Page 1

®

INSTALLATION/OPERATION

VSS200DT

Screen Splitter

C627M-A (8/03)

Page 2

GENERAL

IMPORTANT SAFEGUARDS AND WARNINGS

DESCRIPTION

Observe the following WARNINGS before installing and using this product.

1. Installation and servicing should be done only by qualified service personnel and conform to all local codes.

2. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is designed for indoor use

only and it must not be installed where exposed to rain and moisture.

3. The installation method and materials should be capable of supporting four times the weight of the unit.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage

constituting a risk of electric shock is present

within this unit.

This symbol indicates that there are important

operating and maintenance instructions in the

literature accompanying this unit.

Thoroughly familiarize yourself with the information in this manual prior to installation and operation.

The VSS200DT screen splitter displays video from a single camera or simultaneously displays selected portions of video from

two cameras onto one monitor. This feature also allows both cameras to be recorded onto a single video tape recorder (VCR).

The VSS200DT screen splitter uses high reliability CMOS technology.

CAUTION:

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

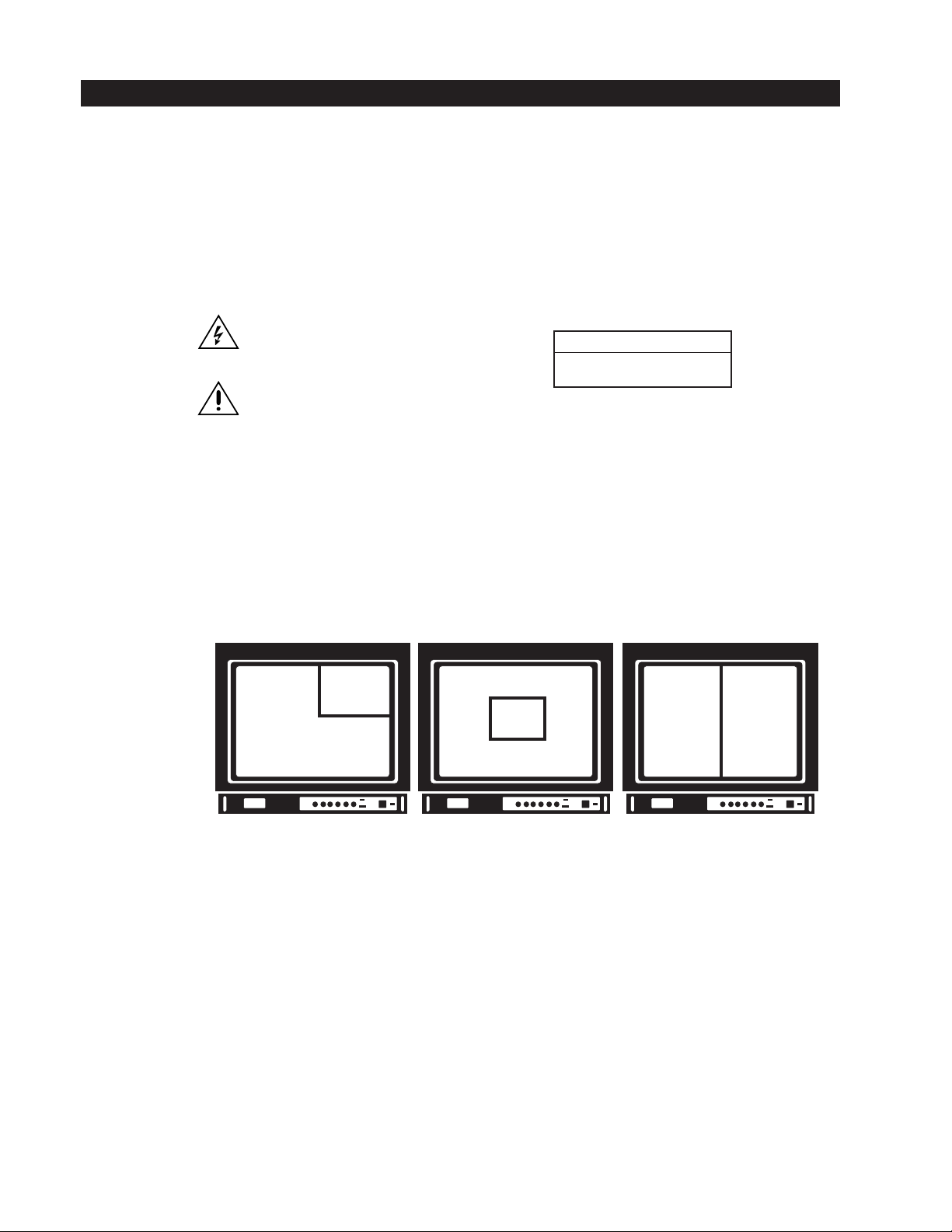

Front panel controls let you adjust the size and position of a second camera’s picture on the monitor. Either camera can be

displayed full screen.

1

CAMERA REQUIREMENTS

• Camera 2 can be black and white only; camera 1 can be color or black and white

•Two externally synchronized cameras

or

One random interlaced camera as a master with one camera having horizontal and vertical drive input as a slave

or

One 2:1 interlaced camera as a master with one camera having horizontal and vertical drive as a slave

2

1

221

Figure 1. Camera 2 Video Positioning Example

OPTIONS

R300 Rack mount kit for up to three units; blank filler panels provided for less than three units

DT200 Dual desktop mount kit; two units can be mounted side-by-side in one desktop chassis

2 C627M-A (8/03)

Page 3

INSTALLATION

VIDEO INPUTS

Each of the two camera inputs is terminated in 75 ohms inside the splitter. So, if you loop a camera video line through a

monitor before routing to the splitter, be sure to set the monitor termination switch to HI-Z.

The camera whose video is routed to the camera 1 input will be the master camera. That is, pictures from the camera 2 input

will be inserted into the pictures from the camera 1 input.

The master camera can be an economical, random interlace type because the splitter can provide horizontal and vertical

synchronization for the second camera. However, a master camera having 2:1 interlace will provide greater synchronization

stability. Refer to the

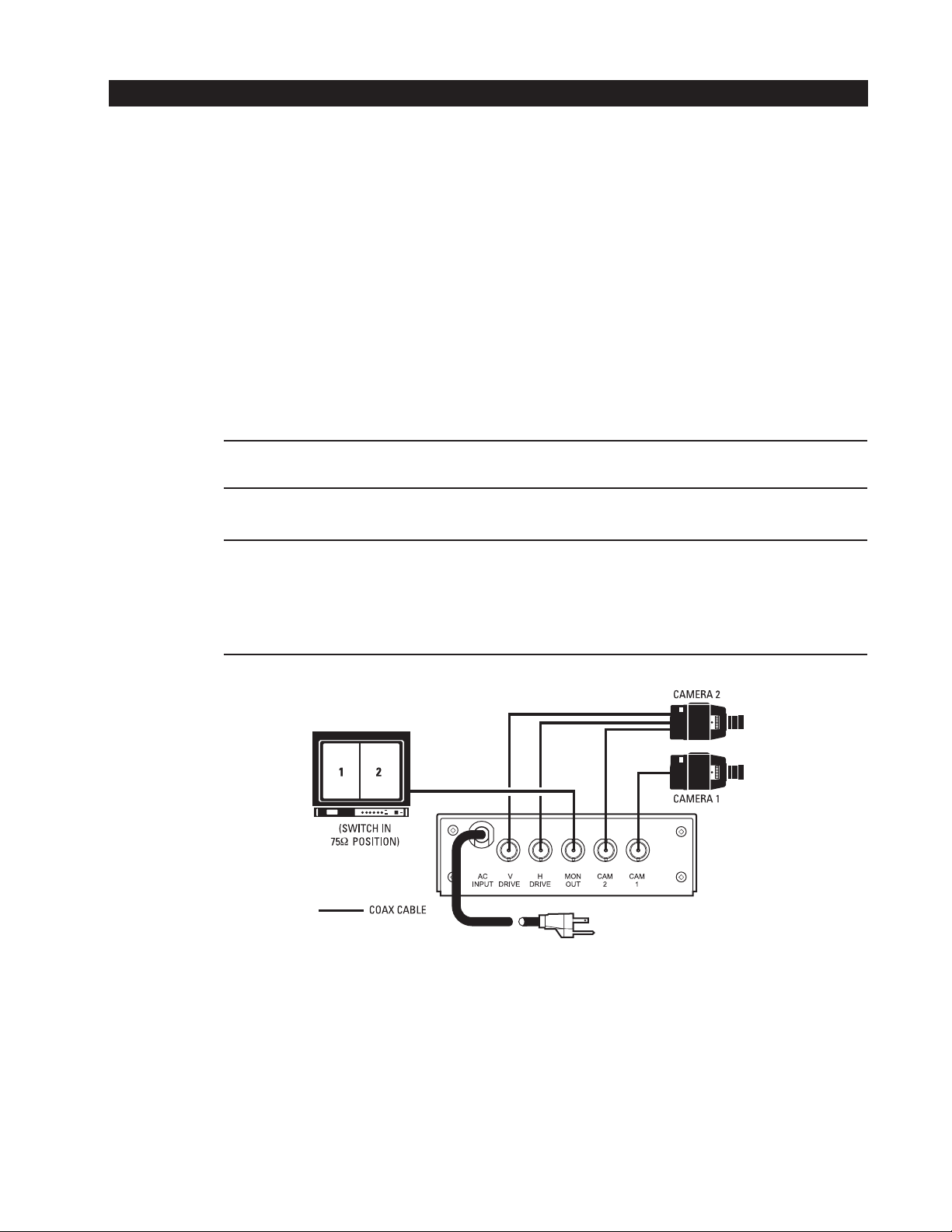

The second camera either must be independently synchronized to the master camera, or it must be a camera that can accept

horizontal and vertical synchronization from the splitter (refer to Figure 2). Refer to the

Connectors)

Figure 2 illustrates a typical configuration.

NOTE: (Applies to Figure 2 only.) Camera 2 must be equipped with three BNC connectors (one for VERT drive, one for HORIZ drive,

and one for VIDEO), and hooked to the VSS200DT. Camera 1 only needs to be equipped with one BNC connector for the VIDEO.

If you are using a camera with Gen. Lock, the configuration in Figure 3 applies.

Sync Output (H Drive – V Drive BNC Connectors)

section.

section.

Sync Output (H Drive – V Drive BNC

NOTE: For installations using cameras with Gen. Lock only, the input termination resistor (R1) must be removed to let the

VSS200DT and the camera function properly.

During normal operation CAM 1 is designated as the master camera.

If you want to change CAM 2 to be the master camera, slide the S2 switch on the motherboard in the opposite direction.

Figure 2. VSS200DT Typical Configuration

C627M-A (8/03) 3

Page 4

Figure 3. VSS200DT Configuration for Cameras with Gen. Lock

VIDEO OUTPUT

This output must be terminated with a 75-ohm load. So, if you loop the output through monitors or other accessories, be sure

their terminations are set to HI-Z. Only the last unit on the line should have its termination set to 75 ohms.

SYNC OUTPUT (H DRIVE – V DRIVE BNC CONNECTORS)

When a camera having random interlace is used as the master camera, the second camera must be synchronized by using the

H Drive and V Drive outputs. Refer to Figure 2.

POWER

The supplied five-foot (1.5 m), three-wire line cord with grounded plug complies with safety standards. The unit operates over

a voltage range from 95 to 230 VAC, 50/60 Hz and draws about three watts at 120 VAC.

4 C627M-A (8/03)

Page 5

OPERATION

FRONT PANEL CONTROLS

Figure 4. Front Panel Controls

CAM 1/CAM 2/SPLIT This switch selects camera 1 full screen, camera 2 full screen, or split/insert.

BAL This screwdriver adjustment controls the contrast on camera 2 (the black and white camera).

V SIZE and V POS These screwdriver adjustments control vertical size and position of the split/insert (camera 2 only).

H SIZE and H POS These screwdriver adjustments control horizontal size and position of the split/insert (camera 2 only).

ON/OFF This switch controls power to the unit. The red light indicates the unit is on.

SETUP

1. Turn on the two cameras, the VSS200DT, and the monitor.

2. Set the select switch to CAM 1 (full screen).

3. Adjust camera 1 position and lens until the desired portion of its picture is in the correct position for the composite

display.

4. Set the select switch to CAM 2 (full screen).

5. Adjust camera 2 as in step 3.

6. Set the select switch to SPLIT (split screen).

7. Alternately adjust the insert/split V SIZE/POS (vertical size and position) and H SIZE/POS (horizontal size and position)

screwdriver adjustments until you get the composite picture you want. This moves the camera 2 video only. (You may

have to readjust the position and lens of one or both cameras to get the best composite picture.)

8. Adjust the video contrast of camera 2 (only) using the BAL screwdriver adjustment, if necessary.

C627M-A (8/03) 5

Page 6

SPECIFICATIONS

VIDEO

Inputs: Two

Input Level: 0.5 Vp-p to 2.0 Vp-p

Output Level: Same as input ±0.5 dB

Input/Output Impedance: 75 Ohm

Channel Gain Match: ±0.5 dB

Video Bandwidth: 12 MHz

ELECTRICAL

Input Voltage: 95-135 VAC, 50/60 Hz (230 VAC optional)

Input Power: 3 watts at 120 VAC

Connectors

Video: BNC

H&V Sync: BNC

GENERAL

Temperature Range: -10°F to +140°F (-23°C to +60°C)

Construction: Steel chassis and cover

Finish: Semigloss black enamel with white silk screen

Dimensions: 5.5 (W) x 9.2 (D) x 1.8 (H) inches (14 x 23.5 x 4.6 cm)

Weight: 2 lb (0.5 kg)

Shipping Weight: 4 lb (1.8 kg)

6 C627M-A (8/03)

Page 7

WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or

workmanship for a period of one year after the date of shipment. Exceptions to this warranty are

as noted below:

• Five years on Pelco manufactured cameras (CC3500/CC3600/CC3700 and MC3500/

MC3600 Series); two years on all other cameras.

• Three years on Genex® Series (multiplexers, server, and keyboard) and 090 Series

Camclosure® Camera System.

•Two years on 100/150, 200 and 300 Series Camclosure® Camera Systems.

•Two years on all standard motorized or fixed focal length lenses.

•Two years on Legacy®, CM6700/CM6800/CM8500/CM9500/CM9740/CM9760 Matrix, DF5

and DF8 Series Fixed Dome products.

•Two years on Spectra®, Esprit®, and PS20 Scanners, including when used in continuous

motion applications.

•Two years on Esprit and WW5700 series window wiper (excluding wiper blades).

• Eighteen months on DX Series digital video recorders.

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion

applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco

shipment. All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis,

California. Repairs made necessary by reason of misuse, alteration, normal wear, or accident

are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from the

specific use or application made of the Products. Pelco’s liability for any claim, whether based on

breach of contract, negligence, infringement of any rights of any party or product liability, relating

to the Products shall not exceed the price paid by the Dealer to Pelco for such Products. In no

event will Pelco be liable for any special, incidental or consequential damages (including loss of

use, loss of profit and claims of third parties) however caused, whether by the negligence of

Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have

additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or (559) 292-1981 to

obtain a Repair Authorization number (RA), and provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the warranty conditions

stated above, please include a written explanation with the product when returned.

Method of return shipment shall be the same or equal to the method by which the item was received by

Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at (800) 289-9100

or (559) 292-1981 to obtain an authorization number (CA number if returned for credit, and RA number if

returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA number and

freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico:

Intermediate Consignee Ultimate Consignee

American Overseas Air Freight Pelco

320 Beach Road 3500 Pelco Way

Burlingame, CA 94010 Clovis, CA 93612-5699

USA USA

REVISION HISTORY

Manual # Date Comments

C627M 8/92 Original version.

C627M-A 8/03 Removed a drawing and references to certain cameras. Removed material on cascading. Changed camera requirements to indicate camera 2 must be black and

® Pelco, the Pelco logo, Spectra, Genex, Legacy, Esprit, and Camclosure are registered trademarks of Pelco. © Copyright 2003, Pelco. All rights reserved.

C627M-A (8/03) 7

white only. Added figure illustrating camera 2 positioning. Reformatted the manual.

Page 8

®

World Headquarters

3500 Pelco Way

Clovis, California 93612 USA

USA & Canada

Tel: 800/289-9100

Fax: 800/289-9150

International

Tel: 1-559/292-1981

Fax: 1-559/348-1120

www.pelco.com

ISO9001

Orangeburg, New York Las Vegas, Nevada Eindhoven, The Netherlands Wokingham, United Kingdom Montreal, Canada

Loading...

Loading...