Page 1

Page 2

Purchase Agreement

P&E Microcomputer Systems, Inc. reserves the right to make changes without further notice to any

products herein to improve reliability, function, or design. P&E Microcomputer Systems, Inc. does not

assume any liability arising out of the application or use of any product or circuit described herein.

This software and accompanying documentation are protected by United States Copyright law and

also by International Treaty provisions. Any use of this software in violation of copyright law or the

terms of this agreement will be prosecuted.

All the software described in this document is copyrighted by P&E Microcomputer Systems, Inc.

Copyright notices have been included in the software.

P&E Microcomputer Systems authorizes you to make archival copies of the software and

documentation for the sole purpose of back-up and protecting your investment from loss. Under no

circumstances may you copy this software or documentation for the purpose of distribution to others.

Under no conditions may you remove the copyright notices from this software or documentation.

This software may be used by one person on as many computers as that person uses, provided that

the software is never used on two computers at the same time. P&E expects that group programming

projects making use of this software will purchase a copy of the software and documentation for each

user in the group. Contact P&E for volume discounts and site licensing agreements.

P&E Microcomputer Systems does not assume any liability for the use of this software beyond the

original purchase price of the software. In no event will P&E Microcomputer Systems be liable for

additional damages, including any lost profits, lost savings or other incidental or consequential

damages arising out of the use or inability to use these programs, even if P&E Microcomputer Systems

has been advised of the possibility of such damage.

By using this software, you accept the terms of this agreement.

© 2009 P&E Microcomputer Systems, Inc. “MS-DOS” and “Windows” are registered trademarks of

Microsoft Corporation. “Freescale” and “ColdFire” are registered trademarks of Freescale, Inc. “IBM”

and “PowerPC” are registered trademarks of IBM corporation.

P&E Microcomputer Systems, Inc.

98 Galen St.

Watertown, MA 02472

617-923-0053

http://www.pemicro.com

Manual version 1.06

Page 3

1 INTRODUCTION ............................................................................................ 1

1.1 Overview ........................................................................................................ 1

1.2 Package Contents .......................................................................................... 1

1.3 Supported Devices ......................................................................................... 1

1.4 Recommended Materials On Breaking Bit Boundaries DVD-ROM................ 2

1.5 Handling Precautions ..................................................................................... 2

2 HARDWARE FEATURES............................................................................... 2

2.1 DEMOQE Base Board Features .................................................................... 2

2.2 On-Board Logic Analyzer ............................................................................... 4

2.3 On-Board Virtual Serial Port........................................................................... 4

2.4 DEMOQE Daughter Card Features................................................................ 5

2.5 DEMOQE128 JUMPER/CONNECTOR QUICK REFERENCE ...................... 5

3 GETTING STARTED WITH THE DEMOQE128............................................. 6

3.1 Quick Start Guide ........................................................................................... 7

3.2 LAB 1: Learn How to use DEMOQE Toolkit Utilities ...................................... 9

3.3 LAB 2: Migrate Quickly from 8-Bit To 32-Bit................................................. 11

3.4 LAB 3: Measure Performance between 8-Bit and 32-Bit.............................. 14

3.5 LAB 4: Learn how to use CodeWarrior......................................................... 19

4 SYSTEM SETUP .......................................................................................... 20

4.1 Overview ...................................................................................................... 20

4.2 Operating System Requirements ................................................................. 20

4.3 Software Setup............................................................................................. 20

4.4 Quick Startup................................................................................................ 21

4.5 Hardware Setup ........................................................................................... 22

5 OPERATING MODES................................................................................... 25

5.1 Overview ...................................................................................................... 25

5.2 Debug Mode................................................................................................. 25

5.3 Run Mode..................................................................................................... 26

5.4 External BDM Mode ..................................................................................... 26

6 DEMOQE TOOLKIT PC APPLICATIONS .................................................... 26

6.1 DEMOQE Logic Analyzer Application .......................................................... 26

DEMOQE User Manual ii

Page 4

6.2 DEMOQE Terminal Application ....................................................................27

6.3 DEMOQE Unsecure Application ...................................................................28

6.4 DEMOQE Accelerometer Demo Application.................................................29

6.5 DEMOQE Serial Grapher Application...........................................................31

7 DEMONSTRATION MICROCONTROLLER APPLICATIONS...................... 34

7.1 Quick Start Application .................................................................................34

7.2 Serial Accelerometer Application ..................................................................35

8 JUMPER SETTINGS .................................................................................... 35

8.1 System Power...............................................................................................35

8.2 RS232 Communications ...............................................................................37

8.3 LED Display Port ..........................................................................................39

8.4 Input and Reset Switches .............................................................................39

8.5 3-Axis Accelerometer Jumper Settings.........................................................41

8.6 Buzzer...........................................................................................................43

8.7 IIC Pull-up .....................................................................................................43

8.8 Analog Input Potentiometer ..........................................................................44

8.9 Optional External Crystal Circuitry Jumper Enable.......................................44

8.10 Optional Jumpers For Various VDD And VSS..............................................44

9 DEMOQE128 CODE DEVELOPMENT SOFTWARE................................... 44

9.1 Using CodeWarrior With The DEMOQE128.................................................45

9.2 Using P&E Software With The DEMOQE128...............................................45

10 TRANSITIONING TO YOUR OWN TARGET............................................... 46

10.1 Hardware Solutions At A Glance ..................................................................46

10.2 Working With P&E’s USB Multilink ...............................................................47

10.3 Working With P&E’s Cyclone PRO ...............................................................48

11 TROUBLESHOOTING.................................................................................. 49

11.1 DEMOQE128 Is Undetected.........................................................................49

11.2 CodeWarrior Installation Fails (WinDriver Error)...........................................51

iii DEMOQE User Manual

Page 5

1 INTRODUCTION

1.1 Overview

The DEMOQE128 is a low-cost development system designed for

demonstrating, evaluating, and debugging the Freescale MC9S08QE128 and

MCF51QE128 microcontrollers. P&E’s Embedded Multilink circuitry on the

DEMOQE128 board allows the processor on the DEMOQE128 to be

debugged and programmed via USB from the PC. In addition, the demo

board can be powered using the USB bus.

1.2 Package Contents

The DEMOQE128 package includes the following items:

• DEMOQE Base Board with a MC9S08QE128 Daughter Card

installed

• MCF51QE128 Daughter Card

• DVD Breaking Bit Boundaries - Getting Started With QE128

• 2-cell AAA battery package

• USB Cable

• Quick Start Guide

• Freescale Warranty Card

1.3 Supported Devices

The DEMOQE128 supports the following devices:

• MC9S08QE128CLH

• MCF51QE128CLH

DEMOQE128 User Manual 1

Page 6

1.4 Recommended Materials On Breaking Bit Boundaries DVD-ROM

• Freescale MC9S08QE128 reference manual and datasheet

• Freescale MCF51QE128 reference manual and datasheet

• DEMOQE Base Board Schematic

• DEMOQE128 Daughter Card Schematic

• DEMOQE Toolkit Applications

• P&E Embedded Multilink driver installation guide and resources

1.5 Handling Precautions

Take care to handle the package contents, including the DEMOQE base

board, MC9S08QE128 daughter card, and MCF51QE128 daughter card, in a

manner such as to prevent electrostatic discharge.

2 HARDWARE FEATURES

The DEMOQE128 is a demonstration and development system for

Freescale’s MC9S08QE128 and MCF51QE128 microcontrollers. Application

development is quick and easy using P&E’s Embedded Multilink circuitry and

the included software tools and examples. An optional BDM port is provided

to allow use of an external BDM interface such as P&E’s Cyclone PRO

automated programmer or USB Multilink. The USB Multilink is functionally

comparable to the DEMOQE128’s Embedded Multilink circuitry.

Note: The DEMO board’s onboard Embedded Multilink circuitry is intended to

function with the onbaord processor and any daughter cards that may be

included. It cannot be used to communicate with other devices.

2.1 DEMOQE Base Board Features

• On-board Logic Analyzer

• On-board Virtual Serial Port

• Asymmetrically positioned 4 8x2 male connectors for interchangeable

daughter cards

• P&E’s Embedded Multilink circuitry populated on the bottom

• RS-232 Serial Port w/ DB9-F Connector

2 DEMOQE128 User Manual

Page 7

• SCI signals connected to P&E’s Embedded Multilink through jumpers

• ON/OFF Power Switch w/ LED indicator

• A 5VDC to 8VDC power supply input barrel connector

Note: The DEMOQE board power connector is incorrectly labelled as 5-12VDC.

The maximum voltage is 8VDC.

• Power Input Selection Jumpers for selecting the input voltage source:

• Power Input from Embedded Multilink to LDO regulator

• Power Input from DC Power Jack to LDO regulator

• Regulated VDD Output at 3.0V

• Regulated VDD Output at 2.1V

• Power Input from Battery

• Power Input from MCU_PORT connector

• RESET Push Button and LED indicator w/ Enable

• Optional External Crystal Circuitry Layout (not populated)

• User Features:

• 3-axis Accelerometer w/Enable

• 8 User LED’s w/ Enable

• 4 User Push Buttons w/ Enable

• 1 Piezzo Buzzer w/ Enable

• IIC Pullups w/ Enable

• 10K Ohm POT w/ Enable

• Option Jumpers:

• COM_EN for 1.8V to 4.25V RS232 Transceiver

• TXD_EN for SCI_TXD to Embedded Multilink

• RXD_EN for SCI_RXD to Embedded Multilink

• INPUT_EN for two input channels to Embedded Multilink

• Specifications:

• Board Size 3.5 x 4.0

DEMOQE128 User Manual 3

Page 8

• Power Input:

• USB Cable: 5VDC, 500mA max

• DC Power Jack: 2.5/5.5mm barrel connector, 5VDC to 8VDC

Center Positive

Note: The DEMOQE board power connector is incorrectly labelled as 5-12VDC.

The maximum voltage is 8VDC.

• Two AAA Battery Cells

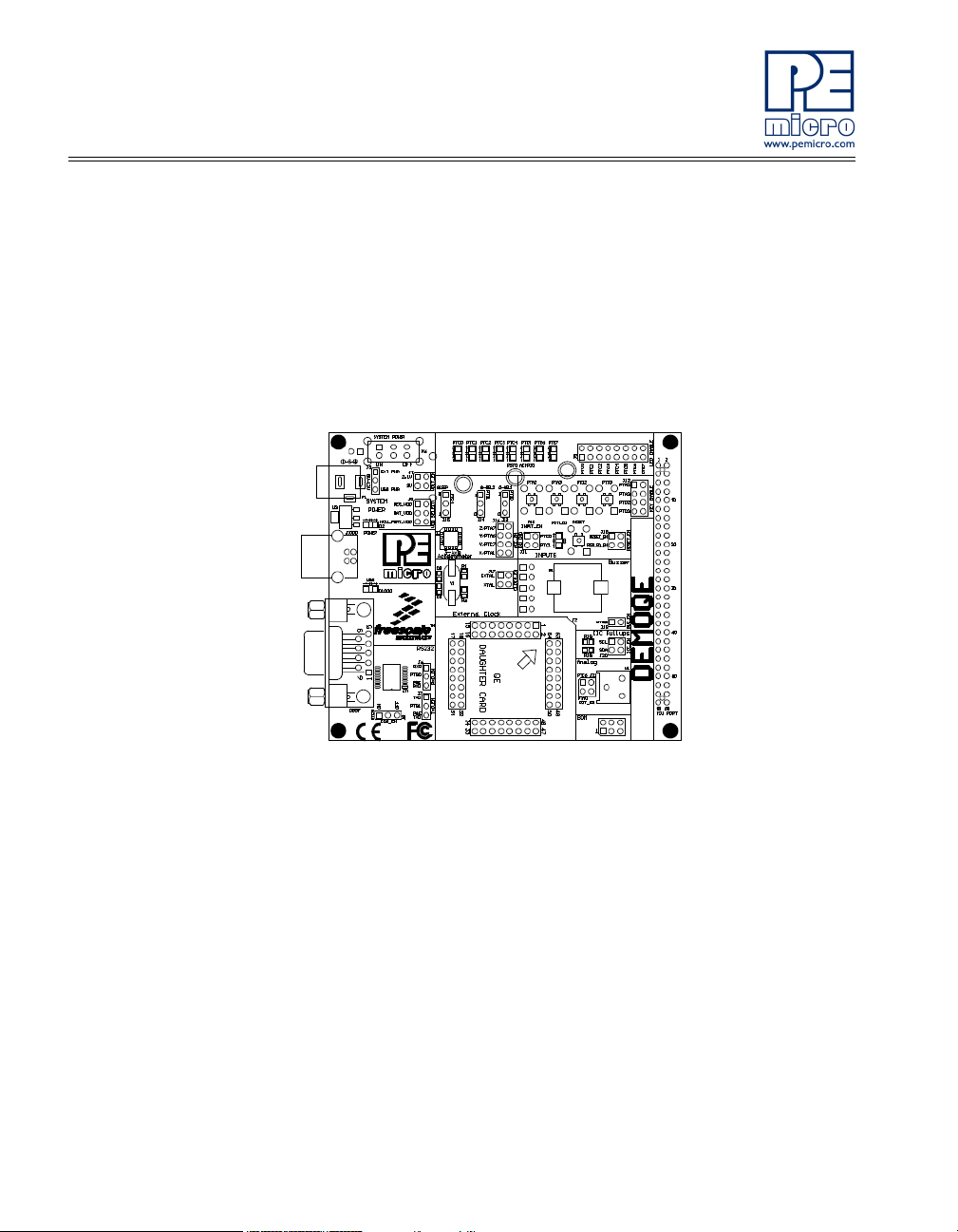

Figure 2-1: DEMOQE128 Top Component Placement

2.2 On-Board Logic Analyzer

The DEMOQE board has a built-in 2-channel logic analyzer which may be

used to display captured data in real-time on a host PC. The logic analyzer

channels (IN0/IN1) are connected to the PTC0 and PTC1 signals on the

DEMOQE board by default via the J11 jumpers. The channels may be

connected to any of the processor pins by wire jumpers (not included).

The DEMOQE Logic Analyzer Utility, included in the DEMOQE Toolkit on the

accompanying DVD-ROM, displays the logic analyzer signals on a PC.

2.3 On-Board Virtual Serial Port

The DEMOQE board has a built-in virtual serial port which may be connected

4 DEMOQE128 User Manual

Page 9

to the QE processor’s SCI RXD/TXD. This allows certain PC applications to

be able to connect in a serial fashion to the microcontroller without the actual

use of serial port hardware.

The DEMOQE Terminal Window Utility, included in the DEMOQE Toolkit on

the accompanying DVD-ROM, is a generic serial port utility which works with

the DEMOQE virtual serial port or actual serial port hardware.

2.4 DEMOQE Daughter Card Features

• Four bottom-mounted asymmetrically positioned 8x2 female

connectors to mate with the DEMOQE Base Board

• A top-mounted MC9S08QE128CLH or MCF51QE128CLH chip

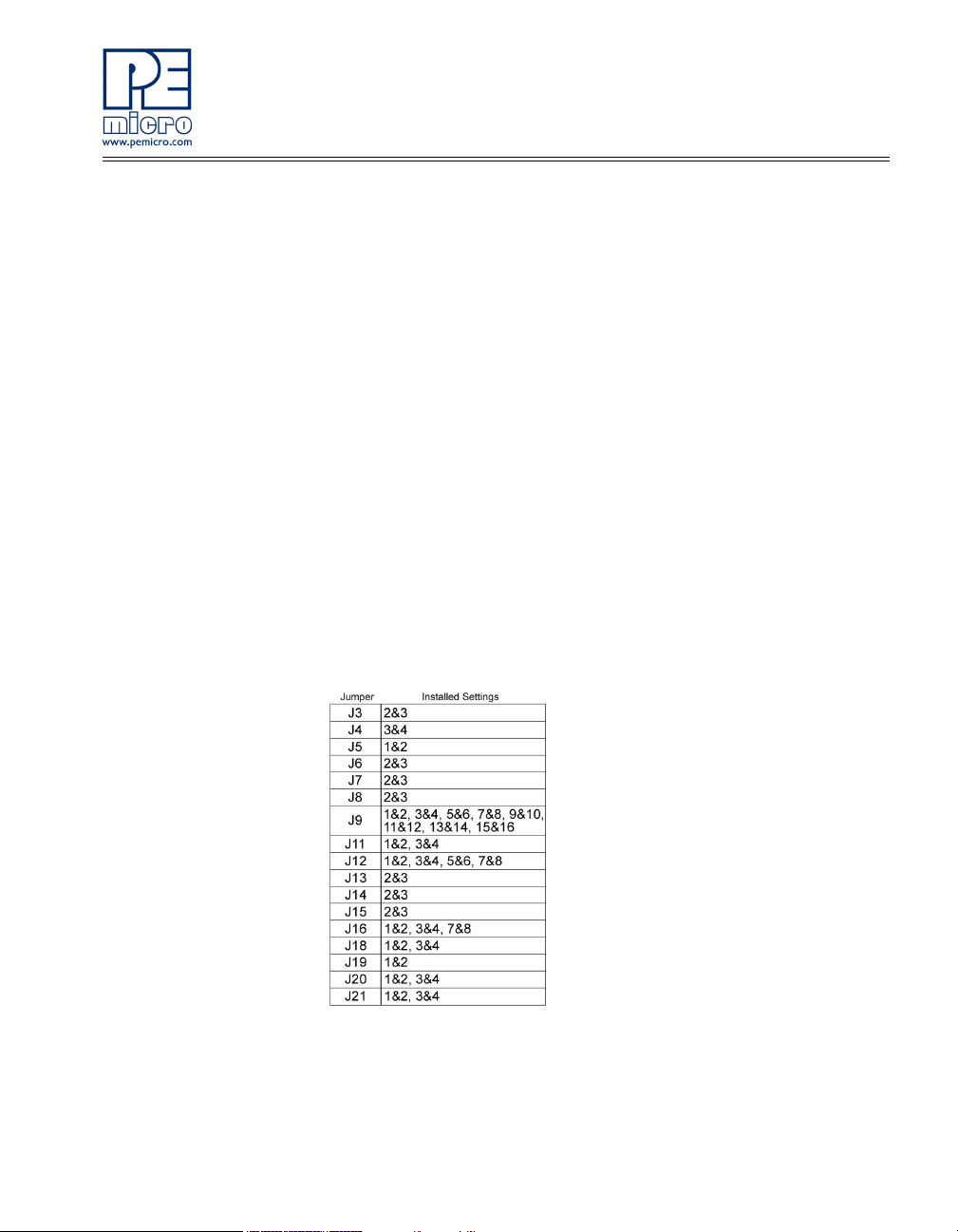

2.5 DEMOQE128 JUMPER/CONNECTOR QUICK REFERENCE

Default Jumper Settings

The following is a list of default jumper settings for DEMOQE board. The

settings listed indicated the “on” (or installed) position.

Figure 2-2: Default Jumper Settings

DEMOQE128 User Manual 5

Page 10

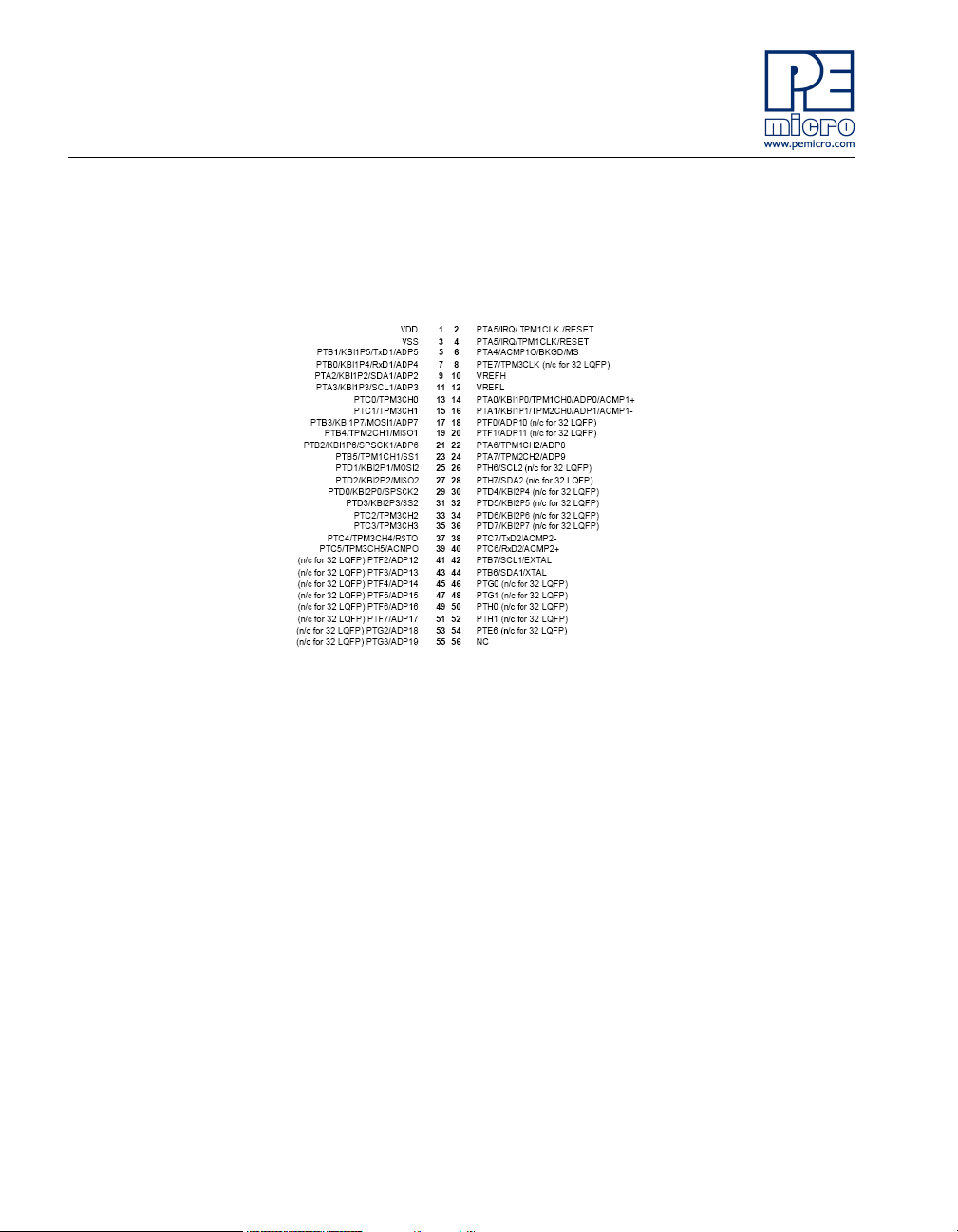

MCU Port Connector Pinout

The following is the pinout for the MCU Port connector on the DEMOQE

board.

Figure 2-3: MCU Port Connector Pinout

3 GETTING STARTED WITH THE DEMOQE128

The DEMOQE128 is a low-cost board targeting quick microcontroller

evaluation. The board includes two plug-in daughter cards to demonstrate the

ease of migration between the Flexis QE128, 8-bit S08 and 32-bit ColdFire V1

microcontrollers. The board also includes a power terminal to measure the

ultra-low power consumption of the Flexis QE128 devices.

This getting started chapter serves two purposes. The first is to install all

necessary software and demonstrate some basic DEMOQE128 features. The

second is to demonstrate with a few simple labs the key benefits of the

QE128 microcontroller.

6 DEMOQE128 User Manual

Page 11

3.1 Quick Start Guide

The quick start guide walks you through the initial software installation and

board test.

STEP 1: INSTALL CODEWARRIOR FOR MICROCONTROLLERS

CodeWarrior installation is a one-time required step before connecting the

board to your computer.

1. Insert the provided Breaking Bit Boundaries DVD into your computer

and a menu page will appear on your default browser.

2. Click on the following image to download the CodeWarrior installer to

your computer. Follow the prompts to save file CW_MCUs_V6_0.exe

to your computer.

3. Once the download is complete, double-click on the

CW_MCUs_V6_0.exe executable file to run the installation.

4. Follow the on-screen instructions until the installation is complete.

STEP 2: INSTALL DEMOQE TOOLKIT

DEMOQE Toolkit install is a one-time required step. The DEMOQE Toolkit

includes graphical utilities that run on your computer and help speed up your

development. These utilities take development beyond the hardware. They

interact with the target microcontroller over the same USB Multilink reference

design on the board that allows you to debug using CodeWarrior. Additionally,

you can debug your microcontroller in CodeWarrior while simultaneously

using one of the following utilities: Logic Analyzer, Serial Grapher, Terminal

Window, and Accelerometer Demo Grapher.

1. Insert the provided Breaking Bit Boundaries DVD into your computer

and a menu page will appear on your default browser.

2. Click on “DEMOQE128” and then on “Other DEMOQE128

Resources” in the navigation panel on the left side of the DVD menu.

DEMOQE128 User Manual 7

Page 12

This will launch the P&E DEMOQE Resources menu.

3. From this new menu, click on “Drivers & DEMOQE Toolkit” to launch

the appropriate menu for downloading the toolkit.

4. From this new menu, click on “DEMOQE Toolkit.” Follow the prompt

to save file “DEMOQE_Toolkit.zip” to your computer.

5. Extract the zip file to the desired location on your computer, creating a

DEMOQE_Toolkit folder that includes all the graphical utilities.

Some of the toolkit applications capture and display data from the

DEMOQE128 board. The faster the PC is, the more rapid and smooth the

data display in these utilities will be.

For more information on the DEMOQE Toolkit, see the board user manual

(DEMOQE128UM.pdf) included in the DVD under “DEMOQE128 >

DEMOQE128 User Manual” in the navigation panel on the left side of the

DVD menu. For new and upgraded utilities to the DEMOQE Toolkit visit http://

www.pemicro.com/fixedlinks/demoQEtoolkit.html.

STEP 3: CONNECT DEMOQE128 BOARD TO COMPUTER

USB driver installation is a one-time required step that requires CodeWarrior

installation first.

1. Remove the board from the anti-static pouch. The green 8-bit

MC9S08QE128 daughter card will be mounted on the base board.

2. Connect the provided USB cable from a free USB port on your computer to the USB connector on the board. If a HUB is used, it must be

self-powered.

3. The operating system will recognize your board as new hardware and

will prompt you to install the USB drivers. Choose the recommended

option to install the software automatically. (USB drivers for your

board were pre-loaded in CodeWarrior installation.)

4. Follow the on-screen instructions until all USB driver installations are

complete. The green USB LED on the board should illuminate.

8 DEMOQE128 User Manual

Page 13

STEP 4: TEST BOARD BY RUNNING QUICK START APPLICATION

Now that you have successfully completed the software and hardware setup,

test your board by interacting with the Quick Start Application that is preloaded in the microcontroller’s on-chip flash memory.

The programmed application samples the microcontroller’s general purpose

input pins. These pins are connected to push buttons and perform two

actions. The first action is to illuminate the respective LED with either a

general purpose output pin or a pulse-width modulated signal pin. The second

action is to play a different tone per push button on the speaker, using a

pulse-width modulated signal programmed at different frequencies. The

application samples the potentiometer using the microcontroller’s analog-todigital converter and uses the result to vary the light intensity of two LEDs by

changing their pulse-width modulated signal’s duty cycle.

1. Turn the SYSTEM POWER switch to the ON position. The red

POWER LED will illuminate and the application will start automatically.

2. Press push buttons labeled PTA2, PTA3, PTD2, and PTD3. A differ-

ent tone will be emitted from speaker when each push button is

pressed, and the corresponding LEDs labeled PTC1, PTC2, PTC3,

and PTC4 will illuminate.

3. Rotate the potentiometer (W1) to vary the light intensity of the LEDs

labeled PTC0 and PTC5.

4. Now that your board is functional, try out the provided labs in

DEMOQE128 Labs section to learn more about the Flexis QE128

microcontrollers and other features included with your board.

3.2 LAB 1: Learn How to use DEMOQE Toolkit Utilities

This lab will show you how to use one of several graphical utilities in

DEMOQE Toolkit included with your board. Instructions to download these

utilities to your computer are provided in Step 2 of the Section 3.1 - Quick

Start Guide. Make sure to use only one utility at a time, as the utilities all

share the same USB resource. The toolkit utilities may be used at the same

DEMOQE128 User Manual 9

Page 14

time that an application is being debugged and programmed on the

DEMOQE128 board from within CodeWarrior.

With the Quick Start Application (which comes pre-loaded in the

microcontroller’s on-chip flash memory) running we will use the DEMOQE

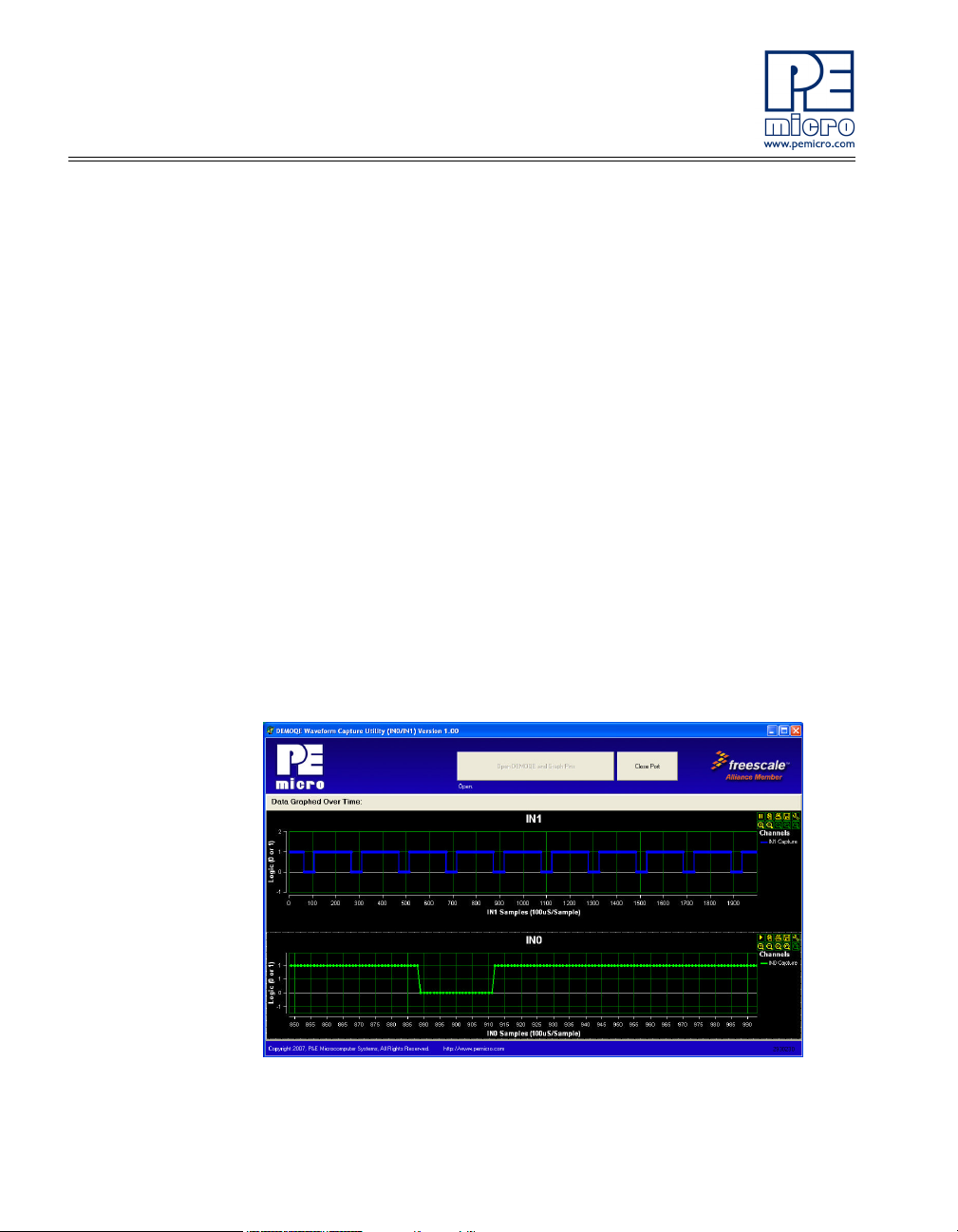

Logic Analyzer utility. This PC-based utility graphs the IN0 and IN1 signals on

the board. For convenience, if both J11 jumpers are installed, IN0 graphs

PTC0 activity and IN1 graphs PTC1 activity. If you would like to graph other

microcontroller signals, you can use wire jumpers from IN0 and IN1 to the

respective signals on the board’s MCU PORT.

1. Make sure the board is powered ON and that the Quick Start Application is running.

2. Open the DEMOQE Logic Analyzer utility from within the

DEMOQE_Toolkit folder by double-clicking on the LogicAnalyzer.exe

file.

3. In the utility, click on the “Open DEMOQE and Graph Pins” button to

begin graphing IN0 and IN1. These signals will be continually

graphed at a sampling rate of 10Khz.

Figure 3-4: DEMOQE Logic Analyzer

10 DEMOQE128 User Manual

Page 15

4. Press the push button labeled PTA2. This will cause a fixed duty cycle

pulse-width modulation signal to be output on the PTC1 pin. The

PTC1 waveform is shown on analyzer channel IN1.

5. Rotate the potentiometer W1. This will change the duty cycle of the

variable pulse-width modulation signal output on the PTC0 pin. The

PTC0 waveform is shown on analyzer channel IN0.

6. Click on the “Close Port” button when you are finished using the util-

ity.

Some of the toolkit applications capture and display data from the

DEMOQE128 board. The faster the PC is, the more rapid and smooth the

data display in these utilities will be.

Note that the above image is shown with the IN0 channel zoomed in. Each

analyzer channel has several features including the ability to be zoomed and

paused. For more information on DEMOQE Toolkit, see the board user

manual (DEMOQE128UM.pdf) included in the DVD under “DEMOQE128 >

DEMOQE128 User Manual” in the navigation panel on the left side of DVD

menu. For the latest DEMOQE Toolkit utilities, please visit http://

www.pemicro.com/fixedlinks/demoQEtoolkit.html.

3.3 LAB 2: Migrate Quickly from 8-Bit To 32-Bit

This lab will show you how to quickly migrate an application between the 8-bit

and 32-bit Flexis QE128 microcontrollers. The Flexis brand delivers pin-to-pin

compatibility, one development tool, and the same peripherals between the 8bit and 32-bit devices. This lab will demonstrate an upward migration from 8bit to 32-bit, but the opposite is just as simple. Continuing with the Quick Start

Application that is pre-loaded in the microcontroller’s on-chip flash memory,

you will now use the CodeWarrior MCU Change Wizard to retarget and

rebuild your project from the 8-bit to the 32-bit QE128 microcontroller.

1. Open CodeWarrior for Microcontrollers. From the Windows Start

menu, locate it under “Programs>Freescale CodeWarrior>CW for

Microcontroller V6.0>CodeWarrior IDE” path.

DEMOQE128 User Manual 11

Page 16

2. Click on “Load Example Project” from the CodeWarrior startup dialog.

If the startup dialog is not shown, it may be opened from the

CodeWarrior menu by clicking “File” and then “Startup Dialog…”.

3. From the Example Projects menu, open the tree to select:

HCS08>Evaluation Board Examples>DEMOQE128>DEMOQE128_Quick_Start_S08.

4. Give the example a new project name (e.g., Lab2), set desired location, and click “Create Project.” This will open the project for the preloaded Quick Start Application you are running on the 8-bit microcontroller.

5. Open the MCU Change Wizard to switch the project to the 32-bit

microcontroller by clicking on the following button in the project panel:

Figure 3-5: MCU Change Wizard Button

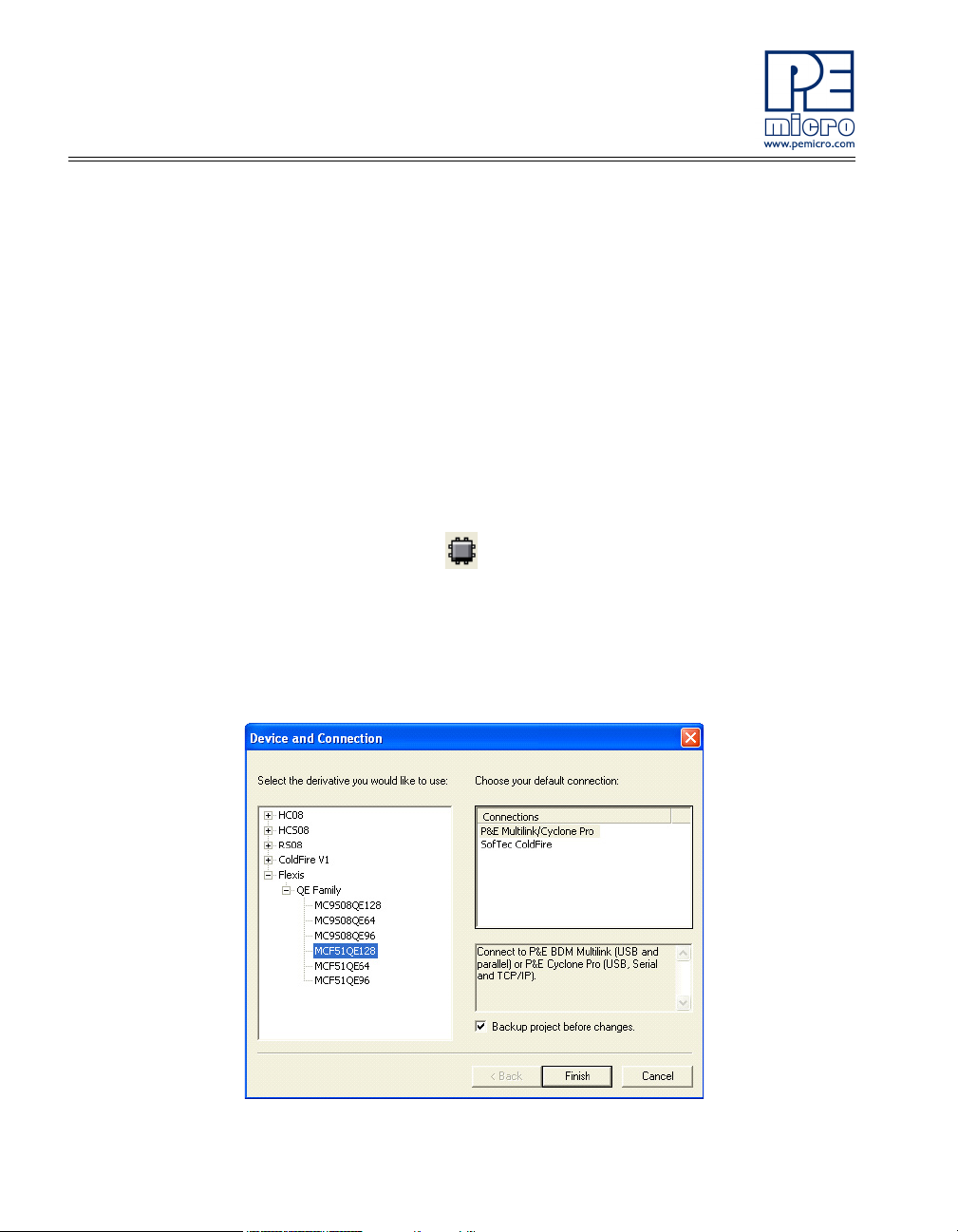

6. From the wizard, change the microcontroller selection from the 8-bit

“MC9S08QE128” to the 32-bit “MCF51QE128” in the Flexis>QE Family tree as shown in image below.

12 DEMOQE128 User Manual

Page 17

Figure 3-6: MCU Change Wizard

7. Click “Finish.” In the background CodeWarrior will transform your

project to the 32-bit microcontroller with no software changes needed.

An informational “Project Messages” window may appear letting you

know that changes have been made to the project.

8. If the Logic Analyzer utility is open, click the “Close Port” button on

that utility.

9. Turn the board power switch to OFF.

10. Switch the green 8-bit S08 daughter card with the red 32-bit Cold-

Fire V1 daughter card. Make sure to align pin 1 (as marked by

arrows) on the daughter card with pin 1 on the board.

11. Turn the board power switch to ON.

12. Compile the transformed Quick Start Application and start the pro-

cess of programming it into the flash on the 32-bit QE128 microcontroller by clicking on the debugger launch button shown here :

Figure 3-7: IDE Debugger Launch Button

13. From the Connection Manager menu, select “USB1: DEMOQE”

port and click on “Connect (Reset).”

14. From the Loader Warning menu, click on “OK” to allow the debug-

ger to mass erase the microcontroller’s on-chip flash memory and

program it with the new application.

15. Click on the GO button in the debugger to run the application. The

GO button is shown here:

Figure 3-8: Debugger GO Button

16. Repeat Step 4 of the Quick Start Guide instructions to observe the

32-bit QE128 device running the same application as the 8-bit

QE128 device did previously.

DEMOQE128 User Manual 13

Page 18

17. Repeat Lab 1 instructions to graph the PTC0 and PTC1 signals in

the Logic Analyzer utility.

18. Click on the “Close Port” button and close the Logic Analyzer utility

when you are finished using it.

3.4 LAB 3: Measure Performance between 8-Bit and 32-Bit

This lab will highlight the performance differences between the 8-bit and 32bit QE128 microcontrollers and demonstrate how these microcontrollers can

interface easily with an external sensor. You will also see how to use another

one of several software utilities included with your board. Instructions to

download these utilities to your computer are provided in Step 2 of this Quick

Start Guide. Make sure to use only one utility at a time, as the utilities share

the same USB resource.

The Accelerometer Application reads the X, Y, and Z axes of the 3-axis

accelerometer on the DEMOQE board using the microcontroller’s analog to

digital converter. It outputs a processed version of the accelerometer data on

the microcontroller’s serial communication interface. This processed data is a

rolling average of the raw accelerometer data, or a filtered version of the raw

accelerometer data, depending on the selected mode. The application in this

lab will output the data as 16-bit integer values to highlight the data

processing capabilities of the 32-bit ColdFire V1. The application also

displays the cycle count (“C”), which is the number of MCU bus cycles

required for the CPU to process the last 16 accelerometer readings for the

selected mode.

Setup demo:

1. Open CodeWarrior for Microcontrollers. From the Windows Start

menu, locate it under “Programs>Freescale CodeWarrior>CW for

Microcontroller V6.0>CodeWarrior IDE” path.

2. Click on “Load Example Project” from the CodeWarrior startup dialog.

If the startup dialog is not shown, it may be opened from the

CodeWarrior menu by clicking “File” and then “Startup Dialog…”.

3. From the Example Projects menu, open the tree to select:

14 DEMOQE128 User Manual

Page 19

HCS08>Evaluation Board Examples>DEMOQE128>DEMOQE_Accelerometer_S08.

4. Give the example a new project name (e.g., Lab3), set the desired

location, and click “Create Project.” This will open the Accelerometer

Application for the 8-bit microcontroller.

5. Launch the AccelerometerDemo utility from within the

DEMOQE_Toolkit folder by double-clicking on the AccelerometerDemo.exe file.

6. See the DEMOQE128 User Manual for more details on the Acceler-

ometer Demo utility.

7. Set “Port” to “USB COM.”

8. Set “Baud” rate to 115200.

9. Turn the board power switch to OFF position.

10. Make sure the green 8-bit S08 daughter card is plugged in to the

board. The board jumpers should all be set to the default settings

shown in the Quick Start Guide.

11. Turn the board power switch to the ON position and make sure that

the debugger window is closed.

Run demo on 8-bit S08:

1. Compile the Accelerometer Application and start the process of pro-

gramming it into the flash of the 8-bit QE128 microcontroller by clicking on the debugger launch button shown here :

2. From Connection Manager menu, select “DEMOQE on the USB1”

port and click on “Connect (Reset).”

3. From the Erase and Program Flash menu, click on “Yes” to allow the

debugger to mass erase the microcontroller’s on-chip flash memory

and program it with the new application.

4. Click on the GO button in the debugger to run the application. The

GO button is shown here:

DEMOQE128 User Manual 15

Page 20

5. Bring the Accelerometer Demo utility to the front and click the “Open

Serial Port and Start Demo” button.

Figure 3-9: AccelerometerDemo running on 8-bit S08 QE128 in data averaging

mode. Yellow arrow highlights the bus cycles required to average the last 16

readings of the 3 axes. Value shown in orange circle is the number of bus cycles

in hex.

6. Move the board around to demonstrate the 3-axis accelerometer.

7. Observe the output in the Accelerometer Demo utility.

8. Click the button labeled PTA3 on the board to enable data averaging,

and move the board.

16 DEMOQE128 User Manual

Page 21

9. Click the button labeled PTA2 on the board to enable data filtering,

and move the board.

Change device to 32-bit ColdFire V1:

1. Click “Close Port” in the Accelerometer Demo utility.

2. Close the “True-Time Simulator & Real-Time Debugger” window.

3. Bring the CodeWarrior IDE window to the front with the Accelerome-

ter Application project for the 8-bit microcontroller.

4. Open the MCU Change Wizard to switch the project to the 32-bit

microcontroller by clicking on the following button in the project panel:

5. From the wizard, change the microcontroller selection from the 8-bit

“MC9S08QE128” to the 32-bit “MCF51QE128” in the Flexis>QE Family tree.

6. Click “Finish.” In the background CodeWarrior will transform your

project to the 32-bit microcontroller with no software changes needed.

7. Turn board power switch to OFF.

8. Switch the green 8-bit S08 daughter card with the red 32-bit ColdFire

V1 daughter card. Make sure to align pin 1 (as marked by arrows) on

daughter card and with pin 1 on the board.

9. Turn board power switch to ON.

Run demo on 32-bit ColdFire V1:

1. Compile the Accelerometer Application and start the process of pro-

gramming it into the flash of the 32-bit QE128 microcontroller by clicking on the debugger launch button shown here :

2. From the Connection Manager menu, select the “USB1: DEMOQE”

port and click on “Connect (Reset).”

3. From the Loader Warning menu, click on “OK” to allow the debugger

DEMOQE128 User Manual 17

Page 22

to mass erase the microcontroller’s on-chip flash memory and program it with the new application.

4. Click on the GO button in the debugger to run the application.

5. Bring the Accelerometer Demo utility to the front and click the “Open

Serial Port and Start Demo” button.

Figure 3-10: Accelerometer Demo running on 32-bit ColdFire V1 QE128 in data

averaging mode. Yellow arrow highlights the bus cycles required to average the

last 16 readings of the 3 axes. Value shown in orange circle is the number of bus

cycles in hex.

6. Move the board around to demonstrate the 3-axis accelerometer.

7. Observe the output in the Accelerometer Demo utility.

8. Click the button labeled PTA3 on the board to enable data averaging,

18 DEMOQE128 User Manual

Page 23

and move the board.

9. Click the button labeled PTA2 on the board to enable data filtering,

and move the board.

The accelerometer demo shows the performance gains of the 32-bit ColdFire

V1 CPU over the 8-bit S08 CPU. In the data averaging and data filtering

modes, a considerable amount of 16-bit and 32-bit math is required. The S08

CPU is capable of performing these tasks, but it requires a substantial portion

of its bandwidth. In contrast, the ColdFire V1 CPU performs the same tasks

with only a very small portion of its bandwidth. With Flexis QE128

microcontrollers, you can pick and choose the CPU that best matches your

performance needs.

3.5 LAB 4: Learn how to use CodeWarrior

This lab will direct you to several CodeWarrior tutorials that will show you how

to maximize your time to market. The tutorials walk you through various

development tool features, and cover the following types of projects:

•C Programming

•Assembly Programming

•Using Processor Expert

•C Programming with Device Initialization

•Assembly Programming with Device Initialization

1. Open CodeWarrior for Microcontrollers. From the Windows Start

menu locate it under “Programs>Freescale CodeWarrior>CW for

Microcontroller V6.0>CodeWarrior IDE” path.

2. Click on “Run Getting Started Tutorial” from the CodeWarrior startup

dialog. If the startup dialog is not shown, it may be opened from the

CodeWarrior menu by clicking “File” and then “Startup Dialog…”.

3. From the Freescale CodeWarrior Tutorials menu select the tutorial

you would like to view.

DEMOQE128 User Manual 19

Page 24

4. Select “Click here to start tutorial” and follow on-screen instructions.

4 SYSTEM SETUP

4.1 Overview

P&E’s Embedded Multilink driver is required to operate the DEMOQE128

using a PC. The Embedded Multilink driver should be installed with the

CodeWarrior Development Studio software or from the DEMOQE Resources

in the DVD-ROM before the PC is connected to the DEMOQE128.

4.2 Operating System Requirements

The following are the resources required to run the CodeWarrior Development

Studio and the DEMOQE128:

• A PC-compatible system running Windows 2000, Windows XP, or

Windows Vista

• 128MB of available system RAM, and 1GB of available hard disk

space

• A DVD-ROM drive for software installation

• A USB port

4.3 Software Setup

4.3.1 Installing CodeWarrior Development Studio

To install the CodeWarrior Development Studio, Follow the instructions in the

Section 3.1 - Quick Start Guide.

4.3.2 Installing P&E Resources

Use the DEMOQE Resources in the DVD-ROM to access and install P&E

resources for the DEMOQE128. These materials are not required for

operation. The DEMOQE Resources in the Breaking Bit Boundaries DVDROM contains the following supporting materials:

• DEMOQE128 Embedded Multilink hardware interface driver

• DEMOQE128 User Manual (this document)

20 DEMOQE128 User Manual

Page 25

• DEMOQE128 Quick Start Guide

• DEMOQE128 Quick Start Application Source Code

• DEMOQE128 Base Board and Daughter Cards Schematics

• DEMOQE128 Component Breakdown List

• DEMOQE Toolkit Applications

• Links to P&E Evaluation Software

• Links to Freescale documentation, P&E Discussion Forums, and

DEMOQE128 FAQs.

4.4 Quick Startup

Only a few steps are required to get the DEMOQE128 up and running. Please

reference Section 3.1 - Quick Start Guide.

DEMOQE128 User Manual 21

Page 26

4.5 Hardware Setup

4.5.1 First-Time Connection

The DEMOQE128 may be connected to a PC through a USB port.

Connection steps are listed below in typical order:

1. Install the required software, as described in the previous section.

2. Make sure the jumpers for USB_PWR, 3V for VOLT_EN, and

REG_VDD for VDD_SELECT are installed.

3. Plug the USB cable A-M connector into a free USB port of the PC.

4. Plug the USB cable B-M connector into the USB connector on the

DEMOQE Base Board.

5. The operating system will recognize P&E’s Embedded Multilink circuitry and P&E’s USB to Serial circuitry. Depending on the operating

system, you may see the “Found New Hardware Wizard” dialog, helping you to install software for “PEMicro USB Multilink (i0). On Windows XP (SP2), the following dialog will appear:

Figure 4-11: Found New Hardware Wizard Dialog (1 of 4)

Select the “Install the software automatically (Recommended)” option

22 DEMOQE128 User Manual

Page 27

and click the “Next” button.

6. Windows will install the driver files to your system. At the end of the

installation, the following dialog box will appear:

Figure 4-12: Found New Hardware Wizard Dialog (2 of 4)

Click the “Finish” button to exit the current “Found New Hardware

Wizard”.

7. Depending on the operating system, you may see the “Found New

Hardware Wizard” dialog again, helping you to install software for

“PEMicro USB Serial Port (i1). On Windows XP (SP2), the following

dialog will appear:

DEMOQE128 User Manual 23

Page 28

Figure 4-13: Found New Hardware Wizard Dialog (3 of 4)

Select the “Install the software automatically (Recommended)” option

and click the “Next” button.

8. Windows will install the driver files to your system. At the end of the

installation, the following dialog box will appear:

24 DEMOQE128 User Manual

Page 29

Figure 4-14: Found New Hardware Wizard Dialog (4 of 4)

Click the “Finish” button to exit the “Found New Hardware Wizard”.

If the DEMOQE128 hardware interface driver is now properly installed on your

system, the green USB LED on the DEMOQE Base Board should be

illuminated. In addition, if you turn on the system power of the DEMOQE128

you will see the red Power LED illuminate.

5 OPERATING MODES

5.1 Overview

The DEMOQE128’s Embedded Multilink circuitry, featured hardware

components, and optional external BDM header make it a versatile

development tool. Below are some of the featured operating modes of the

DEMOQE128.

5.2 Debug Mode

A host communicates with the DEMOQE128 through the Embedded Multilink

circuitry. Either the CodeWarrior Development Studio or P&E’s HCS08/CFV1

software tools will work with the DEMOQE128. Please refer to Section 9 -

DEMOQE128 User Manual 25

Page 30

DEMOQE128 CODE DEVELOPMENT SOFTWARE for more information.

5.3 Run Mode

The DEMOQE128’s rich component list empowers it to perform a variety of

tasks. Once an application is developed, debugged, and programmed

properly into the QE128 internal flash memory, it can run with or without

connecting to a host.

5.4 External BDM Mode

The DEMOQE128 has an optional BDM header for debugging and

programming the on-board QE128 device using an external BDM hardware

tool, such as P&E’s USB Multilink or Cyclone PRO. Please refer to Section

10 - TRANSITIONING TO YOUR OWN TARGET for more information. A user

can take advantage of this mode to develop a target-specific QE128 system

and compare it with the DEMOQE128 when necessary.

6 DEMOQE TOOLKIT PC APPLICATIONS

P&E provides several Windows PC-based applications which work with the

DEMOQE128 board. These applications are collectively referred to as the

DEMOQE Toolkit. The following applications are included in the toolkit:

6.1 DEMOQE Logic Analyzer Application

The DEMOQE board has a built-in two-channel logic analyzer. This analyzer

allows the IN0 and IN1 signals to be captured by the PC and displayed for the

user. The IN0 and IN1 signals may be connected to any of the MCU signals

which the user would like to view. By default, they are connected to the PTC0

and PTC1 pins of the MCU by jumper J11. At the time of this release, the logic

analyzer runs at a capture rate of 10khz.

26 DEMOQE128 User Manual

Page 31

Figure 6-1: Logic Analyzer Application

This PC-based application is used to display the logic analyzer data on the

PC. The logic analyzer data is displayed in real-time and each waveform may

be paused, zoomed, and printed.

To start using this application, please plug in a USB cable into the evaluation

board. Once the USB and Power LEDs light up, indicating the proper

enumeration on the USB port, click on the Open DEMOQE and Graph Pins

button. The logic channel graphs should be reflecting data captured from IO

pins connected to IN0 and IN1 header pins on the DEMOQE evaluation

board.

If the microcontroller-based Quick Start Application is programmed into the

MCU, the IN0 channel will show the PWM output on pin PTC0 whose duty

cycle is controlled by the potentiometer (W1). The IN1 channel shows the

PWM output on channel PTC1 which drivers the buzzer.

This PC-based application is included on the DVD-ROM that accompanys the

DEMOQE, and may also be found at:

http://www.pemicro.com/fixedlinks/demoQEtoolkit.html.

6.2 DEMOQE Terminal Application

This PC-based application acts as a standard serial port terminal application

on the PC. It works with standard serial ports as well as the virtual serial port

on the DEMOQE board. The application includes settings to adjust the COM

DEMOQE128 User Manual 27

Page 32

port number, baud rate, parity, and number of data bits. There is a button to

take a file on the PC and transmit it out of the serial port. There are also

delays which are automatically inserted in the transmission output to prevent

overruns. It is recommended that these defaults not be changed.

Figure 6-2: DEMOQE Terminal Application

The terminal window may be set for full duplex or half duplex. In full duplex

mode, only received characters are displayed in the terminal window. In half

duplex mode, both transmitted and received characters are displayed.

To start using this application, please choose a COM or virtual USB COM

settings from a drop down Port menu. By doing so, you are specifying the port

on the evaluation board that will be used for serial data transmission. Please

make sure that jumpers on headers J6 and J7 are set accordingly. Prior to

starting serial data capture, please specify Baud, Parity and Bits settings to

reflect the parameters at which your serial communication interface is

operating. Once your port settings are configured, please plug a USB or DB9

serial cable into the evaluation board and click on the Open Serial Port button.

This PC-based application is included on the DVD-ROM that accompanys the

DEMOQE, and may also be found at:

http://www.pemicro.com/fixedlinks/demoQEtoolkit.html.

6.3 DEMOQE Unsecure Application

This application allows secure CFV1 and HCS08 microcontrollers to be

unsecured. The Unsecure application will erase a secure device to make it

28 DEMOQE128 User Manual

Page 33

unsecure. This application works with the DEMOQE board as well as other

user hardware connected to the PC via the USB Multilink or Cyclone PRO

hardware interfaces.

Figure 6-3: DEMOQE Unsecure Application

In order to unsecure a device with this application, please specify the

hardware interface that you are using. If your P&E Multilink or Cyclone Pro is

successfully detected, the name of a corresponding device will appear in the

Port text box. Please select HCS08 or CFV1 from the Select Architecture drop

down menu and press the Perform Unsecure button. The application will

finish unsecuring and erasing the device shortly after.

This PC-based application is included on the DVD-ROM that accompanys the

DEMOQE, and may also be found at:

http://www.pemicro.com/fixedlinks/demoQEtoolkit.html.

6.4 DEMOQE Accelerometer Demo Application

This PC-based application will graph serial data output from the

microcontroller-based serial accelerometer application documented in

Section 7.2 - Serial Accelerometer Application. The graphed data includes

the magnitude of the X, Y, and Z accelerometer signals, as well as the current

processor loading. For this application to work properly, the microcontroller-

based serial accelerometer application must be programmed into the

microcontroller which is plugged into the DEMOQE board.

DEMOQE128 User Manual 29

Page 34

Figure 6-4: Accelererometer Demo Application

The data that is graphed may come from either the PC serial port or the virtual

serial port on the DEMOQE board. The serial port of the microcontroller on

the DEMOQE board is routed to either serial port hardware or the virtual COM

port based upon the setting of jumpers J6 and J7. To properly configure

accelerometer and potentiometer resources on the DEMOQE evaluation

board, please make sure that these headers are populated with jumpers in

the following manner: J16 (Z/PTA7 -populated, Y/PTA6 –populated, Y/PTC7 populated, X/PTA1 –populated); J14 (set to 0); J16 (set to 0); J15 (set to 1);

J21 (PTA0 –populated, PTC6 –populated).

To start using this application, please choose COM or virtual USB COM

settings from the drop-down Port menu. By doing so, you are specifying the

port on the evaluation board that will be used for transmitting captured

accelerometer data via a COM or USB serial port. Please make sure that

jumpers on headers J6 and J7 are set accordingly. Prior to starting serial data

capture, please specify the Baud setting to reflect the parameter at which your

serial communication interface is operating. Once your port settings are

configured, please plug a USB or DB9 serial cable into the evaluation board

and click on the Open Serial Port and Start Demo button. After the serial data

is captured by the application you will see raw data in the Terminal Window. In

the meantime, the Data Snapshot window will display the accelerometer and

potentiometer data levels in the form of a bar graph. The graphing of data can

be paused and the scale of the X and Y axes can be changed via a tool bar

30 DEMOQE128 User Manual

Page 35

located in the top right corner of the DEMOQE Accelerometer Demo

Application.

This PC-based application is included on the DVD-ROM that accompanys the

DEMOQE, and may also be found at:

http://www.pemicro.com/fixedlinks/demoQEtoolkit.html.

6.5 DEMOQE Serial Grapher Application

This PC-based application is a more generalized version of the accelerometer

demo application. It may be used with the microcontroller based serial

accelerometer application or customer microcontroller code which transmits

data in the correct format. The serial graphing utility allows incoming data on

the PC serial port, or one of P&E’s virtual serial ports, to be automatically

graphed in time or displayed upon a series of bar graphs. The virtual serial

port exists on several of P&E’s embedded USB multilink designs including the

DEMOQE board.

To start using this application, please choose COM or virtual USB COM

settings from the drop-down Port menu. By doing so, you are specifying the

port on the evaluation board that will be used for transmitting captured

accelerometer data via a COM or USB serial port. Please make sure that the

jumpers on headers J6 and J7 are set accordingly. Prior to starting serial data

capture, please specify the Baud setting to reflect the parameter at which your

serial communication interface is operating. Once your port settings are

configured, please plug a USB or DB9 serial cable into the evaluation board

and click on the Open Serial Port and Start Demo button. The graphing of

data can be paused and the scale on the X and Y axes can be changed via a

tool bar located in the top right corner of the DEMOQE Serial Grapher

Application.

This PC-based application is included on the DVD-ROM that accompanys the

DEMOQE and may also be found at:

http://www.pemicro.com/fixedlinks/demoQEtoolkit.html.

All data to be displayed must be in hexadecimal format. The data can be

accepted and displayed either as incoming byte values ($00-$FF) or word

values ($0000-$FFFF). The data format indicates whether the data is byte or

word data. The graphical components automatically size their range

depending upon the incoming data.

DEMOQE128 User Manual 31

Page 36

6.5.1 Visual Components

The Bar Graph has four separate bars A, B, C, and D. On each bar a

percentage value is displayed which indicates the current value relative to the

full range. A byte value of $7F (max is $FF) would show up as approximately

50% as would a word value of $7FFF (max is $FFFF). As can be seen in the

data formatting section, all four bars must be written at the same time. The

bars are shown here:

Figure 6-5: Serial Grapher Bar Graph

The graphing component shows four waveforms X, Y, Z, and W. The

magnitude axis either has a range of $00-$FF (if byte values are incoming on

the serial port) or $0000-$FFFF (if word values are incoming). Each new set

of values which comes through the serial port is added to the far right side of

the graph and the rest of the data values move to the left. The vertical axis

displays the incoming data as the magnitude of each waveform, and the

horizontal axis displays the number of samples. The graph has a limited size,

so older samples will eventually fall off the left part of the graph. As can be

seen in Section 6.5.2 - Data Format, each incoming data command affecting

the graphing component must have new data for all four waveforms. An

example graph is shown here:

32 DEMOQE128 User Manual

Page 37

Figure 6-6: Serial Grapher Graphing Component

6.5.2 Data Format

The data format is broken into two sections depending upon whether the

incoming data is in byte format or word format.

6.5.2.1 Byte Formatted Data

There are two commands which may be accepted. Both commands must end

in the special characters #$0D and #$0A which are CR (carriage return) and

LF (line feed). The accepted commands are:

WnnZnnYnnXnn

The nn values are 00-FF and correspond in order to the data displayed on the

following graph lines : W, Z, Y, X.

AnnBnnCnnDnn

The nn values are 00-FF and correspond in order to the data displayed on the

following bar graphs lines : A, B, C, D.

6.5.2.2 Word Formatted Data

There are three commands which may be accepted. All commands must end

DEMOQE128 User Manual 33

Page 38

in the special characters #$0D and #$0A which are CR (carriage return) and

LF (line feed). The accepted commands are:

nnnn,nnnn,nnnn,nnnn

The nnnn values are 0000-FFFF and correspond in order to the data

displayed on both the graph and bar graphs as follows: X/A, Y/B, Z/C, W/D.

nnnn:nnnn:nnnn:nnnn

The nnnn values are 0000-FFFF and correspond in order to the data

displayed the graphing component as follows: X, Y, Z, W.

nnnn=nnnn=nnnn=nnnn

The nnnn values are 0000-FFFF and correspond in order to the data

displayed on the bar graph component as follows: A, B, C, D.

7 DEMONSTRATION MICROCONTROLLER APPLICATIONS

The following microcontroller applications are designed to run on the QE128

processors.

7.1 Quick Start Application

The function of the Quick Start microcontroller application is to play a different

tone and illuminate a different LED for each of the buttons which may be

pressed on the DEMOQE128 board. The potentiometer controls the intensity

of two LEDs on the DEMOQE128 board, via PWM signals. This application

comes pre-programmed into the memory of the QE128 processor.

Usage of this application can be seen in the Section 3.1 - Quick Start Guide

of the manual.

34 DEMOQE128 User Manual

Page 39

7.2 Serial Accelerometer Application

This microcontroller application samples the state of the on-board three-axis

accelerometer using on-chip A/D converter channels. This data is converted

into ASCII characters and sent out using the serial pins of the QE128

processor. These serial pins may be connected to either serial port hardware

or to P&E’s virtual serial port (which is part of the Embedded Multilink design).

This connection is controlled by jumpers J6 and J7.

P&E has two PC-based DEMOQE Toolkit applications which allow the serial

port data generated by this application to be graphed. These are documented

in Section 6.4 - DEMOQE Accelerometer Demo Application and Section

6.5 - DEMOQE Serial Grapher Application.

Usage of this application is documented in the Section 3.4 - LAB 3: Measure

Performance between 8-Bit and 32-Bit.

8 JUMPER SETTINGS

8.1 System Power

The QE128 processor may obtain its power from either the on-board

regulator, a 2-cell battery pack, or through MCU_PORT J1. The on-board

regulator obtains its input from either the Embedded Multilink circuitry or a

2.5mm barrel connector. The on-board regulator can regulate the output to

either 2.1V or 3V. The DEMOQE128 is fully functional at both voltages. Power

input and voltage selection are achieved by using 3 option headers.

8.1.1 J3 - Regulator Input Selection Jumper

Jumper 3 determines whether the DEMOQE128’s on-board regulator obtains

its power from the DC power jack or from the Embedded Multilink circuitry.

The regulator input selection is mutually exclusive. It prevents power input

contention from damaging the board and the host. Figure 8-1 shows the

regulator input selection details.

Select regulator input from DC power jack. A 5-8VDC center positive

DEMOQE128 User Manual 35

Page 40

power supply must be used.

Note: The DEMOQE board power connector is incorrectly labelled as 5-12VDC.

The maximum voltage is 8VDC.

Select regulator input from the Embedded Multilink circuitry,

which derives its power from the USB bus

Figure 8-1: PWR Selection Header (J3)

8.1.2 J4 - Regulator Output Selection Jumper VOLT_EN

The regulator can output either a 2.1VDC or 3VDC voltage for the

DEMOQE128. The VOLT_EN jumper J4 selects the voltage. Figure 8-2

shows the regulator output selection details.

Select regulator output to be 2.1V.

Select regulator output to be 3V

Figure 8-2: Regulator Voltage Output Selection VOLT_EN (J4)

8.1.3 J5 - VDD Source Selection Jumper VDD_SELECT

Select the regulator to supply microcontroller VDD. This is the default

setting.

36 DEMOQE128 User Manual

Page 41

Select the battery pack to supply microcontroller VDD

Select the MCU_PORT to supply microcontroller VDD. This setting

also allows power to be supplied to the target connected to the

MCU_PORT. By default this jumper is installed.

Figure 8-3: VDD_SELECT Option Header (J5)

8.2 RS232 Communications

The DEMOQE128 integrates an RS232 transceiver for the microcontroller

SCI signals. The transceiver operates from 1.8V to 4.25V, and it can be

enabled or disabled via jumper settings or through firmware control. The

DEMOQE128 also integrates the SCI signal into the Embedded Multilink

circuitry. A user can communicate with the microcontroller SCI module via

either the on-board DB9 connector or the Embedded Multilink circuitry. There

are three jumpers associated with SCI communication.

8.2.1 J6 - SCI RXD Signal Selection Jumper RXD_EN

Connects the microcontroller PTB0/RXD signal to the RS232

transceiver.

DEMOQE128 User Manual 37

Page 42

Connects the microcontroller PTB0/RXD signal to the Embedded

Multilink SCI circuitry. This is the default setting.

Figure 8-4: SCI RXD Signal Selection Jumper RXD_EN (J6)

8.2.2 J7 - SCI TXD Signal Selection Jumper TXD_EN (J7)

Connects the microcontroller PTB1/TXD signal to the RS232

transceiver.

Connects the microcontroller PTB1/TXD signal to the Embedded

Multilink SCI circuitry. This is the default setting.

Figure 8-5: SCI TXD Signal Selection Jumper TXD_EN (J7)

8.2.3 J8 - SCI Transceiver Enable COM_EN (J8)

Enables the SCI Transceiver. The user may control PTC5 in firmware

to enable or disable the transceiver.

38 DEMOQE128 User Manual

Page 43

Disables the SCI Transceiver. This is the default setting.

Figure 8-6: SCI Transceiver Enable/Disable Selection COM_EN (J8)

8.3 LED Display Port

The DEMOQE128 has 8 LEDs connected to signals PTC0, PTC1, PTC2,

PTC3, PTC4, PTC5, PTE6, and PTE7. They can be enabled or disabled by

installing or removing the corresponding jumper, J9, in the LED_ENABLE

header.

8.3.1 J9 - LED Display Enable Port LED_ENABLE

Enables all LED outputs. This is the default setting.

Figure 8-7: LED Display Enable Header LED_ENABLE (J9)

8.4 Input and Reset Switches

The DEMOQE128 has an option to connect two signals, PTC0 and PTC1, to

the Embedded Multilink for signal processing. The two signals are connected

or disconnected to IN0 or IN1 correspondingly, via jumpers P&E INPUT_EN

(J11).

The DEMOQE128 has 4 switches that are connected to signals PTA2, PTA3,

PTD2, and PTD3 respectively, and are enabled or disabled by the 4

corresponding jumpers KEY_ENABLE (J12).

The DEMOQE128 has one Reset switch and one Reset LED associated with

it. These are enabled or disabled by the two corresponding jumpers

RESET_EN (J18).

DEMOQE128 User Manual 39

Page 44

8.4.1 J11 - P&E’s Logic Analyzer Inputs IN0/IN1

The logic analyzer inputs are marked on one side of the J11 jumper. The

inputs allow P&E’s PC-based logic analyzer application to display these

signals in real-time.

By installing both jumpers, the logic analyzer pins IN0 and IN1 will be

connected to PTC0 and PTC1 respectively.

By removing these jumpers IN0 and IN1 will be unconnected. The

user may connect these signals, via wires, to any other signals on the

processor which they wish to view on the PC.

Figure 8-8: Jumper Settings for Input Signals to P&E’s Embedded Multilink, P&E

INPUT_EN (J11)

8.4.2 J12 - Light Touch Switch Enable Jumper KEY_ENABLE

Enables the corresponding switch. Each jumper may be individually

installed or removed. By default, all jumpers are installed to enable all

the switches.

Figure 8-9: Jumper Settings for Light Touch Switches KEY_ENABLE (J12)

8.4.3 J18 - Reset Switch Enable and Reset LED Display Enable Jumper

RESET_EN

Enables the Reset Switch and the Reset LED Display. Each jumper

40 DEMOQE128 User Manual

Page 45

may be individually installed or removed. This is the default setting.

Figure 8-10: Reset Switch and Reset LED enable Jumper (J18)

Note: The J29 labels for RSTLED_EN and RESET_EN are incorrectly switched on

the DEMOQE board silk screen. The correct label is as displayed above.

8.5 3-Axis Accelerometer Jumper Settings

The DEMOQE128 integrates a 3-axis accelerometer. Its enable or disable,

sensitivity levels, and output signal connections are all jumper settable.

Jumpers J13, J14, J15 and J16 are associated with the accelerometer.

TABLE 1. Accelerometer G-Select Pin Descriptions

G-SEL2 G-SEL1 g-Range Sensitivity

0 0 1.5g 800 mV/g

0 1 2g 600 mV/g

1 0 4g 300 mV/g

1 1 6g 200 mV/g

8.5.1 J13 - Accelerometer g-Select1 Jumper G-SEL1

Selects g-Select1 to be logic low. This is the default setting.

Selects g-Select1 to be logic high. A user may control PTD0 in

firmware to set g-Select1.

Figure 8-11: Accelerometer g-Select1 Jumper settings (J13)

DEMOQE128 User Manual 41

Page 46

8.5.2 J14 - Accelerometer g-Select2 Jumper G-SEL2

Selects g-Select2 to be logic low. This is the default setting.

Selects g-Select2 to be logic high. A user may control PTD0 in

firmware to set g-Select2

Figure 8-12: Accelerometer g-Select2 Jumper settings (J14)

8.5.3 J15 - Accelerometer Sleep Mode Select Jumper SLEEP (J15)

Enables the 3-axis accelerometer. This is the default setting.

Puts the 3-axis accelerometer into sleep mode. The user may control

PTC4 in firmware to enable or disable the accelerometer. In this

configuration, the user needs to pay close attention to LED PTC4 and

RSTO configuration.

Figure 8-13: Accelerometer Sleep Mode Jumper settings (J15)

42 DEMOQE128 User Manual

Page 47

8.5.4 J16 - Accelerometer 3-axis Signals Connection Jumper ACC_EN

The accelerometer output signals are jumper settable to PTA7, PTA6,

PTC7, and PTA1. PTA6 and PTC7 share the same Y-axis signal. By

default, the Y-axis signal is connected to PTA6.

Figure 8-14: Accelerometer Signal Output ACC_EN (J16)

8.6 Buzzer

The DEMOQE128 integrates a Piezo Transducer whose resonant frequency

is 4.0KHz. Jumper J19 connects to PTB5 to control this buzzer.

8.6.1 J19 - Buzzer enable jumper BUZ_EN

Enables Buzzer to be controlled by PTB5. This is the default setting.

Figure 8-15: Accelerometer Signal Output ACC_EN (J19)

8.7 IIC Pull-up

The DEMOQE128 provides external pull-up resistors for SCL and SDA lines,

enabled by installing the corresponding jumpers on J20. By default both

jumpers are installed.

8.7.1 J20 - IIC Pullup Enable Jumpers IIC_EN

Enables IIC external pullup. This is the default setting.

Figure 8-16: IIC External Pullup Enable IIC_EN (J20)

DEMOQE128 User Manual 43

Page 48

8.8 Analog Input Potentiometer

The DEMOQE128 provides an easy access 10Kohm potentiometer whose

output may be connected to PTC6 and/or PTA0, selectable by J21, POT_EN.

8.8.1 J21 - Potentiometer Output Selection Jumpers POT_EN

Selects the potentiometer output connection. By default it is

connected to PTA0.

Figure 8-17: Potentiometer Output Selection Jumpers POT_EN (J21)

8.9 Optional External Crystal Circuitry Jumper Enable

The DEMOQE128 provides external crystal circuitry without components

populated. A user may use jumper J17, CLOCK_EN, to enable the external

crystal circuitry.

8.9.1 J17 - External Crystal Circuitry Enable Jumpers CLOCK_EN

Enables or disables the external crystal circuitry. Both positions must

be installed to enable use of crystal circuitry.

Figure 8-18: External Crystal Circuitry Enable Jumper CLOCK_EN (J17)

8.10 Optional Jumpers For Various VDD And VSS

The DEMOQE128 provides 5 jumpers, J22 through J26, for different VDD and

VSS connections on the bottom of the board. By default, they are not

populated and are shorted correspondingly with zero-ohm resistors in parallel,

except J24 which is populated. A user may take off the zero-ohm resistor and

install a corresponding jumper.

9 DEMOQE128 CODE DEVELOPMENT SOFTWARE

The DEMOQE128 includes P&E’s Embedded Multilink circuitry, so no

44 DEMOQE128 User Manual

Page 49

external hardware BDM tool is needed to debug and program the

DEMOQE128. A user only needs to connect the DEMOQE128 to their PC to

start developing code for it.

The DEMOQE128 package comes with a special edition of Freescale’s

CodeWarrior studio. In addition, P&E’s evaluation software for HCS08 and

ColdFire® V1 is available online at www.pemicro.com. A user may use either

CodeWarrior or P&E software tools to develop code for the DEMOQE128.

9.1 Using CodeWarrior With The DEMOQE128

The CodeWarrior studio supports Freescale’s HCS08 and ColdFire V1

devices. It offers C, C++, and assembly-level support, and provides

debugging capabilities based on P&E’s debug and programming

technologies.

A programming or debug session with the project-based CodeWarrior IDE

may be launched by double-clicking on the project name (the format is

projectname.mcp) from your file storage. Its tutorials, FAQs, and quick start

guides are easy to follow and will allow you use pre-built templates to begin

creating a new project in a short time. Codewarrior tutorials can be followed

based on the instructions of Section 3.5 - LAB 4: Learn how to use

CodeWarrior.

9.2 Using P&E Software With The DEMOQE128

P&E offers software tools for Freescale’s HCS08 and ColdFire V1 devices

that can be used to develop code for the DEMOQE128 board.

9.2.1 P&E Software Tools for HCS08 Microcontrollers

For Freescale’s HCS08 devices, P&E offers an integrated development

environment, which combines a command-line assembler, in-circuit debugger,

and flash memory programmer. The assembler includes features such as a

full string replacement macro, conditional assembly, include files, and more.

The debugger supports both assembly and C source-level debugging. The

programmer can program/reprogram both internal and external flash devices

in-circuit.

9.2.2 P&E’s Software Tools for ColdFire® V1 Microcontrollers

For Freescale’s ColdFire V1 devices P&E offers an integrated development

DEMOQE128 User Manual 45

Page 50

environment, which combines a GNU C compiler, in-circuit debugger, and

flash memory programmer. The debugger supports both assembly and C

source-level debugging. The programmer can program/reprogram both

internal and external flash devices in-circuit.

10 TRANSITIONING TO YOUR OWN TARGET

Once you have finished working with the DEMOQE128 and are ready to build

your own target, you will need a hardware tool to allow you to develop using

your own board. P&E’s USB Multilink and P&E’s Cyclone PRO offer two

effective solutions, depending on your needs. Both work with Freescale’s

CodeWarrior as well as P&E software, and both provide a seamless transition

to working with your own hardware.

The USB Multilink is a development tool that is functionally comparable to the

Embedded Multilink circuitry on the DEMOQE128. It will enable you to debug

your code and program it onto your target. The Cyclone PRO is a more

versatile and robust development tool with advanced features and production

capabilities.

More information is available below to assist you in choosing the appropriate

development tool for your needs.

10.1 Hardware Solutions At A Glance

The USB Multilink offers an affordable and compact solution for your

development needs, and allows debugging and programming to be

accomplished simply and efficiently. Those doing rapid development will find

the USB Multilink easy to use and fully capable of fast-paced debugging and

programming.

The Cyclone PRO is a more complete solution designed for both development

and production. The Cyclone PRO featues automated power switching,

multiple communications interfaces (including USB, Ethernet, and Serial),

stand-alone programming functionality, and many other advanced

capabilities.

Below is an overview of the features and intended use of the USB Multilink

and Cyclone PRO.

10.1.1 USB Multilink Key Features

• Direct user control of target’s execution

46 DEMOQE128 User Manual

Page 51

• Programming and debugging capabilities

• Read/write registers and memory values

• Compact and lightweight

• Communication via USB 2.0

• Supported by P&E software and Freescale’s CodeWarrior

10.1.2 Cyclone PRO Key Features

• Advanced programming and debugging capabilities, including:

• PC-Controlled and User-Controlled Stand-Alone Operation

• Interactive Programming via Host PC

• In-Circuit Debugging, Programming, and Testing

• Compatible with Freescale’s ColdFireV1, HCS08, RS08, and

HC(S)12(X) microcontroller families

• Communication via USB, Serial, and Ethernet Ports

• Multiple image storage

• LCD screen menu interface

• Supported by P&E software and Freescale’s CodeWarrior

10.2 Working With P&E’s USB Multilink

Figure 10-1: P&E’s USB Multilink (USB-ML-12 shown)

10.2.1 Product Features & Implementation

P&E’s USB Multilink Interface (USB-ML-12) connects your target to your PC

and allows the PC access to the Background Debug Mode (BDM) on

DEMOQE128 User Manual 47

Page 52

Freescale’s ColdFireV1, HCS08, RS08, and HC(S)12(X) microcontrollers. It

connects between a USB port on a Windows 2000/XP/2003 machine and a

standard 6-pin debug connector on the target.

By using the USB Multilink Interface, the user can take advantage of the

background debug mode to halt normal processor execution and use a PC to

control the processor. The user can then directly control the target’s

execution, read/write registers and memory values, debug code on the

processor, and program internal or external FLASH memory devices.The

USB Multilink enables you to debug, program, and test your code on your

board.

10.2.2 Software

The USB Multilink Interface works with Codewarrior as well as P&E’s in-circuit

debugger and flash programmer to allow debug and flash programming of the

target processor. P&E’s USB Multilink Development Packages come with the

USB Multilink Interface, as well as flash programming software, in-circuit

debugging software, Windows IDE, and register file editor.

10.3 Working With P&E’s Cyclone PRO

Figure 10-2: P&E’s Cyclone PRO

10.3.1 Product Features & Implementation

P&E’s Cyclone PRO is an extremely flexible tool designed for debugging,

testing, and in-circuit flash programming of Freescale’s ColdFireV1, HC08,

HCS08, RS08, and HC(S)12(X) microcontrollers. The Cyclone PRO connects

your target to the PC via USB, Ethernet, or Serial Port and enables you to

debug your code, program, and test it on your board. After development is

complete the Cyclone PRO can be used as a production tool on your

48 DEMOQE128 User Manual

Page 53

manufacturing floor.

For production, the Cyclone PRO may be operated interactively via Windowsbased programming applications as well as under batch or .dll commands

from a PC. Once loaded with data by a PC it can be disconnected and

operated manually in a stand-alone mode via the LCD menu and control

buttons. The Cyclone PRO has over 3Mbytes of non-volatile memory, which

allows the onboard storage of multiple programming images. When

connected to a PC for programming or loading it can communicate via the

ethernet, USB, or serial interfaces.

10.3.2 Software

The Cyclone PRO comes with intuitive configuration software and interactive

programming software, as well as easy to use automated control software.

The Cyclone PRO also functions as a full-featured debug interface, and is

supported by Freescale’s CodeWarrior as well as development software from

P&E.

P&E’s Cyclone PRO is also available bundled with additional software as part

of various Development Packages. In addition to the Cyclone PRO, these

Development Packages include in-circuit debugging software, flash

programming software, a Windows IDE, and register file editor.

11 TROUBLESHOOTING

11.1 DEMOQE128 Is Undetected

Q: The connection assistant indicates that my DEMOQE128 is undetected

even though I have connected the hardware to my USB port. What should I

do?

A: The connection assistant, which displays in either Codewarrior or P&E’s

development software, is a dialog which allows the user to connect to the

DEMOQE128 hardware. If this dialog indicates that the DEMOQE128

hardware is not connected to the PC, the first step is to make sure that the

DEMOQE128 hardware is connected to the PC via a USB 2.0 high-speed

cable. If it is connected, unplug and then plug in the USB cable on the

DEMOQE128 board and click refresh in the connection assistant. If the

hardware still does not show up, try the following remedies:

(A) Re-Enable the USB driver

DEMOQE128 User Manual 49

Page 54

If you connected the DEMOQE128 interface prior to installing P&E’s

Embedded Multilink drivers, Windows will not have been able to find the

appropriate driver and may have disabled the device. The DEMOQE128

board shows up in Window’s device manager as a “P&E Multilink,” since it

contains P&E’s Embedded Multilink circuitry. If you unplug and then plug in

the device, Windows will automatically disable it even if you have installed the

drivers. To force windows to try to load the driver again, perform the following

steps while the DEMOQE128 interface is connected to the computer:

1. Open the Control Panel (Start Button->Settings->Control Panel)

2. Double Click the "System" Icon

3. Select the "Hardware" tab

4. Click the "Device Manager" Button

5. The "P&E Multilink" device will be shown with an exclamation mark

next to it. Double-click this device.

6. Click the "Reinstall Driver…" button and follow the dialog instructions

to have Windows automatically install the driver.

(B) Re-Install the USB driver

If the Multilink device does not show up in the device manager, use the driver

installation utility located in the DEMOQE Resouces on the DVD-ROM. After

driver installation, unplug the DEMOQE128 from the PC and reboot the PC.

When the reboot has completed, connect the interface to the PC with the USB

2.0 cable. Run the software again to see if the interface is now detected.

If you have an error attempting to install the drivers, please view the

installation troubleshooting FAQ on P&E’s website at:

http://www.pemicro.com/faqs/faq_view.cfm?id=89.

(C) Test for installation of the USB driver files

To test the driver installation, use the driver test utility in the DEMOQE

Resources of the DVD-ROM to make sure all files were properly installed.

This may give some indication of what the problem is.

(D) Using a USB Hub

The DEMOQE128 is a high-power USB device. If a USB Hub is used, it must

be a self-powered hub (i.e., with its own power supply). If the Hub is not selfpowered the DEMOQE128 will not work. In general, USB ports located

directly on the PC are high-power (self-powered) ports.

50 DEMOQE128 User Manual

Page 55

11.2 CodeWarrior Installation Fails (WinDriver Error)

Q: When I try to install the Codewarrior or P&E software, installation fails with

this message: “There are currently 2 open applications using WinDriver.

Please close all applications and press Retry. To reload WinDriver, press

Cancel and reboot.“ How do I solve this?

A: Some software applications on your PC are connected to the Windriver

system driver which manages P&E's USB connections. This system driver

needs to be disabled for the installation to continue. Directions to disable

Windriver are as follows:

In Windows Explorer, right-click on My Computer and select Properties from

the drop-down menu.

1. Select the Hardware tab.