Page 1

®

SB26/SB2600

Discreet

Surveillance

Domes

Installation/

Operation Manual

C1402M-B (2/98)

Pelco • 3500 Pelco Way, Clovis • CA 93612-5699 USA • www.pelco.com

In North America and Canada: Tel (800) 289-9100 or FAX (800) 289-9150

International Customers: Tel (1-559) 292-1981 or FAX (1-559) 348-1120

Page 2

CONTENTS

Section Page

1.0 GENERAL .................................................................................................. 5

1.1 IMPORTANT SAFEGUARDS AND WARNINGS ............................... 5

2.0 DESCRIPTION ..........................................................................................6

2.1 Models ................................................................................................ 7

3.0 INSTALLATION .......................................................................................... 8

3.1 CONDUCTOR AND CABLE REQUIREMENTS (ALL MODELS

EXCEPT SB26) .................................................................................8

3.2 WIRING INSTRUCTIONS ..................................................................8

3.3 MOUNTING INSTRUCTIONS ..........................................................13

3.3.1 Fixed Ceiling Mounting ..........................................................13

3.3.2 Dropped Ceiling, Tile Replacement Mounting ....................... 14

3.3.3 Camera/Lens Installation ....................................................... 15

3.4 CONNECTOR ASSEMBLY ............................................................... 16

3.5 J-BOX INSTALLATION ...................................................................... 17

3.6 ADJUSTMENTS ............................................................................... 19

4.0 MAINTENANCE ........................................................................................20

5.0 EXPLODED ASSEMBLY DIAGRAMS ...................................................... 21

6.0 SPECIFICATIONS .................................................................................... 29

7.0 WARRANTY AND RETURN INFORMATION ...........................................32

2 Pelco Manual C1402M-B (2/98)

Page 3

LIST OF ILLUSTRATIONS

Figure Page

1 SB2600 Wiring Diagram ....................................................................9

2 SB2600-SL Wiring Diagram .............................................................. 10

3 SB2600SL-PP Wiring Diagram ......................................................... 11

4 SB2600-PP Wiring Diagram .............................................................12

5 Fixed Ceiling Mounting .....................................................................13

6 Dropped Ceiling Mounting with Optional Mounting Kit ..................... 14

7“T-Bar” Clip Installation ......................................................................14

8 Attaching Camera/Lens to Tilt Table ................................................. 15

9 Attaching Dome to Drive Unit ............................................................ 15

10 Connector Assembly .........................................................................16

11 Attachment of J-Box to Back Box for Plenum Applications ...............18

12 Limit Stop Locations .........................................................................19

13 SB26 Exploded Assembly Diagram ..................................................21

14 SB2600 Series Pan/Tilt Exploded Assembly Diagram ......................22

15 SB2600 Hardware Exploded Assembly Diagram ............................. 25

16 SB26 Fixed Series Exploded Assembly Diagram .............................27

17 SB2600 Dimension Drawing ............................................................. 30

LIST OF TABLES

Table Page

A SB26 Exploded Assembly Parts List ................................................. 21

B SB2600 Series Pan/Tilt Exploded Assembly Parts List .................... 23

C SB2600 Hardware Exploded Assembly Parts List ............................26

D SB26 Fixed Series Exploded Assembly Mechanical Parts List ........ 28

E SB26 Fixed Series Exploded Assembly Associated Hardware

Parts List ...........................................................................................28

REVISION HISTORY

Manual # Date Comments

C1402M 9/94 Original Manual.

C1402M-A 9/95 Rev. A. Revised Section 4.4, Connector Assembly and

C1402M-B 8/96 Rev. B. Revised hardware configuration for SB2600

10/97 Changed manual to new format.

2/98 Revised Section 4.0, Maintenance. Changed manual

updated item no. 30, 45 and 46 on the SB2600 Series

mechanical parts list.

pan/tilt, changing spindle design. In addition, part No.

changed on items No. 6 and 29 on the SB2600 Series

mechanical parts list (Figure 15). Revised Sections 7.0

and 8.1, Mechanical Parts Lists, regarding dome part

numbers. Revised Sections 7.0 and 8.1, Mechanical

Parts Lists, regarding dome part numbers.

pagination.

Pelco Manual C1402M-B (2/98) 3

Page 4

(This page intentionally left blank.)

4 Pelco Manual C1402M-B (2/98)

Page 5

1.0 GENERAL

1.1 IMPORTANT SAFEGUARDS AND WARNINGS

CAUTION:

This device

is designed to operate at

24 volts AC power. Input

voltage must not exceed

28 volts or drop below 22

volts or else

DAMAGE TO

THE MOTORS WILL

OCCUR.

Should you

need technical assistance, please call (800)

289-9100.

Prior to installation and use of this product, the following WARNINGS should be

observed.

1. Installation and servicing should only be done by Qualified Service Personnel

and conform to all Local codes.

2. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or

6P enclosure, it is designed for indoor use only and it must not be installed

where exposed to rain and moisture.

3. Only use replacement parts recommended by Pelco.

4. After replacement/repair of this unit’s electrical components, conduct a resistance measurement between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

5. The installation method and materials should be capable of supporting four

times the weight of the enclosure, pan/tilt, camera and lens combination.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage constituting a

risk of electric shock is present within this unit.

This symbol indicates that there are important operating and

maintenance instructions in the literature accompanying this

unit.

CAUTION:

RISK OF

ELECTRIC SHOCK.

DO NOT OPEN.

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

DO NOT REMOVE COVER. NO USER-

SERVICEABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

CAUTION:

Please thoroughly familiarize yourself with the information

in this manual prior to installation and operation.

Pelco Manual C1402M-B (2/98) 5

Page 6

2.0 DESCRIPTION

The SB26 is a discreet surveillance, low profile, hemisphere dome for CCD type

cameras designed for ease of installation, relocation, and service in fixed ceilings

or standard 2' x 2' (.61 m x .61 m) or 2' x 4' (.61 m x 1.22 m) false ceiling tiles. The

black opaque lower dome effectively conceals the camera while providing an inconspicuous viewing window. The dome is attached to the drive to keep the viewing

window and camera aligned.

To simplify installation even further, Pelco offers system packages with factory installed standard components from its regular product line. Options include a 24 VAC

pan/tilt with factory pre-wired feedthrough for all control functions (i.e., pan/tilt, motorized zoom lens, camera power [24 VAC] and video), continuous 360° pan rotation, and a position feedback package for presets.

The dome and camera assembly rotate at a speed of 24 degrees/second and offer

complete 360 degree surveillance coverage (SL series).

The back box is constructed of aluminum to meet fire code requirements for installation in open plenum ceilings.

6 Pelco Manual C1402M-B (2/98)

Page 7

2.1 MODELS

NOTE:

All of the models are listed

by Underwriters Laboratories Inc.

SB26 Drop ceiling discreet surveillance enclosure with black opaque

lower dome with 1 f-stop light loss and all aluminum back box

which mounts above the ceiling. (Camera mount supplied.)

(UL)

SB26-1 Same as SB26 except supplied with clear viewing slot for

virtually zero light loss. (UL)

SB26-2 Same as SB26 except supplied with mirrored lower dome with

2 f-stop light loss. (UL)

SB2600 This system package includes the SB26 black opaque dome

enclosure plus a 24 VAC pan/tilt factory assembled inside the

back box. It provides factory pre-wired feedthrough for all

control functions (i.e., pan/tilt, motorized zoom lens, camera

power [24 VAC] and video). All connections are made at the

input connector, eliminating wiring harnesses made in the

field. (CE, UL)

SB2600-PP Same as the SB2600, except this package features the factory

installed preset (PP) option. (CE, UL)

SB2600-SL Same as the SB2600, except this package features 360°

continuous pan rotation. (CE, UL)

SB2600SL-PP Same as the SB2600-SL with the addition of the preset (PP)

option. (CE, UL)

SB2601 Same as SB2600 except supplied with black opaque lower

dome with clear viewing slot for virtually zero light loss.

(CE, UL)

SB2601-PP Same as SB2601 except with preset (PP) option. (CE, UL)

SB2601-SL Same as SB2601 except supplied with 360° continuous pan

SB2601SL-PP Same as SB2601-SL except with preset (PP) option. (CE, UL)

SB2602 Same as SB2601 except supplied with mirrored lower dome,

SB2602-PP Same as SB2602 except with preset (PP) option.

SB2602-SL Same as SB2602 except supplied with 360° continuous pan

SB2602SL-PP Same as SB2602-SL except with preset (PP) option. (CE, UL)

rotation. (CE, UL)

with 2 f-stop light loss.

rotation. (CE, UL)

Pelco Manual C1402M-B (2/98) 7

Page 8

3.0 INSTALLATION

Save the shipping box and any inserts in case the unit must be returned for credit or

repair.

3.1 CONDUCTOR AND CABLE REQUIREMENTS (ALL MODELS EXCEPT SB26)

A minimum of 12 conductors plus coax is required, which includes common requirements for motorized zoom lens and camera AC power.

NOTE:

The following are cable

requirements. A relay box (RB24) is

available to extend the operating distance up to 13,000 feet (3962.4 m)

over 16 Awg wire.

Non-PP Models

12 Conductor 13 Conductor*

20 Awg 130 ft (39.62 m) 185 ft (56.38 m)

18 Awg 205 ft (62.48 m) 290 ft (88.39 m)

16 Awg 326 ft (99.36 m) 461 ft (140.51 m)

Models with PP

18 Conductor 19 Conductor*

20 Awg 130 ft (39.62 m) 185 ft (56.38 m)

18 Awg 205 ft (62.48 m) 290 ft (88.39 m)

16 Awg 326 ft (99.36 m) 461 ft (140.51 m)

*Using 2-conductor common.

Calculations are based on a 10% cable loss with both motors running.

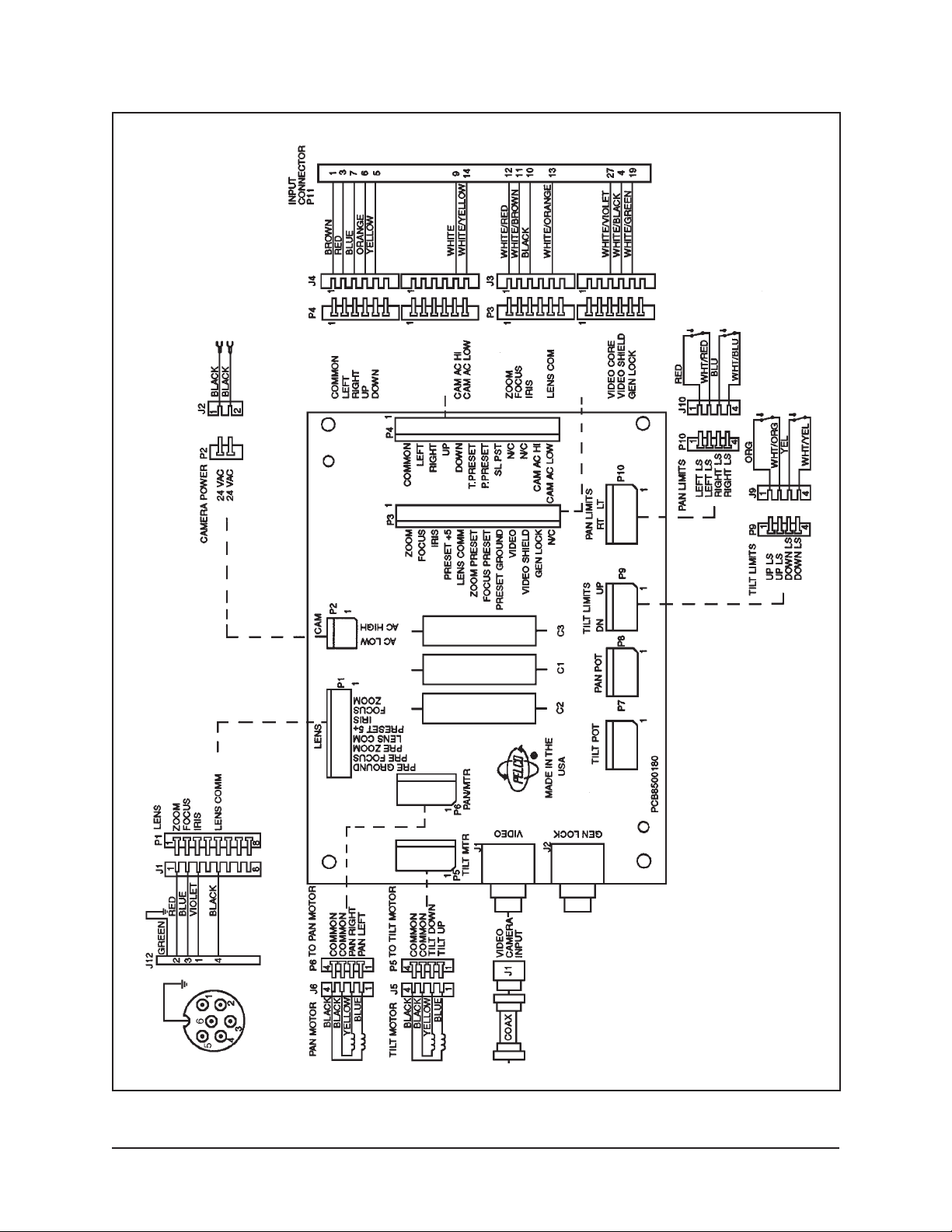

3.2 WIRING INSTRUCTIONS

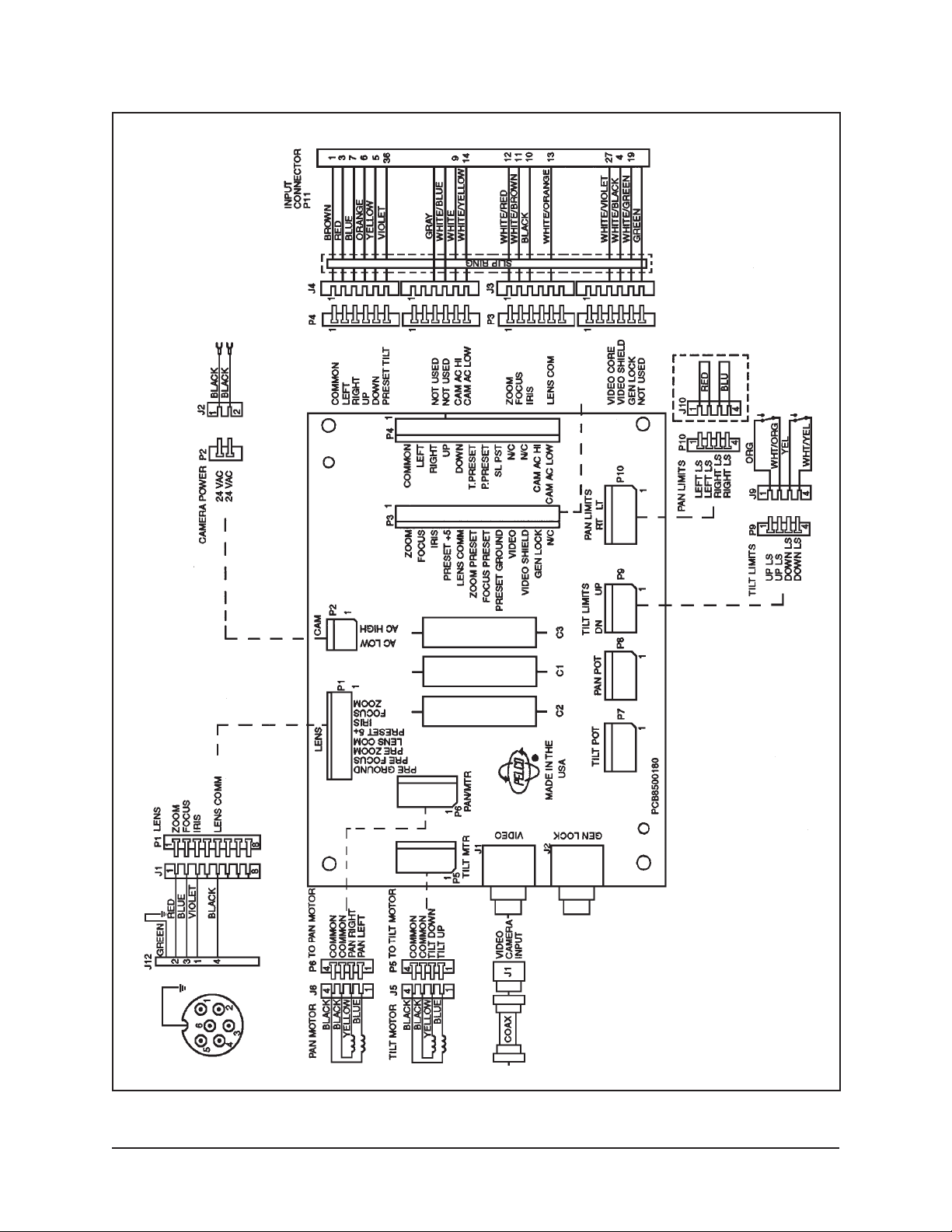

The SB2600 and SB2600-SL include a pan/tilt which is pre-wired for all control

functions (pan/tilt, motorized zoom lens, camera power [24 VAC], and video). All

connections are made to the input connector, eliminating the need for wiring harnesses made in the field. Wire the control cable according to the wiring diagram in

Figures 1 and 2 (non-PP models), or Figures 3 and 4 (PP models).

8 Pelco Manual C1402M-B (2/98)

Page 9

Figure 1. SB2600 Wiring Diagram

Pelco Manual C1402M-B (2/98) 9

Page 10

Figure 2. SB2600-SL Wiring Diagram

10 Pelco Manual C1402M-B (2/98)

Page 11

Figure 3. SB2600SL-PP Wiring Diagram

Pelco Manual C1402M-B (2/98) 11

Page 12

Figure 4. SB2600-PP Wiring Diagram

12 Pelco Manual C1402M-B (2/98)

Page 13

3.3 MOUNTING INSTRUCTIONS

Handle the lower dome with care so as not to scratch or get fingerprints on the

viewing window.

Determine the type of mounting desired. The enclosure can be mounted in a fixed

ceiling, or completely replace a standard 2' x 2' (.61 m x .61 m) ceiling tile.

3.3.1 Fixed Ceiling Mounting

To mount the enclosure directly into a fixed ceiling, perform the following steps

(refer to Figure 5):

1. Determine the location and direction of the enclosure. Ideally, the enclosure

cutout should be parallel and adjacent, or perpendicular, to any ceiling structure. Cut opening.

2. Remove the dome and drill holes into the side of the back box at the locations

where the fasteners need to be located.

3. Insert the back box into the opening. Using the appropriate fasteners (not

supplied), attach the back box to any adjacent structure through the drilled

holes in the box.

4. Mount the camera/lens onto the pan/tilt assembly with the camera/lens cen-

tered on the tilt table. Use the mounting screw provided.

5. Hook up camera power, video, and lens with the connectors supplied.

6. Ensure there is sufficient initial clearance between the camera/lens and dome

as you carefully attach dome to the drive unit as shown in Figure 9. Align the

four ball studs on the dome to the four ball stud receivers on the dome drive

and push the dome until a snapping sound occurs.

7. You are now ready to tilt the camera/lens up and down to check for clearance

between the lens and the dome. If proper clearance is not achieved the dome

will be dislodged from the dome drive. Also, pay attention to camera and wiring clearance up inside the drive.

Figure 5. Fixed Ceiling Mounting

Pelco Manual C1402M-B (2/98) 13

Page 14

3.3.2 Dropped Ceiling, Tile Replacement Mounting

To mount the enclosure into a dropped ceiling grid, perform the following steps

(refer to Figure 6):

IMPORTANT:

When installing the

enclosure in a 2' x 4' (.61 m x 1.22 m)

ceiling grid, cut the ceiling tile in half

and install an additional “T” bar for

support.

1. Determine the location for mounting the enclosure and remove the appropriate ceiling tile.

2. Remove trim ring and dome. Angle the back box through the grid opening and

set the box into the grid. If additional support of the back box is required,

thread the two (2) 1/4-20 eye bolts (supplied) into the two attachment points in

the top of the back box and hang the unit per local code.

3. From an opening in a grid adjacent to the beck box, apply the four (4) clips

supplied to the “T” bar for support (refer to Figure 7).

4. Mount the camera/lens onto the pan/tilt (fixed mount) assembly with the

camera/lens centered on the tilt table. Use the mounting screw provided.

5. Hook up camera power, video, and lens with the connectors supplied.

6. Attach the safety chain to the lower dome and install the dome.

7. Operate the pan/tilt to verify that there are no obstructions within the back box

or dome.

Figure 6. Dropped Ceiling Mounting with

Figure 7. “T-Bar” Clip Installation

Optional Mounting Kit

14 Pelco Manual C1402M-B (2/98)

Page 15

3.3.3 Camera/Lens Installation

Install the camera/lens that you have selected for use with the SB2600 Series dome

as follows:

NOTE:

Remove “shipping

bracket” at this time. Refer to Figure 14, item 65.

NOTE:

Fixed speed units must

have power on and you must be

able to activate the tilt functions.

Do

not rotate fixed speed dome

caves by hand. Damage will occur to the motors.

1. Loosen the 1/4-20 lens support fastener and slide lens support down (see

Figure 8).

2. Place camera/lens atop the tilt table and thread the provided 1/4-20 x 1/2-inch

fastener through the tilt table into the camera (see Figure 8). Snug the fastener

at this time to allow for camera/lens repositioning.

3. Connect camera power spade lugs, coax video cable and lens connector, paying

special attention to the routing of the cabling so as not to interfere with the

camera/lens swing.

4. Ensure there is sufficient initial clearance between the camera/lens and dome

as you carefully attach dome to drive unit as shown in Figure 9. Align the four

ball stud receivers on the dome drive and push dome until snapping sound

occurs. You are now ready to tilt the camera/lens combination up and down to

check for clearance between the lens and the dome. If proper clearance is not

achieved, the dome will be dislodged from the dome drive. Also pay attention

to camera and wiring clearance up inside the drive.

5. Adjust camera/lens and wire routing as necessary to achieve proper clearances. Always keep in mind that if the camera/lens can be balanced the unit

life will be extended.

6. After satisfactory clearances have been achieved, remove dome and tighten

all three camera/lens fasteners. The unit is now ready for operations test and,

if applicable, pan limit stop adjustments.

BALL STUD RECEIVERS

(1)

(3)

(2)

Figure 8. Attaching Camera/Lens to Tilt Table Figure 9. Attaching Dome to Drive Unit

Pelco Manual C1402M-B (2/98) 15

Page 16

3.4 CONNECTOR ASSEMBLY

14

59

15 10

22 16

28 23

33 29

37 34

Assemble the connector parts according to the instructions below. Detail B, below,

reflects the pin arrangement specific to all SB26/SB2600 Series. Refer to Figure 10

during assembly. For best results use an AMP style crimper when making the wire

to pin connection.

The instructions that follow apply to all AMP style connectors regardless of pin size

or pin number.

1. Slide the connector clamp assembly over the conductor cable. If the diameter

of the conductor cable is such that the rubber boot will slide over it easily then

slide the rubber boot onto the conductor cable at this time. If not, discard the

rubber boot.

2. Prepare the wires from the conductor cable as follows:

a. Strip at least 1" from the cable jacket to expose the wires. You may need

to strip more from the cable jacket if you have more wires.

b. Strip 1/8" from each wire.

c. Using an AMP style crimper, crimp the wires and their insulation to the

connector pins. Refer to Detail A in Figure 10.

3. Slide the connector pins into the appropriate holes in the connector body until

they snap into place. Refer to Figure 10 for correct pin arrangement, depending on model and options.

4. Push the connector clamp assembly (with boot, if used) toward the connector

body. Screw the clamp assembly onto the connector body, being careful not to

disturb the wires.

OR

5. To complete the assembly, attach the appropriate clamp with the screws provided and tighten.

1"

1/8"

FRONT VIEW

37-PIN

Figure 10. Connector Assembly

16 Pelco Manual C1402M-B (2/98)

Page 17

3.5 J-BOX INSTALLATION

For installations requiring full plenum rating, perform the following step:

Installations Requiring Conduit

When conduit must be run to the enclosure back box:

1. Attach the provided J-box to the top of the enclosure back box as shown in

Figure 11 using the supplied 6-32 screws.

2. Remove one of the knockouts from the J-box and attach the conduit to the

J-box (hardware not supplied).

3. Run the cabling through to the conduit.

4. Assemble the connector onto the end of the cable that is in the J-box, per

Section 3.4.

5. Place the J-box cover onto the J-box with two (2) 6-32 screws (supplied).

or

Installations Not Requiring Conduit

When conduit is not required at the enclosure back box:

1. Attach the provided J-box to the top of the enclosure back box as shown in

Figure 11 using the supplied 6-32 screws.

2. Remove the knockout from the edge of the J-box cover.

3. Run the assembled cable (see Section 3.4) into the J-box and place the cover

onto the J-box with the cable going through the knockout section of the cover.

Attach with 6-32 screws (supplied).

Pelco Manual C1402M-B (2/98) 17

Page 18

Figure 11. Attachment of J-Box to Back Box for Plenum Applications

18 Pelco Manual C1402M-B (2/98)

Page 19

3.6 ADJUSTMENTS

CAUTION:

Do not attempt to adjust limit stops

when the pan/tilt is in operation. Damage to the

equipment can result.

not

operate pan/tilt with-

Do

out limit stops.

Do not

remove or repo-

sition fixed limit stop.

DAMAGE WILL OCCUR.

Note the SL models are

supplied without pan limit

stops, therefore, no adjustments are necessary.

To adjust the pan limits, perform the following steps. Refer to Figure 12 for limit stop

locations. Factory pan limits are set at 0-355°, tilt limits are set at 0-90° (horizontal

to vertical).

To adjust limit stops, perform the following steps:

1. Pan unit to the desired left or right position; adjust the appropriate limit stop

position. If necessary, disconnect drive from back box to make required adjustments.

2. Replace drive in back box. Again, pan unit to left and right limit stop positions.

If position of stops is incorrect, repeat the procedure in step 1.

3. Pan to the right and left to verify the exact positioning and tighten both stops

securely.

4. The tilt limit is designed to allow for 0-90° travel (horizontal to vertical).

LIMIT STOPS

LIMIT STOPS

Figure 12. Limit Stop Locations

Pelco Manual C1402M-B (2/98) 19

Page 20

4.0 MAINTENANCE

Clean the acrylic dome as necessary to maintain a clear picture. Be careful not to

scratch the surfaces of the dome.

Exterior Surface - Clean the dome's exterior surface with a nonabrasive cleaning

cloth and cleaning agent that is safe for acrylic plastic. Either liquid or spray cleaner/

wax suitable for fine furniture is acceptable.

Interior Surface (Except Chrome) - Clean the same as the exterior surface.

Interior Surface (Chrome) - The inside surface of a chrome dome is easily scratched.

Use the following precautions to maintain the dome's surface.

a. Always handle the dome from the outside of its circular flange.

b. Never touch the coated inside surface. The acid in your fingerprints will even-

tually etch the coating if the fingerprints are not carefully removed according

to the recommended cleaning procedure in item “e.”

c. If dust or other contaminants accumulate on the dome's interior, remove the

debris with compressed air. Compressed air cans are available from photographic equipment or electronic supply dealers.

d. If heavy residue accumulates and cannot be removed with air pressure, rinse

with water and immediately dry with air pressure so that water spots will not

remain. Avoid wiping the coated surface with direct hand pressure - it will easily abrade unless extreme care is taken. Once scratched, the dome cannot be

recoated.

e. If internal wiping is necessary, avoid hand rubbing. Instead, make a wick as

follows:

Use a very soft paper towel. Roll a section into a tightly wound tube. Tear the

tube in half, and wet the fuzzy end of the wick with a solution of isopropyl

alcohol diluted with water. Hold the dome with its opening facing downward

and wipe the interior of the dome with the wet end of the wick. Use a circular

motion, starting from the outside and spiraling into the center. Use a new wick

for each two passes over the dome.

20 Pelco Manual C1402M-B (2/98)

Page 21

5.0 EXPLODED ASSEMBLY DIAGRAMS

Refer to Figure 13 for an exploded assembly diagram of the SB26 Enclosure, Figures 14 and 15 for the SB2600 Series Pan/Tilt, and

Figure 16 for the SB26 fixed mount.

Figure 13. SB26 Exploded Assembly Diagram

Table A. SB26 Exploded Assembly Parts List

Item No Quantity Description Part Number

11 Back box 25001010WASSY

21 Trim ring SB262ASSY

Pelco Manual C1402M-B (2/98) 21

Page 22

Figure 14. SB2600 Series Pan/Tilt Exploded Assembly Diagram

22 Pelco Manual C1402M-B (2/98)

Page 23

Table B. SB2600 Series Pan/Tilt Exploded Assembly Parts List

Item No. Quantity Description Part Number

11Bracket, drive mount 25004103COMP

2-4 - Not Used

51Slip ring lead 28010000

Slip ring lead, preset (PP) models only 250010000

61Spindle 8004024COMP

73Stop, pan limit 80010050

(Not shown) 2 Connector CPC, 37 pos pin plug CON206305-1

(Not shown) 2 Connector CPC cable clamp, size 23 CON206138-1

(Not shown) 2 Connector boot CON9779-513-8

8-Not Used

91Bracket, pan limit 8004013COMP

10 1 Gear, pan 80010012

11A, 11B 3, 1 Washer, thrust .030", Washer thrust .060" 90010002, 90010024

12 2 Bearing, thrust 90010001

13 1 Bearing, bronze, 1.5" ID x .125 thick 90010029

14 1 Boss, pan bearing 800400COMP

15 1 Backplane PCB8500180ASSY

16-20 - Not Used

21 1 Frame, dome drive 8141000WA

22 1 Gear, tilt 80010013

23 1 Shaft, tilt 8004018COMP

24 1 Table, tilt 8144005COMP

25 1 Grommet, neoprene GRO2172N

26, 27 - Not Used

28 2 Gear, motor 80010101

29 1 Snap ring, 1.5" dia (not shown) 80010019

30 1 Gear, preset, pan spindle 8104006COMP

31 1 Bracket, dome 8144001COMP

32 1 Dome, 14" acrylic:

Black opaque w/smoked viewing window 81410001-0*

Black opaque w/clear viewing window 81410001-1*

Chrome finish f/2 81410001-2*

33 4 Ball stud PT180410000

34 4 Receiver, ball stud PT180410001

35 2 Actuator, switch (tilt) SWIJS138B

36 4 Switch, micro SWIlSM1

2 Switch, micro (SL) SWIlSM1

37 2 Actuator, switch SWIJS221

38 1 Motor, tilt:

24 VAC, 14 rpm, w/gearhead type 2 drive 8008214

39 1 Pin, pan limit 8004011COMP

40 2 Bearing, sealed .375" ID, .875" OD 80010000

41 1 Spring, wave 80010002

42 1 Boss, bearing, tilt 8004000COMP

43 1 Preset tilt pot POTP010.OK

44 1 Gear, preset tilt 280110017

45 1 Preset pan pot POTP010.OK

* Part number is for the dome only. To order a complete dome assembly, specify the part numbers 8144100COMP (smoked),

8144101COMP (clear), and 8144102COMP (chrome). These part numbers include items 32, 33, 53, 54, and 55.

Continued on next page

Pelco Manual C1402M-B (2/98) 23

Page 24

Table B SB2600 Series Pan/Tilt Exploded Assembly Parts List (continued)

Item No. Quantity Description Part Number

46 1 Bracket, pan preset potentiometer 8104012COMP

47 1 Gear, pan preset potentiometer 90010020

48 2 Ring, snap 15510000

50 1 Support, lens 8144006COMP

51 1 Bracket, rear, dome 8144009COMP

52 1 Bracket, front, dome 8144007COMP

53 1 Plate, dome (receiver side) 8144002COMP

54 1 Plate, dome (tilt side) 8144003COMP

55 1 Bracket, tilt side, dome 8144004COMP

56 1 Motor, pan:

24 VAC, 48 rpm, w/gearhead, type 2 drive 8008248

57 1 Connector, mating, lens:

9-pin, PP lens (not shown) 1751000COMP

6-pin, non-PP lens (not shown) CONMAS6100

58 1 Connector, lens, panel mount:

9-pin, PP lens (not shown) CON206705-1

6-pin, non-PP lens (not shown) CONMAB6100

59 9 Pins, loose piece (not shown) CON66399-1

(for use with item #58, CON206705-1)

60 1 Shim ZHSHIM.047

61 1 Adapter, connector 30014025COMP

62 1 Gland, UL approved EH400010003

63 1 Mount, spindle strain relief 6804001COMP

64 1 Nut, UL approved EH400010004

65 1 Bracket, shipping stabilizer* 8144012COMP

(*Remove Before Operating)

24 Pelco Manual C1402M-B (2/98)

Page 25

Figure 15. SB2600 Hardware Exploded Assembly Diagram

Pelco Manual C1402M-B (2/98) 25

Page 26

Table C. SB2600 Hardware Exploded Assembly Parts List

Item No. Quantity Description Part Number

A4Spacer, 1/4" O.D. x 1/8" L, #6 clear SPA8500

B10Nut, hex 6-32 SS ZH6-32NUTSH

C2Screw, 8-32 x 3/8", hex hd, m/s, SS ZH8-32X.375HMSS

D2Spacer 1/4" hex x 1/2. L, 6-32 tapped SPA8423

E-Not Used -

F3Screw, 6-32 x 38" pan hd, phil, SS ZH6-32X.375SPP

G3Screw, 8-32 x 3/4" L flat hd, phil, SS ZH8-32X.750SFS

H6Screw, 6-32 x 3/8" flat hd, phil, SS ZH6-32X.375SFP

I2Screw, 8-32 x 1/2" flat hd, phil, SS ZH8-32X.500SFS

J5Screw, 8-32 x 3/8" flat hd, phil, SS ZH8-32X.375SFP

K8Screw, 2-56 x 7/16" flat hd, phil, SS ZH2-56X.437SPP

4 Screw, 2-56 x 7/16" flat hd, phil, SS (SL models only) ZH2-56X.437SPP

L40Screw, 6-32 x 3/8" pan hd, phil, black oxide ZH6-32X.375BPP

M3Washer, internal star #4, SS ZH4LWSIS

N 36 Washer, internal star #6, SS ZH6LWSIS

O 3Screw, 8-32 x 1/2" pan hd, phil, SS ZH8-32X.500SPP

P2Washer, split lock, 1/4", SS ZH1/4LWSSL

Q8Washer, internal star #8, SS ZH8LWSIS

R8Washer, flat #8, SS ZH188X435X60C

S 3Screw, 4-40 x 1/4" pan hd, phil, SS ZH4-40X.250SPP

T1Screw, 1/4-20 x 1/2", hex hd, SS ZH1/4-20X.500CH

U 1Washer, flat 3/16" spcl size pltd ZH260X562X65C

V 1Set screw, 8-32 x 1/4" knur, hex soc, blk ZH8-32X.250S

W 4Set screw, 8-32 x 3/16" knur, hex soc, blk ZH8-32X.187S

X1Screw, 10-32 x 1/2" flat hd, phil, ss ZH10-32X.500CFS

Y 8Screw, 8-32 x 1/2" hex soc, C/S, SS ZH8-32X.500CS

Z1Screw, 1/4-20 x 3/4" hex hd, C/S, SS ZH1/420X361X62N

AA 4 Washer, nylon ZH131X361X62N

26 Pelco Manual C1402M-B (2/98)

Page 27

Figure 16. SB26 Fixed Series Exploded Assembly Diagram

Pelco Manual C1402M-B (2/98) 27

Page 28

Table D. SB26 Fixed Series Exploded Assembly Mechanical Parts List

Item No. Quantity Description Part Number

11 Bracket, drive mount, upper 25004103COMP

21 Adapter bracket, spindle, fixed mount 8004137COMP

31 Frame 14", fixed mount 8004019COMP

42 Bracket, dome, 14" fixed mount 8004020COMP

51 Tilt table, fixed mount 8004021COMP

61 Dome, 14", acrylic:

Black opaque w/smoked viewing window 81410001-0*

Black opaque w/clear viewing window 81410001-1*

Chrome finish f/2 81410001-2*

Gold finish f/2 81410001-3*

72 Knob, grey, 1/4-20 tapped CM1610003

84 Receiver, ball stud PT180410001

91 Cross bar, 14" fixed mount 8008043COMP

* Part number is for the dome only. To order a complete dome assembly, specify the part numbers 8144100COMP (smoked),

8144101COMP (clear), 8144102 (chrome) and 8144103 (gold). These part numbers include items 32, 33, 53, 54, and 55 shown

separately in Figure 14.

Table E. SB26 Fixed Series Exploded Assembly Associated Hardware Parts List

Item No. Quantity Description Part Number

A-Not Used -

B1Screw 1/4-20 x 1" soc hd c/s, SS ZH1/420X1.00SS

C1Nut, lock, hex, 1/4-20, nylon insert, SS ZH1/420NUTCHN

D4Screw 6-32 x 3/8" pan hd phil, SS ZH6-32X.375SPP

E17Washer, internal star #6, SS ZH6LWSIS

F-Not Used -

G4Screw 8-32 x 1/2" pan hd phil, SS ZH8-32X.375SPP

H4Washer, internal star #8, SS ZH8LWSIS

I14Screw 6-32 x 3/8" flat hd phil, black oxide ZH6-32X.375BPF

J-Not Used -

K1Washer, fender, 1/4 x 1.5 x 14 ga, black oxide ZH255X1.50X62

L1Washer, split lock, 1/4" SS ZH1/4LWSSL

M13Nut, hex, 6-32, SS ZH6-32NUTSH

N4Spacer 1/4" O.D. x 1/8" L, #6 clear SPA8500

28 Pelco Manual C1402M-B (2/98)

Page 29

6.0 SPECIFICATIONS

MECHANICAL

Construction

Pan/tilt: Aluminum

Back box: Aluminum

Lower dome: Acrylic hemisphere with distortion free viewing window; rotates

Max. Camera/Lens

Length: (Including BNC connector):

with the pan/tilt/camera/lens.

12.5"H x 4.5"W x 3.25"H (31.75 cm x 11.43 cm x 8.25 cm)

Pan: 0-355° movement in horizontal plane

Pan Speed: 24°/sec ±1° (no load condition)

Tilt: -90° movement from horizontal plane

Tilt Speed: 12°/sec ±.5° (no load condition)

Maximum Load: 10 lbs (4.6 kg)

Gearing: Spur gear, direct drive (pan and tilt)

Bearings

Pan: Heavy duty ball bearing and Oilite bronze bushing

Tilt: Oilite bronze bushing

Duty Cycle: 50% duty cycle; 30 minute rating

Braking: Friction

ELECTRICAL

Input Voltage: 24 VAC required for pan/tilt

Power Requirements

Pan: .30 amp

Tilt: .38 amp

Connectors

Pan/Tilt: Amp CPC type (mate supplied) installed onto a pigtail exiting

Lens: Hirschmann MAB6100 (mate supplied) for non-PP models

Video: BNC

(Models SB2600, SB2600-PP)

360° continuous rotation (Models SB2600-SL, SB2600SL-PP)

from the rear of the back box. All functions (camera power, lens,

pan/tilt and video).

AMP CPC type (mate supplied) for PP models

Camera Power: Spade lugs, 24 VAC

Motors: Two-phase induction type, continuous duty, instantaneous

Limit Switches

Pan: 5 amp, on non-SL

Tilt: 5 amp

Conductor

Requirements: As listed, plus coax cable Non-PP models Pan/tilt (5 plus

reversing

ground), Lens (4), Camera AC (2) PP models Pan/tilt (9 plus

ground), Lens (4), Camera AC (2)

Pelco Manual C1402M-B (2/98) 29

Page 30

GENERAL

Environment: Indoor

Temperature

Range: 14° to 122° F (-10° to 50° C)

Dimensions: See Figure 17

Rating: NEMA 1

(Design and product specifications subject to change without notice.)

Figure 17. SB2600 Dimension Drawing

30 Pelco Manual C1402M-B (2/98)

Page 31

NOTES

Pelco Manual C1402M-B (2/98) 31

Page 32

7.0 WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or

workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

Pelco, the Pelco logo, Camclosure, Esprit,

Genex, Legacy, and Spectra are registered

trademarks of Pelco.

Endura and ExSite are trademarks of Pelco.

© Copyright 1998, Pelco. All rights reserved.

• Five years on FT/FR8000 Series fiber optic products.

• Three years on Genex

• Three years on Camclosure

CC3751H-2, CC3651H-2X, MC3651H-2, and MC3651H-2X camera models, which have a fiveyear warranty.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy

dome products.

• Two years on Spectra

continuous motion applications.

• Two years on Esprit

• Eighteen months on DX Series digital video recorders, NVR300 Series network video

recorders, and Endura

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion applications

(that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco shipment.

All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis, California. Repairs

made necessary by reason of misuse, alteration, normal wear, or accident are not covered under

this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from the

specific use or application made of the Products. Pelco’s liability for any claim, whether based on

breach of contract, negligence, infringement of any rights of any party or product liability, relating

to the Products shall not exceed the price paid by the Dealer to Pelco for such Products. In no event

will Pelco be liable for any special, incidental or consequential damages (including loss of use, loss

of profit and claims of third parties) however caused, whether by the negligence of Pelco or

otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have

additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or (559) 292-1981

to obtain a Repair Authorization number (RA), and provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the warranty

conditions stated above, please include a written explanation with the product when returned.

Method of return shipment shall be the same or equal to the method by which the item was received

by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at (800)

289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned for credit,

and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA number

and freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico, send goods to:

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico and are instructed

to return goods to the USA, you may do one of the following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

If the goods are to be sent by a FREIGHT FORWARDER, send the goods to:

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

®

Series products (multiplexers, server, and keyboard).

®

and fixed camera models, except the CC3701H-2, CC3701H-2X,

®

, CM6700/CM6800/CM9700 Series matrix, and DF5/DF8 Series fixed

®

, Esprit®, ExSite™, and PS20 scanners, including when used in

®

and WW5700 Series window wiper (excluding wiper blades).

™

Series distributed network-based video products.

32 Pelco Manual C1402M-B (2/98)

Loading...

Loading...