System 450 Series Modular Controls Product

Bulletin

LIT-12011458

2021-07-21

Introduction

The System 450™ is a family of modular, digital electronic

controls that you can assemble and set up to provide

reliable temperature, pressure, and humidity control for a

wide variety of HVAC, commercial, and industrial process

applications.

The System 450 control system replaces the System

350™ and System 27 control systems, and provides

additional features and benefits with fewer than 20 model

variations. The System 450 control modules provide a

field-configurable out-of-the-box solution. Most System

450 control modules can control temperature, pressure,

and humidity systems simultaneously.

You can set up a single C450 control module as a standalone control or to connect with expansion modules to

control up to 10 On/Off relay and proportional analog

outputs, based on any of the three available inputs.

Use the System 450 control modules with communications

to connect System 450 control systems to Modbus® or

Ethernet networks for remote monitoring and setup. The

Modbus communications control module is an RS485,

rooftop unit (RTU) compliant subordinate device. The

Ethernet communications control module has an integral

web server that can deliver web pages through a direct

connection, on your LAN, or across the internet.

The System 450 reset control modules provide many of

the features of the standard models for temperature

and humidity control. In addition, these modules provide

setpoint reset, real-time setback scheduling, and equal

run-time balancing capability.

The System 450 control module with hybrid analog output

has a single self-selecting analog output to optimize and

extend the controlled speed range of variable speed

electronically commutated (EC) motors.

Figure 1: System 450 Control System with control,

power, and expansion modules

Features and benefits

Durable, compact, interchangeable modular

components with plug-together connectors and DIN

rail or direct wall mount capability

Eliminate field wiring between modules and quickly and

easily design, assemble, install, and upgrade your control

systems.

Versatile, multipurpose, field-configurable control

modules and expansion modules designed for global

use

Create a wide variety of application-specific control

systems to control temperature, pressure, or humidity, or

all three conditions simultaneously, with only a small suite

of module models.

Control modules with bright backlit LCDs and fourbutton touchpad UIs, up to three hard-wired input

sensors, and up to 10 relay or analog outputs in any

combination for each control system

Provide a quick, clear, visual status of your System 450

control system inputs and outputs with the touch of a

button and quickly and easily set up and adjust your

control system.

Extensive suite of compatible temperature and

humidity sensors and pressure transducers

Monitor and control a wide range of HVAC and process

conditions in a variety of standard and global units of

measurement.

Differential control

Enables your control system to monitor and maintain a

temperature, pressure, or humidity differential between

two sensor points within a system, process, or space.

On/Off delays

Configure an on delay and an off delay to set the times

between a setpoint trip and the energizing or deenergizing of a relay.

C450Cxx, C450Rxx, C450Sxx, C450Yxx

Overview

The System 450 Series is a family of compact digital

electronic control, expansion, and power modules that

you can assemble and set up to provide reliable on/

off and proportional control of temperature, pressure,

and humidity conditions in a wide variety of HVAC,

commercial, and industrial process applications.

A System 450 Series control system includes the following

features:

• A single control module with LCD and 4-button

touchpad

• One to three inputs

• One to 10 relay or analog outputs provided by the

control module and expansion modules

• An optional power module

Compact modular plug-together design

All System 450 modules feature a compact, durable,

gray LEXAN® housing with DIN rail clips and slotted

mounting holes molded into the back of the housing for

easy installation.

The System 450 modules also feature 6-pin connectors on

the sides of the housing for easy assembly, upgrade of

your control systems, and to eliminate the need for field

wiring between modules.

A System 450 control system provides compact, clean, and

consistent control system assemblies that are simple to

build, install, and maintain.

Multipurpose and field-configurable design

The System 450 control, expansion, and power modules

are multipurpose devices that you can configure in the

field to control temperature, pressure, and humidity

simultaneously.

On/Off relay control

Relay outputs provide low and line-voltage on/off control

for devices and equipment in the controlled systems.

Each relay is a single-pole, double-throw (SPDT) set of dry

contacts.

Note: The System 450 output relays are SPDT dry

contact relays only and do not provide any power

source for the controlled equipment.

See Technical Specifications for output relay electrical

rating information. See Table 1 for information on the

System 450 control modules with this feature.

Analog proportional control

Analog outputs provide proportional analog signals for

devices and equipment in your controlled systems.

Each analog output can generate either a 4 mA to 20

mA or 0 VDC to 10 VDC signal. The output signal type is

self-selecting; after you connect the analog output to

the controlled equipment, the output detects the analog

input on the controlled equipment and generates the

appropriate analog signal for the connected input.

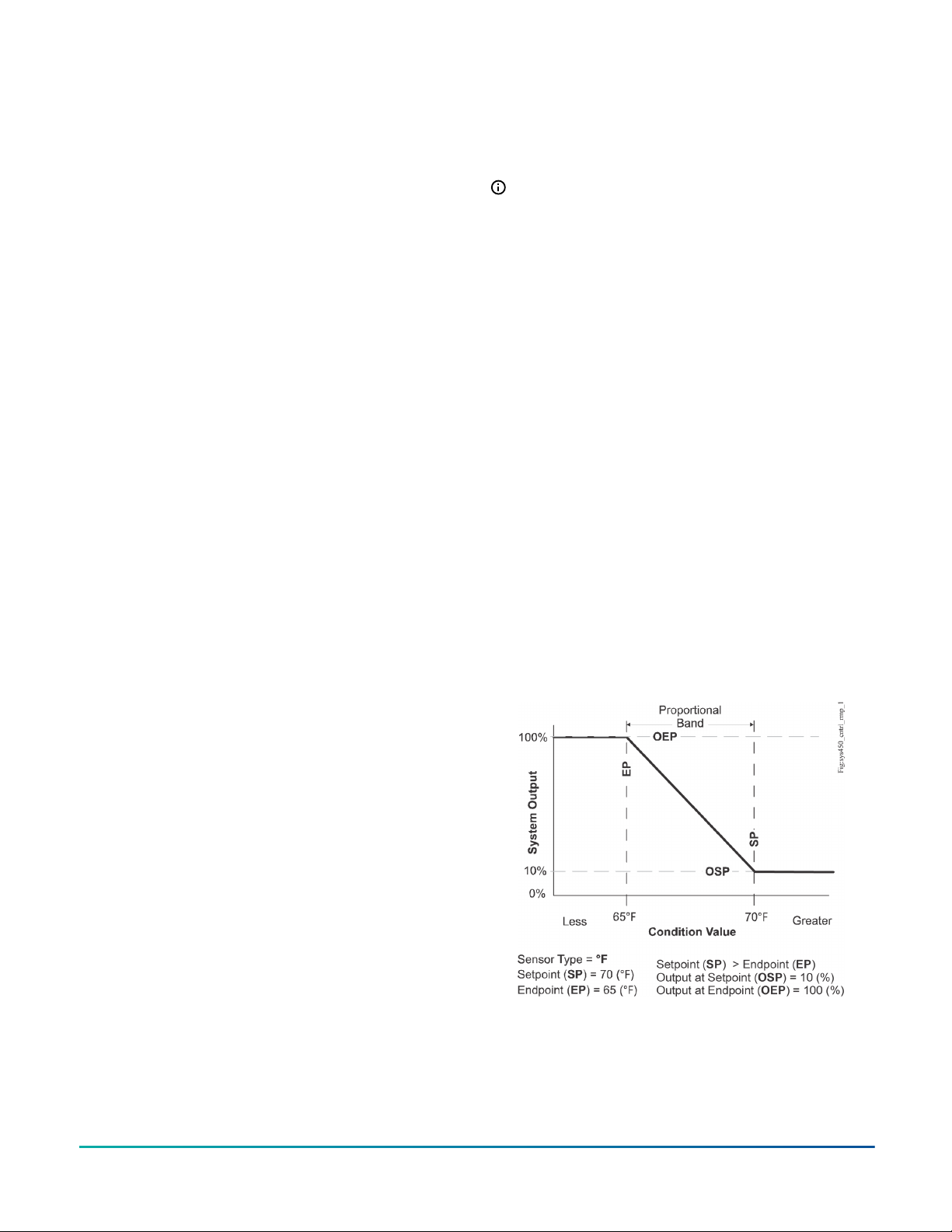

You can set up an analog output to generate a direct

acting or reverse acting proportional output signal. You

can also set up the output signal strength to increase

or decrease in either the direct acting or reverse acting

mode. See the example in Figure 4.

An analog output’s control action is automatically

determined by the setup values you select for the

setpoint, end point, % output at setpoint, and % output at

endpoint values when you set up the output in the UI.

A control ramp indicator appears on the output status

screen for each analog output to represent the analog

output’s control action.

Figure 2: Proportional analog output operation for

reverse acting room heating application

Global design

A System 450 control system is the next generation of

System 350 and System 27 modular controls.

The System 450 modular control system has fewer than

20 model variations and provides far more features and

flexibility than either the System 350 modular control

system with 54 models, or the System 27 modular control

system with 40 models.

The System 450 modules are designed, tested, and

certified for global application and are Underwriters’

Laboratories, Inc. (cULus) Listed and CE compliant.

You can set up the System 450 control systems in the

global standard units of measurement such as Fahrenheit,

Celsius, psi, bar, inches water column (in. W.C.), and

relative humidity (RH).

Control capabilities

The System 450 control system provides a variety of

control capabilities depending on the model you select.

See Table 1 for information on System 450 control

modules with specific features.

System 450 Series Modular Controls Product Bulletin2

See Table 1 for information on the System 450 control

modules with this feature.

Proportional plus integral control

In addition to standard proportional only control analog

signals, a System 450 control system provides integral

control capability and six time integral selections that

you can use to set up analog outputs to generate a

proportional plus integral signal.

Proportional plus integral (PI) control incorporates a

time-integral control action with proportional control

action. If correctly set up, a PI control loop can effectively

eliminate offset error and enable a controlled system to

drive much closer to the preferred setpoint, even under

large constant loads. On a properly sized system with

predictable loads, PI control can maintain the controlled

system very close to the setpoint.

The integration constant that you select establishes the

rate at which the control readjusts the analog output

signal. The faster the integration constant, the faster the

control readjusts the output signal, and the faster the

recovery rate of a properly sized and setup control loop.

See Table 1 for information on the System 450 control

modules with this feature.

Multistage On/Off and proportional control

You can set up multiple outputs to create a variety of

equipment staging control systems. Depending on the

control module and expansion modules, a System 450

multistage application may use On/Off control relay

outputs or proportional control analog outputs. See Table

1 for information on the System 450 control modules with

this feature.

High input signal select

The High Input Signal Selection feature enables a System

450 control system to monitor a temperature, pressure, or

humidity condition with two or three sensors of the same

type and control relay and analog outputs based on the

highest condition value sensed.

See Table 1 for information on the System 450 control

modules with this feature.

Differential control

The Differential Control feature enables a System 450

control system to monitor and maintain a temperature,

pressure, or humidity differential between two sensors

of the same type. This feature also enables the control

system to control relay outputs, analog outputs, or a

combination of relay and analog outputs, based on

the sensed differential value relative to user-selected

differential values. An example is the water pressure drop

across an in-line water filter. See Table 1 for information

on the System 450 control modules with this feature.

Reset control

The System 450 reset control modules automatically

adjust the setpoint for a supply control loop, based on

input from the outdoor or ambient master sensor and the

user-selected reset setpoint settings. This functions saves

energy by using only the required capacity of the supply

to heat, cool, dehumidify, or humidify the preferred space

or environment.

See Figure 3 for an example of Setpoint Reset Control for

both a chilled water temperature reset application and a

boiler water temperature reset application. See Table 1 for

information on the System 450 control modules with this

feature.

Figure 3: Reset setpoint application for boiler water

supply (BWS) and chiller water supply (CWS) showing

relationships between the reset

Setback scheduling

Use the reset control module’s real-time clock to schedule

outputs by day of week and time of day.

You can also set up setback temperatures and humidity

to create an occupied or unoccupied setback schedule

for the outputs in your control system. You can select a

negative setback value for heating or humidification, or

a positive setback value for cooling or dehumidification

control. See Table 1 for information on the System 450

control modules with this feature.

Run-time balancing

The reset control module’s run-time balancing feature

enables your control system to even out the runtimes of

staged equipment by automatically selecting the stage

with the smallest runtime when it responds to increases in

the system load.

Use run-time balancing to control up to four staged

outputs. See Table 1 for information on the System 450

control modules with this feature.

Analog output signal limiting

The analog output signal limiting feature on the System

450 control modules with communications reduces the

rate at which an analog output updates its output signal

strength in response to input signal changes.

When it controls a device such as a modulating actuator,

the analog output signal limiting feature can help

lengthen actuator life by reducing the actuator position

update frequency. The following parameters control this

feature:

• Output signal update rate: Select the rate in seconds

at which an analog output updates the output signal to

the controlled equipment

System 450 Series Modular Controls Product Bulletin 3

• Output signal dead band: Create a deadband for the

analog output signal within which the output signal

strength remains constant

See Table 1 for information on the System 450 control

modules with the analog output signal limiting feature.

Binary input control for relay outputs

A binary input is a user-supplied pair of dry contacts.

Connect a binary input to any of the three control module

input terminals and control the output relays in your

control system based on whether the binary input’s state

is open or closed. Examples of dry contacts include door

switches, timers, occupancy sensors, and other switching

devices.

A sensor set up as a binary input can be referenced

only by a relay output. Analog outputs cannot reference

sensors set up as binary inputs.

On/Off duration time control

Use the four time control parameters on the control

modules with communications to set up the relay outputs

with On or Off time delays and minimum On or Off times.

You can set each of the four On or Off duration control

parameters from 0 seconds to 300 seconds or 5 minutes,

in 1-second intervals.

Hybrid analog output control

The hybrid analog output control on C450CPW-400 control

modules enables an analog VDC output to transition to a

pulse output at low signal levels.

This function ensures more efficient low-speed control of

variable speed EC motors in condenser fan applications.

Network communications

The System 450 communications control modules provide

network connectivity and communications. Depending

on the communications control module, your controls

system can connect to and communicate over either

Ethernet networks or Modbus networks. See Table 1 for

information on the System 450 control modules with this

feature.

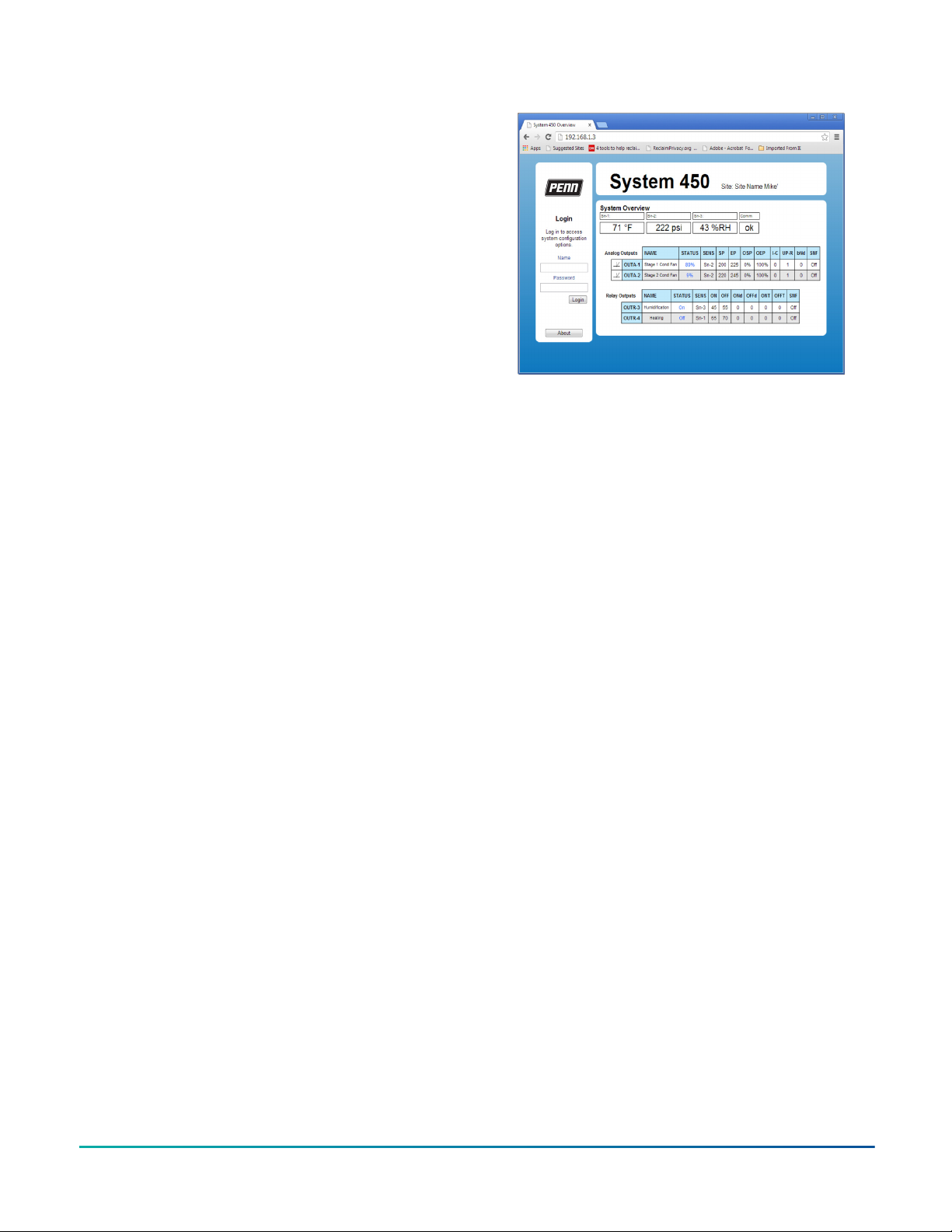

Ethernet communications

The System 450 control modules with Ethernet

communications have an integral web server that delivers

web pages to client browsers on desktop and laptop

computers, as well as smart phones, devices, and tablets.

Use the System 450 web UI to monitor your control

system status and set up or change the configuration

in simple, user-friendly web pages delivered to your

computer through a direct connection, a LAN connection,

or the internet.

Figure 4: System 450 System Overview page example

You can monitor control system status and configure the

control system parameters in both the local UI through

the LCD and four-button touchpad, and the web UI.

Use the System 450 control modules with Ethernet

communications to perform the following tasks:

• Directly connect your computer to the System 450

control module with an Ethernet cable, and set up,

monitor, and modify your control system

• Connect your control system to an existing network

and establish a static IP address or use a Dynamic Host

Configuration Protocol (DHCP) server to provide a

dynamic address

• Set up Dynamic Domain Name Server and browse to

your System 450 control system on a local network or

across the internet using a text-based host name URL

instead of a numeric IP address and port number

The System 450 web UI provides easy remote access to

your System 450 controls systems through your LAN or

the internet. Use the web UI to log on directly, locally, or

remotely and view the web UI system status, system setup

parameters, and parameter values in the UI.

Use the system configuration web pages to set up or

change the parameters for your system outputs in the

web UI. When the remote access lock feature is activated

in the web UI, users can view the control system status

but cannot make system changes.

RS485 Modbus communications

The System 450 control module with Modbus

communications is an RS485, RTU compliant Modbus

subordinate device. You can use it to connect your

System 450 control system to Modbus networks and

communicate over them.

The System 450 Modbus communication control module

also enables your entire control system to respond to data

requests and commands from a Modbus master device on

the Modbus network.

System 450 Series Modular Controls Product Bulletin4

Table 1: System 450 Control Module capabilities

Control by ________

Controlled condition

Temperature X X X X

Pressure X X - X

Humidity X X X X

Combination of

conditions

Control capabilities

On/Off relay control X X X X

Analog proportional

control (direct and

reverse action)

Analog proportional

plus integral control

(direct and reverse

action)

Combination of On/

Off relay and analog

output control

Stand-alone control X - X X

Multi-stage control

(relay or analog)

Network

communications

High input signal

selection

Differential control X X - X

Output signal

limiting

output signal

update rate

Output signal

deadband

Binary input control

for relay outputs

On/Off duration

time control

Minimum On/Off

time

On/Off time delay

Temperature and

humidity reset

control

Scheduling and

temperature

setback control

Reset setpoint

control

Setback scheduling - - X -

Run-time balancing - - X -

Hybrid analog

output control

1 Only on output OUTA1.

System 450 Control Modules

Standard Communications Reset Hybrid

C450CPN-4

C450CQN-4

C450CBN-4

C450CCN-4

C450CEN-1

C450CRN-1

X X X X

X X X X

X X X X

X X X X

X X X X

- X - -

X X - X

X X - -

X X - -

X X - -

- - X -

- - X -

- - X -

- - -

C450RBN-3

C450RCN-3

C450CPW-400

1

1

X

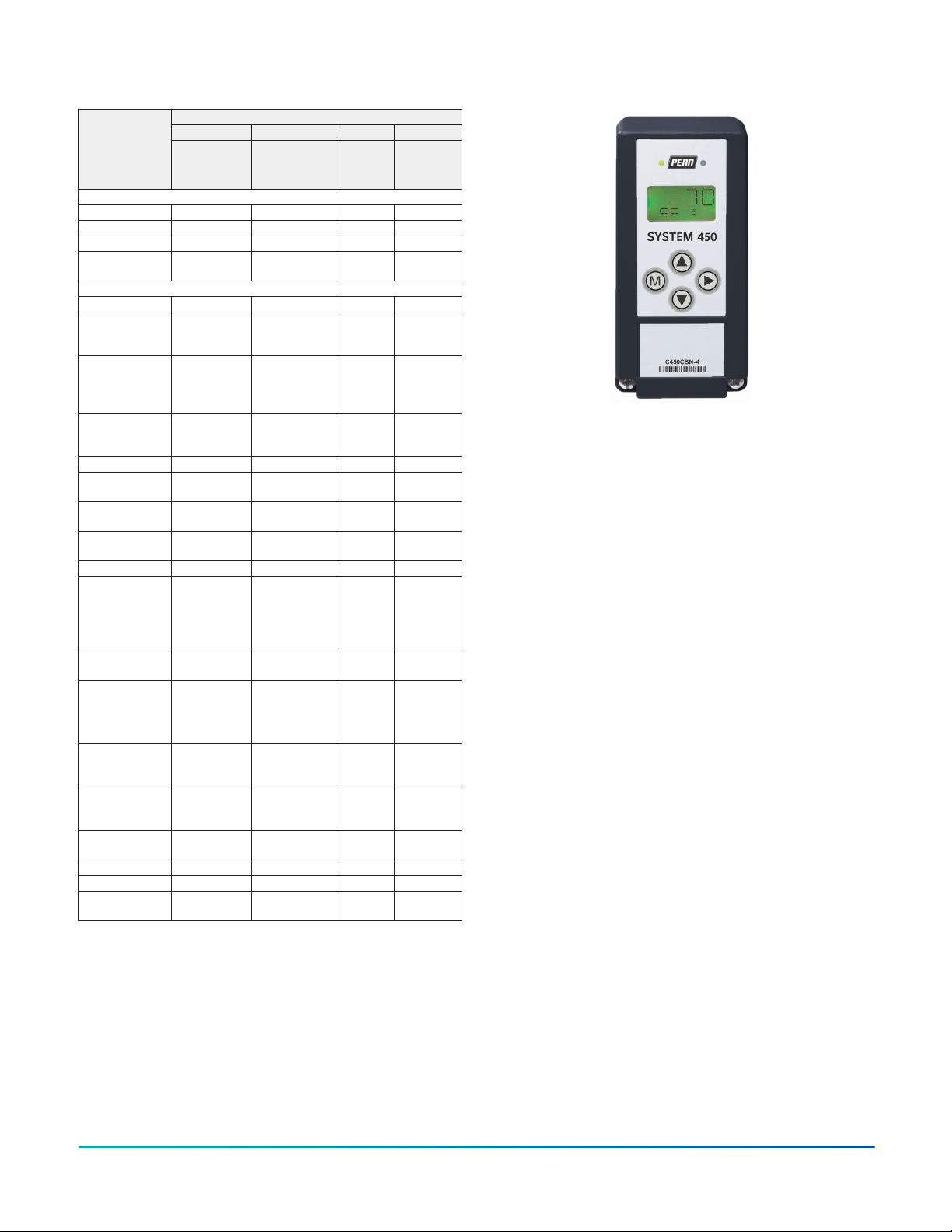

System 450 control modules

The System 450 control module is the supervisor of your

control system and the interface for the system’s inputs,

supply power, and outputs.

Figure 5 shows an example System 450 control module.

See Table 1 and Table 2 for information on all of the

available control modules.

Figure 5: C450CBN Standard control module

All System 450 control systems require a control module

to set up the control system’s inputs and outputs, monitor

the control system’s status, and control the system’s

outputs.

System 450 control modules can monitor up to three

inputs and control up to 10 outputs in any combination of

relay and analog outputs provided by expansion modules.

User-friendly LCD and touchpad UI

The System 450 control modules feature a backlit LCD

screen that displays the real-time status of the sensors

that are set up in your control system during normal

operation. The four-button touchpad enables you to

quickly scroll through and view the output status screens

and access the system setup screens to set up or adjust

the sensors and outputs in your control system.

After you assemble and power your control system, and

select the Sensor Types in the UI, the control module

automatically determines the output numbers and output

types. The control module then generates the menubased setup screens and supplies all of the default setup

values required to set up your custom control system.

System 450 standard control modules

Configure the System 450 standard control modules out

of the box as stand-alone controls that can provide SPDT

control or proportional analog signal control, depending

on the model, for a wide range of HVAC, commercial, and

industrial process applications. The following standard

control modules are available:

• C450CBN-4 control module has one SPDT relay output

• C450CCN-4 control modules have two SPDT relay

outputs

• C450CPN-4 control modules have one analog output

(0VDC to 10 VDC or 4 mA to 20 mA)

• C450CQN-4 control modules have two analog outputs

(0 VDC to 10 VDC or 4 mA to 20 mA)

With a standard control module and the available sensors

and transducers, almost any temperature, pressure, or

humidity control you may encounter in the field can be

System 450 Series Modular Controls Product Bulletin 5

quickly replaced with a System 450 control system. See

Table 1 for capabilities of the standard control modules.

System 450 reset control modules

Reset control modules provide many of the features of the

standard control modules for temperature and humidity

control. In addition, these modules provide temperature

and humidity reset, real-time setback, and run-time

balancing capability. The following reset control modules

are available:

• C450RBN-3 (one SPDT relay output)

• C450RCN-3 (two SPDT relay outputs)

See Table 1 for capabilities of the System 450 reset control

modules.

Reset control modules control temperature and humidity,

but not pressure.

System 450 hybrid analog output control modules

A System 450 hybrid analog output control module

can provide the same control as the standard control

modules, while providing a hybrid analog output control

option for controlling EC motors.

The hybrid analog output control feature enables an

analog VDC output to transition to a pulse output at

low signal levels. This provides more efficient lowspeed control of EC variable speed motors. These EC

variable speed motors are typically used in condenser fan

applications on a wide variety of refrigeration and HVAC

condensing units.

The onboard analog output can also be configured

for High Input Signal Selection, which enables precise

and efficient EC motor speed control on multi-circuit

condensing units.

See Table 1 for capabilities of the System 450 Hybrid

Analog Output control modules.

including multipurpose control systems that control

temperature, pressure, and humidity simultaneously.

You do not need to purchase additional and unnecessary

features and components associated with packaged

control systems, which reduces your control system costs

to just the inputs, outputs, and features required by your

application.

System 450 components allow you to build control

systems that include:

• one to 10 outputs provided by the control module and

expansion modules, each output providing either on/

off control or a proportional analog signal (0 VDC to

10 VDC or 4 mA to 20 mA) to the equipment in your

controlled system

• one to three sensors or transducers, which are hardwired directly to the control module and provide input

signals for monitoring and controlling your system

equipment

• an optional power module to provide power to the

control module, expansion modules, and the input

sensors and transducers

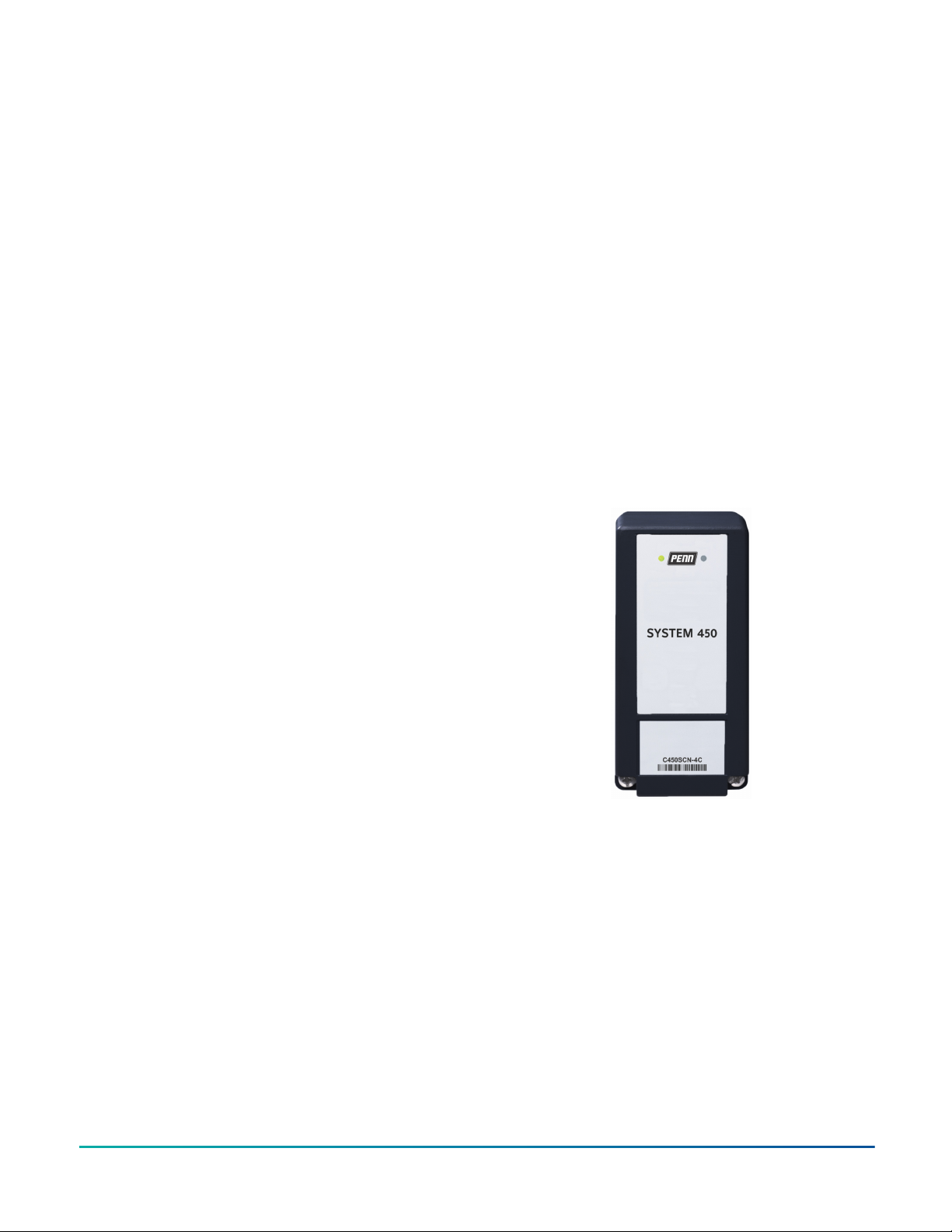

Expansion modules

Figure 6: C450SCN Relay Expansion Module

System 450 control modules with communications

A System 450 control module with communications

provides the same types of control as the standard control

modules. See Table 1 for capabilities of the System 450

control modules with communications.

C450CEN-1 control modules feature an RJ45 Ethernet

network port that enables you to connect your control

system to an Ethernet network and communicate across

it.

C450CRN-1 control modules feature an RS485 terminal

block that enables you to connect your control system to

an RS485 MODBUS network and communicate on it.

System 450 communications control modules do not

provide onboard outputs and require expansion modules

to provide outputs.

Other System 450 components

The System 450 suite of components enables you to

build a wide variety of cost-effective, custom control

systems that meet your specific application requirements;

System 450 Series Modular Controls Product Bulletin6

The System 450 expansion modules allow you to increase

the number of outputs in your control system to meet

your application requirements. The following models are

available:

• C450SBN-4 or C450SBG-4: Relay expansion module with

one relay output

• C450SCN-4 or C450SCG-4: Relay expansion module with

two relay outputs (Figure 6)

• C450SPN-4: Analog expansion module with one analog

output

• C450SQN-4: Analog expansion module with two analog

outputs

For further information, see Ordering Information and

Technical Specifications.

Power module

Figure 7: C450YNN power module

The System 450 modules require 24 VAC - Class 2 power.

The C450YNN-1 Power module (Figure 7) provides a

convenient means of transforming 120/240 VAC to 24 VAC

to power System 450 control systems.

System 450 compatible sensors and transducers

System 450 control modules are designed to operate with

a variety of compatible sensors and transducers. The

System 450 compatible sensors and transducers cover

a wide range of temperature, pressure, and humidity

conditions.

System 450 compatible sensors and transducers come in a

variety of styles and configurations, allowing you to select

the sensor or transducer that best fits your control system

requirements.

For ease of installation and setup, the Sensor Type

that you select in the UI for a sensor or transducer

automatically determines the sensed condition, unit of

measurement, minimum differential, setup value ranges,

and the default setup values for each control system

output that references the sensor or transducer.

See Table 4 for compatible A99 Series Temperature

Sensors (Figure 8). Refer to the A99B Series Temperature

Sensors Product/Technical Bulletin (LIT-125186) for further

information.

Figure 8: A99B Series temperature sensors

See Table 5 for compatible TE-6000 Series temperature

sensing elements (Figure 9). Refer to the TE-6000 Series

Temperature Sensing Elements Product Bulletin (LIT-216288)

for further information.

Figure 9: TE-6000-1 temperature sensing element

See Table 6 for compatible TE-6300 Series Temperature

Sensors (Figure 10). Refer to the TE-6300 Series

Temperature Sensors Product Bulletin (LIT-216320) for

further information.

Figure 10: TE-6300 Series temperature sensors

See Table 7 for compatible TE-6800 Series Wall Mount

Temperature Sensors (Figure 11). Refer to the TE-6800

Series Temperature Sensors Product Bulletin (LIT-12011542)

for more information.

System 450 Series Modular Controls Product Bulletin 7

Figure 11: TE-6800 Series wall mount temperature

sensor

See Table 9 for compatible HE-6800 Series Humidity

Transmitters with Temperature Sensors (Figure 12).

Refer to the HE-6800 Series Humidity Transmitters with

Temperature Sensor Product Bulletin (LIT-12011625) for more

information.

Figure 12: HE-6800 Series humidity transmitter with

temperature sensor

Figure 14: DPT265 Series low pressure differential

pressure transducers

See Table 11, Table 12, and Table 13 for compatible P599

Series pressure transducers (Figure 15). Refer to the P599

Series Electronic Pressure Transducers Product/Technical

Bulletin (LIT-12012446, Part No. 24-7664-3264) for more

information.

Figure 15: P599 Series pressure transducers

See Table 8 for compatible HE-69S0NP Type humidity

sensors with integral A99B temperature sensor (Figure

13). Refer to the HE-69xx Series Duct Probe Humidity and

Temperature Sensors Product Bulletin (LIT-12013478) for

more information.

Figure 13: HE-69SxONP humidity sensor

See Table 10 for compatible DPT265 Series low pressure

differential transducers (Figure 14). For further

information, see the Setra Systems Model DPT265 Very Low

Differential Pressure Transducer Catalog Page.

System 450 applications

You can create a wide variety of custom, applicationspecific control systems with System 450 modules.

The following are some common control application

examples, most of which can be enhanced by using one of

the System 450 control modules with Communication:

• Temperature control

• Pressure control

• Humidity control

• Multipurpose control

• Reset and setback control

• High input-signal selection

• Differential control

Temperature control

• Temperature monitoring and alarming

• On/Off staged control of boilers and chillers

• Proportional stage control of boilers and chillers

• Boiler and chiller pump control

• Heating and cooling control with deadband

• Floating temperature control of damper and valve

actuators

System 450 Series Modular Controls Product Bulletin8

• Cooling tower fan speed/stage control based on water

temperature

• Supply, make-up, and mixed air temperature control

• Temperature actuated valve control

• Supply and make-up air damper and fan control

• Condenser fan staging or speed control based on

condenser temperature

Refrigerant pressure control

• Condenser fan cycling and stage control

• Multispeed condenser fan control

• Floating pressure control of damper and valve

actuators

• Condenser fan speed and damper control

• High and low pressure cutout control

• Staged compressor control

• Cooling tower fan speed control based on high-side

pressure

• Direct speed control of EC condenser fan motors

(C450CPW-400 model)

Other pressure control

• Relief damper and fan control for building

pressurization

• Constant static pressure control

Humidity control

• On/Off humidification and dehumidification control

• Proportional humidification and dehumidification

control

• Multistage humidification and dehumidification control

• Humidity monitoring and alarming

Multipurpose control

• Temperature and pressure-based refrigeration rack

control

• Temperature and humidity control of wine cellars and

greenhouses

• Temperature, humidity, and static pressure control of

clean rooms and greenhouses

• Dehumidification with reheat control

Reset control

• Boiler supply water temperature reset control based on

outside air temperature

• Chiller supply water temperature reset control based

on outside air temperature

• VAV zone temperature control based on outside air

temperature

• Humidity reset based on outside air temperature

• Staged applications with run-time balancing

• Real-time Occupied/Unoccupied setback

Differential control

• Air and fluid pump-flow monitoring and alarming

• Air and fluid filter-status monitoring and alarming

• Chiller barrel flow monitoring, control, and alarming

• Solar air and water heating applications

System 450 control system examples

With System 450 control and expansion modules, you

can build a wide variety of cost-effective, custom control

systems. Each of the following examples is accompanied

by an illustration of the module assembly, including

wiring diagrams for system sensors and outputs.

For menu flow charts showing typical Main screens and

System Status screens, along with System Setup screens

and example setup values, refer to one of the following

technical bulletins:

• For control systems with standard control modules

and the control module with hybrid analog output,

refer to the System 450™ Series Modular Control

Systems with Standard Control Modules Technical Bulletin

(LIT-12011459).

• For control systems with reset control modules, refer

to the System 450™ Series Modular Control Systems with

Reset Control Modules Technical Bulletin (LIT-12011842).

• For control systems with communications control

modules, refer to the System 450™ Series Modular

Control Systems with Communications Control Modules

Technical Bulletin (LIT-12011826).

Note: The physical configurations, wiring, and setup

values shown in the following examples are meant

to illustrate typical control system applications and

control features. Your control applications may

require different modules, module configurations,

sensors, and wiring.

Multipurpose cooling application with Modbus communications

Figure 16 shows an example System 450 control system

with Modbus network communications that controls a

cooling system and provides condenser fan speed control.

Figure 16: Example system 450 Control with Modbus

communications showing a room cooling application

with condenser fan speed control

High input signal selection

• Pressure-based fan speed or fan cycling control on

multi-circuit condensers

• Temperature-based fan speed or fan cycling control on

multi-circuit condensers

System 450 Series Modular Controls Product Bulletin 9

Multipurpose application for a clean room

Figure 17 shows a standard System 450 control system

for a clean room application that controls temperature,

pressure, and humidity with both relay and analog

outputs.

System 450 solar water heating example with differential control

Figure 19 shows a Modbus System 450 control system

example of a solar water heating and storage application

that uses the differential control feature to control two

circulation pumps.

Figure 17: Example system 450 control showing a clean

room application that controls temperature, pressure,

and humidity simultaneously

Boiler water temperature reset example with three-staged boilers

Figure 18 shows a System 450 reset control system that

uses an outdoor air temperature master sensor and a

supply water temperature sensor configured to reset

the boiler supply water temperature relative to the

outdoor air temperature. This control system can also

be configured to use the run-time balancing feature to

equalize the time that each of the three boilers run.

Figure 18: Example System 450 reset control system

for a three-stage boiler with or without run-time

balancing

Figure 19: Example System 450 control system with

Ethernet communications showing a solar water

heating application that uses the differential control

feature

Ordering information

Table 2: System 450 modules and accessories ordering

information

Product code

number

C450CBN-4 Standard control module with LCD, four-button

C450CCN-4 Standard control module with LCD, four-button

C450CPN-4 Standard control module with LCD, four-button

C450CQN-4 Standard control module with LCD and four-

Product description

touchpad UI, and relay output; provides one relay

output (SPDT line-voltage relay) for SPDT control.

touchpad UI, and relay output; provides two

relay outputs (SPDT line-voltage relays) for SPDT

control.

touchpad UI, and analog output; provides

one analog output (0–10 VDC or 4–20 mA selfselecting signal) for proportional control.

button touchpad UI, and analog output; provides

two analog outputs (0–10 VDC or 4–20 mA selfselecting signals) for proportional control.

System 450 Series Modular Controls Product Bulletin10

Table 2: System 450 modules and accessories ordering

information

Product code

number

C450RBN-3 Reset control module with LCD, four-button

C450RCN-3 Reset control module with LCD, four-button

C450CEN-1 Control module with Ethernet communications,

C450CRN-1 Control module with RS485 Modbus

C450CPW-400 Hybrid analog output control module with LCD,

C450SBN-4 Relay output expansion module; provides one

C450SCN-4 Relay output expansion module; provides two

C450SBG-4 Relay output expansion module; provides one

C450SCG-4 Relay output expansion module; provides two

C450SPN-4 Analog output expansion module; provides

C450SQN-4 Analog output expansion module; provides

C450YNN-1 Power module; provides 24 V to System 450

Product description

touchpad UI, and SPDT relay output; provides one

SPDT output relay. One A99BC-25C temperature

sensor with 0.25 m (9-1/4 in.) silicon leads and

one A99BC-300C temperature sensor with 3 m (9

ft 10 in.) silicon leads are included in the box with

the Reset control Module.

touchpad UI, and SPDT relay output; provides two

SPDT output relays. One A99BC-25C temperature

sensor with 0.25 m (9-1/4 in.) silicon leads and

one A99BC-300C temperature sensor with 3 m (9

ft 10 in.) silicon leads are included in the box with

the reset control module.

LCD, and four-button touchpad UI. (No onboard

outputs available on control modules with

network communications capabilities.)

communications, LCD, and four-button touchpad

UI. (No onboard outputs available on control

modules with network communications

capabilities.)

four-button touchpad UI, hybrid analog output

and optional high input signal select; provides

one hybrid analog output and optional high input

signal select primarily used for variable-speed EC

motor speed control.

Only analog output 1 (OUTA1) can be configured

as a hybrid analog output and/or use the high

input signal selection feature. These features

are not available for any of the other outputs

in a System 450 control system that uses the

C450CPW-400C as the control module.

SPDT line-voltage relay output.

SPDT line-voltage relay outputs.

SPDT low voltage/current output.

SPDT low voltage/current relay outputs.

one analog output (0–10 VDC or 4–20 mA selfselecting signal) for proportional control.

two analog outputs (0–10 VDC or 4–20 mA selfselecting signals) for proportional control.

Module Assembly; 120 VAC or 240 VAC supply

power input terminals.

Table 3: System 450 mounting accessories

Product Code

Number

BKT287-1R DIN rail; 0.30 m (12 in.) long

BKT287-2R DIN rail; 1 m (39-1/3 in.) long

BKT287-3R DIN rail; 0.61 m (24 in.) long

BKT287-4R DIN rail; 0.36 m (14 in.) long

PLT344-1R DIN rail end clamps (2 clamps)

WHA-

C450-100C

Product Description

System 450 module connection extension cable,

100 cm (3.3 ft) long

Table 4: System 450 Compatible A99B Temperature

Sensors and accessories ordering information

1

Product code

number

A99BA-200C PTC silicon sensor with shielded cable; cable

A99BB-25C PTC silicon sensor with PVC cable; cable length

A99BB-200C PTC silicon sensor with PVC cable; cable length 2

A99BB-300C PTC silicon sensor with PVC cable; cable length 3

A99BB-500C PTC silicon sensor with PVC cable; cable length 5

A99BB-600C PTC silicon sensor with PVC cable; cable length 6

A99BC-25C PTC silicon sensor with high temperature silicon

Product description

1

length 2 m (6-1/2 ft);

Sensor temperature range: -40 to 120°C (-40 to

250°F)

Cable jacket temperature range: -40 to 100°C

(-40 to 212°F)

0.25 m (9-3/4 in.);

Sensor temperature range: -40 to 120°C (-40 to

250°F)

Cable jacket temperature range: -40 to 100°C

(-40 to 212°F)

m (6-1/2 ft);

Sensor temperature range: -40 to 120°C (-40 to

250°F)

Cable jacket temperature range: -40 to 100°C

(-40 to 212°F)

m (9-3/4 ft);

Sensor temperature range: -40 to 120°C (-40 to

250°F)

Cable jacket temperature range: -40 to 100°C

(-40 to 212°F)

m (16-3/8 ft);

Sensor temperature range: -40 to 120°C (-40 to

250°F)

Cable jacket temperature range: -40 to 100°C

(-40 to 212°F)

m (19-1/2 ft);

Sensor temperature range: -40 to 120°C (-40 to

250°F)

Cable jacket temperature range: -40 to 100°C

(-40 to 212°F)

cable; cable length 0.25 m (9-3/4 in.)

Sensor temperature range: -40 to 120°C (-40 to

250°F)

Cable jacket rated for full sensor temperature

range.

System 450 Series Modular Controls Product Bulletin 11

Table 4: System 450 Compatible A99B Temperature

Sensors and accessories ordering information

1

Product code

number

Product description

1

A99BC-300C PTC silicon sensor with high temperature silicon

cable; cable length 3 m (9-3/4 ft)

sensor temperature range: -40 to 120°C (-40 to

250°F)

Cable jacket rated for full sensor temperature

range.

A99BC-1500C PTC silicon sensor with high temperature silicon

cable; cable length 15 m (49 ft)

Sensor temperature range: -40 to 120°C (-40 to

250°F)

Cable jacket rated for full sensor temperature

range.

BOX10A-600R PVC enclosure for A99 sensor; includes wire nuts

and conduit connector for outdoor sensor

WEL11A-601R Immersion well for A99 sensor liquid sensing

applications

A99-CLP-1 Mounting clip for A99 temperature sensor

ADP11A-600R Conduit adaptor, 1/2 in. snap-fit EMT conduit

adaptor (box of 10)

TE-6001-1 Duct mounting hardware with handy box for

A99 sensor

TE-6001-11 Duct mounting hardware without handy box for

A99 sensor

SHL10A-603R Sun shield for use with outside A99 sensors in

sunny locations

1 Refer to the A99B Series Temperature Sensors Product/

Technical Bulletin (LIT-125186) for more information.

Table 5: System 450 Compatible TE-6000 Series 1,000

Ohm Nickel Temperature Sensors and accessories

ordering information

Product code

number

TE-6000-1

TE-6000-1x

TE-6000-6

Product description

TE6000 Series 1,000 ohms at 21°C (70°F) nickel

temperature sensors (only). Only the TE-6000-6

sensor can be used for the entire HI°C and

HI°F temperature range. Different sensing

element packages are available for various

applications. For a complete list of compatible

1,000 ohm nickel sensors, including sensor

descriptions, technical specifications, and

mounting accessories, refer to theTE-6000 Series

Temperature Sensing Elements Product Bulletin

(LIT-216288). (System 450 Sensor Types HI°C and

HI°F)

Table 6: System 450 Compatible TE-6300 Series 1,000

Ohm Nickel Temperature Sensors and accessories

ordering information

Product code

number

TE-631xx-x TE6300 Series 1,000 ohm at 21°C (70°F) nickel

Product description

averaging and 1,000 ohm thin-film nickel

temperature sensors only. For a complete

list of compatible 1,000 ohm nickel averaging

and thin-film nickel sensors, including sensor

descriptions, technical specifications, and

mounting accessories, refer to the TE-6300 Series

Temperature Sensors Product Bulletin (LIT-216320).

(System 450 Sensor Types HI°C and HI°F.)

Table 7: System 450 Compatible TE-68NT-0N00S 1,000

Ohm Nickel Temperature Sensor ordering information

Product code

number

TE-68NT-0N00S TE6800 Series 1,000 ohm at 21°C (70°F)

Product description

nickel temperature sensor for wall-mount

applications. For more information, including

sensor description, technical specifications,

and mounting accessories, refer to the TE-6800

Series Temperature Sensors Product Bulletin

(LIT-12011542).

Note: For correct readings, set the

temperature sensor to HI°C or HI°F.

Table 8: System 450 Compatible HE-69Sx0NP

Type Humidity Sensors with 100 ohm NTC nickel

temperature sensor ordering information

1

Product code

number

1

HE-69Sx0NP Duct mount humidity sensor with 1,000 ohm

1 The HE-69Sx0NP sensors require 24 VAC input and must

use the 0–5 VDC output. Refer to the HE-69xx Series Duct

Probe Humidity and Temperature Sensors Product Bulletin

(LIT-12013478) for more information, including technical

specifications and mounting accessories.

Product description

NTC nickel temperature sensor: 10% to 90% RH;

0 to 60°C (32 to 140°F)

System 450 Series Modular Controls Product Bulletin12

Table 9: System 450 Compatible HE6800 Series

Humidity Transmitters with Temperature Sensor

ordering information

1

Product code number

HE-68N2-0N00WS Wall mount humidity transmitter

HE-68N3-0N00WS Wall mount humidity transmitter

1 The HE-6800 transmitters require 24 VAC input and must

use the 0–5 VDC output. Refer to the HE-6800 Series Humidity

Transmitters with Temperature Sensor Product Bulletin

(LIT-12011625) for more information, including technical

specifications and mounting accessories.

1

Product description

with nickel temperature sensor:

10 to 90 ±2% RH; 0 to 55°C (32 to

131°F)

with nickel temperature sensor:

10 to 90 ±3% RH; 0 to 55°C (32 to

131°F)

Table 10: System 450 Compatible Low Pressure

Differential Transducer ordering information

1, 2

Product code number

DPT2650-R25B-AB Low pressure differential

DPT2650-0R5D-AB Low pressure differential

DPT2650-2R5D-AB Low pressure differential

DPT2650-005D-AB Low pressure differential

DPT2650-10D-AB Low pressure differential

1 Refer to the Setra Systems Model DPT265 Very Low Differential

Pressure Transducer Catalog Page for more information.

2 The DPT265 sensors require 24 VAC input and must use the

0–5 VDC output. Refer to the Setra Systems Model DPT265 Very

Low Differential Pressure Transducer Catalog Page for more

information.

3 Used only with communications control modules.

1,2

Product description

transducer: -0.25 to 0.25 in. W.C.

3

(System 450 Sensor Type:

ixia_locid="207">P 0.25)

transducer: 0 to 0.5 in. W.C.

(System 450 Sensor Type:

ixia_locid="213">P 0.5)

transducer: 0 to 2.5 in. W.C.

(System 450 Sensor Type:

ixia_locid="218">P 2.5)

transducer: 0 to 5.0 in. W.C.

(System 450 Sensor Type:

ixia_locid="223">P 5)

transducer: 0 to 10 in. W.C.

(System 450 Sensor Type:

ixia_locid="228">P 10)

3

Table 11: System 450 Compatible P599 Series

Transducers with 1/4 in. SAE 45 Flare Internal Thread

with Depressor (Style 47) ordering information

1

Product code

number

1

Product description

P599RCPS100C -10 to 100 psis, sealed for wet and freeze/

thaw applications; order WHA-PKD3 type wire

harness separately

P599RCPS100K -10 to 100 psis, sealed for wet and freeze/thaw

applications; WHA-PKD3-200C wire harness

included

P599RCPS102C 0 to 200 psis, sealed for wet and freeze/thaw

applications; order WHA-PKD3 type wire

harness separately

P599RCPS102K 0 to 200 psis, sealed for wet and freeze/thaw

applications; WHA-PKD3-200C wire harness

included

P599RCPS101C 0 to 100 psig; order WHA-PKD3 type wire

harness separately

P599RCPS101K 0 to 100 psig; WHA-PKD3-200C wire harness

included

P599RCPS105C 0 to 500 psig; order WHA-PKD3 type wire

harness separately

P599RCPS105K 0 to 500 psig; WHA-PKD3-200C wire harness

included

P599RCPS107C 0 to 750 psig; order WHA-PKD3 type wire

harness separately

P599RCPS107K 0 to 750 psig; WHA-PKD3-200C wire harness

included

1 The P599 sensors must be powered with the +5 VDC and C

terminals and the output is 0.5 to 4.5 VDC. Refer to the P599

Series Electronic Pressure Transducers Product/Technical Bulletin

(LIT-12012446, Part No. 24-7664-3264) for more information.

Table 12: System 450 Compatible P599 Series

Transducers with 1/8 in. 27 NPT External Thread (Style

49) ordering information

1

Product code

number

1

P599RAPS100C -10 to 100 psis, sealed for wet and freeze/

P599RAPS100K -10 to 100 psis, sealed for wet and freeze/thaw

P599RAPS102C 0 to 200 psis, sealed for wet and freeze/thaw

P599RAPS102K 0 to 200 psis, sealed for wet and freeze/thaw

P599RAPS101C 0 to 100 psig; order WHA-PKD3 type wire

P599RAPS101K 0 to 100 psig; WHA-PKD3-200C wire harness

Product description

thaw applications; order WHA-PKD3 type wire

harness separately

applications; WHA-PKD3-200C wire harness

included

applications; order WHA-PKD3 type wire

harness separately

applications; WHA-PKD3-200C wire harness

included

harness separately

included

System 450 Series Modular Controls Product Bulletin 13

Table 12: System 450 Compatible P599 Series

Transducers with 1/8 in. 27 NPT External Thread (Style

49) ordering information

1

Product code

number

1

Product description

P599RAPS102C 0 to 200 psig; order WHA-PKD3 type wire

harness separately

P599RAPS105C 0 to 500 psig; order WHA-PKD3 type wire

harness separately

P599RAPS105K 0 to 500 psig; WHA-PKD3-200C wire harness

included

P599RAPS107C 0 to 750 psig; order WHA-PKD3 type wire

harness separately

P599RAPS107K 0 to 750 psig; WHA-PKD3-200C wire harness

included

1 The P599 sensors must be powered with the +5 VDC and C

terminals and the output is 0.5 to 4.5 VDC. Refer to the P599

Series Electronic Pressure Transducers Product/Technical Bulletin

(LIT-12012446, Part No. 24-7664-3264) for more information.

Table 13: WHA-PKD3 Wire Harnesses ordering

information

1

Product code

number

1

WHA-PKD3-200C Plug and 3-Wire Harness for P599 Electronic

WHA-PKD3-400C Plug and 3-Wire Harness for P599 Electronic

WHA-PKD3-600C Plug and 3-Wire Harness for P599 Electronic

1 Refer to the P599 Series Electronic Pressure Transducers

Product/Technical Bulletin (LIT-12012446, Part No.

24-7664-3264) for more information.

Product description

Pressure Transducers: 2.0 m (6-1/2 ft) cable

Pressure Transducers: 4.0 m (13 ft) cable

Pressure Transducers: 6.0 m (19-5/8 ft) cable

System 450 Series Modular Controls technical specifications

Table 14: C450CPN-4 and C450CQN-4 Control Modules

with Analog Output technical specifications

Specification Description

Product C450CPN-4 and C450CQN-4: System 450

Control Module models are sensing controls

and operating controls with LCD, four-button

touchpad, and SPDT analog output

C450CPN-4: Control Module with one analog

output

C450CQN-4: Control Module with two analog

outputs

Power

consumption

Supply power Internal supply power: C450YNN-1 Power

Ambient

operating

conditions

Ambient shipping

and storage

conditions

Input signal 0 VDC to 5 VDC for humidity sensors and

Analog output

C450CPN-4: 1.3 VA maximum using 0 V to 10 V

out; 1.5 VA maximum using 4 mA to 20 mA out

C450CQN-4: 2.0 VA maximum using 0 to 10 V

out; 2.4 VA maximum using 4 mA to 20 mA out

Supply Module

External supply power: 24 VAC (20 VAC –

30 VAC) Safety Extra-Low Voltage (SELV)

(Europe), Class 2 (North America), 50/60 Hz,

10 VA minimum

Note: A System 450 control module or

module assembly can use an internal

or an external supply power source,

but must not be connected to both

simultaneously.

Temperature: -40 to 66°C (-40 to 150°F) when

using 0 VDC to 10 VDC outputs;-40 to 40°C (-40

to 104°F) when using 4 mA to 20 mA outputs

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

Temperature: -40 to 80°C (-40 to 176°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

static pressure transducers

0.5 VDC to 4.5 VDC for ratiometric pressure

transducers

1,035 ohms at 25°C (77°F) for A99 PTC

temperature sensors

1,000 ohms at 21.1°C (70°F) for TE-6xxx Nickel

temperature sensors

Voltage Mode (0–10 VDC):

10 VDC maximum output voltage

10 mA maximum output current

Requires an external load of 1,000 ohms or

more

The AO operates in Voltage Mode when

connected to devices with impedance greater

than 1,000 ohms. Devices that fall below

1,000 ohms may not operate as intended with

Voltage Mode applications.

Current mode (4 mA to 20 mA):

Requires an external load between 0–300

ohms

The AO operates in Current Mode when

connected to devices with impedance less

than 300 ohms. Devices that rise above 300

ohms may not operate as intended with

Current Mode applications.

System 450 Series Modular Controls Product Bulletin14

Table 14: C450CPN-4 and C450CQN-4 Control Modules

with Analog Output technical specifications

Specification Description

Analog input

accuracy

Control

construction

Dimensions

(H x W x D)

Weight C450CPN-4: 195 g (0.43 lb)

Compliance United States: cULus Listed; UL 60730-1, File

Resolution: 14 bits

Independently mounted control, surface

mounted with Lexan® 950 enclosure suitable

for DIN rail mounting or direct mounting to a

hard, even surface.

127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

C450CQN-4: 195 g (0.43 lb)

E27734; FCC Compliant to CFR47, Part 15,

Subpart B, Class B

Canada: cULus Listed; CAN/CSA-E60730-1, File

E27734; Industry Canada (IC) Compliant to

Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls declares

that this product is in compliance with the

essential requirements and other relevant

provisions of the EMC Directive.

Australia and New Zealand: RCM mark,

Australia/NZ Emissions Compliant

Table 15: C450CEN-1 Control Module with Ethernet

Communications technical specifications

Specification Description

Product C450CEN-1: System 450 control modules are

sensing controls and operating controls with

LCD and four-button touchpad UI, Ethernet

communications capability, and no outputs.

C450CEN-1: Control module with Ethernet

communications capability

Supply power Internal Supply Power: C450YNN-1 Power

Supply Module

External Supply Power: 24 VAC (20 VAC to

30 VAC) Safety Extra-Low Voltage (SELV)

(Europe), Class 2 (North America), 50/60 Hz,

10 VA minimum

Note: A System 450 control module or

module assembly can use an internal

or an external supply power source,

but must not be connected to both

simultaneously.

Ambient

operating

conditions

Ambient shipping

and storage

conditions

Input signal 0–5 VDC; 1,035 ohms at 25°C (77°F) for an A99

Analog input

accuracy

Temperature: -40 to 66°C (-40 to 150°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

Temperature: -40 to 80°C (-40 to 176°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

PTC Temperature Sensor

Resolution: 16 bits

Table 15: C450CEN-1 Control Module with Ethernet

Communications technical specifications

Specification Description

Control

construction

Dimensions (H x

W x D)

Weight C450CEN-1: 207 g (0.46 lb)

Compliance United States: cULus Listed; UL 60730-1, File

Independently mounted control, surface

mounted with Lexan® 950 enclosure suitable

for DIN rail mounting or direct mounting to a

hard, even surface.

127 x 63 x 63 mm (5 x 2-3/8 x 2-3/8 in.)

E27734; FCC Compliant to CFR47, Part 15,

Subpart B, Class B

Canada: cULus Listed; CAN/CSA-E60730-1, File

E27734; Industry Canada (IC) Compliant to

Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls declares

that this product is in compliance with the

essential requirements and other relevant

provisions of the EMC Directive.

Australia and New Zealand: RCM mark,

Australia/NZ Emissions Compliant

Table 16: C450CRN-1 Control Module with RS485

MODBUS Communications technical specifications

Specification Description

Product C450CRN-1: System 450 control modules are

sensing controls and operating controls with

LCD and four-button touchpad UI and no

outputs. This control module is an RS485, RTU

compliant MODBUS subordinate device.

Supply power Internal supply power: C450YNN-1 Power

Supply Module

External supply power: 24 VAC (20–30 VAC)

Safety Extra-Low Voltage (SELV) (Europe),

Class 2 (North America), 50/60 Hz, 10 VA

minimum

Note: A System 450 control module or

module assembly can use an internal

or an external supply power source,

but must not be connected to both

simultaneously.

Ambient

operating

conditions

Ambient shipping

and storage

conditions

Input signal 0–5 VDC; 1,035 ohms at 25°C (77°F) for an A99

Analog input

accuracy

Control

construction

Dimensions

(H x W x D)

Temperature: -40 to 66°C (-40 to 150°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

Temperature: -40 to 80°C (-40 to 176°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

PTC Temperature Sensor

Resolution: 16 bits

Independently mounted control, surface

mounted with Lexan® 950 enclosure suitable

for DIN rail mounting or direct mounting to a

hard, even surface.

127 x 63 x 63 mm (5 x 2-3/8 x 2-3/8 in.)

System 450 Series Modular Controls Product Bulletin 15

Table 16: C450CRN-1 Control Module with RS485

MODBUS Communications technical specifications

Specification Description

Weight C450CRN-1: 207 g (0.46 lb)

Compliance United States: cULus Listed; UL 60730-1, File

E27734; FCC Compliant to CFR47, Part 15,

Subpart B, Class B

Canada: cULus Listed; CAN/CSA-E60730-1, File

E27734; Industry Canada (IC) Compliant to

Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls declares

that this product is in compliance with the

essential requirements and other relevant

provisions of the EMC Directive; CISPR22, class

B

Australia and New Zealand: RCM mark,

Australia/NZ Emissions Compliant

Table 17: C450CPW-400 Control Module with Hybrid

Analog Output technical specifications

Specification Description

Product C450CPW-400 System 450 control module

is a sensing control and operating control

with LCD, four-button touchpad, and

analog output with pulse-width modulation

capability.

Power

consumption

Supply power Internal supply power: C450YNN-1 Power

Ambient

operating

conditions

Ambient shipping

and storage

conditions

Input signal 0–5 VDC for humidity sensors and static

C450CPW-400: 1.3 VA maximum using 0>–10 V

out; 1.5 VA maximum using 4 mA –20 mA out

Supply Module

External supply power: 24 VAC (20>–30 VAC)

Safety Extra-Low Voltage (SELV) (Europe),

Class 2 (North America), 50/60 Hz, 10 VA

minimum

Note: A System 450 control module or

module assembly can use an internal

or an external supply power source,

but must not be connected to both

simultaneously.

Temperature: -40 to 66°C (-40 to 150°F) when

using 0–10 VDC outputs; -40 to 40°C (-40 to

104°F) when using 4–20 mA outputs

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

Temperature: -40 to 80°C (-40 to 176°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

pressure transducers

0.5–4.5 VDC for ratiometric pressure

transducers

1,035 ohms at 25°C (77°F) for A99 PTC

temperature sensors

1,000 ohms at 21.1°C (70°F) for TE-6xxx Nickel

temperature sensors

Table 17: C450CPW-400 Control Module with Hybrid

Analog Output technical specifications

Specification Description

Analog output

Analog input

accuracy

Control

construction

Dimensions

(H x W x D)

Weight C450CPW-400: 195 g (0.43 lb)

Compliance United States: cULus Listed; UL 60730-1, File

Voltage mode (0–10 VDC):

10 VDC maximum output voltage

10 mA maximum output current

Requires an external load of 1,000 ohms or

more

The AO operates in Voltage Mode when

connected to devices with impedance greater

than 1,000 ohms. Devices that fall below

1,000 ohms may not operate as intended with

Voltage Mode applications.

Current mode (4–20 mA):

Requires an external load between 0–300

ohms

The AO operates in Current Mode when

connected to devices with impedance less

than 300 ohms. Devices that rise above 300

ohms may not operate as intended with

Current Mode applications.

Resolution: 14 bits

Independently mounted control, surface

mounted with LEXAN 950 enclosure suitable

for DIN rail mounting or direct mounting to a

hard, even surface.

127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

E27734; FCC Compliant to CFR47, Part 15,

Subpart B, Class B

Canada: cULus Listed; CAN/CSA-E60730-1, File

E27734; Industry Canada (IC) Compliant to

Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls declares

that this product is in compliance with the

essential requirements and other relevant

provisions of the EMC Directive.

Australia and New Zealand: RCM mark,

Australia/NZ Emissions Compliant

System 450 Series Modular Controls Product Bulletin16

Table 18: C450CBN-4 and C450CCN-4 Control Modules

with Relay Output technical specifications

Specification Description

Product C450CBN-4 and C450CCN-4: System 450

Control Module models are sensing controls

and operating controls with LCD, four-button

touchpad, and SPDT relay output

C450CBN-4: Control Module with one SPDT

output relay

C450CCN-4: Control Module with two SPDT

output relays

Power

consumption

Supply power Internal supply power: C450YNN-1 Power

Ambient

operating

Conditions

Ambient shipping

and storage

conditions

Input signal 0–5 VDC for humidity sensors and static

contacts

Analog input

accuracy

Control

construction

Dimensions

(H x W x D)

Weight C450CBN-4: 209 g (0.46 lb)

C450CBN-4: 0.9 VA maximum

C450CCN-4: 1.3 VA maximum

Supply Module

External supply power: 24 VAC (20–30 VAC)

Safety Extra-Low Voltage (SELV) (Europe),

Class 2 (North America), 50/60 Hz, 10 VA

minimum

Note: A System 450 control module or

module assembly can use an internal

or an external supply power source,

but must not be connected to both

simultaneously.

Temperature: -40 to 66°C (-40 to 150°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

Temperature: -40 to 80°C (-40 to 176°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

pressure transducers

0.5–4.5 VDC for ratiometric pressure

transducers

1,035 ohms at 25°C (77°F) for A99 PTC

temperature sensors

1,000 ohms at 21.1°C (70°F) for TE-6xxx Nickel

temperature sensors

General: 1/2 HP at 120/240 VAC, SPDTOutput relay

Specific:

AC Motor Ratings:

120 VAC

• AC Full-load amperes: 9.8 A

• Locked-rotor amperes: 58.8 A

208/240 VAC

• AC full-load amperes: 4.9 A

• Locked-rotor amperes: 29.4 A

10 amperes AC non-inductive at 24/240 VAC

Pilot duty: 125 VA at 24/240 VAC

Resolution: 14 bits

Independently mounted control, surface

mounted with LEXAN 950 enclosure suitable

for DIN rail mounting or direct mounting to a

hard, even surface.

127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

C450CCN-4: 222 g (0.49 lb)

Table 18: C450CBN-4 and C450CCN-4 Control Modules

with Relay Output technical specifications

Specification Description

Compliance United States: cULus Listed; UL 60730-1, File

E27734; FCC Compliant to CFR47, Part 15,

Subpart B, Class B

Canada: cULus Listed; CAN/CSA-E60730-1, File

E27734; Industry Canada (IC) Compliant to

Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls declares

that this product is in compliance with the

essential requirements and other relevant

provisions of the EMC Directive.

Australia and New Zealand: RCM mark,

Australia/NZ Emissions Compliant

Table 19: C450RBN-3 and C450RCN-3 Reset Control

Modules with Real-Time Clock and Relay Output

technical specifications

Specification Description

Product C450RBN-3 and C450RCN-3: System 450 Reset

Control Module models are sensing controls

and operating controls with LCD, four-button

touchpad, and SPDT relay output

C450RBN-3: Control Module with one SPDT

output relay

C450RCN-3: Control Module with two SPDT

output relays

Power

consumption

Supply power Internal supply power: C450YNN-1 Power

Ambient

operating

conditions

Ambient shipping

and storage

conditions

Input signal 0–5 VDC for humidity sensors

C450RBN-3: 0.9 VA maximum

C450RCN-3: 1.3 VA maximum

Supply Module

External supply power: 24 VAC (20–30 VAC)

Safety Extra-Low Voltage (SELV) (Europe),

Class 2 (North America), 50/60 Hz, 10 VA

minimum

Note: A System 450 control module or

module assembly can use an internal

or an external supply power source,

but must not be connected to both

simultaneously.

Temperature: -40 to 66°C (-40 to 150°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

Temperature: -40 to 80°C (-40 to 176°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

1,035 ohms at 25°C (77°F) for A99 PTC

temperature sensors

System 450 Series Modular Controls Product Bulletin 17

Table 19: C450RBN-3 and C450RCN-3 Reset Control

Modules with Real-Time Clock and Relay Output

technical specifications

Specification Description

General: 1/2 HP at 120/240 VAC, SPDTOutput relay

contacts

Clock accuracy ±4 minutes per year

Clock backup

power

Setback events One occupied and one unoccupied event per

Analog input

accuracy

Control

construction

Dimensions

(H x W x D)

Weight C450RBN-3: 209 g (0.46 lb)

Compliance United States: cULus Listed; UL 60730-1, File

Specific:

AC Motor ratings

120 VAC

• AC full-load amperes: 9.8 A

• AC locked-rotor amperes: 58.8 A

208/240 VAC

• AC full-load amperes: 4.9 A

• AC locked-rotor amperes: 29.4 A

10 amperes AC non-inductive at 24/240 VAC

Pilot duty: 125 VA at 24/240 VAC

12 hours, capacitor reserve

day; 7 day schedule

Resolution: 14 bits

Independently mounted control, surface

mounted with LEXAN 950 enclosure suitable

for DIN rail mounting or direct mounting to a

hard, even surface.

127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

C450RCN-3: 222 g (0.49 lb)

E27734; FCC Compliant to CFR47, Part 15,

Subpart B, Class B

Canada: cULus Listed; CAN/CSA-E60730-1, File

E27734; Industry Canada (IC) Compliant to

Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls declares

that this product is in compliance with the

essential requirements and other relevant

provisions of the EMC Directive.

Australia and New Zealand: RCM mark,

Australia/NZ Emissions Compliant

Table 20: C450SPN-4 and C450SQN-4 Expansion

Modules with Analog Output technical specifications

Specification Description

Product C450SPN-4: System 450 Expansion Module

with one Analog output

C450SQN-4: System 450 Expansion Module

with two Analog outputs

Power

consumption

Supply power Internal supply power: C450YNN-1 Power

Ambient

operating

conditions

Ambient shipping

and storage

conditions

Analog output

Control

construction

Dimensions

(H x W x D)

Weight C450SPN-4: 150 g (0.33 lb)

C450SPN-4: 1.1 VA max using 0–10 V out; 1.3

VA maximum using 4–20 mA out

C450SQN-4: 1.8 VA max using 0–10 V out; 2.2

VA maximum using 4–20 mA out

Supply Module

External supply power: 24 VAC (20–30 VAC)

Safety Extra-Low Voltage (SELV) (Europe),

Class 2 (North America), 50/60 Hz, 10 VA

minimum

Note: A System 450 control module or

module assembly can use an internal

or an external supply power source,

but must not be connected to both

simultaneously.

Temperature: -40 to 66°C (-40 to 150°F) when

using 0 to 10 VDC outputs; -40 to 40°C (-40 to

104°F) when using 4 to 20 mA outputs

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

Temperature: -40 to 80°C (-40 to 176°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

Voltage mode (0 to 10 VDC):

10 VDC maximum output voltage

10 mA maximum output current

Requires an external load of 1,000 ohms or

more

Note: The AO operates in Voltage

Mode when connected to devices with

impedance greater than 1,000 ohms.

Devices that drop below 1,000 ohms

may not operate as intended with

Voltage Mode applications.

Current mode (4 to 20 mA):

Requires an external load between 0 to 300

ohms

Note: The AO operates in Current

Mode when connected to devices

with impedances less than 300 ohms.

Devices that exceed 300 ohms may not

operate as intended with Current Mode

applications.

Independently mounted control, surface

mounted with Lexan® 950 enclosure suitable

for DIN rail mounting or direct mounting to a

hard, even surface.

127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

C450SQN-4: 150 g (0.33 lb)

System 450 Series Modular Controls Product Bulletin18

Table 20: C450SPN-4 and C450SQN-4 Expansion

Modules with Analog Output technical specifications

Specification Description

Compliance United States: cULus Listed; UL 60730-1, File

E27734; FCC Compliant to CFR47, Part 15,

Subpart B, Class B

Canada: cULus Listed; CAN/CSA-E60730-1, File

E27734; Industry Canada (IC) Compliant to

Canadian ICES-003, Class B limits

Europe: CE Mark - Johnson Controls declares

that this product is in compliance with the

essential requirements and other relevant

provisions the EMC Directive.

Australia and New Zealand: RCM mark,

Australia/NZ Emissions Compliant

Table 21: C450Sxx-4 Expansion Modules with Relay

Output technical specifications

Specification Description

Product C450SBN-4: System 450 Expansion Module

with one SPDT output relay

C450SCN-4: System 450 Expansion Module

with two SPDT output relays

C450SBG-4: System 450 Expansion Module

with one SPDT low current/voltage output

relay

C450SCG-4: System 450 Expansion Module

with two SPDT low current/voltage output

relays

Power

consumption

Supply power Internal supply power: C450YNN-1 Power

Ambient

operating

conditions

Ambient shipping

and storage

conditions

C450SBx-4: 0.8 VA maximum

C450SCx-4: 1.2 VA maximum

Supply Module

External supply power: 24 VAC (20–30 VAC)

Safety Extra-Low Voltage (SELV) (Europe),

Class 2 (North America), 50/60 Hz, 10 VA

minimum

Note: A System 450 control module or

module assembly can use an internal

or an external supply power source,

but must not be connected to both

simultaneously.

Temperature: -40 to 66°C (-40 to 150°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

Temperature: -40 to 80°C (-40 to 176°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

Table 21: C450Sxx-4 Expansion Modules with Relay

Output technical specifications

Specification Description

Output relay

contacts

Control

construction

Dimensions

(H x W x D)

Weight C450SBx-4: 172 g (0.38 lb)

Compliance United States: cULus Listed; UL 60730-1, File

C450SxN-4

General: 1/2 HP at 120/240 VAC, SPDT

Specific:

AC motor ratings:

120 VAC

• AC full-load amperes: 9.8 A

• Locked-rotor amperes: 58.8 A

208/240 VAC

• AC full-load amperes: 4.9 A

• Locked-rotor amperes: 29.4 A

10 amperes AC non-inductive at 24/240 VAC

Pilot duty: 125 VA at 24/240 VAC

C450SxG-4

General: 2 amperes resistive at 48 VDC

Pilot duty: 360VA at 120VAC

Recommended dry circuit rating:

400 mW maximum at 28 VAC/VDC

Independently mounted control, surface

mounted with Lexan® 950 enclosure suitable

for DIN rail mounting or direct mounting to a

hard, even surface.

127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

C450SCx-4: 186 g (0.41 lb)

E27734; FCC Compliant to CFR47, Part 15,

Subpart B, Class B

Canada: cULus Listed; CAN/CSA-E60730-1, File

E27734; Industry Canada (IC) Compliant to

Canadian ICES-003, Class B limits

Europe: CE Mark - Johnson Controls declares

that this product is in compliance with the

essential requirements and other relevant

provisions the EMC Directive.

Australia and New Zealand: RCM mark,

Australia/NZ Emissions Compliant

Table 22: C450YNN-1 Power Supply Module technical

specifications

Specification Description

Product C450YNN-1: System 450 Power Supply

Module; 120 or 240 VAC stepdown to 24 VAC

Class 2 (North America) or SELV (Europe),

50/60 Hz, 10 VA minimum

Supply power 110/120 VAC or 220/240 VAC at 50/60 Hz (100

mA maximum)

Secondary power 24 VAC, 10 VA

Ambient

operating

Conditions

Ambient shipping

and storage

conditions

Temperature: -40 to 66°C (-40 to 150°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

Temperature: -40 to 80°C (-40 to 176°F)

Humidity: Up to 95% RH noncondensing;

maximum dew point 29°C (85°F)

System 450 Series Modular Controls Product Bulletin 19

Table 22: C450YNN-1 Power Supply Module technical

specifications

Specification Description

Control

construction

Dimensions

(H x W x D)

Weight C450YNN-1: 390 gm (0.86 lb)