Page 1

®

AUX

AUX

PAN

1

CAM

3

AUTO

ON

UP

ZOOM

WIRETRON

2

4

LEFT

MAN

OFF

DOWN

FOCUS

IRIS

TELE

NEAR

RIGHT

OPEN

WIDE

FAR

CLOSE

MPT8000 Series

Wiretron Digital

Transmitter/

Controller and

WX8000 Series

Receiver/Driver

ON

OFF

Installation/

Operation Manual

C585M-B (11/98)

Pelco • 3500 Pelco Way, Clovis • CA 93612-5699 USA

In North America and Canada: Tel (800) 289-9100 or FAX (800) 289-9150

International Customers: Tel (1-559) 292-1981 or FAX (1-559) 348-1120

Page 2

CONTENTS

Section Page

1.0 GENERAL ..................................................................................................5

1.1 IMPORTANT SAFEGUARDS AND WARNINGS ............................... 5

1.2 UNPACKING INSTRUCTIONS .......................................................... 6

1.3 RECOMMENDED TOOLS ................................................................. 6

2.0 DESCRIPTION .......................................................................................... 7

2.1 MODELS ............................................................................................ 7

2.1.1 Wiretron Digital Transmitter/Controller ................................... 7

2.1.2 Wiretron Receiver/Driver ....................................................... 8

2.2 CERTIFICATIONS ............................................................................. 8

3.0 INSTALLATION .......................................................................................... 9

3.1 RECEIVER 24 VAC POWER INPUT MODIFICATION ...................... 10

3.2 MOUNTING ...................................................................................... 12

3.2.1 Transmitter/Controller ........................................................... 12

3.2.2 Receiver ................................................................................ 12

3.3 WIRING ............................................................................................ 12

3.3.1 Control Wiring ....................................................................... 12

3.3.1.1 Wiring the Transmitter/Controller to the Receiver .12

3.3.1.2 Wiring from the Receiver/Driver to the Pan/Tilt .... 13

3.3.2 Auxiliary Functions ................................................................ 16

3.3.3 Video Wiring ......................................................................... 16

3.3.3.1 Long Distance Cable Installation .......................... 18

3.4 POWER ............................................................................................ 19

4.0 OPERATION ............................................................................................. 21

4.1 AUTO/RANDOM OPERATION ......................................................... 21

5.0 MAINTENANCE ........................................................................................22

6.0 TROUBLESHOOTING .............................................................................. 22

6.1 RECEIVER PIN ASSIGNMENTS ..................................................... 23

7.0 SPECIFICATIONS .................................................................................... 24

8.0 WARRANTY AND RETURN INFORMATION ........................................... 28

2 Pelco Manual C585M-B (11/98)

Page 3

LIST OF ILLUSTRATIONS

Figure Page

1 Basic Wiretron System Configuration ................................................ 9

2 Multiple Camera Wiretron System ..................................................... 9

3 Circuit Board Electrical Connections ................................................ 10

4 24 VAC Power Input Modification Diagram ....................................... 11

5 Basic Wiretron Interconnect Diagram ...............................................13

6 Connector Assembly .........................................................................14

7 Receiver Control Output/Input Pin Assignments............................... 15

8 Jumper Settings on the Receiver Circuit Board ................................ 16

9 Auxiliary Functions Wiring Diagram .................................................. 17

10 External Device Wiring Diagram ....................................................... 17

11 Receiver Pin Assignments ................................................................ 23

12 MPT8000 Series Controller Dimension Drawing .............................. 25

13 WX8000 Series Receiver Dimension Drawing (Outdoor Models) ..... 27

14 WX8000 Series Receiver Dimension Drawing (Indoor Models) ....... 27

LIST OF TABLES

Table Page

A Control Cable Wiring Distances ........................................................12

B Video Coaxial Cable Wiring Distances ............................................. 20

C 24 VAC Wiring Distances .................................................................. 20

REVISION HISTORY

Manual # Date Comments

C585M 1985 Original version.

C585M-A 4/90 Rev A. Revised manual to include instructions on

C585M-B 11/98 Rev B. Changed manual to new format. Completely

converting the WX802RX and WX8024RXI receiver/

drivers to operate on 24 VAC input voltage.

revised installation and operation instructions, and

added agency compliance certifications.

Pelco Manual C585M-B (11/98) 3

Page 4

(This page intentionally left blank.)

4 Pelco Manual C585M-B (11/98)

Page 5

1.0 GENERAL

1.1 IMPORTANT SAFEGUARDS AND WARNINGS

Prior to installation and use of this product, the following WARNINGS should be

observed.

1. Installation and servicing should only be done by qualified service personnel

and conform to all local codes.

2. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or

6P enclosure, it is designed for indoor use only and it must not be installed

where exposed to rain and moisture.

3. Only use replacement parts recommended by Pelco.

4. After replacement/repair of this unit’s electrical components, conduct a resistance measurement between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage constituting a

risk of electric shock is present within this unit.

This symbol indicates that there are important operating and

maintenance instructions in the literature accompanying this

unit.

CAUTION:

RISK OF

ELECTRIC SHOCK.

DO NOT OPEN.

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

DO NOT REMOVE COVER. NO USER-

SERVICEABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

CAUTION:

Please thoroughly familiarize yourself with the information

in this manual prior to installation and operation.

Pelco Manual C585M-B (11/98) 5

Page 6

1.2 UNPACKING INSTRUCTIONS

Unpack and inspect all parts carefully.

The following items are supplied:

1 MPT8000 Series Wiretron Controller

or

1 WX8000 Series Receiver/Driver

1 Installation/Operation Manual (C585M-B)

Be sure to save the shipping carton, boxes and inserts. They are the safest

materials in which to make future shipments.

If an item appears to have been damaged in shipment, replace it properly in its box

and contact the factory at 1-800-289-9100 or 1-559-292-1981 for a replacement.

(International customers fax 1-559-348-1120 for authorization and instructions.)

If an item needs to be returned to the factory for repair, consult the WARRANTY

AND RETURN INFORMATION section of this manual for instructions.

1.3 RECOMMENDED TOOLS

Pelco does not supply the basic tools needed for the installation process. The

following tools are recommended.

Wire stripper

Wire cutter

AMP type crimper

Medium Phillips screwdriver

Power drill

6 Pelco Manual C585M-B (11/98)

Page 7

2.0 DESCRIPTION

The Wiretron digital control system operates over a two-conductor cable and controls CCTV equipment such as pan/tilts, enclosures, and motorized zoom lenses

from a remote location up to 10 miles (16 km) away.

Wiretron can be configured to control a single site or interfaced with Pelco video

switching equipment to provide a convenient video/control system with multiple

control sites and/or multiple camera sites.

The Wiretron control system provides up to 15 remote control functions:

1. Pan Left 9. Iris Open

2. Pan Right 10. Iris Close

3. Tilt Up 11. Auto/Manual Scan

4. Tilt Down 12. Aux 1 (Manual Iris)

5. Zoom In 13. Aux 2 (Auto Iris)

6. Zoom Out 14. Aux 3

7. Focus Near 15. Aux 4

8. Focus Far

Functions 1 through 10 are momentary; that is, they are actuated only while the

associated control switch is operated. Function 11 is latching; that is, auto scan

remains on until turned off. Aux 1, 2, 3, and 4 are low power outputs that may be

used to control such things as lights and gates. More auxiliary power output is

available when the controller is used with the AUX2000 Auxiliary Control Box. Aux

1-4 are jumper selectable for momentary/latching operation.

Functions 1 through 10 can be operated simultaneously. Functions 11 through 15

must be used individually, although any one of these functions may be used

simultaneously with functions 1 through 10.

Wiretron provides the following standard functions on a single circuit board and

chassis with integral power supply:

1. Pan/tilt (24 VAC or 120 VAC as ordered from the factory)

2. Zoom lens–zoom, iris, focus with adjustable speed (speed not remotely

controllable)

3. Camera power (24 VAC or 120 VAC as ordered from the factory)

4. An open collector transistor output (latching) for use in the manual override of

an automatic iris control

Wiretron is designed to combat erroneous control and execution by providing the

following protective functions:

1. Simultaneous commands from two different sources are processed to ensure

that manual iris control cannot be inadvertently selected in place of automatic

control.

2. A sustained (20-to-40 second) illegal command condition results in the following:

a. Automatic iris

b. Manual pan

2.1 MODELS

2.1.1 Wiretron Digital Transmitter/Controller

MPT8000CZ Desktop Wiretron transmitter/controller with pan/tilt joystick

MPT8000CZ/220 Same as MPT8000CZ except 230 VAC input

and zoom lens control, 120 VAC input.

Pelco Manual C585M-B (11/98) 7

Page 8

2.1.2 Wiretron Receiver/Driver

Outdoor

WX8024RX Wiretron receiver in weatherproof box for 24 VAC pan/tilts with

WX8024RX/220 Same as WX8024RX except 230 VAC input

WX8115RX Wiretron receiver in weatherproof box for 120 VAC pan/tilts with

WX8220RX Same as WX8115RX except 230 VAC input, 230 VAC pan/tilt

WX8224RX Same as WX8024RX except 24 VAC input

Indoor

WX8024RXI Same as WX8024RX except for indoor use, 120 VAC input

WX8024RXI/220 Same as WX8024RXI except 230 VAC input

WX8224RXI Same as WX8024RXI except 24 VAC input

power supply for pan/ tilt, zoom lens, 24 VAC camera power,

120 VAC input

power supply for pan/ tilt, zoom lens, 120 VAC camera power,

120 VAC input

output

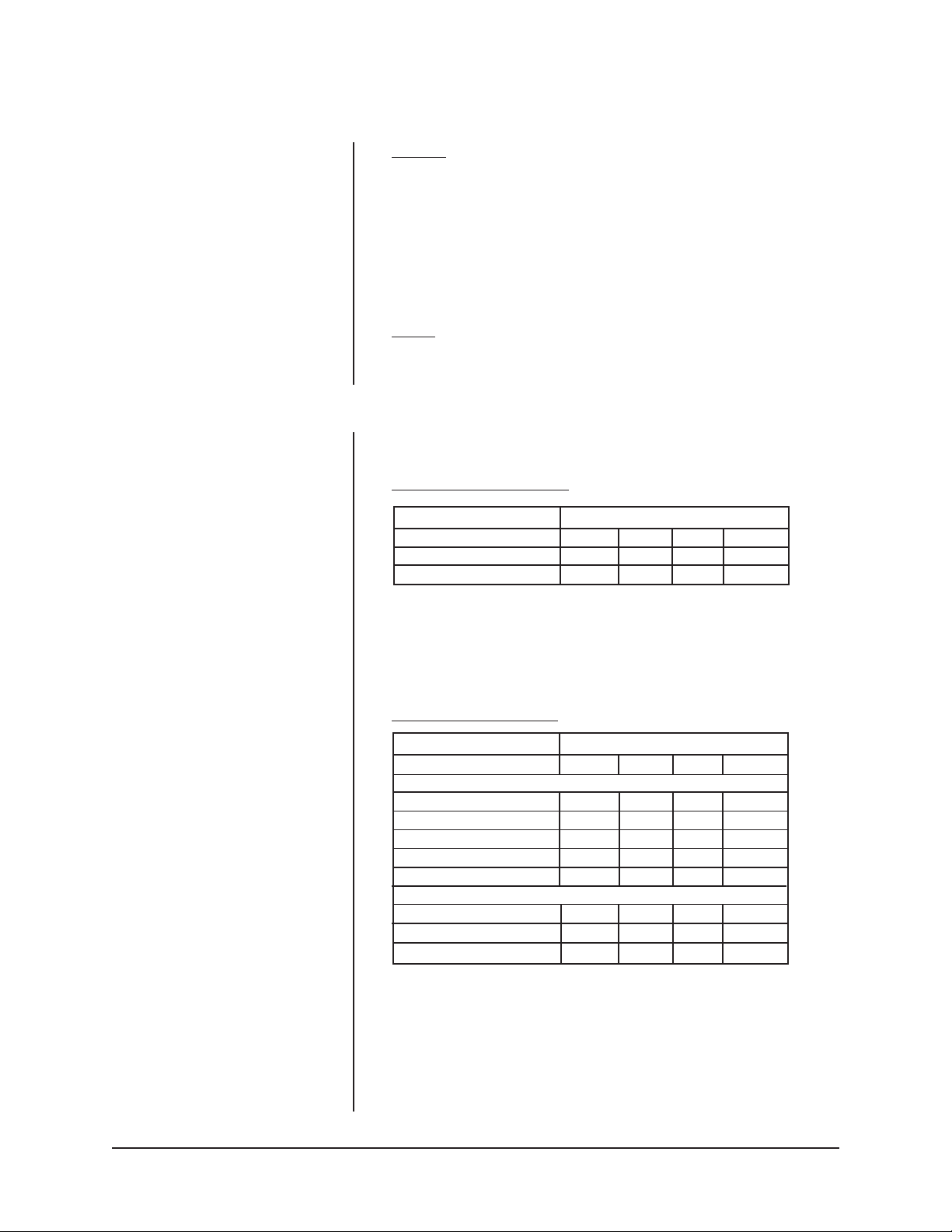

2.2 CERTIFICATIONS

The products identified below have been tested and certified for agency compliance as noted.

Wiretron Digital Controller

Agency Compliance Certification

Model CE FCC UL CSA/cUL

MPT8000CZ X

MPT8000CZ/220

Applicable CE, FCC, UL, and CSA/cUL standards:

• UL Standard 2044

Additional applicable standards:

• NEMA Type 1

• IP 20

Wiretron Receiver/Driver

Agency Compliance Certification

Model CE FCC UL CSA/cUL

Outdoor

WX8024RX X

WX8024RX/220

WX8115RX X

WX8220RX

WX8224RX X

Indoor

WX8024RXI X

WX8024RXI/220

WX8224RXI X

Applicable CE, FCC, UL, and CSA/cUL standards:

• UL Standard 2044

Additional applicable standards:

• NEMA Type 1 (RXI models)

• NEMA Type 4 (WX8024RX/220; WX8024RXI/220; WX8220RX)

• NEMA Type 4X (WX8024RX; WX8115RX; WX8224RX)

• IP 20 (RXI models)

• IP 56 (RX models)

8 Pelco Manual C585M-B (11/98)

Page 9

3.0 INSTALLATION

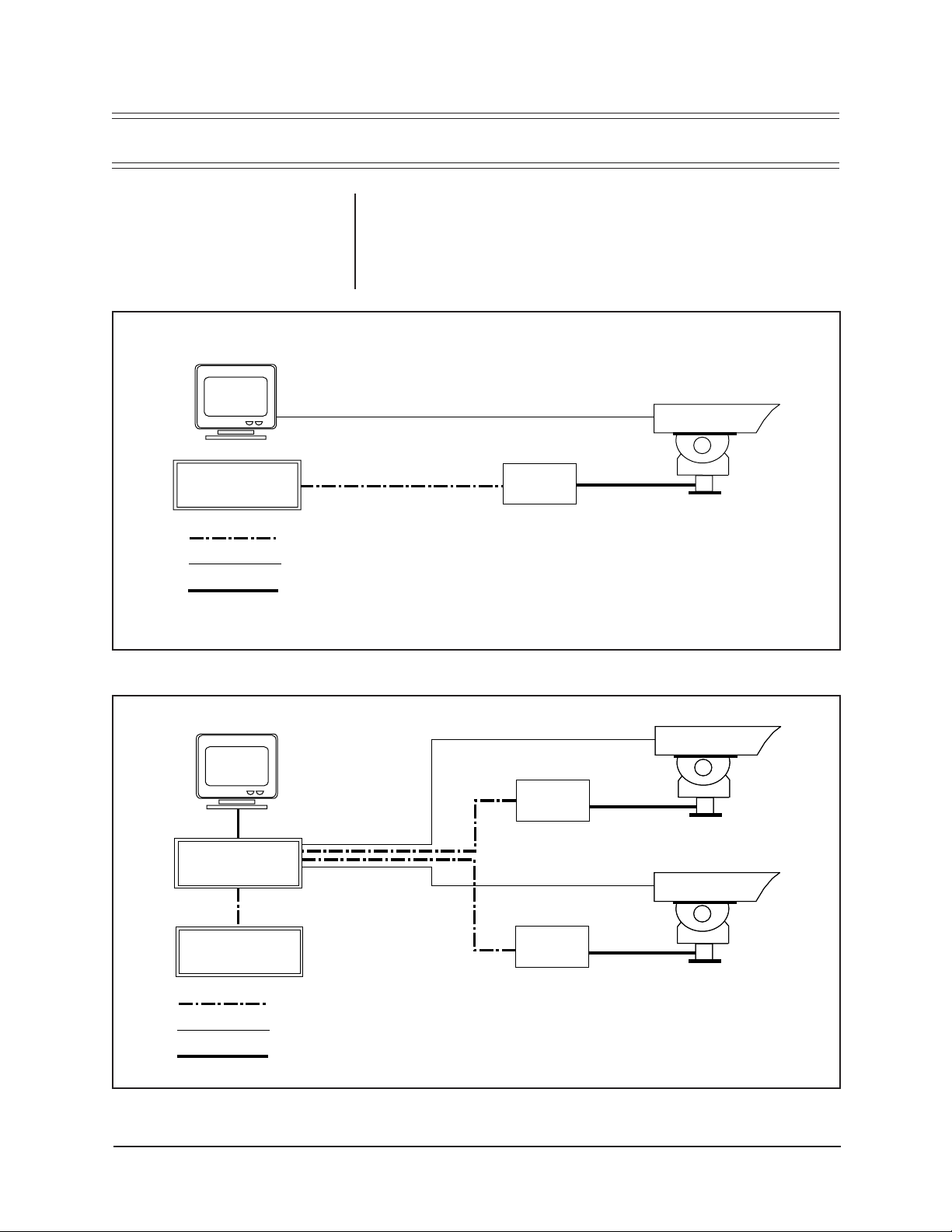

The simplest Wiretron system, consisting of the control transmitter and receiver, is

shown in Figure 1. Up to 15 control functions are transmitted over the transmission

line to the remotely located receiver. These signals are then converted to drive

voltages or relay switching for auxiliary equipment being controlled. The basic system can be expanded to control multiple camera sites with the addition of a manual

video switcher with balanced audio follow (BAF), as shown in Figure 2.

WIRETRON

TRANSMITTER/

CONTROLLER

MANUAL SWITCHER

WITH BAF OPTION

WIRETRON

RECEIVER

TWISTED PAIR

COAXIAL CABLE

MULTI-CONDUCTOR CABLE

Figure 1. Basic Wiretron System Configuration

WIRETRON

RECEIVER

WIRETRON

TRANSMITTER/

CONTROLLER

TWISTED PAIR

COAXIAL CABLE

MULTI-CONDUCTOR CABLE

WIRETRON

RECEIVER

Figure 2. Multiple Camera Wiretron System

Pelco Manual C585M-B (11/98) 9

Page 10

3.1 RECEIVER 24 VAC POWER INPUT MODIFICATION

The WX8024RX series receivers can be converted to operate with 24 VAC input.

To convert the receiver, disconnect the receiver circuit board and assembly from

the enclosure. The patch panel circuit board is located on the bottom of the receiver

circuit board mounting plate and requires the following modifications for 24 VAC

operation (refer to Figures 3 and 4.)

NOTE:

Parts needed for modifi-

cation: one 3 A fuse for F3.

WARNING:

High voltage is present on the T3

transformer wires when

the unit is connected to

power. Be sure the wires

are insulated for safety.

NOTE:

When operating with 24

VAC input power, the distance from

the receiver to the 24 VAC power

supply is typically limited to any

conductor size/length combination

resulting in less than 5 ohms total

circuit resistance.

1. Turn off the power to the receiver and remove the power cord.

2. Remove all wires from patch panel sections T2 and T3 with the exception of

the red wire connected to T3-1 and the red/white wire connected to T3-3.

3. Remove jumper wires from J4 pins 8 and 9 and J5 pins 8 and 9.

4. Remove transformer T2 (small transformer) and store for future use or

discard.

5. On transformer T3 (large transformer), insulate the wire ends on the black,

brown, black/white and brown/white wires.

6. Locate the blue wire connecting fuse F3 to pin 7 of P7 (labeled F3) and

disconnect at the P7 location. Reconnect to T3-3.

7. Connect a jumper from J4 pin 9 to T3-1.

8. Locate the wire connecting fuse F2 to pin 6 of P7 (labeled F2) and disconnect

at the P7 location. Reconnect to T2-3.

9. Connect a jumper from J5 pin 9 to T2-1.

10. Change fuse F2 from 2/10 ASB to 1 AG.

11. Change fuse F3 from 1 ASB to 3 AG.

1P6

66 94V0

9648

24V P/T

1P7

T3 T2 T1

J2

3

2

1

GND

5

6

110V

4

110V

J1

7

88

J4

J5 F1 F2 F3

}

GND

AC LOW

J3

220V

8

J6J4 J5

999

J6

24V CAM

3

1

}

AC HIGH

110V

J2

110V

J1

5

6

4

7

28VCT

J3

220V

®

J2

110V

110V

J1

5

6

4

7

3

2

1

PCB1500526

REV. G

MADE IN U.S.A.

J3

220V

Figure 3. Circuit Board Electrical Connections

10 Pelco Manual C585M-B (11/98)

Page 11

1P6

T3 T2 T1

24V P/T

J2

3

110V

2

110V

J1

1

88

GNDJ4J5 F1 F2 F3

24V CAM

5

J3

6

220V

4

7

8

J6J4 J5

999

J6

J2

3

110V

110V

1

J1

28VCT

5

J3

6

220V

4

7

BLUE/WHITE

YELLOW

BLUE

66 94V0

9648

J2

110V

110V

5

J3

6

220V

4

7

J1

3

2

1

1P7

T3

BROWN/WHITE

BROWN

BLACK/WHITE

BLACK

CUT WIRES

SHORT AND

INSULATE

RED

RED/WHITE

24 VAC INPUT

24 VAC OUTPUT

WHITE

BLUE

GREEN

BLACK

VIOLET

F2

CAM

1A

F3

P/T

3A

Figure 4. 24 VAC Power Input Modification Diagram

Pelco Manual C585M-B (11/98) 11

Page 12

3.2 MOUNTING

3.2.1 Transmitter/Controller

NOTE:

Never mount the receiver

with wiring connectors facing up.

Always have the connectors facing

down to prevent water damage.

NOTE:

When installing the

WX8000 receiver to a wall outdoors, seal the bolt holes with an

appropriate sealant. Apply the

sealant around the bolt holes between the unit and the mounting

surface. This will prevent possible

water damage to the wall caused

by rainwater leaking through the

mounting bolt holes. (This may only

be a problem when the mounting

bolts go completely though the

wall.)

Transmitter/controllers in the MPT8000 Series are desktop units. Determine the

best location for the unit.

Proceed to Section 3.2.2, RECEIVER.

3.2.2 Receiver

1. Determine the best location to install the unit.

2. Using the WX8000 receiver box as a template, mark the hole pattern on the

mounting surface. Drill holes in the mounting surface.

3. Attach the WX8000 receiver securely with four fasteners of appropriate length

(not supplied.)

Proceed to Section 3.3, WIRING.

3.3 WIRING

3.3.1 Control Wiring

3.3.1.1 Wiring the Transmitter/Controller to the

Receiver

Run the control cable between the controller/transmitter and the receiver (refer to

Figures 1 and 2.)

The control cable should be unshielded twisted pair wire. Maximum operating distances should be determined by referring to Table A, Control Cable Wiring

Distances.

Table A. Control Cable Wiring Distances

Wire Gauge* Maximum Distance

22 AWG 5 miles (8 km)

20 AWG 10 miles (16 km)

* Control cable operating distances are approximate according to wire used.

To wire the MPT8000 control wires, refer to Figure 5 and perform the following

instructions:

1. Attach one wire from the terminal labeled HI on the MPT8000 Series

controller to the terminal labeled HI on the WX8000 Series receiver.

2. Attach one wire from the terminal labeled LOW on the MPT8000 Series

controller to the terminal labeled LOW on the WX8000 Series receiver.

If you want to use a configuration that includes a switching device, refer to the

manual provided with the switcher for the appropriate connections.

Proceed to Section 3.3.1.2, WIRING FROM THE RECEIVER/DRIVER TO THE

PAN/TILT.

12 Pelco Manual C585M-B (11/98)

Page 13

CAUTION:

HAZARDOUS

VOLTAGE

MAY EXIST

AC

INPUT

3

2

1

WX8000 SERIES RECEIVER

AC

LOW

GND

AC

HIGH

AUTO/RANDOM

SCAN MODULE

F3

A9000

F2

22 1 P3

TEST

MODULE

CX900TLC

HI

LOW

GND

F1

PS 1 8

HI LOW GND

10 1 P2

J2

P1 1 14

MPT8000 SERIES CONTROLLER

AC INPUT

Figure 5. Basic Wiretron Interconnect Diagram

3.3.1.2 Wiring from the Receiver/Driver to the Pan/Tilt

1. Run multi-conductor cable between the receiver/driver and the pan/tilt (refer

to Figures 1 and 2.)

TB1

HI LOW GND

2. Assemble the connector parts according to the following instructions. Detail B,

in Figure 6, reflects the pin arrangement specific to the WX8000 Series

receiver/drivers. Refer to Figures 6 and 7 during assembly. For best results,

use an AMP style crimper when making the wire-to-pin connection.

The instructions that follow apply to all AMP style connectors regardless of pin size

or pin number.

1. Slide the connector clamp assembly over the conductor cable. If the diameter

of the conductor cable is such that the rubber boot will slide over it easily then

slide the rubber boot onto the conductor cable at this time. If not, discard the

rubber boot.

2. Prepare the wires from the conductor cable as follows:

a. Strip at least 1-inch (2.54 cm) from the cable jacket to expose the wires.

You may need to strip more from the cable jacket if you have more wires.

b. Strip 1/8-inch (0.318 cm) from each wire.

c. Using an AMP style crimper, crimp the wires and their insulation to the

connector pins. Refer to Detail A in Figure 6.

Pelco Manual C585M-B (11/98) 13

Page 14

3. Slide the connector pins into the appropriate holes in the connector body until

14

59

15 10

22 16

28 23

33 29

37 34

they snap into place. Refer to Figures 4 and 5 for correct pin arrangement,

depending on model and options.

4. Push the connector clamp assembly (with boot, if used) toward the connector

body. Screw the clamp assembly onto the connector body, being careful not to

disturb the wires.

5. To complete the assembly, attach the appropriate clamp with the screws pro-

vided and tighten.

6. When you are finished wiring the connector, connect the 37-pin assembly to

the WX8000 Series receiver/driver and the pan/tilt.

Proceed to Section 3.3.2, AUXILIARY FUNCTIONS.

1/8"

1" (2.54 cm)

(0.318 cm)

14 Pelco Manual C585M-B (11/98)

OR

FRONT VIEW

37-PIN

Figure 6. Connector Assembly

Page 15

14

59

15 10

22 16

28 23

33 29

37 34

RECEIVER CONTROL

INPUT

PIN ASSIGNMENT

P1

RECEIVER CONTROL

OUTPUT

PIN ASSIGNMENT

3

5

8

7

6

4

9

12

11

10

14

13

1

2

P2

10

9

8

7

6

5

4

3

2

1

BRN P/T COM

ORG LEFT

N/C

GRN DOWN

BLU UP

VIO RIGHT

GRAY GROUND

BLK IRIS

W/BRN FOCUS

W/RED ZOOM

W/ORG LENS COM

RED MAN IRIS

WHITE CAM AC HIGH

W/YEL CAM AC LOW

BRN/W N/C

RED/W N/C

ORG/W AUX 1

YEL/W N/C

GRN/W AUX 4

BLU/W AUX 3

VIO/W AUX 2

GRY/W LOGIC RESET

W/GRY GROUND

BLK/W +10V

10

11

12

13

14

28

29

30

31

32

33

34

35

36

37

1

3

4

5

6

7

8

G

1

3

LENS

INPUT

2

4

5

2

9

CAMERA

POWER

AUXILIARY WIRING

PROVIDED IN

OUTDOOR MODELS

O N LY.

NOTE: N/C MEANS NOT CONNECTED.

Figure 7. Receiver Control Output/Input Pin Assignments

Pelco Manual C585M-B (11/98) 15

Page 16

3.3.2 Auxiliary Functions

WARNING:

Mechanical

relays used must not exceed 10 VDC at 25 mA.

Applications with higher

power requirements

should be used with the

AUX2000 Auxiliary Control Box. Refer to the

AUX2000 manual for installation and operation

instructions.

The Wiretron receiver is capable of operating up to four remotely activated auxiliary

functions. Each auxiliary output may be individually converted at the receiver for

momentary or latching operation. Refer to Figure 8 to set jumpers for auxiliary functions. When in the latching mode, activating the same AUX function will toggle the

function from on to off.

The AUX outputs are buffered to provide a continuous 10 VDC at 25 mA to drive

small relays, lights or other external devices such as gates. Refer to Figures 9 and

10 for examples of typical circuits used for auxiliary functions.

Proceed to Section 3.3.3, VIDEO WIRING.

3.3.3 Video Wiring

Install a video cable from the video output of the camera to the video input of the

monitor (refer to Figures 1 and 2.) Proper termination of the video cable is vital to

the operation of the equipment. Be sure 75-ohm cable termination is made at the

monitor. Refer to Table B when wiring video coaxial cable distances up to 1,500 ft

(457 meters).

Proceed to Section 3.4, POWER, if finished wiring video.

Proceed to Section 3.3.3.1, LONG DISTANCE CABLE INSTALLATION, when

wiring longer distances.

AUXILIARY JUMPER

SETTINGS ON THE

WIRETRON RECEIVER

BOARD. JUMPERS ARE

SHOWN IN THE MOMENTARY

“POSITION” OR “MODE”.

P 2

37-PIN

CONNECTOR

POWER INPUT

LATCHING

JP1 AUX1

JP2 AUX2

JP3 AUX3

JP4 AUX4

MOMENTARY

P 1

CIRCUIT BOARD

WIRETRON RECEIVER

Figure 8. Jumper Settings on the Receiver Circuit Board

16 Pelco Manual C585M-B (11/98)

Page 17

WIRETRON

Figure 9. Auxiliary Functions Wiring Diagram

+ 12 VDC

NORMALLY-OPEN

CONTACTS

WIRETRON

RECEIVER/DRIVER

37-PIN CONNECTOR

1

2

3

8

1N4005

MANUAL IRIS

NOTE: CUSTOMER SUPPLIES PARTS AND 12 VDC

POWER SUPPLY

GROUND

10 VDC RELAY

25 mA COIL

CURRENT MAXIMUM

CONNECT TO NEGATIVE

SIDE OF 12 VDC SUPPLY

Figure 10. External Device Wiring Diagram

Pelco Manual C585M-B (11/98) 17

Page 18

3.3.3.1 Long Distance Cable Installation

Because of the many options available, long distance video wiring is at your discretion. Review the following to determine the best method of wiring video for your

application.

Maximum Distance Recommendations for Coaxial Cable

There are a number of variables to consider when specifying the type of coaxial

cable to run. It is best to avoid the use of video amplifiers. Video amplifiers should

be regarded as a remedy for an existing problem not as an installation aid.

Coaxial Splicing

Although not recommended, a splice in a coaxial cable is sometimes unavoidable

in long runs or difficult conduit pulls. A female-to-male BNC splice is the first choice

when splicing coaxial cable. An acceptable substitute is female-to-female with a

barrel adapter (although there is more signal loss inherent in this type of splice.)

The use of “F” connectors or barrels is not preferable because of the inferior

mechanical connections and poor signal transmission characteristics inherent in

those connectors.

Direct Burial

Direct burial cabling should only be used when the cabling is specifically rated for

direct-burial use. Dig trenches and lay cable to a sufficient depth to accommodate

climate and other conditions and local codes. Protect cabling from damage that

may result from backfilling, traffic, burrowing animals, trenching, and other

conditions.

Underground Conduit

Ensure that the cable is appropriate for use in underground conduit. Direct burial

cable is usually not acceptable for use inside a buried conduit that may fill with

water. Direct burial type of cable utilizes the earth surrounding the cable to wick

moisture away from the cable. Call your cable supplier or manufacturer for their

recommendations on the correct type of cable to use in circumstances where the

cable will be used in conduit.

One-inch PVC is the minimum recommended size for underground conduits. Allow

no more than two 90-degree bends between pull boxes. Make sure pull boxes and/

or splice boxes are as water-resistant as possible and that splices stay above any

water accumulation.

When using PVC, be sure to separate high voltage carrying conduits from video

conduits by enough distance to ensure that the video signal is not degraded. When

dealing with 120 VAC, about 12 inches of separation should be sufficient.

Aerial Spans

In some applications, it is preferable to run cable to a location overhead. If you want

to use existing poles consult with the owners, warrantors, or maintaining entities.

The poles may not be available for your use if the poles are owned by a public

service, utility, or cable TV provider.

If poles are in use by others, make sure that the addition of your cable and wire

complies with local codes and regulations. Proper spacing from existing wire and

cable, the descending order of voltage-carrying cable, and the minimum

low-clearance specifications over roads, alleys, and driveways etc. should be maintained.

Be aware of electrical inference that might be generated by high-voltage cables

sharing the poles with the video cabling. Legal spacing may not be enough to prevent electrical inference if radiated levels are high.

Hardware on poles should be appropriate to sustain the weight and stress of the

cable during adverse weather conditions.

Microwave

The WX8000 Series is excellent for microwave control. Consult with microwave

equipment manufacturers and/or suppliers for recommendations regarding operating specifications, and installation.

18 Pelco Manual C585M-B (11/98)

Page 19

Fiber Optic Cabling

Fiber optic transmission of both video and control presents some distinct

advantages. Higher quality and longer distance transmission characteristics,

inherent noise resistance, greater flexibility for usage, and reduced cabling

diameter are but a few of these advantages. The incorporation of fiber optics systems are encouraged, especially when covering long distances and when seeking

to maintain the highest quality video signals. Consult with equipment manu

facturers and fiber optic cabling manufacturers or suppliers for recommendations

regarding fiber optic type, operating specifications, and installation requirements.

Proceed to Section 3.4, POWER.

3.4 POWER

1. Run wiring and connect receiver input power to AC HIGH, AC LOW, and ground.

If using 24 VAC to power the receiver, refer to Table C for the maximum

recommended wiring distances.

2. Power up the controller and receiver.

Pelco Manual C585M-B (11/98) 19

Page 20

Table B. Video Coaxial Cable Wiring Distances

Cable Type* Maximum Distance

RG59/U 750 ft (229 m)

RG6/U 1,000 ft (305 m)

RG11/U 1,500 ft (457 m)

*Minimum cable requirements:

75 ohms impedance

All-copper center conductor

All-copper braided shield with 95% braid coverage

Table C. 24 VAC Wiring Distances

The following are the recommended maximum distances for 24 VAC applications

and are calculated with a 10-percent voltage drop. (Ten percent is generally the

maximum allowable voltage drop for AC-powered devices.)

Wire Gauge

EXAMPLE:

An enclosure that requires 80 vA and is installed 35 feet

(10 m) from the transformer would

require a minimum wire gauge of

20 AWG.

NOTE:

Distances are calculated in

feet; values in parentheses are

meters.

20 18 16 14 12 10

10 283 451 716 1142 1811 2880

(86) (137) (218) (348) (551) (877)

20 141 225 358 571 905 1440

(42) (68) (109) (174) (275) (438)

30 94 150 238 380 603 960

(28) (45) (72) (115) (183) (292)

40 70 112 179 285 452 720

(21) (34) (54) (86) (137) (219)

50 56 90 143 228 362 576

(17) (27) (43) (69) (110) (175)

60 47 75 119 190 301 480

(14) (22) (36) (57) (91) (146)

70 40 64 102 163 258 411

(12) (19) (31) (49) (78) (125)

80 35 56 89 142 226 360

(10) (17) (27) (43) (68) (109)

90 31 50 79 126 201 320

(9) (15) (24) (38) (61) (97)

100 28 45 71 114 181 288

(8) (13) (21) (34) (55) (87)

110 25 41 65 103 164 261

(7) (12) (19) (31) (49) (79)

120 23 37 59 95 150 240

Total vA consumed

(7) (11) (17) (28) (45) (73)

130 21 34 55 87 139 221

(6) (10) (16) (26) (42) (67)

140 20 32 51 81 129 205

(6) (9) (15) (24) (39) (62)

150 18 30 47 76 120 192

(5) (9) (14) (23) (36) (58)

160 17 28 44 71 113 180

(5) (8) (13) (21) (34) (54)

170 16 26 42 67 106 169

(4) (7) (12) (20) (32) (51)

180 15 25 39 63 100 160

(4) (7) (11) (19) (30) (48)

190 14 23 37 60 95 151

(4) (7) (11) (18) (28) (46)

200 14 22 35 57 90 144

(4) (6) (10) (17) (27) (43)

Maximum distance from transformer to load

20 Pelco Manual C585M-B (11/98)

Page 21

In general, all controller operating controls are self-explanatory. All controls, except

the ON/OFF power switch, are center-off, spring return switches (momentary onoff-momentary on.)

When using Aux 1-4 in the latching mode, operating the switch once will latch the

function and operating it again will unlatch the function.

The camera on/off switch is non-functional; the receiver is permanently in the ON

condition.

Reset causes latching functions to revert to the following:

1. Manual scan

2. Automatic iris

4.1 AUTO/RANDOM OPERATION

Auto scan and random scan modes are available when the A9000 Auto/Random

Scan plug-in module is installed in the Wiretron receiver. This module, when used

with the MPT8000 Series controller, allows control of pan and tilts. Refer to the

A9000 manual for installation and operation instructions.

Advantages of random scan:

1. Because the scan direction, scan period, and dwell period are unpredictable,

unauthorized activities or intrusions are discouraged.

4.0 OPERATION

2. Because of the reduced duty cycle, gear train wear, cable fatigue, drive motor

wear, and temperature rise are reduced. These factors contribute to system

reliability and increased equipment life.

Pelco Manual C585M-B (11/98) 21

Page 22

5.0 MAINTENANCE

6.0 TROUBLESHOOTING

Regularly scheduled maintenance is not required. Clean the outer surface of the

controller or receiver with a non-abrasive cleaning cloth and antistatic cleaner. Do

not use kerosene or similar substances that may damage the surface.

If you experience operating problems with either the controller or receiver, first check

all fuses and voltage readings to make sure they are in working order.

Auxiliary Functions

Aux 1, 2, 3, and 4 are low power outputs that may be used to control such things as

lights and gates. More auxiliary power output is available when the controller is

used with the AUX2000 Auxiliary Control Box. Refer to the AUX2000 manual for

installation and operation instructions.

CX900TLC Manual Test Module

The CX900TLC Manual Test Module can be used to verify the receiver functions

and accessories are operational. The CX900TLC is a dual-purpose plug-in module

that permits local operation of all functions directly from the receiver unit, and serves

to verify that the receiver and accessories are operating properly by providing

visual confirmation. This module also aids in troubleshooting receiver or controller

operational problems. Refer to the CX900TLC manual for installation and operation instructions.

Also refer to Figure 11 for troubleshooting information.

For additional troubleshooting information contact your local dealer or Pelco.

22 Pelco Manual C585M-B (11/98)

Page 23

6.1 Receiver Pin Assignments

Refer to Figure 11, Receiver Pin Assignments, when servicing the receiver.

MANUAL

CONTROL

FUNCTIONS

PIN 1 RIGHT

PINPIN 2 LEFT

PIN 3 UP

PIN 4 DOWN

PIN 5 ZOOM TELE

PIN 6 ZOOM WIDE

PIN 7 FOCUS FAR

PIN 8 FOCUS NEAR

PIN 9 IRIS OPEN

PIN 10 IRIS CLOSE

PIN 11 AUX 1

PIN 12 AUX 2

PIN 13 AUTO IRIS

PIN 14 AUX 3

PIN 15 AUX 4

PIN 16 CAM OFF

PIN 17 CAM ON

PIN 18 MAN SCAN

PIN 19 AUTO SCAN

PIN 20 ACTIVE LINE

PIN 21 GROUND

PIN 22 +10 VDC

PIN 9 GROUND

PIN 10 14 VAC

PIN 11 GROUND(C)

PIN 12 14 VAC

J3 (CX900TLC

TEST BOARD)

R55

DO NOT ADJUST!

JUMPER PIN 22 TO

PINS 1-19 OF J3 TO

ACTIVATE CONTROL

FUNCTIONS

A9000 (AUTO/RANDOM SCAN BOARD) PLUG-IN STRIP

XXXXXXXX XXXX

HARNESS TO PRESET BOARD

LENS SPEED

R21

R50

DO NOT ADJUST!

+18 VDC

-18 VDC

INPUT POWER

PIN 6 N/C

PIN 7 N/C

PIN 8 GROUND

P3

1

2

GND

MOMENTARY

3

4

K2

(LEFT)

K3

(RIGHT)

LATCHING

J2

HARNESS TO AUX 2000

PIN 1 CAM HIGH

PIN 2 CAM LOW

PIN 3 N/C

PIN 4 PT HIGH

PIN 5 PT LOW

K5

(UP)K4(DOWN)K1(CAM)

HARNESS TO PTZ

JP4 JP2

JP3 JP1

WX8115RX

PINS 1,2,4, AND 5 ARE

120 VAC.

WX8024/WX8224 MODELS

PINS 1,2,4, AND 5 ARE

24 VAC.

J1

OUTPUTS TO

37-PIN CONNECTOR

P1

CAM HIGH PIN 1

CAM LOW PIN 2

PT COMMON PIN 3

RIGHT PIN 4

LEFT PIN 5

UP PIN 6

DOWN PIN 7

N/C PIN 8

GROUND PIN 9

ZOOM PIN 10

FOCUS PIN 11

IRIS PIN 12

MAN IRIS PIN 13

LENS COMMON PIN 14

P2

N/C PIN 10

N/C PIN 9

TTL AUX 1 PIN 8

N/C PIN 7

TTL AUX 4 PIN 6

TTL AUX 3 PIN 5

TTL AUX 2 PIN 4

RESET PIN 3

GROUND PIN 2

+10 VDC PIN 1

KEY TO SYMBOLS

SOCKET ADJUSTABLE POT

PIN

SOLDER LAND

X

RELAY

K

Figure 11. Receiver Pin Assignments

Pelco Manual C585M-B (11/98) 23

Page 24

7.0 SPECIFICATIONS

MPT8000 CONTROLLER

ELECTRICAL

Input Voltage

MPT8000CZ: 120 VAC, 60 Hz

MPT8000CZ/220: 230 VAC, 60 Hz

Power Consumption: 2.5 vA

Control Method: 15 pulse train (pulse width modulated)

Pulse Amplitude: 35 mA current loop

Connectors: One 3-contact terminal block

Fuse Protection

MPT8000CZ,

MPT8000CZ/220: One 1/16 A, 3AG, slow blow fuse

Power Cord: 3-wire grounded #18 AWG

Cable Requirements: Twisted pair, unshielded

Operating Distance: Control cable distances are approximate according to wire

CONTROLS

Power ON/OFF: Rocker switch

Pan/Tilt: 8-position joystick

ZOOM: Paddle switch, TELE/WIDE

FOCUS: Paddle switch, NEAR/FAR

IRIS: Paddle switch, OPEN/CLOSE

PAN AUTO/MAN: Paddle switch (latching function in receiver)

CAMERA ON/OFF: Paddle switch (non-functional; receiver permanently in ON

AUX 1, 2, 3, 4: Paddle switch (receiver provides +10 V, 20 mA output which

Pilot Lamp: Long life neon

used.

Wire Gauge Maximum Distance

22 AWG 5 miles (8 km)

20 AWG 10 miles (16 km)

condition)

can be used as latching or momentary functions)

24 Pelco Manual C585M-B (11/98)

Page 25

GENERAL

Construction

and Finish: Black polyester powder coated steel

Operating

Temperature: 32° to 120°F (0° to 49°C)

Dimensions: See Figure 12

Weights Unit Shipping

MPT8000CZ 7.5 lb (3.36 kg) 8 lb (3.62 kg)

MPT8000CZ/220 7.5 lb (3.36 kg) 8 lb (3.62 kg)

WX8000 RECEIVER/DRIVER

ELECTRICAL

Input Voltage

WX8024RX,

WX8024RXI: 120 VAC, 50/60 Hz

WX8024RX220,

WX8024RXI/220: 230 VAC, 50/60 Hz

WX8115RX: 120 VAC, 50/60 Hz

WX8220RX: 230 VAC, 50/60 Hz

WX8224RX,

WX8224RXI: 24 VAC, 50/60 Hz

AC INPUT

Power Consumption

Receiver: 5 vA (120 VAC or 24 VAC)

Pan/Tilt Supply: 140 vA max. (120 VAC) 50 vA max. (24 VAC)

Lens Supply: 0-4 vA max.

Camera Supply: 15 vA (typical)

Control Method: 15-pulse train (pulse width modulated)

Pulse Amplitude: 35 mA current loop

10.16 REF

14.32

(36.37)

AUX

AUX

PAN

CAM

1

3

AUTO

ON

2

4

MAN

OFF

UP

LEFT RIGHT

DOWN

ZOOM

FOCUS

IRIS

TELE

NEAR

OPEN

WIDE

FAR

CLOSE

ON

OFF

1.77

(4.50)

(25.81)

8.50

(21.59)

FRONT VIEW FRONT VIEW

TB1

HI LOW GND

REAR VIEW

NOTE: VALUES IN PARENTHESES ARE CENTIMETERS; ALL OTHERS ARE INCHES.

Figure 12. MPT8000 Series Controller Dimension Drawing

Pelco Manual C585M-B (11/98) 25

Page 26

Connectors

Receiver Input: 3-contact terminal block

Receiver Output: 37-pin AMP CPC for control output (mate supplied)

Fuse Protection

WX8024RX, Fuse 1: Not used

WX8024RXI Fuse 2: 2/10 A, 3AG, slow blow fuse

WX8024RX/220, Fuse 1: Not used

WX8024RXI/220 Fuse 2: 1/10 A, 3AG, slow blow fuse

Fuse 3: 1 A, 3AG, slow blow fuse

Fuse 3: 1/2 A, 3AG, slow blow fuse

WX8115RX Fuse 1: 2/10 A, 3AG, slow blow fuse

WX8220RX Fuse 1: 1/10 A, 3AG, slow blow fuse

WX8224RX, Fuse 1: Not used

WX8224RXI Fuse 2: 1 A, 3AG, slow blow fuse

Power Cord: 3-wire grounded, #18 AWG

Control Cable: Twisted pair, unshielded

GENERAL

Construction and Finish

Outdoor Models: Dark gray fiberglass

Indoor Models: Alodine aluminum

Latching

Outdoor Models: Two latches (accommodates padlocks - not supplied)

Operating

Temperature: -4° to 140°F (-20° to 60°C)

Environment: Indoor (RXI models)

Fuse 2: 2/10 A, 3AG, slow blow fuse

Fuse 3: 1 A, 3AG, slow blow fuse

Fuse 2: 1/10 A, 3AG, slow blow fuse

Fuse 3: 1/2 A, 3AG, slow blow fuse

Fuse 3: 3 A, 3AG, slow blow fuse

Outdoor (All other models)

Weight Unit Shipping

Dimensions

Outdoor Models: See Figure 13

Indoor Models: See Figure 14

4 lb (1.81 kg) 6 lb (2.72 kg)

(Design and product specifications subject to change without notice.)

26 Pelco Manual C585M-B (11/98)

Page 27

9.44

(23.98)

4.32

(10.97)

8.00

(20.32)

7.00

(17.78)

6.00

(15.24)

10.75

(27.31)

O .31 (.79) [4X]

NOTE: VALUES IN PARENTHESES ARE CENTIMETERS;

10.00

(25.40)

11.62

(29.51)

ALL OTHERS ARE INCHES

11.31

(28.73)

Figure 13. WX8000 Series Receiver Dimension Drawing (Outdoor Models)

7.87 (19.99)

5.09 (12.93)

4.18

(10.62)

9.75

(24.76)

11.25

(28.58)

10.50

(26.67)

4.18

(10.62)

NOTE: VALUES IN PARENTHESES ARE CENTIMETERS; ALL OTHERS ARE INCHES

Figure 14. WX8000 Series Receiver Dimension Drawing (Indoor Models)

Pelco Manual C585M-B (11/98) 27

Page 28

8.0 WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or

workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

Pelco, the Pelco logo, Camclosure, Esprit,

Genex, Legacy, and Spectra are registered

trademarks of Pelco.

Endura and ExSite are trademarks of Pelco.

© Copyright 1999, Pelco. All rights reserved.

• Five years on FT/FR8000 Series fiber optic products.

• Three years on Genex

• Three years on Camclosure® and fixed camera models, except the CC3701H-2, CC3701H-2X,

CC3751H-2, CC3651H-2X, MC3651H-2, and MC3651H-2X camera models, which have a fiveyear warranty.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy

dome products.

• Two years on Spectra

continuous motion applications.

• Two years on Esprit

• Eighteen months on DX Series digital video recorders, NVR300 Series network video

recorders, and Endura

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion applications

(that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco shipment.

All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis, California. Repairs

made necessary by reason of misuse, alteration, normal wear, or accident are not covered under

this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from the

specific use or application made of the Products. Pelco’s liability for any claim, whether based on

breach of contract, negligence, infringement of any rights of any party or product liability, relating

to the Products shall not exceed the price paid by the Dealer to Pelco for such Products. In no event

will Pelco be liable for any special, incidental or consequential damages (including loss of use, loss

of profit and claims of third parties) however caused, whether by the negligence of Pelco or

otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have

additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800)289-9100 or (559) 292-1981

to obtain a Repair Authorization number (RA), and provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the warranty

conditions stated above, please include a written explanation with the product when returned.

Method of return shipment shall be the same or equal to the method by which the item was received

by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at (800)

289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned for credit,

and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA number

and freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico, send goods to:

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico and are instructed

to return goods to the USA, you may do one of the following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

If the goods are to be sent by a FREIGHT FORWARDER, send the goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

®

Series products (multiplexers, server, and keyboard).

®

, CM6700/CM6800/CM9700 Series matrix, and DF5/DF8 Series fixed

®

, Esprit®, ExSite™, and PS20 scanners, including when used in

®

and WW5700 Series window wiper (excluding wiper blades).

™

Series distributed network-based video products.

28 Pelco Manual C585M-B (11/98)

Loading...

Loading...