Page 1

Page 2

Purchase Agreement

P&E Microcomputer Systems, Inc. reserves the right to make changes without further notice to any products herein to

improve reliability, function, or design. P&E Microcomputer Systems, Inc. does not assume any liability arising out of the

application or use of any product or circuit described herein.

This software and accompanying documentation are protected by United States Copyright law and also by International

Treaty provisions. Any use of this software in violation of copyright law or the terms of this agreement will be prosecuted.

All the software described in this document is copyrighted by P&E Microcomputer Systems, Inc. Copyright notices have

been included in the software.

P&E Microcomputer Systems authorizes you to make archival copies of the software and documentation for the sole

purpose of back-up and protecting your investment from loss. Under no circumstances may you copy this software or

documentation for the purpose of distribution to others. Under no conditions may you remove the copyright notices from

this software or documentation.

This software may be used by one person on as many computers as that person uses, provided that the software is never

used on two computers at the same time. P&E expects that group programming projects making use of this software will

purchase a copy of the software and documentation for each user in the group. Contact P&E for volume discounts and site

licensing agreements.

P&E Microcomputer Systems does not assume any liability for the use of this software beyond the original purchase price

of the software. In no event will P&E Microcomputer Systems be liable for additional damages, including any lost profits,

lost savings or other incidental or consequential damages arising out of the use or inability to use these programs, even if

P&E Microcomputer Systems has been advised of the possibility of such damage.

By using this software, you accept the terms of this agreement.

©2012 P&E Microcomputer Systems, Inc.

Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc. All other product or service names

are the property of their respective owners. Kinetis and ColdFire are registered trademarks of Freescale Semiconductor,

Inc.

P&E Microcomputer Systems, Inc.

98 Galen St.

Watertown, MA 02472

617-923-0053

http://www.pemicro.com

TRACELINKUM

Manual version 1.00

August 2012

Page 3

1 INTRODUCTION ............................................................................................ 1

2 QUICK START GUIDE ................................................................................... 3

3 TRACELINK HARDWARE.............................................................................. 4

3.1 Tracelink Power Supply ..................................................................................4

3.2 Ethernet Connector.........................................................................................4

3.3 USB Connector...............................................................................................5

3.4 Target Debug Connectors ..............................................................................5

3.5 Target Power ................................................................................................13

4 EXTERNAL TRACE OVERVIEW ................................................................. 15

4.1 How External Trace Works ...........................................................................15

4.2 Trace Types..................................................................................................15

4.3 Trace Filtering...............................................................................................16

4.4 Board Design Considerations .......................................................................16

5 ETHERNET CONFIGURATION ................................................................... 18

5.1 Network Architectures...................................................................................18

5.2 Network Parameters .....................................................................................19

5.3 Internet Protocol ...........................................................................................20

5.4 Connecting The Tracelink Device .................................................................20

5.5 Tracelink IP Setup Utility User Interface (ConfigureIP).................................22

5.6 Using ConfigureIP.exe To Configure The Tracelink .....................................24

6 USB CONFIGURATION ............................................................................... 27

7 CODEWARRIOR 10.x CONFIGURATION ................................................... 28

8 PRODUCTION PROGRAMMING................................................................. 33

8.1 Cyclone Key Features ..................................................................................33

8.2 Cyclone In-Depth ..........................................................................................34

Tracelink User Manual i

Page 4

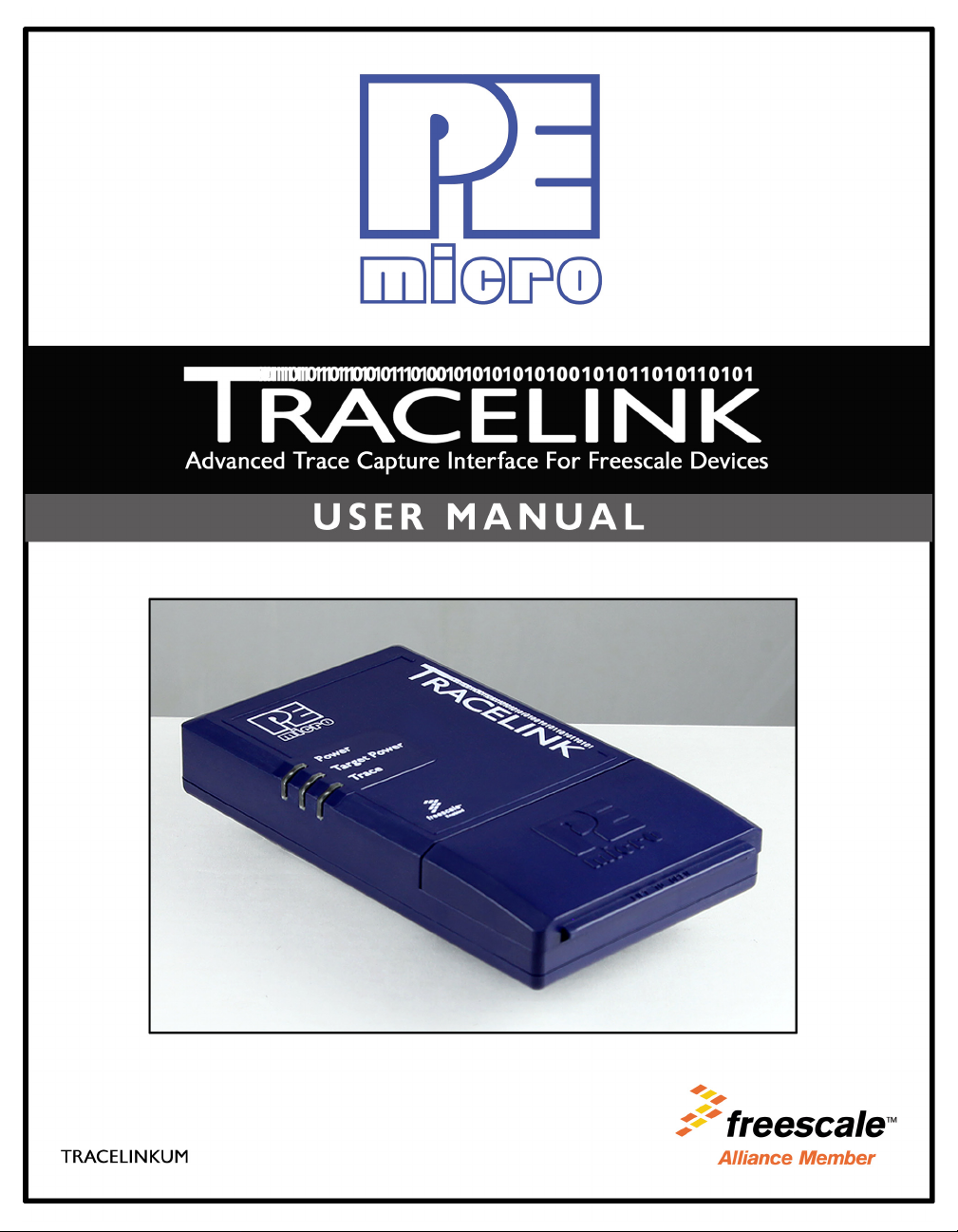

1 INTRODUCTION

The Tracelink is a powerful development interface capable of capturing external trace

data on Freescale microcontrollers.

The Tracelink is designed to help developers find and diagnose software bugs quickly

and efficiently. While a microcontroller is running, the Tracelink is constantly recording

trace information into its internal memory buffer, which can later be used by

supporting software to provide program flow charts and profiling statistics.

Figure 1-1: P&E’s Tracelink

In addition to trace capture, the Tracelink also supports all standard run control

operations, such as single-stepping, setting breakpoints, register/memory access,

and flash programming. The following features make the Tracelink an extremely

valuable debug tool:

Tracelink User Manual 1

Page 5

• Multiple Freescale Architecture Support

• ColdFire V2-4

• Kinetis

• S12Z (coming soon)

• External Trace Capture

• Supports trace port speeds up to 250 MHz

• 128MB of trace storage

• Multiple Voltage Operation

• Automatically detects and caters to target voltages ranging from 1.8V to 5V

• Target Power Generation

• Can generate 2V, 3V, or 5V to directly power target microcontroller

• Multiple Communication Interfaces

• Ethernet 10/100 baseT

• USB 1.1

Additional Tracelink resources can be found at pemicro.com/tracelink.

Tracelink User Manual 2

Page 6

2 QUICK START GUIDE

Step 1. Install Software

The accompanying software includes all necessary drivers and configuration utilities

needed for the Tracelink. After installation is complete, make sure the PC is rebooted

before moving on to the configuration step.

Step 2. Power On Tracelink

Power up the Tracelink by connecting the included 9V power supply. A blue LED will

be illuminated on the Tracelink to indicate it is receiving power.

Step 3. Ethernet Configuration

Connect the Tracelink to the PC using a USB connection. Run the ConfigureIP

software utility to set up the network parameters (IP address, subnet mask, etc.). The

Ethernet port will not function properly until this one-time configuration is complete.

You may wish to refer to Section 5 - ETHERNET CONFIGURATION. If the Tracelink

Ethernet connection is not required, this step may be skipped.

Step 4. Hardware Setup

Connect the appropriate ribbon cable between the Tracelink and the target board. The

Tracelink case flips open for easy access to the ribbon cable connectors. Power up

the target board. A yellow LED on the Tracelink will be illuminated to indicate that it is

detecting target power.

Finally, connect the USB or Ethernet cable from the Tracelink to the host PC.

Step 5. Launch PC Software

The Tracelink is now ready to be used with PC software to debug and analyze trace.

Please refer to the documentation from the software vendor (e.g., P&E software,

Freescale

TM

CodeWarrior) for more details on any additional configuration that may be

required.

Tracelink User Manual 3

Page 7

3 TRACELINK HARDWARE

This chapter provides more in-depth technical detail about the features and interfaces

of the Tracelink unit.

3.1 Tracelink Power Supply

The Tracelink requires a regulated 9V DC center positive power supply with a 2.5/

5.5mm female plug. The power supply plugs into the power jack located on the top of

the unit.

3.2 Ethernet Connector

Figure 3-1: Power Jack

The Tracelink provides a standard RJ45 socket to communicate with a host PC

through the Ethernet Port (10/100 BaseT).

Figure 3-2: Ethernet Connector

Tracelink User Manual 4

Page 8

3.3 USB Connector

The Tracelink provides a USB connector for Universal Serial Bus communications

with the host PC. The Tracelink is a USB 1.1 compliant device.

Figure 3-3: USB Connector

3.4 Target Debug Connectors

The different families of Freescale microcontrollers are supported via the multiple

debug headers located on the Tracelink. These headers are accessed by flipping

open the plastic case. Pin 1 of each header is marked with the number “1” and also

has a rounded corner.

Note: To avoid improper connections, the red stripe of the ribbon cable should always be

oriented towards Pin 1.

Warning: Do not attempt to use multiple ports at once, as this may damage both the target

processors and the Tracelink.

Tracelink User Manual 5

Page 9

Figure 3-4: Tracelink Headers, Pin 1 Highlighted

Note: For signals requiring pull-up or pull-down resistors, please note that most

microprocessors implement internal resistors to meet these requirements. Otherwise,

an external resistor must be used.

Tracelink User Manual 6

Page 10

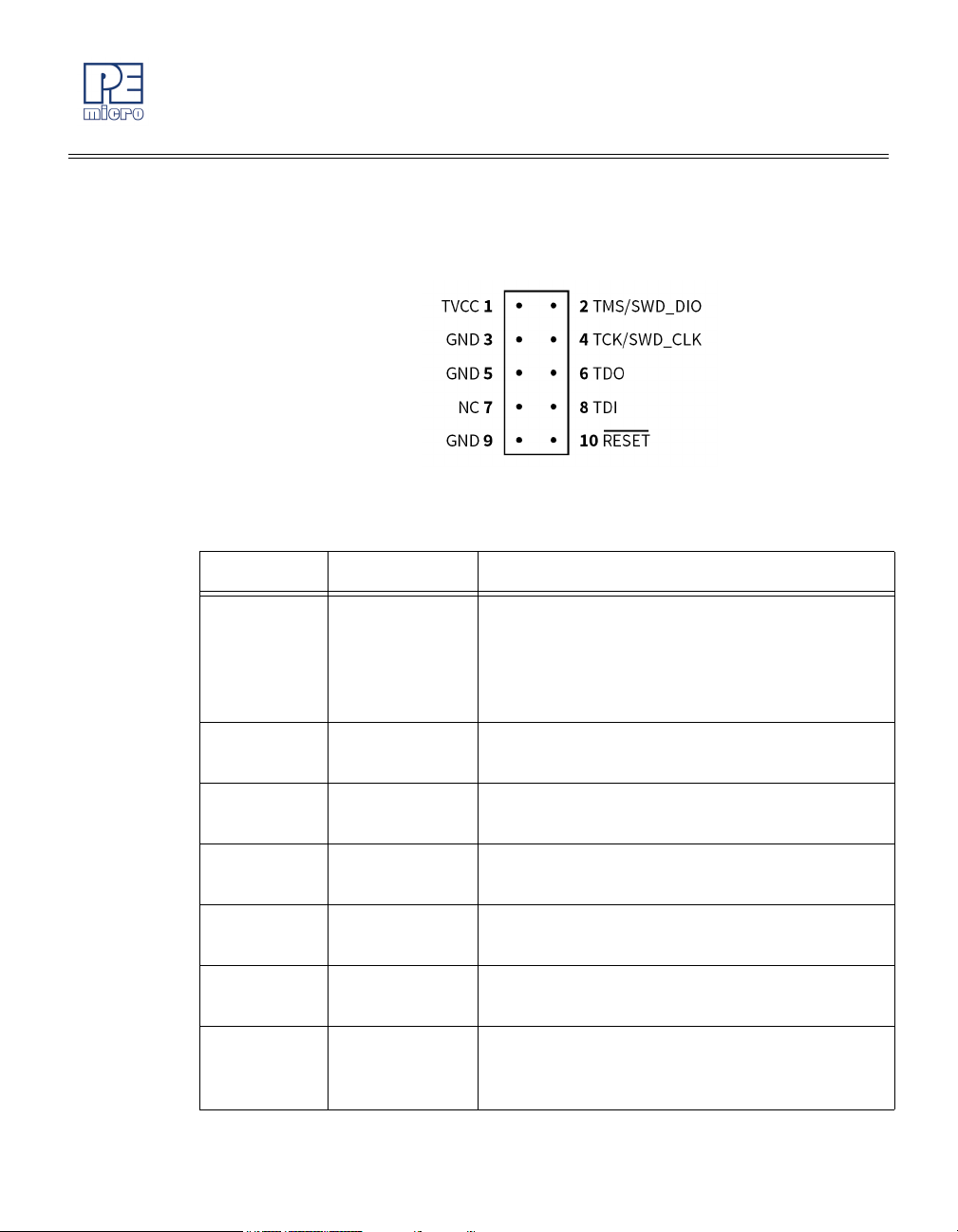

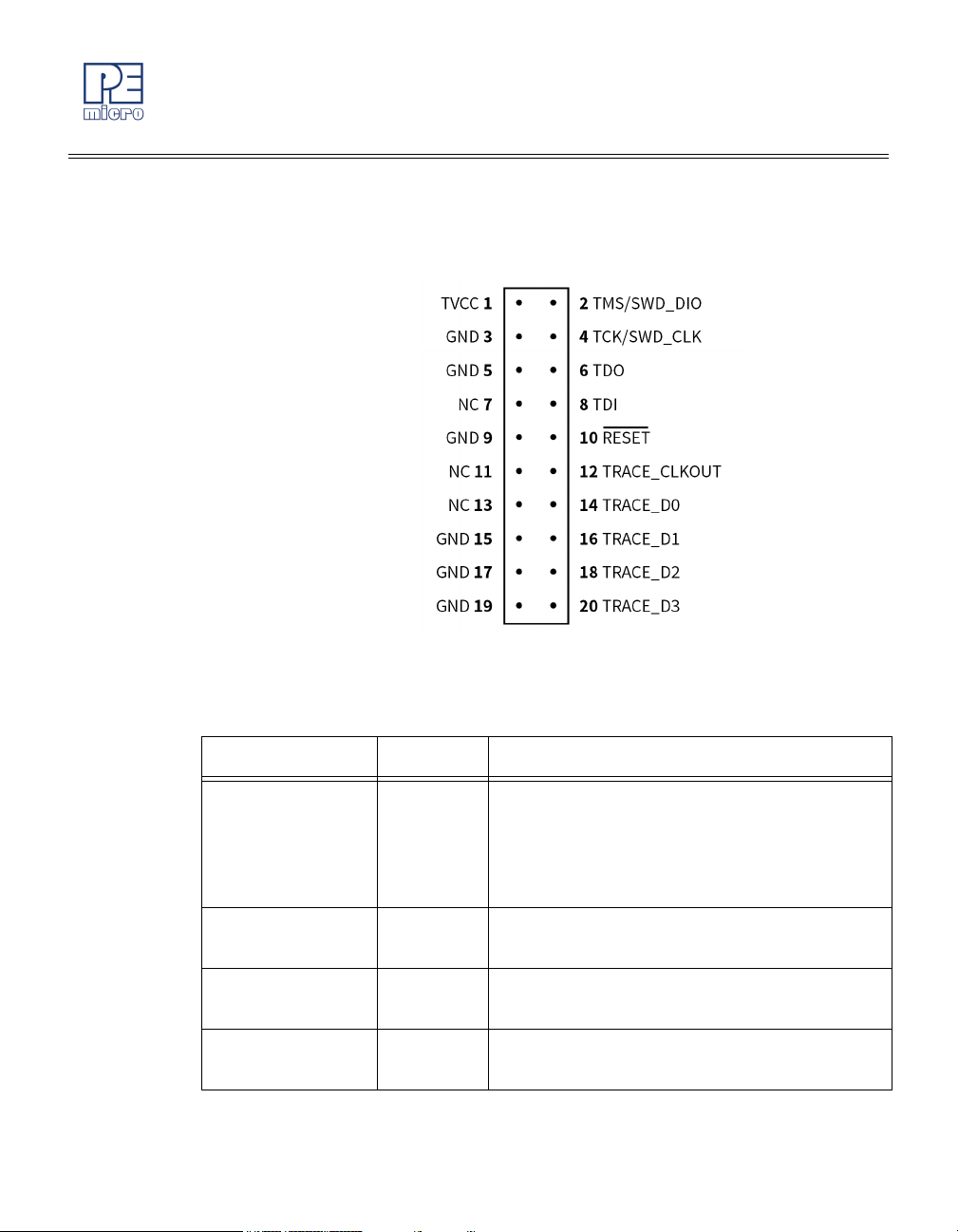

3.4.1 PORT A: Kinetis (Mini-10)

Table C-1. Kinetis Mini-10 Signals (PORT A)

Signal Direction Description

TVCC Input Target reference voltage. Needs to be con-

Figure 3-5: Port A Pinout

nected to the microprocessor’s operating voltage (1.8V to 5V) and is used by the Tracelink

to determine the correct voltage level to use on

output signals. Required.

TMS/

SWD_DIO

GND Input Ground signal. Connect to the digital ground

TCK/

SWD_CLK

TDO Input Debug communication signal. Pull-up resistor

TDI Output Debug communication signal. Pull-up resistor

RESET I/O Microprocessor reset signal. This signal is

Tracelink User Manual 7

I/O Debug communication signal. Pull-up resistor

required. Required.

signal of the microprocessor. Required.

Output Debug communication signal. Pull-down resis-

tor required. Required.

recommended. Recommended.

required. Recommended.

driven low during initial debug mode entry. Pullup resistor required. Required.

Page 11

3.4.2 PORT B: Kinetis (Mini-20)

Table C-1. Kinetis Mini-20 Signals (PORT B)

Signal Direction Description

Figure 3-6: Port B Pinout

TVCC Input Target reference voltage. Needs to be con-

nected to the microprocessor’s operating

voltage (1.8V to 5V) and is used by the

Tracelink to determine the correct voltage

level to use on output signals. Required.

TMS/SWD_DIO I/O Debug communication signal. Pull-up resistor

required. Required.

GND Input Ground signal. Connect to the digital ground

signal of the microprocessor. Required.

TCK/SWD_CLK Output Debug communication signal. Pull-down

resistor required. Required.

Tracelink User Manual 8

Page 12

Table C-1. Kinetis Mini-20 Signals (PORT B)

Signal Direction Description

TDO Input Debug communication signal. Pull-up resistor

recommended. Recommended.

TDI Output Debug communication signal. Pull-up resistor

required. Recommended.

RESET I/O Microprocessor reset signal. This signal is

driven low during initial debug mode entry.

Pull-up resistor required. Required.

TRACE_CLKOUT Input Trace clock input. Required for external

trace capture.

TRACE_D[3:0] Input Trace data input. Required for external

trace capture.

Tracelink User Manual 9

Page 13

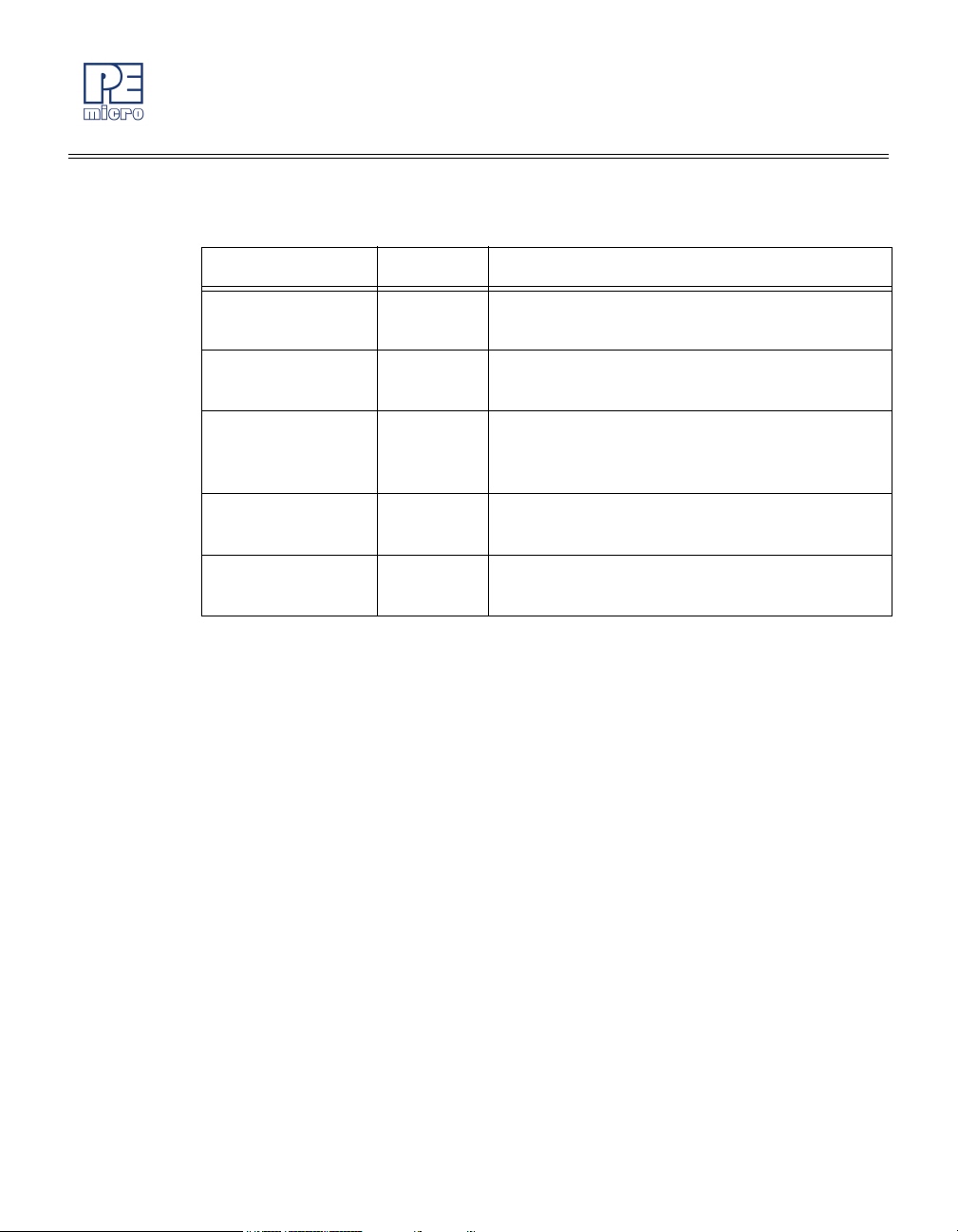

3.4.3 PORT C: ColdFire V2/3/4

Figure 3-7: Port C Pinout

Table C-1. ColdFire V2/3/4 Signals (PORT C)

Signal Direction Description

BKPT Output Debug communication signal. Pull-up resistor

required. Required.

GND Input Ground signal. Connect to the digital ground

signal of the microprocessor. Required.

DSCLK Output Debug communication signal. Pull-up resistor

required. Required.

Tracelink User Manual 10

Page 14

Table C-1. ColdFire V2/3/4 Signals (PORT C)

Signal Direction Description

TCK Output Debug communication signal. Pull-up resistor

required. This signal is currently only used by

P&E when unsecuring ColdFire processors

with internal flash. Recommended.

RESET I/O Microprocessor reset signal. This signal is

driven low during initial debug mode entry.

Pull-up resistor is required. Required.

DSI Output Debug communication signal. Pull-up resistor

recommended. Required.

TVCC Input Target reference voltage. Needs to be con-

nected to the microprocessor’s operating voltage (1.8V to 5V) and is used by the Tracelink

to determine the correct voltage level to use on

output signals. Required.

DSO Input Debug communication signal. Pull-up resistor

recommended. Required.

PST[3:0]/

PSTDDATA[7:4]

DDATA[3:0]/

PSTDDATA[3:0]

PSTCLK Input Trace clock input. Required for external

TA Output Transfer acknowledge signal. Pull-up resistor

Tracelink User Manual 11

Input Trace data input. Required for external trace

capture.

Input Trace data input. Required for external trace

capture.

trace capture.

is required. Some ColdFire processors do not

implement this signal and this pin can be left

as a no connect (NC) in these cases. Highly

recommended for applications which use

external memory.

Page 15

3.4.4 PORT D: Kinetis

Figure 3-8: Port D Pinout

Table C-1. Kinetis Signals (Port D)

Signals Direction Description

TVCC Input Target reference voltage. Needs to be connected

to the microprocessor’s operating voltage (1.8V

to 5V) and is used by the Tracelink to determine

the correct voltage level to use on output signals.

Required.

TRST Output JTAG signal to reset debug logic. Pull-up resistor

required. Optional.

GND Input Ground signal. Connect to the digital ground sig-

nal of the microprocessor. Required.

TDI Output Debug communication signal. Pull-up resistor

required. Recommended.

Tracelink User Manual 12

Page 16

Table C-1. Kinetis Signals (Port D)

Signals Direction Description

TMS/

SWD_DIO

TCK/

SWD_CLK

TDO Input Debug communication signal. Pull-up resistor

RESET I/O Microprocessor reset signal. This signal is driven

3.5 Target Power

The Tracelink is capable of generating 2V, 3V, or 5V directly to the TVCC pin of the

debug header. This can be used to power target microprocessors requiring up to

500mA of current without the need for a separate power supply.

To enable this feature, a jumper needs to be installed onto option J2, which can be

accessed by flipping open the plastic case. This jumper is NOT installed by default.

I/O Debug communication signal. Pull-up resistor

required. Required.

Output Debug communication signal. Pull-down resistor

required. Required.

recommended. Recommended.

low during initial debug mode entry. Pull-up resistor required. Required.

Tracelink User Manual 13

Page 17

Figure 3-9: J2 Jumper

There is additional configuration needed on the PC software to turn on the target

voltage and to specify target voltage value (2V, 3V, or 5V). Refer to the software

documentation for more details.

Tracelink User Manual 14

Page 18

4 EXTERNAL TRACE OVERVIEW

This section provides an introduction to the vocabulary and methodologies of

debugging with external trace. Also discussed are general board and layout

guidelines to help improve signal integrity for the high-speed trace signals.

4.1 How External Trace Works

Below is a simple diagram of the trace process.

Figure 4-10: “Trace Flow” Diagram

When a microprocessor is properly configured for external trace and is executing

code, it will continuously generate trace data on designated output pins. The width of

the trace data port varies depending on the Freescale family and can range from a

single bit to 32-bits and higher. The trace data is always synchronized to the rising

and/or falling edges of the trace clock signal.

Note: On many microprocessors, the trace pins are often multiplexed with other functions

and will default as a general purpose input/output. These pins need to be configured

for trace functionality in the application’s initialization code.

The Tracelink monitors the trace clock signal and records the value of the trace data

pins when the appropriate clock edges occur. The data is saved into the Tracelink’s

internal 128MB buffer, which is later downloaded onto the host PC for analysis. The

software running on the host PC is responsible for decoding the trace data and

displaying it in a useful format to the developer.

4.2 Trace Types

Tracelink User Manual 15

Page 19

Generally there are two categories of trace data being generated by the processor:

instruction trace and data trace.

Instruction trace provides “change of flow” information and is mostly concerned with

branch and jump type instructions. Instruction trace packets will tell the developer

whether a branch was taken and also the destination address of the branch.

Instruction trace is the most common type of trace and allows the application’s code

execution path to be fully reconstructed.

Data trace provides “data access” information and is mostly concerned with load and

store type instructions. Data trace packets will tell the developer the address of the

memory access, the data value of the memory access, or both. Due to the potentially

high bandwidth requirements of data trace, many microprocessors do not directly

implement this type of trace.

4.3 Trace Filtering

Trace filtering is a technique used to reduce the amount of trace data generated by

the target microprocessor. This is typically done to make better use of the available

trace buffer if the user is able to narrow down the scope of the application code where

the bug is occurring. For example, a large loop which is used to perform delays may

take up a large portion of the 128MB trace buffer but does not contribute useful

program flow information to the developer.

Trace filtering focuses primarily on determining when to start and stop trace

generation. For example, the microprocessor can be configured to begin generating

trace when the program counter matches a specific value and to stop generating trace

at a different value.

Each microprocessor family has different trace filtering capabilities, but the goal is the

same: try to reduce the amount of trace data generated to only include the most

relevant code paths or memory accesses. This allows the developer to make optimal

use of the available trace buffer, which may only be large enough to hold a few

seconds worth of trace information on a high-speed processor.

4.4 Board Design Considerations

High-speed digital design rules must be observed in order to avoid signal integrity

issues that can cause the Tracelink to capture incorrect data. Even with slower trace

clock ports, the slew rates of the trace signals can be extremely fast. At a minimum,

the following guidelines should be applied to all of the microprocessor trace signals,

with emphasis particularly on the trace clock.

Tracelink User Manual 16

Page 20

4.4.1 Avoid impedance discontinuities

Stubs are printed circuit board tracks that branch off from the main track and are

usually formed when placing test points or connecting multiple components to the

same net. Stubs should be avoided at all costs as even short stubs can cause serious

signal integrity issues.

Vias are a source of impedance change and the number of vias used should be

minimized.

Keep track widths constant throughout the signal path.

4.4.2 Minimize skew

Try to match the length of all printed circuit board tracks used to carry the trace

signals.

4.4.3 Ground plane

A solid ground plane will ensure a good return path and minimize noise. Avoid having

breaks in the ground plane if possible. Ideally the ground plane should be situated in

the layer next to the signal layer carrying the trace signals.

4.4.4 Minimize crosstalk

If the design has multiple signals running parallel to each other for long distances,

increase the spacing between them to avoid crosstalk issues. Note that crosstalk can

also occur across layers if two signal layers are adjacent to each other.

4.4.5 Signal termination

To eliminate reflections on the signal path, three impedances must match: the source,

the printed circuit board track, and the load. There are two common termination

schemes to minimize reflection:

• Series termination: A resistor is placed in series with the signal as close

as possible to the source. The resistor value plus the output impedance of

the source should equal the printed circuit board track impedance.

• Parallel termination: A resistor is connected between the signal and

ground. This resistor is placed as close as possible to the load (eg. the

debug header). The value of the resistor is equal to the printed circuit

board track impedance.

Tracelink User Manual 17

Page 21

5 ETHERNET CONFIGURATION

This section describes the mechanism used by the Tracelink device to transact data

over an Ethernet network. It primarily focuses on the User Datagram Protocol (UDP),

which is a popular method for sending data over a network when the speed of a data

transaction is of more concern than the guarantee of its delivery. The Tracelink takes

advantage of the UDP protocol’s penchant for speed, and adds an extra layer of logic

to guarantee the delivery of UDP packets in order to offer a best-of-both-worlds

solution.

5.1 Network Architectures

Before delving into the innards of Ethernet message passing, it is prudent to briefly

describe the different network architectures in use today, and how they pertain to the

operation of the Tracelink. Computers are, of course, connected to one another

through intermediary devices in order to form networks. There are several classes of

these intermediary devices, but they generally fall into one of the following three

groups:

Hubs

At the most basic level, computers are connected to one another through a

Hub. A Hub is a device with several ports that are used to connect multiple

computers together. It is a repeater device – a Hub simply copies the data

incoming on one port as data outgoing on the other ports. In this manner, if

there are four computers connected through a Hub, and if the first computer is

sending data to the second computer, then the third and the fourth computers

will also receive an identical copy of that data. Hubs are usually used to set up

a small Local Area Network (LAN), which may have on the order of 10 to 20

computers.

Tracelink User Manual 18

Page 22

Switches

The aforementioned type of process, where the data is simply replicated onto

every available port, quickly becomes inefficient for larger sized networks. For

this reason, a larger sized LAN employs the usage of Switches instead of Hubs.

A Switch is essentially a smart Hub, in that it limits the input and output of data

to the two transacting computers.

Routers

Larger networks, such as Wide Area Networks (WANs), or the Internet for that

matter, use progressively more sophisticated devices to transact data. At the

core of these devices is the Router, which functions as a switch between

networks.

The Tracelink performs irrespective of the connection mechanism, with one very

important caveat: it needs to be set up with the appropriate network parameters for

the underlying network architecture.

5.2 Network Parameters

A typical network becomes operational not after the physical connections have been

established, but after network parameters in the form of IP (Internet Protocol)

numbers have been assigned to the individual computers. An IP number is a unique

string that consists of four numbers ranging between 0 and 255, separated by dots,

e.g., 192.168.1.2. Every computer that is on a network needs to have a unique IP

number. The computer uses this IP number to identify itself on the network, and also

to address the recipient of its data.

Assignation of this IP number is sufficient information to transact data on a simple

network connected by a hub. On a more complex network, however, routing

information becomes important. The routing information consists of two more IP

numbers. The first of these is called the Subnet Mask, and is used to determine

whether or not the destination address resides on the same subnet (i.e., doesn’t need

to be forwarded to another network). The other IP number is the Gateway Address,

which is the address of the computer that handles forwarding and receiving of packets

to and from other networks.

Before first use, the Tracelink needs to be programmed with a unique IP number, the

Subnet Mask IP number, and also the default Gateway’s IP number. This can be done

via the USB port and is described in greater detail in the “Configuring the Tracelink”

section of this manual.

Tracelink User Manual 19

Page 23

5.3 Internet Protocol

Once the network has been established, and the IP numbers have been assigned,

data can be transacted over a network with one of several protocols. By far the most

prevalent protocol is the Transmission Control Protocol (TCP), which runs on top of

the Internet Protocol in what is collectively known as the TCP/IP protocol. The TCP/IP

protocol was developed by the Department of Defense to connect different computers

from different vendors by a “network of networks,” which has become what is known

as the Internet today.

The primary purpose of the TCP/IP protocol was to prevent a complete network

outage in the case of a nuclear attack, by automatically rerouting data traffic through

the functioning part of the network. As such, the TCP/IP mechanism guaranteed

delivery of data packets by introducing a system of acknowledgements and sequence

numbers for the data packets. This mechanism, while good for transacting large

amounts of data (such as email or file transfers), is unsuitable in the real-time type

environment in which the Tracelink operates. Because the Tracelink needs to transact

data as quickly as possible to the target, it takes advantage of TCP/IP’s alternative,

the UDP/IP protocol.

Unlike TCP/IP, the UDP/IP protocol is a connectionless, single-packet protocol that

sends short data packets at the expense of not guaranteeing their delivery. This

makes the UDP/IP protocol efficient in real-time applications such as broadcasting

video over the Internet, where the occasional loss of a frame of data is not going to

hamper the overall viewing experience. Left unmodified, the UDP/IP, with its lack of

guarantees for packet delivery, would be unusable in an environment where the

delivery of a single byte of data needs to be guaranteed. The Tracelink firmware adds

mechanisms to the UDP/IP protocol, without affecting its underlying efficiency, to

guarantee delivery of data packets.

5.4 Connecting The Tracelink Device

There are two methods for establishing a connection between a Tracelink and a PC

with an Ethernet cable. The most basic method is to connect the Tracelink directly to a

PC, via a cross-over Ethernet cable. However, the more common method is to place

the Tracelink and the PC on the same network through a Hub.

5.4.1 Connecting the Tracelink to the PC over a network:

The Tracelink was intended for use on a network of multiple computers (and other

Tracelinks). There are many possible network configurations, and to describe them all

is beyond the scope of this document. However, most configurations are a

Tracelink User Manual 20

Page 24

modification of a basic theme, which is that of connecting one or more PCs through a

Hub to one or more Tracelinks.

In order to connect these devices to the Hub, you will need to use the provided

straight-through Ethernet cable. The straight-through cable, which is the “standard”

Ethernet cable, is used to connect devices of different types together, such as a PC to

a Hub, or a Hub to a Tracelink.

At this point it once again becomes necessary to program the Tracelink with valid IP

numbers, the process for which is described in greater detail in the following section.

However, it is important for the Tracelink and the PCs to have matching Subnet and

Gateway IP numbers, and for each to have a unique IP number on the network. An

example of a setting for above is as follows:

IP Number

PC1 192.168.100.1 192.168.100.3 255.255.255.0

PC2 192.168.100.2 192.168.100.3 255.255.255.0

Tracelink 192.168.100.4 192.168.100.3 255.255.255.0

Gateway 192.168.100.3 192.168.100.3 255.255.255.0

It is important to briefly touch upon the underlying network architecture, which can be

a 10Mb (Megabit), 100Mb, 10/100Mb, half-duplex, or a full-duplex connection. The

details of the underlying network architecture are beyond the scope of this document,

but it is sufficient to note that most modern network cards, as well as the Tracelink

device, have the capability to configure themselves for the underlying network through

the Auto-negotiation mechanism. Auto-negotiation is performed as soon as a network

cable is connected to the device, and it sets the operating parameters of the device to

match those of the network.

Gateway IP Subnet Mask

5.4.2 Connecting Tracelink-to-PC via an Ethernet cable

In order to connect the Tracelink to a PC directly via an Ethernet cable, you need to

use what is known as a cross-over cable. A cross-over cable, which is not provided by

P&E, is normally used to connect two similar devices such as a PC to a PC, or a Hub

to a Hub. It is a cable that has its receive and transmit wires crossed over so that the

similar devices can effectively communicate with one another.

With this configuration, it is still important to assign IP numbers to both the PC and the

Tracelink device. Although at first glance it may not seem necessary to assign a

Gateway address in this configuration, the Tracelink was designed to operate on a

network of more than two computers, and therefore it needs to be programmed with a

Gateway address.

Tracelink User Manual 21

Page 25

Assuming the desktop’s IP number to be 192.168.100.1, this is an example of the

three IP numbers that would need to be programmed into the Tracelink:

IP Number

PC 192.168.100.1 none 255.255.255.0

Tracelink 192.168.100.2 192.168.100.1 255.255.255.0

For more information on programming these IP numbers into the Tracelink device,

please see the following section.

Gateway IP Subnet Mask

5.5 Tracelink IP Setup Utility User Interface (ConfigureIP)

Before the Tracelink device transacts data on an Ethernet network, it will need to be

configured with the relevant network parameters. The application that provides this

capability is the Tracelink IP Setup Utility (ConfigureIP), which can be found as part of

the distribution software.

This utility is used to configure the Tracelink with network parameters, and also to

update the firmware of the Tracelink.

Figure 5-1: IPSetup.exe Default Screen

Tracelink User Manual 22

Page 26

(1) Drop-down Box 1

There are two options available in this drop-down box: "Ethernet Port" and

"USB Port". Changing to any one of these Ports will list the devices which are

found over that specific Port.

(2) Drop-down Box 2

Once one of the communication interfaces (USB or Ethernet) has been

selected in the first drop-down box, a list of all available Tracelink devices over

that interface will be displayed for selection.

(3) Close Button

The “Close” button is active only when a device has been opened for access.

Once a device has been opened for access, it needs to be closed before

another device can be opened for access.

(4) Open Button

The “Open” button opens a device for access. This is a required step before

changing the parameters on the selected device. Once a device has been

selected through the second drop-down box and is opened for access, its

information will be displayed at the bottom of the dialog box.

(5) Refresh List

Will refresh the dialog boxes by searching for devices which are currently

connected via the USB or Ethernet interfaces.

(6) Tracelink IP Number

This is the IP number which will be associated with the Tracelink. It needs to

be a unique IP number which can be accessible on the network.

(7) Tracelink Device Name

This is a label which can be used to identify the Tracelink by name, e.g.,

“John’s Tracelink.”

(8) MAC Address

This is the Media Access Control address, the unique number of an Ethernet

device on the network. This is programmed by P&E and cannot be modified.

(9) Gateway IP Number

The IP number of a gateway on the network.

(10) Subnet Mask

The subnet mask of the network.

Tracelink User Manual 23

Page 27

(11) Firmware Version

A read-only field which returns information pertaining to the build date and

firmware version of the Tracelink device.

(12) Program Tracelink Parameters

This button saves the information as it appears in the "Reconfigure IP

Numbers" area onto the Tracelink device.

(13) Specify IP Button

If the Tracelink cannot be automatically detected over the network, this button

allows the user to manually specify the Tracelink IP address.

5.6 Using ConfigureIP.exe To Configure The Tracelink

Before the Tracelink is ready to communicate over an Ethernet network, it will need to

be configured with the relevant network parameters. The application that provides this

capability is the Tracelink Configuration Utility (IPSetup.exe), and is provided as part

of the standard Tracelink software distribution.

In order to update the network parameters, perform the following steps:

1. Connect a Tracelink to the PC via a USB cable, and make sure that it is powered before launching the Tracelink Configuration Utility. The Tracelink Configuration Utility starts up with the following screen:

Tracelink User Manual 24

Page 28

Figure 5-2: Tracelink IP Setup Utility - Initial Screen

2. Click “Open” to get a dialog box similar to the following:

Figure 5-3: Tracelink IP Setup Utility - Continue Setup

Tracelink User Manual 25

Page 29

3. The Tracelink now needs to be programmed with IP numbers for the network

on which it will operate. The Tracelink IP Number field must contain a unique

IP number.

Tracelink User Manual 26

Page 30

6 USB CONFIGURATION

Standard USB cables may be used for Tracelink USB port configuration. The user

may use network hubs as necessary.

Tracelink User Manual 27

Page 31

7 CODEWARRIOR 10.x CONFIGURATION

This section provides a walkthrough of the configuration steps required to begin using

the Tracelink in Freescale’s CodeWarrior 10.x development suite. CodeWarrior 10.2

or higher (with all available updates installed) is required. Before following these

steps, the Tracelink should already be connected to the target board and both should

be powered up.

Step 1. Project Creation

To create a new project, click on File -> New -> Bareboard Project.

After providing a project name and selecting the appropriate Freescale

microprocessor, you will be prompted for a run control device:

Figure 7-1: CodeWarrior: Select Run Control Device

Tracelink User Manual 28

Page 32

Select the “P&E TraceLink USB” and/or “P&E TraceLink Ethernet” option. Continue

with the remaining steps in the wizard to finalize the project.

Step 2. Add Initialization Code

If necessary, add any device specific initialization code to configure the

microprocessor for trace generation. For example, the trace pins may be configured

as general purpose input/output by default and you may need to add a few lines of

code to initialize them for trace output. Once the changes are made, make sure to

compile/build the project.

Step 3. Configure Trace Settings

Click on Run -> Debug Configurations. Select the appropriate configuration (Flash,

RAM, etc.) from the left panel. Within the “Main” tab, click on the “Edit” button inside

the “Connection” groupbox.

Figure 7-2: CodeWarrior: Select Configuration (Edit Button Highlighted)

Inside the P&E connection dialog that appears, look for the “Trace Max Buffer Size”

Tracelink User Manual 29

Page 33

option. This controls the size of the Tracelink’s internal buffer. By default, this is set to

the lowest value (128KB). As this capacity is increased, the Tracelink can store more

trace data, but PC download and processing times are also increased. P&E

recommends using one of the center values such as 2MB and increasing it as

necessary. Click “OK” to apply the settings.

Figure 7-3: CodeWarrior: Set Trace Max Buffer Size

Navigate to the “Trace and Profile” tab and check the “Enable Trace and Profile”

checkbox. There are additional device specific settings in this panel that the user

should review. These settings control what type of trace filtering will be applied by the

CodeWarrior debugger. Click “Apply” and then “Debug” to launch the debug session.

Tracelink User Manual 30

Page 34

Figure 7-4: CodeWarrior: Enable Trace and Profile

Step 4. Run the project

When the microprocessor halts (eg. after a single-step, run/breakpoint, or run/user

halt), CodeWarrior will query the Tracelink for trace data. This data is automatically

downloaded and parsed by the CodeWarrior software analysis engine. The results are

displayed in the “Software Analysis” tab. Clicking on the individual links (Trace,

Timeline, Critical Code, Performance, Call Tree) will display the corresponding view of

the trace data.

Tracelink User Manual 31

Page 35

Figure 7-5: CodeWarrior: Display Trace Data

Tracelink User Manual 32

Page 36

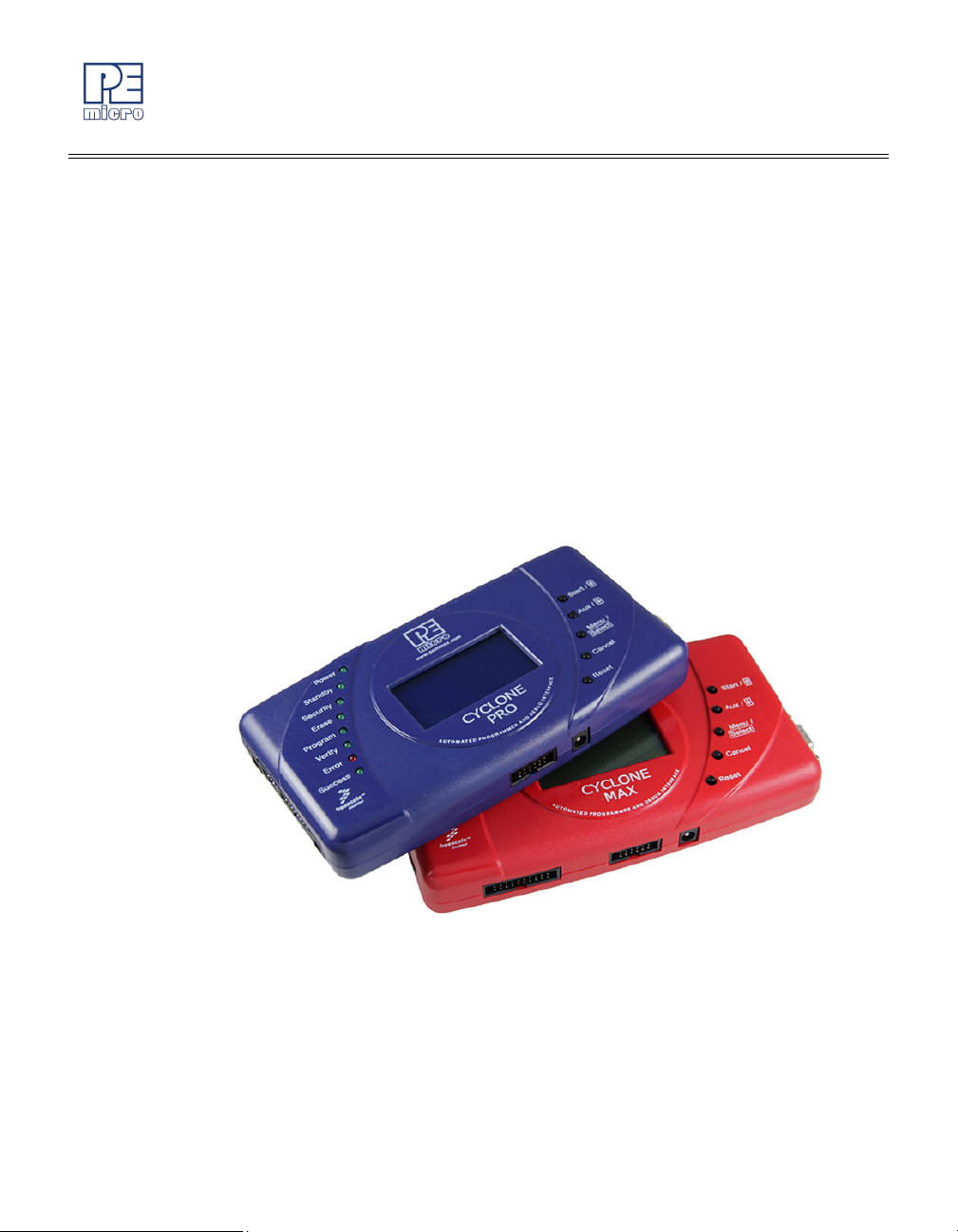

8 PRODUCTION PROGRAMMING

Once you have accomplished the development stage of your project, you may need a

hardware tool to allow you to easily execute low- or high-volume production

programming. P&E’s Cyclone MAX and Cyclone PRO are versatile and robust

programming tools with advanced features and production capabilities. Each supports

a different set of Freescale architectures. They each feature multiple communications

interfaces (USB, Ethernet, and Serial), stand-alone programming functionality, and

many other advanced capabilities. They work with Freescale’s CodeWarrior as well as

P&E’s software to help provide a seamless transition to programming.

For more information about the Cyclones, please visit us at pemicro.com/

cyclonemax or pemicro.com/cyclonepro.

Figure 8-1: Cyclone PRO & Cyclone MAX Stand-Alone Programmers

8.1 Cyclone Key Features

• Advanced programming and debugging capabilities, including:

• PC-Controlled and User-Controlled Stand-Alone Operation

• Interactive Programming via Host PC

Tracelink User Manual 33

Page 37

• In-Circuit Debugging, Programming, and Testing

• Compatible with many Freescale microcontroller families:

Cyclone MAX

• ColdFire® V2/V3/V4

•Power

•Qorivva

• Kinetis

•Power

®

MPC5xx/8xx

®

MPC55xx/56xx

®

ARM

®

Architecture PX Series

• DSC (MC56F80xx, MC56F82xx, MC56F83xx, and MC56F84xx)

• ARM (MAC7xxx)

Cyclone PRO

•HC08

•HCS08

• S12Z (coming soon)

•HC(S)12(X)

•RS08

• ColdFire +V1/ColdFire V1

• Communication via USB, Serial, and Ethernet Ports

• Multiple image storage

• LCD screen menu interface

• Supported by P&E software and Freescale’s CodeWarrior

8.2 Cyclone In-Depth

P&E’s Cyclones are extremely flexible tools designed for debugging, testing, and incircuit flash programming of Freescale microcontrollers. The Cyclone connects your

target to the PC via USB, Ethernet, or Serial Port and enables you to debug your

code, program, and test it on your board. After development is complete the Cyclone

can be used as a production tool on your manufacturing floor.

For production, the Cyclone may be operated interactively via Windows-based

programming applications as well as under batch or .dll commands from a PC. Once

loaded with data by a PC it can be disconnected and operated manually in a standalone mode via the LCD menu and control buttons. The Cyclone has over 7 Mbytes

Tracelink User Manual 34

Page 38

(MAX) or 3Mbytes (PRO) of non-volatile memory, which allows for the onboard

storage of multiple programming images. When connected to a PC for programming

or loading it can communicate via the ethernet, USB, or serial interfaces.

8.2.1 Software

The Cyclone comes with intuitive configuration software and interactive programming

software, as well as easy to use automated control software. The Cyclone also

functions as a full-featured debug interface, and is supported by Freescale’s

CodeWarrior as well as development software from P&E.

P&E’s Cyclones are also available bundled with additional software as part of various

Development Packages. In addition to the Cyclone programming hardware, these

Development Packages include in-circuit debugging software, flash programming

software, a Windows IDE, and register file editor.

8.2.2 Enhancements

P&E also offers add-on features that can increase the Cyclone’s versatility.

• The CompactFlash port can be activated, which enables a very useful

memory expansion, making it easier to manage larger and/or multiple

orgramming images.

• The Cyclone Automated Control Package allows you to control and fully

automate multplie Cyclones for efficient gang programming capability.

• The Cyclone Power Pack gives you the ability to power the Cyclone out in the

field where a standard power source may be hard to come by. This allows you

to ge the most out of the Cyclone’s stand-alone programming ability.

For more information about P&E’s Cyclones, please visit us at pemicro.com/

cyclonemax or pemicro.com/cyclonepro.

Tracelink User Manual 35

Page 39

Loading...

Loading...