OPERATION AND

MAINTENANCE

MANUAL FOR THE

PEMSERTER®

SERIES 2000® PRESS

(Original instruction)

OPERATION AND MAINTENANCE MANUAL

PEMSERTER

SERIES 2000

PRESS

MODEL SERIES 2000

FASTENER INSTALLATION PRESS

SERIAL NUMBER 20010- ___

20110- ___

®

PennEngineering

99 Chenfeng Middle Road

Kunshan, Jiangsu Province . PRC

+86(512)5726-9310 www.pemnet . com

PRODUCED IN CHINA BY PEM (CHINA) Co., Ltd

Document Part Number 8021244

Main Document Number 8022050

Revision B July-2016

Copyright 2016 by PennEngineering®, Inc. All rights reserved.

No part of this documentation may be reproduced, copied or transmitted in any form, or by any

electronic, digital or other means, without permission in writing from PennEngineering®, Inc.

(referred to herein as the “Company”). This includes photocopying and information storage and

retrieval systems. The material in this documentation is subject to change without notice.

PLEASE READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THE

SOFTWARE INCLUDED WITH THE EQUIPMENT. BY USING THE SOFTWARE

ACCOMPANYING THE EQUIPMENT YOU AGREE TO BE BOUND BY THE TERMS

AND CONDITIONS OF THIS LICENSE.

All software furnished with the equipment is on a licensed basis. The Company grants to the

user a non-transferable and non-exclusive license to use such software in object code only and

solely in connection with the use of the equipment. Such license may not be assigned,

sublicensed, or otherwise transferred by the user apart from the equipment. No right to copy a

licensed program in whole or in part is granted. Title to the software and documentation shall

remain with the Company. The user shall not modify, merge, or incorporate any form or portion

of a licensed program with other program material, create a derivative work from a licensed

program, or use a licensed program in a network. The user agrees to maintain the Company’s

copyright notice on the licensed programs delivered with the equipment. The user agrees not to

decompile, disassemble, decode, or reverse engineer any licensed program delivered with the

equipment, or any portion thereof.

LIMITED WARRANTY: The Company warrants only that the software will perform in

accordance with the documentation accompanying the equipment during the equipment warranty

period. The Company does not warrant that the software is error free. The user’s exclusive

remedy and the Company’s sole liability for defects in the software as to which the Company is

notified during the equipment warranty period is to repair or replace the software at the

Company’s option. This limited warranty does not apply if the software has been altered, the

user has failed to operate the software in accordance with this documentation, or the software has

been subject to abnormal physical or electrical stress, misuse, negligence or accident.

EXCEPT FOR THE EXPRESS WARRANTY SET FORTH ABOVE, THE SOFTWARE IS

PROVIDED “AS IS” WITH ALL FAULTS. THE COMPANY DISCLAIMS ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION,

THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND

NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR

TRADE PRACTICE.

IN NO EVENT SHALL THE COMPANY BE LIABLE FOR ANY INDIRECT, SPECIAL,

CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT

LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE

USE OR INABILITY TO USE THE EQUIPMENT, THE SOFTWARE OR ANY PART OF

THIS DOCUMENTATION, EVEN IF THE COMPANY HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES.

PEMSERTER

SERIES 2000

FASTENER INSTALLATION PRESS

OPERATION AND MAINTENANCE MANUAL

TABLE OF CONTENTS

SECTION TITLES PAGE

1. INTRODUCTION 1

2. IDENTIFYING AND LOCATING MAJOR COMPONENTS OF THE PRESS 6

3. SAFETY SYSTEM OPERATION 15

4. PRESS INSTALLATION 17

5. GENERAL FUNCTION DESCRIPTIONS 23

6. TOUCH-SCREEN CONTROLS 27

7. PNEUMATIC-HYDRAULIC SYSTEM 70

8. ELECTRICAL SYSTEM 73

9. TOOLING SET-UP 79

10. PRESS OPERATION 94

11. MAINTENANCE 97

12. TROUBLE SHOOTING 109

13. SPARE PARTS 119

Read Manual Before Operating Press!

SECTION 1

INTRODUCTION

The PEMSERTER Series 2000 Fastener Installation Press is available in three configurations:

Manual, Automatic, and as TRU-Motion® systems integrated with material handling systems

such as assembly conveyors, X-Y positioning tables, and robotic arms. This manual describes

the standard Automatic version of the Series 2000 press. The Manual version of the Series

2000 operates the same as the Automatic version with the same control software, except that

the autofeed hardware is not available. A Manual Series 2000 can be upgraded to Automatic by

adding the autofeed system components.

Features:

• Safety and Protection System, sensitive down to 0.4 mm (0.015”)

• Unique high speed ram approach with energy efficient power stroke.

• Computer control system with touch screen interface. Provides simple and precise controls

for the operator. Designed for easy set-up, operation, maintenance and diagnostics.

• Quick Set-up/change-over automatic feed tooling system. Provides an extensive selection of

tooling for different fasteners using the same feeder bowl.

Specifications:

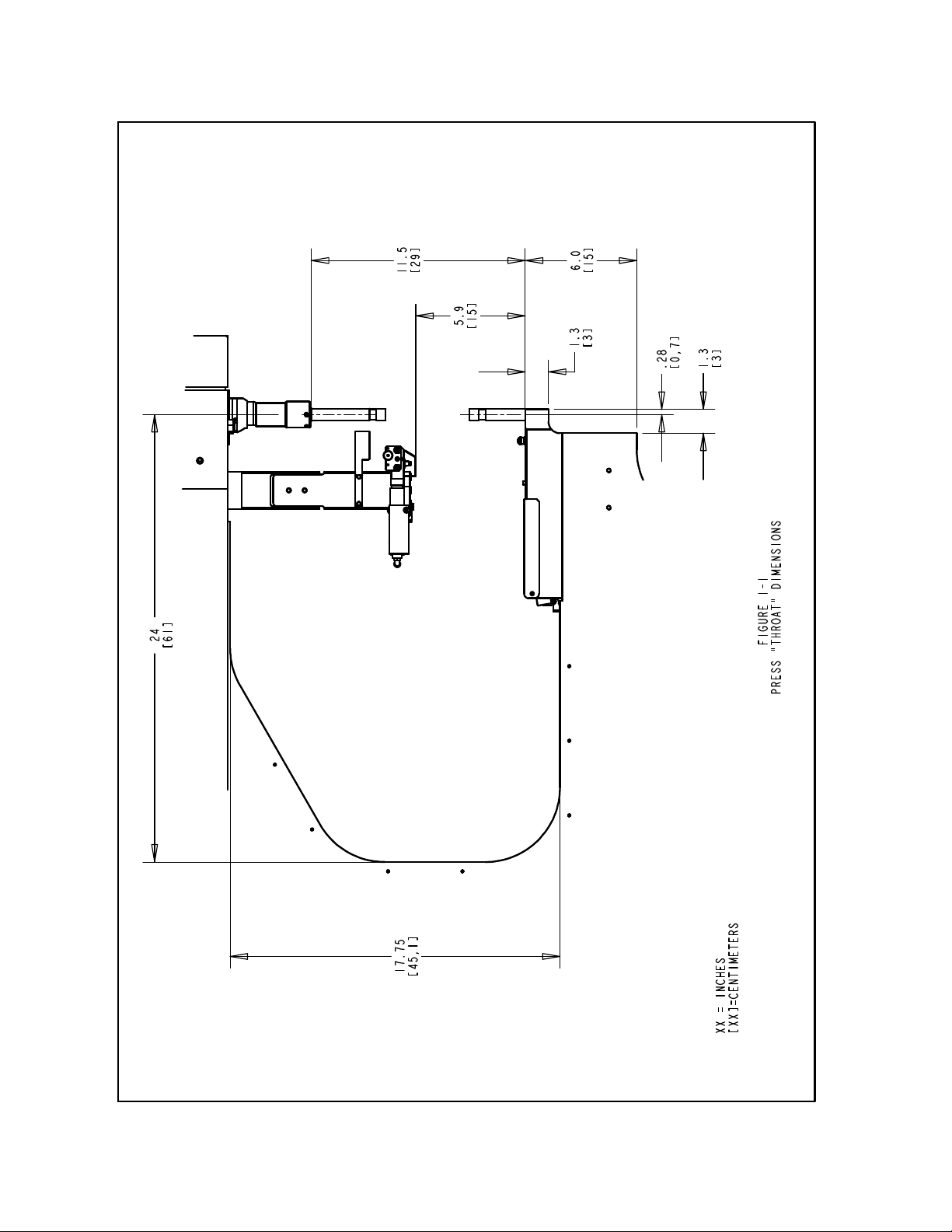

• Ram Force 1.8 to 71.2 KN (400 to 16,000 lbs)

• Pressure System Type Air-Over-Oil

• Air Requirements 6 to 7 BAR (90 to 100 PSI)

12 mm (1/2”) dia. minimum line flow

• Throat Depth 61 cm (24”)

• Height 193 cm (76”)

• Width 92 cm (36”)

• Depth 126 cm (49.5”)

• Weight 1,135 kg (2,500 lbs.)

• Electrical (North America) 120VAC(+/-12 VAC), 60 Hz(+/-1 Hz), 5A, 1φ

• Electrical (Europe and Pacific Rim) 230VAC(+/-23 VAC), 50 Hz(+/-1 Hz), 3A, 1φ

• Air Consumption approx. 7 liters/sec air at 1 Atm (15 Scfm)

30 insertions per minute at 20 KN (4500 Lbf)

• Electrical Power Consumption approx. 250 Watts with auto feed bowl running

• Ambient Temperature 41° F to 104° F (5° C to 40° C)

• Transport / Storage Temperature -13°F to +130°F (-25°C to +55°C) and for short

periods not to exceed 24 hours up to 160°F (70°C)

• Ambient Humidity 30% to 95% (Not reflective of inlet air)

• Installation Altitude Max 1000m

Copyright 2016 by PennEngineering®

1 of 119

SAFETY

The Series 2000 was designed to conform to applicable ISO, ANSI, OSHA, CEN and CSA

safety standards.

The Series 2000 is compliant to applicable European Union (EU) directives and bears the

CE Mark.

The Series 2000 conforms to the essential requirements of the following directives:

Machinery Directive 2006/42/EC.

Electromagnetic Compatibility (EMC) Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

Please read and follow the safety precautions listed below.

SAFETY PRECAUTIONS

♦ Always use safety goggles when operating or maintaining the press

♦ Ear Protection is recommended.

♦ Always shut off the electrical power and remove the power cord before servicing the press.

♦ Before using the press, make sure that a shutoff device has been fitted on the air supply line

and the location is easily accessible, so that the air supply to the press can be shut off in an

emergency. Make sure that surge protection is installed in the electrical supply to the press.

♦ Check the air hose and fittings regularly for wear.

♦ Use only approved parts for maintenance and repairs.

♦ Do not use chipped, cracked or damaged accessories and tools.

♦ Attach air line securely.

♦ Keep body parts away from moving parts.

♦ Never wear jewelry, loose clothing or anything that could get caught in moving parts.

♦ If a new user is operating the press, be sure these instructions are readily available.

♦ Do not use the press in any way, other than for its intended purposes.

♦ Do not modify the press in any way.

♦ Fasteners are blown at a high velocity. Tubing must always be secured before machine is

operated. Check integrity of tubing before use.

♦ Press contains hydraulic fluid. See enclosed Material Safety Data Sheet for proper handling.

Follow all applicable local safety standards.

The sound emission values (acoustic pressure level) at the operator position is 93dB(A)

Within the scope of 1 meter ,The sound emission values (sound power level) is 103 dB(A)

Within the scope of 1 meter , uncertainty K=2dB(A) .

However , If the machine is operated in a room with other machines ,the sound emission

level (rated level) can be over 85 dB(A) .

If this is the case , improve the acoustics in the room . If you do not , the hearing of the

operators may be damaged .

WARNING: Immediately upon receipt of your press, establish a “Maintenance

Code” for your supervisor/maintenance personnel only, as it is possible, however

difficult, to operate the press without the standard safeguards in place in the

Copyright 2016 by PennEngineering®

2 of 119

Maintenance Mode. Only trained personnel should use the Maintenance Mode.

PennEngineering

is not responsible for improper maintenance mode procedures,

which result in a loss of operation of the press or operator safety.

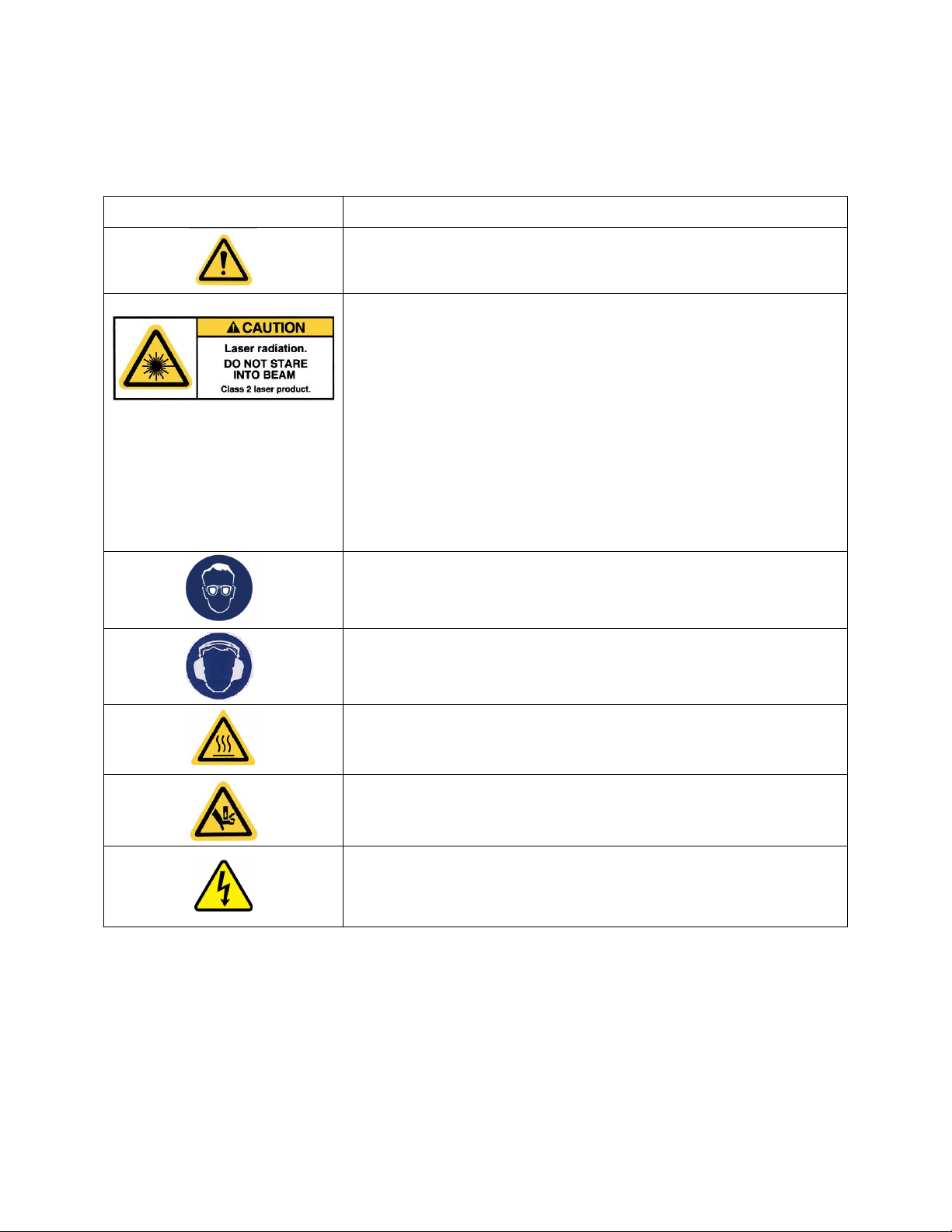

Label Definition

General Warning Label – There are items that require attention.

These are specified in the operator’s manual.

CAUTION: Laser Radiation. Do not stare into beam.

Class 2 laser product.

Per EN 60825 and ANSI Z136.1: Class 2 lasers are low power

devices emitting visible radiation in the wavelength range

400mm to 700mm. Momentary viewing is not considered

hazardous since the upper radiant power limit on this type of

device is less than the MPE (Maximum Permissible Exposure)

for momentary exposure of 0.25 second or less. Intentional

extended viewing, however, is considered hazardous.

Never aim the spotting light anywhere except at the workpiece.

Eye Protection Label – Eye protection must be worn when

operating the press.

Ear Protection Label – Ear protection must be worn when

operating the press.

Hot Surface Label – Hot Surface. Do not touch.

Pinch Point Label – Keep hands away from area.

Electrical Shock/Electrocution Warning Label –Electrical shock

hazard. Do not touch

Copyright 2016 by PennEngineering®

3 of 119

WARRANTY

PennEngineering® warrants that this product, when correctly used according to directions and under normal

operating conditions, will be free from defects in material and workmanship for a period of two (2) years from the

date of purchase.

This warranty shall not apply to any product which has been altered, changed or repaired, normal maintenance

excluded, except as authorized by PennEngineering®. This warranty shall not apply to any product that has been

subject to misuse, negligence or accident.

The purchaser’s exclusive and sole remedy shall be limited to repair, modification or replacement at the discretion

of PennEngineering®. In no event shall PennEngineering® be liable for the cost of any indirect or consequential

damage. In no case shall PennEngineering® liability exceed the purchase price of the product.

This warranty is exclusive and in lieu of all other warranties. No oral or written information by PennEngineering®,

its employees, representatives, distributors or agents shall increase the scope of the above warranty or create any

new warranty.

Should any questions or problems arise concerning your Series 2000 press, contact the PennEngineering® Service

Department. Toll-free telephone number 1-800-523-5321 (in North America) or 215-766-8853.

Set-up, Training and Repair Service is available to you as long as you own your press. Free telephone

instruction and Service is available for the lifetime of your press by calling the PennEngineering® Service

Department.

Copyright 2016 by PennEngineering®

4 of 119

Copyright 2016 by PennEngineering®

5 of 119

SECTION 2

IDENTIFYING AND LOCATING MAJOR COMPONENTS OF THE PRESS

Identifying Major Components of the Press

This section introduces the user to the major components of the press.

Frame

The frame is the structure of the press. The main section is made of solid steel with welded

components that form the base and the other support sections. All parts are directly or indirectly

mounted onto the frame.

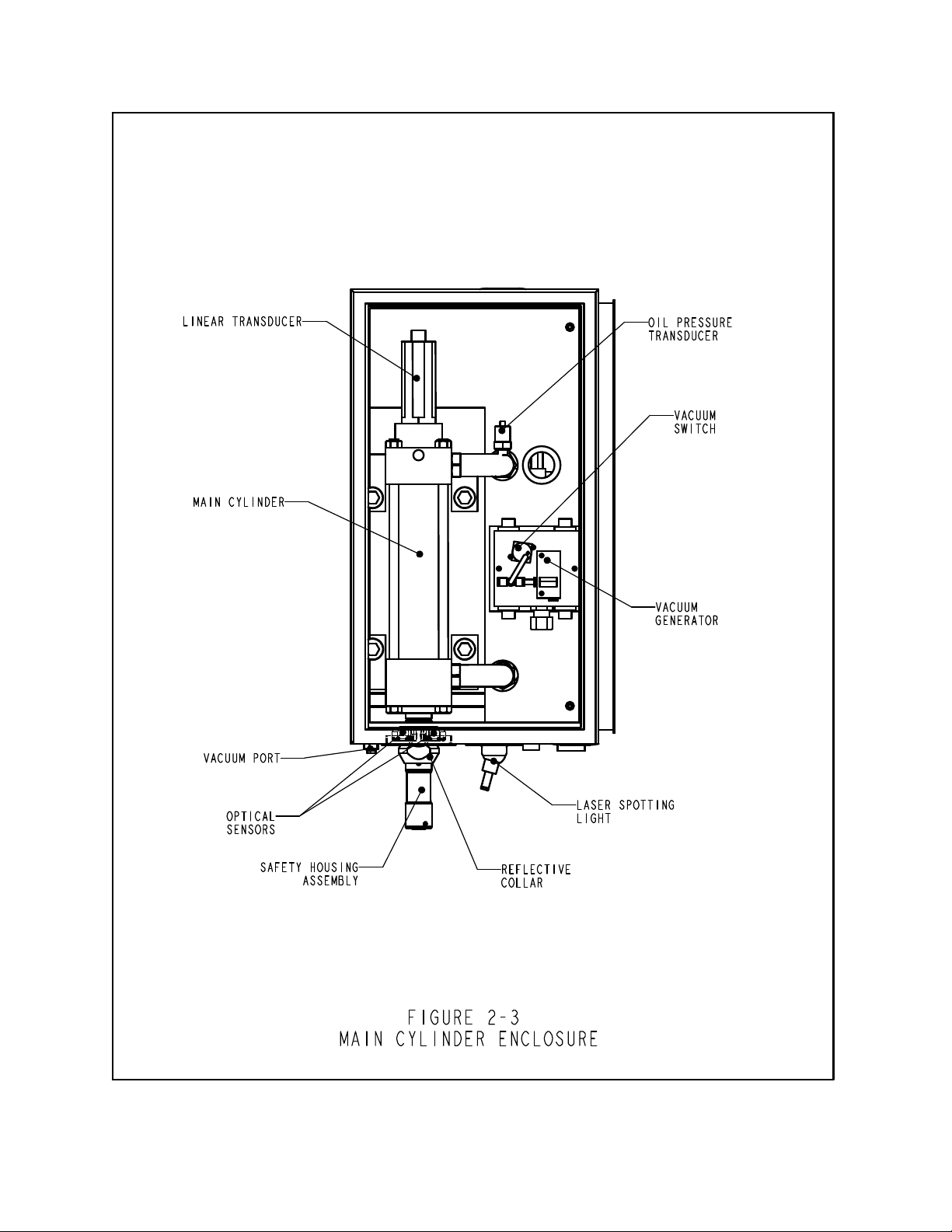

Main Cylinder/Ram

The ram force of the press is exerted by a hydraulic cylinder called the Main Cylinder. It is

mounted directly onto the frame surrounded by the front enclosure. Attached to the main

cylinder, at the back end, is a sensor probe called a Linear Transducer, which reads the location

of the main cylinder piston. Attached to the end of the main cylinder rod is the safety assembly,

described in Section 3. The main cylinder rod is referred to as the Ram.

Operator Controls

All the operator controls are located on the door of the Front Enclosure except the foot pedal.

These include the Touch Screen, the E-Stop button, the Power ON button, the Power OFF

button, the Audible Beeper, and the Spotting Light button.

• Touch Screen - This is the primary interface to the press control system (the PLC). It is

used for installation and automatic feed setup and configuration, feedback to the user and

diagnostics. The screen displays text and graphical information and allows the operator to

make selections by touching different parts of the screen as indicated by what is displayed on

the screen. The touch screen is programmed with an automatic screen save mode that blanks

the screen when not in use after 10 minutes. To reactivate the screen, just touch anywhere on

the screen. Detailed explanations of each screen are provided in Section 6 of this manual.

• E-Stop Button - Pressing this button disconnects power to the quick exhaust/supply valve

(see air supply inlet system on page 9). When pressure is exhausted, all pneumatic motion

stops. During an E-Stop condition all outputs are turned off. The control system remains online and detects the E-stop.

Copyright 2016 by PennEngineering®

6 of 119

• Power ON Button - If the press is on, this button is lit green. When the press is off, pressing

this button will provide power to the press control system which will initialize the press,

including pressurizing the press and moving the Ram to it’s retracted “home” position.

• Power OFF Button – This button is lit amber if there is electricity connected to the press but

the press is off. When the press is on, the amber light will be off. Press this button to turn

the press off, power will be switched off from the control system and all moving components

including the quick exhaust/supply valve.

• Audible Beeper - This beeper is controlled by the PLC and is used to indicate to the operator

when the press or operation requires special attention. The volume can be adjusted by

turning the outer ring and adjusting the aperture of the beeper.

• Spotting Light Push Button – Push this button to turn the spotting light on and off. This

button is lit when the laser spotting light is on. Never aim the spotting light anywhere except

at the workpiece and, never look directly into the spotting light.

• Foot Pedal - The foot pedal is used by the operator to control the start of a press cycle. It

frees the operator to use his hands to manipulate the workpiece.

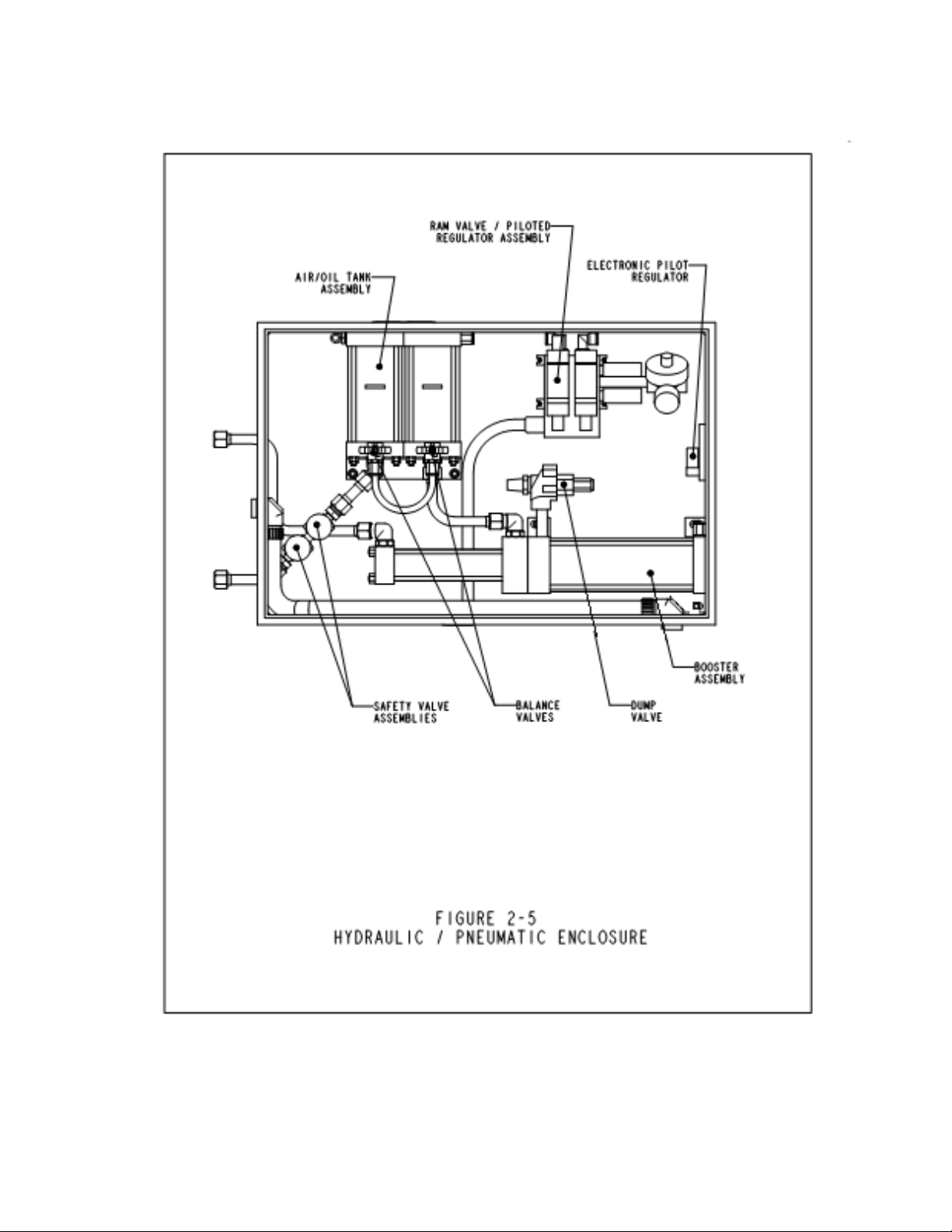

Pneumatic/Hydraulic Enclosure

The Pneumatic/Hydraulic Enclosure on the right side of the press houses all the major

components of the Air-Oil System that control the main cylinder. These components include the

computer controlled pressure regulator system, the ram valve assembly which includes the ram

valve and the booster valve, the Air-over-Oil tanks, the Air-Oil booster, and the hydraulic safety

valves.

Electrical Enclosure

The Electrical Enclosure, under the Pneumatic/Hydraulic Enclosure, houses the computer control

system (PLC) and various electrical components and distribution terminals. Electric Power and

the Foot Pedal connect to this enclosure. The door is key-locked and located on the back is the

electrical on-off switch. This switch must be ON for the press to be powered on. Turning off

this switch removes all power to the press. The electrical power cord plugs in next to the switch.

Removing the power cord can be used to lock out all power to press when performing

maintenance.

Copyright 2016 by PennEngineering®

7 of 119

Vibratory Feeder Bowl (Automatic Fastener Feeding Component)

The Vibratory Feeder Bowl, on the left side of the press, is used for automatic feeding of

fasteners. It is an electrically driven device, which holds and moves different types of fasteners.

Various types of tooling components are attached to the bowl to orient the fasteners being fed out

of the bowl. The vibratory bowl comes equipped with a "Universal Escapement" adapter, which

is used for all nut-type tooling and some stud-type tooling. The Vibratory Feeder Bowl is

controlled by a dial and a switch on the Bowl Control Box, above the bowl.

• Bowl Amplitude Dial - The bowl's amplitude or force of vibration is regulated by a dial

control. The amplitude adjustment is used to control the feed rate and performance of the

automatic feeding process.

• Bowl Three Mode Switch - A 3 position switch is used to select whether the bowl is always

on, always off or automatically controlled by the PLC. When the switch is set to auto, the

PLC turns on the bowl during run mode and during diagnostics. During run mode the PLC

will turn the bowl off if there is a period of inactivity. The PLC will restart the bowl

automatically when the next fastener is fed. When loading or unloading fasteners , turn the

bowl ON/OFF as desired. Return the switch to AUTO when finished.

Shuttle Support Assembly (Automatic Fastener Feeding Component)

The Shuttle Support Assembly located next to the Vibratory Feeder Bowl is used to hold and

actuate tooling shuttle components, route air supplies and hold the Stud-in-tube-Sensor and

"Puffer" Flow Control Valve. The Shuttle Air Cylinder on the Shuttle Support Assembly

actuates tooling shuttles. The shuttle receives the parts fed from the vibratory feeder bowl,

singulates the parts and feeds them out to the punch/anvil area. The Shuttle Support Assembly is

aligned with the vibratory feeder bowl. Proper alignment is important to the functioning of the

shuttle tooling.

• Stud-in-tube Sensor - The PLC uses this ring sensor to monitor and control the feeding

process of stud-type tooling.

• Puffer Flow Control Valve - This valve controls the air flow to the Vibratory Feeder Bowl

tooling attachments and is used to regulate various aspects of the escapement and nutgate

performance.

Copyright 2016 by PennEngineering®

8 of 119

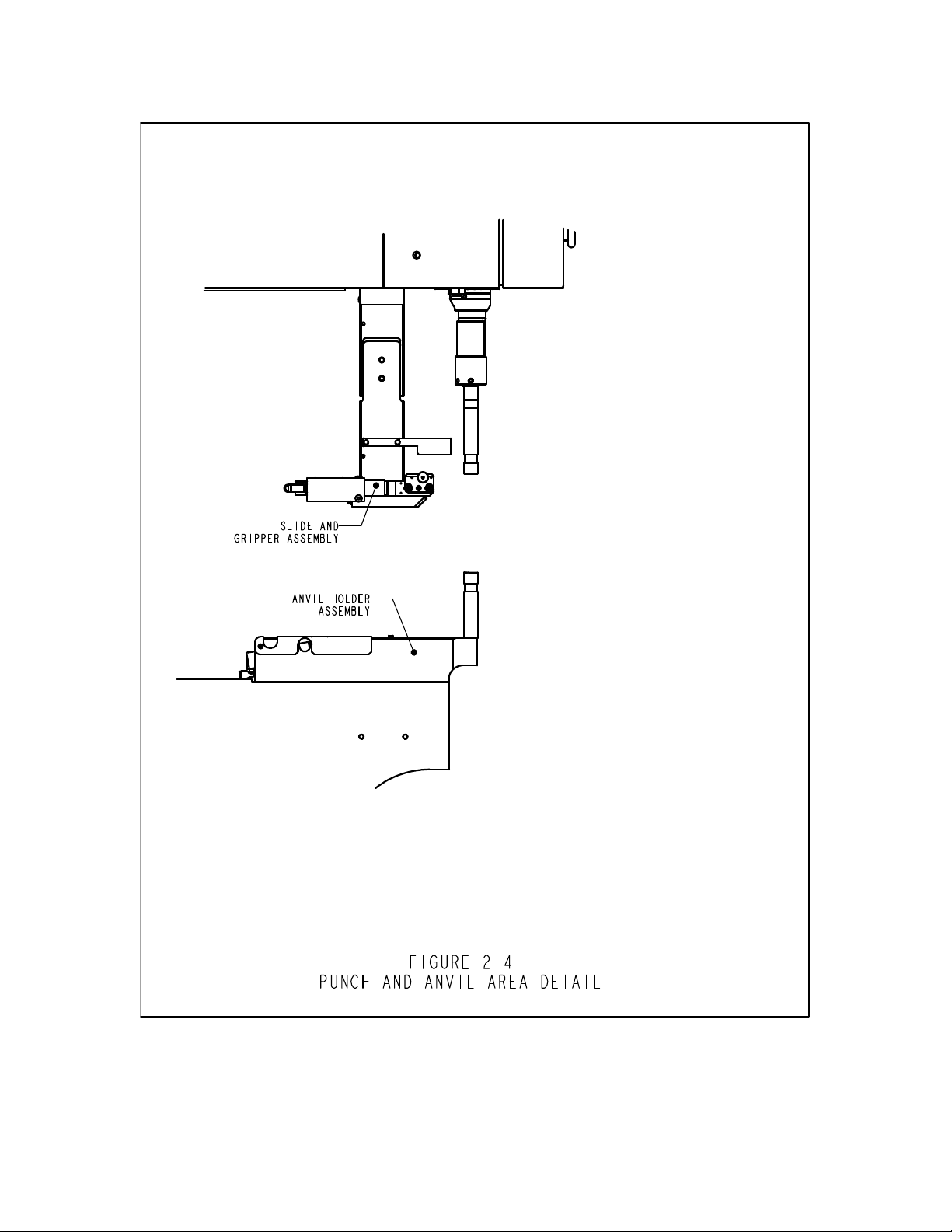

Slide and Gripper Assembly (Automatic Fastener Feeding Component)

The Slide and Gripper Assembly mounted to the top of the frame throat is used to hold top-feed

tooling components and has two pneumatic actuators. The two actuators are a linear slide

cylinder and a parallel acting gripper. The gripper is used to actuate the tooling jaws that hold

fasteners. The gripper opens and closes to receive and release fasteners. The gripper is attached

to the end of the linear slide. The linear slide is used to move the gripper and jaws from its

retracted position out to the punch position. This system is used to feed fasteners out to tooling

punches. The Slide and Gripper Assembly also holds tube extension tooling for stud-type

tooling. The Slide and Gripper Assembly can be removed for special workpiece accessibility.

Anvil holder Assembly

The Anvil Holder Assembly mounted to the bottom of the frame throat is used to hold the anvil

tooling components and has a single air cylinder. The Bottom Feed Cylinder is used to actuate

Bottom Feed Nut Tooling Modules.

Tooling Valve/Storage Enclosure

The Tooling Valve/Storage Enclosure is located underneath the Vibratory Feeder Bowl. Behind

the door is another enclosure that contains the pneumatic valves that control the different tooling

actuators and blowers. Under that enclosure is the Tooling Air Accumulation Tank. The tank

provides a steady supply of compressed air to the tooling valves for consistent tooling feeding

performance.

Air Supply Inlet System

The supply of compressed air enters the press in the back through a system, which includes a

filter/regulator and an electrically controlled quick exhaust/supply valve. The regulator is

manually set to control the supply line pressure. Turning on the quick exhaust/supply valve

supplies air to the press. When the quick exhaust/supply valve is turned off the valve closes and

exhausts all downstream compressed air in the press quickly.

Tooling Storage Cabinet (Optional)

The Tooling Storage cabinet is located on the left side of the press.

Copyright 2016 by PennEngineering®

9 of 119

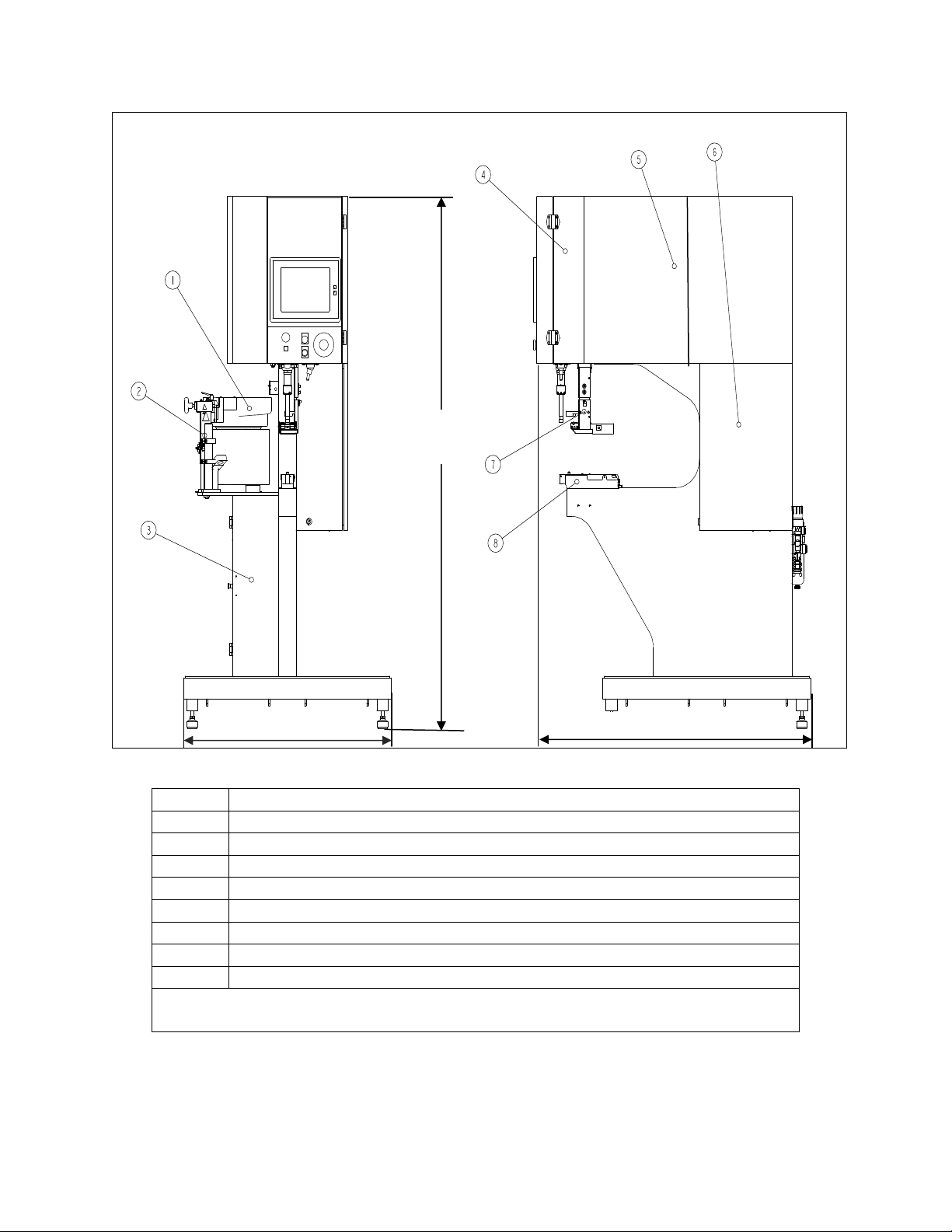

92cm (

36

inch)

126cm(

49.5

inch)

193cm

(76inch)

ITEM DESCRIPTION

1 VIBRATORY FEEDER BOWL

2 SHUTTLE SUPPORT ASSEMBLY

3 TOOLING VALVE/STORAGE ENCLOSURE

4 MAIN CYLINDER ENCLOSURE

5 PNEUMATIC / HYDRAULIC ENCLOSURE

6 ELECTRICAL ENCLOSURE

7 SLIDE AND GRIPPER ASSEMBLY

8 ANVIL HOLDER ASSEMBLY

FIGURE 2-1

SERIES 2000 PRESS

Copyright 2016 by PennEngineering®

10 of 119

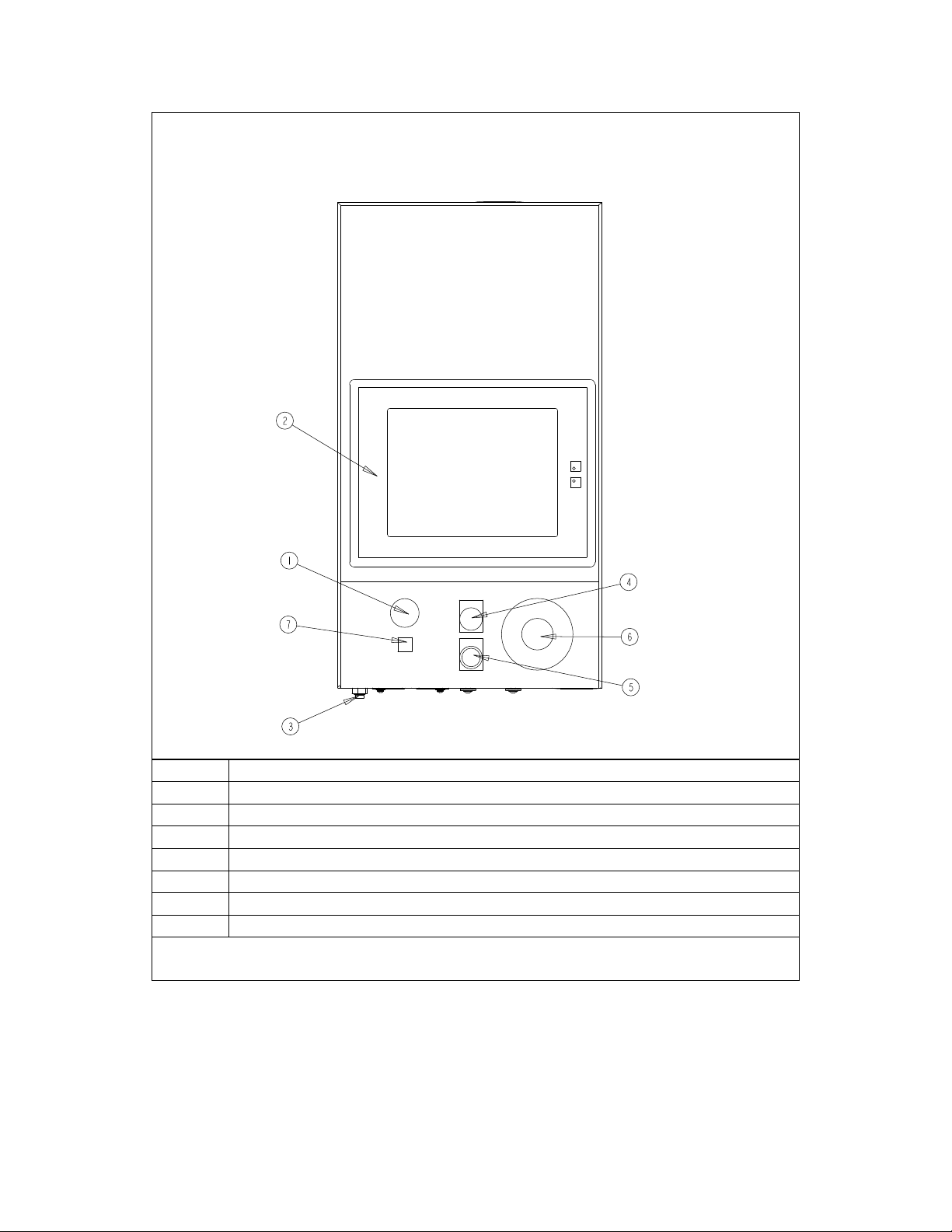

ITEM DESCRIPTION

1 AUDIBLE BEEPER

2 TOUCH SCREEN

3 VACUUM PORT

4 POWER “OFF” BUTTON

5 POWER “ON” BUTTON

6 E-STOP BUTTON

7 SPOTTING LIGHT ON/OFF BUTTON

FIGURE 2-2

OPERATOR CONTROLS

Copyright 2016 by PennEngineering®

11 of 119

Copyright 2016 by PennEngineering®

12 of 119

Copyright 2016 by PennEngineering®

13 of 119

Copyright 2016 by PennEngineering®

14 of 119

SECTION 3

SAFETY SYSTEM OPERATION

WARNINGS - To avoid injury:

1. Always shut off the electrical power, and remove the power cord, before servicing this

machine.

2. Only authorized and trained personnel should maintain, repair, setup, or operate this

equipment.

3. Always use eye protection when operating or maintaining the press.

SYSTEM SAFETY FEATURES

1. Shutting off the electrical power, with either the “OFF” push-button, the ON / OFF switch, or

pushing the E-Stop button, will cause the electric quick exhaust/supply valve to exhaust all

air pressure in the press. WITHOUT ANY CONTAINED PRESSURE, ALL PNEUMATIC

MOTION STOPS.

2. The electrical cabinet door is key-locked to discourage unauthorized access.

3. The patented safety system can distinguish between a work piece properly set-up between the

ram and the anvil, and a foreign object placed between the ram and the anvil. The safety

system operates as follows:

• A sensor called a linear transducer is installed on the top of the main cylinder. The linear

transducer senses the position of the main cylinder piston and transmits that information

back to the PLC.

• A device called the "safety assembly" is installed in the bottom of the ram. The assembly

consists of a fixed section called the housing and a compressible spring-loaded section

called the adapter. The adapter holds the punch tooling. When the ram extends and the

adapter or punch tooling contacts an object, the safety assembly compresses.

• Two redundant pairs of optical thru-beam sensors are located inside the front enclosure,

under the main cylinder. Each pair of sensors maintains an individual optical beam path

that is reflected through one of two holes in the ram by the "reflective collar". When the

safety assembly is compressed, part of the safety assembly inside the ram, blocks both

beam paths and the sensors are triggered.

• When the sensors are triggered, because, either the safety assembly is compressed, the

reflective collar is moved, or the beam path is blocked in some other way, the PLC

immediately senses the change.

Copyright 2016 by PennEngineering®

15 of 119

• During a Setup Cycle, the PLC uses this system to "learn" where the fastener and

workpiece location is by moving the ram down, compressing the safety assembly, sensing

the contact and reading the Linear Transducer. The data of the contact location is saved

and used for a comparison during each press/run cycle.

• During Press Cycling, the PLC determines each time it senses that the safety

assembly/punch has contacted something, whether it is "legitimate" or "not legitimate".

A "safety window" is used to allow for minor variations with workpiece or operator

precision.

• Only if BOTH redundant signals agree and the latest contact point is within the "safety

window", does the PLC allow the safety assembly to fully compress and for the air-oil

system to apply the predetermined high force needed for fastener installation.

4. Three levels of access security are available, each with a different four digit pass code

WARNING: Immediately upon receipt of your press, establish a “Maintenance

Code” for your supervisor/maintenance personnel only, as it is possible, however

difficult, to operate the press without the standard safeguards in place in the

Maintenance Mode. Only trained personnel should use the Maintenance Mode the

PennEngineering® is not responsible for improper maintenance mode procedures

which result in a loss of operation of the press or operator safety.

5. If the Linear Transducer or either of the ram safety sensors should develop an open or a

shortfault, the entire system, including the ram, will come to an immediate stop and not

operate further, until repairs are made.

Copyright 2016 by PennEngineering®

16 of 119

SECTION 4

PRESS INSTALLATION

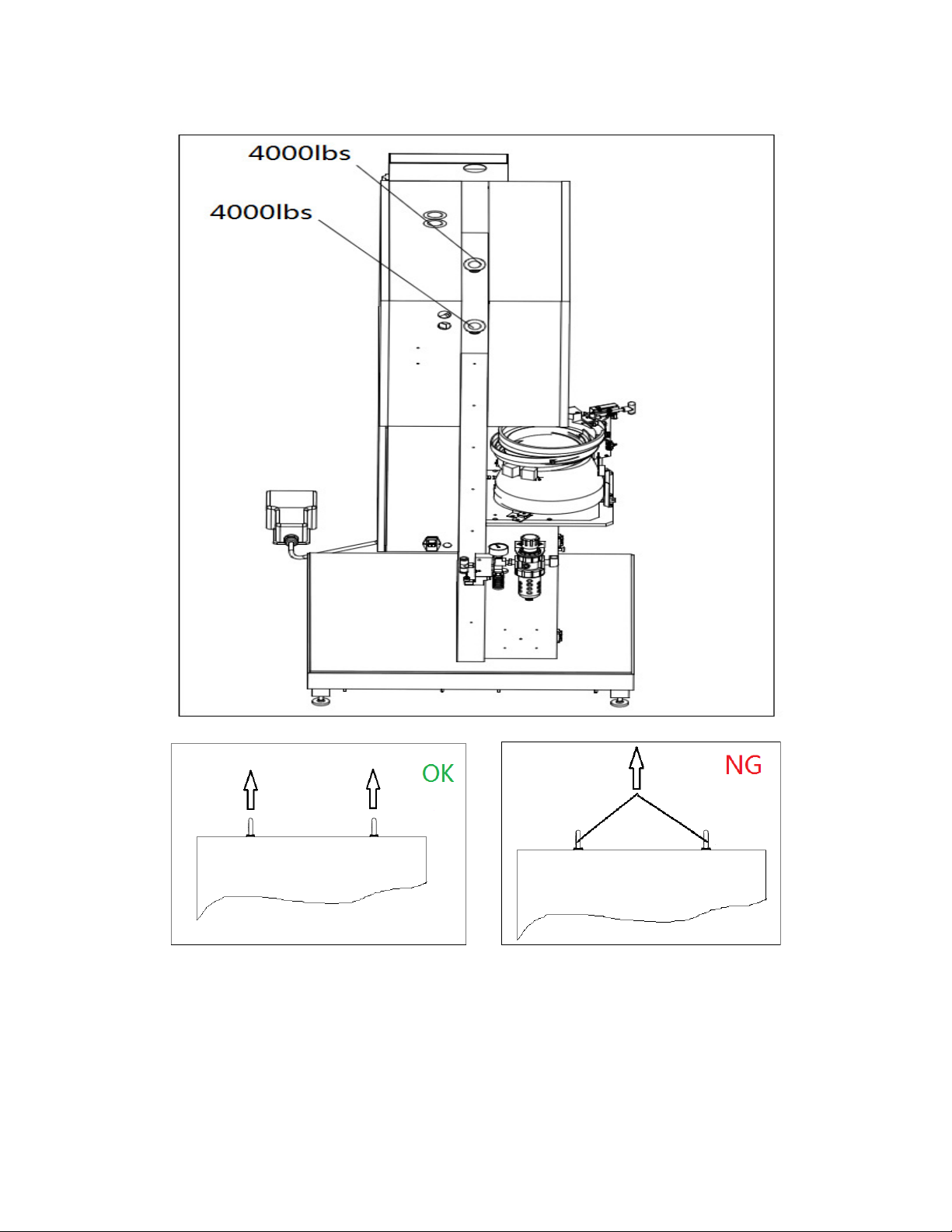

Moving The Press

• When using a forklift or pallet jack be sure that the forks are properly located between the

fork guide tabs under the base of the press. When hoisting from above (See Fig 4-1), be sure

to balance the chain or strap between the two eyebolts to prevent swinging.

WARNING: unbalanced loading of the press or sudden stops may lead to toppling of the

press.

Locating The Press

• Select a well-lit clean area with a (relatively) level floor. The floor must be able to support

the weight of the press.

Leveling The Press

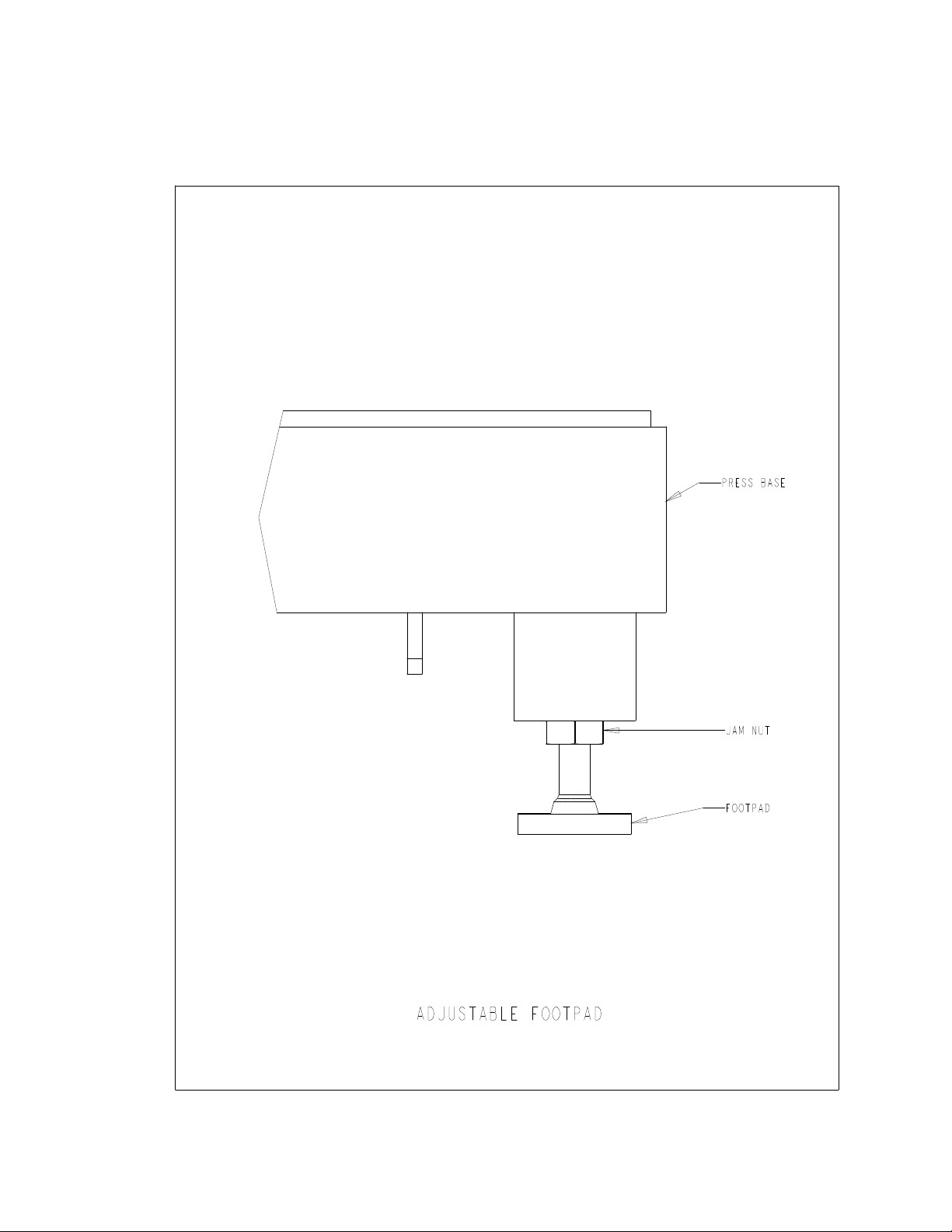

• The press should be leveled and stabilized after it has been located. This is done by adjusting

the height of each footpad then locking each footpad in position by tightening a jam nut. This

task requires two 3/4” wrenches (See Fig 4-2). An adjustable wrench may also be used.

Adjust the foot pad while reading the level at the tooling nut gate adapter. The universal

escapement adapter must sit level for proper functioning of the feed systems.

Open Space Requirements

• PennEngineering® has no specific requirements for providing open space around the

perimeter of a press. However, be sure to comply with any national or regional safety codes

that may dictate otherwise. For example, In the US the National Electrical Code requires that

there be at least thirty-six inches of clearance in front of the electrical enclosure. We do

recommend that you at least leave enough space around the press so the various storage and

maintenance enclosures can be opened fully and so the largest workpieces can be

accommodated.

Original Installation Requirements

After the final installation of the press verify the continuity of the protective bonding circuit

(TN-System) in accordance with EN 60204-1 Clause 18.2.2 standards.

Copyright 2016 by PennEngineering®

17 of 119

FIGURE4-1 Cable Suspension Diagram

Copyright 2016 by PennEngineering®

18 of 119

2

FIGURE 4 - 2

Copyright 2016 by PennEngineering®

19 of 119

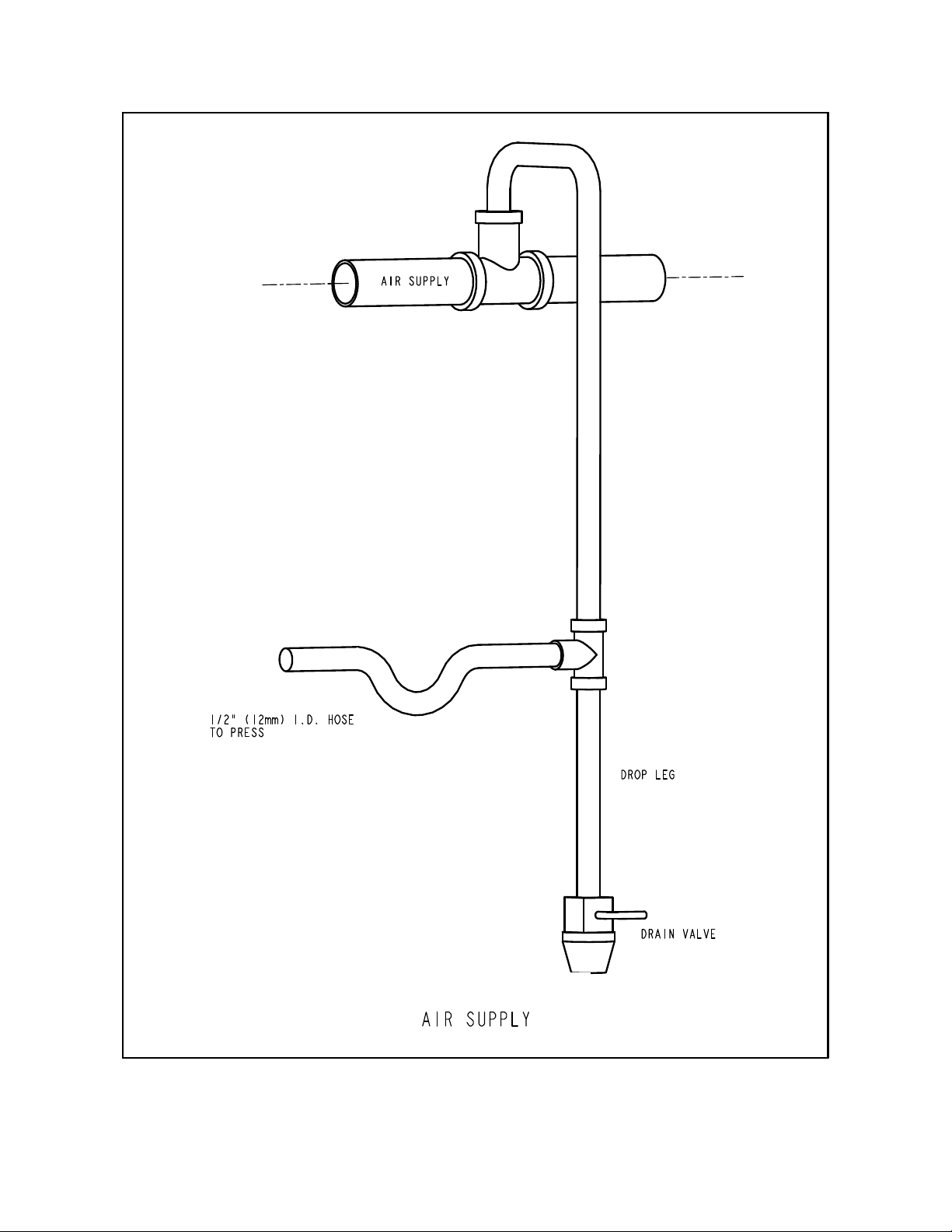

Recommended Air Supply Hook-Up Arrangement

Proper air supply is very important to the performance and maintenance of the press. Following

these simple guidelines will ensure good press performance.

• Air Quality - The quality of the air supply is very important. The air must be clean and dry.

Moisture and debris will contaminate the oil and valve systems and lead to press performance

and maintenance problems.

• Air Supply Flow - Use a minimum 12mm (1/2”) inside diameter line and fittings from the

compressed air source to the press. Shop pressure ranging between 6 to 7 BAR (90 psi to

100 psi) is acceptable. Inadequate air flow will affect press performance.

• Air Consumption - Air consumption in automatic mode is about 4.5 liters of compressed air

per cycle. Average air consumption running at 20 KN (4500 Lbf) at 30 insertions per minute

is about 7 liters/sec at 1 atm. (15 Scfm). Air Supply Flow requirements are higher than these

values as air is only being consumed for half the time of each cycle.

• Piping Installation – Proper piping hookup will help achieve the above requirements. See

figure 4-3 on the next page.

Connect to your supply line with a pipe pointing upwards that curves over and down. This

arrangement will help prevent water and compressor oil from entering the press.

Connect to that drop with your supply fitting for a 12mm (1/2”) or larger hose.

Continue the end of the drop to a drain valve. This will help collect additional water and oil

and allow the system to be purged.

If your factory air supply falls short of the above recommendations, an air reservoir tank of

an appropriate size for your location can be used.

An auxiliary filter/separator installed immediately outside the machine is recommended.

Install An Appropriate Power Cord.

• The press is equipped with a Male IEC 320/CEE22 Universal Connector for power. Outside

North America, unless special arrangements have been made, a customer supplied power

cord must be installed. No other electrical system modifications are necessary. Connection

should be in accordance with your local electrical code.

Install The Foot Switch

• Plug the foot switch into the receptacle located at the lower left corner of the front of the

electrical enclosure.

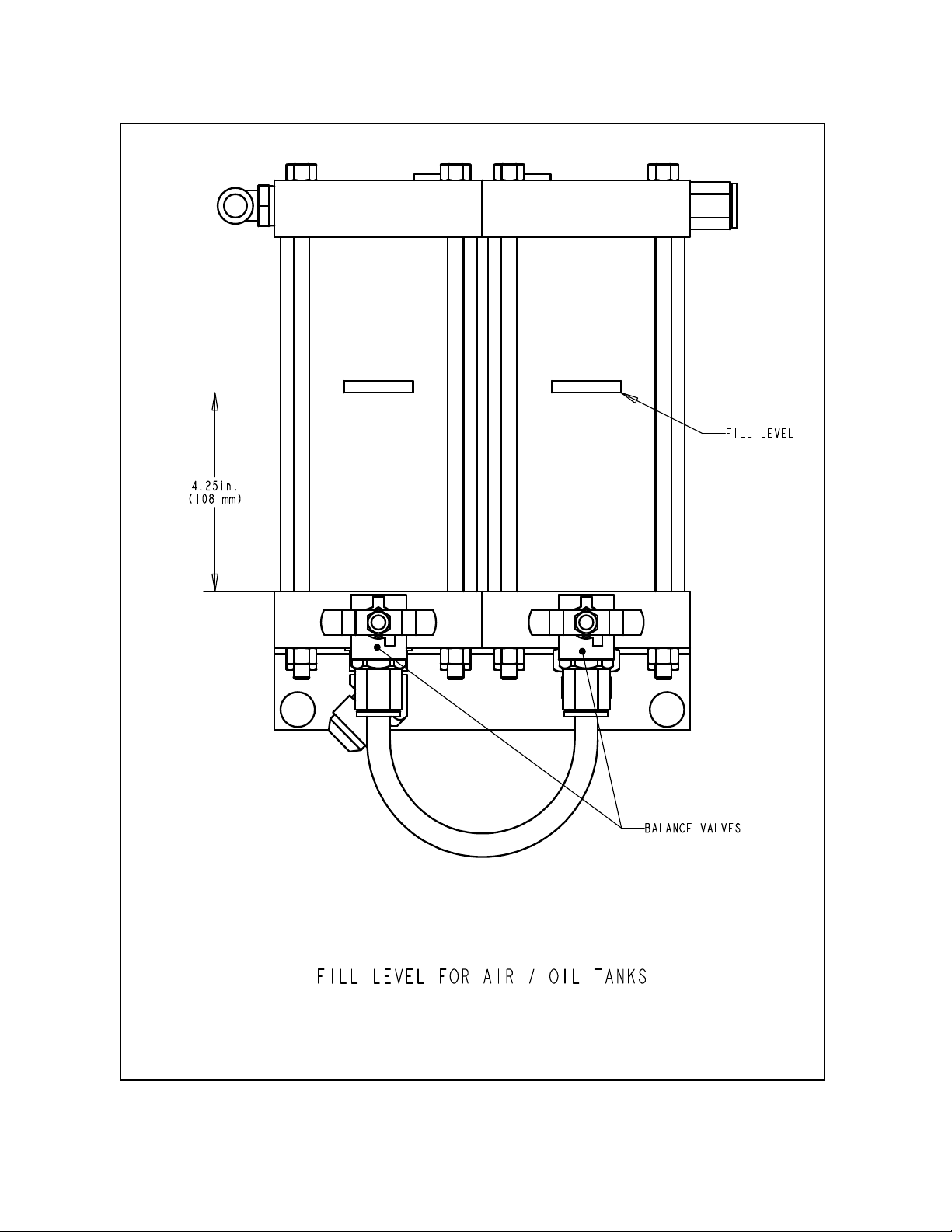

Check The Hydraulic Fluid Level In Both Air-Oil Tanks

• Check to be sure the hydraulic fluid is level with, but not over, the fill lines on the air-oil

tanks. If the fluid level is too high or too low correct the problem by following the procedures

provided in section eleven of this manual.

Copyright 2016 by PennEngineering®

20 of 119

Copyright 2016 by PennEngineering®

21 of 119

Copyright 2016 by PennEngineering®

22 of 119

SECTION 5

GENERAL FUNCTION DESCRIPTIONS

System Function:

The function of a PEMSERTER

SERIES 2000

FASTENER INSTALLATION PRESS is

to safely, quickly and consistently install PEM brand self-clinching fasteners in various types of

sheet material. To do this the press uses:

• A patented point-of-operation safety system that controls the descent of the ram and does not

allow the ram to descend if it contacts any object other than the intended fastener and

workpiece.

• Automatic fastener feeding system that locates the fastener at the point of insertion, so that

the operator is free to handle just the workpiece.

• Air-oil-booster system that provides quick ram travel with high installation forces at the point

of insertion.

• Precise installation tools and computer controlled installation forces.

Self-clinching Fastener Installations:

PEM self-clinching fasteners are installed into punched or drilled holes in ductile sheet

material. To install a PEM self-clinching fastener:

• The shank of the fastener is placed into the installation hole until the part of the fastener that

is larger than the hole called the displacer (such as the knurls for nuts, or the head for

standoffs) sits on the edge of the hole.

• A parallel squeezing force is applied to press the displacer (overhanging part) of the fastener

into the sheet material.

• The force causes the sheet material to cold flow into the undercut of the fastener that is

between the displacer and the shank. This traps the fastener within the sheet metal.

Copyright 2016 by PennEngineering®

23 of 119

Setting up the Press:

The following section of the manual describes the setup process in general. For details on setting

up and operating the press see the appropriate section in the manual.

Step 1 - Setup Tooling

Tooling setup consists of selecting appropriate tooling for the fastener being fed and the

workpiece, installing the tooling on the press and adjusting the feed controls.

Different types of tooling that feed the same size fastener are selected for accessing

different shapes and sizes of work pieces.

See the Tooling Section of this manual on selecting the right tooling.

Step 2 - Select the Setup for the Tooling and Fastener on the Touchscreen

Once the tooling is installed, the next step is to setup the press by using the touchscreen.

The touchscreen setup is simple and can be done one of three ways.

• New Tool Set-up – Choose tooling mode, fastener size and workpiece material.

• Recall A Job – Select from a previously programmed Job stored in the press

• Recall Last Job – Run the same Job that was just run, the press remembers, even if it is

turned off between jobs.

See the Touchscreen Controls section of this manual on choosing the right selections for

setup.

When the selections are complete, the press automatically sets the values for operation

and moves onto safety setup.

Step 3 - Safety Setup

The next step is very quick and simple but very important.

Safety Setup is the step where the press learns the position of installation called the

Safety Set point. The operator positions the materials for an installation, but the press

does not actually install the fastener. The ram extends and touches the fastener and

workpiece. The touch point teaches the press where the proper installation point should

be. The Press is ready to install fasteners.

Copyright 2016 by PennEngineering®

24 of 119

Fastener Automatic Feed Functions:

Automatic Fastener Feeding is done from the vibratory feeder bowl to the insertion point in the

workpiece. The following steps are taken:

• The vibratory feeder bowl moves the fasteners around the bowl and past a tooling component

called a nutgate for nut-type tooling or an escapement for stud-type tooling.

• The fasteners are oriented in the tooling and fed into a tooling shuttle. The shuttle takes the

first fastener and separates it from the rest. That fastener is blown with compressed air out of

the shuttle into a plastic tube that leads to the punch and anvil area.

• Depending on the type of tooling the fastener is either fed directly into a tooling module like

a stud-injector module or bottom feed nut module or into a set of jaws on the top feed slide

and gripper system.

• During a top-feed tooling installation, the fastener is picked up from the jaws either by a

vacuum punch or pin punch and the jaws open and pull back.

• The workpiece is placed with the installation hole onto either a fastener or tooling guide pin.

When the operator has located the workpiece, the foot pedal can be depressed to begin the

installation process.

Installation Process:

• When the foot pedal is depressed, the ram extends down quickly bringing the punch to the

workpiece.

• When the fastener contacts the workpiece the safety sensors are tripped. The Press Control

System checks that the position called the insertion point, is at the same position as the

learned position at setup, the safety set point. Only if the insertion point is within a certain

range of the safety set point, does the installation proceed.

• If the insertion point is good then the high installation force is applied to install the fastener

and the ram returns up.

Copyright 2016 by PennEngineering®

25 of 119

Special Features and Conditions:

• Dwell/Force Verification (Quality Assurance System) – Dwell time is the period of time

from when the press control system starts the high force cycle to when the high force cycle ends.

The Dwell software system monitors pressure feedback signals throughout the cycle to assure a

quality installation.

• Soft Touch Mode – When running in Soft Touch Mode the press will slow down just before

contacting the workpiece and fastener. This mode is slightly slower, but can insure against

damage to soft and brittle work pieces.

• Interrupted Mode – When running in Interrupted Mode the press will slow down and stop

upon contacting the workpiece and fastener. This mode is the ultimate in assurance just before

installation that a workpiece or layers of work pieces are properly aligned.

• Setpoint Tolerance – Can be selected for Standard Tolerance or Narrow Tolerance. Narrow

Set point Tolerance sets a smaller range for the allowed deviation of each installation from the

Safety Set point. Narrow Tolerance is used for smaller fasteners and more precise operations to

assure proper installation in the workpiece hole. This mode is less tolerant of work pieces not

held level and poor hole quality or hole debris.

• Start at Minimum Setup – This mode changes the setup sequence. Instead of pre-selecting a

force at setup, the press interrupts the dwell time of the first installation and allows the operator

to adjust the force as the fastener is being installed. This function allows for the most precise

installation force setup. Once the installation force is established, it can be saved within one of

the Recall Job memory locations.

• Fastener Length Monitoring (FLM) – This mode requires optional tooling hardware to be

installed. During the automatic fastener feeding process for long fasteners such as stud and long

standoffs, the length of each fastener is checked to insure that it is the correct length. If a

fastener is too long or short, it is rejected and not installed. During shop operation, fasteners of

different lengths can become mixed. Long fastener tooling is typically designed to accept

various lengths of fasteners to increase the value of the tooling and decrease the costs of

installing different size fasteners. FLM Hardware and Software can be setup to check for any

length fastener.

• Safety Fault Error - If the difference between the insertion point and the safety set point is

outside the range of the set point tolerance then a safety fault error condition occurs. When a

safety fault occurs the redundant safety valves close, immediately stopping downward ram

motion. The ram reverses direction and retracts the punch. The safety assembly on the end of the

ram never fully compresses and the boost cycle is never initiated.

Copyright 2016 by PennEngineering®

26 of 119

SECTION 6

TOUCH-SCREEN CONTROLS

A programmable logic controller (PLC) controls the functions of the Series 2000™. The

operator sends commands to the PLC and reads data from the PLC through a system of menus

and information displayed on the touch screen. An operator need only touch the buttons

displayed on the touch screen to make a selection.

The touch screen controls allow the operator to setup the press for operation, operate special

functions and maintain and troubleshoot the press.

The following sections describe the information and functions available on each of the screens.

Below each screen is a description of the information and functions available on the screen.

Each button that leads to a different screen is listed with the section of this document that

describes the next screen.

Number Entries (Pop-Up Key Pad Function)

In several of the screens where a number must be entered, a special feature is used, called a popup keypad. Each digit of the number is entered by pressing the specific number button. The

Number Entry is not accepted until an Enter button is pressed. Where decimal points are a part

of the number, the placement is established.

HELP Screens

Help Screens are available throughout the touchscreen system of menus. They offer immediate

explanations of the functions on the screens like the ones in this document.

The Help Screens are online documentation. Actual pictures of the Help screens are not included

in this documentation. The buttons on the Help screens all function in the same way.

[BACK] – Returns the touch screen control back to the screen where the Help Screen

was originally called from.

[NEXT] – Proceeds to the next Help Screen available on the same topic. Some help

buttons may have more than one page of information.

[PREVIOUS] – Returns to the previous Help Screen.

Copyright 2016 by PennEngineering®

27 of 119

6.1 Title Screen

When the system is powered up, “Connecting to Host” appears for one second, before displaying

the “PEMSERTER®” title screen. The Touch Screen’s “Host” is the PLC. Here you may find

the PennEngineering® and our Sales Representative's addresses and phone numbers.

“PLC Version” is the version number of the PLC software.

“Screen Version” is the version number of the Screen software.

“Hardware Version” is the model number of the press.

[CONTINUE] to 6.2 Access Code Screen

Dual Language Option: PEMSERTER® Presses are sold worldwide. The touchscreen menus

can be ordered in different available languages. Also a single press can be equipped with

touchscreen software that can display text in one of two languages by selecting on screen. If the

press is equipped with a Dual Language Option, there will be two CONTINUE buttons, one for

each language. The press will function identically; independent of what language the screen is

displaying.

Copyright 2016 by PennEngineering®

28 of 119

6.2 Access Code Screen

This screen appears and limits access to different levels of functions depending on which access

codes have been established. See 6.20 Access Code Setup Screen. If the access code is set to

0000 then this screen will be bypassed and the touchscreen menu will proceed to the next

function. This same screen appears in different places for Operator Access, Setup Access and

Maintenance Access.

To proceed to the next screen:

Enter the Correct 4-digit Access Code.

[↵↵↵↵] – Proceeds to the appropriate screen

If in Operator Access Screen – Proceeds to Mode Selection

to 6.3 Mode Selection Screen

If in Setup Access Screen - Proceeds to Run Value Change screens

to 6.x Force, Dwell, Blower, or Run Parameters Screen

If in Maintenance Access Screen - Proceeds to Maintenance Menu Screen

to 6.16 Maintenance Menu Screen

If the code is entered incorrectly, an audible alarm is sounded.

If the access code is forgotten, call your PennEngineering® Service Representative.

Copyright 2016 by PennEngineering®

29 of 119

6.3 Mode Selection Screen

This screen allows you to enter into a selected type of installation setup procedure or

maintenance mode, and to toggle certain operations.

[TOOL SET-UP MODE] – Proceeds to a setup process, which allows the operator to select the

installation mode, fastener size, material type and to change the installation force.

to 6.4 Tooling Selection screen

[RECALL A JOB] – Proceeds to a menu of previously setup jobs.

to 6.14 Recall Job screen

[RECALL LAST JOB] – Proceeds directly to safety setup of press using the values defined in

the last setup, even if the press had been turned off.

to 6.8 Safety Setup Procedure screen

[MAINTENANCE] –

If the Maintenance access code has been set this button proceeds to the Maintenance Access

Screen

to 6.2 Access Code screen

If the Maintenance access code has been set to 0000 this button proceeds to the Maintenance

Menu Screen directly

to 6.16 Maintenance Menu screen

[MAIN AIR] – Turns the main air on and off.

[LOGO SCREEN] – Returns to main title screen

to 6.1 Title screen

Copyright 2016 by PennEngineering®

30 of 119

6.4 Tooling Selection Screen 1

There are two screens of tooling mode selections to choose from. This is the first one. It is very

important to select the correct tooling mode to match the installation tools and fastener that is

being installed. Selecting a different tooling mode will cause the press to operate differently.

After selecting a tooling mode the control screen will automatically proceed to the proper setup

screen.

[MANUAL NUT] or [MANUAL STUD] – Manual Mode means that the operator must

manually place a fastener and no automatic feeding is enabled. Fastener and workpiece must be

manually placed together between the tooling. Selecting Nut or Stud mode changes the

recommended installation forces and the safety window tolerances.

to 6.6 Size and Material screen

[TOP FEED NUTS/SO] – Top Feed Nut and Short Standoff Mode is for automatic feeding of

nuts to the Top Feed Hanger Assembly, for punch pick-up through the internal hole of the

fastener. See Tooling Section for description of tools and operation.

to 6. 6 Size and Material screen

[BOTTOM FEED NUTS] – Bottom Feed Nut Mode is for automatic feeding of nuts to a

Bottom Feed Module Tool mounted on the anvil holder. See Tooling Section for description of

tools and operation.

to 6. 6 Size and Material screen

Copyright 2016 by PennEngineering®

31 of 119

[STUDS/BSO] – Top Feed Stud and Blind Standoff Mode is for automatic feeding of studs and

blind standoffs to the Top Feed Hanger Assembly, for punch pick-up by vacuum. See

Tooling Section for description of tools and operation.

to 6. 6 Size and Material screen

[LONG STANDOFFS] – Top Feed Long Standoff Mode is for automatic feeding of longer

standoffs to the Top Feed Hanger Assembly, for punch pick-up through the internal hole of the

fastener. See Tooling Section for description of tools and operation.

to 6. 6 Size and Material screen

[MODE] – Returns to Mode Selection Screen

to 6.3 Mode Selection screen

[NEXT] – Proceeds to an additional Tooling Selection Screen

to 6.5 Tooling Selection Screen 2

[HELP] - Mode Selection Help Screens

to Help Screens

Copyright 2016 by PennEngineering®

32 of 119

6.5 Tooling Selection Screen 2

There are two screens of tooling mode selections to choose from. This is the second one. It is

very important to select the correct tooling mode to match the installation tools and fastener that

is being installed. Selecting a different tooling mode will cause the press to operate differently.

After selecting a tooling mode the control screen will automatically proceed to the proper setup

screen.

[DOUBLE STROKE NUTS] – Top Feed/Bottom Installation Double Stroke Nuts Mode is for

automatic feeding of nuts to the Top Feed Hanger Assembly, for punch pick-up through the

internal hole of the fastener and deposit onto a double stroke bottom installation anvil. See

Tooling Section for description of tools and operation.

to 6. 6 Size and Material screen

[J-ANVIL NUT] or [J-ANVIL STUD] – J-Anvil Nut or Stud is a manual installation mode

with the Top Mount Anvil Holder installed. See Tooling Section for description of tools and

operation. Selecting Nut or Stud changes the recommended installation forces and the safety

window tolerances.

to 6. 6 Size and Material screen

[INJECTOR STUDS] – Injector Studs Mode is for automatic feeding of studs to an Injector

Module Tool mounted on the ram. See Tooling Section for description of tools and operation.

to 6. 6 Size and Material screen

Copyright 2016 by PennEngineering®

33 of 119

[PANEL FASTENERS] – Panel Fastener Mode is for automatic feeding of Large Head Panel

Fasteners to the Top Feed Hanger System for punch pick-up with vacuum. See Tooling Section

for description of tools and operation.

to 6. 6 Size and Material screen

[CUSTOM] – Custom Mode is for special custom modes defined especially for specific

fasteners and applications. See Documentation that accompanied tooling for description of tools

and operation.

to 6. 6 Size and Material screen

[MODE] – Returns to Mode Selection Screen

to 6.3 Mode Selection screen

[PREVIOUS] – Returns to previous Tooling Selection Screen

to 6.4 Tooling Selection Screen 1

[HELP] - Mode Selection Help Screens

to Help Screens

Copyright 2016 by PennEngineering®

34 of 119

6.6 Size and Material Selection Screen

This screen allows the operator to select the fastener size being installed and workpiece material

it is being installed into. Based on the operators selections, the Series 2000:

1) Limits the maximum installation force for operator safety.

2) Selects automatic feeding function settings

3) Presets a suggested installation force

[ANY SIZE] + [ANY MATERIAL] – Select a size or material, after selecting one, the operator

can change the selection just by pressing a different selection. As soon as BOTH a size and a

material is selected the setup process will move onto the Ram Force Adjustment Screen.

to 6.7 Ram Force Adjustment Screen

[BACK to Tooling Select] – Returns to Tooling Selection Screen

to 6.4 Tooling Selection Screen 1

Copyright 2016 by PennEngineering®

35 of 119

6.7 Ram Force Adjustment Screen

When this screen appears a recommended installation force will be preset. The operator can

continue with the recommended setting, or adjust the value and then continue or select Start @

Minimum mode.

[↑↑↑↑] – Increases Force Setting up to limit imposed by fastener size and workpiece material setting.

[↓↓↓↓] – Decreases Force Setting down to minimum

[MODE] – Returns to mode selection screen.

to 6.3 Mode Selection Screen

[START @ MIN.] – Proceeds to the Safety Setup Screen in Start at Minimum Force mode. In

this mode, at the first installation stroke ONLY, the ram will remain down. The press will

display this Force Selection screen again, with the force at minimum. Using the arrows,

the operator can adjust the actual installation force being applied gradually. The operator

can observe the installation process and stop at the minimum force necessary for delicate

operations. After the Force is set the next installation will proceed normally. The

operator will still be allowed to readjust that force value from the Run Mode screen.

to 6.8 Safety Setup Procedure Screens

Copyright 2016 by PennEngineering®

36 of 119

[CONTINUE] – Continues Setup Process or Returns to Run Mode if done setting the force at

Start @ Minimum Mode.

If in Continuing with Setup the next screen will be safety setup.

to 6.8 Safety Setup Procedure Screens

If in making a force adjustment from Run Mode or START @ Minimum the screen will return to

run mode.

to 6.9 Run Mode Screen

Copyright 2016 by PennEngineering®

37 of 119

6.8 Safety Setup Procedure Screens

If the press was setup in a fastener feeding mode, the system will automatically feed a fastener to

the insertion area.

This screen directs the operator to check that the fastener and workpiece is properly setup for the

safety position learn sequence and directs the operator to initiate the sequence. The instructional

text may differ, depending on the tooling mode selected.

It is very important that the fastener and workpiece be held flat to the top of the

anvil. (see Section 10)

The last step of each every sequence directs the operator to Depress The Footpedal. The Ram

will extend down and touch the fastener and workpiece and return back up, without installing the

fastener. The PLC uses this step to learn the position at which it is safe to install, called the

Safety Setpoint.

It is very important that, at the bottom of the ram stroke when the ram contacted the

fastener and the work piece, that the fastener was fully in the workpiece hole and both

were flat to the anvil. If this did not occur, use the Re-setup function on the run screen to

repeat the process. See 6.9 Run Mode Screen for Re-Setup details. (see Section 10)

[MODE] – Returns to mode selection screen.

to 6.3 Mode Selection Screen

Copyright 2016 by PennEngineering®

38 of 119

[MANUAL FEED] – Initiates a feed sequence to bring a fastener into position for the safety

learn sequence, if first fastener lost.

(Successful Learn Sequence) – After the operator performs a successful safety setup operation

the screen will automatically move onto the Run Mode, ready to install the fastener.

to 6.9 Run Mode Screen

Copyright 2016 by PennEngineering®

39 of 119

6.9 Run Mode Screen

This screen functions as a main control panel while the press is operating in production mode.

Various buttons and displays on the screen perform the following functions:

SAFETY SETPOINT – Displays the current value of the learned touch position for a safe

installation.

INSERTION POINT – Displays the value of the touch position of the last attempted

installation, successful or not

[STROKES/HOUR] – Button/Display, Displays a counter of the average rate of good

insertions. This value resets to zero after each setup. Press the display button to turn this

feature on or off. If this feature is off, the display will be 0, all the time.

[SAFETY SETPOINT RE-SETUP] - Enables the press to learn a new Safety Setpoint, without

leaving RUN mode. Touch this button and the button flashes. Depress the foot pedal and the

press will perform a learn sequence and reset the Safety Setpoint to the new position. The press

WILL NOT perform an insertion. (See 6.8 Safety Setup Procedure Screen)

[ABORT CYCLE] - Cancels an Interrupted Cycle at the wait point and allows the operator to

start over again.

Copyright 2016 by PennEngineering®

40 of 119

Ram Position Display Bars –

Left Display Bar – Indicates the adjusted return position of the ram. The dark bar

represents the amount of extension of the ram. A white bar indicates that the ram will

fully retract. A half-dark and half-white bar indicates that the ram will retract half way.

The lowest setting for the return position is approximately 25mm (1 inch) above the

safety setpoint. The arrow buttons on either end of the bar display are used to change the

return position of the ram. This function can be used to reduce the stroke in certain

modes and increase cycle rate. This function is disabled for tooling modes requiring the

Top Feed System. The two arrow buttons are dark when they are enabled and light when

they are disabled.

[↑↑↑↑] – Raises the return position of the ram.

[↓↓↓↓] – Lowers the return position of the ram.

Right Display Bar – Indicates real-time position of the ram. Use this for diagnostic

purposes.

[FORCE FEEDBACK] – Button/Display, Displays the actual insertion force calculated from

the hydraulic ram pressure. This value resets to zero at the beginning of an insertion attempt and

displays the insertion force during insertion. The value at the end of insertion is locked until the

next insertion attempt. Touch this button to go to the screen to adjust the preset force.

This button is SETUP access password protected. See 6.2 Access Code Screen and

6.20 Access Code Setup Screen

to 6.7 Ram Force Adjustment Screen

[DWELL] – Button/Display, displays set total insertion dwell time.

Touch this button to go to the screen to adjust the dwell time.

This button is SETUP access password protected. See 6.2 Access Code Screen and

6.20 Access Code Setup Screen

to 6.10 Smart Dwell Time Screen

Copyright 2016 by PennEngineering®

41 of 119

[BLOWER TIME] - Allows the blower time for automatic feed modes to be adjusted. The

blower time is the duration that the air stays on to blow the fastener from the shuttle mechanism

through the feed tubing to the insertion area. Touch this button to go to the screen to adjust the

blower time.

This button is SETUP access password protected. See 6.2 Access Code Screen and

6.17 Access Code Setup Screen

to 6.11 Blower Time Adjustment Screen

[CLEAR PASSWORD] – This button flashes after a SETUP access code is entered at one of

the protected functions. While the button is flashing, the operator can access any of the protected

functions without re-entering the SETUP access password again. Touching this button clears the

SETUP access code, the button will stop flashing, and the next time a protected function is

selected the access code screen (see 6.2) will appear again.

[RUN MODE PARAMETERS] – Button/Display displays job setup information, including

mode selections. The dark filled circles indicate the mode is activated. Touch this button to go

to the run mode parameter screen.

to 6.12 Run Mode Parameters Screen

[SAVE JOB] – Allows the operator to save the current settings of the Run Mode into a preset

memory location for Recall with the Recall Job function. The Save function will save the

following settings:

Tooling Mode Workpiece Complete Notify Setting

Fastener Size Selection Soft Touch Mode Setting

Workpiece Material Selection Cycle Mode (Continuous/Interrupted)

Preset Force Setpoint Tolerance (Standard/Narrow)

Blower Time Safety Fault Auto Reset Mode

Dwell Time Vacuum Check Mode

Fasteners/Workpiece Count Stud-In-Tube Sensor Mode

Fastener Length Monitoring Mode

A summary of some of this information is displayed in the Summary Box.

Current Workpiece and Fastener Counts and Workpieces/Batch WILL NOT be saved.

Any adjustments made to the recommended values will be saved with the job. If

Fasteners/Workpiece Count is set, when the job is recalled, the count will be set to zero but will

be enabled and start counting. If it is desired for the counter not to be enabled for every

job, set the counter to zero.

to 6.14 Store Job Screen

Copyright 2016 by PennEngineering®

42 of 119

[FASTENERS] – Display/Button, The first larger number is the current number of fasteners

installed in the current workpiece. Touch and hold this button to reset the count to 0. The second

smaller number is the number of fasteners per workpiece, set at the counters screen, see below.

When the first number reaches the second number the workpiece will be complete and the

fastener count will automatically reset to zero. The second number does not change during run.

[WORKPIECES] – Display/Button, The first, larger number is the current number of

workpieces completed since the last reset of this counter. Touch and hold this button to reset

the current count to 0. The second smaller number is the number of workpieces per batch, set at

the counters screen, see below. When the first number reaches the second number the batch will

be complete and the workpiece count will automatically reset to zero. The second number does

not change during run.

[-1] – Shift Decrement Button, Touch this button and touch either the Workpieces Button or the

Fasteners Button to decrement the current count by 1.

[COUNTERS] - Allows the Workpiece and Fastener Counters to be set. Touch this button to go

to the screen to set both counters.

to 6.15 Counters Setup Screen

[REDO] – In any automatic tooling mode, it enables the press to attempt another insertion

without feeding another fastener. Touch this button and the button flashes. Depress the foot

pedal and the ram will extend, insert and return again without feeding a new fastener. The Safety

Window becomes set to the standard tolerance during the REDO cycle only, negating “Narrow

Setpoint Tolerance” for just the redo stroke. If it is enabled, touching the button again will

disable it. This function can be used for a restrike of a partially installed fastener or for a manual

insertion during an automatic feed run without leaving the run screen.

[FEED] - By pushing this button the operator can cause the system to feed another fastener to

the workpiece area, without activating the ram. This feature is used only if a fastener is lost

during the standard feed process.

[HELP] – Run Mode Help Screens

to Help Screen

[MODE] – Returns to mode selection screen.

to 6.3 Mode Selection Screen

Copyright 2016 by PennEngineering®

43 of 119

6.10 Smart Dwell Time Screen

This screen allows the operator to adjust the set dwell time.

Smart Dwell Time

Set the value with the pop-up keypad (0.00-2.99 sec). If the dwell time is set to 0.00 the press

will reach high force and end the installation stroke. If high force is not reached after 3.00

seconds the press will fault.

Example: Dwell Time = 0.25. The press will reach high force and then wait 0.25

seconds before ending the installation stroke. If high force is not achieved after a fixed

time of 3.00 seconds, a “Force Too Low” alarm will occur.

[BACK] – Returns to Run Mode screen.

to 6.9 Run Mode Screen

Copyright 2016 by PennEngineering®

44 of 119

6.11 Blower Time Adjustment Screen

This screen allows the operator to adjust the fastener feed blower time. The initial setting of this

time is preset to the suggested values based on the fastener size selection. Use the pop-up

keypad to adjust each digit of the values.

Blower Time – Is displayed in seconds with a maximum setting of 2.00 sec. It is the duration

that the air stays on to blow the fastener from the shuttle mechanism through the feed tubing to

the insertion area. Increasing this value will insure that the fastener is properly fed to the

insertion area. Decreasing this value will reduce the cycle time for each insertion.

[BACK] – Returns to Run Mode screen.

to 6.9 Run Mode Screen

Copyright 2016 by PennEngineering®

45 of 119

6.12 Run Mode Parameter Screen

This screen functions as a main control panel while the press is operating in production mode.

Various buttons and displays on the screen perform the following functions:

[ENABLE SOFT TOUCH] – This button will turn the Soft Touch mode on and off. With SoftTouch mode ON the ram will decelerate before contacting the fastener/workpiece and coast to a

stop immediately before collapsing the safety housing (note that all of the safety features are still

operational during this mode). Once the ram has come to a stop, the booster turns on to complete

the high force installation process. Soft Touch mode is suggested when installing into soft

materials (i.e. PCBs) or during applications where hard installation marks are detrimental to the

workpiece.

[CONTINUOUS/ INTERRUPTED CYCLE] – Button/Display, Displays what mode the press

is operating in Continuous Cycle Mode or Interrupted Cycle Mode. Touch this button to toggle

between the two modes.

Continuous Cycle Mode – When the operator depresses the foot pedal, the ram will complete

a full insertion cycle, extend, insert the fastener and return.

Interrupted Cycle Mode – When the operator depresses the foot pedal, the ram will extend,

STOP and WAIT. When the operator depresses the foot pedal again, the ram will insert the

fastener and return. This provides for some specialized applications, the opportunity to

examine or adjust the fastener/workpiece positions just before the actual insertion.

Copyright 2016 by PennEngineering®

46 of 119

[STANDARD/NARROW SETPOINT TOLERANCE] – Toggles the Setpoint Tolerance

window from Standard to Narrow. Standard tolerance allows for normal variations of workpiece

and fastener dimensions and operator handling of the workpiece. Narrow tolerance requires

more precise dimensions and operator handling. A narrow tolerance is typically used for the

most delicate workpieces with consistent thickness.

[ENABLE SAFETY FAULT AUTO RESET] – This button turns Auto Reset function on and

off. In Auto Reset mode, if a safety fault occurs, the operator is not required to touch the screen

to reset. These two safety faults are automatically reset:

Safety Sensors tripped ABOVE setpoint, during Run mode, the ram contacted something

before it reached the minimum allowable insertion distance.

Safety Sensor tripped BELOW setpoint, during Run mode, the ram did not contact

anything before it reached the maximum allowable insertion distance.

[ENABLE VACUUM CHECK] – This button will turn the Vacuum Check function on and off.

If the press is operating in stud mode, this feature will check for the presence of the fastener on

the vacuum punch.

[ENABLE STUD-IN-TUBE SENSOR] – Toggles whether stud-in-tube sensor is checked

during stud or long-standoff mode. Dark is ON and enabled. Normally, when this sensor is

enabled, if the sensor does not detect a fastener, the shuttle sequence will not blow and will

automatically attempt to feed another fastener. When this sensor is disabled, no check is done

and the feed blower will blow immediately.

[ENABLE FASTENER LENGTH MONITORING] – Touch this button to enable the

Fastener Length Monitoring check in stud or long-standoff mode. When enabling the feature the

Fastener Length Monitoring screen will display the operating instructions.

to 6.13 Fastener Length Monitoring Screen

[METRIC/UNIFIED RUN SCREEN UNITS] – Touch this button to change the display to

either metric or unified units. The unit selected is displayed in dark.

[BACK] – Returns to Run Mode screen.

to 6.9 Run Mode Screen

[HELP] – Run Mode Parameters Help Screens

to Help Screen

Copyright 2016 by PennEngineering®

47 of 119

6.13 Fastener Length Monitoring Screen

This screen assists the operator in setting up the Fastener Length Monitoring (FLM) System

hardware for the correct length part.

Follow the step by step instructions on the screen. If the FLM System is already setup, just use

the BACK button to return to the previous screen.

[BOWL] – Touch this button to turn the bowl on. This moves the fasteners around and into the

shuttle. Wait for the fasteners to line up and move into the shuttle. IMPORTANT: Be sure that

only fasteners of the correct length are in the bowl, escapement and shuttle.

[SHUTTLE] – Touch this button to move the shuttle and separate the first fastener from the line

of fasteners.

[BLOWER] – Touch this button to turn on the blower that blows the fastener up and into the

Fastener Length Monitoring chamber attached to the shuttle.

Fastener Length OK – This display will be dark if the FLM sensors detect a good part. An

audible alarm will also sound. If the fastener length is not ok then either the FLM sensor

assembly is too low, or too high, adjust until this display is consistently ON. If this display does

not turn ON, check that a fastener has been blown into the chamber.

[EJECT PART] – Touch this button when the setup is done and the fastener in the chamber will

be blown out to the top feed gripper/slide area.

Copyright 2016 by PennEngineering®

48 of 119

[DROP PART] – Touch this button to drop the part, to get ready for installation.

[BACK] – Returns to Run Mode Parameters screen.

to 6.12 Run Mode Parameters Screen

Copyright 2016 by PennEngineering®

49 of 119

6.14 Store/Recall Job Screen

This screen allows the operator to recall preset job settings or save preset job settings depending

on whether this screen was accessed from the Mode Selection Screen or the Run Mode Screen.

Job Summary Box – Displays the important setup values that are stored with each job. When

storing a job from Run Mode this summary will display the values that the operator was

currently running, including any adjustments made at Run Mode. When recalling a job from the

Mode Selection screen, the saved values for a job will appear, as the operator selects a numbered

job. Dwell and Blower Times are stored and recalled but not displayed in the summary box.

Tooling Mode Workpiece Complete Notify Setting

Fastener Size Selection Soft Touch Mode Setting

Workpiece Material Selection Cycle Mode (Continuous/Interrupted)

Preset Force Setpoint Tolerance (Standard/Narrow)

Blower Time Safety Fault Auto Reset Mode

Dwell Time Vacuum Check Mode

Fasteners/Workpiece Count Stud-In-Tube Sensor Mode

Fastener Length Monitoring Mode

Copyright 2016 by PennEngineering®

50 of 119

Job Reference No. – Displays and allows input of an optional, 8-digit reference number

associated with a job. For example: This data field can be used to reference a shop work order

number. This number can be entered before storing a job. Press Job Reference No. and a pop-up

keypad will appear, enter the Job Reference No. and press “ENT” to continue.

Operator can also recall a job using the Job Reference No. by pressing [SEARCH] the system

will search for the job number associated with this Reference No. This number will also appear

on the run screen summary box.

Job No. – Displays and allows input of a job No., from 1 to 300. In Store Mode, press Job No.

and enter a job No. using the pop-up keypad, then press [STORE]. A blinking message will

appear: “Job successfully stored” if the job No. selected is currently available. If however, the

number is already occupied, a blinking message will appear: “Job No. is occupied”. In Recall

Mode, press Job No. and enter a job No. using the pop-up keypad. If the job is stored, the

information will appear in the [Job Summary] fields. If there is no job stored under the number,

a blinking message will appear: “Job No. is not occupied”.

[CLEAR] – This function will clear all data associated with a job No. After entering Job No. to

be cleared, press the [CLEAR] button. A blinking message will appear: “Clearing a Job No. will

delete all associated stored data. Do you really want to clear the displayed job?” Press [YES] to

proceed or [NO] to cancel.

[SETUP/RUN Mode] or [BACK TO RUN Mode] – In Store Mode, after selecting a memory

location Storing a Job, use BACK TO RUN Mode button to return to the Run Mode. If the

operator does not store the job in a memory location before returning to Run Mode then the Job

values will not be able to be recalled later. In Recall Mode, after selecting a Job, use

SETUP/RUN Mode button to proceed to the Safety Setup Procedure Screen to complete the

setup.

The safety setpoint is NOT saved with the Job. It must be re-learned to insure that each run is

safe.

If [SETUP/RUN Mode]

to 6.8 Safety Setup Procedure Screen

If [BACK TO RUN Mode]

to 6.9 Run Mode Screen

[MODE] – Returns to mode selection screen.

to 6.3 Mode Selection Screen

Copyright 2016 by PennEngineering®

51 of 119

6.15 Counters Setup Screen

This screen allows the operator to change the fasteners per workpiece and workpieces per batch

counter presets.

Counter Pop-Up Keypad – The operator uses the pop-up keypad to set the value of each digit

for either counter. The range of each counter is from 0 to 9999.

[↵↵↵↵ WORKPIECES per BATCH] – Touch this button to display the pop-up keypad to the

preset value of workpieces per batch. If this is set to zero, the counter will be disabled. If this

counter is set to a value greater than zero, completed workpieces will be counted. The workpiece

count is incremented after the fasteners per workpiece count is reached. When workpiece count

on the Run Mode Screen reaches this preset value, a Batch Complete warning may be displayed

and the Workpiece counter will be reset to zero.

[↵↵↵↵ FASTENERS per WORKPIECE] – Touch this button to display the pop-up keypad to the

preset value of fastener insertions per workpiece. If this is set to zero, the counter will be

disabled. If this counter is set to a value greater than zero, completed insertions will be counted.

The fastener count is incremented after the end of the insertion force dwell. When the fastener

count on the Run Mode Screen reaches this preset value, one workpiece completed will be

counted, a Workpiece Complete warning may be displayed and the Workpiece counter will be

incremented by 1 and the Fastener counter will be reset to zero.

Copyright 2016 by PennEngineering®

52 of 119

Workpiece Complete Warning Screen Selection Buttons –

[AUTO] – Toggles Workpiece Complete Warning Screen to automatically return to run

screen after a brief flash and audio warning.

[MANUAL] – Toggles Workpiece Complete Warning Screen to require the operator to

touch the reset button on the screen, when the Workpiece Complete Warning Message

Screen appears. There is an audio warning when the screen appears.

[OFF] – Toggles Workpiece Complete Warning Screen to not appear. There is only an

audible warning.

[BACK] – Returns to Run Mode screen.

to 6.9 Run Mode Screen

[HELP] – Fastener and Workpiece Help Screen

to Help Screen

Copyright 2016 by PennEngineering®

53 of 119

6.16 Maintenance Menu Screen

This screen allows the operator to access the maintenance functions. Here the operator can

access certain setup screens, a maintenance control screen and automatic feed tooling test modes.

[PLC I/O] – Proceed to PLC Inputs/Outputs Control Screen, which allows maintenance

personnel to independently control PLC Input/Output signals for diagnostic purposes.

to 6.21 PLC Input/Output Control Screen

[FORCE CALIBRATION] – Proceeds to Force Calibration Screen, which allows maintenance

personnel to check and calibrate force settings.

to 6.17 Force Calibration Screen

[TEST TOOLING/SETTINGS] – Proceeds to Test Tooling / Settings screen, which allows

maintenance personnel to test auto tooling and to turn On/Off sensor settings and Fastener

Length Monitoring function.

to 6.18 Test Tooling/Settings Screen

WARNING: The tooling test modes must be used with care. Always install the

proper tooling before operating any test mode. Failure to follow these requirements

may result in damage to tools and a safety hazard.

Copyright 2016 by PennEngineering®

54 of 119

[RAM JOG] – Proceeds to Jog Screen, allows operator to control ram position at various speeds

for setup purposes.

to 6.22 Ram Jog Screen

[TOP FEED SLIDE TIMING] – Allows the Top Feed Slide Timing to be adjusted. The Top

Feed Slide Timing affects the performance of the top feed automatic nut pick-up sequence.

Touch this button to go to the screen to adjust the timing.

to 6.19 Top Feed Slide Timing Adjustment Screen

[SECURITY CODES] – Allows the Access and Maintenance Access Codes to be enabled and

changed.

to 6.16 Access Code Setup Screen

[MAIN AIR] – Turns the main air on and off.

Total Cycles - Displays a permanent cycle counter for machine.

[MODE] – Returns to mode selection screen.

to 6.3 Mode Selection Screen

Copyright 2016 by PennEngineering®

55 of 119

6.17 Force Calibration Screen

This screen allows maintenance personnel to check the calibration of the electronic pressure

regulator for force and the hydraulic pressure sensor feedback. Maintenance personnel can move

the ram up and down, adjust the force setting, boost to high force and check the readings.

[JOG UP] – Touch and hold this button to move the Ram Up.

[JOG DOWN] – Touch and hold this button to move the Ram Down.

JOG SPEED – Displays the ram speed % of full speed setting. This is a coarse adjustment