service and inspection.

OUTDOOR INSTALLATION

Stackless, applies to all

MiniMax 100 outdoor models

25 1/2"

ON

HOT

COLD

OFF

POOL TEMP

INDOOR INSTALLATION

Applies to all MiniMax 100

indoor models,

Draft hood stack diameter = 5 in.

Stack (USA only)

Outdoor shelter (Canadian)

18 3/8"

15"

5"

14 1/4"

19 11/32"

15 1/2"

Outdoor Installation

Indoor Installation

P/N 471105 Rev. F 1-22-04

Page 13

Installation (contd.)

MiniMax 100

High Performance Heater

COLD

POOL TEMP

HOT

OFF

ON

PacFab

GATE VALVE

PUMP

GATE VALVE

FILTER

HEATER

FROM POOL

VALVE

CHECK

TO POOL

13

PLUMBING CONNECTIONS

The MiniMax 100 heater has the unique capability of

direct schedule 40 or 80 CPVC/ABS/PVC plumbing

connections. Either a Quick-Flange or Quick-Flange II

(depending on model ordered) has been included with the

MiniMax 100 to insure conformity with Pentair Pool

Products recommended CPVC/ABS plumbing procedure;

see Figure 9. Other plumbing connections can be used.

The instructions on the following pages show the methods

for successfully connecting plumbing to the inlet/outlet

header with either the Quick-Flange or Quick-Flange II.

PRESSURE SWITCH

The pressure switch will keep the circuit open when the

pump is not on and operating. When the filter pump

turns on, the pressure switch closes the circuit and the

heater will operate. When the heater is installed below

water level of a spa or pool, adjustment of the pressure

switch may be required. For adjustment of pressure

switch, we recommend the following procedures.

1. Backwash the filter and clean the pump hair and

lint basket before making any adjustment to the

pressure switch.

2. Switch the circulation pump on and make sure it

is primed.

3. Push the heater power switch on and set the

thermostats to their highest temperature settings.

4. Clean the locktight off of the pressure switch

adjustment knob threads.

5. Turn the adjustment knob clockwise or away

from the micro-switch, until the heater shuts

down; see Figure 11.

6. Turn the adjustment knob counter-clockwise 1/2

turn and the heater should refire.

Figure 9.

7. Turn the pump off

and the heater should

shut down. If the

Adjustment

Knob

heater does not shut

MANUAL BY-PASS

down, repeat the

procedure.

Where the flow rate exceeds the maximum 80 GPM, a

manual by-pass should be installed and adjusted. After

adjustments are made, the valve handle should be

removed to avoid tampering.

8. Switch the pump off

and on several times

to assure proper

Figure 11.

adjustment.

Model Min. Max.*

100 20 80

* Do not exceed the maximum recommended

flow rate for the connecting piping.

VALVES

When any equipment is located below the surface of

the pool or spa, valves should be placed in the

circulation piping system to isolate the equipment from

the pool or spa.

Check valves are recommended to prevent back

siphon; see Figure 10.

Caution: Exercise care when installing chemical

feeders so as to not allow back siphoning of

chemical into the heater, filters or pump.

Rev. F 1-22-04 P/N 471105

Figure 10.

Page 14

Installation (contd.)

WATER CONNECTIONS

QUICK-FLANGE II INSTALLATION INSTRUCTIONS

FOR 1½ SCHEDULE 40 CPVC or ABS PIPE or SCHEDULE 80 PVC

(you may adapt to SCH 40 PVC 12 inches beyond the Quick Flange II)

(1½ in. npt x 1½ in. CPVC/ABS slip male adaptor may be required )

Figure 12.

14

1. Insert 2 in. rubber gaskets over 2 in. gasket retainer rings molded to bottom of Quick-Flange II;

see Figure 12.

2. Bolt Quick-Flange II to header using supplied 3/8 in. bolts and 3/8 in. washers.

3. Using pipe dope, thread pipe directly to Quick-Flange II.

a. Or, first thread a 1½ in. npt x 1½ in. slip CPVC/ABS male adaptor (not supplied) to the

Quick-Flange II ,and after preparing the joint by sanding with a medium grit sandpaper,

glue the pipe to the adaptor with a quality solvent glue.

NOTE

ALL VERSIONS OF THE MINIMAX 100 INCLUDE A QUICK-FLANGE II ADAPTOR

Each MiniMax 100 Quick-Flange II Accessory Kit, p/n 471083,

contains the following items:

One (1) Quick-Flange II unit

Two (2) 2 in. Rubber Gaskets

Four (4) 3/8 in. Bolts

Four (4) 3/8 in. Washers

PRESSURE RELIEF VALVES

Where local, (or Canadian), codes require the use of a Pressure Relief Valve (PRV), the PRV may be

installed in a tee fitting placed as close as possible to the heater water outlet with no intervening valves

between the PRV and the heater.

P/N 471105 Rev. F 1-22-04

Page 15

Installation (contd.)

P

IL

O

T

A

D

J

IN

O

N

O

F

F

VENT

TH

TP

TH

TP

R

egulator A

djustm

ent C

ap

GAS CONNECTIONS

15

GAS LINE INSTALLATIONS

Before installing the gas line, be sure to check which gas

the heater has been designed to burn. This is important

because different types of gas require different gas pipe

sizes. The rating plate on the heater will indicate which

gas the heater is designed to burn. Table 3 shows which

size pipe is required for the distance from gas meter to the

heater. The table is for natural gas at a specific gravity of

.65 and propane at specific gravity of 1.5.

When sizing gas lines, calculate three (3) additional feet

of straight pipe for every elbow used.

When installing the gas line, avoid getting dirt, grease or

other foreign material in the pipe as this may cause damage

to the gas valve, which may result in heater failure.

The gas meter should be checked to make sure that it will

supply enough gas to the heater and any other heaters that

may be used on the same meter.

The gas line from the meter will usually be of a larger size

than the gas valve supplied with the heater. Therefore a

reduction of the connecting gas pipe will be necessary.

Make this reduction as close to the heater as possible.

The heater and any other gas appliances must be

disconnected from the gas supply piping system during

any pressure testing on that system, (greater that ½ PSIG).

The heater and its gas connection must be leak tested

before placing the heater in operation. Do not use flame

to test the gas line. Use soapy water or another nonflammable method.

A manual main shutoff valve must be installed

external to the heater.

REGULATED MANIFOLD

PRESSURE TEST

1. Attach the manometer to the heater jacket.

2. Shut off the main gas valve.

3. Remove 1/8" NPT plug on the outlet side of the

valve and screw in the fitting from the manometer

kit.

4. Connect the manometer hose to the fitting.

5. Fire the heater.

6. The manometer must read 4" WC for natural gas,

11" WC for propane gas, while the heater is

operating.

7. For adjustment, remove the Regulator Adjustment

Cap and using a screwdriver turn the screw

clockwise to increase - counterclockwise to

decrease gas pressure; see Figure 13.

Robertshaw

valves

Regulator Adjustment Cap

Figure 13.

SIT valve

WARNING

Do not install the gas line union inside the heater

PENTAIR POOL PRODUCTS GAS

PRESSURE SETTINGS*

cabinet. This will void your warranty.

CAUTION

The use of Flexible Connectors (FLEX) is NOT

Normal Altitudes

(0-2500 ft. Above Sea Level)

Maximum inlet gas pressure 10" WC 14" WC

Minimum inlet gas pressure 5" WC 12" WC

Normal manifold pressure 4" WC 11" WC

Natural Propane

recommended as they cause high gas pressure drops.

Natural PropaneHigh Altitudes

(2500-7000 ft. Above Sea Level)

Pipe Sized For Length Of Run In Equivalent Feet

1"3/4"1/2"

Model Nat LP Nat LP Nat LP

100 DSI 20' 50' 50' 150' 150' 600'

100 MV 20' 50' 50' 150' 150' 600'

75 20' 50' 50' 150' 150' 600'

Rev. F 1-22-04 P/N 471105

Table 3.

Maximum inlet gas pressure 10" WC 14" WC

Minimum inlet gas pressure 5" WC 12" WC

Normal high altitude 3" WC 7" WC

manifold pressure

* All Readings are taken with heater fired. Any

adjustments made with heater off will give

incorrect readings.

Table 4.

Page 16

Installation (contd.)

VENTILATION

OUTDOOR INSTALLATION

16

This heater is certified by International Approval

Services (AGA & CGA) for outdoor installation. If

the heater is installed in very cold areas proper precautions are needed for freeze protection. The heater

must be placed in a suitable area on a level, noncombustible surface. Do not install heater under an

overhang with clearances less than 3 feet from top of

the heater. The area under an overhang must be open

on three side.

IMPORTANT!

In an outdoor installation it is important to

protect your heater from water damage.

Ensure water is diverted from overhanging

eves with a proper gutter/drainage system.

The heater must be set on a level foundation

for proper rain drainage.

The heater should not be installed closer than 6 inches

to any fences, walls or shrubs at any side or back, nor

closer than 18 inches at the plumbing side. A minimum

clearance of 24 inches must be maintained at front of

heater; see Figure 14.

24 in.

6 in.

6 in.

18 in.

Figure 14.

IMPORTANT!

When locating the heater, consider that high

winds can roll over or deflect off adjacent

buildings and walls. Normally, placing the

heater at least three feet from any wall will

minimize downdraft.

Unusually high prevailing wind condition and

downdrafts may require the use of a stack type

outdoor vent kit (available at additional cost).

NOTE

This unit shall not be operated outdoors at

temperatures below 0

o

F. for propane and -20o F.

for natural gas.

NOTE

Overhangs must be such that flue products are

not diverted into living spaces. From the point

where the flue products leave the heater, that

point MUST be a minimum of four (4) feet below,

four (4) horizontally from or one (1) foot above

any door, window or gravity inlet into the building;

see Figure 15.

Figure 15.

P/N 471105 Rev. F 1-22-04

Page 17

Installation - Ventilation (contd.)

17

INDOOR INSTALLATION

The installation of venting system should conform with

the latest edition of ANSI Z223.1, the National Fuel

Gas Code, and/or in Canada, CAN/CGA-B149.1 or .2

or applicable provision of the local codes.

All products of combustion and vent gases must be

completely removed to the outside atmosphere through

a vent pipe which is connected to the draft hood. A

vent pipe extension of the same size must be

connected to the draft hood and extended at least 2

feet higher than highest point of the roof within a 10

foot horizontal radius, and at least 3 ft. higher than the

point at which it passes through the roof, or as

permitted by local code; see Figure 16. The vent

should terminate with an approved vent cap (weather

cap) for protection against rain or blockage by snow.

Double-wall vent pipe and an approved roof jack shall

be employed through the roof penetration. The use of

double-walled type B vent pipe is recommended.

The draft hood must be installed so as to be in the

same atmospheric pressure zone as the combustion air

inlet to the pool heater. The certified (factory) draft

hood

must not be modified in any way and must be

employed in every indoor installation.

The heater must be located as close as practical to a

chimney or gas vent. The Heater should be installed at

least 5 feet away from the pool or spa.

NOTE

The heater requires two uninterrupted air

supply openings; one for ventilation and one to

supply oxygen for proper gas combustion; see

Figure 17.

Minimum requirements for free air supply openings:

one 12 inches from the ceiling for ventilation and one

12 inches from the floor for combustion air as outlined

in the National Fuel Gas Code, ANSI Z223.1, or Local

Building Codes.

The air supply openings should be sized according to

table 5.

CAUTION

Chemicals should not be stored near the heater

installation. Combustion air can be contaminated by

corrosive chemical fumes which can void the

warranty.

Vent terminated at

least 24 in. above

any object within 10 ft.

10 ft.

Ridge

2 ft. min.

3 ft. min.

Vent

Cap

Roof

Jack

The heater must be placed in a suitable room on a noncombustible floor and in an area where leakage from

heat exchanger or water connections will not result in

damage to the area adjacent to the heater or the

structure. When such locations cannot be avoided, it is

recommended that a suitable drain pan with adequate

drainage, be installed under the heater. The pan must

not restrict air flow.

Installations in basements, garages, or underground

structures where flammable liquids may be stored must

have the heater elevated 18 inches from the floor using

a noncombustible base. The following minimum

clearances from combustible materials must be

provided.

Side Front Top

Water Connection 18 in. 24 in.

Remaining 6 in. 6 in.

Ceiling Clearance 36 in.*

*To ceiling or roof.

Figure 16.

*Rise

*1" Rise Per Foot

Recommended

Chimney

Figure 17.

Vent Cap And

Riser Furnished

By Installer

Air Supply

Ventilation

Air Supply

Gas Combustion

Air Opening Requirements

Air For

Model

Combustion

Ventilation

100 DSI 100 sq. in. 100 sq. in.

100 MV 100 sq. in. 100 sq. in.

Air

Table 5.

Rev. F 1-22-04 P/N 471105

Page 18

Installation - Ventilation (contd.)

18

VENT TEST

Use the following steps to

perform a quick check of

your venting installation.

Allow the heater to operate

for 15 minutes. Close the

doors in the room, then

strike a wooden match and

blow out the flame. Hold

the smoking match next to

the draft hood; see Figure 18. If the smoke is pulled

up into the vent and out of the room, the venting is

correct. If it does not, you must make venting

corrections.

Stack Type Indoor Draft Hood Kit

Model Draft Hood Product No. Vent Dia.

100 DSI DH 10 471187 5 in.

100 MV DH 10 471187 5 in.

75 DH 10 471187 5 in.

Indoor Draft Hood Installation

1. Take out slotted outer top piece after first removing

sheet metal screws, attaching it to the cabinet.

2. Install adapter (vent kit).

3. Install top cover (vent kit).

4. Install draft hood (vent kit).

Fig. 18. Draft Hood.

the terminal block located inside the junction box before

removing the cord and strain relief from the cabinet. The

heater may be hard wired with either 120 or 240 VAC to convert to 240 VAC, change the transformer wiring

connected to the output side of the terminal block first.

The heater must be grounded and the heater electrically

bonded.

All wiring must comply with all local codes, or in the

absence of local codes with the NEC ANSI/NFPA 70.

Electrical Rating

60 Hz 115 V.A.C. or 230 V.A.C.

50/60 Hz 208 V.A.C. or 240 V.A.C.

NOTE

If any of the original wiring supplied with this heater

must be replaced, installer must supply (No. 18

awg 105° C. U.L. approved AWM low energy

stranded) copper wire or it's equivalent.

In Canada: wires must be CSA approved.

CAUTION

The heater must be electrically grounded and bonded in

accordance with local codes or, in the absence of local

codes, with the latest national electrical codes

ANSI/NFPA No. 70.

In Canada: CSA standard C22.1 Canada Electrical

Code Part 1 and/or local codes.

Figure 19.

Use provided screws to secure the vent assembly;

see Figure 19.

ELECTRICAL, DSI UNITS

Some versions of the MiniMax DSI Heater have a

standard 120 VAC, grounded, 3-blade cordset factory

installed for your convenience. The plug must be

plugged into an outdoor rated watertight GFCI

protected receptacle rated for 10 amps minimum - a

constant power source is recommended. If the heater

must be hard wired, you must remove the cord from

TRANSFORMER WIRING

INSTRUCTION

P/N 471105 Rev. F 1-22-04

Page 19

Installation (contd.)

MiniMax 100 Electronic Direct Spark Ignition Wiring Diagram

19

EXTERNAL

BOND LUG

MODULE

V2/GRD

SPARK

IGNITER

GRN

TERMINATE SUPPLY SAFETY GROUND WIRE (GREEN) HERE

GROUND SCREW WITH PAINT CUTTING WASHER

CHASSIS

SHEET METAL

WHT BLUE

GAS VALVE

GRN

V1

TH

RED

12

MiniMax 100 ELECTRONIC WIRING DIAGRAM

IF ORIGINAL FACTORY WIRING MUST BE REPLACED, INSTALLER MUST SUPPLY

UL OR CSA (IF CANADA) APPROVED WIRE, 18 GAUGE, 600V, 150˚ C TEMPERATURE RATING.

THERMAL FUSE WIRING MUST BE REPLACED WITH UL OR CSA (IF CANADA) APPROVED

WIRE, 18 GAUGE, 600V, 150˚ C TEMPERATURE RATING..

INTERCONNECTING WIRING TO APPLIANCE MUST CONFORM TO THE NATIONAL ELECTRICAL

CODE OR SUPERCEDING LOCAL (WIRING) CODES.

WATER

PRESSURE SW.

WHT

WHT

THERMAL

FUSE

HI LIMIT SW.

WHT WHT WHT

WHT

WHT

ORN

ORN

ON/OFF SW.

ELECTRONIC

THERMOSTAT

NH

TRANSFORMER WIRING :

WHT/RED

WHT/BLK

3

BLK

4

115V CONN

LINE : 1 & 2 (TIED)

LINE : 3 & 4 (TIED)

230V CONN

2 & 3 (TIED)

LINE : 1

LINE : 4

MiniMax 100 Millivolt Wiring Diagram

Remote Wiring Hook-up

The MiniMax 100 may be

connected to a two wire remote

control by disconnecting the wire

connector from the hot

(transformer) side terminal of the

"ON/OFF" switch and connecting

the two wire remote across the end

of this wire and the aforementioned

terminal.

NOTE

When connecting a remote control

to the MiniMax 100 you must install

the low voltage remote control

wires in a separate conduit from

ANY line voltage wires. Do not

exceed 25 ft. wire run for remotes

on millivolt models.

Rev. F 1-22-04 P/N 471105

Page 20

TROUBLESHOOTING - GENERAL

Possible Cause Remedy

Heater will not come on

Automatic ignition system fails Check if electrical connections are

correct and securely fastened –

If YES, call serviceman.

Pump not running Place pump in operation

Pump air locked Check for leaks

Filter dirty Clean filter

Pump strainer clogged Clean strainer

Defective wiring or connection Repair or replace wires

20

Defective pressure switch Replace Switch

Defective gas controls Call serviceman

On-Off switch in "OFF" position Turn switch to "ON"

Heater Short Cycling (Rapid On and Off Operation)

Insufficient water flow Clean filter and pump strainer

Defective wiring Repair or replace wiring

Defective or stuck by-pass valve Call serviceman

Defective hi-limit and/or thermostat Call serviceman

Heater Makes Knocking Noises,

Make sure all valves on systems are open

Heater operating after pump has shut off Shut off gas supply and call serviceman

Heater exchanger scaled Shut off gas supply and call serviceman

P/N 471105 Rev. F 1-22-04

Page 21

ITEM DESCRIPTION QTY. P/N

PARTS LIST

Rev. F 1-22-04 P/N 471105

1* Indoor Draft Hood Kit consisting of: 1 471187

Indoor Draft Hood (471198) and items 2 & 3

1A Outdoor Top 1 471213

2* Indoor Top (Cover) 1 471075

3* Indoor Stack Adaptor 1 471214

4 Middle Top 1 471069

5 Flue Collector 1 471059

6 Return Header 1 471096

7 Bolt 3/8 x 16 UNC x 3/4 4 471200

8 Rubber Seal tube 10 470742

9 Heat Exchanger Less Heads 1 471093

10 Main Header (Inlet/Outlet) 1 471094

11 Combustion Chamber 1 N.A.

12 Ignitor Electrode Bracket 1 471058

13 Burner Natural Gas 1 471122

Burner Propane 1 471136

Burner (75) Natural Gas 1 471851

13a Burner Tray Assy. (complete) Natural Gas Millivolt 1 471219

Burner Tray Assy. (complete) Propane Millivolt 1 471236

Burner Tray Assy. (complete) Natural Gas DSI 1 471076

Burner Tray Assy. (complete) Propane DSI 1 471077

Burner Tray Assy. (75) - (complete) Natural Gas 1 471850

14 Ignitor Electrode 1 471090

15 Gas Valve-Nat. Gas DSI-Robertshaw 1 471088

Gas Valve-Propane DSI-Robertshaw 1 471089

Gas Valve-Nat. Gas Millivolt-Robertshaw 1 471192

Gas Valve-Propane Millivolt-Robertshaw 1 072125

Gas Valve-Nat. Gas Millivolt-SIT 1 471436

Gas Valve-Propane Millivolt-SIT 1 471435

16 Thermostat-Millivolt Models 1 072022

Thermostat (Electronic)-Direct Spark Models 1 471431

17 On/Off Switch spst 1 471128

18 Heat Shield Burner Tray 1 471070

19 Control Panel Assy 1 471078

20 Door Assembly 1 471067

21 Control Bracket 1 471159

22 Ignition Control DSI 1 471091

23 Transformer 1 074033

24 Jacket Assembly 1 N.A.

25 Inspection Panel 1 471071

26 Burner Tray Back Support 1 471169

27 Burner Tray Side Support 2 471166

28 Heat Exchanger Support Brackets 2 471164

29 Hi-Limit Safety Switch 2 071017

30 Flow Valve, assy. 1 471095

31 Pressure Switch 1 471097

32 Baffle Hold Down Bracket 1 471064

33 Flue Baffle 4 471065

** Items Below Not Shown

** Washer 3/8 I.D. 4 072169

** Thermal Cutoff Switch 1 075173

** Pilot Natural Gas Millivolt 1 471239

** Pilot Propane Millivolt 1 471238

** Thermopile Generator 1 071515

** Quick-flange Kit for 2" slip connection 1 471215

** Quick-flange II Kit for 1½" thd. connection 1 471083

** Kit Wiring MMX 100 Millivolt 1 471201

** Kit Wiring MMX 100 DSI 1 471202

** Knob 1 470184

** Knob Stopper 1 470414

** Presslite Piezo Ignitor Assy-Millivolt 1 075459

** Valve D rain 1/4 n pt 1 072136

** Hi-Tension Ignition Cable 1 471092

** Rubber Bushing, 2" i.d. 2 070544

** Pilot Bracket/Shield, Millivolt 471221

** Manifold 471260

** Cord-6' w/Plug 155138

21

Page 22

EXPLODED VIEW

22

13a

33

14

P/N 471105 Rev. F 1-22-04

Page 23

NOTES

23

Rev. F 1-22-04 P/N 471105

Page 24

24

SAVE THESE INSTRUCTIONS.

Pentair Pool Products

1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

P/N 471105 Rev. F 1-22-04

Loading...

Loading...