Penn C450CBN, C450CCN, C450CPN, C450CQN, C450CPW Technical Bulletin

...

System 450 Series Modular Control

Systems with Standard Control Modules

Technical Bulletin

C450CBN, C450CCN, C450CPN, C450CQN, C450CPW, C450SPN, C450SQN, C450SBN, C450SCN, C450YNN

Johnson Controls LIT-12011459

www.penncontrols.com

2021-07-21

2 System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin

Contents

Contents

Introduction.................................................................................................................................................... 5

System 450 Overview..................................................................................................................................... 5

System 450 Control Systems with standard control modules....................................................... 6

Control module and UI....................................................................................................................... 7

Expansion modules, module assemblies, and outputs.................................................................. 9

Module assemblies, output types, and output numbers...................................................................... 9

Hybrid analog output........................................................................................................................ 10

System 450 compatible sensors and transducers......................................................................... 11

System 450 sensors and transducers for standard control modules................................................ 12

Binary input sensor.................................................................................................................................. 13

System 450 functional sensors............................................................................................................... 13

Relay outputs............................................................................................................................................ 14

Analog outputs......................................................................................................................................... 18

High input signal selection............................................................................................................... 24

Differential control............................................................................................................................ 24

Sensor Failure mode................................................................................................................................ 26

System 450 control system examples............................................................................................. 26

Control system example......................................................................................................................... 26

Hybrid analog and high input signal selection control system example.......................................... 31

Designing and building System 450 control systems.............................................................................. 33

Selecting, installing, and setting up sensors............................................................................................ 33

Assembling System 450 modules............................................................................................................... 34

Locating System 450 modules.................................................................................................................... 34

Mounting....................................................................................................................................................... 34

Mounting modules on DIN rail........................................................................................................ 34

Direct-mounting modules................................................................................................................ 35

Wiring System 450 components................................................................................................................. 35

Wiring System 450 sensors and transducers................................................................................. 39

Setting up a System 450 control system................................................................................................... 39

Determining output numbers and output types........................................................................... 39

System 450 UI navigation guidelines.............................................................................................. 40

Accessing and navigating the UI..................................................................................................... 40

Viewing the System Status screens....................................................................................................... 41

Accessing the System Setup screens..................................................................................................... 41

Setting up the sensors and transducers........................................................................................ 43

Setting up control system outputs............................................................................................................ 45

Relay output setup............................................................................................................................ 45

Setting up a relay output.................................................................................................................. 46

Analog output setup......................................................................................................................... 48

Setting up an analog output.................................................................................................................. 49

Pulse region hybrid analog output setup............................................................................................. 51

System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin 3

Setting up a pulse region hybrid analog output.................................................................................. 51

Setting up outputs that reference a P 110 sensor............................................................................... 52

Determining the integration constant for an analog output................................................................. 53

Testing the slowest to fastest time integral to determine I-C setting........................................ 53

Using the response time to a step change to determine the I-C Setting................................... 54

Troubleshooting System 450 control systems.......................................................................................... 56

Specified voltage ranges for sensors.............................................................................................. 56

Repair and ordering information............................................................................................................... 57

Related documentation............................................................................................................................... 61

System 450 Series Modular Control Systems with Standard Control modules technical specifications

62

North American emissions compliance..................................................................................................... 67

United States...................................................................................................................................... 67

Canada................................................................................................................................................ 67

Glossary of terms......................................................................................................................................... 68

Product warranty......................................................................................................................................... 76

Single point of contact................................................................................................................................. 76

Contact information..................................................................................................................................... 76

System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin4

Introduction

This document describes the System 450™ features and functions, and provides guidelines and

instructions to design, select, install, set up, and troubleshoot the System 450 controls that use

standard control modules (C450CBN-4, C450CCN-4, C450CPN-4, C450CQN-4) or the hybrid analog

output module (C450CPW-400).

This document also provides information and instructions to select, install, and set up sensors,

expansion modules, and the power module in your control systems with standard control modules

or the hybrid analog control module.

This document also provides System 450 Related Documentation and references to System 450

System 450 Overview.

For information about System 450 modules with reset control (C450RxN-x), refer to the System 450

Series Modular Control Systems with Reset Control Modules Technical Bulletin (LIT-12011842).

For information about System 450 modules with network communications, refer to the System 450

Series Modular Control Systems with Communications Control Modules Technical Bulletin (LIT-12011826).

Important: Use this System 450 Series Modular Control Systems with Standard Control

Modules only as an operating control. Where failure or malfunction of the System 450 Control

System could lead to personal injury or property damage to the controlled equipment or

other property, additional precautions must be designed into the control system. Incorporate

and maintain other devices, such as supervisory or alarm systems or safety or limit controls,

intended to warn of or protect against failure or malfunction of the System 450 Control

System.

Important: Utiliser ce System 450 Series Modular Control Systems with Standard Control

Modules uniquement en tant que dispositif de contrôle de fonctionnement. Lorsqu'une

défaillance ou un dysfonctionnement du System 450 Control System risque de provoquer des

blessures ou d'endommager l'équipement contrôlé ou un autre équipement, la conception

du système de contrôle doit intégrer des dispositifs de protection supplémentaires. Veiller

dans ce cas à intégrer de façon permanente d'autres dispositifs, tels que des systèmes de

supervision ou d'alarme, ou des dispositifs de sécurité ou de limitation, ayant une fonction

d'avertissement ou de protection en cas de défaillance ou de dysfonctionnement du [nom

abrégé de l'appareil].

System 450 Overview

The System 450 Series is a family of compact digital electronic control, expansion, and power

modules that you can assemble and set up to provide on/off and proportional control of

temperature, pressure, and humidity conditions in a wide variety of HVAC, commercial, or industrial

process applications.

The System 450 Series replaces the System 350 Series and System 27 Series control systems, and

provides more features and flexibility with fewer model variations. Most System 350 and System 27

modules are designed for single condition applications, such as temperature, pressure, or humidity;

you cannot configure them to control multiple conditions with a single control system. Based on the

control module model you have, a single System 450 control system can monitor and control both

temperature and humidity, or temperature, pressure, and humidity simultaneously.

Note: System 450 modules are not compatible with System 350 or System 27 modules.

However, you can build all of the System 350 and System 27 control systems and many more

with fewer System 450 modules.

The System 450 Series has several model variations. Each module is designed to be multi-purpose,

adaptable, and completely field configurable for temperature, pressure, and humidity applications.

Use the System 450 Series to build a wide range of inexpensive, compact, durable, and versatile

5System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin

custom control systems to monitor and control multiple control loops in your controlled system. A

System 450 control system can monitor temperature, pressure, and humidity simultaneously and

control up to 10 analog, relay, or both outputs based on the monitored conditions.

Note: System 450 communications control modules, System 450 standard control modules,

and the System 450 control module with hybrid analog output can monitor and control

temperature, pressure, and humidity applications simultaneously. System 450 reset control

modules can monitor and control temperature and humidity applications simultaneously.

A System 450 standard control system includes the following features:

• A single System 450 standard control module that provides the control system UI to set up,

monitor, and control your system and the sensor wiring terminals for connecting the sensors

to your control system

• One to 10 outputs provided by the control module and expansion modules. Each output

provides either on/off control or a proportional analog signal of 0 VDC to 10 VDC or 4 mA to 20

mA to the equipment in your controlled system

• One to three sensors or transducers that you can hard-wire directly to the control module and

can provide input signals to monitor and control your system equipment

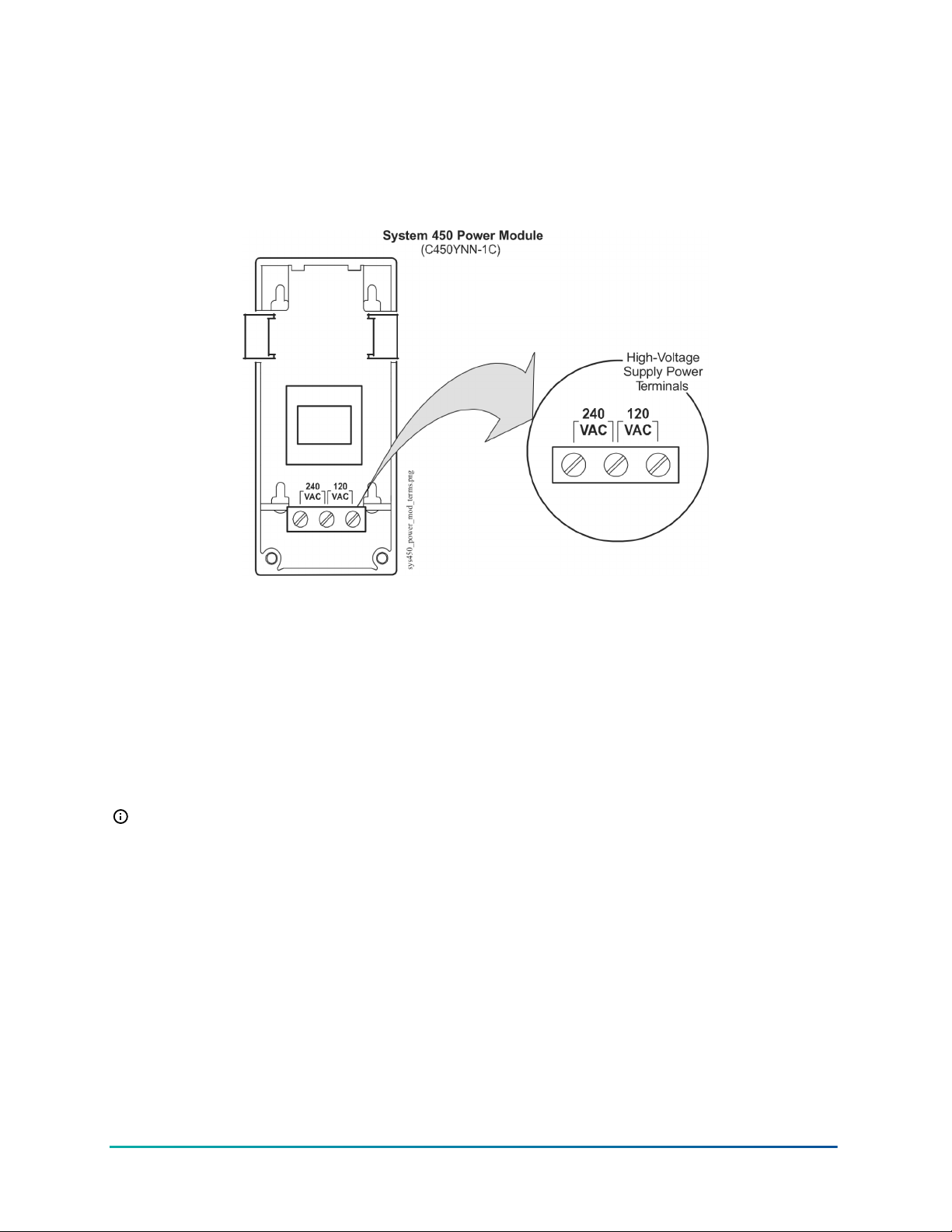

• An optional power module to provide power to the connected control module and expansion

modules

See Table 12 for a list of System 450 modules that can be used in standard and hybrid analog

output control systems. Refer to the System 450 Series Modular Controls Product Bulletin

(LIT-12011458) for a complete list and description of the System 450 modules, compatible sensors

and transducers, and accessories.

System 450 Control Systems with standard control modules

A System 450 Control system with a standard control module can provide the following types of

control to your application:

• On/off control: includes multi-stage control for temperature, pressure, and humidity

applications. See Relay Outputs.

• Proportional analog control: includes multi-stage control for temperature, pressure, and

humidity applications. See Analog Outputs.

• Combination of on/off relay and analog output control: includes up to 10 outputs for each

control system and any combination of relay and analog outputs.

• Multi-stage control for relay or analog: for temperature, pressure, and humidity

applications.

• Multi-purpose control: includes simultaneous monitoring and control of temperature,

pressure, and humidity conditions.

• Stand-alone control: a single standard control module that you can configure to replace a

wide variety of specialized controls in the field.

• Binary input control: connect a set of binary contacts or dry contacts to any System 450 input

and control your system’s relay outputs. See Binary Input Control for Relay Outputs.

• Direct and reverse action proportional control. See Direct and Reverse Control Actions for

Analog Outputs.

• Proportional plus integral control. See Proportional Plus Integral Control and Integration

Constants.

System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin6

• High input signal selection: monitor a condition with two or three identical sensors at

different locations in your controlled system and control system outputs according to the

highest condition value monitored by the sensors. See High Input Signal Selection.

• Differential control: monitor and control a condition differential in a controlled system; for

example, the water pressure drop across an in-line water filter. See Differential Control.

• Hybrid analog output control: C450CPW-400 enables an analog VDC output to transition to

a pulse output at low signal levels to provide more efficient low-speed control of electronically

commutated (EC) motors in condenser fan applications. See Hybrid Analog Output.

• Output update rate: select the rate at which an analog output updates the output signal to

the controlled equipment. See Analog Output Update Rate.

• Output signal deadband : create a deadband for the analog output signal within which the

output signal strength remains constant. See Analog Output Deadband.

• Four time control parameters : set up the relay outputs with On or Off time delays and

minimum On or Off times. See Relay On and Off Duration Control.

• On/off delay: configure an on delay for the time between a setpoint trip and the energizing of

a relay, and an off delay for the time between a setpoint trip and the de-energizing of a relay.

Note: The C450CPW-400 model only provides a hybrid analog output for direct control of EC

motors. See Hybrid Analog Output.

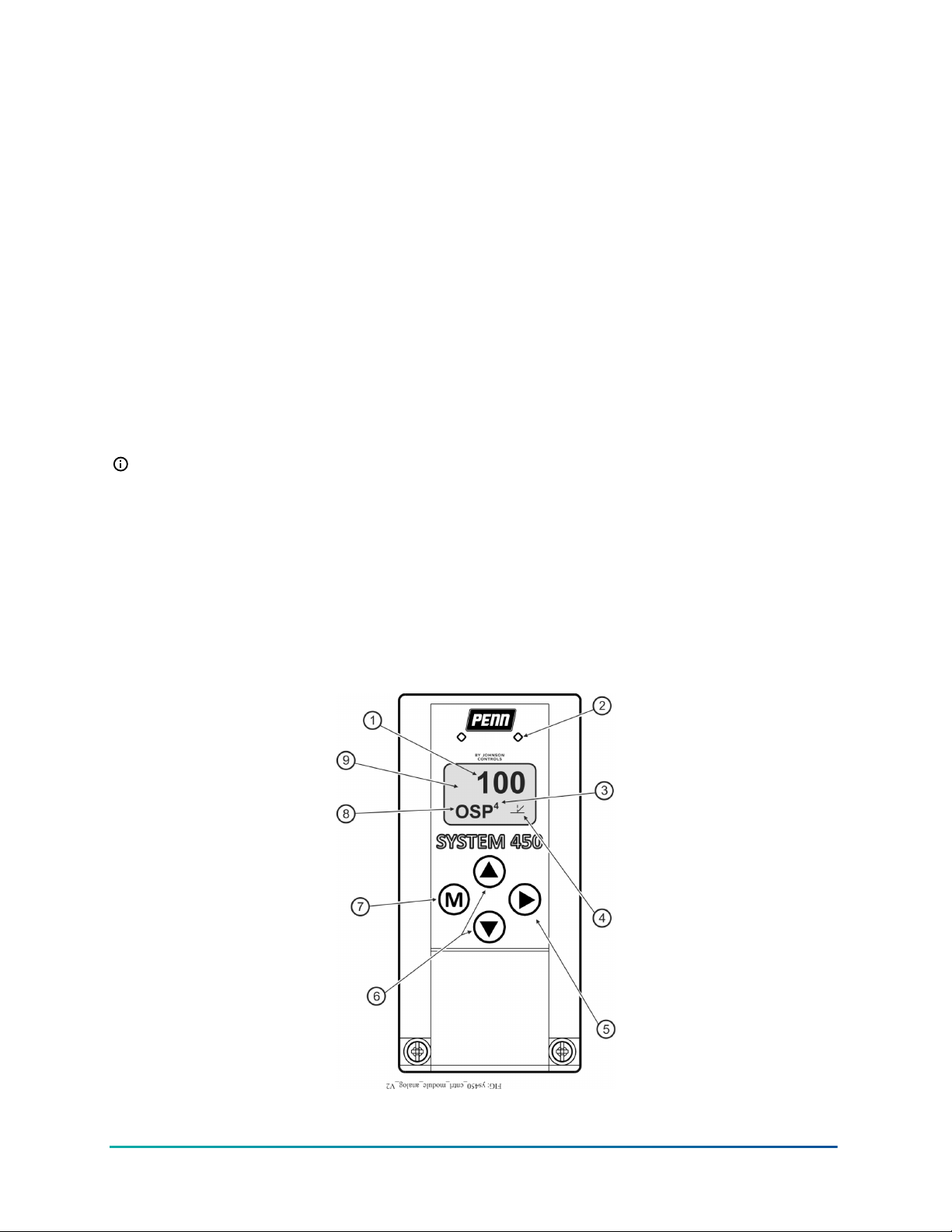

Control module and UI

Each System 450 standard control system requires a single control module. System 450 Control

modules have an LCD that you can use to set up and monitor your control system, along with a

four-button touchpad to navigate the control system status and setup screens, and set up the

system parameters. Figure 1 shows a control module and Table 1 describes the features of the

System 450 control system UI for control modules.

Figure 1: System 450 control module output analog LEDs, LCD, four-button touchpad UI

7System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin

Table 1: System 450 control module output analog LEDs, LCD, four-button touchpad UI

Callout Feature Description

1 Status or setup value Displays the current input status, output status, or setup parameter value for

the displayed input for the Main screens. Press Up or Down to select a different

parameter value when the value flashes. Here, 100 = 100%.

2 LED Green LEDs on the control module and expansion modules indicate if the associated

relay or analog output is on or off. If the analog output is partially on between 0 V–10

V, the LED blinks. The higher the output signal strength, the longer the LED is on.

3 Output number Displays a numerical value that identifies the output associated with the status or

setup value shown on the screen. Output numbers are automatically determined

by the outputs' physical positions of left to right in the module assembly. Here, 4 =

Output 4.

4 Control Ramp icon Displays whether an analog output is set as direct-acting or reverse-acting, and

whether the output signal strength is at minimum or maximum when the sensed

property is at setpoint. The control ramp icon displayed is determined by the

output's SP, EP, OSP, and OEP setup values.

5 Next button In the Main screens, press Next to scroll through the system status screens. In a

setup screen, press Next to save the flashing setup value and go to the next setup

screen.

6 Up and Down buttons Press Up or Down to select a different value for any flashing value in the setup value

field. In the Main sensor status screens, press and hold both Up and Down for 5

seconds to access the setup Start screens.

7 Menu button Press M to move through the sensor and output setup start screens. When you

move through the status or setup screens, press M to return to the status start

screen or setup start screen.

8 Status or setup identifier Displays the unit of measurement, output, sensor number, or setup parameter for

the displayed status or setup value. Here, the setup identifier OSP represents %

output signal strength at setpoint.

9 LCD Backlit LCD screen. The LCD brightness is adjustable. During normal operation, the

LCD displays the main screens.

Standard System 450 control modules are available with one or two relay outputs or with one or

two analog outputs and the standard System 450 firmware. See Table 12 for model descriptions and

System 450 Control Systems with Standard Control Modules for more information.

The System 450 control module with hybrid analog output has a single analog output that can be

configured as a hybrid analog output to optimize and extend the controlled speed range of variable

speed EC motors. See Hybrid Analog Output for more information.

All System 450 control modules can control both relay outputs and analog outputs, regardless of

the type of outputs that the control module has on-board. You set up all of the sensors and all of

the relay and analog outputs, including the expansion module outputs, in the control module UI.

You can also configure a standard control module as a simple stand-alone control system when

your application requires only one or two relay outputs, or one or two analog outputs.

During normal operation, the LCD displays the Main System 450 sensor status screens, which

automatically scroll through and display the status of the hard-wire and functional sensors in your

control system. You can also view the status of all the outputs in your control system and access

the System Setup screens from the Main screens in the System 450 UI. See Setting up a System 450

Control System.

The System 450 System Status screens display the status of each output in the control system in

addition to the sensor status screens. A relay output status displays as On or OFF. An analog output

status displays as a percentage of the total output signal strength, 0% to 100%. The analog output

status screens also display an icon that indicates the control action of the analog output. See Direct

and Reverse Control Actions for Analog Outputs.

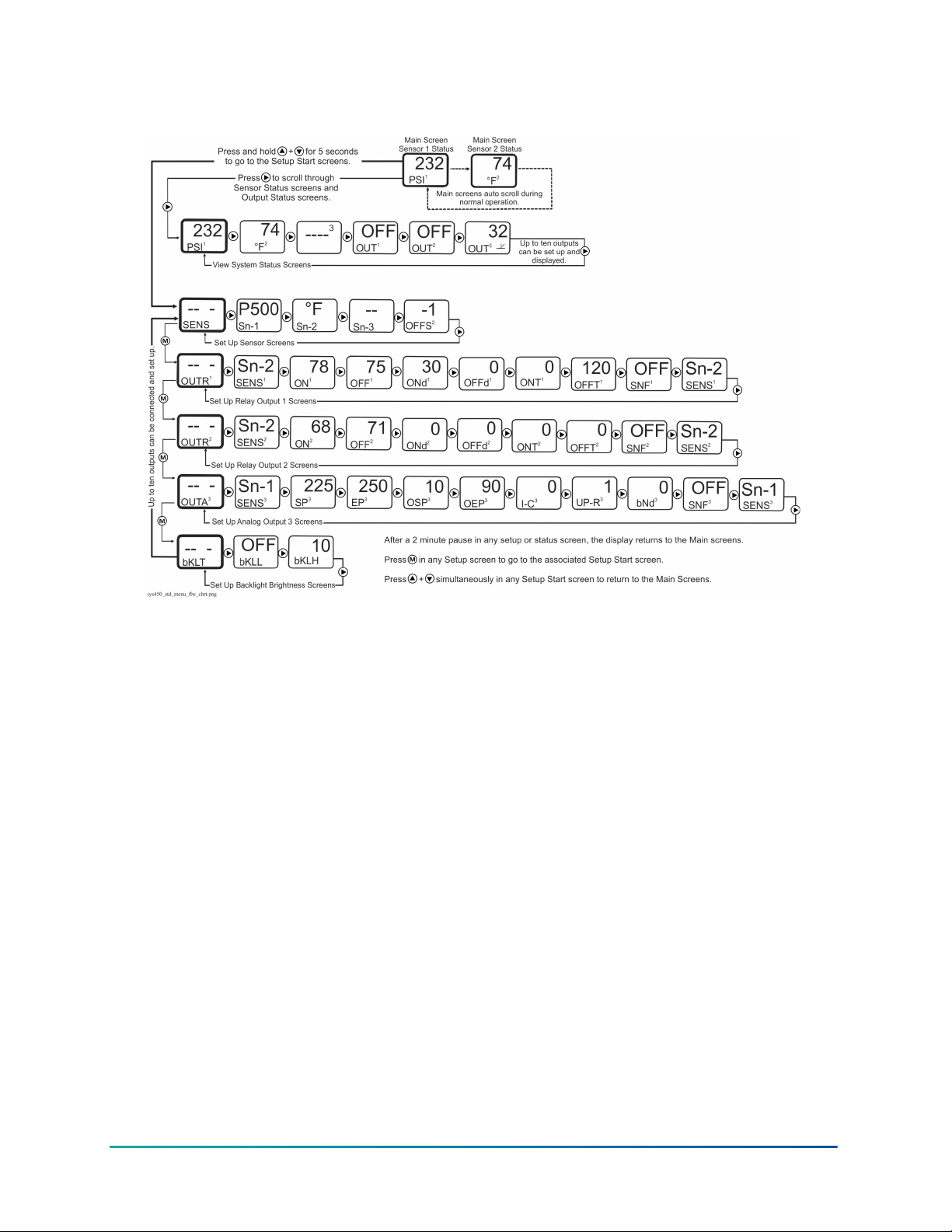

Figure 3 illustrates the System 450 UI navigation paths, parameter designations, and values for

the control system example, shown in Figure 2, using a System 450 standard control module.

System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin8

Figure 3 shows the Main screens, the Sensor Status screens, the System Status screens, the System

Setup screens, and the Output Setup screens for examples of the System 450 standard control

application.

Expansion modules, module assemblies, and outputs

System 450 expansion modules provide additional outputs to expand your control systems and

meet your specific application requirements.

A System 450 control system provides up to 10 outputs, and can consist of any combination of relay

and analog outputs. Expansion modules are available with one or two relay outputs, or with one or

two analog outputs. See Table 12 for information about the System 450 modules that you can use in

a control system.

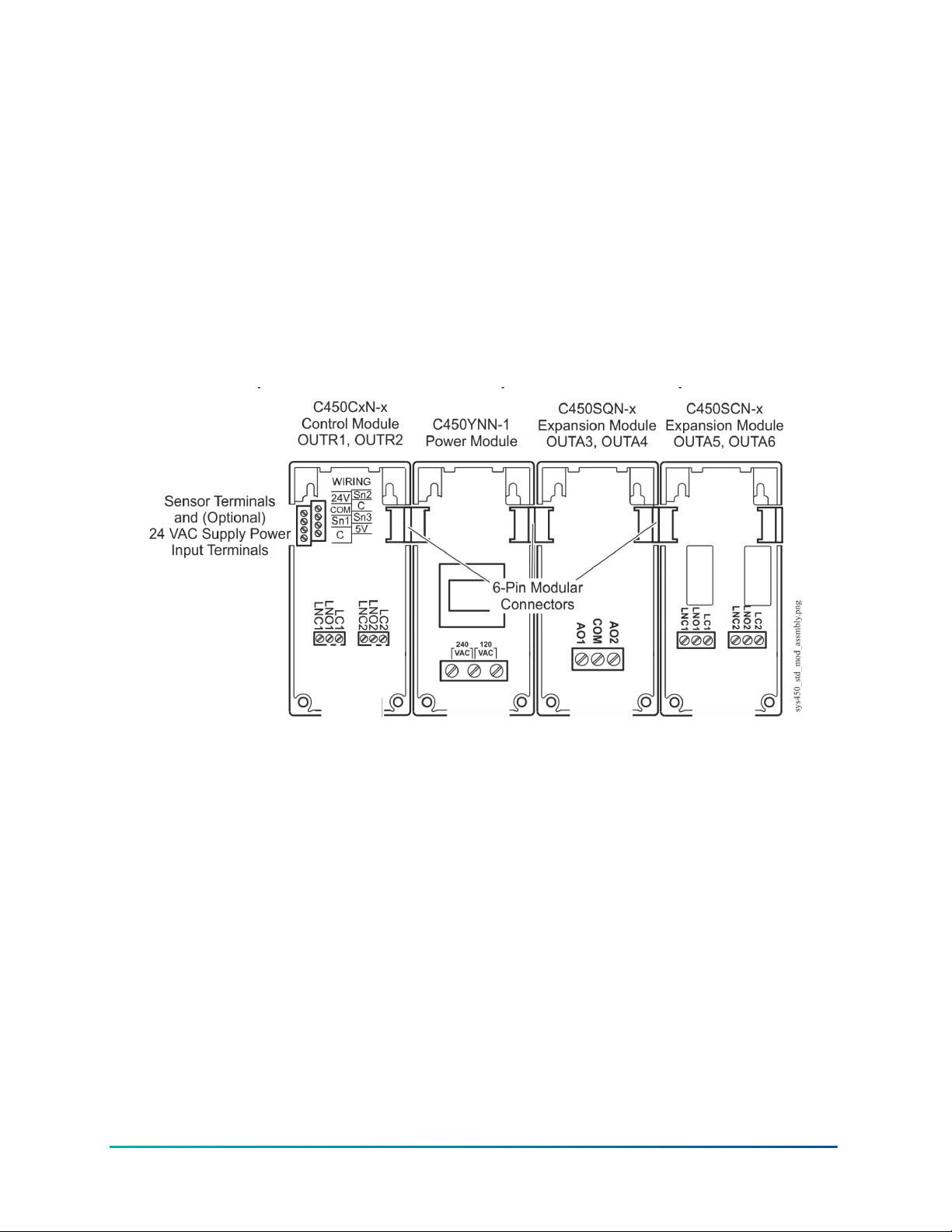

Figure 2: System 450 module assembly example showing standard control module and

expansion module positions, output positions, and output numbers

Module assemblies, output types, and output numbers

You can plug System 450 modules together using the 6-pin connectors located on the sides of the

modules’ housings and mount these module assemblies on a recommended standard 35 mm DIN

rail or directly to a hard, even surface. See Mounting.

Figure 2 shows a System 450 module assembly example, the module positions, the output types,

and the automatically assigned output numbers that the System Setup screens in the control

module UI use.

The control module is always mounted on the left side of the module assembly. If a System 450

power module is used, the power module is always plugged into the right side of the control

module. If expansion modules are used, you can plug them into the assembly in any order on the

right side of the power module, or on the right side the control module, if a power module is not

used in the assembly. See Assembling System 450 Modules.

Each time a System 450 module assembly is powered on, the control module polls all of the

modules to identify if the output type is relay or analog, and assigns an output number from 1 to

9 and 0 = 10 to each output, starting with the first output of the control module, and then polling

each expansion module connected to the right. Output numbers display on the control module

LCD to identify the output that you view as you navigate the system status and setup screens in the

System 450 UI (Figure 3).

9System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin

Figure 3: System 450 control module UI menu flow chart example showing navigation paths

and example settings in the Main, System Status, Sensor Setup, and Output Setup screens

Hybrid analog output

You can use the C450CPW-400 control module with variable speed EC fan motors on a wide variety

of refrigeration and HVAC condensing units.

The C450CPW-400 module has a single onboard analog output that you can configure as a hybrid

analog output to optimize and extend the controlled speed range of variable speed EC motors. You

can also set up the onboard analog output for High Input Signal Selection to enable precise and

efficient EC motor speed control on multi-circuit condensing units.

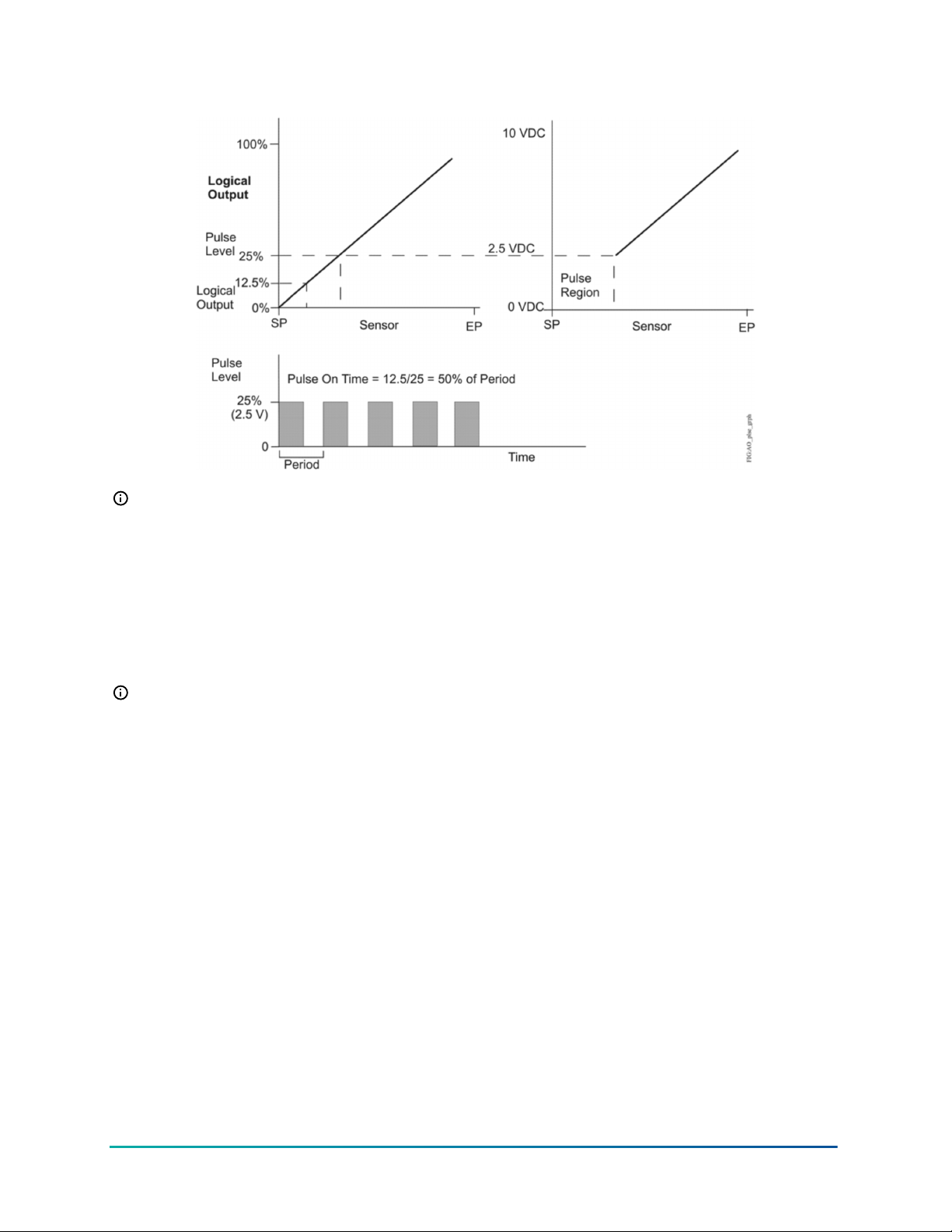

Hybrid analog output control enables the C450CPW-400 control module’s hybrid analog output

to transition between a pulse output and a standard VDC output, depending on the sensor value

relative to the proportional band. At low output levels, the pulse output signal provides an average

motor speed that is less than the EC motor’s fixed minimum speed (Figure 4).

System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin10

Figure 4: Pulse signal with pulse level = 25% and logical output = 12.5%

Note: You can configure Analog Output 1 (OUTA1) only on the C450CPW-400 control module

as a hybrid analog output and use the High Input Signal Selection feature. These features are

not available for any of the other outputs in control systems that use a C450CPW-400 control

module.

System 450 compatible sensors and transducers

System 450 standard control modules can operate with a variety of compatible sensors and

transducers. The System 450 compatible sensors and transducers cover a wide range of

temperature, pressure, and humidity conditions.

Note: System 450 compatible sensors consist of temperature sensors, humidity sensors,

and pressure transducers. The term sensor refers to all System 450 compatible input devices

including transducers, unless noted otherwise.

System 450 compatible sensors also come in a variety of styles and configurations; you can select

the sensor or transducer that best fits your control system requirements. See Table 14 through

Table 23 in Repair and ordering information for more information about System 450 compatible

sensors for communications control modules.

You can connect up to three sensors to a System 450 control module at the low-voltage terminal

block. See Wiring System 450 Components for more information on System 450 sensor wiring

terminals on control modules. Refer to the System 450 module installation instructions and the

sensor installation instructions referenced in System 450 Overview for information about how to

install, wire, operate, troubleshoot, and replace System 450 compatible sensors.

For each sensor in your control system, select the sensor’s corresponding Sensor Type when you

set up the sensors in the System 450 UI. A sensor’s corresponding Sensor Type determines the

controlled condition, unit of measurement, minimum differential, setup values, and ranges for each

output that is set up to reference the sensor.

See Table 2 for information about Sensor Types, the corresponding output setup values and ranges,

sensor models, and transducer models used in standard System 450 control systems.

The System 450 control automatically designates the sensor connected to the Sn1 terminal and

a common (C) terminal as the Sn-1 sensor in the UI. The sensor connected to the Sn2 and a C

11System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin

terminal is designated Sn-2, and the sensor connected to Sn3 and a C terminal is designated Sn-3.

You set up each sensor in the corresponding sensor setup screens in the UI.

Note: For a System 450 control system to operate properly, you must wire the correct sensor

or transducer model to the correct sensor input terminals on the control module and select

the correct Sensor Type in the corresponding Select Sensor Type screen in the System 450 UI.

See Setting up a System 450 Control System and Setting Up the Sensors and Transducers for more

information and procedures about how to set up sensors and Sensor Types in the System 450 UI.

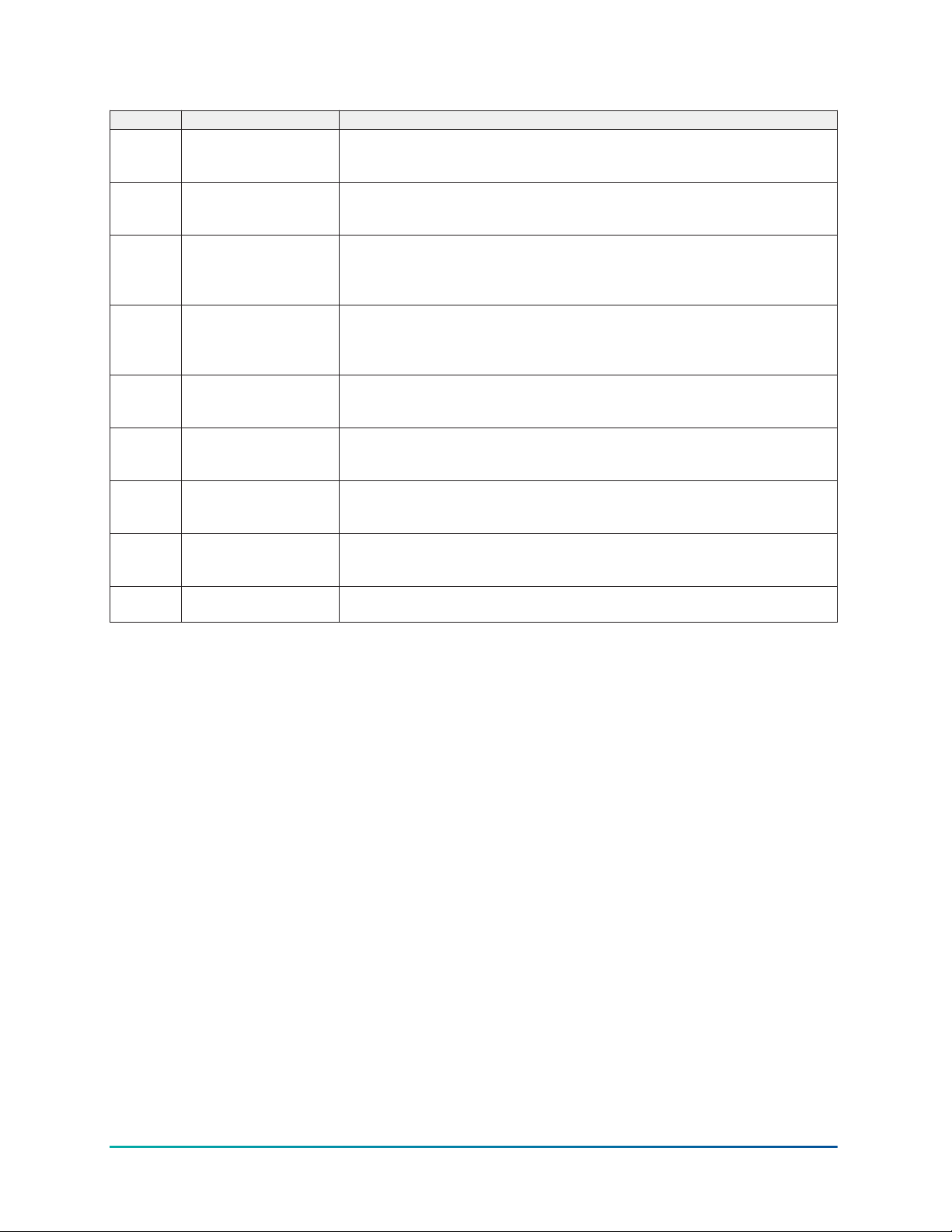

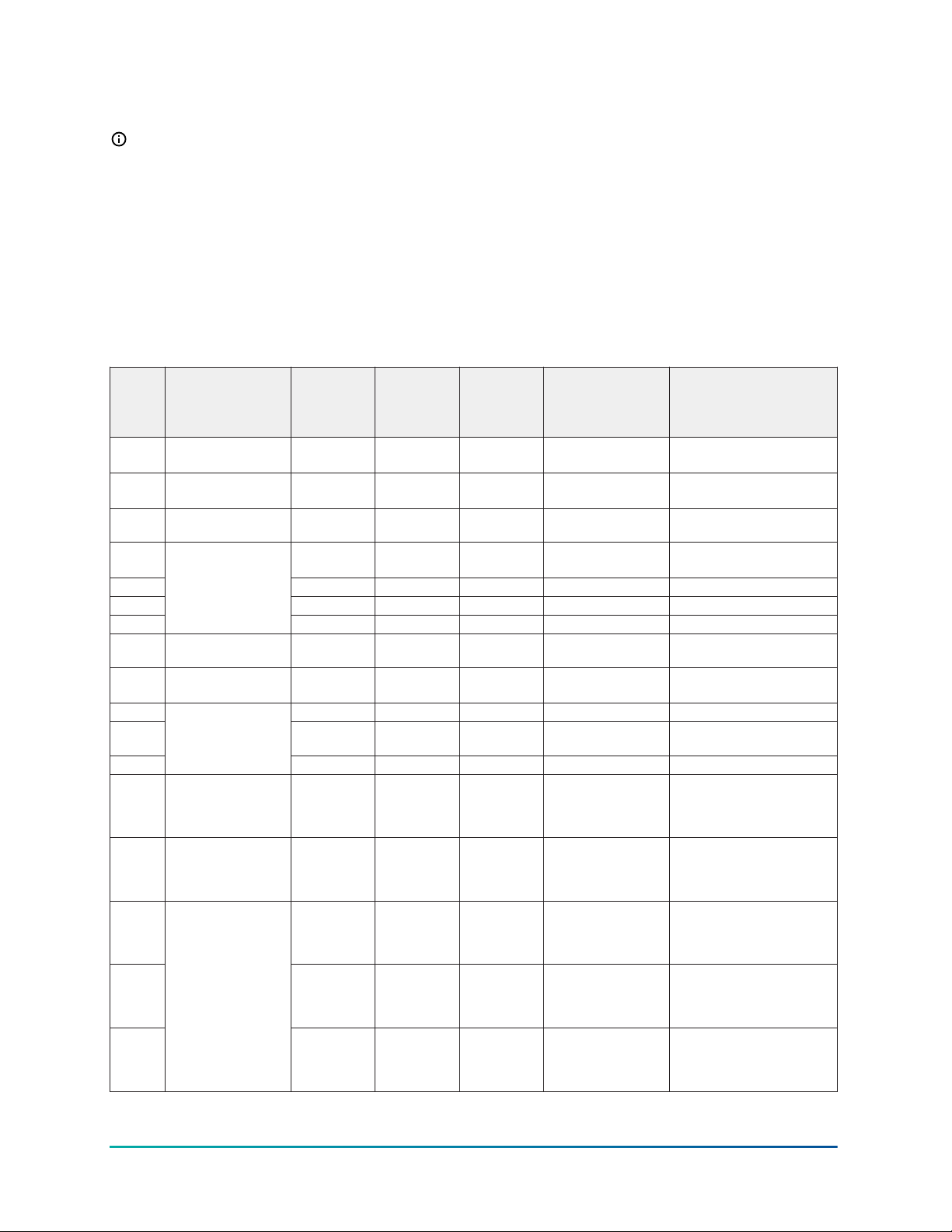

System 450 sensors and transducers for standard control modules

The following table shows the Sensor Types, output setup values, value ranges, and product types

for the temperature sensors, humidity sensors, and pressure transducers that are compatible with

System 450 standard control modules.

Table 2: System 450 sensor types, setup values, and senso and transducer product codes

Sensor

type

°F °F; temperature or

°C °C; temperature or

rH %; humidity or %RH 1 to 100 10 to 95 1 2 HE-68Nx-0N00WS

P 0.25 -0.250 to

P 0.5 0 to 0.5 0.025 to 0.5 0.005 0.010 DPT2650-0R5D-AB

P 2.5 0 to 2.5 0.1 to 2.5 0.02 0.1 DPT2650-2R5D-AB

P 5

P 8 bAR; pressure or bar -1 to 8 -1 to 8 0.05 0.1 P599RCHS401C

P 10 INWC; pressure or

P 15 -1 to 15 -1 to 15 0.1 0.2 P599RCPS402C

P 30 0 to 30 0 to 30 0.1 0.4 P599RCHS404C

P 50

P 100 PSI; pressure or psi 0 to 100 0 to 100 0.5 1 P599RAPS101C

P 110 Hg/PSI; pressure or

P 200 0 to 200 0 to 200 1 1 P599RAPS102C

P 500 0 to 500 90 to 500 1 5 P599RAPS105C

P 750

Unit of

measurement

value; condition or

units

degrees

degrees

INWC; pressure or

in. W.C.

in. W.C.

bAR; pressure or bar

Hg-psi

PSI; pressure or psi

Effective

sensing

range

-46 to 255 -40 to 250 1 1 A99x-xxx

-43 to 124 -40 to 121 0.5 0.5 A99x-xxx

0.250

0 to 5.0 0.25 to 5.0 0.05 0.25 DPT2650-005D-AB

0 to 10 0.5 to 10 0.05 0.2 DPT2650-10D-AB

0 to 50 0 to 50 0.2 0.4 P599RCPS405C

-10 to 100 -10 to 100 0.5 1 P599RAPS100C

0 to 750 150 to 750 2 6 P599RAPS107C

Range of

usable

values

-0.225 to

0.250

Resolution

increment

value

0.005 0.010 DPT2650-R25B-AB

Minimum

proportional or

control band

Sensor product type

number

HE-69Sx0NP

P599RCPS401C

P599RCPS404C

P599RAPS101K

P599RCPS101C

P599RCPS101K

P599RAPS100K

P599RCPS100C

P599RCPS100K

P599RAPS102K

P599RCPS102C

P599RCPS102K

P599RAPS105K

P599RCPS105C

P599RCPS105K

P599RAPS107K

P599RCPS107C

P599RCPS107K

System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin12

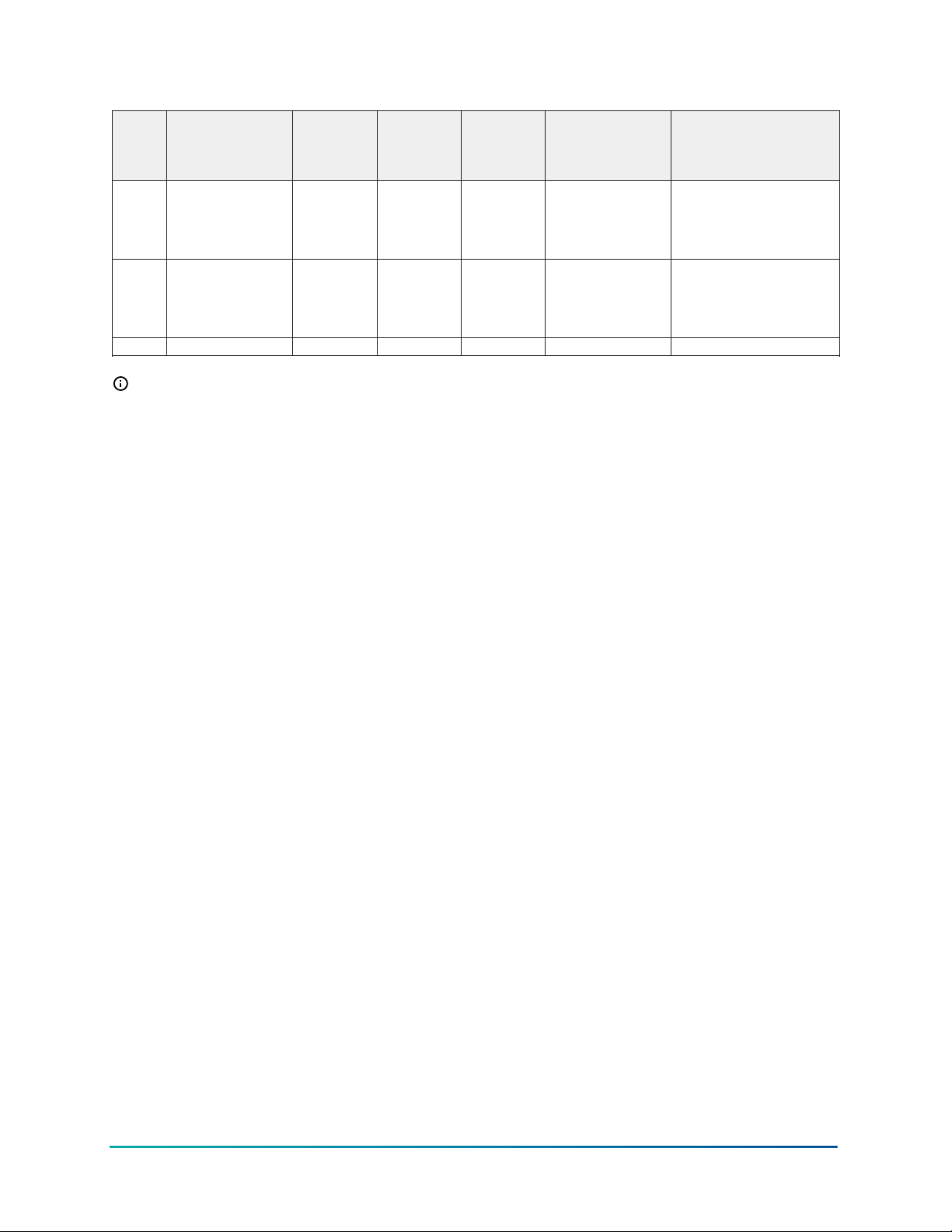

Table 2: System 450 sensor types, setup values, and senso and transducer product codes

Sensor

type

HI°F °F; temperature or

HI°C °C; temperature or

bin Open or Closed N/A N/A N/A N/A N/A

Unit of

measurement

value; condition or

units

degrees

degrees

Effective

sensing

range

-50 to 360 -40 to 350 1 1 TE-631x

-45.5 to 182 -40 to 176 0.5 0.5 TE-631x-x

Range of

usable

values

Resolution

increment

value

Minimum

proportional or

control band

Sensor product type

number

TE-6000-1

TE-6000-1x

TE-6000-6

TE-68NT-0N00S

TE-6000-1

TE-6000-1x

TE-6000-6

TE-68NT-0N00S

Note:

• The System 450 Differential Sensor Sn-d is set up and calculated with the two identical

sensors Sn-1 and Sn-2. This set up means that the range of usable values is twice as large

as a single sensor. See Differential control for the range of usable values when an output

references Sn-d.

• See Repair and ordering information for more information about the compatible sensors

for the System 450.

• See Setting up control system outputs for information about how to set up System 450

outputs that reference the P110 Sensor Type.

• Many of the temperature sensors that you can set up as HI°F or HI°C Sensor Types are not

designed for use across the entire range of usable values for HI°C HI°F and Sensor Types.

See Repair and ordering information or System 450 Series Modular Control Systems with

Standard Control modules technical specifications to determine the sensor hardware

configuration and temperature. The TE-6000-6 Nickel Sensor is the only sensor that you

can use over the entire temperature range.

• If you select the bin Sensor Type for a Sn-1, Sn-2, or Sn-3 sensor, the input sets up to

control the relay outputs only, based on the state of the binary input contacts, open or

closed, connected to the Sn1, Sn2, or Sn3 sensor input . See Binary input control for relay

outputs.

Binary input sensor

You can connect a binary input with dry contacts to any of the three System 450 control module

Sn1, Sn2, or Sn3 inputs and control output relays in your control system based on the binary input

state of open or closed.

A Sn1, Sn2, or Sn3 input set up as a binary input can be referenced by relay outputs only. Sensors

set up as binary inputs are not available for selection when you set up an analog output. When you

select a sensor in the UI that is set up as a binary input, the On value and the OFF value selection

screens are not available in the Relay Output Setup screens. See Binary Input Control for Relay

Outputs.

System 450 functional sensors

System 450 control modules also enable several functional sensors based on the input from one or

more of the hard-wired sensors in your control system. Selecting a functional sensor for an output

13System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin

on a System 450 control system enables the differential or high signal selection control features on

the output.

System 450 standard control modules provide for three functional sensors:

• When Sn-1 and Sn-2 are set up as the same Sensor Type, the High Input Signal Selection

functional sensor (HI-2) and Differential Control functional sensor (Sn-d) are enabled and

available in the Sensor Selection screens for each output in the control system.

• When Sn-1, Sn-2, and Sn-3 are the same Sensor Type, the High Input Signal Selection functional

sensor (HI-3) is also enabled and available.

See High Input Signal Selection and Differential Control for more information about these

functional sensors and system control features.

Relay outputs

Relay outputs provide low and line-voltage on/off control for devices and equipment in your

controlled systems. Each relay output is a single-pole, double-throw (SPDT) set of dry contacts. See

Figure 18.

Note: System 450 output relays are SPDT dry contact relays only and they do not provide any

power source for your controlled equipment.

Selecting an ON value that is less than the OFF value (ON < OFF) turns the relay on when the sensed

condition value decreases, which is the typical heating mode in temperature applications and

referred to as reverse-acting on/off control.

Selecting an ON value that is greater than the OFF value (ON > OFF) turns the relay on when the

sensed condition value increases, which is the typical cooling mode in temperature applications and

referred to as direct-acting on/off control.

You can set up multiple relay outputs to create a variety of equipment staging control systems.

See Wiring System 450 Components for information on wiring output relays. See Related

Documentation for the relay output electrical ratings.

A green LED on the relay control and relay expansion module housings (Figure 1) indicates the

relay output status.

When a relay output is On:

• the corresponding green LED on the module housing is lit

• the LC to line normally open (LNO) relay contact is closed

• the LC to line normally losed (LNC) relay contact is open

• the corresponding Output Status screen in the UI displays On

When a relay output is Off:

• the corresponding green LED on the module housing is not lit

• the LC to LNO relay contact is open

• the LC to LNC relay contact is closed

• the corresponding Output Status screen in the UI displays OFF

System 450 control and expansion modules are available with one or two relay outputs. See Table

12 and Related Documentation for more information about the System 450 series modules.

A relay output’s control action is determined by the values that you select in the ON and OFF relay

output setup screens:

• Relay ON values (ON) are the values at which the relay turns On.

System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin14

• Relay Off values (OFF) are the values at which the relay turns Off.

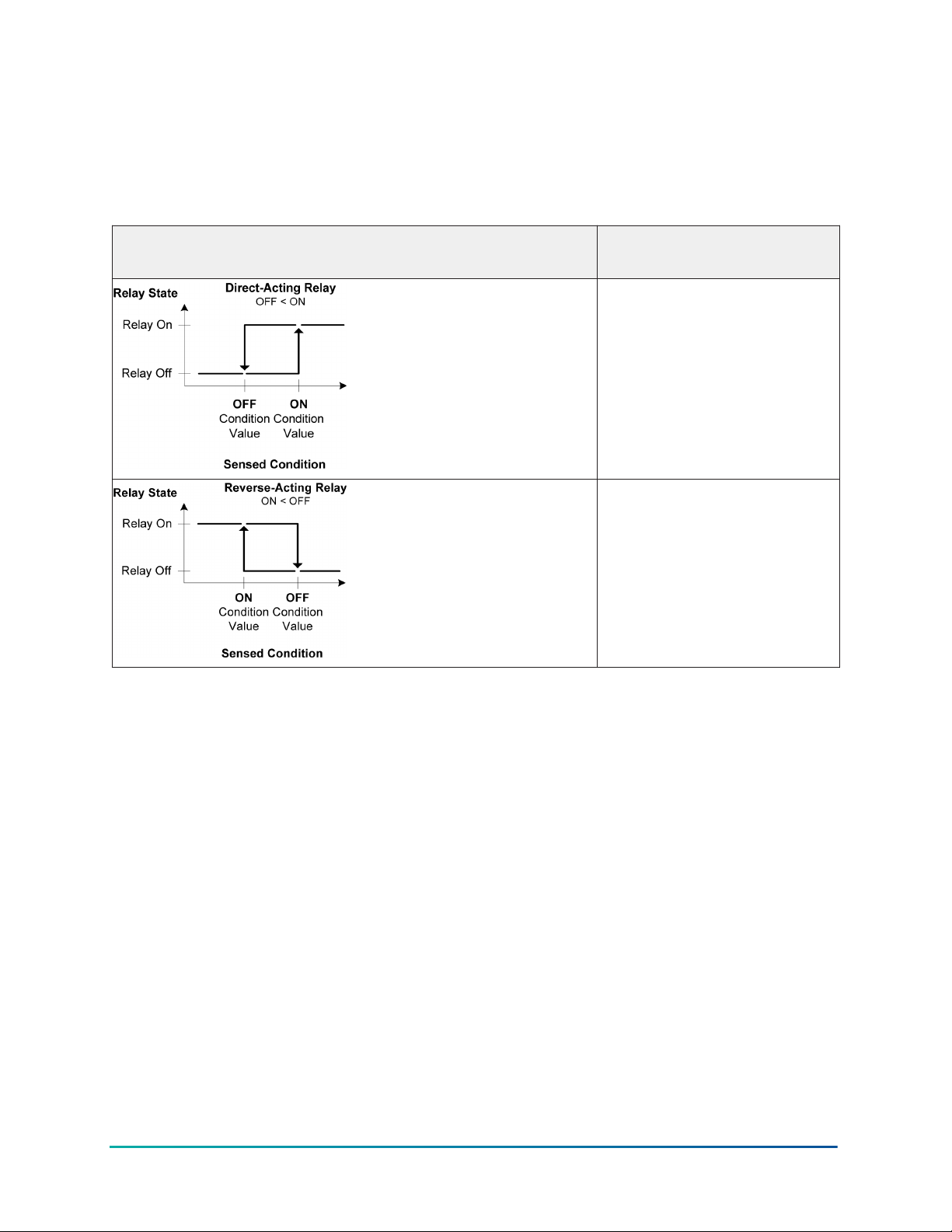

Table 3 illustrates direct and reverse relay actions. When you select On/Off condition values where

OFF is less than On, the output relay is a direct-acting relay. When you select condition values

where On is less than Off, the output relay is a reverse-acting relay.

Table 3: System 450 output relay control actions and the relationship between ON and OFF

values

Control action Set the relay output ON/OFF value

relationships for the preferred control

action

OFF < ON

ON < OFF

In temperature applications, direct-acting relays are often used to control cooling equipment, while

reverse-acting relays are often used to control heating equipment.

In pressure applications, direct-acting relays are often used for condenser fan cycling control or

pump-down control, while reverse-acting relays may be used for high pressure cut-out.

In humidity applications, direct-acting relays often control dehumidification equipment, and

reverse-acting relays often control humidification equipment.

Binary input control for relay outputs

You can connect a binary input or a set of dry contacts to any of the three Sn-1, Sn-2, orSn-3 and

C control module inputs and control the output relays in your control system based on the binary

input’s state of open or closed.

A Sn-1, Sn-2, or Sn-3 sensor set up as a binary input can only be referenced by a relay output.

Sensors set up as binary inputs are not available for selection when you set up an analog output.

When a relay output references a Sn-1, Sn-2, or Sn-3 sensor that is set up as a binary input, the

ON and OFF parameter screens are not available as you set up the output. The relay output’s On/

Off state is controlled by the binary input’s state and any of the ONT, OFFT, ONd, or OFFd timer

parameters that you set up for the relay output. When the binary input is closed, the relay is On.

When the binary input is open, the relay is Off. If no timer parameters are used, the relay output

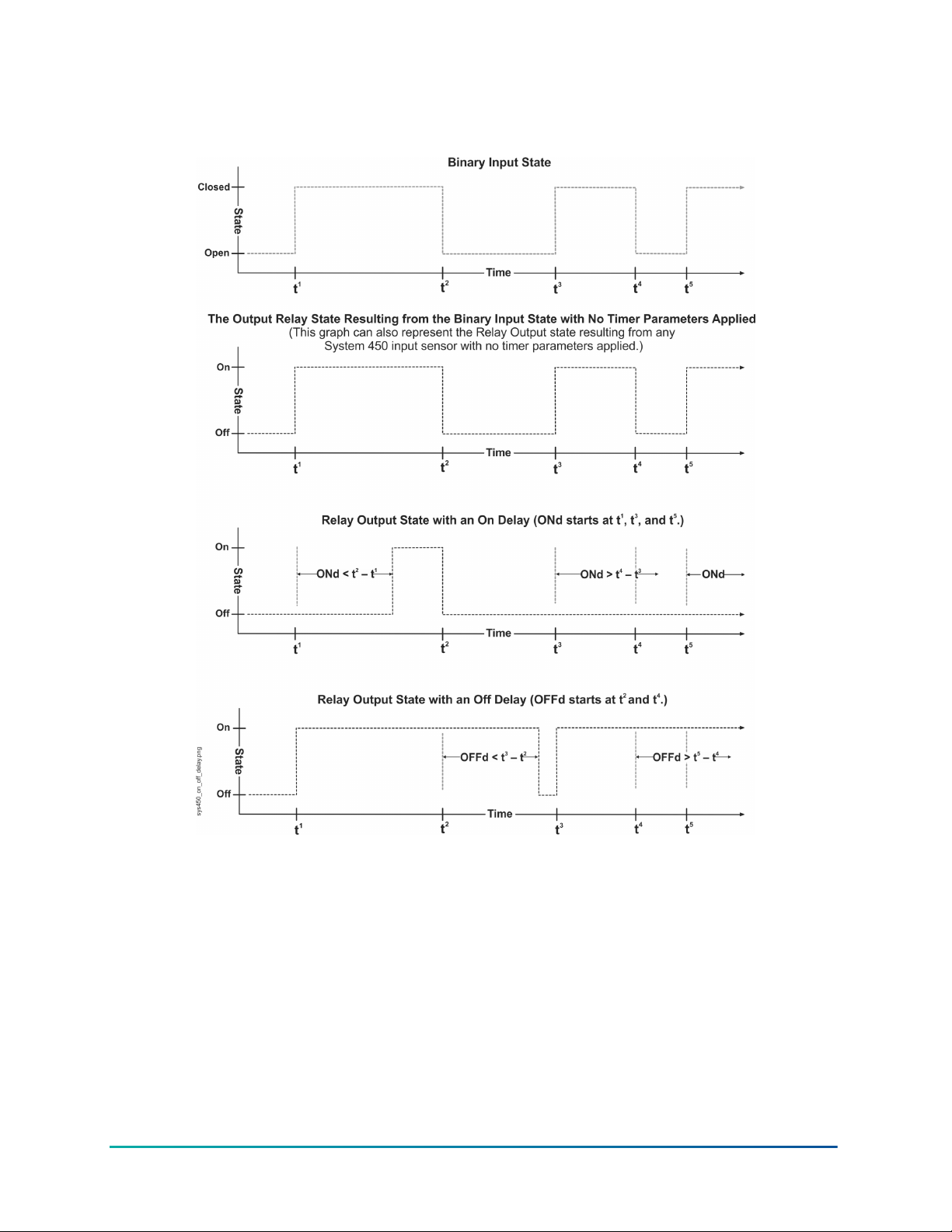

state directly follows the binary input state. Figure 5 and Figure 6 show examples of the binary

input state and the resulting output states with and without the timer parameters applied to the

output.

15System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin

See Relay On and Off Duration Control for more information about binary input control, relay

output behavior, and the resulting On/Off behaviors when applying the On/Off Delay Time and the

Minimum On/Off Time parameters.

Relay on and off duration control

The System 450 provides four time duration control parameters that can be applied to the relay

output On or Off times generated by an input sensor or a binary input. Each of the four On or Off

duration control parameters can be set up for 0 to 300 seconds (5 minutes) in 1-second intervals.

The four time duration control parameters are as follows:

• On delay: (ONd) Delays the time that a relay output goes to the On state after reaching the On

condition. See the third graph in Figure 5.

• Off delay: (OFFd) Delays the time that a relay output goes to the Off state after reaching the

Off condition. See the bottom graph in Figure 5.

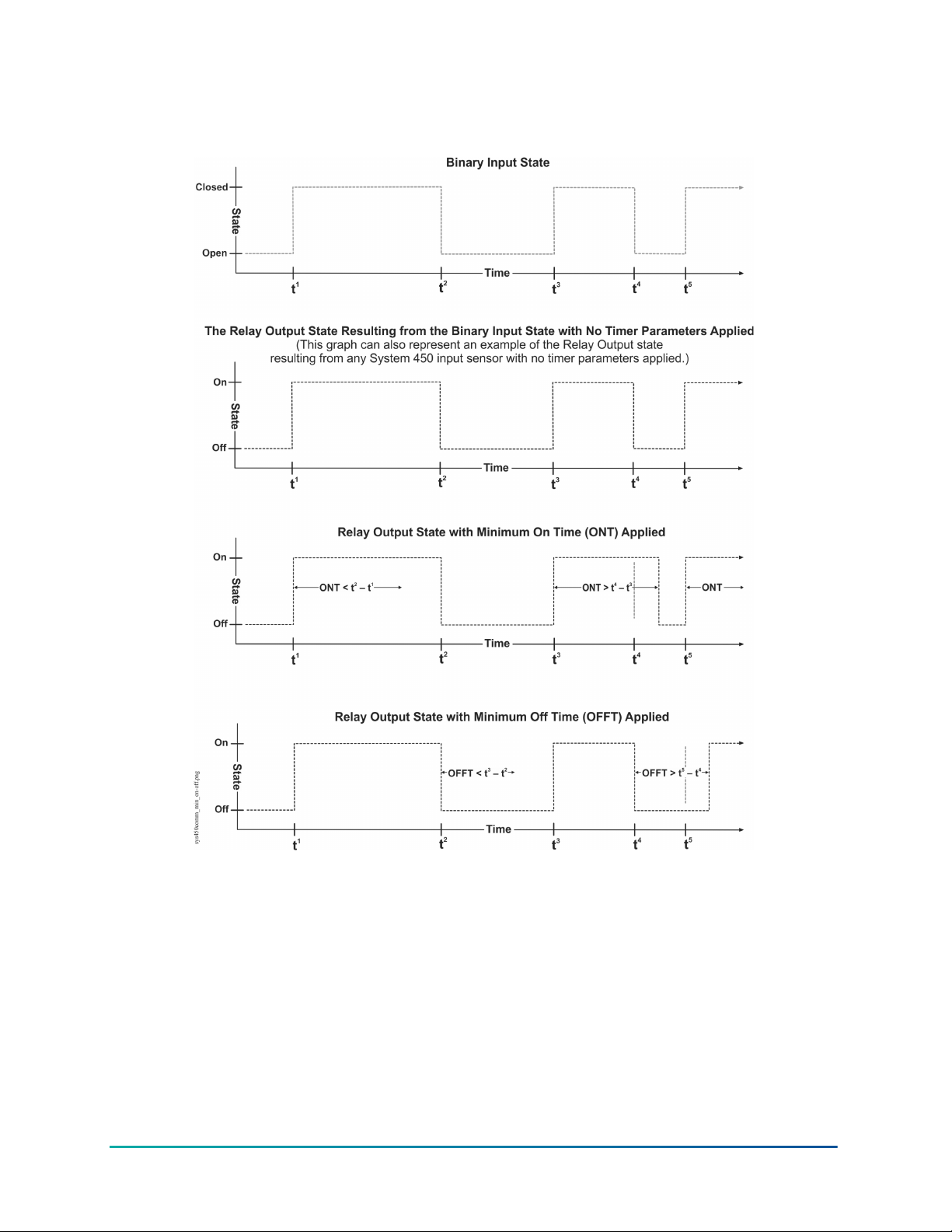

• Minimum on time: (ONT) Maintains the relay in the On state for the selected minimum time

after reaching the On condition and overrides any sensor input that would normally switch the

relay off during the Minimum On Time interval. See the third graph in Figure 6.

• Minimum off time: (OFFT) Maintains the relay in the Off state for the selected minimum time

after reaching the Off condition and overrides any sensor input that would normally switch the

relay on during the Minimum Off Time interval. See the bottom graph in Figure 6.

The top two graphs in Figure 5 and Figure 6 show an example of a binary input opening and closing

(top graph in each figure) and the resulting behavior of the referenced relay output with no On/Off

duration parameter applied to the relay output (second graph in each figure).

The second graph in each figure can also represent a typical example of a relay output responding

to the On and Off values for any System 450 compatible sensor.

The third and the bottom graphs in Figure 5 and Figure 6 show the behavior of the output relay

when the On and Off Delay parameters are applied (Figure 5) and when the Minimum On and

Minimum Off parameters are applied (Figure 6) to the output.

The bottom two graphs in Figure 5 show an example of the relay output behavior when the On

or Off Delay parameter is applied to the relay output (regardless of whether the relay output

references a binary input or another compatible sensor).

System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin16

Figure 5: Behavior of a relay output referencing a binary input or other System 450

compatible sensor and the resulting output states with the on delay and off delay

parameters applied

The bottom two graphs in Figure 6 show an example of the relay output behavior when the

Minimum On or Off Time parameter is applied to the relay output (regardless of whether the relay

output references a binary input or another compatible sensor).

17System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin

Figure 6: Behavior of a relay output referencing a binary input or other System 450 sensor

and the resulting output states with the minimum on and minimum off time parameters

applied

Analog outputs

Analog outputs provide proportional analog signals for devices and equipment in your controlled

systems. Each analog output can generate either a 4 mA to 20 mA or 0 VDC to 10 VDC signal.

The output signal type is self-selecting; after you connect the analog output to the controlled

equipment, the output detects the analog input on the controlled equipment and generates the

appropriate analog signal for the connected input.

You can set up an analog output to generate a direct-acting or reverse-acting proportional output

signal. You can also set up the output signal strength to increase or decrease in either the directacting or reverse-acting mode. See Direct and Reverse Control Actions for Analog Outputs for more

information.

System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin18

The System 450 also provides six integration constants that allow you to set up a proportional plus

integral control signal, which can provide more precise setpoint control. See Proportional Plus

Integral Control and Integration Constants for information on determining the integration constant

for an analog output.

For procedures on setting up analog outputs on control modules, see Setting up an analog output.

The System 450 expansion modules are available with one or two analog outputs. See Table 12 and

Related Documentation for more information about the System 450 Series module models that are

used to build the control systems

Direct and reverse control actions for analog outputs

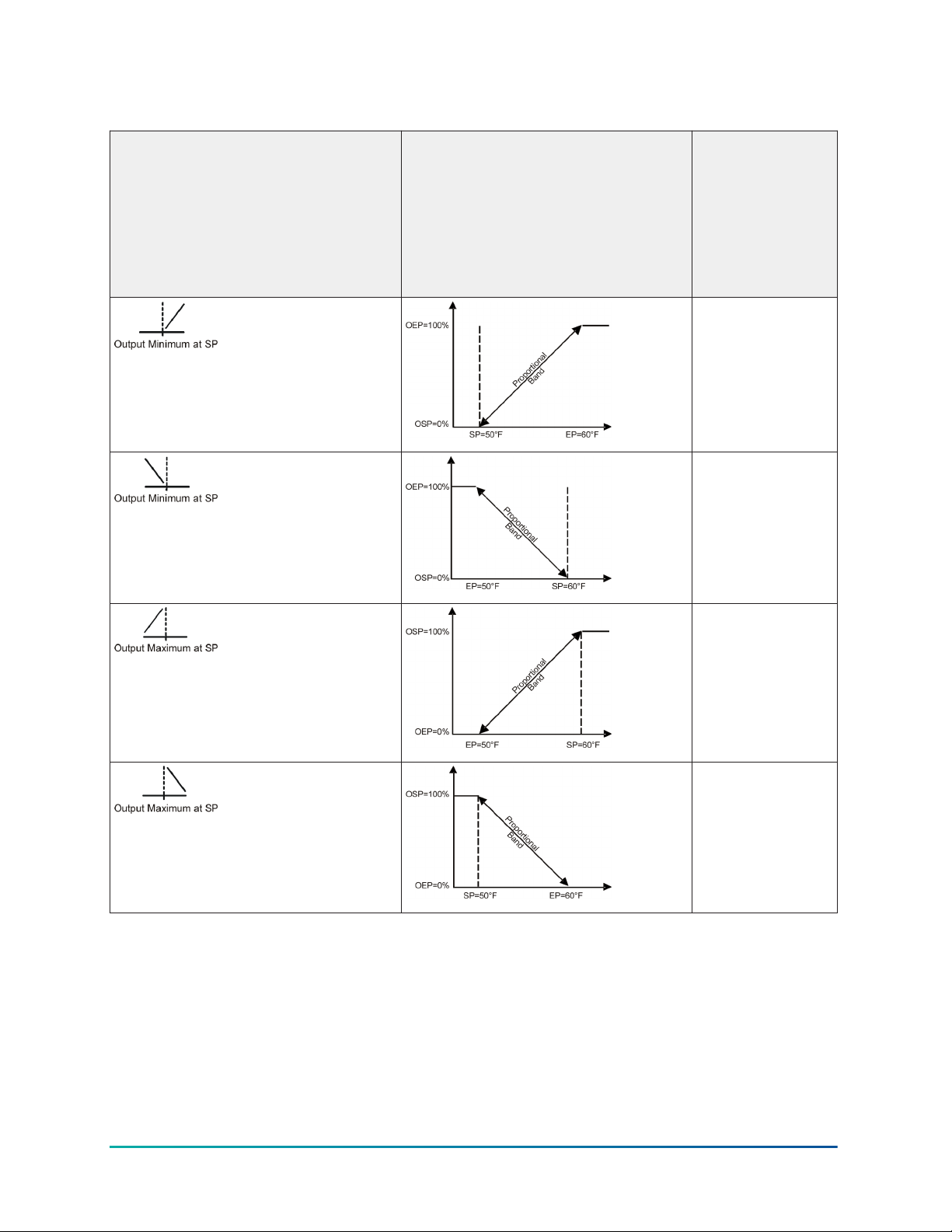

An analog output can be set up to provide one of four different control actions, which allow you to

match the output signal to the requirements of your control system and the controlled equipment.

The proportional output signal can provide direct-acting or reverse-acting control. In addition,

the output signal can be set up to generate either the minimum or the maximum output signal

strength at Setpoint.

A control ramp icon is displayed on the status screens for all analog outputs in your control system.

See Figure 1. The displayed control ramp icon represents the control action of the analog output

signal. See Table 4 for more information on analog output control actions and control ramp icons.

An analog output’s control action and the corresponding control ramp are automatically

determined by the values that you select in four analog output setup screens:

• Setpoint value (SP) is the target value that the control system drives toward, and along with

the End Point, defines the analog output’s proportional band.

• End Point value (EP) is the maximum deviation from the target value (Setpoint). The control

system applies maximum output at the EP to drive the process back toward the SP. The SP and

EP define the analog output’s proportional band.

• Output at Setpoint value (OSP) is the signal strength level of the analog output when the

input sensor is at Setpoint (SP). The OSP is expressed as a percentage (0 to 100%) of the full

scale output.

• Output at Endpoint value (OEP) is the signal strength level of the analog output when the

input sensor is at the End Point (EP). The OEP is expressed as a percentage (0 to 100%) of the

full scale output.

Note: System 450 analog outputs that reference the differential control sensor (Sn-d) use a

Differential Setpoint (dSP) and Differential End Point (dEP) to define the output’s proportional

band. See Differential Control for more information.

Table 4 shows the four control ramp icons and describes their corresponding control actions and

the setup value relationships required to configure the four control actions. See Figure 27 and

Figure 28 for examples.

19System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin

Table 4: System 450 control ramps, analog output control actions, and system setup value

relationships

Control ramp displayed Control action Set the analog

output value

relationships for

the preferred

control

action and

corresponding

control ramp

SP < EP

OSP < OEP

SP > EP

OSP < OEP

SP > EP

OSP > OEP

SP < EP

OSP > OEP

Proportional plus integral control and integration constants

In addition to standard proportional control, System 450 provides Proportional plus Integral (PI)

control capability. The addition of integral control enables a properly set up analog output to drive

a controlled condition closer to Setpoint (Figure 7).

Standard proportional-only controls continuously adjust the output in proportion to the difference

(offset error) between the setpoint value and the sensor value. As the load on the system increases,

the offset error increases. A proportional-only control responds to the increased offset error by

changing the output signal, which drives the controlled equipment to compensate for the load

change (Figure 7). Proportional-only control loops are relatively easy to set up and adjust.

System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin20

Typically, under constant system load, proportional-only control loops do not drive a system to

the selected setpoint. Instead, the controlled system is maintained at a control point within the

proportional band (throttling range) between setpoint and end point. The larger the load on the

system, the further the control point drifts from setpoint. Still, for many applications, proportionalonly control is the best choice for analog output control.

Figure 7: Proportional-only control versus proportional plus integral control

Proportional plus Integral (PI) control incorporates a time-integral control action with

proportional control action and, if properly set up, a PI control loop can effectively eliminate offset

error and enable a controlled system to drive to setpoint even under large constant loads (Figure

7). On a properly sized system with predictable loads, PI control can maintain the controlled system

very close to setpoint.

A system’s output capacity, the size of the load on the system, and the integration constant

selected determine the speed (recovery rate) at which the PI control drives the system to setpoint.

The integration constant establishes the rate at which the control readjusts the analog output

signal. The faster the integration constant, the faster the control readjusts the output signal and the

faster the recovery rate of a properly sized and setup control loop.

Note: PI control is not suitable for all controlled systems. Improperly applied PI control

loops are unstable and can overshoot setpoint, resulting in control loop oscillation. Also,

with PI control, the proportional band (throttling range) and the integration constant are

interdependent and you must properly set up these values in relation to each other. You must

also properly size the system equipment to handle the maximum load. Close observation over

several cycles and under different load condition is required to properly set up a PI control

loop. On a properly sized system, a PI control loop can drive the system condition much closer

to setpoint than proportional-only control.

In addition to a proportional-only setting, System 450 provides six time-integral settings in

the Integration Constant Setup screen for matching the analog signal’s response rate to the

controlled system’s recovery rate. The seven integration constant settings are shown in Table 9.

See Determining the Integration Constant for an Analog Output for more information and the

procedures for determining an integration constant and testing a PI control loop in your controlled

system.

21System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin

The Analog Output Update Rate and Output Deadband contain two parameters that can be used

to minimize the frequency of changes to the output signal from the control. When controlling a

device such as an actuator, these features can lengthen the actuator life by reducing the actuator

position update frequency. See Analog Output Update Limiters and Analog Output Deadband for

more information.

Analog output update limiters

The Output Update Rate and Output Deadband minimize the frequency of changes to the output

signal from the control. When controlling a device such as an actuator, these features can lengthen

actuator life by reducing the actuator position update frequency.

Analog output update rate

The output update rate feature allows you to select the rate, in seconds, during which the control

does not allow an update to the analog output’s signal strength. The Output Update Rate value

range is 1 to 240 seconds and the default value is 1 second.

The Output Update Rate and Output Deadband are used to minimize the frequency of changes to

the output signal from the control. When controlling a device such as an actuator, these features

can lengthen actuator life by reducing the actuator position update frequency.

The System 450 control module calculates the input-induced output signal strength once per

second. The default Output Update Rate is one second. The actual output signal strength is

updated to the calculated output signal strength once every second when the control is set to the

default update value. In some control applications, a 1-second update rate may be too frequent and

may result in premature wear on the controlled equipment, such as actuators.

When you select an Output Update Rate value greater than 1 second, the control module delays

updating the output and maintains the output signal strength for the duration of the selected

update rate. At the end of the selected update rate, the control updates the output signal strength

to the current calculated output signal strength and maintains the new output signal strength value

for the selected output update rate value.

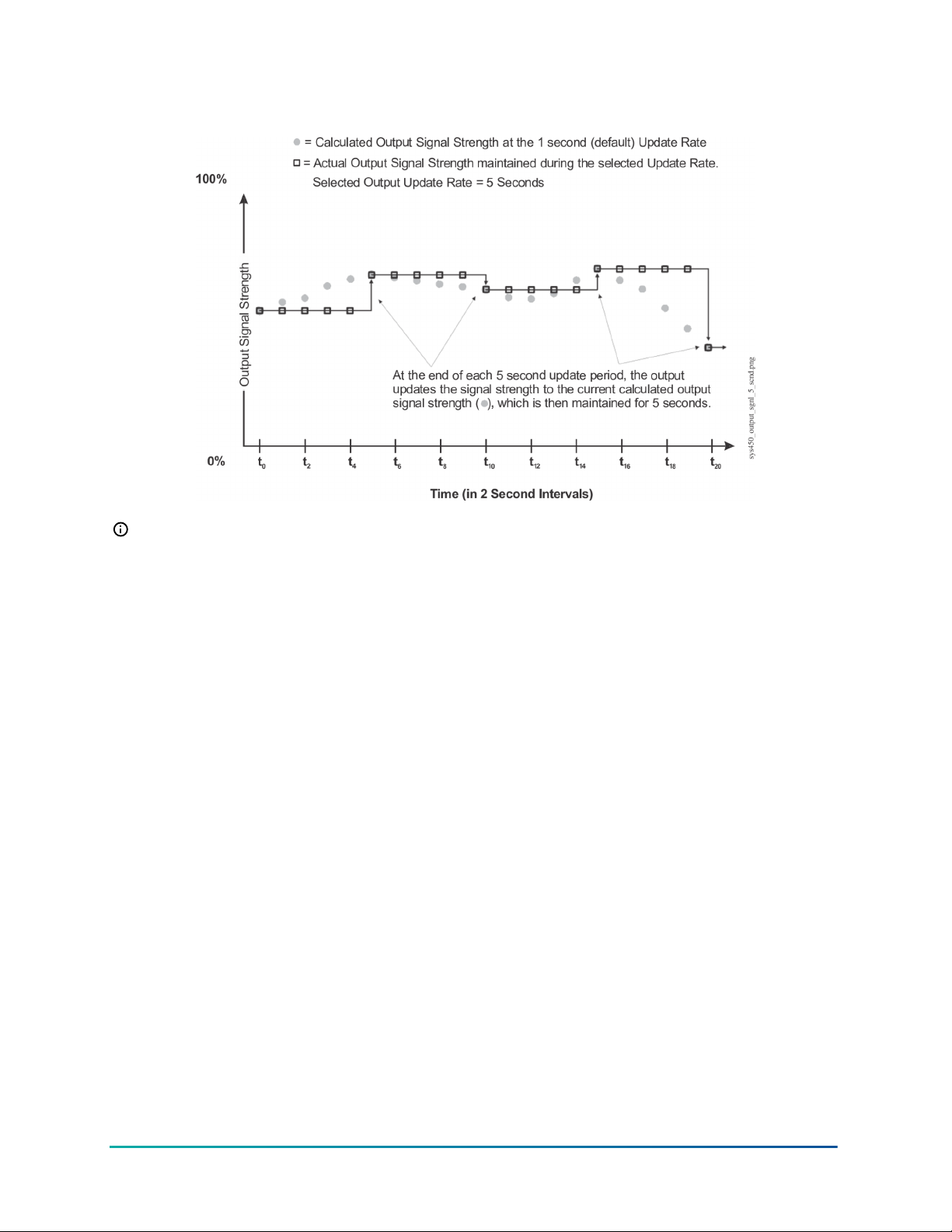

For example, if you select an Output Update Rate value of 5 (seconds), the control module updates

the output signal strength every 5 seconds, reducing changes at the controlled equipment to 20%

of the default update rate. See Figure 8.

System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin22

Figure 8: Graph showing calculated output signal strength and output signal strength

maintained by a 5-second update rate

Note: The Output Update Rate feature can be used in conjunction with the Output Deadband

feature, but care must be taken when selecting these values for your control system. In

process loops where the condition (temperature, pressure, or humidity) value can change

quickly over a large range, the delay in updating the actual output signal strength can cause

the controlled equipment to oscillate out of range and drive the process away from the desired

setpoint. After selecting new Output Update Rate and Output Deadband values, observe

your controlled system through several cycles to determine the affect of the new values. If

the calculated output signal strength is 0 or 100%, the actual output signal strength changes

immediately.

Analog output deadband

The Output Deadband feature allows you to establish a deadband value around the calculated

output signal strength. The Output Deadband value is expressed as a percent of the output signal

strength range. The Output Deadband value range is 0 to 50 (percent of the OSP to OEP range) and

the default value is 0 (percent).

The Output Update Rate and Output Deadband are used to minimize the frequency of changes to

the output signal from the control. When controlling a device such as an actuator, these features

can lengthen actuator life by reducing the actuator position update frequency.

The System 450 control module responds to a changing input signal and updates the analog

output’s calculated output signal strength at the rate selected in the Output Update Rate screen. At

each update of the calculated output signal strength, the control determines if the new calculated

output signal strength is within the selected Output Deadband or not.

If the calculated output signal strength is within the selected Output Deadband, the actual output

signal strength is not updated and remains unchanged.

If the calculated output signal falls outside the Output Deadband, the actual output signal strength

is updated, and the selected Output Deadband is applied to the new output signal strength value.

See Figure 9.

23System 450 Series Modular Control Systems with Standard Control Modules Technical Bulletin

Loading...

Loading...