Pengo LDS User Manual

Planetary Auger Drive

LDS/MDS Series

Single Speed

Operators / Parts

Manual

10-7-05, 135471 - Rev A

CONTENTS

To the Purchaser 2

Operator & General Safety 3

Preparation Before Set-up 4

Set Up Instructions 5

Operating Instructions 6

Description Diagram 7

LDS-4K5 Exploded View 8

LDS-4K5 Parts List 9

LDS-6K Exploded View 10

LDS-6K Parts List 11

MDS-8K Exploded View 12

MDS-8K Parts List 13

MDS-12K Exploded View 14

MDS-12K Parts List 15

MDS-17K Exploded View 16

MDS-17K Parts List 17

Lubrication 18

Troubleshooting 19

Warranty Statement 20

TO THE PURCHASER

Thank you for purchasing your new PENGO product.

Pengo products are designed and manufactured to give dependable service, to keep them running

efciently, and for safety reasons ENSURE ALL OPERATORS READ this

OPERATORS/PARTS MANUAL and the RISK MANAGEMENT STRATEGIES MANUAL.

Should you require extra manuals please contact your PENGO DEALER.

Optional extras are available for special applications or extreme conditions; these are noted

throughout each manual.

Contact your PENGO Dealer for any further information or spare parts you may require.

Record your PENGO Product details in the spaces below.

Your PENGO Dealer will need these details to give you prompt, efcient service.

2

PENGO

Serial No.

Flow

Pressure

Weight

Purchased From:

NOTE: As PENGOcontinually strives to improve and increase it’s range of products, the right to

alter specications at any time without notice or obligation, is reserved.

MAX: LPM

MAX:

BAR

KG

Date of Manufacture...../..../....

PENGO

500 East Highway 10, Laurens, IA 50554

PH:(712)845-2540

FAX:(712)845-2497

Date:______/_______/________

OPERATOR and GENERAL SAFETY

KG

The safety of the operator and the safety of everyone within the work area depend on the operator’s knowledge of

the PENGO Product. Before any operation commences with the PENGO Product ENSURE ALL OPERATORS

READ this OPERATORS/PARTS MANUAL and RISK MANAGEMENT STRATEGIES MANUAL and adhere

to all safety guidelines.

CAUTION: Complete a daily inspection prior to operating any PENGO product.

CAUTION: Replace worn parts. Worn parts may endanger safety.

CAUTION: Wear close tting protective clothing and correct safety footwear.

CAUTION: Always ensure onlookers are at least Twenty (20) Feet from all moving parts.

CAUTION: Keep all hands, feet and clothing well away from all moving parts.

CAUTION: Be alert at all times while operating the PENGO product and always ensure you are in complete

control.

CAUTION: Always be aware of any obstructions that may cause injury to the operator or damage the

PENGO product.

3

CAUTION: Be aware at all times of any Warning, Caution or other signs within the working area.

NOTE: It is your responsibility as the operator to check for all underground services such as

Gas lines, Electricity, Water lines, Telephone lines, Cable Television etc. before Drilling or

Trenching.

Alert yourself to the weight(s) of the PENGO Product(s) you operate.

Refer Pg 4

Typical Caution Sticker

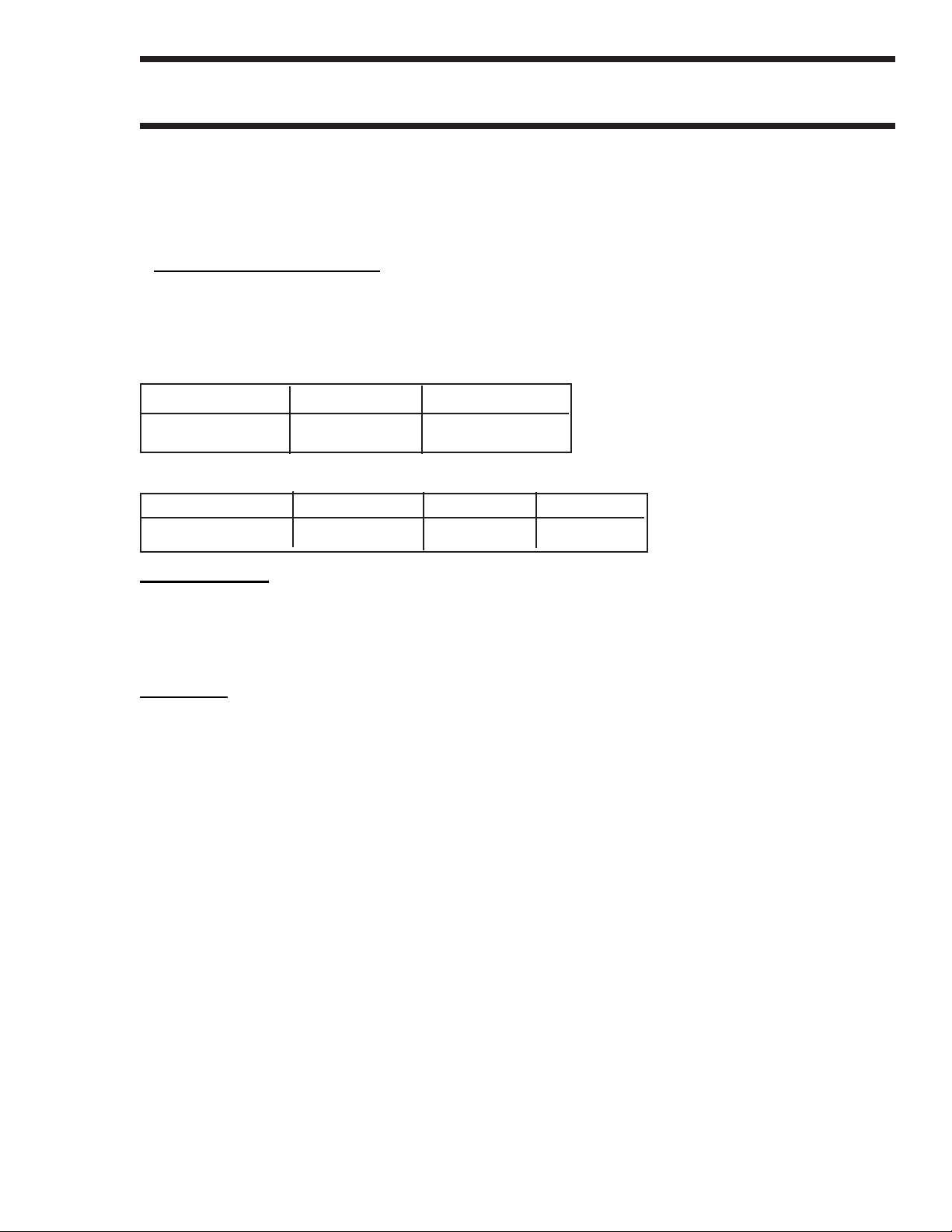

PREPARATION BEFORE SETUP

This OPERATORS/PARTS MANUAL covers the

following PENGO product.

AUGER DRIVE UNITS

LDS-4K5, LDS-6K

MDS-8K, MDS-12K, MDS-17K

UNIT LDS 4K5 LDS 6K

WEIGHT(lbs) 154 154

UNIT MDS-8K MDS-12K MDS-17K

WEIGHT(lbs) 242 253 463

4

CHECKLIST

To avoid any inconvenience before operation, please check that you have received the

Items (covered in this manual) which you may have ordered.

EXAMPLE

1 x Auger Drive Unit

1 x Swivel Arm

1 x Bail Pin complete with 1 x Spring Clip.

1 x Auger Pin with 1 x Spring Clip.

2 x Hydraulic Hoses.

1 x Frame (For mounting Auger Drive Unit to Parent Machine)

Augers

Wearparts

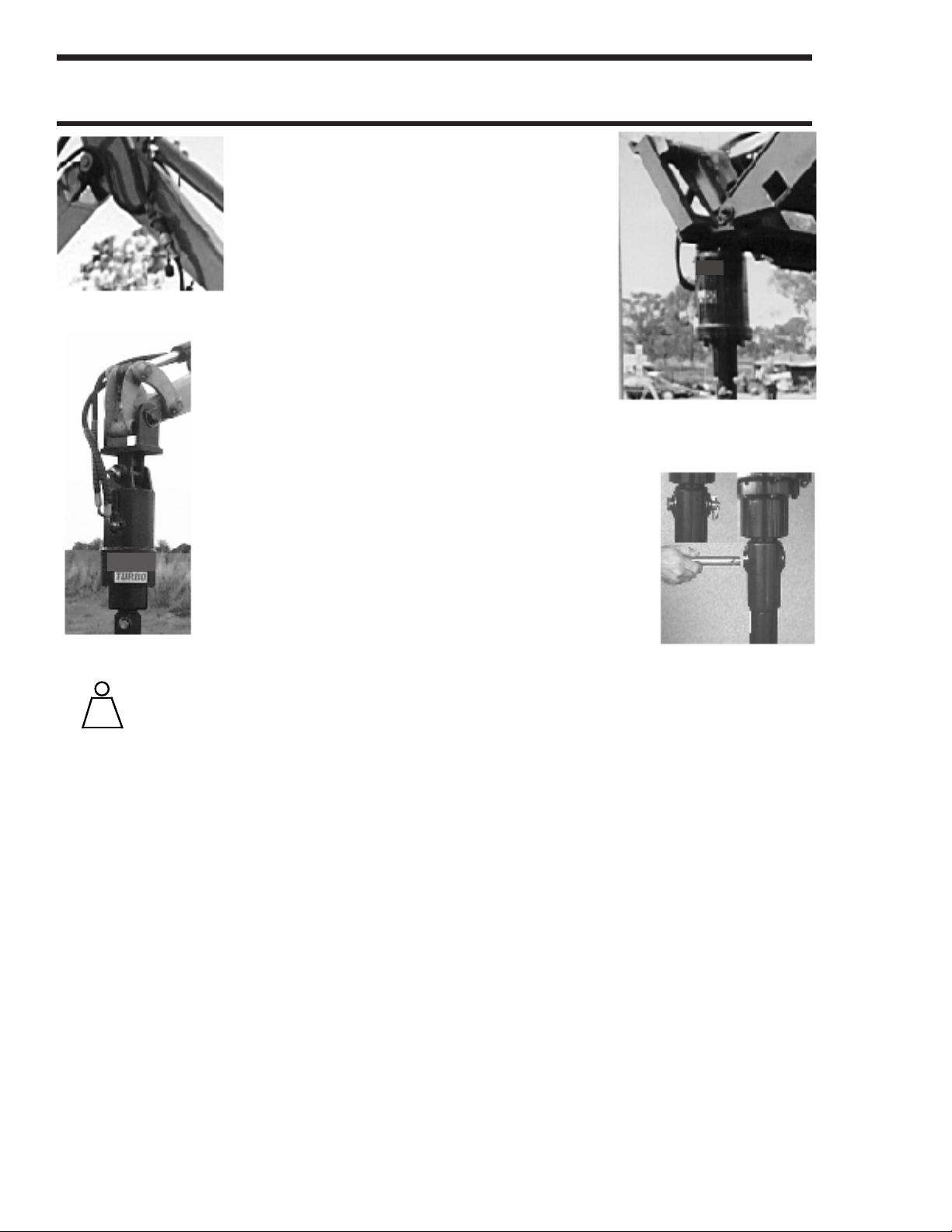

SET UP INSTRUCTIONS

KG

The PENGO Earth Auger Drive Unit

receives its Hydraulic oil ow and

pressure from the Parent Machine

through the Auxiliary Hydraulic

(Attachment) Circuit via two Quick

Release Couplers normally located

near the end of the Loader arms,

Fig 1

Excavator Dipper or Truck Crane

Booms etc.

Mounting Frames are attached to

the Bucket Attaching Points on

Loader arms and Excavators. On

Truck Cranes a Linkage is normally

located between the Hook Pin and the

PENGO Earth Auger Drive Unit.

FIG 2: Typical mounting for

Excavators.

FIG 3: Typical mounting for Skid

5

Fig 3

Fig 2

CAUTION: Alert yourself to the weight(s) of the PENGO product(s) Refer Pg 4

You operate. Do not exceed your machine operating weight

or lifting capacity. (Refer to your machine manual)

Ensure your machines Flow & Pressures do not exceed the maximum rated Flow & Pressures

of the PENGO Earth Auger Drive Unit. (Refer Pg 2 To the Purchaser)

(1) Fit Mounting Frame (Refer Above)

(2) Fit PENGO Earth Auger Drive Unit using Bail and Pins.

(3) Hook up hoses to Auxiliary Hydraulic Circuit. ENGINE MUST BE SHUT OFF.

(4) Check that the drilling rotation on PENGO Earth Auger Drive Unit is clockwise.

NOTE: Two-way ow is required for anticlockwise rotation.

(5) To assure optimum Hydraulic Motor life, run new PENGO Earth Auger Drive Unit for one hour

on approx. 1/3rd RPM before application of full load.

(6) Fit Auger. (See Fig 4) Use only genuine PENGO Auger Pin and Spring Clip.

REMOVAL PROCEDURE: Reversal of Set up Instructions.

Fig 4

OPERATING INSTRUCTIONS 6

Before operating, always ensure that the PENGO Earth Auger Drive Unit and Auger are tted

correctly to the parent machine. (Refer to Set up Instructions Pg 5).

CAUTION: Do not operate on excessive slopes, embankments or near edges of excavations.

When travelling or manoeuvring Parent Machine to the required drilling area, reduce ground speed

to prevent the Earth Auger Drive Unit and Auger from swinging.

NOTE: Some mounting Frames are tted with a support

bracket. When tted ensure support bracket locates the

Earth Auger Drive Unit and Auger during travelling or

manoeuvring (See Photo, Typical for Skid Steer Loaders)

To commence drilling, locate Auger Pilot (on pre marked spot)

and engage machine auxiliary lever to rotate the Auger in a

clockwise direction.

Lower the machine arm(s) to push the Auger into the ground. The harder the ground the more down

pressure you will need.

NOTE: Do not continually stall the Earth Auger Drive Unit. Continual stalling may cause excessive

heating of the hydraulic system.

As the Auger digs into the ground , the machine arm(s) may travel through an arc. You may therefore

have to continually reposition the Earth Auger Drive Unit or Parent machine to drill vertically.

Do not drill the Auger deep into the ground in one operation. Continually clearing the hole during

drilling will facilitate a faster and easier operation.

NOTE: Extension shafts are available for extra depth.

Disengage machine auxiliary lever and rest Earth Auger Drive Unit and Auger on the ground before

making any adjustments or leaving the Parent Machine.

DESCRIPTION DIAGRAM 7

Loading...

Loading...