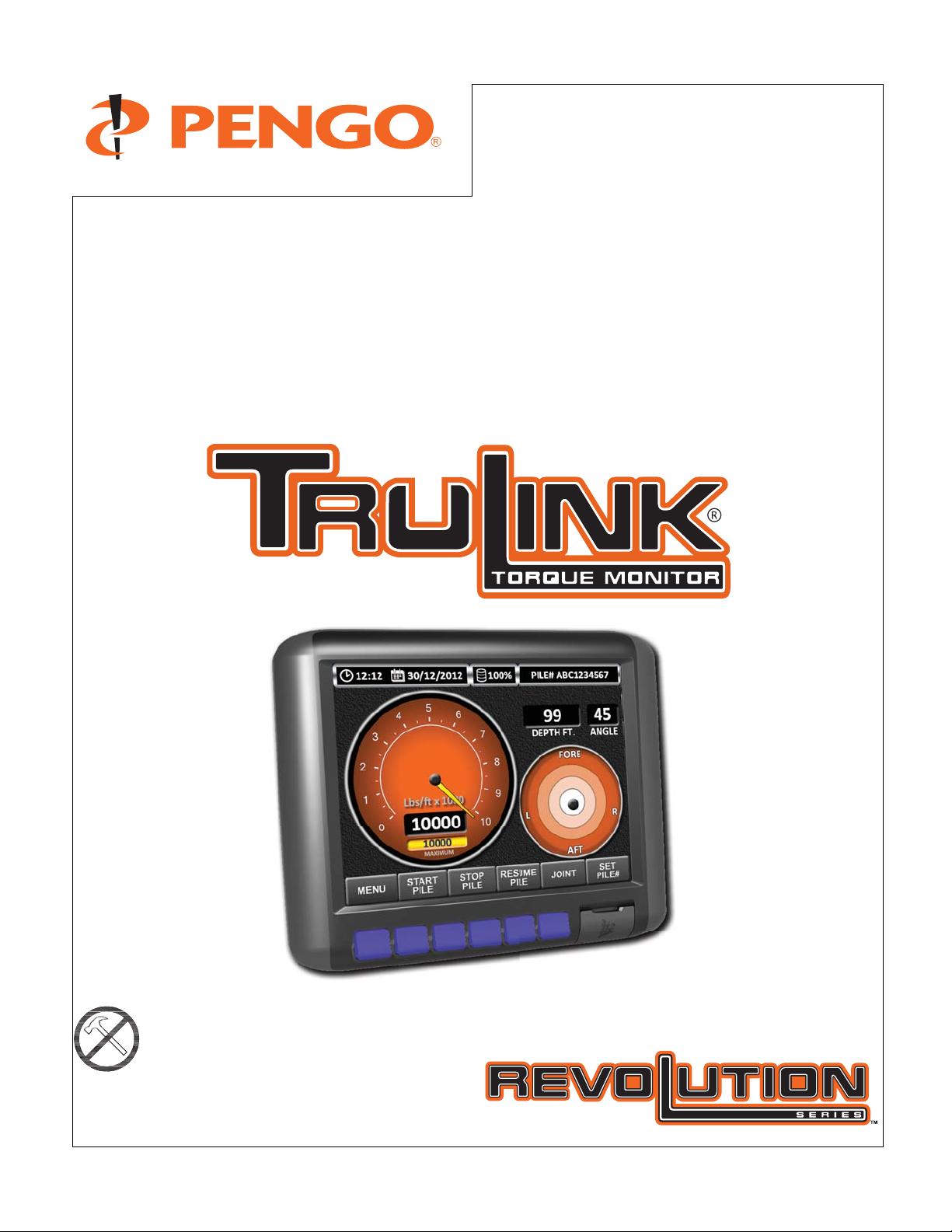

Pengo TruLink User Manual

Printed in the USA

TORQUE MONITORING SYSTEM

Manual ID: TruLink Manual.indd

Release Date: March 18, 2015

Owner’s Manual

Parts Manual

Safety Precautions

Operating Instructions

OWNER’S & OPERATOR’S MANUAL

(4" and 8" Display Systems)

Patent Pending

NOTE: Do NOT use a hammer or any other

object at any time during the installation of the

T ruLink pin. Hitting the head of the pin with a

object will damage the CPU processor and will

VOID the warranty .

800-599-0211 l www.pengoattachments.com l PENGO: 500 East Highway 10, Laurens, IA 50554, USA

PENGO TruLink Manual 1

The TruLink™ system is designed specifi cally for use with

Pengo® Revolution™ series Anchor Drives.

PREFACE

This manual is used to familiarize you with safety , assembly, operation, adjustment, troubleshooting, and maintenance.

Read and follow the recommendations in this manual to ensure safe and effi cient operation. Keep this manual with the

product at all times for future reference.

We want you to be completely satisfi ed with your new product, feel free to contact your local Authorized Service Dealer for

help with service, replacement parts, or any other information you may require. If you need assistance in locating a dealer,

visit our web site at www.pengoattachments.com or call customer service at 1-800-599-0211.

The descriptions and specifi cations in this manual are subject to change without notice. Pengo® reserves the right to improve

products. Some product improvements may have taken place after this manual was printed. For the latest information on

Pengo® products, visit our web site at www.pengoattachments.com or call customer service at 1-800-599-021 1.

Thank you for buying and using Pengo® products!

TABLE OF CONTENTS

General Safety and Product Information

Preface / Table of Contents ................................................................................................................................. 2

Table of Contents ............................................................................................................................................ 3

Safety Statements ............................................................................................................................................ 4

General Precautions ........................................................................................................................................... 5

Product Introduction. ........................................................................................................................................... 6

Product Classes and Items Lists By Class ......................................................................................................... 7

Component Identifi cation 4” Display Option ........................................................................................................ 8

Component Identifi cation 8” Display Option ........................................................................................................ 9

Anchor Drive Pin Installation .............................................................................................................................. 10

Anchor Drive Pin Installation ...............................................................................................................................11

Anchor Drive Pin Installation .............................................................................................................................. 12

TruLink Pin Cable Connections .......................................................................................................................... 13

TruLink System Overview ................................................................................................................................... 14

TruLink Data Charting ........................................................................................................................................ 15

4” Display Operation (TL4-C1 & TL4-C2)

4” TruLink Operation Cover Page ....................................................................................................................... 16

Touch Screen Display Set-Up ............................................................................................................................ 17

Display Layout and Function ............................................................................................................................. 18

Operating Procedures ........................................................................................................................................ 19

Display Adjustment - Brightness / Time and Date ............................................................................................ 20

Changing Units / Pin Orientation Guide ............................................................................................................. 21

Job Management Input - New Job ..................................................................................................................... 22

Job Management Input - New Job Cont. ........................................................................................................... 23

Using Data Logger ........................................................................................................................................... 24

Setting Target T orque ........................................................................................................................................25

Setting Inclinometer ........................................................................................................................................... 26

Setting Pile Number / Start Pile / Pause Pile ..................................................................................................... 27

Pause Pile - Add Pile Joint ................................................................................................................................. 28

End Pile / Saving data to USB Device ............................................................................................................... 29

Recorded Data Export ....................................................................................................................................... 30

TruLink Pin Calibration ....................................................................................................................................... 31

2 PENGO TruLink Manual

TABLE OF CONTENTS

8” Display Operation (TL8-C1, TL8-C2, TL8-C3 & TL8-C4)

8” TruLink Operation Cover Page ....................................................................................................................... 32

Touch Screen Display Set-Up ............................................................................................................................ 33

Display Layout and Function ............................................................................................................................. 34

Operating Procedures ........................................................................................................................................ 35

Display Adjustment - Brightness / Time and Date ............................................................................................ 36

Changing Torque Units ...................................................................................................................................... 37

Changing Length Units ....................................................................................................................................... 38

Pin Orientation Guide ......................................................................................................................................... 39

Job Management Input - New Job ..................................................................................................................... 40

Job Management Input - New Job Cont. ........................................................................................................... 41

Using Data Logger ........................................................................................................................................... 42

Setting Target T orque ........................................................................................................................................43

Setting Inclinometer ........................................................................................................................................... 44

Setting Pile Number / Setting Pile Length ......................................................................................................... 45

Start Pile / Pause Pile / Add Pile Joint ............................................................................................................... 46

End Pile / Saving Data to USB Device ............................................................................................................... 47

Recorded Data Export ....................................................................................................................................... 48

TruLink Pin Calibration ....................................................................................................................................... 49

Software Update Guide ...................................................................................................................................... 50

Warranty Policy / Returned Goods Policy .......................................................................................................... 51

PENGO TruLink Manual 3

SAFETY STATEMENTS

DANGER

WARNING

CAUTION

WARNING

THIS STATEMENT IS USED WHERE SERIOUS INJURY OR DEATH WILL RESULT IF THE

INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS STATEMENT IS USED WHERE SERIOUS INJURY OR DEATH COULD RESULT IF

THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS STATEMENT IS USED WHERE MINOR INJURY COULD RESULT IF THE

INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS SYMBOL BY ITSELF OR USED WITH A SAFETY SIGNAL WORD THROUGHOUT

THIS MANUAL IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING

YOUR PERSONAL SAFETY OR THE SAFETY OF OTHERS. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN INJURY OR DEATH.

READ MANUAL PRIOR TO INSTALL

Improper installation, operation, or maintenance of the equipment could result in serious

injury or death. Operators and maintenance personnel should read this manual as well as

all manuals related to this equipment. FOLLOW ALL SAFETY INSTRUCTIONS IN THIS

MANUAL.

WARNING

WARNING

READ AND UNDERSTAND ALL SAFETY STATEMENTS

Read all safety decals and safety statements in all manuals prior to operating or working

on this equipment. Know and obey all OSHA regulations, local laws and other professional

guidelines for your operation. Know and follow good work practices when assembling,

maintaining, repairing, mounting, removing or operating this equipment.

KNOW YOUR EQUIPMENT

Know your equipment’s capabilities, dimensions and operations before operating. Visually

inspect your equipment before you start, and never operate equipment that is not in proper

working order with all safety devices intact. Check all hardware to assure it is tight. Make

certain that all locking pins, latches, and connection devices are properly installed and

secured. Remove and replace any damaged, fatigued or excessively worn parts. Make

certain all safety decals are in place and are legible. Keep decals clean, and replace them if

they become worn and hard to read.

DO NOT MODIFY EQUIPMENT

Modifi cations may weaken the integrity of the equipment and may impair the functions, safety,

life, and performance of the equipment. When making repairs, use only the manufactures

genuine parts, following authorized instructions. Other parts may be substandard in fi t and

quality.

4 PENGO TruLink Manual

GENERAL PRECAUTIONS

PREPARE FOR EMERGENCIES

• Be prepared if a fi re starts.

• Keep a fi rst aid kit near by when operating equipment.

WARNING

CAUTION

WARNING

WARNING

OPERA TOR SAFETY

• Protective clothing and equipment should be worn at all times.

• Wear protective clothing and equipment appropriate for the job. Avoid loose fi tting clothing.

• Prolonged exposure to excessive noise can cause hearing loss. Wear suitable hearing protection

such as ear plugs.

• Operating equipment safely requires the full attention of the operator. Avoid distractions.

• Never let a minor or inexperienced person operate equipment.

PRODUCT SAFETY

• Inspect the entire product before operation.

• Replace parts that are cracked, chipped or damaged in any way before operation.

• Keep others away when making any adjustments to the unit.

PRACTICE SAFE MAINTENANCE

• Use proper tools and equipment when conducting maintenance, refer to this manual for additional

information.

• Work in a clean dry area.

• Inspect all parts. Be sure parts are in good working condition and installed properly .

• Remove build up of grease, oil or any debris.

• Remove all tools and unused parts from equipment before beginning operation.

BE ALERT ON THE JOB SITE

Tragic accidents can occur if the operator is not alert and aware of the surroundings. Interface with

the system only when it is safe to do so. Operating machinery while distracted can result in loss of

machinery control.

WARNING

LOWER OR SUPPORT RAISED EQUIPMENT

During installation of the TruLink system:

• Do not work under raised booms without supporting them.

• Do not use support material made of concrete blocks, logs, buckets, barrels, or any other material

that could suddenly collapse or shift positions.

• Make sure support material is solid, not decayed, warped, twisted, or tapered.

• Lower booms to ground level or on blocks.

• Lower booms and attachments to the ground before leaving the cab or operator’s station.

• Keep others away when making any adjustments to the unit.

PENGO TruLink Manual 5

PRODUCT INTRODUCTION

The Pengo® TruLink™ system allows operators installing helical piers to monitor and record all installation data.

TruLink™ is a true torque system that delivers a high degree of accuracy (+/- 2%) while providing the operator with

real time data. TruLink™ records actual torque being applied to the helical pile, the installation angle and the depth.

Toque is measured at two points within the connection pin located between the anchor drive attachment and the prime

mover. The TruLink™ pin simply replaces the OEM pin ensuring that no additional height is added to the installation

equipment. This feature is important in low clearance applications.

The systems patent pending technology contained within the pin omits downward (perpendicular) force. Isolating only

the necessary torque values improves accuracy and durability. All gages and electronics are completely sealed for

use in all installation environments.

The TruLink™ user interface is available in either a 4” or 8” touch screen display that can be easily mounted within the

operating cab of most prime movers. The rugged display is housed in an IP67 rated weather and shock proof casing.

The high visibility touch screen allows the operator to easily interface with the system during installation. The intuitive

layout of the display indicates all data in real time.

All installation data is recorded independently for each pier and collectively for all helical piers on a given project. All

data is stored within the display and is easily exported to a fl ash drive. The data is saved in an industry standard fi le

format that can be exported into Microsoft® Excel. All data is easy to read and is ready for immediate job submittal

without additional formatting.

Complete System Part Numbers:

DESCRIPTION PART NO.

TL4-C1 - 4" Screen (Pin Dia. 45mm) 615000

TL4-C2 - 4" Screen (Pin Dia. 45mm) 615001

TL8-C1 - 8" Screen (Pin Dia. 45mm) 615002

TL8-C2 - 8" Screen (Pin Dia. 75mm) 615003

TL8-C3 - 8" Screen (Pin Dia. 3.967") 615004

TL8-C4 - 8" Screen (Pin Dia. 4.5" ) 615005

The TruLink™ system is designed specifi cally for use with

Pengo® Revolution™ series Anchor Drives.

6 PENGO TruLink Manual

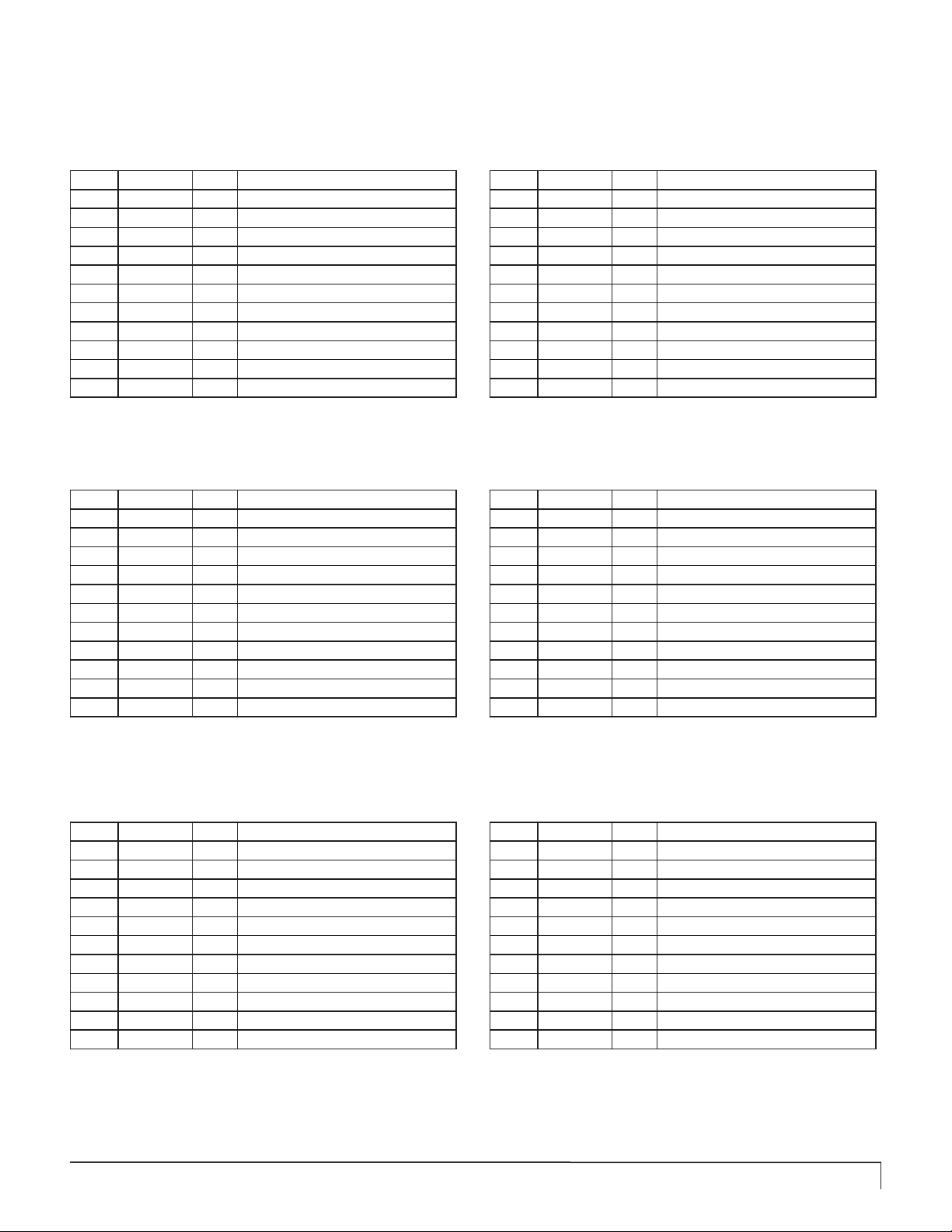

PRODUCT CLASSES / ITEM LISTS

CLASS 1 - DISPLA Y 4” (TL4-C1)

Part Number: 615000 - 20,000 ft/lb Capacity

ITEM PART No. QTY DESCRIPTION

1 615011 1 DISPLAY 4.3” TOUCH SCREEN

2 615007 1 TRULINK PIN 45mm CLASS 1

3 615025 1 PIN END CAP KIT CLASS 1

4 615014 1 BATTERY BACK-UP KIT 4” DSPY

5 615013 1 CABLE MAIN 15’

6 615026 1 CABLE EXTENSION 15’

7 615030 1 4”.3” DISPLAY MOUNT (RAM)

8 615028 1 DISPLAY STORAGE CASE

9 615016 1 ANTI-ROTATION BLOCK KIT

10 615036 1 USB FLASH DRIVE (2GB)

11 615037 1 STYLUS

CLASS 2 - DISPLA Y 4” (TL4-C2)

Part Number: 615001 - 70,000 ft/lb Capacity

ITEM PART No. QTY DESCRIPTION

1 615011 1 DISPLAY 4.3” TOUCH SCREEN

2 615008 1 TRULINK PIN 75mm CLASS 2

3 615027 1 PIN END CAP KIT CLASS 2

4 615014 1 BATTERY BACK-UP KIT 4” DSPY

5 615023 1 CABLE MAIN 25’

6 615026 1 CABLE EXTENSION 15’

7 615030 1 4”.3” DISPLAY MOUNT (RAM)

8 615028 1 DISPLAY STORAGE CASE

9 615016 1 ANTI-ROTATION BLOCK KIT

10 615036 1 USB FLASH DRIVE (2GB)

11 615037 1 STYLUS

CLASS 1 - DISPLA Y 8” (TL8-C1)

Part Number: 615002 - 20,000 ft/lb Capacity

ITEM PART No. QTY DESCRIPTION

1 615012 1 DISPLAY 8” TOUCH SCREEN

2 615007 1 TRULINK PIN 45mm CLASS 1

3 615025 1 PIN END CAP KIT CLASS 1

4 615015 1 BATTERY BACK-UP KIT 8” DSPY

5 615013 1 CABLE MAIN 15’

6 615026 1 CABLE EXTENSION 15’

7 615031 1 8” DISPLAY MOUNT (RAM)

8 615028 1 DISPLAY STORAGE CASE

9 615016 1 ANTI-ROTATION BLOCK KIT

10 615036 1 USB FLASH DRIVE (2GB)

11 615037 1 STYLUS

CLASS 2 - DISPLA Y 8” (TL8-C2)

Part Number: 615003 - 70,000 ft/lb Capacity

ITEM PART No. QTY DESCRIPTION

1 615012 1 DISPLAY 8” TOUCH SCREEN

2 615008 1 TRULINK PIN 75mm CLASS 2

3 615027 1 PIN END CAP KIT CLASS 2

4 615015 1 BATTERY BACK-UP KIT 8” DSPY

5 615023 1 CABLE MAIN 25’

6 615026 1 CABLE EXTENSION 15’

7 615031 1 8” DISPLAY MOUNT (RAM)

8 615028 1 DISPLAY STORAGE CASE

9 615016 1 ANTI-ROTATION BLOCK KIT

10 615036 1 USB FLASH DRIVE (2GB)

11 615037 1 STYLUS

CLASS 3 - DISPLA Y 8” (TL8-C3)

Part Number: 615004 - 150,000 ft/lb Capacity

ITEM PART No. QTY DESCRIPTION

1 615012 1 DISPLAY 8” TOUCH SCREEN

2 615009 1 TRULINK PIN 100mm CLASS 3

3 615032 1 PIN END CAP KIT CLASS 3

4 615015 1 BATTERY BACK-UP KIT 8” DSPY

5 615024 1 CABLE MAIN 65’

6 615034 1 CABLE JIB 15’

7 615031 1 8” DISPLAY MOUNT (RAM)

8 615028 1 DISPLAY STORAGE CASE

9 615035 1 JUNCTION BOX

10 615036 1 USB FLASH DRIVE (2GB)

11 615037 1 STYLUS

Pengo continually looks for new ways to improve its products. Therefore, Pengo reserves the right to make changes to our

products and specifi cations without notice.

CLASS 4 - DISPLA Y 8” (TL8-C4)

Part Number: 615005 - 300,000 ft/lb Capacity

ITEM PART No. QTY DESCRIPTION

1 615012 1 DISPLAY 8” TOUCH SCREEN

2 615010 1 TRULINK PIN 114mm CLASS 4

3 615033 1 PIN END CAP KIT CLASS 4

4 615015 1 BATTERY BACK-UP KIT 8” DSPY

5 615024 1 CABLE MAIN 65’

6 615034 1 CABLE JIB 15’

7 615031 1 8” DISPLAY MOUNT (RAM)

8 615028 1 DISPLAY STORAGE CASE

9 615035 1 JUNCTION BOX

10 615036 1 USB FLASH DRIVE (2GB)

11 615037 1 STYLUS

PENGO TruLink Manual 7

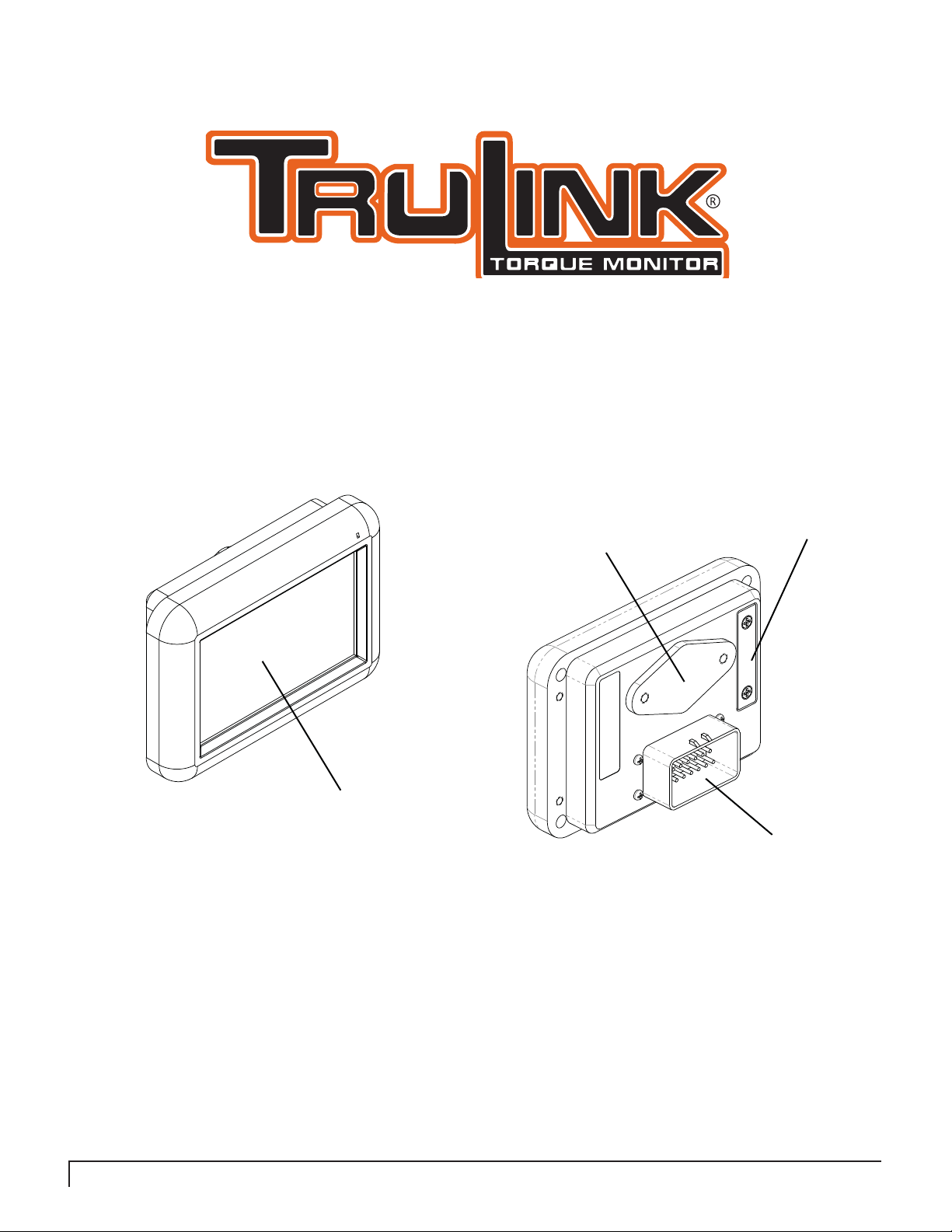

COMPONENT IDENTIFICATION (4” DISPLAY OPTION)

Parts list shown on this page are for the 4” Display option only .

1) 4.3” T ouch Screen Display

CAN-based display module with a 4.3” TFT LCD touch

screen. Windows CE operating platform. Input power

supply range from 9 V to 32 V . Operating temperature

range of -20 C to +70 C. IP67 (ingress protection) allows

for outdoor use if required. USB port for data export.

2) TruLink Pin - Classes 1 and 2

Pin contains CPU, inclinometer and strain gages.

Class 1: 45mm diameter pin. 20,000 ft/lbs torque

capacity.

Class 2: 75mm diameter pin. 70,000 ft/lbs torque

capacity.

3) TruLink End Cap Kit - Class 1 and 2

End Cap Kit is comprised of the end cap, fastening bolt

and installation rod.

4) Display Power Harness (4.3” Display)

Wire harness provides power to the display via auxiliary

power coupler. Aux power coupler plugs into the auxiliary

(cigarette lighter) port. Wire harness also connects to

the main cable which links the TruLink pin to the display .

5) Cable Main 15’

Wire harness provides power to the display and CAN

logger via a auxiliary power coupler. Aux power coupler

plugs into the auxiliary (cigarette lighter) port. Wire

harness also connects the display and CAN logger to the

electrical cable running to the Anchor Drive wire harness.

7) Cable Extension 15’

Cable is used to extend main cable in applications

8) 4.3” Display Mount

Mount is used to position the touch screen display within

the operators cab. Mount can be used with suction cups

(provided) or hard mounted using hardware (not provided).

9) Display Protective / Storage Case

Waterproof and impact resistant protective case. Used to

store the TruLink display when not in use.

10) Anti-Rotation Block Kit

Anti-Rotation block is used to position the TruLink pin in

the correct orientation plane. Kit is provided with several

types of hardware to outfi t all Pengo Revolution Series

Anchor Drives.

11) USB Flash Drive

2 GB fl ash drive provided for data export from TruLink

12) Stylus

Silicone tipped stylus, used as a section tool for the touch

screen display .

6) Battery Back-Up Kit

Kit (harness and back-up box) provides power to the

Display. A Battery Back-Up Box is included with the

cable assembly. The Battery Back-Up Box is used to

turn the display on and off by use of the switch located

on the Battery Back-Up Box.

Pengo continually looks for new ways to improve its products. Therefore, Pengo reserves the right to make changes to our

products and specifi cations without notice.

8 PENGO TruLink Manual

COMPONENT IDENTIFICATION (8” DISPLAY OPTION)

Parts list shown on this page are for the 8” Display option only .

1) 8.4” T ouch Screen Display

CAN-based display module with a 8.4” TFT LCD touch

screen. Windows CE operating platform. Input power

supply range from 9 V to 32 V. Operating temperature

range of -20 C to +70 C. IP67 (ingress protection) allows

for outdoor use if required. USB port for data export.

2) TruLink Pin - Classes 1, 2, 3 and 4

Pin contains CPU, inclinometer and strain gages.

Class 1: 45mm diameter pin. (20,000 ft/lbs torque)

Class 2: 75mm diameter pin. (70,000 ft/lbs torque)

Class 3: 100mm diameter pin. (150,000 ft/lbs torque)

Class 4: 1 14mm diameter pin. (300,000 ft/lbs torque)

3) TruLink End Cap Kit

End Cap Kit is comprised of the end cap, fastening bolt

and installation rod. Used on classes 1 and 2 only .

4) Display Power Harness (8.4” Display)

Wire harness provides power to the display via auxiliary

power coupler. Aux power coupler plugs into the auxiliary

(cigarette lighter) port. Wire harness also connects to

the main cable which links the TruLink pin to the display .

5) Cable Main (lengths are class specifi c)

Wire harness provides power to the display and CAN

logger via a auxiliary power coupler. Aux power coupler

plugs into the auxiliary (cigarette lighter) port. Wire

harness also connects the display and CAN logger to the

electrical cable running to the Anchor Drive wire harness.

Lengths: Class 1: 15’ / Class 2: 25’ / Class 3 & 4: 65’.

6) Battery Back-Up Cable

Kit (harness and back-up box) provides power to the

Display . A Battery Back-Up Box is included with the cable

assembly . The Battery Back-Up Box is used to turn the

display on and off by use of the switch located on the

Battery Back-Up Box.

7) Cable Extension 15’ (Classes 1 & 2)

Cable is used to extend main cable in applications

8) 8.4” Display Mount

Mount is used to position the touch screen display within

the operators cab. Mount can be used with suction cups

(provided) or hard mounted using hardware (not provided).

9) Cable Jib (Classes 3 & 4)

15’ cable used to connect the Pin to the Junction Box.

10) Junction Box

Junction Box used on Class 3 & 4 systems. Junction Box

is located near the end of the excavator boom near the pin.

Allows for quick disconnect when Drive is not in use.

11) Display Protective / Storage Case

Waterproof and impact resistant protective case. Used to

store the TruLink display when not in use.

12) Anti-Rotation Block Kit

Anti-Rotation block is used to position the TruLink pin in the

correct orientation plane. Kit is provided with several types

of hardware to outfi t all Pengo Revolution Series Anchor

Drives.

13) USB Flash Drive

2 GB fl ash drive provided for data export from TruLink

14) Stylus

Silicone tipped stylus, used as a section tool for the touch

screen display .

Pengo continually looks for new ways to improve its products. Therefore, Pengo reserves the right to make changes to our

products and specifi cations without notice.

PENGO TruLink Manual 9

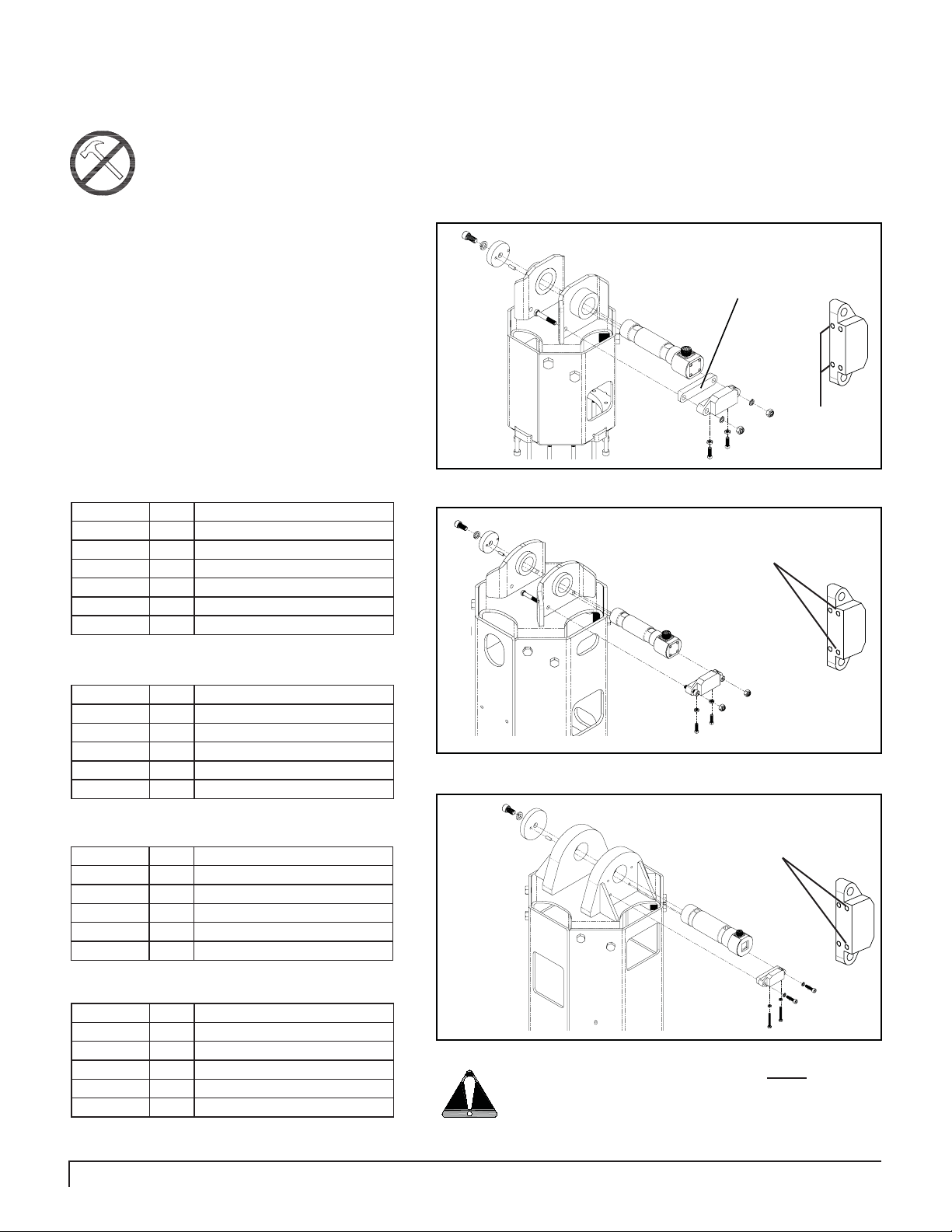

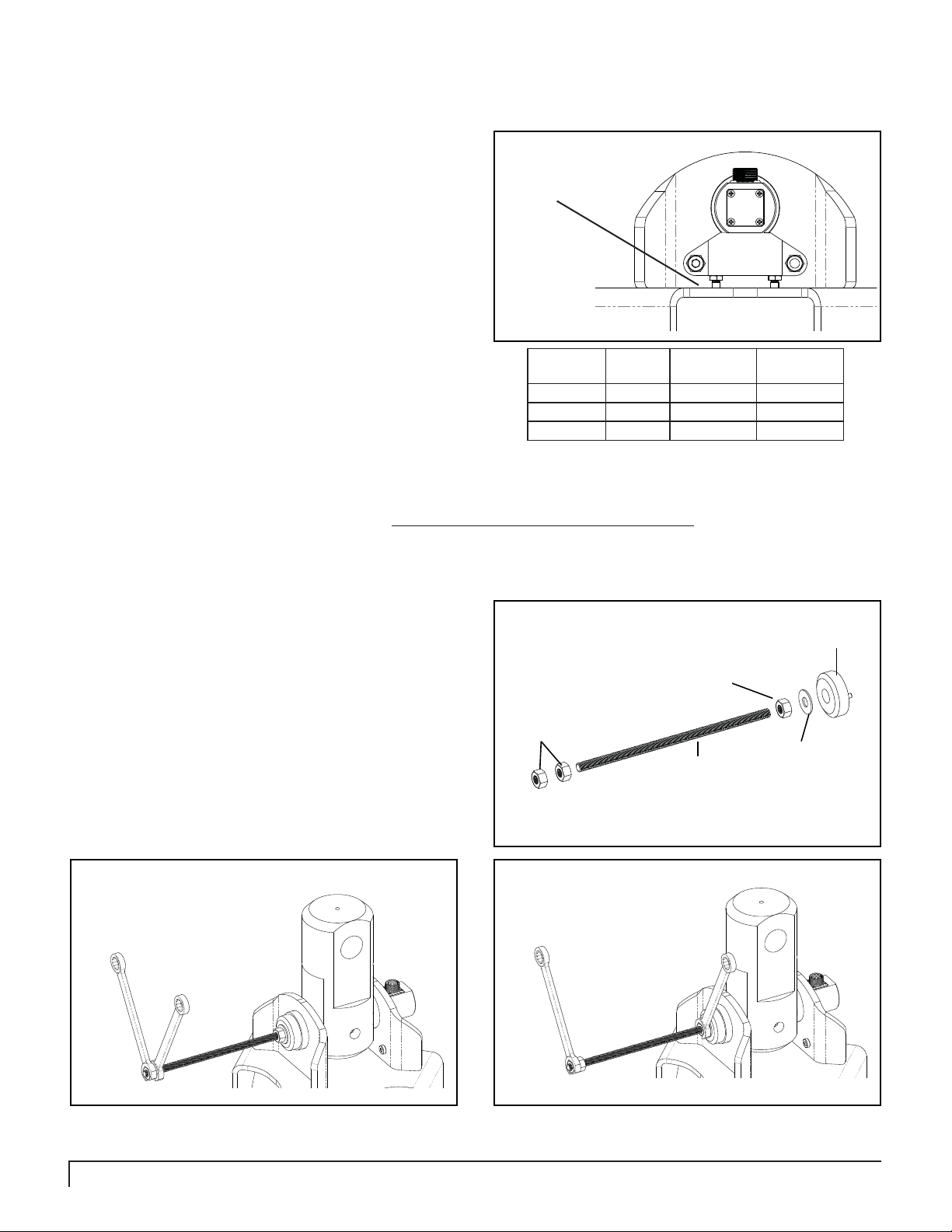

ANCHOR DRIVE TRULINK PIN INSTALLATION

NOTE: Do NOT use a hammer or any other object at any time during the installation of

the TruLink pin. Hitting the head of the pin with a object will damage the CPU processor

and will VOID the warranty .

Position the Anchor Drive in a manner

1

connection pin.

2

to the RT/DV 40 series.

Use the illustrations shown on the right to identify

the correct set-up instructions for your specifi c

Pengo Anchor Drive.

DS-3 & RS-7 Requires:

DT-5, RS-12, RT -9 & RT -12 Requires:

RT-20 Requires:

in which it will be safe to work on during

the pin installation. Remove the existing

Install the Anti-Rotation Block to the

Anchor Drive. The Anti-Rotation Block is

designed to fi t all Pengo Anchor Drives up

PART No. QTY DESCRIPTION

615006 1 ANTI-ROTATION BLOCK

610610 2 SCREW SOCHD M10 X 60mm

615029 1 SPACER CLASS 1

610298 2 NUT HEX LOCK M10

610663 2 SET SCREW 5/16” X 1”

610664 2 JAM NUT 5/16”

PART No. QTY DESCRIPTION

615006 1 ANTI-ROTATION BLOCK

610610 2 SCREW SOCHD M10 X 60mm

610298 2 NUT HEX LOCK M10

174526 2 BOLT HEX 5/16” X 2-1/4”

610664 2 JAM NUT 5/16”

PART No. QTY DESCRIPTION

615006 1 ANTI-ROTATION BLOCK

700534 2 LOCK WASHER 10mm

670175 2 SCREW SOCHD M10 X 40mm

610663 2 SET SCREW 5/16” X 1”

610664 2 JAM NUT 5/16”

Figure 1A

Figure 2A

DS-3 & RS-7 Installation.

Spacer Bar used on

DS-3 & RS-7 Only .

Use this set

of holes for

adjustment

screws.

RS-12, RT -9 & RT -12 Installation.

Use this set of holes for

adjustment screws.

RT -20, RT -30 & RT -40 Installation.

Use this set of holes for

adjustment screws.

RT-20, RT -30 & RT -40 Requires:

PART No. QTY DESCRIPTION

615006 1 ANTI-ROTATION BLOCK

700534 2 LOCK WASHER 10mm

670175 2 SCREW SOCHD M10 X 40mm

174526 2 BOLT HEX 5/16” X 2-1/4”

610664 2 JAM NUT 5/16”

10 PENGO TruLink Manual

Figure 3A

Use of the Anti-Rotation Block is NOT optional.

It must be used in order for the torque and

inclinometer values to be accurate!

ANCHOR DRIVE TRULINK PIN INSTALLATION

NOTE: If your Anchor Drive does not have existing mounting holes located on the Bail Ears:

1) Place the TruLink Pin into the Bail Ears, ensuring the connecting port is facing up and parallel with the Anchor Drive.

2) Position the Anti-Rotation Block on the underside of the pin head (opposite of the connecting port) and mark the location

of the holes. Drill two 7/16” diameter holes. The 30 and 40 series Drives require the holes to be tapped to M10 x 1.5 threads.

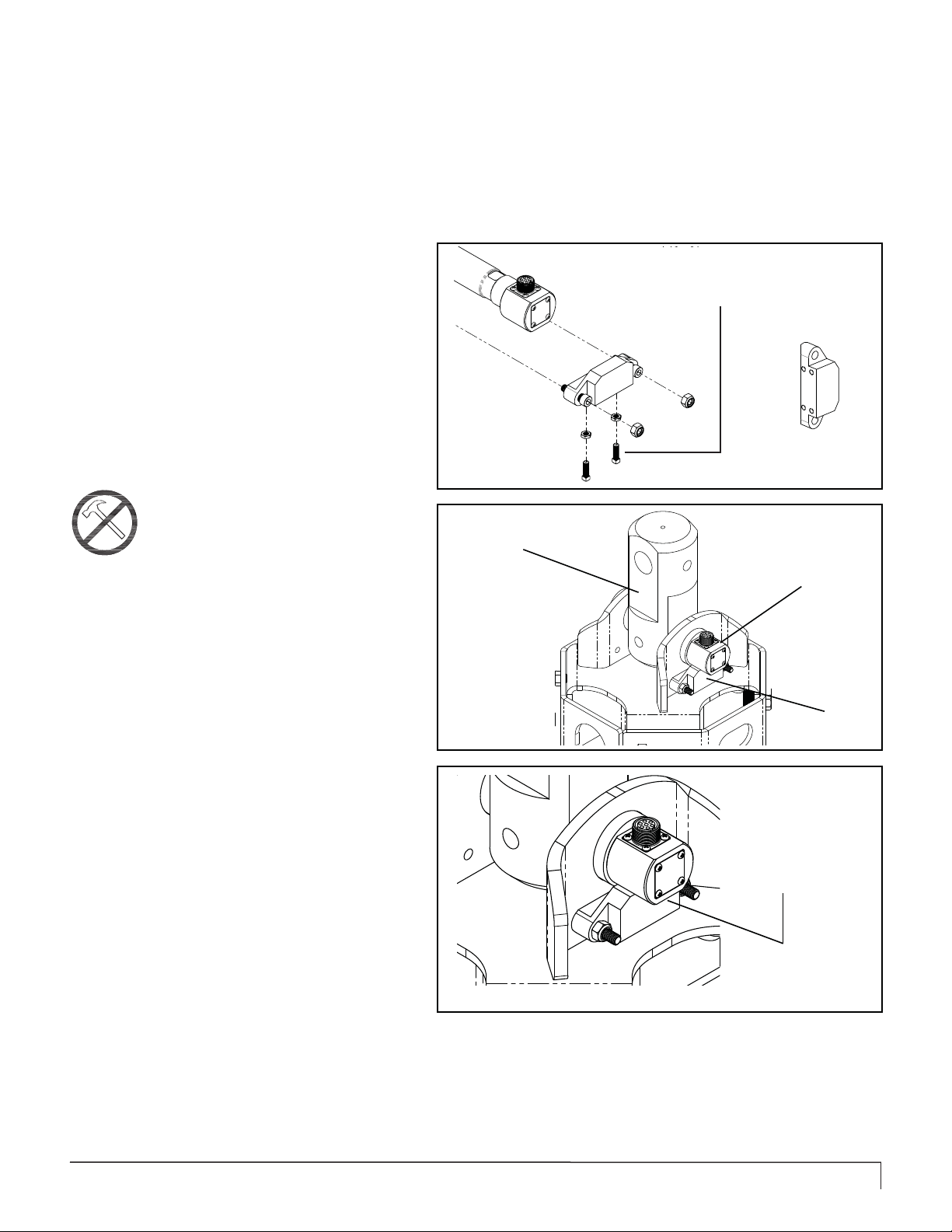

Install the appropriate adjustment screws

into the bottom face of the block. Screw the

3

adjustment screws all the way into the block.

The adjustment screws need to be installed before

the block can be bolted to the Bail Ears.

Once the Anti-Rotation Block is in place the

TruLink Pin can now be installed. Position the

4

Link Arm or desired mounting bracket between

the Bail Ears. Install the TruLink Pin with the large

end of the pin facing the front of the Anchor Drive.

See fi gure 5A.

Note: Do NOT hammer or tap the Pin into

place. The Pin should slide easily through

the Bail Ear Bushings.

Figure 4A

Link Arm

Install adjustment screws first

before bolting block to Bail.

ATTENTION!

If the TruLink Pin is not easily installed use the

Installation Rod provided. Instructions on how to use

the Installation Rod are listed on page 12.

Push the Pin into the Drive as far as it will go.

The head of the Pin should align with the Anti-

5

Rotation Block. The opposite end of the Pin

should be fl ush with the outer-edge of the bushing.

The Pin should not protrude past the bushing. See

fi gure 6A.

Install the Pin End Cap by inserting the provided

dowel into the small off center hole in the end

6

of the Cap. Align the dowel and the main hole

of the End Cap with the dowel hole and threaded hole

on the end of the TruLink Pin.

Continue on page 12.

Figure 5A

Figure 6A

TruLink Pin

Anti-Rotation

Block

Bottom of pin

should rest on

the top surface of

the Anti-Rotation

Block.

PENGO TruLink Manual 11

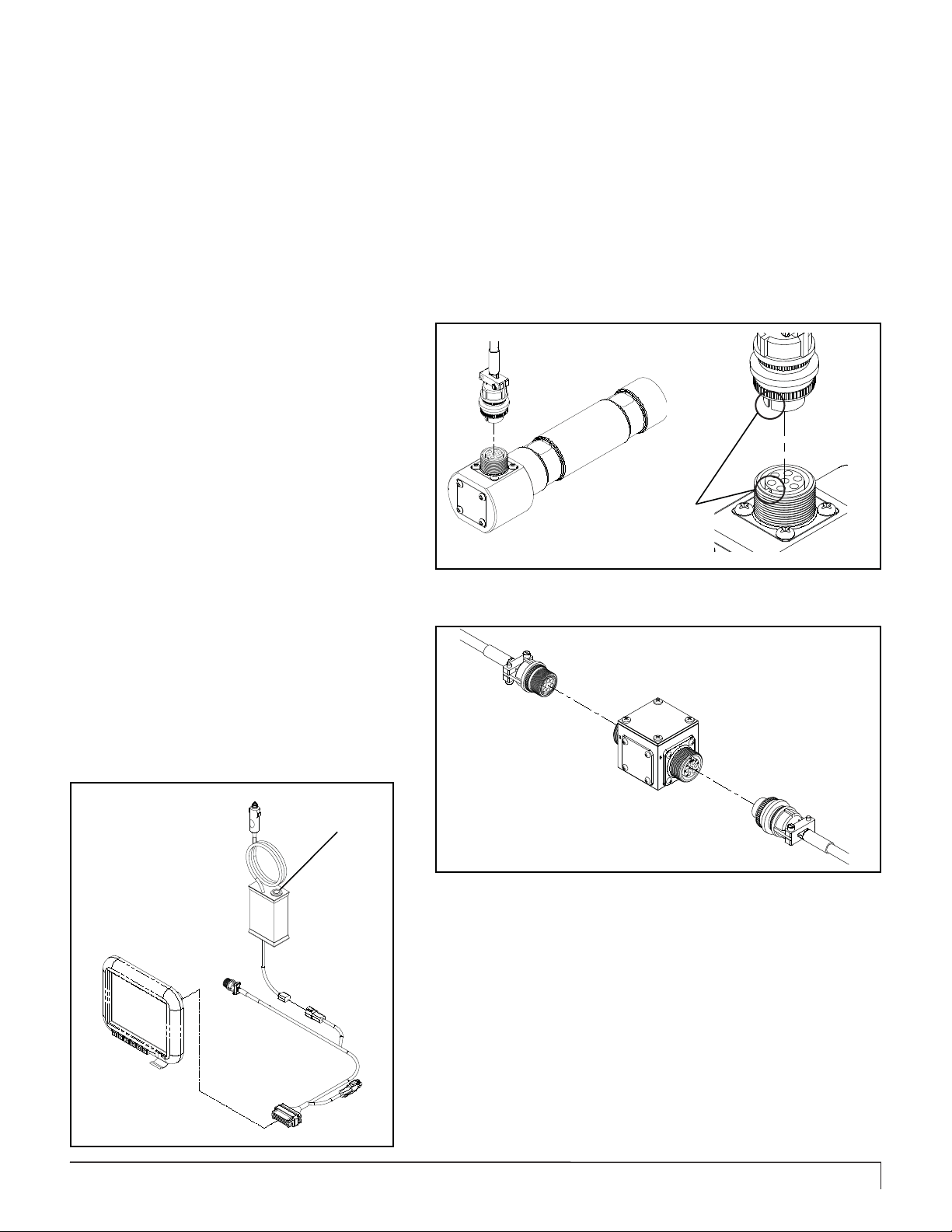

ANCHOR DRIVE TRULINK PIN INSTALLATION

Slide the Anti-Rotation Block tight up against the

head of the TruLink Pin eliminating any gap between

7

the Pin and the block. Unscrew the adjustment

screws until they make contact with the top surface of the

Bail. Make sure the adjustment screws are of equal length

and the block remains parallel with the Bail top plate. See

fi gure 7A.

Secure the End Cap to the TruLink Pin using

8

appropriate class on Pin being installed. The chart lists the

correct tightening torque for the socket head cap screws.

When screws are to be tightened or replaced, refer to this

chart to determine the proper torque.

When installing the TruLink Pin into the Drive it might be necessary to use the Pin-Install Rod. The Install Rod is designed

to draw the TruLink Pin through the Drive ears. The T ruLink Pin can not be forced into place. The Pin should slide easily

through the bushings. When needed use the Install Rod as shown below.

the provided socket cap screw and lock washer.

Tighten screw to the recommended torque for the

Assemble the Installation Rod as shown in fi gure 1B. Note the Pin End Cap will be used in the this step.

Ensure set-screws

make contact with

the top plate of the

Bail.

Figure 7A

Pin

Class

1 1/2” 100 135.5

2 3/4” 340 460.9

3 & 4 1” 800 1084.6

Ft-Lbs = Foot Pounds / Nm = Newton Meters

Screw

Dia

Torque

Ft-Lbs

Torque

N/m

1

Position the two end nuts on the Rod and adjust

according to the amount of Rod required to effectively

2

pull the TruLink Pin through the ears of the Drive.

Using two 7/8” wenches tighten the end nuts against one

another. See fi gure 2B.

Hold the 2nd Nut tight while steadily turning the nut

closest to the End Cap in a clockwise motion. This

3

action will draw the TruLink Pin through the ears of

the Drive. Be careful not to apply too much pressure as this

may damage the threaded hole in the end of the TruLink

Pin. See fi gure 3B.

End Cap

Nut

Nut

Washer

Install Rod

Figure 1B

Figure 3BFigure 2B

When installing large TruLink Pins such as Class 3 and 4 Pins it is highly recommended that the Install Rod be used.

12 PENGO TruLink Manual

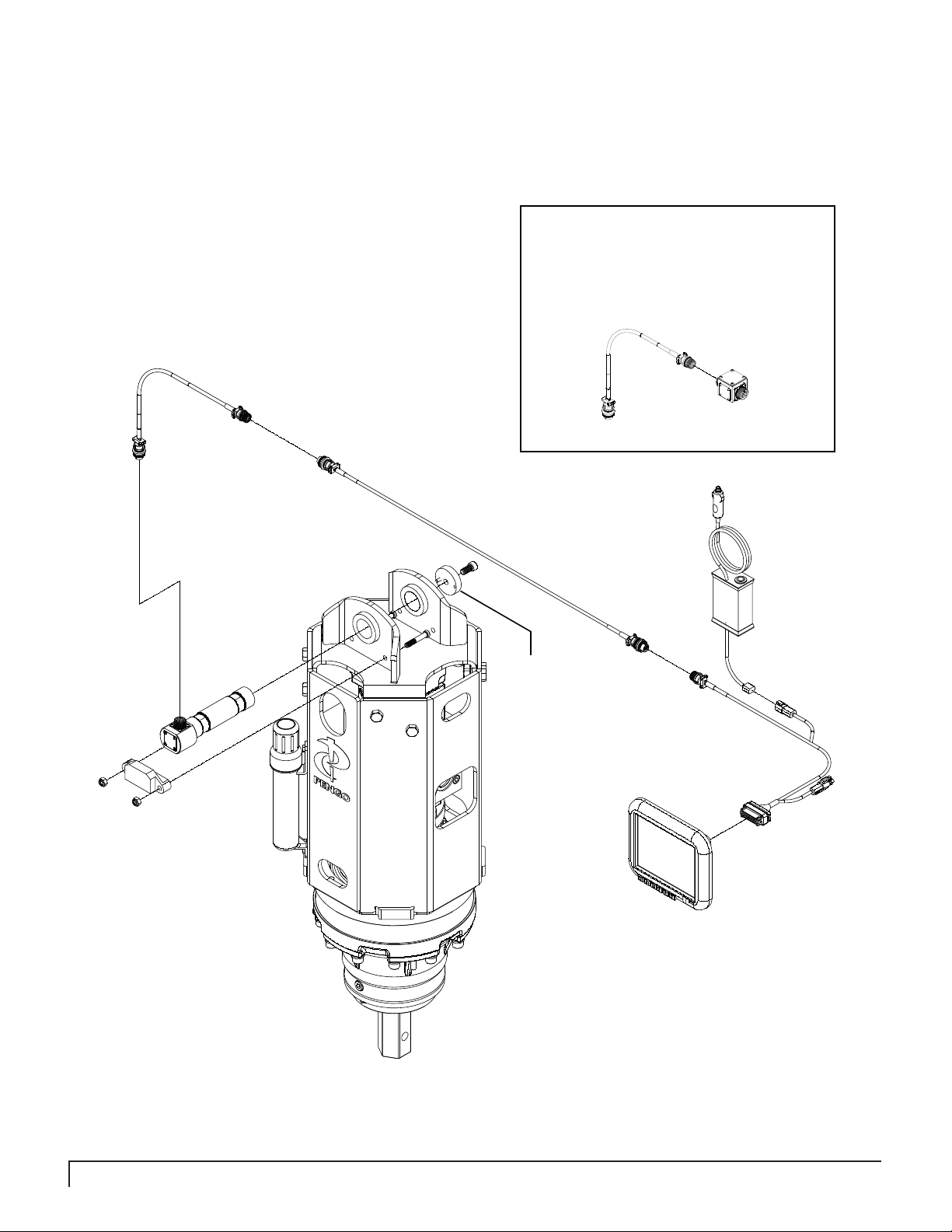

TRULINK PIN / CABLE CONNECTION

Depending on the distance from the Anchor Drive to the Display select the appropriate Cable(s). All T ruLink systems have

a Main Cable and an Extension Cable.

Main Cable will connect to the display harness and the TruLink Pin if the length is suffi cient.

Extension Cable (if necessary) connects the Main Cable to the TruLink Pin.

Note: Ensure that the cable(s) have enough “slack” to allow for full range or movement . Most cables can be run next to

the hydraulic hoses.

Attach the selected cable to the TruLink

Pin. Be sure to align the pins inside the

1

cable connector with the holes on the

TruLink connecting base. The tab and slot must

align with each other in order to ensure a positive

connection. See fi gure 1C.

On class 3 & 4 TruLink systems it is

1a

a Junction Box and Jib Cable close to the Anchor

Drive will allow for easy disconnect. Using a Jib

Cable near the Anchor Drive will prevent damage

to the Main Cable and is easier to replace in the

event the cable is damaged. See fi gure 2C.

recommended to use the provided

Junction Box and Jib Cable. Installing

Align Slot with T ab

(All Connections)

Figure 1C

Ensure Cable connections are solid and not binding or pinched.

Run all Cables next to the hydraulic hoses

running along prime movers arms and

2

or boom. It is recommended to zip tie

the Cables to the hydraulic hoses. The Cables

should be run in a manner that does not expose

the Cables to excessive heat or pinching.

On / Off

Switch

Figure 2C

BATTERY BACK-UP CABLE CONNECTION

The Battery Back-Up Cable plugs into the Display Power Harness as

shown in fi gure 3D.

Use the ON / OFF switch located on top of the Battery Box to power on

and power off the Display .

PENGO TruLink Manual 13

TRULINK SYSTEM OVERVIEW

Use the illustration below to help familiarize yourself with the various components and overall system layout.

Note: The Jib Cable and Junction box are included

on Class 3 and 4 systems only . On Class 3 and

4 systems it is recommended to use the provided

Junction Box and Jib Cable. Installing a Junction

Box and Jib Cable close to the Anchor Drive will

allow for easy disconnect.

Extension Cable

TruLink

Pin

Jib Cable

Junction

Box

Main Cable

Battery Back-Up

Pin

End Cap

Display Power

Harness

Anti-Rotation

Block

Display

Anchor Drive

14 PENGO TruLink Manual

Job Name: PENGO TEST

Job Number: AQ1356

Customer: PENGO

Location: LAURENS, IOWA

Operator: JON DAVIS

Machine: CAT 320B

Date Time Pile Number Torque Depth X Inclinometer Y Inclinometer

25/01/2013 12:20:12 101 115 0 0 0

25/01/2013 12:20:13 101 222 0 0 0

25/01/2013 12:20:14 101 677 0 0 0

25/01/2013 12:20:15 101 4740 0 0 0

25/01/2013 12:20:16 101 6485 0 0 0

25/01/2013 12:20:17 101 13015 0 0 0

25/01/2013 12:20:18 101 16756 0 0 0

25/01/2013 12:20:19 101 18456 0 0 0

25/01/2013 12:20:20 101 22924 0 0 0

25/01/2013 12:20:21 101 25317 0 0 0

25/01/2013 12:20:22 101 28151 0 0 0

25/01/2013 12:20:23 101 29895 0 0 0

25/01/2013 12:20:24 101 32183 0 0 0

25/01/2013 12:20:25 101 34759 0 0 0

25/01/2013 12:20:26 101 37106 0 0 0

25/01/2013 12:20:27 101 39272 0 0 0

25/01/2013 12:20:28 101 41105 0 0 0

25/01/2013 12:20:29 101 42885 0 0 0

25/01/2013 12:20:30 101 44578 0 0 0

25/01/2013 12:20:31 101 46294 0 0 0

25/01/2013 12:20:32 101 48020 0 0 0

25/01/2013 12:20:33 101 49909 0 0 0

25/01/2013 12:20:34 101 54457 0 0 0

25/01/2013 12:20:35 101 58119 0 0 0

25/01/2013 12:20:36 101 62238 0 0 0

25/01/2013 12:20:37 101 66220 0 0 0

25/01/2013 12:20:38 101 68521 0 0 0

25/01/2013 12:20:39 101 70791 0 0 0

TRULINK DATA CHARTING

DATA CHARTING (RAW DATA)

Below is an example of the raw data recorded by the TruLink system and opened with Microsoft Excel. This data has

not been formatted or manipulated. This is the recorded data in its raw format.

Note: Torque and Depth values will be recorded in the units selected by the user. The default units are Ft/lbs

and Feet.

Date

(DD.MM.YY)

Time

(HH:MM:SS)

(Entered by Operator at beginning of install)

Job Information

T orque V alue

(Ft/Lbs)

(Entered by Operator)

Pile Angle

(Shown in X & Y)

Pile Depth

PENGO TruLink Manual 15

4”

DISPLAY OPERATION SECTION

Mounting Platform

T ouch Screen

4” Touch Screen Display (615011)

This display is available on Class 1 and Class 2 TruLink systems.

USB Port

Communication Port

16 PENGO TruLink Manual

Loading...

Loading...