K.D. Defiant II Locker

Assembly Instructions

Updated

9/06

PN 86179

K.D. DEFIANT II LOCKER

ASSEMBLY INSTRUCTIONS

These Instructions Cover GUARDIAN DEFIANT AND

INVINCIBLE II DEFIANT SINGLE POINT LATCH LOCKERS

CONTENTS

General Instructions 1

Major Locker Components 2

Hardware and Small Locker Parts 3

Basic Defiant Assembly Instructions (Single Row Lockers) 4-5

Guidelines for Rear Leg Spacing 4

Hook and Coat Rod Guidelines 5

Individual Closed Bases 6

Zee Base 6

Unit Slope Tops, Slope Top Kits, Continous Slope Hoods 7

Invincible II Group End Kits 8

Double Row Invincible II Lockers 8

GENERAL INSTRUCTIONS

1. These instructions are for the person who will actually perform or supervise the assembly of the lockers.

2. Check material received against the packing list. First check the number of packages received and then check

the contents of each package.

3. Check material received for damage. If any of it is damaged, secure a “damage notation” from the carrier.

4. Identify each part as it is unpacked and put like parts together as close as possible to the working area in which

they are to be assembled.

5. Be careful to use the correct hardware as specified in the assembly instructions.

CAUTION

It is the responsibility of the persons assembling the lockers to properly install all components and hardware as specified in

these instructions and any accompanying drawings for specific installation.

· INSTALL ALL UNITS PLUMB AND LEVEL

· TIGHTEN ALL HARDWARE SECURELY

PENCO PRODUCTS, INC. 99 Brower Ave., PO Box 378,

Oaks, PA 19456-0378 · 800-562-1000 · Fax 610-666-7561

double row lockers must be floor anchored and if possible wall or ceiling anchored.

Single row lockers must be floor and wall anchored,

www.pencoproducts.com

1

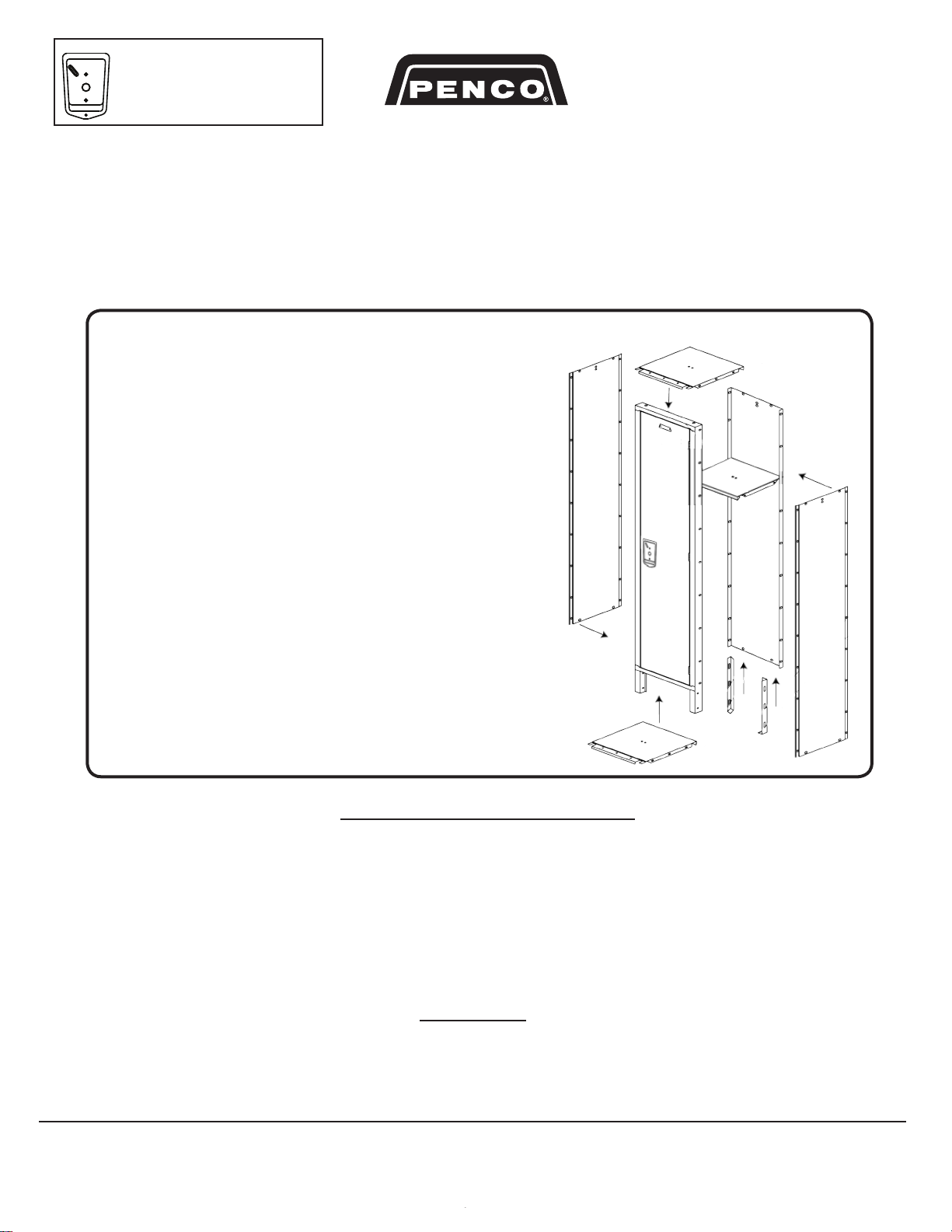

MAJOR LOCKER COMPONENTS For 1,2,3,4,5,6 TIER AND MULTI-TIER DOORS

18

o

DIVISIONS

FLAT & SLOPED

FLAT & SLOPED

Flat Top Locker

Body Parts

Slope Top Locker

Body Parts

Flat

Top Divisions

Divisions for flat

top locker are

the same for left

and right

(just turn panel

180 degrees).

Bottom of divisons and back panels have the first hole on flange 1-3/4” from edge, (top of divisons and back panel have the first hole 1-1/4” from edge).

Illustration of Number Plate, Lock Hole Cover Plate or

Built -in Locks Positioning

Defiant II Locker

(Single Point Latch)

Number

Plate

Flat

Top

Back

Panel

Top and

bottom

flanges

are 90°

Slope Top

Divisions

Slope

Top

Back

Divisions for sloped tops

are left and right specific.

The top of the division is

cut at a 18° angle.

Panel

Top of the

flange is cut

at an

18°angle.

Locker Tops, Bottom (T.A.B.) and Shelves

Flat Top (T.A.B.)

Shelf

or Slope Top

Flat Top

(T.A.B.)

Defiant II Single

Point Latch

See page 5 for

more details on

Deant II Lockers

Anti-Pry / Lock

Alignment

Bracket with

Cover Plate

or

Built-in Lock

with

Anti-Pry / Lock

Alignment

Bracket

1 Tier

2 Top and Bottom T.A.B.)

1 Intermediate Shelf

Flat Top Slope Top

Flat Tops (same part

Bottom

(T.A.B.)

2 Tier

3 Top and Bottom (T.A.B.)

as bottoms)

Note: Shelf front has

a return flange

Slope Top

Shelf

Top and Bottoms are

often called a T.A.B.

(top and bottom)

Bottom

(Same part

as flat top)

3 Tier

4 Top and Bottom (T.A.B.)

Single row lockers must be floor and wall anchored,

double row lockers must be floor anchored and if possible wall or ceiling anchored.

2

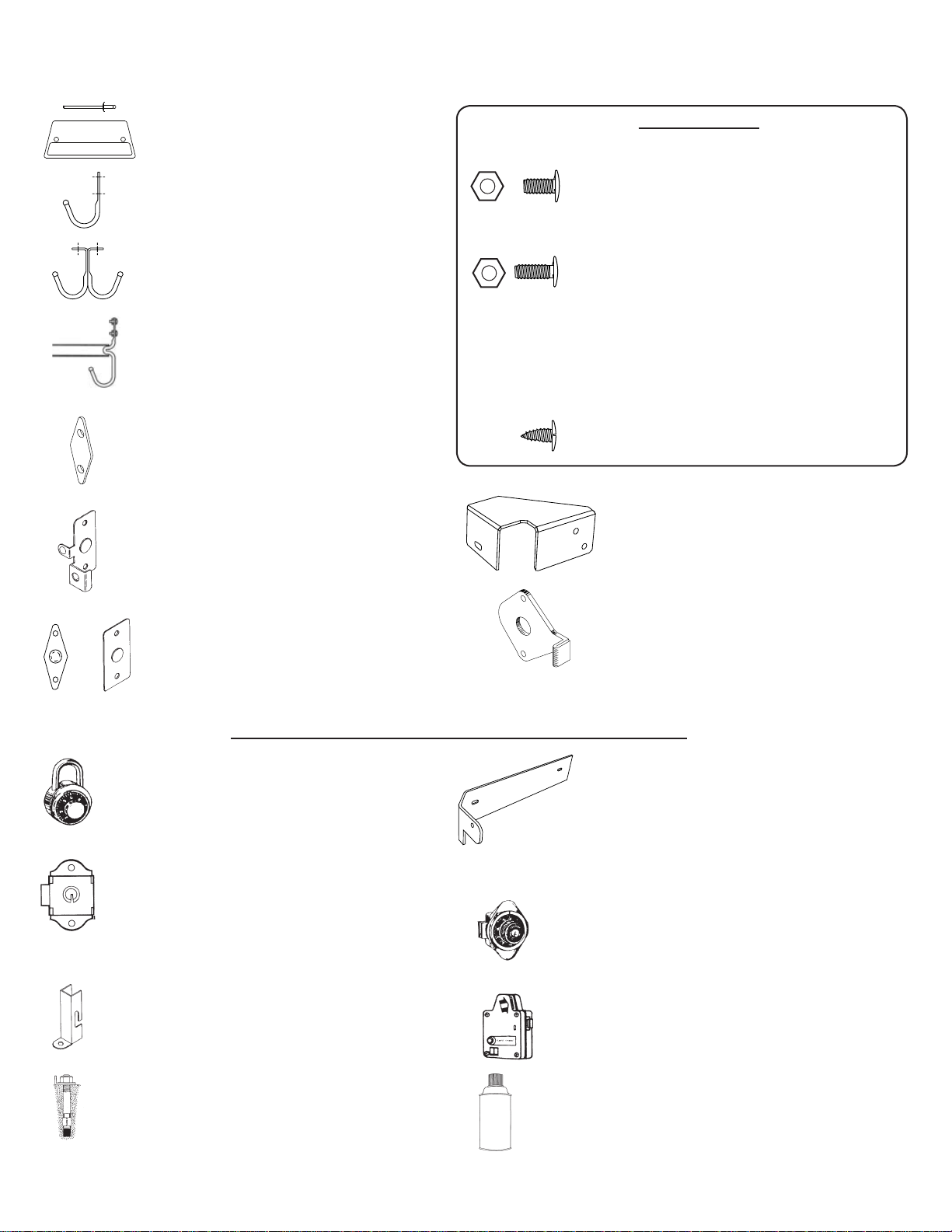

HARDWARE AND SMALL LOCKER PARTS

1

PENCO PRODUCTS INC.

www.pencoproducts.com

Not all parts come with all lockers. Check packing list for what parts are to be used with what models of lockers.

or

Number Plate and Rivet

To be riveted to top of locker door.

Single Prong Wall Hook

To be bolted to divisions and to back panel.

Single & Double Prong Ceiling Hook

To be bolted to bottom of shelf or top of locker.

Coat Rod Hooks with Rod

Hooks to be bolted to divisions with coat

rod in between, used in single tier, Duplex,

2,7,8 person and Dual lockers 18” or more in

depth.

Hook Clip

Used to attach single prong wall hooks and

coat rod hooks in lockers with Diamond

Perforated divisions at ends only.

Door Pull

Used on box locker door unless a built-in

lock is used. To be mounted on inside of

door with pull tab inserted through vertical

slot in door.

Lock Hole Cover Plate

Used to cover hole in door when built-in locks

are not used. To be mounted on inside of

door.

Nuts and Bolts

10—24 x 3/8” Truss fin head bolt and nut for assembly of

locker body parts. Tighten nut with a wrench or

nut driver. (bolt is tamper resistant so it has no

slot for a screw driver)

10—24 x ½” Truss fin head bolt and nut for assembly of

the entire Invinicible II locker. In the

Vanguard and Guardian lockers this nut and

bolt is used in joining locker groups, locker

legs and 2 hooks with the partition betweeen

the hooks. Tighten nut with a wrench or nut

driver (bolt is tamper resistant so it has no

slot for a screw driver)

NO. 8 x 3/8 “ Sheet metal screw for slope tops only.

Bracket Support (Defiant II)

Strengthens locking point on Defiant II lockers.

Bolts to Defiant II hasp and to side of locker.

Anti-Pry / Lock Alignment Bracket

(Defiant II) Used on back of recessed pocket

in Defiant II Lockers (Single Point Latch).

Optional Items That are Ordered Separately from Locker

Combination Padlock (9/32” or .281” Shackle)

Used to secure locker door when built in lock is not

used. Lock may come from another supplier other

than Penco Products.

Built-in Key Lock

Used to secure locker door when padlock is not

used. This lock replaces Lock Hole Cover Plate or

Door Pull. To be mounted on inside of door. Lock

may come from another supplier other than Penco

Products.

Locker Shoe

Can be used on the front legs of locker to secure to

floor. Protects floor along with leveling lockers on an

uneven floor.

Concrete Floor Anchor

1/4 x 2” Used to secure locker to a concrete floor.

Bolt type will vary with floor type.

Single row lockers must be floor and wall anchored,

double row lockers must be floor anchored and if possible wall or ceiling anchored.

Side Stiffener

(Defiant II Guardian Doors Only)

When built-in locks are used on Defiant II Guardian Lockers (24 gauge side panels), the last locker in

a row of lockers, is to have a Side Stiffener bolted to

the Defiant II lock hasp and side of locker (replaces

Bracket Support if built-in lock are used).

Built-in Combination Lock

Used to secure locker door when padlock is not used.

This lock replaces Lock Hole Cover Plate or Door

Pull. To be mounted on inside of door. Lock may come

from another supplier other than Penco Products.

Safe-O-Mat Coin Operated Lock

Used to secure locker door when padlock is not used.

This lock replaces Lock Hole Cover Plate. Lock engages when token or coin is deposited.

Touch Up Paint

Used to touch up paint finish (21 standard colors).

3

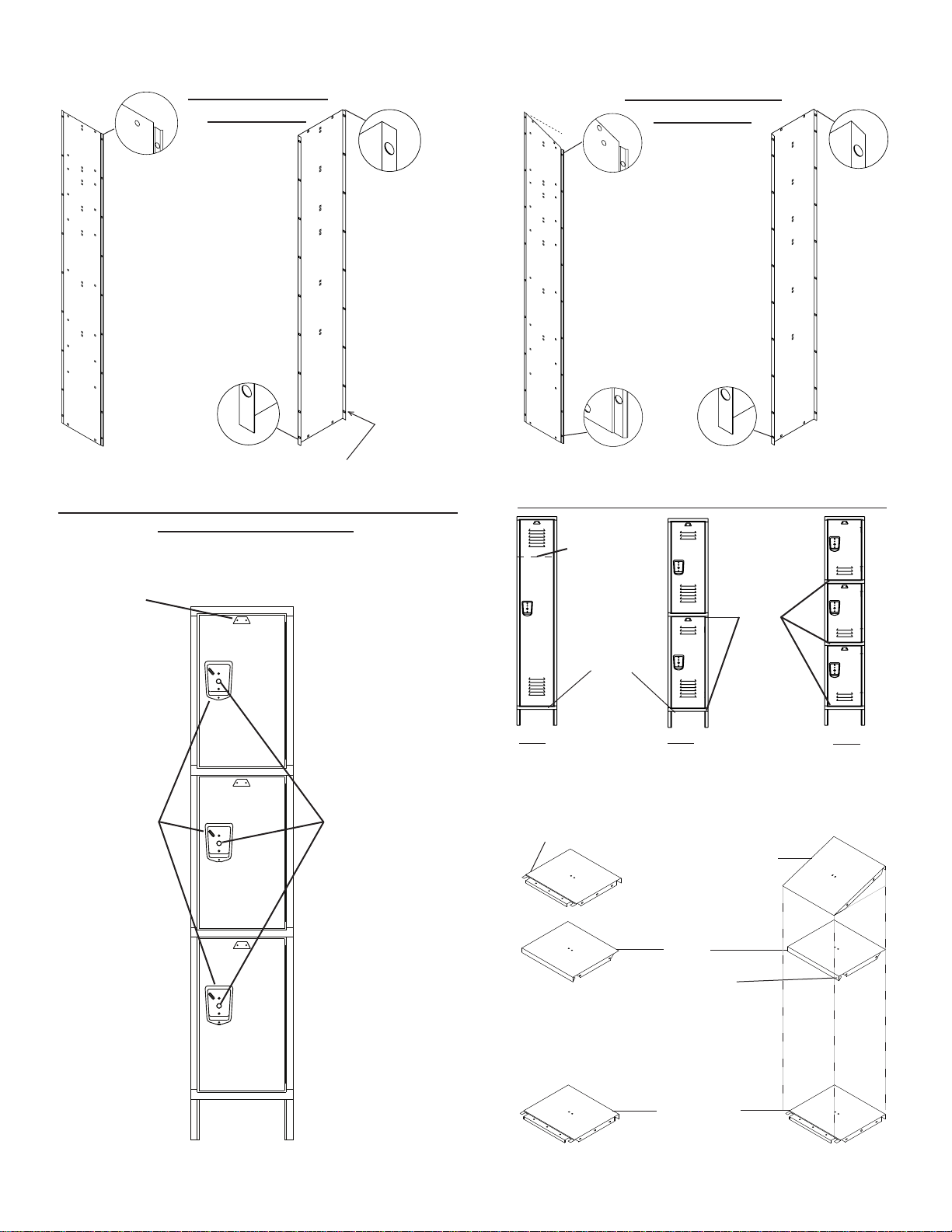

DefiAnT LockeR ASSeMBLY inSTRUcTionS

START

Place Locker Back on a at surface or

1

saw horses and Bolt Top and Bottom

5

(TAB) to inside of Back

Top and Bottom (TAB)

Back

FOR SINGLE

LOCKER

3

Bolt Shelf

to Side

Panel

and Back

Side

Panel

FOR SINGLE TIER

Bolt Division (Side Panel) to inside of

2

Back and outside of Top (TAB)

Shelf

Adj. Leg

4

If legs are supplied, bolt Adjustable Leg inside of Side Panel (leg height can be adjusted to

level and anchor locker)

FOR ROW OF

LOCKERS

Back

Top and

Bottom

(TAB)

Side

Panel

6

FOR 2 TIER

Bolt Division (Side Panel) to inside of

2

Back and outside of Top (TAB)

Adj. Leg

4

FOR 2 TIER

Bolt Top

and Bottom

(TAB) to Side Panel

and Back (repeat

step if 3 Tier)

Top and

Bottom

(TAB)

Back

3

Side

Panel

FOR 3 TIER

FOR 3 TIER

2

Back

Adj. Leg

4

FOR SINGLE TIER

If Coat Rod

is supplied

(Single tier

lockers only)

Before bolting

TAB and Shelf to

division, install

coat rod hooks

on the inside of

divisions. Spread

apart division and

then insert coat

rod into coat rod

holder on coat rod

hook.

FOR SINGLE

LOCKER

Bolt Bottom (TAB) to

inside of Back and

then bolt Divisions to

Back, TAB, and shelf

or shelves if provided.

ReAR Leg SpAcing foR SingLe Row LockeRS

IMPORTANT: If lockers have been ordered with grouping specied, assemble lockers

as ordered. Back legs should not exceed 45” distance between legs. If grouping has

not been specied assemble lockers using the chart.

Width of Single Locker (inches) 7-1/2” 9” 12” 15” 18” 24”

Lockers in a Single Row Grouping 9 8 7 6 4 3

Back Legs in Each Grouping 9 6 5 4 3 2

FOR ROW OF

LOCKERS

Bolt Bottom (TAB) to inside of Back and Divisions.

Then bolt through Back, Division and the next locker’s

back. If legs are supplied, see Rear Leg Spacing for

Single Row Lockers below. Then repeat steps 1 to

5. Due to size and bulk, it is best to build lockers in

groups of no more than 3 wide before putting doors on

and then putting them in place.

Back

Locker Frames show with legs

Place Locker Door and Frame over edges of Divisions (Side

Panels), and edges of Top and Bottom (TAB). Open Door and

bolt Door Frame to Divisions, Top and Bottoms (TABS). If needed, loosen bolts on Legs to level locker and then re-tighten.

Joining LockeR gRoUpingS

Top View of Two Groupings of Three Lockers

First

Locker

Group

Second

Locker

Group

FOR SAFETY PURPOSES WE STRONGLY RECOMMEND THAT ALL LOCKERS BE EITHER FLOOR OR WALL ANCHORED

Single row lockers must be floor and wall anchored,

double row lockers must be floor anchored and if possible wall or ceiling anchored.

4

COMBINATION

LOCK

STAINLESS

STEEL

DEFIANT II

RECESSED

HANDLE

ANTI-PRY / LOCK ALIGNMENT

BRACKET

UNIT

COMBINATION LOCK

Table of Locker Coat Hook and Rod Quantities

Number of Pieces Supplied per Locker FRAME * - Standard Construction Only

1 Tier

2

Tier

3 Tier

4,5,6,8,9

Tier

2 Person 7 Person 8 Person

16

Person

Duplex Dual

Single Prong Hooks

Depth Less than 18" AND:

. . . Width less than 15"

3 6 9 - n/a n/a n/a n/a n/a 4

. . . Width =15" or more

4 8 12 - 4 n/a n/a n/a 4 4

Depth 18" or more AND:

. . . Width less than 15"

1 6 12 - n/a - - n/a n/a -

. . . Width =15" or more

2 8 12 - - - - n/a - -

Double Prong Hooks

Depth 18" or more - - - - - - - - - -

Depth LESS than 18" AND:

. . . Width is LESS than 21"

1 ** 2 - - - n/a n/a n/a - -

. . . Width is 21" or more

2 4 - - n/a n/a n/a n/a n/a -

Coat Rod Hooks

Depth Less than 18"

- - - - - n/a n/a n/a - -

Depth 18" or more

2 - - - 4 2 4 - 4 4

Coat Rods

Depth Less than 18"

- - - - - n/a n/a n/a - -

Depth 18" or more

1 - - - 2 1 2 1 2 2

n/a: Not Applicable in Standard Construction

* Exceptions: 7, 8 & 16 Person quantities are for entire unit.

** Exception: Single Tier 9" wide x 15" deep has N0 Double Prong Hooks

DefiAnT LockeR ASSeMBLY inSTRUcTionS

1

PENCO PRODUCTS INC.

www.pencoproducts.com

7

Bracket Support

Bolts to

Side Panel

Open door(s) and use 2

bolts to mount bracket

support to lock hasp and

one bolt to side panel.

If built-in locks are to be

used on the left hand end

of a row and the locker

has light gauge side panels replace the bracket

support with a side stiffener (see page 3).

Bolts to

Locker Hasp

Lock Hasp

(welded to

Locker Frame)

9

If supplied, bolt Double Pronged Ceiling Hook to Shelf and

Single Prong Wall Hooks to Division or Back. If coat rod

is supplied, refer to step 5. See Hook and Rod Guidelines

below for more details.

8

foR : LockeRS w/ pADLockS

Insert bolts into recessed

pocket and then attached

Anti-Pry/Lock Alignment

Bracket and then the Lock

Hole Cover Plate and then

tighten bolts. Open and close

locker door(s) and adjust

bracket as needed.

or

10

Rivet number plates to top of doors.

foR : LockeRS w/

BUiLT-in LockS

Place the Anti-Pry / Lock Alignment

Bracket on the back side of the

recessed pocket rst, followed by

the back of the lock unit as shown

in the drawing. Insert the combination dial mechanism in the front of

the pocket, and attach with 2 nuts.

Open and close locker door(s) and

adjust bracket as needed.

Hook and Coat Rod Guidelines

double row lockers must be floor anchored and if possible wall or ceiling anchored.

Single row lockers must be floor and wall anchored,

5

INDIVIDUAL CLOSED BASES

Front and end bases are designed to fit between standard Penco 6” legs. The front base

snaps in between the front legs. The end base slips over legs during locker assembly.

1. Before standing locker up and placing the locker in position, slide the End

Base up the leg of the end of the locker row.

2. Stand locker up and put the lockers in proper position.

3. Snap Front Base between the front legs of each locker so that the two tabs on

either side of Front Base match up with the square slots in the front legs.

Front Base

End Base (Available in single or double row)

ZEE BASE: for lockers to be anchored to wall

Zee Base raises lockers without legs off the floor and provides a continuous closed base. It is used when there is no concrete

or wood base. Available in lengths of 72” only, the Zee Base shall be cut by installer when shorter lengths are needed.

Side View of Zee Base and Locker

Locker

Bottom

Locker

Division

Floor

5/16” Hole to be used to

anchor Zee Base to floor.

Installer to field drill

1/4” Hole in Zee

Base

Locker Door

Frame

Zee Base

Instructions

1. Match Zee Bases and Splice/End Bases to lockers, site

plan and installation location.

2. Use Splice/End Base as a template to position Zee Base.

3. Place Splice/End Base flush against wall (thinner side with

holes) or create a chalk line as a positioning guide.

4. Create a chalk line for Zee Base positioning using Splice/

End Bases as a measuring device.

5. Butt Zee Base against other side of Splice/End Base.

6. Measure locker depth and make sure Locker Door Frame

will rest on Zee Base. (there should be a 1/4 inch space

between the end of Zee Base and outside edge of Locker

Door Frame).

7. Use the two sets of holes on the Splice/End Base to bolt

together 2 lengths of the Zee Base.

8. Recheck measurements of Locker, Zee Base position, and

site plans.

Single row lockers must be floor and wall anchored,

double row lockers must be floor anchored and if possible wall or ceiling anchored.

6

View of Zee Base with and without Locker

Lockers

Splice/End Base

available in single

and double row

Zee Base

Zee Base

9. Anchor Zee Bases and Splice/End Base to floor with

proper drill and bolt for the floor surface.

10. Assemble Single Row Lockers as per instructions on

page 4 or assemble Double Row Lockers as per

instructions on page 8 except when installing Door and

Door Frame leave bolts at bottom of Door Frame off.

11. Place assembled locker on Zee Base (there should be a

1/4 inches space between the end of Zee Base and

outside edge of Locker Door Frame).

12. Use the bottom hole of the Door Frame to position drill

and drill a 1/4”” hole through the top of the Zee Base.

13. Place bolt through Door Frame and Zee Base. Place nut

on Zee Base side of bolt and tighten. Repeat steps

12 and 13 for each door.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Unit Slope Tops

spoTepolStinU

)sehcnI(eziS

.oN.taC

W D H

9

9

9

21

51

81

-

-

-

C23306

C43306

C63306

21

21

21

21

21

51

81

12

-

-

-

-

C83306

C04306

C24306

C44306

51

51

51

51

21

51

81

12

-

-

-

-

C054306

C6430

6

C84306

C05306

81

81

81

81

12

42

-

-

-

C25306

C45306

C65306

42

42

42

81

12

42

-

-

-

C46306

C66306

C86306

stiKpoTepolS

)tikediw3(

)sehcnI(eziS

.oN.taC

W D H

21

21

21

21

51

81

4

5

6

H03206

H23206

H43206

515151815

6

H83206

H04206

81 81 6 H44206

sdooHepolS

)sehcnI(eziS

.oN.taC

W D H

27

27

27

27

27

21

51

81

12

42

5

6

7

8

9

H44166

H74166

H05166

H35166

H65166

eziS

)sehcnI(

sdnEepolS

HRHL

dooH

ecilpS

lasrevinU

dooHraeR

troppuS

D H .oN.taC .oN.taC .oN.taC

21

51

81

12

42

5

6

7

8

9

H95166H85166

H16166H06166

H36166H26166

H56166H46166

H76166H66166

C86166

C96166

C07166

C

17166

C27166

07066

)llastifeziseno(

Installer to cut Hood to

Suit Condition and

Conceal Cut Edge

Under Splice Assembly

UNIVERSAL

HOOD SUPPORT

(2 required per hood)

SLOPE TOP DOUBLE ROW

FINISHED END PANEL

STD. 72-3/16" SLOPE HOOD

(Slope hoods length not to scale)

SLOPE TOP

CORNER FILLERS

HOOD SPLICE

SLOPE END L. H.

(Specify Left or Right)

FINISH END PANEL

(2 required per 6' hood)

Are shipped flat and are

to be bent to size in field.

Each Rear Hood Support has

locker depths scribed onto

surface. Bend rear hood

support on

a 90 degree

surface at the

location that

matches the

locker’s depth.

Two Rear Hood

Supports are

required for

each 6” Hood.

Field Bend

Ships Flat

Hood Bolts to Hole

UNIVERSAL

REAR

HOOD

SUPPORT

Unit Slope Tops are used with

Slope Top Divisions. One Unit

Slope Top covers the width of one

locker frame. (Not for use on In-

vincible II or All-Welded lockers).

1. Open door to locker so you have

access to top of locker.

2. Bolt unit slope top to divisions

and back.

3. Insert sheet

metal screws up

the hole in the

top of the door

frame and fasten

the front of the

unit slope top to

locker.

4. Repeat steps 1-4 as

needed.

Slope Top Kit

Designed to convert stock flat top lockers into slope top lockers in groups

of 3 wide. Each 3 wide Kit

contains 3 tops, 3 backs

and 4 ends. (Not for use

on Invincible II or All

Welded lockers.)

1. If there is a Flat Top

(T.A.B.) on locker, remove

bolts on sides and back.

2. Bolt Slope End to inside of

locker.

3. Bolt Slope Back to outside of

locker back and inside of Slope

End.

4. Bolt slope top to sides and

back.

5. Repeat steps 1-4 as needed.

Continuous slope hoods fit on top

of flat top lockers. They can be

used on new lockers, or on a retrofit basis. All hoods are furnished

in 72” lengths and must be cut to

length during installation. Intermediate splices, ends and rear supports (2 per hood) complete the

installation, and must be ordered

separately.

double row lockers must be floor anchored and if possible wall or ceiling anchored.

Continuous Slope Hoods

Single row lockers must be floor and wall anchored,

Slope Hood Detail with Optional Slope End Panels

7

TYPICAL INSTALLATION

INVINCIBLE II LOCKERS

Invincible II Group End Kits

Invincible II

Lockers

Invincible II

Group Ends

Invincible II lockers do not automatically come with

group ends, they must be ordered separately. If you

are short group ends, check with the person who

ordered the lockers.

NOTE: solid divisions (group ends) are sometimes

ordered to end rows of lockers that have perforated

divisions everywhere else. Refer to drawings provided by the person who ordered the lockers for all

layout details.

Double Row Invincible II Lockers

Invincible II lockers do not use a double row division. Two single row divisions are joined together with a back angle and use

a common back. This back angle is bolted to the back and then bolted to the division of the second row of lockers. Add these

steps to Operation 1 and 3 of the Assembly of Double Row (Back to Back) Lockers on page 8.

Top View of Double Row Invincible II Locker

Doors

Division

Back Angle

Back Panel

Doors

PENCO PRODUCTS, INC.

99 Brower Ave., PO Box 378,

Oaks, PA 19456-0378

800-562-1000 · Fax 610-666-7561

www.pencoproducts.com

Single row lockers must be floor and wall anchored,

double row lockers must be floor anchored and if possible wall or ceiling anchored.

8

Back Panel

Division

2006 Penco Products, Inc. All rights reserved

9/06 LockerAssemblyDeant07.indd/pdf

Loading...

Loading...