II

4031 600 90401

May 2017- Seventh Edition

© 2017 Pendulum Instruments / Altaria Services

III

Table of Contents

1 Introduction

Introduction ................ 1-2

About this Manual............ 1-2

Warranty................. 1-2

DeclarationofConformity .......1-2

Safety Precautions ............. 1-3

CautionandWarningStatements....1-3

Symbols................. 1-3

If in Doubt about Safety .........1-4

2 Preparation for Use

Unpacking................. 2-2

CheckList................ 2-2

Identification .............. 2-2

ReadingtheElectronicManuals......2-2

Installation................. 2-2

Supply Voltage ............. 2-2

Setting ................ 2-2

Fuse.................. 2-2

Grounding ................ 2-3

RearPanel................ 2-3

LinePowerInlet ...........2-3

ReferenceOutput...........2-3

External Reference Input .......2-3

External Arming Input ........2-3

GPIB/IEEE-488 Connector ......2-3

USBConnector............ 2-4

Optional Main Input Connectors . . . 2-4

Fan.................. 2-4

TypePlate............... 2-4

OrientationandCooling......... 2-4

Fold-Down Support ...........2-4

Rackmount Adapter ........... 2-4

3 Operating the Counter

Introduction ................ 3-2

UserInterface............... 3-2

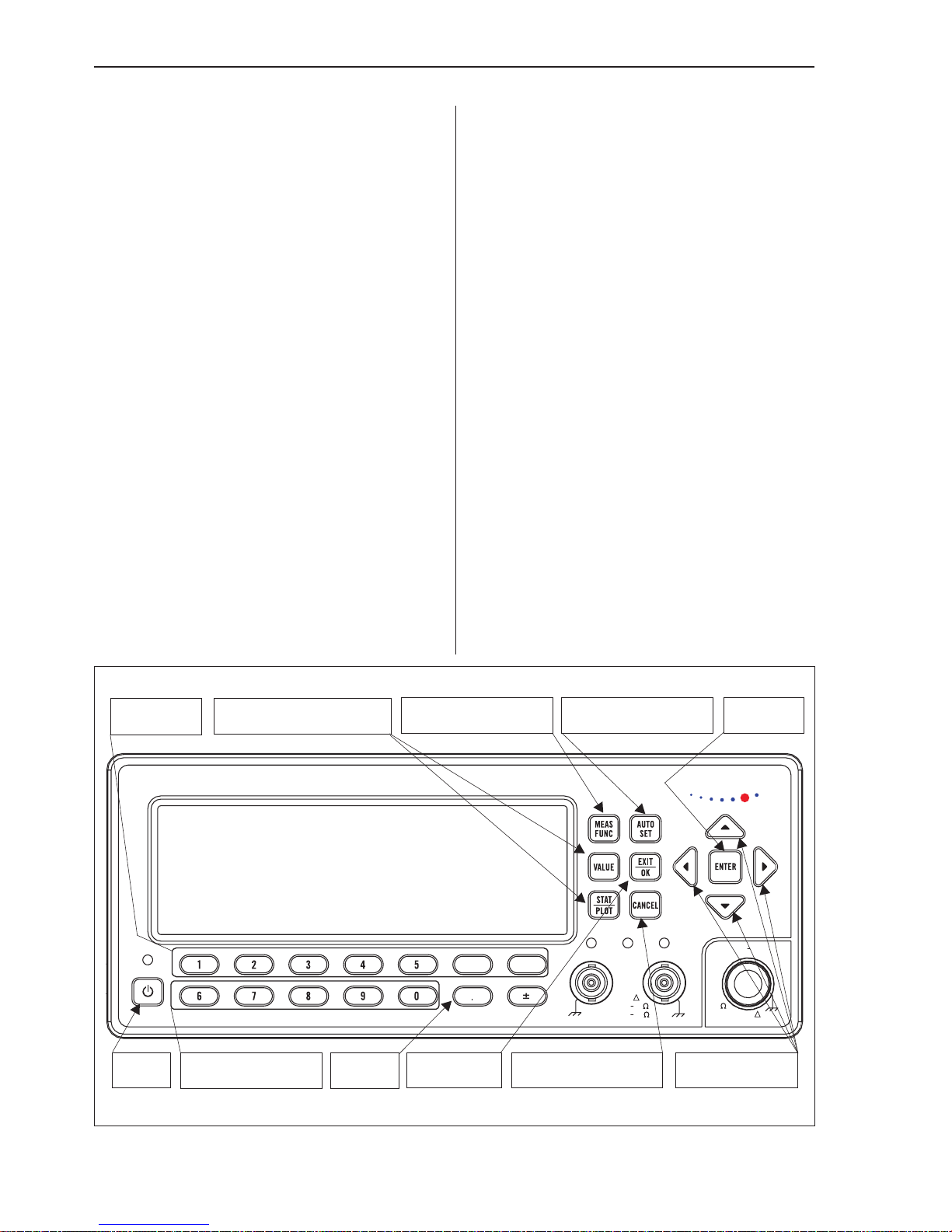

Getting Familiar with the Counter .....3-2

DescriptionofKeys............3-3

Power.................. 3-3

SelectFunction............. 3-3

Autoset/Preset.............. 3-3

MoveCursor .............. 3-3

Enter................... 3-3

Exit/OK ................. 3-3

Cancel.................. 3-3

PresentationModes...........3-4

VALUE................ 3-4

STAT/PLOT.............. 3-4

Remote................ 3-5

HardMenuKeys ............ 3-5

Input A ................ 3-5

Input B ................ 3-5

Settings................ 3-6

Math/Limit.............. 3-7

UserOptions............. 3-8

Hold/Run............... 3-9

Restart ................ 3-9

EnteringNumericValues........3-9

IV

4 Exercises

Preparation................. 4-2

BasicStartup................ 4-2

High-Resolution Frequency Measurement . 4-2

Built-InMathProcessing .........4-2

High-SpeedMeasurements ........ 4-3

UndertheINPUTMenus:........ 4-3

Under the SETTINGS Menu: ......4-3

TimeMeasurements............4-4

Jitter Measurements (Statistics) ......4-4

Other Single-Channel Measurements . . . 4-4

DutyCycle ............... 4-4

RiseTime................ 4-5

FallTime ................ 4-5

Remarks................. 4-5

VoltMax/MinMeasurements......4-5

ChannelSwapping............ 4-5

Two-ChannelMeasurements........4-6

TimeInterval.............. 4-6

Phase .................. 4-6

UsingAutotosetfixedtriggerlevels

(AutoOnce).............. 4-6

Procedure............... 4-6

MemorySettings ............ 4-6

Auxiliary Functions ............ 4-7

Time-Out ................ 4-7

Summary.................. 4-7

Sales&ServiceOffices...........V

Chapter 1

Introduction

Introduction

Congratulations on your choice of instrument.

It will serve you well for many years to

come.

Even though we know that you are eager to

get going, we urge you to take a few minutes

to read through the sections on safety in the

first two chapters carefully before plugging

the line connector into the wall outlet.

It is essential for your own safety to know the

restrictions that are applicable to all equip

ment that can be connected to line power.

Therefore, read about Safety Precautions on

page 1-3 and Installation on page 2-2.

That chapter is also the key to the comprehensive information that can be found on the

included CD, if you need closer information

on a subject.

About this Manual

This manual contains directions for use that

are common to all Timer/Counter/Analyzers

in the CNT-9X series.

In order to simplify the references, the

CNT-9X is further referred to throughout this

manual as the '9X'.

Warranty

The Warranty Statement is part of the folder

Important Information that is included with

the shipment.

Declaration of Conformity

The complete text with formal statements concerning product identification, manufacturer

and standards used for type testing is available

on request.

Introduction

1-2 Introduction

Safety Precautions

This instrument has been designed and tested

for Measurement Category I, Pollution Degree

2, in accordance with EN/IEC 61010-1:2001

and CAN/CSA-C22.2 No. 61010-1-04 (in

cluding approval). It has been supplied in a

safe condition. The user must have acquired

adequate knowledge of it by thoroughly

studying this manual.

To ensure the correct and safe operation of the

instrument, it is essential that you follow gen

erally accepted safety procedures in addition

to the safety precautions specified in this man

-

ual.

The instrument is designed to be used by

trained personnel only. Removing the cover

for repair, maintenance, and adjustment of the

instrument must be done by qualified personnel who are aware of the hazards involved.

The warranty commitments are rendered

void if unauthorized access to the interior

of the instrument has taken place during

the given warranty period.

Caution and Warning

Statements

CAUTION: Shows where incorrect

procedures can cause damage to,

or destruction of equipment or

other property.

WARNING: Shows a potential danger

that requires correct procedures or

practices to prevent personal in

-

jury.

Symbols

Shows where the protective ground

terminal is connected inside the instrument.

Never remove or loosen this screw.

This symbol is used for identifying the

functional ground of an I/O signal. It is always

connected to the instrument chassis.

Tells the operator to consult the

manual.

Example:

One such symbol is printed on the instrument

below the A and B inputs. It indicates that the

damage level for the input voltage decreases

from 350 V

p

to 12 V

RMS

whenyouswitchthe

input impedance from 1 MW to 50 W.

Safety Precautions 1-3

Introduction

Do not overlook the safety instruc

-

tions!

If in Doubt about Safety

Whenever you suspect that it is unsafe to use

the instrument, you must make it inoperative

by doing the following:

–

Disconnect the line cord.

–

Clearly mark the instrument to prevent its

further operation.

–

Inform your Pendulum representative.

For example, the instrument is likely to be un

-

safe if it is visibly damaged.

Introduction

1-4 Safety Precautions

Chapter 2

Preparation for Use

Unpacking

Check that the shipment is complete and that

no damage has occurred during transportation.

If the contents are incomplete or damaged, file

a claim with the carrier immediately. Also no

-

tify your local Pendulum sales or service orga

nization in case repair or replacement may be

required.

Check List

The shipment should contain the following:

–

The counter, Model CNT-9X

–

Line cord

–

N-to-BNC Adapter (only if an optional

C-channel input with a Type N connector

was ordered)

–

Built-in options as ordered should be installed. See Identification below.

–

Folder with Important Information

–

Certificate of Calibration

–

A CD-ROM including the following documentation in PDF:

•

Getting Started Manual

•

User's Manual

•

Programmer's Handbook

Identification

The type plate on the rear panel shows the

type number and the serial number. See illus

tration on page 2-4. Installed options are listed

under the menu User Options - About,where

you can also find information on firmware

version and calibration date. See page 3-8.

Installed options can also be identified by

checking the full type number on the type

plate.

Reading the

Electronic Manuals

You need the Adobe® Reader® software to

be able to read the manuals on the CD. It is in

cluded on the CD or can be downloaded free

of charge from www.adobe.com

.

Insert the CD into the CD-ROM unit of your

PC or Mac and select the file you are looking

for from the index.

Installation

Supply Voltage

n

Setting

The Counter can be connected to any AC supply with a voltage rating of 90 to 265 V

RMS

,

45 to 440 Hz. The counter automatically adjusts itself to the available line voltage.

n

Fuse

The secondary supply voltages are electroni

-

cally protected against overload or short cir

cuit. The primary line voltage side is protected

by a fuse located in the power supply unit.

The fuse rating covers the full voltage range.

Consequently there is no need for the user to

replace the fuse under any operating condi

-

tions, nor is it accessible from the outside.

CAUTION: If this fuse is blown, it is

likely that the power supply is

badly damaged. Do not replace the

fuse. Send the counter to the local

Service Center.

Removing the cover for repair, maintenance

and adjustment must be done by qualified and

Preparation for Use

2-2 Unpacking

trained personnel only, who are fully aware of

the hazards involved.

The warranty commitments are rendered

void if unauthorized access to the interior

of the instrument has taken place during

the given warranty period.

Grounding

Grounding faults in the line voltage supply

will make all instruments connected to it po

tentially dangerous. Before connecting any

unit to the power line, you must make sure

that the protective ground functions correctly.

Only then can a unit be connected to the

power line and only by using a three-wire line

cord. No other method of grounding is permitted. Extension cords must always have a protective ground conductor.

CAUTION: If a unit is moved from a

cold to a warm environment, condensation may cause a shock

hazard. Ensure, therefore, that the

grounding requirements are strictly

met. Allow enough time for the instrument to adapt to new ambient

conditions before connecting it to

line power.

WARNING: Never interrupt the

grounding cord. Any interruption of

the protective ground connection

inside or outside the instrument or

disconnection of the protective

ground terminal is likely to make

the instrument dangerous.

Rear Panel

See the figure overleaf for the location of the

connectors. The labels refer to the headings

below, where the characteristics are summa

rized. See the User's Manual for technical

specifications.

n

Line Power Inlet

AC 90-265 V

RMS

, 45-440 Hz, no range

switching needed.

n

Reference Output

10 MHz derived from the internal or the exter

nal reference, depending on which of them is

the active Measurement Reference. The choice

is made from the Settings Menu.

n

External Reference Input

If the Measurement Reference is set to Auto in

the Settings Menu, this input will be automati

-

cally selected, provided a valid signal is pres

-

ent.

n

External Arming Input

Supports external arming (synchronization) of

measurements. The main inputs A & B can

also be selected for measurement arming via

the Settings Menu.

n

GPIB/IEEE-488 Connector

The address is set from the User Options

Menu.

n

USB Connector

A serial interface according to USB 2.0

12 Mb/s provides a fast communication link to

your PC.

n

Optional Main Input

Connectors

This factory-installed option replaces the ordi

-

nary front panel main input connectors.

n

Fan

Forced cooling is provided by means of a

speed-controlled fan.

Installation 2-3

Preparation for Use

n

Type Plate

Here you can find the type number and the se-

rial number as well as information on rated

line voltage and power.

Orientation and Cooling

The counter can be operated in any position

desired. Make sure the air flow through the

ventilation slots at the side panels is not ob

structed. Leave 5 centimeters (2 inches) of

space around the counter.

Fold-Down Support

For bench top use, a fold-down support is

available for use underneath the counter. This

support can also be used as a handle to carry

the instrument.

Rackmount Adapter

An optional rackmount kit is available. See

the User's Manual for installation details.

Preparation for Use

2-4 Installation

!

!

!

191125

The CNT-90 rear panel layout.

Ext. Ref. In

Ref. Out Ext. Arm In GPIB Conn.

USB Conn.

Line Power Inlet

Type Plate

Fan

Opt. Main Input Conn.

Fold-down support for comfortable

bench-top use.

Chapter 3

Opera ting the

Counter

Introduction

While this counter has a vast array of features

and operating modes, the majority of the most

useful functions can be learned in just a few

minutes. The following descriptions and exer

-

cises will help you grasp the basics of opera

tion. They will also serve as an introduction to

some of the more advanced features. It will

take you about half an hour to gather experi

ence enough to continue exploring the world

of counting on your own.

User Interface

The fundamental idea has been to facilitate

even complex measurements by a consistent

interactive user interface that fully exploits the

large graphic display. The casual as well as

the frequent user will benefit from a combina

tion of hard and soft keys. In this context hard

keys either act immediately or open fixed

menus, whereas the function of soft keys de

-

pends on the display information.

Getting Familiar with

the Counter

The front panel is laid out in a logical fashion.

Take a few seconds to find the sections described below on the front panel of your counter. See also the figure on this page. It will

help you locate the different keys faster.

Operating the Counter

3-2 Introduction

TRIG

GATE

TRIG

pendulum

TIMER / COUNTER / ANALYZE R

100ps / 300MHz

CNT-90

INPUTINPUT

INPUT A

SETTINGSETTING

SETTINGS

MATH/LIM USER OPUSER OP

USER OPT

HOLD / RU

HOLD / RUN

RESTARTINPUTINPUT

INPUT B

A

300 MHz

B

MAX

12Vrms 50

30Vrms 1M

!

C

MAX +30dBm

50

0.2 8GHz

!

Move CursorSave&Exit Don't Save&ExitPower

Hard Menu Keys

Freeze

Select Function Autoset/Preset Enter

Presentation Modes

Soft Keys

Description of Keys

Power

The ON/OFF key is a toggling secondary

power switch. Part of the instrument is always

on as soon as line power is applied, and this

so-called standby condition is indicated by a

red LED above the key.

Select Function

This hard key is marked MEAS FUNC.

When you depress it, the menu below will

open.

The current selection is indicated by text inversion. Select the measurement function you

want by depressing the corresponding soft key

right below the display. A new menu will appear where the contents depend on the function. If you for instance have selected Fre

-

quency, you can then select between Fre

-

quency, Frequency Ratio and Fre

-

quency Burst. Finally you can also change

the preselected input channel.

Autoset/Preset

By depressing the AUTOSET key once after

selecting the wanted measurement function

and input channel, you will most probably get

a measurement result. The AUTOSET system

ensures that the trigger levels are set optimally

for each combination of measurement func

tion and input signal amplitude, provided that

you apply relatively normal signals.

By depressing the AUTOSET key twice

within two seconds, you will enter the Preset

mode, which takes you another step further to

wards fully automatic settings for your current

measurement. Such auxiliary functions as

measuring time, mathematics, filter and arm

-

ing are then reset to their default values. The

intention is to prevent possible lockups and

misinterpretations when changing measure

-

ment function or test setup, for instance.

Move Cursor

There are four cursor keys for moving the cur

sor, normally marked by text inversion,

around the menu trees.

Enter

When you want to confirm a choice without

leaving your menu position, press this key.

Exit/OK

This hard key performs the Save & Exit operation. You will confirm your selections by depressing the key, and at the same time you

will exit the current level and enter the next

higher level in the menu tree.

Cancel

This hard key performs the Don't Save & Exit

operation. You will exit the current level by

depressing the key and enter the next higher

level in the menu tree without confirming any

selections made.

Description of Keys 3-3

Operating the Counter

Presentation Modes

n

VALUE

The Value Mode gives the result of the main

measurement function as a numerical value in

large characters with full resolution. In addi

-

tion, the results of supplementary measure

ments are displayed in smaller characters with

limited resolution near the bottom of the

screen.

In case the Limits Alarm function is enabled,

Range is the selected Limit Mode,andAlarm

is the selected Limit Behavior,thenasimple

graph is also given in which the result of the

current measurement is shown as an

'emoticon' at a position relative to the limits

set by the operator. Values are represented by

a smiling face when inside the limits and a

frowning face when outside.

If one of the limits has been exceeded, the

limit indicator at the top of the display will be

flashing. Only data inside the limits is used for

autoscaling, so results outside the visible

graph area are replaced by an arrowhead at the

left or the right edge of the display.

n

STAT/PLOT

If you want to analyze a number of successive

measurements using statistical methods, this is

the key to operate. There are three display

modes available by toggling this key:

•

Numerical Mode

•

Histogram Mode

•

Trend Plot Mode

Numerical Mode

In this mode the statistical information is dis

-

played as numerical data containing the fol

-

lowing elements:

•

Mean: running mean value of the main

measurement over N samples

•

Max: maximum value

•

Min: minimum value

•

P-P: peak-to-peak deviation

• Adev: Allan deviation

•

Std: standard deviation

Histogram Mode

Successive measurement results are converted

into a histogram.

The number of bins along the horizontal axis

can be set by the user through the Settings

® Stat menu. The bins in the histogram are

autoscaled based on the measured data. Lim

-

its, if enabled, and the running mean value

X

are shown as vertical dotted lines. The center

of the graph is indicated by a filled triangle on

the X-axis. The corresponding numerical

value is displayed below it and so is the scale

Operating the Counter

3-4 Description of Keys

factor. Enabled limits affect the autoscaling so

as to visualize the current measurements and

the set limits simultaneously.

Trend Plot Mode

This mode is used for observing periodic fluc

-

tuations or possible trends.

A trend plot terminates (if HOLD is activated)

or restarts (if RUN is activated) after the set

number of samples has been completed. The

trend plot is always autoscaled based on the

measured data, starting with 0 at restart. Limits are shown as horizontal lines, if enabled.

n

Remote

When the instrument is controlled from the

GPIB bus, and the remote line is asserted, or

when the instrument is controlled from the

USB bus, then the presentation mode changes

to Remote, indicated by the label REM on

the display. The main measurement result and

the input settings are displayed in this mode.

Hard Menu Keys

These keys are mainly used for opening fixed

menus, from which further selections can be

made, for instance by means of the soft keys.

n

Input A

By depressing this key, the bottom part of the

display will show the settings for Input A.

The active settings are in bold characters and

can be changed by pressing the corresponding

soft key below the display. You can also move

the cursor, indicated by text inversion, with

the RIGHT and the LEFT arrow keys to the

desired position and then make the selection

by pressing the UP or the DOWN arrow keys.

You can also use the ENTER key.

The selections that can be made in this menu

are:

•

Trigger Slope: positive or negative, indi

-

cated by corresponding symbols

•

Coupling: AC or DC

•

Impedance: 50 W or1MW

•

Attenuation: 1x or 10x

•

Trigger: Manual or Auto (always Auto

10/90 % when measuring transition

times).

•

Trigger Level: If Manual has been selected, the absolute level can be adjusted with the up/down arrow keys or

by entering a numerical value from the

keyboard.

•

Filter: On or Off. Pressing ENTER or the

soft key below the text opens up the Fil

-

ter Settings menu. See below.

You can select a fixed 100 kHz analog

filter or an adjustable digital filter. The

equivalent cutoff frequency is set via the

value input menu that opens if you se

lect Digital LP Frequency from the menu

above.

n

Input B

The available settings under Input B are

equal to those available under Input A.

Description of Keys 3-5

Operating the Counter

n

Settings

This key accesses a range of more sophisti

cated instrument settings that usually need not

be changed for basic measurements. The fig

-

ure below shows the display after recalling the

default settings via the USER OPT menu.

A detailed description of all the possibilities is

far beyond the scope of this introductory man

ual. See the User's Manual for full details on

functions mentioned and unmentioned here.

Meas Time

This value input menu is only useful if you select a frequency function. Longer measuring

time means fewer measurements per second

but gives higher resolution. You can change

the Measuring Time by entering a numerical

value, or you can use the UP/DOWN arrow

keys to increase or decrease the current value.

Burst

This settings menu facilitates measurements

on pulse-modulated signals and is only useful

if Frequency Burst is the main measurement

function.

Both the carrier frequency and the modulating

frequency – also known as the pulse repetition

frequency (PRF) – can be measured, often

without the support of an external arming sig

-

nal (see below).

Arm

Arming is the general term used for the means

to control the actual start or stop of a measure

ment. When arming is used, the normal

free-running mode is inhibited, and triggering

takes place only when certain pretrigger con

-

ditions are fulfilled.

The signal(s) used for initiating the arming

can be applied to three channels, and the start

channel can be different from the stop chan

nel. All conditions can be set via the menu

below.

Trigger Hold-Off

In this menu you can set the delay during

which the stop trigger conditions are ignored

after the measurement start. A typical use is to

clean up signals generated by bouncing relay

contacts.

Statistics

In this menu you can find the following

submenus:

•

No. of Samples: Set the number of sam

-

ples used for calculation of various sta

-

tistical measures.

•

No. of Bins: Set the number of bins

used in the histogram mode.

•

Pacing: Set the delay between succes

sive measurements, called Pacing

Time, to ON or OFF.

Operating the Counter

3-6 Description of Keys

•

Pacing Time: Set the pacing time to a

value between 2 ms – 1000 s.

Timebase Reference

Here you can select if the counter is to use the

internal or an external timebase reference. If

Auto is selected, an external timebase will be

used only if it is interpreted as a valid signal,

i.e. both amplitude and frequency must be

within specified limits. This does not imply,

however, that an external reference source has

to be better in any sense than the internal

timebase oscillator. The EXT REF indicator

at the upper right corner of the display shows

that the instrument is using an external

timebase reference.

Miscellaneous

The options in this menu are:

•

Smart Time Interval: When selected, the

counter decides by means of

timestamping which measurement

channel is leading.

•

Auto Trig LF: In a value input menu you

can set the lower frequency limit for au

-

tomatic triggering and voltage measure

ments in the range 1 Hz – 100 kHz. A

higher limit means faster settling time

and consequently faster measurements.

•

Timeout

Switch the Timeout function ON or OFF.

In case the input signal gets interrupted,

the timeout system (if enabled) will hold

the last measurement result on screen

only during the selected period of time

(see next paragraph). Then the screen

will be blanked, and a pending bus

query will read a zero result. In case

timeout is switched off when the signal

gets interrupted, the display will freeze,

i.e. the result of the last complete mea

surement will stay on screen indefinitely.

A pending bus query will also wait indef

initely for a response, unless the test

system controller has enabled its own

timeout.

•

Timeout Time

Set the maximum time the instrument

will wait for a pending measurement to

finish before outputting a zero result.

The range is 10 ms to 1000 s.

n

Math/Limit

Here you will find the menus for mathematical postprocessing of the measurement result

and for setting up the limit testing function.

Math

You can modify the measurement result math

-

ematically by scaling or offsetting before pre

sentation on the display. This feature can be

used for getting revolutions/min instead of Hz

or for recalculating the frequency in case a de

-

vice causing frequency conversion (e.g. a

Description of Keys 3-7

Operating the Counter

multiplier or a mixer) is part of the system un

-

der test.

Select one of four formulas and enter the con

stants K, L and M to make the counter show

directly what you want, without tedious recal

culations. X stands for the current unmodified

measurement result. See the User's Manual for

a closer description.

Limits

This menu is used for setting numerical limits

and selecting the way the instrument will report the measurement results in relation to

them. See the section Presentation Modes on

page 3-4 for a short description or the User's

Manual for a more detailed description.

n

User Options

From this menu you can reach a number of

functions that are not directly involved in the

measurement process.

Save/Recall Menu

Twenty complete front panel setups can be

stored in non-volatile memory; the first ten of

them can be user-protected. The different set

-

ups can be individually labeled to make it eas

-

ier for the operator to remember the applica

-

tion.

The following can be done:

•

Save Current Setup: Select one of

twenty positions.

•

Recall Setup: Here you will find a factory-programmed default setup as well

as any setups you may have stored before.

• Modify Labels: The seven soft keys right

below the display plus the numeric input

keys 6, 7, 8, 9, 0 are used for entering

lower-case letters and digits much in the

same way as you write SMS messages

on a cell phone. Each label can hold

seven characters.

•

Setup Protect: ON or OFF. Only setup

positions 1-10 can be protected against

inadvertent overwriting.

Calibration Menu

This counter has an extensive system for

closed-case calibration by software. Refer to

the Service Manual for details.

Operating the Counter

3-8 Description of Keys

Interface Menu

Set the active interface to GPIB or USB and

enter the GPIB address.

•

Bus Type: Choose GPIB or USB

•

GPIB Mode: There are two alternative

command systems, Native and Compat

-

ible. See the User's Manual and the

Programmer's Handbook for details.

•

GPIB Address: Enter the bus address,

an integer between 0 and 31. The fac

-

tory default value is 10.

Test Menu

Different parts of the hardware can be tested

by means of built-in software support.

Test Mode

You can select among the following test

modes:

•

All (The five individual tests below are

performed in sequence)

•

Memory (RAM) test

•

Memory (ROM) test

•

Logic hardware test

•

LCD & display drivers test

•

Interface test

Start Test

Press this key to run the selected test.

About (Information)

Read status information about the instrument.

•

Model

•

Serial number

•

Firmware version

•

Factory-installed options

•

Calibration date

n

Hold/Run

This key serves the purpose of manual arm

ing. A pending measurement will be finished

and the result will remain on the display until

a new measurement is triggered by pressing

the RESTART key. The HOLD sign in the

upper right corner of the screen indicates that

no new measurements are taking place.

Pressing the key again will resume the contin

-

uous measurement mode.

n

Restart

Often this key is operated in conjunction with

the HOLD/RUN key (see above), but it can

also be used in free-running mode, especially

when long measuring times are being used, to

initiate a new measurement after a change in

the input signal. RESTART will not affect

any front panel settings.

Entering Numeric Values

Sometimes you may want to enter constants

and limits in a value input menu, for instance

after you have pressed the MATH/LIMIT key.

You may also want to select a value that is not

in the list of fixed values available by pressing

the UP/DOWN arrow keys. One example is

Meas T ime under SETTINGS.

Whenever it is possible to enter numeric values, the keys marked with digits (0,1,...9),

decimal point (.)andchange sign (±)takeon

this alternative numeric meaning.

It is often convenient to enter numbers using

the scientific format with mantissa and

exponent. When this is supported in a particu

lar menu, the rightmost soft key will be

marked EE (stands for Enter Exponent), mak

ing it easy to switch between the mantissa and

the exponent.

Press EXIT/OK to store the new value or

CANCEL to keep the old one.

Description of Keys 3-9

Operating the Counter

This page is intentionally left blank.

Operating the Counter

3-10 Description of Keys

Chapter 4

Ex ercises

Preparation

For these exercises you will need a '9X' coun

ter, a function generator and two BNC cables

of approximately equal length. Set up the gen

erator according to the following table, and

connect the main output of the generator to in

-

put A of the counter.

Basic Startup

Since the counter will remember its previous

setting in nonvolatile memory, it is recom

-

mended that you recall the factory default set

-

ting before you begin.

To do so, first key in the following sequence:

USER OPT ® Save/Recall ®

® Recall Setup ® Default.Thenpress

the AUTOSET key twice within two seconds.

The preselected measurement function will be

Frequency, and the trigger levels will be au

tomatically adjusted in relation to the applied

signal.

If a signal with a frequency of 20 Hz or higher

and an amplitude large enough to trigger the

counter is connected to input A, its frequency

will now be displayed.

High-Resolution

Frequency

Measurement

Note the high resolution of the primary

readout. Twelve digits are displayed in a mea

-

suring time of 1 s. Don’t worry about the trig

ger settings, the AUTO trigger will take care

of any input signal above 20 Hz. This fre

quency limit can, if so desired, be changed

down to 1 Hz or up to 100 kHz with a tradeoff

between frequency and measurement speed. If

the generator has been set up properly, you

will now read the frequency (1 MHz) on the

display.

Built-In Math

Processing

With the built-in math functions, you can

make post-processing operations like scaling

and offsetting an easy benchtop task without

having to hook up a computer to the instru

-

ment. You can, for example, display any devi

ation from the desired value instead of directly

showing the result of the measurement itself.

This is known as offsetting.

In the following, the direct, unscaled result of

the counter's measurement process will be re

-

ferred to as 'X'.

Exercises

4-2 Preparation

Set up the generator: Function: Square

Wave

Frequency: 1 MHz

Amplitude: 5 V

pp

Modulation: Off

TRIG

GATE

TRIG

pendulum

TIMER / COUNTER/ ANALYZE R

100ps / 300MHz

CNT-90

INPUTINPUT

INPUTA

SETTINGSETTING

SETTINGS

MATH/ LIM USER OPUSER OP

USEROPT

HOLD/ RU

HOLD/ RUN

RESTARTINPUTINPUT

INPUTB

A

300MHz

B

MAX

12Vrms 50

30Vrms 1M

!

C

MAX+30dBm

50

0.2 8GHz

!

Autoset

5V

pp

1 MHz

TRIG

GATE

TRIG

pendulum

TIMER / COUNTER/ ANALYZE R

100ps / 300MHz

CNT-90

INPUTINPUT

INPUTA

SETTINGSETTING

SETTINGS

MATH/ LIM USER OPUSER OP

USEROPT

HOLD/ RU

HOLD/ RUN

RESTARTINPUTINPUT

INPUTB

A

300MHz

B

MAX

12Vrms 50

30Vrms 1M

!

C

MAX+30dBm

50

0.2 8GHz

!

Math/Limit

To set up the counter to display any deviation

from 1 MHz, press the MATH/LIM key and

select Math. The display will show that Math

is still Off. Press the soft key below the Math

Off indicator to enter the Formula Select

menu. Use the cursor keys to mark the for

-

mula K*X/M + L and confirm by pressing the

EXIT/OK key.

Now enter the numerical values for the con

-

stants K, L and M. The default values are:

K=1, L=0 and M=1. In this case only L has to

bealteredto-1*10

6

in order to get the job

done.

Open the value input menu for L by pressing

the soft key below the menu heading marked

L on the display. Press 1 followed by ±, EE

(short for Enter Exponent) and 6. Confirm and

exit by pressing EXIT/OK.PressEXIT/OK

repeatedly until the display is showing the

measurement result, now modified to reflect

any deviation from 1 MHz.

Change the generator frequency upward and

downward just a little, and watch the counter's

display.

High-Speed

Measurements

The benefits of high speed measurements for

benchtop use become obvious when you use

statistics. For instance, the '9X' can make

1000 7-digit measurements and present the

standard deviation (jitter) in less than one sec

-

ond.

Recall the default setting and press

AUTOSET twice within two seconds before

tweaking the controls to reach the optimum

measurement speed for your application. See

the following two paragraphs.

Under the INPUT Menus:

Auto trigger level settings in this model is so

fast that you will normally not notice any dif

ference in speed if auto is on or off. However,

if you use statistics to make hundreds or thou

-

sands of measurements, the fractions of a sec

ond it takes to calculate trigger levels before

each measurement add up to a considerable

time over the total sequence.

The measuring speed can be increased sub

stantially if you set the trigger levels manually

once, before a lengthy measurement sequence

starts.

Press INPUT A and choose MAN for the

MAN/AUTO setting. Now press Trig to open

the trigger level value input menu. Enter a

level of +0.5 V. Confirm the selection by

pressing EXIT/OK twice.

Under the SETTINGS Menu:

By making the measuring time for each

sample as short as possible you can also increase the overall measuring speed. Remember, however, that there is always a tradeoff

between measuring time and resolution.

Press SETTINGS and then MeasTime.Use

the DOWN arrow key to set the measuring

time to the minimum value. Confirm by press

-

ing EXIT/OK twice.

Now the counter is taking measurements at a

very high speed.

Toggle the STAT/PLOT key to see the statis

tical measures and the graphical presentation

of the result.

The measuring speed can be increased even

more, if you take advantage of the features

that are available over the GPIB. These in

clude commands for turning off the display

update, etc. In this way you can reach speeds

High-Speed Measurements 4-3

Exercises

up to 2000 transferred measurements/s, each

individually triggered. If you save the results

to the internal memory of the instrument for

later transfer, you can even attain an impres

-

sive speed of 250,000 measurements/s.

Time Measurements

So far we have only been using the frequency

function. Now we will use some others.

To measure the period of the signal, simply

press the key MEAS FUNC followed by PE

-

RIOD. Select SINGLE or AVERAGE de

-

pending on the desired resolution and measur

-

ing speed. Finish by selecting the input chan

-

nel.

To measure pulse width, use the keys MEAS

FUNC and PULSE followed by POS or

NEG depending on whether you want to mea-

sure the positive or the negative pulse width.

Finish by selecting the input channel.

Jitter Measurements

(Statistics)

You can make statistical measurements, such

as pulse width jitter, directly via the front

panel of the counter.

Make sure the counter is measuring positive

pulse width on input A. To turn on statistics,

press the STAT/PLOT key. Change the dis

play mode by toggling the same key. Return

to the numerical mode and watch the results.

The display gives you a survey of several sta

tistical measures. See also page 3-4. The rms

jitter is equivalent to the standard deviation of

100 measurements, where 100 is the default

value for the sample size.

If you want to change the default values for

sample size, bin size or pacing time, then you

can press the SETTINGS menu key and after

that the STAT soft key.

Other

Single-Channel

Measurements

The counter/timer can help you characterize

signals even further. Recall the default settings

and press AUTOSET twice.

Duty Cycle

Use the MEAS FUNC key to select Duty and

then Positive A (for positive-pulse duty cycle measurement on channel A). Change the

frequency of the generator to 10 kHz. Then

vary the symmetry (duty cycle) of the square

wave on your generator. The counter’s display

will directly show the duty cycle as a number

between 0 and 1. There is no need to manually

calculate duty cycle by dividing pulse width

by period.

The duty cycle (D) is defined as:

D=W/T

D = 0.5 for a square wave.

Exercises

4-4 Time Measurements

W

1

W

2

T

LOW

DUTY CYCLE

HIGH

DUTY CYCLE

Rise Time

Use the MEAS FUNC key to select Time,

Rise Time and A (for channel A). Press IN

-

PUT A and make sure the following settings

are active:

•

Coupling DC

•

Impedance 50 W.

•

Attenuation 1x

Notice the rise time for a square wave, which

is measured totally automatically.

Now change the generator output to a

triangular waveform. See next figure.

Vary the rise time and notice the difference on

the display.

Fall Time

Fall time is measured in a similar way by se

-

lecting Fall Time instead of Rise Time

above.

Remarks

Varying the symmetry of the waveform will

also vary the rise and fall times.

As you have noticed, there is no need to check

max and min voltages and calculate 10 % and

90 % levels. The counter does it all automati

-

cally.

Volt Max/Min Measurements

The counter can also measure the peak voltage

values of your input signal. Use the MEAS

FUNC key to select Volt. Then select Vpp,

Max or Min as the primary function. The re

sults of the secondary functions are calculated

simultaneously and displayed in a smaller

font.

Set up the

Generator:

Frequency: 200 Hz

Waveform: Square

Symmetry: 50%

Amplitude: 2-5 V

Note that the voltage reading on the counter

may be lower than the setting indicated on the

generator, as some generators indicate the

open output voltage, while the counter is now

set to 50 W input impedance.

Channel Swapping

There is no separate key or function for swapping input channels, as found on some other

counters, yet by exploring the menu trees under MEAS FUNC you will find that all mea

surement functions can be performed on each

of the two input channels, thus eliminating the

need for a swap function.

As both input channels have the same specifi

-

cation, the definition of primary and second

-

ary channel (as seen with some other coun

-

ters) is not relevant with the '9X' from a tech

nical point of view.

Other Single-Channel Measurements 4-5

Exercises

'

'

Two-Channel

Measurements

The counter can measure the timing relationship

between two channels with the Time Interval

AtoBand Phase A rel B functions.

Time Interval

Often function generators have a TTL output in

addition to the main output. We will make use of

this now. Connect a BNC cable from the TTL

output to Input A on the counter and another

BNC cable from the main output on the function

generator to Input B.

Set up the counter: Trigger Level:

AUTO

Function:

TIME INT A-B

Coupling: DC

(both A and B)

You can now read the time difference between

the TTL and main outputs of the generator.

Phase

So far the counter has shown the timing rela

tionship between the TTL and the main output

of the generator as a time delay. You can also

show this as phase shift between the signals.

n

Using Auto to set fixed trigger

levels (Auto Once)

Some measurements like Phase A rel B ben

efit from having fixed trigger levels. This is

because a change in trigger level causes a

change in the measured phase shift, and Auto

might change the trigger level between mea

-

surements.

To avoid calculating the trigger levels yourself,

you can let the counter measure the Auto levels

and then store them as fixed values.

Press INPUT A and check that Auto is still se

-

lected. Read the Auto trigger level for Input

A. Select Man. Note that the automatically

calculated trigger level is now entered as a

fixed manual level.

Press INPUT B and run through the same

steps once more to store this level as a manu

-

ally set trigger level as well.

n

Procedure

Use the MEAS FUNC key to select Phase A

rel B. Now the channel delay is expressed as

phase shift in degrees.

Increase the frequency of the generator to

2 kHz, 20 kHz, 200 kHz, 2 MHz, and

20 MHz. Watch the phase difference change.

Memory Settings

See also page 3-8.

The counter has 20 memory locations in

which you can store frequently used instru

-

ment settings.

–

To save an instrument setting, press the

USER OPT key.

–

Select the Save/Recall key.

–

Press Save Current Setup, and select

one of the memory locations using the

LEFT/RIGHT arrow keys. Note that the

first ten positions may be user-protected.

–

Press EXIT/OK three times to return to the

normal display mode.

–

Now change some settings on the counter,

and repeat the first steps above, until you

have pressed Save/Recall.

Exercises

4-6 Two-Channel Measurements

–

Press Recall Setup and select the mem

ory location in which you stored your

original setup.

–

Press EXIT/OK three times to return to the

normal display mode.

–

Watch the counter restore your original

settings.

The memory is nonvolatile, so it will not

change if you switch off the counter, nor if

you restore the default setup. All settings are

stored including trigger levels, mathematical

constants etc. You can even attach a label to

each stored setup, which helps you identify

the application easier.

Auxiliary Functions

There is a collection of useful, however seldom used auxiliary functions. Only one will

be mentioned here. See the User's Manual for

a more comprehensive description. Before we

go on, first recall the default setup and then

press AUTOSET twice.

Time-Out

Check that the counter is measuring. Discon

nect the Input A signal, and the measurement

result will freeze on the display. Connect the

signal again and the counter resumes

measuring immediately.

Is this a feature? Well, yes and no. Yes, since

this function gives touch-hold characteristics.

No, since interrupted measurements giving

false readouts may be misinterpreted by auto

-

matic test equipment and can even cause con

trol SW to halt. The solution to this problem is

the time-out function.

–

Press the SETTINGS key and then Misc

® Timeout Time.

–

Calculate the time needed to decide if

there is a signal present at the input.

–

Enter this time using the numerical soft

keys, for instance 1 s.

–

Activate the time-out function by toggling

the soft key Timeout to ON.

–

Disconnect the signal and check that the

counter shows '---' after one second.

Keep in mind that the value you select for this

time-out must always be longer than the

selected measuring time.

Summary

This concludes the Getting Started Manual.

Now you have been familiarized with the control structure and the display modes of the

model '9X'.

There are still a great many features to discover, so have a look at the User's Manual and

the Programmer's Handbook, which can be

found on the CD-ROM. Continue to explore

the vast realm of measurement possibilities

that opens up to the user of this instrument.

Auxiliary Functions 4-7

Exercises

V

service@pendulum.se

www.pendulum.se

Altaria Services Sp. z.o.o.

Loading...

Loading...