Page 1

SB3-1/SB3-2 and

SB2800 Series

Discreet Surveillance

Enclosures

Installation/

Operation Manual

C426M-F (2/98)

Pelco • 3500 W. Pontiac Way, Clovis • CA 93612-5699 USA • www.pelco.com

In North America and Canada: Tel (800) 289-9100 or FAX (800) 289-9150

International Customers: Tel (1-559) 292-1981 or FAX (1-559) 348-1120

PELCO Manual C426M-F (2/98)

21

Page 2

TABLE OF CONTENTS

Section Page

PART I - SB3-1/SB3-2 AND SB2800 SERIES ENCLOSURES

1–1.0 WARNINGS.....................................................................................................................................1

1–2.0 SCOPE ...........................................................................................................................................2

1–3.0 DESCRIPTION ................................................................................................................................ 2

1–4.0 INSTALLATION ...............................................................................................................................2

1–4.1 UNPACKING INSTRUCTIONS........................................................................................... 2

1–4.2 WIRING INSTRUCTIONS ..................................................................................................2

1–4.3 INSTALLATION INSTRUCTIONS ....................................................................................... 2

1–4.4 LIMIT/STOP ADJUSTMENTS ............................................................................................ 4

1–5.0 CARE AND MAINTENANCE .......................................................................................................... 4

1–6.0 MODELS .........................................................................................................................................4

1–6.1 OPTIONS ..............................................................................................................................5

1–6.2 RECOMMENDED CONTROLS ............................................................................................ 5

1–7.0 SPECIFICATIONS ........................................................................................................................... 6

1–8.0 EXPLODED ASSEMBLY DIAGRAM ............................................................................................... 7

1–9.0 MECHANICAL PARTS LIST............................................................................................................ 8

Pelco, the Pelco Logo, Camclosure, Esprit, Genex, Legacy, and Spectra are registered trademarks of Pelco. © Copyright 1998, Pelco. All rights reserved.

Endura and ExSite are trademarks of Pelco.

PELCO Manual C426M-F (2/98)22ii PELCO Manual C426M-F (2/98)

Page 3

PART II - MODEL PT2801000ASSY SERIES PAN/TILTS

Section Page

2–1.0 DESCRIPTION ................................................................................................................................ 9

2–2.0 INSTALLATION ...............................................................................................................................9

2–2.1 CONDUCTOR AND CABLE REQUIREMENTS ................................................................. 9

2–2.2 WIRING ..............................................................................................................................9

2–2.3 LIMIT/STOP ADJUSTMENTS .......................................................................................... 13

2–3.0 OPERATIONAL TEST ...................................................................................................................13

2–3.1 CONTROL ........................................................................................................................13

2–3.2 AUTO/RANDOM SCAN OPERATION ..............................................................................14

2–4.0 MAINTENANCE ............................................................................................................................14

2–4.1 RECOMMENDED EQUIPMENT AND TOOLS ................................................................ 14

2–4.2 SERVICE TIPS .................................................................................................................14

2–5.0 EXPLODED ASSEMBLY DIAGRAM (PARTS) .............................................................................. 15

2–6.0 EXPLODED ASSEMBLY DIAGRAM (HARDWARE) .....................................................................16

2–7.0 MECHANICAL PARTS LIST (PAN/TILT ASSY)............................................................................. 17

2–8.0 MECHANICAL HARDWARE LIST (PAN/TILT ASSY) ................................................................... 18

2–9.0 MODELS .......................................................................................................................................19

2–10.0 SPECIFICATIONS ......................................................................................................................... 19

2–11.0 WARRANTY AND RETURN ......................................................................................................... 20

LIST OF ILLUSTRATIONS

Figure Page

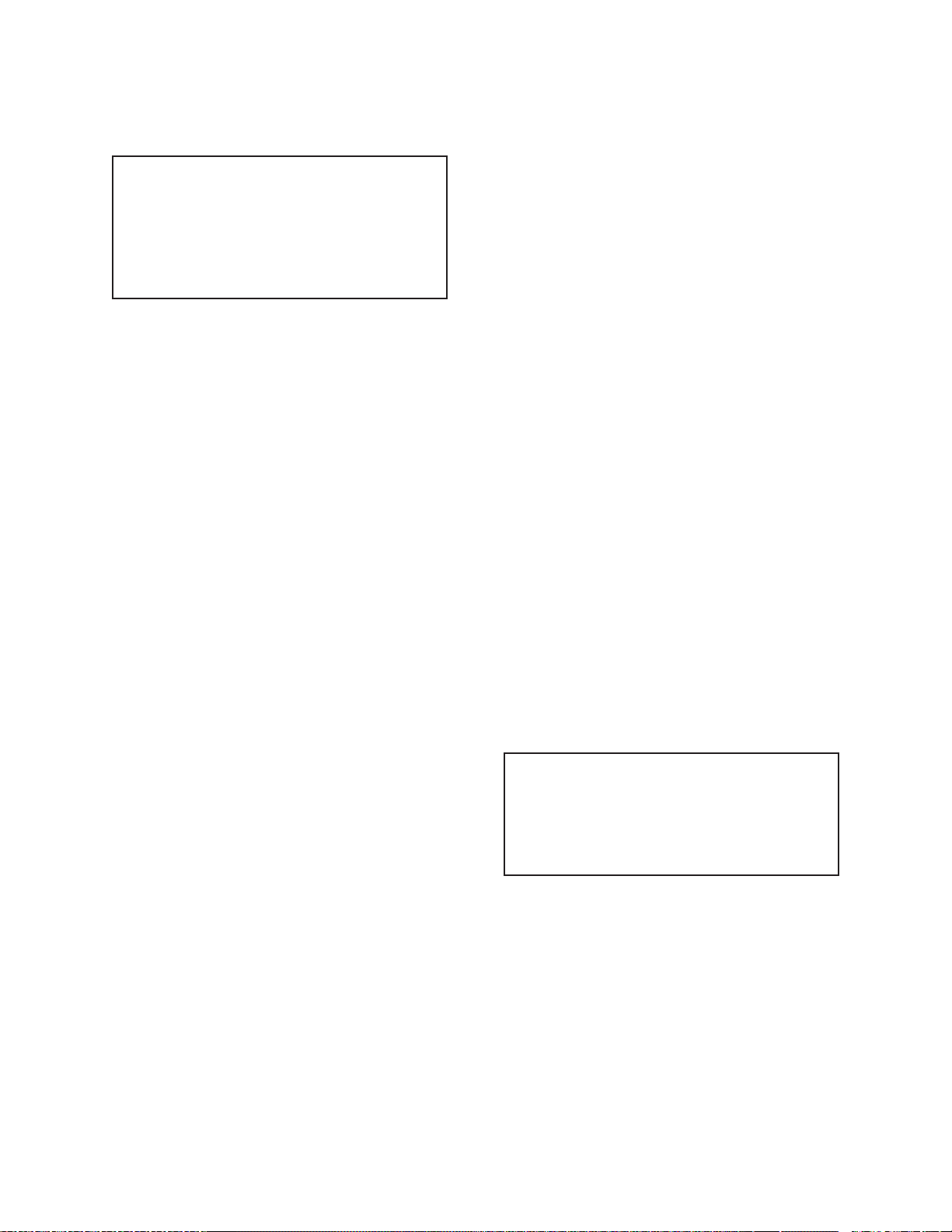

1-1 Inside View of Lower Dome............................................................................................................. 3

1-2 SB2800 System Installation ............................................................................................................3

1-3 SB3-1/SB3-2 Dimension Drawing ...................................................................................................6

1-4 SB2800 Exploded Diagram .............................................................................................................7

2-1 PT2801000ASSY/PT2801001ASSY Wiring Diagram ...................................................................10

2-2 PT2801002ASSY Wiring Diagram ................................................................................................ 11

2-3 PT2801003ASSY Wiring Diagram ................................................................................................ 12

2-4 Limit Stops .................................................................................................................................... 13

2-5 Pan/Tilt Exploded Assembly Parts Diagram.................................................................................. 15

2-6 Pan/Tilt Exploded Assembly Hardware Diagram...........................................................................16

PELCO Manual C426M-F (2/98)

PELCO Manual C426M-F (2/98) iii

23

Page 4

REVISION HISTORY

Manual # Date Comments

C426M 12/88 Original version.

C426M 7/90 Rev. A. Addendum added replacing various pages of the

manual.

C426M 11/90 Rev. B. Incorporated Rev. A addendum and updated

manual.

C426M 9/91 Rev. C. Added Electrical specifications and updated format.

C426M 8/92 Rev. D. Wiring Diagram Updated.

C426M 10/93 Rev. E. Updated to two column format; dropped turbosphere

nomenclature.

C426M-F 3/95 Incorporated ECO 94-141 regarding model inclusion of the

SB2801. Incorporated 24VAC warning label; updated wiring

diagrams per ECO 94-558 and exploded assemblies in

Part II of the manual. Updated entire manual to current

format.

8/96 Revised Section 1-9.0, Mechanical Parts List, regarding

part numbers for domes.

2/98 Revised Section 1-5.0, Care and Maintenance.

iv PELCO Manual C426M-F (2/98)

PELCO Manual C426M-F (2/98)24

Page 5

INSTALLATION/OPERATION MANUAL

MODEL SB3-1/SB3-2 ENCLOSURES

SB2800 SERIES ENCLOSURES

1-1.0 WARNINGS

CAUTION

This device is designed to operate at 24 volts AC

power. Input voltage must not exceed 28 volts or

drop below 22 volts or else damage to the motors

will occur. Should you need technical assistance,

please call (800)289-9100

Prior to installation and use of this product, the following

WARNINGS should be observed.

1. Installation and servicing should only be done by

Qualified Service Personnel and conform to all

Local codes.

2. Unless the unit is specifically marked as a NEMA

Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is

designed for indoor use only and it must not be

installed where exposed to rain and moisture.

3. The weight of the camera/lens and enclosure shall

not exceed 20 lbs. — subject to specific pan/tilt

unit.

The product bears the following marks:

This symbol indicates that dangerous voltage

constituting a risk of electric shock is present

within this unit.

4. Only use replacement parts recommended by

PELCO.

5. After replacement/repair of this unit’s electrical

components, conduct a resistance measurement

between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

6. The installation method and materials should be

capable of supporting four times the weight of the

enclosure, pan/tilt, camera and lens combination.

This symbol indicates that there are important

operating and maintenance instructions in the

literature accompanying this unit.

CAUTION:

TO REDUCE THE RISK OF ELECTRICAL

SHOCK, DO NOT REMOVE COVER. NO

USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

RISK OF ELECTRIC SHOCK.

CAUTION:

DO NOT OPEN.

Please thoroughly familiarize yourself with the information in this manual

prior to installation and operation.

PELCO Manual C426M-F (2/98)

1

Page 6

Part I – SB3-1/SB3-2 and

SB2800 Series Enclosures

PREFACE: There are two parts to this manual.

Part I covers the SB3-1, SB3-2, and SB2800 Series Dome Enclosures. Part II covers the

PT2801000 Series pan/tilt assemblies which are

used in the SB2800 Series Dome Enclosures.

Please refer to the applicable sections of this

manual when installing your system.

1–2.0 SCOPE

The information contained within this manual covers

the installation and operation of the SB3-1/SB3-2 and

SB2800 Series Discreet Surveillance Enclosures.

1–3.0 DESCRIPTION

1–4.0 INSTALLATION

1–4.1 UNPACKING INSTRUCTIONS

Save the shipping carton and plastic packing, in case

the unit has to be returned for credit or repair.

1–4.2 WIRING INSTRUCTIONS

SB2800 Series system packages include pan/tilt assemblies which are pre-wired for all control functions –

pan/tilt, motorized zoom lens, camera power (24VAC)

and video. All connections are made at the input connector, eliminating the need for wiring harnesses made

in the field. Wire the control cable per Section 2-2.0,

Part 2 and the referenced diagrams, or use factory assembled pretested cables C1906, C1906/PP, C1925, or

C9125/PP.

The SB3-1/SB3-2 and SB2800 series are low profile

discreet enclosures designed for ease of installation, relocation and service in standard 2' x 2' or 2' x 4' false

ceiling grids. Available with a black opaque or mirrored

lower dome, these domes combine concealed 355° surveillance (360° on SL models) with distortion-free viewing. The lower dome effectively conceals the camera

while providing an inconspicuous viewing window with

a light attenuation factor of one (1) f-stop for the black

opaque dome and 2 f-stop light loss for the mirrored

dome. There is, of course, no light attenuation factor

for the SB2801 clear dome.

The dome and camera assembly rotate at a speed of 10

degrees/second on a balanced roller system for complete 355°/360° surveillance coverage. The back box is

constructed of aluminum to meet fire code requirements

for installation in open plenum ceilings. The SB3-1/

SB3-2 and SB2800 will accept Pelco lenses up to 110

mm, increasing the flexibility of the system design and

application.

To simplify installation even further, Pelco offers system packages with factory installed standard components from its regular product line. This dramatically

reduces installation time and cost and assures the continued availability of replacement parts.

1–4.3 INSTALLATION INSTRUCTIONS

Your dome is supplied in two ways; as a passive dome

(SB3-1/SB3-2) for use as a dummy dome or with a fixed

camera (utilizing the CM3000 mount), or with a factory installed pan/tilt assembly (SB2800 series models). To install the dome or dome system, perform the

following steps (see Figure 1-2):

1. Handle the lower dome with care so as not to

scratch or get fingerprints on the viewing window.

2. Mount the back box directly into a 2' x 2' false

ceiling grid and make certain that the assembly sits

flat on the grid.

NOTE: When installing the enclosure in a 2' x 4'

ceiling, cut the ceiling tile in half and install an

additional “T” rail for support. If further support is

required, install an eyebolt in the plywood base of

the back box and run a guy wire to secure the surface.

3. Mount the camera/lens onto the optional fixed

mount (CM3000) or pan/tilt assembly with the

camera/lens centered on the tilt table. Hook up camera power, video and lens. Extend the lens to the

maximum focal length and operate the pan/tilt to

verify that there are no obstructions within the back

box.

PELCO Manual C426M-F (2/98)2

Page 7

4. Attach the safety chain to the lower dome and make

certain that the chain does not interfere with proper

seating of the drive tab. (See Figure 1-1.)

CAUTION: Dome will shatter if dropped. Always operate with safety chain attached Do not

rotate pan/tilt by hand. Rotate by controller only.

5. Install the lower dome with viewing slot to the right

of the camera/lens with the lens pointed towards

you. Insert the rim of the dome into two of the rollers. Align the drive tab with the slot in the drive

arm bracket. Press the dome against the rollers and

gently deflect the dome until you are able to insert

the rim into the final rollers. (See Figure 1-1.)

6. Operate pan/tilt to verify that there are no obstructions within the back box or dome.

Figure 1-1. Inside View of Lower Dome

PELCO Manual C426M-F (2/98)

Figure 1-2. SB2800 System Installation

3

Page 8

1–4.4 LIMIT/STOP ADJUSTMENTS

Refer to Section 2-2.3, Part 2 of this manual for limit

adjustments.

1–5.0 CARE AND MAINTENANCE

isopropyl alcohol diluted with water. Hold the dome

with its opening facing downward and wipe the

interior of the dome with the wet end of the wick.

Use a circular motion, starting from the outside

and spiraling into the center. Use a new wick for

each two passes over the dome.

Clean the acrylic lower dome as necessary to maintain

a clear picture. Be careful not to scratch the surfaces of

the dome.

Exterior Surface - Clean the dome's exterior surface

with a nonabrasive cleaning cloth and cleaning agent

that is safe for acrylic plastic. Either liquid or spray

cleaner/wax suitable for fine furniture is acceptable.

Interior Surface (Except Chrome) - Clean the same

as the exterior surface.

Interior Surface (Chrome) - The inside surface of a

chrome dome is easily scratched. Use the following precautions to maintain the dome's surface.

a. Always handle the dome from the outside of its

circular flange.

b. Never touch the coated inside surface. The acid in

your fingerprints will eventually etch the coating

if the fingerprints are not carefully removed according to the recommended cleaning procedure

in item “e.”

c. If dust or other contaminants accumulate on the

dome's interior, remove the debris with compressed

air. Compressed air cans are available from photographic equipment or electronic supply dealers.

d. If heavy residue accumulates and cannot be re-

moved with air pressure, rinse with water and immediately dry with air pressure so that water spots

will not remain. Avoid wiping the coated surface

with direct hand pressure - it will easily abrade unless extreme care is taken. Once scratched, the

dome cannot be recoated.

e. If internal wiping is necessary, avoid hand rubbing.

Instead, make a wick as follows:

1–6.0 MODELS

SB3-1 Drop Ceiling Discreet Surveillance

Enclosure with black opaque lower

dome, all aluminum back box which

mounts above the ceiling. (Camera

mount not supplied. Use CM3000

mount.)

SB3-2 Same as SB3-1, except supplied with

mirrored lower dome, 2 f-stop light

loss.

SB2800 This system package includes the

black opaque dome enclosure plus

the PT2801000ASSY pan/tilt assembly, factory assembled inside the

back box

SB2801 Same as SB2800 except supplied

with clear dome slot

SB2800/PP Same as SB2800 except supplied

with preset position feedback pan/tilt

assembly PT2801002ASSY

SB2800-2 Same as SB2800 except supplied

with mirrored lower dome, 2 f-stop

light loss.

SB2800-SL Same as SB2800 except this pack-

age includes the PT2801002ASSY

with 360° horizontal pan movement.

SB2800-SL/PP Same as SB2800-SL except supplied

with PT2801003ASSY pan/tilt assembly with 360° horizontal pan

movement and preset position feedback.

Use a very soft paper towel. Roll a section into a

tightly wound tube. Tear the tube in half, and wet

the fuzzy end of the wick with a solution of

SB2800SL-2 Same as SB2800-SL except supplied

with mirrored lower dome, 2 f-stoplight loss.

PELCO Manual C426M-F (2/98)4

Page 9

1–6.1 OPTIONS

1–6.2 RECOMMENDED CONTROLS

C1906 Factory assembled, pretested 6 foot

cable for use between Coaxitron receivers and inverted pan/tilt assemblies (SB2800, SB2801, SB2800-2,

SB2800-SL, SB2800SL-2)

C1906/PP Same as C1906 except for use with

preset (PP) pan/tilt assemblies

(SB2800/PP, SB2800-SL/PP)

C1925 Factory assembled, pretested 25 foot

cable for use between Coaxitron receivers and inverted pan/tilt assemblies (SB2800, SB2801, SB2800-2,

SB2800-SL, SB2800SL-2)

C1925/PP Same as C1925 except for use with

PP pan/tilts.

CM3000 Fixed camera mount for use with

SB3-1 or SB3-2 enclosure.

SB3KIT Hardware kit to field retrofit SB3-1

or SB3-2 domes with the following

assemblies: PT2801000ASSY

PT2801001ASSY

PT2801002ASSY

PT2801003ASSY

The following controls are recommended for use with

the TurboSphere System:

Coaxitron System 2000

A9000 Auto/Random Scan module for

CX9024RX receivers (plug-in module)

CM7500 Series/

CM9500 Series

Coaxitron Matrix, System 7500 or

System 9500, for use with SB2800/

PP and SB2800-SL/PP enclosures.

CX900TLC System test and receiver manual con-

trol board for CX9024RX receivers

(plug-in module)

CX9024RX Coaxitron receiver in weatherproof

box for 24 VAC pan/tilts with power

supply for pan/tilt, zoom lens, and 24

VAC camera power.

MPT9000CZ Transmitter/control with pan/tilt joy

stick, zoom lens, and 4 accessory

function controls. Desk top model.

Hardwire Short-Distance Controls for

24 VAC Pan/Tilts

PELCO Manual C426M-F (2/98)

MEH24DT Desk top enclosure control module

for 24 VAC camera on/off

MLZ6DT Desk top zoom lens control module

with auto/manual iris control

MPT24DT Desk top joystick control module for

24 VAC pan/tilts

MPTA24DT Same as MPT24DT except equipped

with Auto/Random Scan operation

5

Page 10

1–7.0 SPECIFICATIONS

The following specifications apply to the dome only.

For detailed information on pan/tilt, refer to Section 2-

10.0, Specifications.

MECHANICAL

Dome Drive: Dome rides on rollers and is

driven by drive arm of pan/tilt

Max. Camera/Lens

Length: 16.0 inches (40.64 cm)

GENERAL

.

Dimensions: See Figure 1-3

Ambient Temperature

Range: 35° to 120°F (1.6° to 48.8°C)

Weight:

SB3-1/SB3-2 9 lbs (4.05 kg)

SB2800, SB2801

SB2800/PP 19 lbs (8.55 kg)

SB2800-SL,

SB2800-SL/PP 20 lbs 8 oz (9.36 kg)

Construction:

Back Box Aluminum

Faceplate White

Lower Dome Acrylic hemisphere with distor-

tion free viewing window with

light attenuation factor of 1 fstop (SB3-1) or 2 f-stop (SB3-2);

rotates with pan and tilt/camera/

lens

Shipping Weight:

SB3-1/SB3-2 17 lbs (7.65 kg)

SB2800, SB2801

SB2800/PP 27 lbs 10 oz (12.20 kg)

SB2800-SL,

SB2800-SL/PP 28 lbs 8 oz (12.96 kg)

Figure 1-3. SB3-1/SB3-2 Dimension Drawing

PELCO Manual C426M-F (2/98)6

Page 11

1–8.0 EXPLODED ASSEMBLY DIAGRAM

PELCO Manual C426M-F (2/98)

Figure 1-4. SB2800 Exploded Diagram

7

Page 12

1-9.0 MECHANICAL PARTS LIST

The following parts list corresponds to the exploded diagram in Figure 1-4 of this manual.

Item No. Quantity Description Part Number

1 1 Bracket PM200C4000COMP

2 — Not Used —

3 1 Pan/Tilt Assembly

0-355° pan rotation (SB2800) PT2801000ASSY

0-360° pan rotation (SB2800-SL) PT2801001ASSY

0-355° pan rotation w/presets (SB2800/PP) PT2801002ASSY

0-360° pan rotation w/presets (SB2800-SL/PP) PT2801003ASSY

4 1 Steel chain SB2511000

5 8 Bushing SB310005

6 4 O-Ring SB310006

7 4 Spacer SB310007

8 — Not Used —

9 1 Dome drive bracket SB34105COMP

10 1 Dome drive tab SB34006COMP

11 — Not used

12 1 Black opaque dome with smoked viewing area SB32009COMP*

1 Black opaque dome with clear viewing area SB282006COMP*

1 Chrome finish SB32007*

13 4 Roller, Delrin, black SB34020COMP

14 1 Back box assembly SB3BB1000

15 1 Plate top, aluminum SB3BB4001ACOMP

16 8 NP sleeving, PVC (not shown) SLV16105N

17 — Not Used —

18 2 Nut, hex 1/4-20 cad ZH1/4-20NUTCH

19 3 Bolt 1/4-20 x 5/8" hex cad ZH1/420X.625CH

20 7 Washer, split lock 1/4" SS ZH1/4LWSSL

21 4 Washer, flat #4 ZH115X209X32C

22 1 Lug ground (not shown) ZH1416-6

23 — Not used

24 4 Nut, hex 4-40 SS ZH4-40NUTSCH

25 — Not used

26 1 Screw, 4-40 x 1/4" Pan Phil, SS ZH4-40X.250SPP

27 1 Screw, 4-40 x 3/8" Pan Phil, Blk ZH4-40X.375BPP

28 4 Screw, 4-40 x 3/4" Pan Phil, SS ZH4-40X.750SPP

29 2 Screw, 4 x 1/2" self tapping, Phil CAD ZH4-SAX.500CPP

30 6 Washer, internal star #4, SS (not shown) ZH4LWSIS

31 4 Screw, 8-32 Pan Phil, Blk ZH8-32X.375BPP

32 1 Snap body for chain assembly (not shown) SB2511001

* Part number is for dome only. To order a complete dome assembly, specify the part numbers

SB34009COMP (smoked), SB284006COMP (clear), and SB34007COMP (chrome). These part

number include items 4, 10, 12, and 32.

Note: Refer to Section 2-7.0, Part 2, for the exploded assembly drawing and parts list for the pan/tilt assembly.

PELCO Manual C426M-F (2/98)8

Page 13

Part II

Pan/Tilt Assemblies

2–1.0 DESCRIPTION

Lens Functions:

22 Awg 600 ft (182.88 m)

20 Awg 1,000 ft (304.80 m)

18 Awg 1,500 ft (457.20 m)

The pan/tilt assembly is a “mini” light duty pan/tilt for

loads up to 15 lbs and is factory pre-wired for all control functions (pan and tilt, motorized zoom lens, camera power (24 VAC), and video). All connections are

made at the input connector, eliminating the need for

wiring harnesses. This greatly reduces installation time,

while increasing reliability and serviceability.

2–2.0 INSTALLATION

In order to insure proper wiring and system operation

of all components, it is highly recommended that the

pan/tilt and the associated control equipment be tested

in your facility before field installation is attempted.

Wire the control cable in accordance with Figures 2-1

through 2-3.

2-2.1 CONDUCTOR AND CABLE

REQUIREMENTS

Conductors

The following are the conductor requirements:

SB2800/SB2801/

SB2800-SL Pan/Tilt (5 plus ground),

Lens (4), Camera AC (2)

SB2800/PP Pan/Tilt (9 plus ground),

Lens (8), Camera AC (2)

SB2800-SL/PP Pan/Tilt (10 plus ground,

Lens (8), Camera AC (2)

Cable Distances – Hard Wire Controls

The following cables distances are for hard wire controls:

Pan/Tilt Functions:

5 Conductors 6 Conductors*

Camera Power

2 Conductors (24 VAC)

Consult the camera manufacturer or factory for transformer power distances.

Cable Distances – Coaxitron

The following cable distances are for Coaxitron controls:

Up to a maximum of 750 feet on a single coax (RG59/

U) from the receiver to the transmitter.

NOTE: To extend the distance to 3,000 feet on

RG59/U coax, use the Pelco EA2000 Half Duplex

Equalizing Amplifier.

2–2.2 WIRING

Cable distances should not exceed the distances specified in Section 2-2.1, Conductor and Cable Requirements. The following are some recommended common

installation practices.

1. Always use jacketed stranded multi-conductor interconnecting cable between the control and the

pan/tilt unit, with additional conductors than

needed for future servicing and or additions.

2. Always use color-coded conductors for ease of

wiring and to identify functions at a later date.

3. Keep a wiring diagram with the system for later

use and reference.

When the pan/tilt assembly is mounted in the inverted

position, the LEFT/RIGHT and UP/DOWN functions

are reversed during operation. To correct this problem,

reverse the LEFT/RIGHT functions in the control cable

(pins 3 and 7) at the pan/tilt or control and the UP/

DOWN functions (pins 5 and 6) at the pan/tilt or control.

20 Awg 110 ft (33.53 m) 210 ft (64.01 m)

18 Awg 180 ft (54.86 m) 330 ft (100.58 m)

16 Awg 290 ft (88.39 m) 530 ft (161.54 m)

*Using 2 conductor motor common

PELCO Manual C426M-F (2/98)

NOTE: If you have purchased the C1906, C1906/

PP, C1925 or C1925/PP factory pre-wired cables,

correction for reversal of these functions has already been made in the cable. You do not need to

reverse the pins for inverted mounting if you use

the above mentioned cables with your pan/tilt.

9

Page 14

Figure 2-1. PT2801000ASSY/PT2801001ASSY Wiring Diagram

PELCO Manual C426M-F (2/98)10

Page 15

Figure 2-2. PT2801002ASSY Wiring Diagram

PELCO Manual C426M-F (2/98)

11

Page 16

Figure 2-3. PT2801003ASSY Wiring Diagram

PELCO Manual C426M-F (2/98)12

Page 17

2-2.3 LIMIT/STOP ADJUSTMENTS

WARNING: Do not operate pan/tilt without limit

stops. Do not remove or reposition fixed limit stop

on the PT 2801000ASSY or PT2801002ASSY.

DAMAGE WILL OCCUR.

NOTE: The PT2801001ASSY and PT2801003ASSY

are not equipped with pan limit stops. (Disregard

steps 1-5 below).

6. Remove the cover plate from the left side of the

tilt table. Loosen the limit stop screws and tilt the

table, using the joystick, to the desired "up” position.

7. Move the “up” limit stop until it touches the tilt

limit switch actuator and “clicks”. Lock the stop

in place.

8. Tilt the table to the desired “down” position and

set the stop in the same manner.

To set limit stops, perform the following steps

(refer to Figure 2-4).

1. Loosen the pan limit stops.

2. Turn the control unit on. Pan the unit to the right

until the desired right pan limit is reached.

3. Move the right pan limit stop until it touches the

pan limit switch actuator. Move the stop a slight

distance further against the actuator until it “clicks”,

indicating opening of the limit switch. Lock the

stop in place.

4. Pan the unit to the desired “left” position. Adjust

the left pan limit stop as described in Step 3.

5. Pan left and right to both limit stops and check for

exact positioning. Tighten both stops securely.

9. Tilt the table up and down and check for exact positioning. Tighten both stops securely. Replace the

cover plate.

After the unit has been tested and stops aligned, turn

off the control and disconnect the AC cord from the

outlet. Remove the multiconductor cable from both the

pan/tilt and control unit. This cable can then be used

for installation by cutting the test cable and splicing

the ends onto the installation cable at the job site. Splice

the ends, color-to-color, onto the cable in the field, using the terminal blocks at each end.

NOTE: When wiring a system it is recommended

that the multiconductor cable have extra conductors for future use.

2–3.0 OPERATIONAL TEST

2–3.1 CONTROL

Connect the cable assembly between the pan/tilt and

the control unit. Plug the control unit into a 120 VAC

outlet and switch the unit on.

Figure 2-4 Limit Stops

PELCO Manual C426M-F (2/98)

Move the joystick to the UP position. Observing the

“Front” label on the pan/tilt, the front of the tilt table

should move up. Move the joystick to the DOWN position, and the front of the tilt table should move down.

Releasing the joystick should allow it to return to center and the tilt table should immediately stop moving.

Move the joystick to the LEFT position and the complete top assembly should rotate counterclockwise.

With the joystick moved to the RIGHT position, the

unit will rotate clockwise.

Both the pan and tilt motors are protected from mechanical over-travel by electrical limits which stop the

motors.

13

Page 18

2–3.2 AUTO/RANDOM SCAN OPERATION

2–4.2 SERVICE TIPS

The PT2801000 will function in the Auto/Random

mode with the addition of the appropriate Pelco control system. The PT2801000 has no additional limit

switches or relays for auto scan operation and is, therefore, only compatible with current sensing auto/random

type circuits employed in our control systems.

2–4.0 MAINTENANCE

2–4.1 RECOMMENDED EQUIPMENT

AND TOOLS

1. Voltmeter or Ohmmeter

2. Allen Wrench Set

3. Wrench Set

4. Screw Driver, Flat Blade, Phillips Head

5. Pliers, Long Nose

Some common problems encountered with pan/tilt systems include mis-wiring, overloading, and not using

the units for the correct application. Should a failure

occur, it is recommended that the following procedures

be used.

1. If the pan/tilt ceases to operate, turn the control

unit off and remove the AC cord from the outlet.

2. Check the fuse in the control unit using either a

voltmeter or ohmmeter. If open (blown), replace

with the proper recommended fuse.

3. Replace the AC cord in the outlet and turn the control on. If the fuse continues to open (blow), turn

the unit off.

4. Check the control cable between the control unit

and pan/tilt for shorts, high resistance, or opens.

5. If the control cable is found to be good, replace the

connector to the control unit, leave the connector

off the pan/tilt, and replace the fuse.

6. Operate the control unit when it is disconnected

from the pan/tilt. If the fuse continues to “blow”

the fault is in the control. Refer to the appropriate

service manual for the control being used.

7. Check the wiring harness in the pan/tilt for shorts.

8. If the wiring harness is found to be good, then the

problem is internal to the unit; consult factory.

PELCO Manual C426M-F (2/98)14

Page 19

2–5.0 EXPLODED ASSEMBLY DIAGRAM (PARTS)

Figure 2-5. Pan/Tilt Exploded Assembly Parts Diagram

PELCO Manual C426M-F (2/98)

15

Page 20

2–6.0 EXPLODED ASSEMBLY DIAGRAM (HARDWARE)

Figure 2-6. Pan/Tilt Exploded Assembly Hardware Diagram

PELCO Manual C426M-F (2/98)16

Page 21

2-7.0 MECHANICAL PARTS LIST (Pan/Tilt ASSY)

The following parts list corresponds to the exploded assembly diagram in Figure 2-5.

Item Qty Description Part Number

1 4 Ring Snap #Q2-18 15510000

2 Ring Snap #Q2-18 (SL) 15510000

2 1 Pin, Pan Limit (Non-SL) 1554049COMP

1 Pin, Pan Limit (P/PP Only) 2804003COMP

3 1 Pin, Tilt Limit 1554049TCOMP

4 2 Tilt Limit Stop 1554050COMP

5 1 Bracket, Tilt Limit 1554052COMP

6 2 Cover Plate Tilt 1554053COMP

7 1 Pin, #1 X 1-1/4 Taper 17510000

8 1 Nut Spindle 25010002

9 1 Clamp Cable (SL Only) 2504007COMP

10 1 Spacer Tilt Collar 2504015COMP

11 2 Bearing Pan Spindle 2506000

12 2 Bearing Tilt FB68-31/4 2506001

13 1 Tilt Shaft Assembly 2701002COMP

14 1 Chain Assembly Pan 2701003COMP

15 1 Chain Assembly Tilt 2701004COMP

16 1 Sprocket, 25B20-3/8 W/SS 27012008

17 1 Tilt Table 2704003COMP

18 1 Cover 2704004COMP

19 1 Bracket, Pan Tilt Motor, Black 2704006COMP

20 1 Sprocket Motor 2704010COMP

21 1 Bracket, Pan Limit (Non-SL Only) 2704051COMP

22 1 Plate Bottom 2704100COMP

23 1 Side plate, Pan 270412COMP

24 1 Spindle 274105COMP

25 1 Sprocket, 25B15-3/8 28012010

1 Sprocket, 25B13-3/8 (not shown) 28012011

26 1 Motor, Pan 2-RPM, 24 VAC 2804001COMP

27 1 Plate Side Tilt (Non PP) 2804002COMP

1 Plate Side Tilt (PP) 2804102COMP

28 1 Bracket Pan Motor 2804012COMP

29 1 Spacer Pan Motor 2804013COMP

30 1 Sprocket Pan Spindle 2804019COMP

31 3 Limit Stop, Pan 5804006COMP

32 1 Connector. 6-Position, (SL and P Only) CONMAB6100

33 2 Grommet, Neoprene GRO2172N

1 Grommet, Neoprene (SL) GRO2172N

34 1 Motor, 24 VAC, 1-RPM PS78001

35 1 Spacer, 5/16 Dia X 1.25 #10 Clear SPA8548

36 4 Switch, Micro SWI1SM1

2 Switch, Micro (SL) SWI1SM1

37 4 Switch Actuator W/Insulator SWIJS138B

2 Switch Actuator W/Insulator (SL) SWIJS138B

38 1 Terminal Strip 7-pin (Non-PP) TRS2007

1 Terminal Strip 9-pin (PP Only) TRS2009

39 1 UL, Gland SL-9 EH400010003

40 1 UL, Nut for EH400010003 EH400010004

41 1 Bracket, PM200C M200C4000COMP

42 1 Bracket Slip Ring (SL/PP) SL28004101COMP

1 Bracket Slip Ring (P/PP) SL28004001COMP

43 1 Cover, Slip Ring SL28004100COMP

44 1 Ring, Slip for Preset (SL/PP) 250010000

1 Ring Slip 24-inch Leads (SL) 28010000

PELCO Manual C426M-F (2/98)

17

Page 22

2-7.0 MECHANICAL PARTS LIST (PAN/TILT ASSY) CONT.

Item Qty Description Part Number

45 1 Gear, SP Delrin (SL/PP) 280010016

1 Gear, 1.875 Plastic (P/PP) PT250010002

46 1 Gear, SP Delrin 28010017

47 1 Bracket, Pot Pan (P/PP) 2804014COMP

1 Bracket, Pot Pan (SL/PP) 2804117COMP

48 1 Bracket, Pot Pan 2804015COMP

49 1 Gear, Preset Pan Spindle 2804016COMP

50 1 Gear, Preset Tilt Shaft 2804020COMP

51 1 Connector, 28-position, (PP Only) 5804130COMP

52 1 Pot, Dual Arm Pre Res (SL/PP) POTDARM010.0K

1 Pot Precision, 10K (P/PP) POT010.0K

53 1 Gear, 1.875 Plastic (P/PP) POT10.0K

2-8.0 MECHANICAL HARDWARE LIST (PAN/TILT ASSY)

The following parts list corresponds to the exploded assembly diagram in Figure 2-6.

Item Qty Description Part Number

A 4 Bolt, 1/4-20 X 5/8, Phil Flat SS ZH1/420X.625SFS

B 3 Screw, 1/4-20 X 5/8, Hex C/S SS (SL Only) ZH1/420X.625CH

C 3 Washer, Split Lock Medium (SL Only) ZH1/4LWSSL

D 1 Screw, 10-32 X 3/8, Pan Phil SS (SL Only) ZH10-32X.375SPP

E 2 Screw, 10-32 X 7/16, Socket Head C/S SS ZH10-32X.437CS

F 6 Screw, 10-32 X 1/2, Socket Head C/S SS ZH10-32X.500CS

G 1 #10 Internal Tooth Lock washer (SL Only) ZH10LWSIS

H 8 Washer, Split Lock #10 SS Medium ZH10LWSSL

I 8 Washer, Flat #10 SS ZH204X436X60C

J 8 Screw, 2-56 X 4/16, Pan Phil SS ZH2-56X.437SPP

4 Screw, 2-56 X 4/16, Pan Phil SS (SL) ZH2-56X.437SPP

K 1 Set Screw, 10/32 X 1/8, Socket Knurl Blk ZH10-32X.187S

L 1 Set Screw, 10/32 X 3/16, Socket Knurl Blk ZH3/8-24X.375SS

M 6 Screw, 4-40 X 1/4, Pan Phil SS ZH4-40X.250SPP

N 4 Screw, 4-40 X 3/8, Pan Phil (PP Only) ZH4-40X.375SPP

O 1 Screw, 4-40 X 5/8, Pan Phil SS ZH4-40X.625SPP

P 6 #4 Internal Tooth Lock washer SS ZH4LWSIS

Q 2 Set Screw, 6-32 X 3/16, Socket Knurl Blk ZH6-32X.187S

R 4 Screw, 6-32 X 1/4, Pan Phil SS ZH6-32X.250SPP

S 4 Screw, 6-32 X 3/8, Socket C/S SS ZH6-32X.375CS

T 2 Screw, 6-32 X 3/8, Pan Phil SS ZH6-32X.375SPP

U 3 Screw, 6-32 X 1/2, Socket C/S ZH6-32X.500CS

V 4 Set Screw, 6-32 X 3/4, SS ZH6-32X.750SS

W 2 Screw, 6-32 X 2, Pan Phil SS ZH6-32X2.00SPS

X 4 Nut, 6-32, Acorn SS ZH6-32NUTCA

Y 4 Nut, Hex, 6-32, SS ZH6-32NUTSH

Z 7 #6 Internal Tooth Lock washer (PP Only) ZH6LWSIS

3 #6 Internal Tooth Lock washer (P Only) ZH6LWSIS

AA 3 Washer, Split Lock, #6 SS Med ZH6LWSSL

BB 6 Screw, 8-32 X 3/8, Pan Phil SS (SL Only) ZH8-32X.375SPP

3 Screw, 8-32 X 3/8, Pan Phil SS (P Only) ZH8-32X.375SPP

CC 1 Screw, 8-32 X 5/8, Pan Phil SS ZH8-32X.375SPP

DD 7 Washer, Internal Star (SL Only) ZH8LWSIS

4 Washer, Internal Star (P Only) ZH8LWSIS

EE 1 Pin Roll, 3/32 X 1/2 ZHPIN3/32X1/2R

FF 1 Pin Roll, 3/32 X 1/2 ZHPIN3/32X3/4R

GG 1 Pin Dowel, 1/8 X 5/8, Harden Steel 1510001

PELCO Manual C426M-F (2/98)18

Page 23

2–9.0 MODELS

ELECTRICAL

PT2801000ASSY Mini light duty pan/tilt, 0-355o pan

rotation, 24 VAC

PT2801001ASSY Mini light duty pan/tilt with 360°

pan rotation, 24 VAC

PT2801002ASSY Same as PT2801000ASSY except

with position feedback modification which allows pan/tilt to be

automatically positioned to various preset positions

PT2801003ASSY Same as PT2801001ASSY except

with position feedback modification which allows pan/tilt to be

automatically positioned to various preset positions

2–10.0 SPECIFICATIONS

MECHANICAL

Pan: Movement in horizontal plane (at

10°/sec ±1°):

Input Voltage: 24 VAC required for pan/tilt

Maximum

Current: 2 amps per conductor (SL models

only)

Power Requirements:

Running:

Pan .31 amp (7.5 vA)

Tilt .38 amp (9.2 vA)

Starting:

Pan .47 amp (11.2 vA)

Tilt .56 amp (13.5 vA)

Connectors:

Pan/Tilt Amp CPC type (mate supplied), in-

stalled onto a pigtail exiting from

the base of the unit (all functions

— camera power, lens, video pan/

tilt)

Lens Hirschmann MAB6100

Video BNC

PT2801000ASSY

PT2801002ASSY—0-355°

PT2801001ASSY

PT2801003ASSY—0-360° circle

Tilt: ±90° movement in vertical plane

at 3°/sec ±.5° (no load condition)

Maximum Load: 15 lbs (6.8 kg)

(Product specifications subject to change

without notice.)

This equipment contains electrical or electronic components that must be recycled properly to comply with Directive 2002/96/EC of the European Union

regarding the disposal of waste electrical and electronic equipment (WEEE). Contact your local dealer for procedures for recycling this equipment.

Camera Power: Spade lugs

Motors: Two-phase induction type, con-

tinuous duty, instantaneous reversing

Limit Switches:

Pan 5 amp,

Tilt 5 amp,

External adjustment

GENERAL

Construction:

Pan/Tilt Aluminum

PELCO Manual C426M-F (2/98)

19

Page 24

2-11.0 WARRANTY AND RETURN

INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved

defective in material or workmanship for a period of one year after the date

of shipment.

Exceptions to this warranty are as noted below:

• Five years on FT/FR8000 Series fiber optic products.

• Three years on Genex

keyboard).

• Three years on Camclosure

CC3701H-2, CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2,

and MC3651H-2X camera models, which have a five-year warranty.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy®, CM6700/CM6800/CM9700 Series matrix, and

DF5/DF8 Series fixed dome products.

• Two years on Spectra

ing when used in continuous motion applications.

• Two years on Esprit

wiper blades).

• Eighteen months on DX Series digital video recorders, NVR300

Series network video recorders, and Endura

network-based video products.

• One year (except video heads) on video cassette recorders (VCRs).

Video heads will be covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in

continuous motion applications (that is, preset scan, tour and auto scan

modes).

Pelco will warrant all replacement parts and repairs for 90 days from the

date of Pelco shipment. All goods requiring warranty repair shall be sent

freight prepaid to Pelco, Clovis, California. Repairs made necessary by

reason of misuse, alteration, normal wear, or accident are not covered

under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or

loss resulting from the specific use or application made of the Products.

Pelco’s liability for any claim, whether based on breach of contract,

negligence, infringement of any rights of any party or product liability,

relating to the Products shall not exceed the price paid by the Dealer to

Pelco for such Products. In no event will Pelco be liable for any special,

incidental or consequential damages (including loss of use, loss of profit

and claims of third parties) however caused, whether by the negligence

of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The

Dealer may also have additional rights, which are subject to variation from

state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800)

289-9100 or (559) 292-1981 to obtain a Repair Authorization number

(RA), and provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice

number

3. Details of the defect or problem If there is a dispute regarding the

warranty of a product which does not fall under the warranty conditions

stated above, please include a written explanation with the product

when returned.

Method of return shipment shall be the same or equal to the method by

which the item was received by Pelco.

®

Series products (multiplexers, server, and

®

and fixed camera models, except the

®

, Esprit®, ExSite™, and PS20 scanners, includ-

®

and WW5700 Series window wiper (excluding

™

Series distributed

RETURNS

In order to expedite parts returned to the factory for repair or credit, please

call the factory at (800) 289-9100 or (559) 292-1981 to obtain an

authorization number (CA number if returned for credit, and RA number

if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking

and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the

assigned CA or RA number and freight should be prepaid. Ship to the

appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto

Rico, send goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto

Rico and are instructed to return goods to the USA, you may do one of the

following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

If the goods are to be sent by a FREIGHT FORWARDER, send the goods

to:

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

PELCO Manual C426M-F (2/98)20

Loading...

Loading...