Page 1

®

SB19/SB1900 Series

Discreet Surveillance Enclosures

Installation/Operation Manual

C467M-D (5/95)

Pelco • 3500 W. Pontiac Way, Clovis, CA 93612-5699 • USA • www.pelco.com

(800) 289-9100 or (1-559) 292-1981 • FAX (800) 289-9150 or (1-559) 292-3827

Page 2

TABLE OF CONTENTS

Section Page

1.0 WARNINGS ........................................................................................................................................ 1

2.0 SCOPE ...............................................................................................................................................2

3.0 DESCRIPTION ...................................................................................................................................2

4.0 INSTALLATION .................................................................................................................................. 2

4.1 CONDUCTOR AND CABLE REQUIREMENTS ....................................................................... 2

4.2 WIRING INSTRUCTIONS ........................................................................................................ 2

4.3 MOUNTING INSTRUCTIONS ..................................................................................................4

4.3.1 Suspended Ceiling Mounting .......................................................................................4

4.3.1.1 Suspended Ceiling-Preferred Method ...........................................................4

4.3.1.2 Suspended Ceiling Tile Replacement Mounting ........................................... 7

4.3.2 Hard Ceiling Mounting ................................................................................................. 8

4.4 CONNECTOR ASSEMBLY ....................................................................................................... 9

4.5 ADJUSTMENTS .......................................................................................................................9

5.0 CARE AND MAINTENANCE ............................................................................................................ 10

6.0 EXPLODED ASSEMBLY DIAGRAM ................................................................................................ 11

7.0 EXPLODED ASSEMBLY MECHANICAL PARTS LIST ....................................................................12

8.0 MODELS .......................................................................................................................................... 14

9.0 RECOMMENDED CONTROLS ....................................................................................................... 14

9.1 MODELS SB1900 AND SB1900-SL .......................................................................................14

9.2 MODELS SB1900, SB1900-SL, SB1900-PP AND SB1900SL-PP .........................................15

10.0 OPTIONS ......................................................................................................................................... 15

11.0 SPECIFICATIONS ............................................................................................................................15

12.0 WARRANTY AND RETURN INFORMATION ................................................................................... 17

LIST OF ILLUSTRATIONS

Figure Page

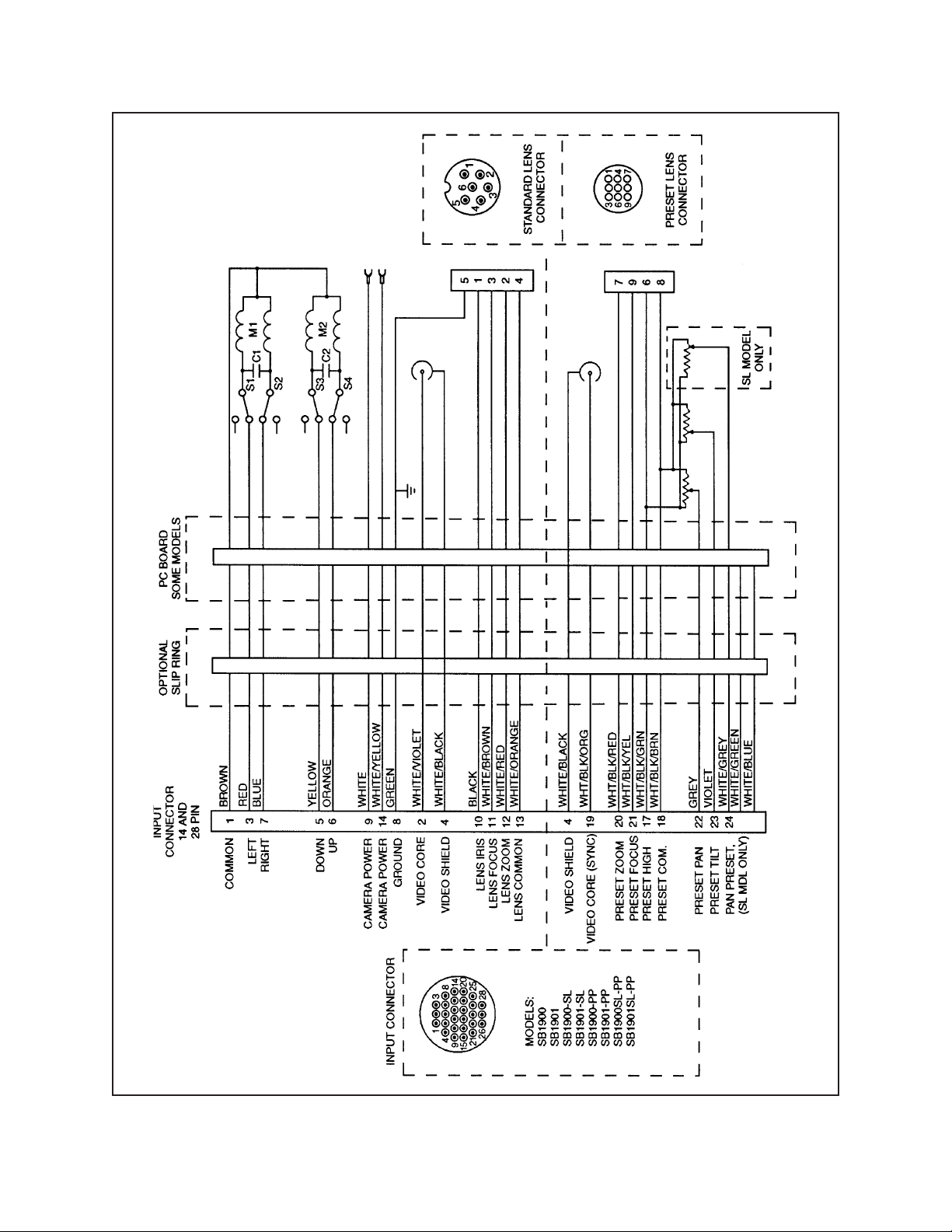

1 SB1900 Series Wiring Diagram ..................................................................................................... 3

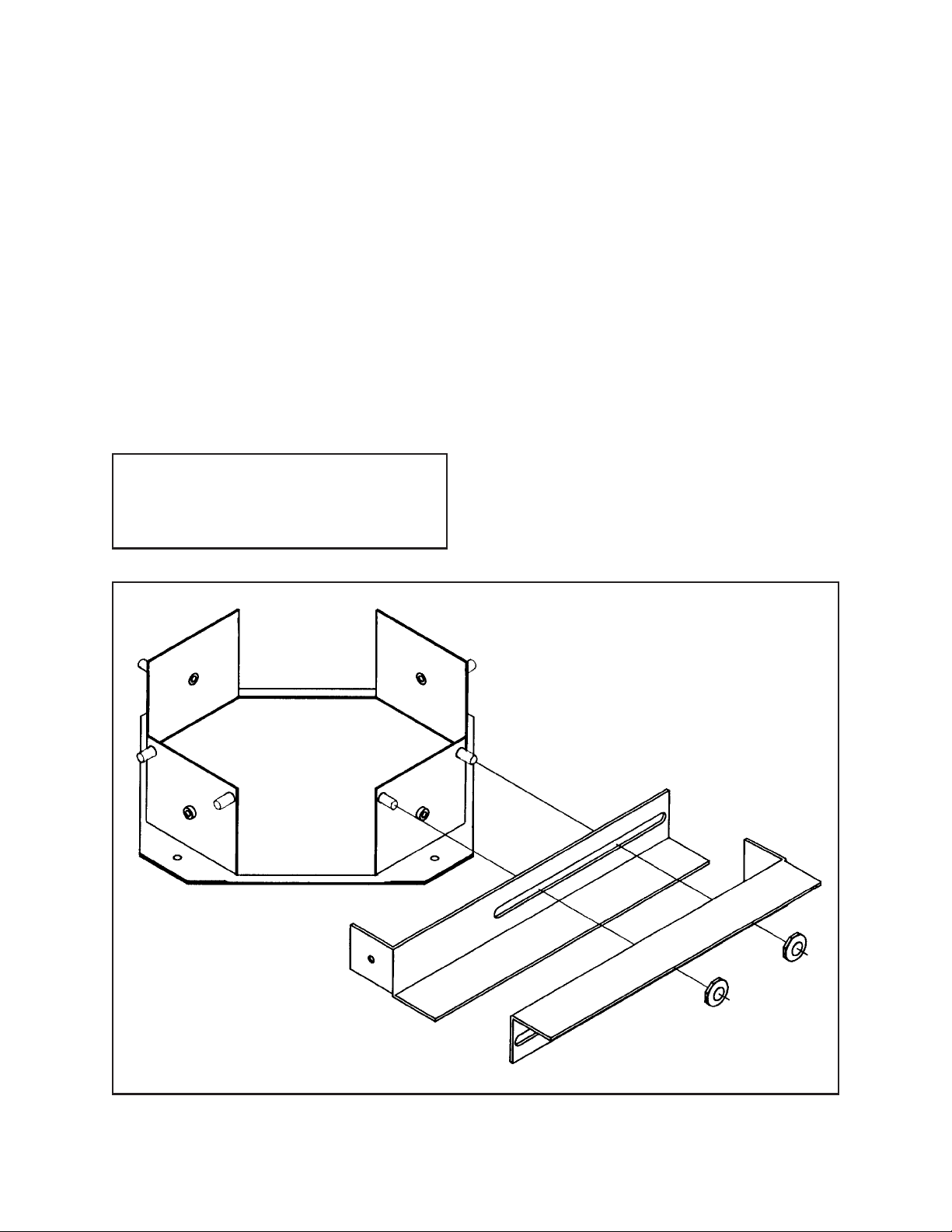

2 Back Box Mounting Rail Installation ................................................................................................4

3 Camera/Lens Mounting Dimensions ...............................................................................................5

4 Pan/Tilt Mounting Detail ..................................................................................................................6

5 Limit Stop Locations ........................................................................................................................9

6 Tilt Limit Stop Modification ............................................................................................................10

7 SB19 Exploded Assembly Diagram .............................................................................................. 11

8 SB19 Dimension Drawing .............................................................................................................16

REVISION HISTORY

Manual # Date Comments

C467M 2/90 Original Version.

C467M 3/90 Rev. A. “Scope” section expanded to include warnings. Updated model

and options section. Figure 5 Added.

C467M 11/90 Rev. B. Addendum incorporated @ Figure 19 Exploded Assy Diagram.

Wiring diagram changes added. Previous Figure 3 deleted; wiring table

made up.

C467M 5/92 Rev. C. Incorporated addendum.

C467M-D 4/95 Update a new format. Incorporate ECO’s 94-064. Add exploded

assembly drawing for pan/tilt (Figure 8 ) and corresponding parts list.

8/96 Added clear dome to Section 7.0, Exploded Assembly Mechanical Parts List.

Pelco, the Pelco Logo, Camclosure, Esprit, Genex, Legacy, and Spectra are registered trademarks of Pelco. © Copyright 1996, Pelco. All rights reserved.

Endura and ExSite are trademarks of Pelco.

ii Pelco Manual C467M-D (5/95)

Page 3

INSTALLATION AND OPERATION MANUAL

DISCREET SURVEILLANCE ENCLOSURES:

MODEL SB19/SB1900 SERIES

MODEL SB19-1/SB1901 SERIES

MODEL DD1900 SERIES

1.0 WARNINGS

CAUTION

This device is designed to operate at 24VAC power.

Input voltage must not exceed 28 volts or drop below 22 volts or else damage to the motors will occur.

Should you need assistance with this or any Pelco

product, please call 1-800-298-9100 or 1-559-

292-1981.

Prior to installation and use of this product, the following

WARNINGS should be observed.

1. Installation and servicing should only be done by

Qualified Service Personnel and conform to all

Local codes.

2. Unless the unit is specifically marked as a NEMA

Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is

designed for indoor use only and it must not be

installed where exposed to rain and moisture.

The product may bear the following

marks:

This symbol indicates that dangerous voltage

constituting a risk of electric shock is present

within this unit.

3. Only use replacement parts recommended by Pelco.

4. After replacement/repair of this unit’s electrical

components, conduct a resistance measurement

between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

5. The installation method and materials should be

capable of supporting four (4) times the weight of

the enclosure, pan/tilt, camera and lens combination.

This symbol indicates that there are important

operating and maintenance instructions in the

literature accompanying this unit.

CAUTION:

TO REDUCE THE RISK OF ELECTRICAL

SHOCK, DO NOT REMOVE COVER. NO

USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

RISK OF ELECTRIC SHOCK.

CAUTION:

DO NOT OPEN.

Please thoroughly familiarize yourself with the information in this manual

prior to installation and operation.

Pelco Manual C467M-D (5/95) 1

Page 4

2.0 SCOPE

The information contained within this manual covers

the SB19/SB1900 Series of Discreet Surveillance Enclosures.

3.0 DESCRIPTION

The SB19 is a low profile, hemisphere, discreet surveillance dome for CCD type cameras designed for ease

of installation, relocation, and servicing in hard ceiling

applications or in a standard 2' x 2' or 2' x 4' suspended

ceiling grid.

The black opaque lower dome effectively conceals the

camera while providing an inconspicuous viewing window. The dome mounts directly to the pan/tilt (or fixed

camera mount), thus keeping the viewing window and

camera aligned.

To simplify installation even further, Pelco offers

system packages with factory installed standard components from its regular product line. Options include

a 24 VAC pan/tilt with factory pre-wired feed-through

for all control functions (i.e., pan/tilt, motorized zoom

lens, camera power (24 VAC) and video), continuous

360° pan rotation, and a position feedback package for

presets.

The dome and camera assembly rotate at a speed of 24

degrees/second for complete 360 degree surveillance

coverage.

The back box is constructed of aluminum to meet most

fire code requirements for installation in open plenum

ceilings.

4.0 INSTALLATION

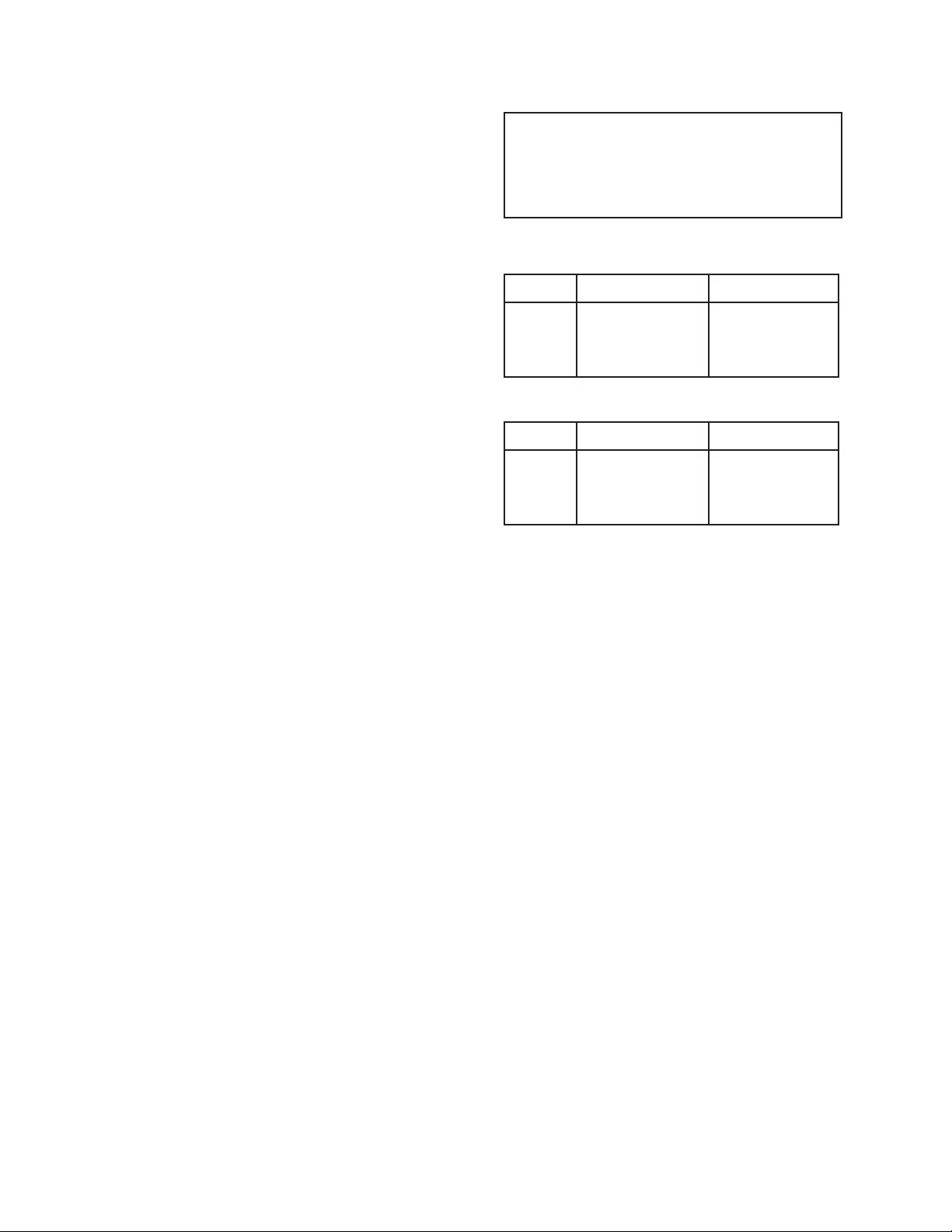

NOTE: The following are the cable require-

ments. A relay box (RB24) is available to

extend the operating distance. Consult the

factory for details.

Non-PP Models

12 Conductors 13 Conductors*

20 Awg 190 ft (57.91 m) 380 ft (115.82 m)

18 Awg 300 ft (91.44 m) 600 ft (182.88 m)

16 Awg 480 ft (146.3 m) 960 ft (292.61 m)

Models with PP

18 Conductors 19 Conductors*

20 Awg 190 ft (57.91 m) 380 ft (115.82 m)

18 Awg 300 ft (91.44 m) 600 ft (182.88 m)

16 Awg 480 ft (146.3 m) 960 ft (292.61 m)

*Using 2 conductor common.

Calculations are based on a 10% cable loss with both

motors running.

4.2 WIRING INSTRUCTIONS

The SB1900 and SB1900-SL include a pan/tilt which

is pre-wired for all control functions (pan/tilt, motorized zoom lens, camera power (24 VAC), and video).

All connections are made to the input terminal block in

the J-box on top of the back box, eliminating the need

for wiring harnesses made in the field. Wire the control

cable according to the wiring diagram in Figure 1.

Save the shipping carton and plastic packaging in case

the unit must be returned for credit or repair.

4.1 CONDUCTOR AND CABLE

REQUIREMENTS

(All Models Except SB19)

A minimum of 12 conductors plus coax is required,

which includes common requirements for motorized

zoom lens and camera AC power. (An additional coax

is required for camera sync.)

2 Pelco Manual C467M-D (5/95)

Page 5

Figure 1. SB1900 Series Wiring Diagram

Pelco Manual C467M-D (5/95) 3

Page 6

4.3 MOUNTING INSTRUCTIONS

Determine the type of mounting desired. The enclosure can be mounted in a hard ceiling, completely replace a standard 2' x 2' suspended ceiling tile using the

APSB19 optional faceplate, or be inserted through a

cut-out in a standard 2' x 2' suspended ceiling tile.

Handle the lower dome with care so as not to scratch or

get fingerprints on the viewing window.

4.3.1 Suspended Ceiling Mounting

4.3.1.1 Suspended Ceiling -

Preferred Method

1. Determine the location for mounting the enclosure

and remove the appropriate ceiling tile.

IMPORTANT: When installing the enclosure in a 2' x 4' ceiling grid, cut the ceiling tile

in half and install an additional “T” rail for

support.

2. Remove the factory assembled 12.5" round faceplate from the back box by disengaging the serrated studs.

3. Remove the factory assembled 14.5" square mounting plate by removing the four (4) 1/4-20 bolts.

4. Place the 14.5" square mounting plate on the removed ceiling tile, centering all four edges of the

plate to the tile. Draw an outline of the octagon

opening in the sub-plate onto the tile.

5. Using a sharp knife or keysaw, cut out the octagon

outlined on the tile.

6. Replace the ceiling tile and place the mounting

plate on top of it, centering the plate on the tile.

Attach the back box mount rails with 1/4-20 nuts

(provided) to two opposite sides of the mounting

plate. Use these mount rails to secure the back box

in place so that it can’t move when inserting or

removing the dome drive unit, and so that all of

the weight of the unit is not on the ceiling tile, per

local code. (Refer to Figure 2.)

Figure 2. Back Box Mounting Rail Installation

4 Pelco Manual C467M-D (5/95)

Page 7

7. Slide the back box through the ceiling tile and

mounting plate and replace the four (4) 1/4-20 bolts

and tighten to secure the back box to the mounting

plate.

8. Check the alignment of the back box to the ceiling

tile by attaching the 12.5" round faceplate trim to

the bottom of the back box, aligning the two studs

with two of the holes in the flanges of the back

box and engaging the studs. The studs should engage, while leaving a very minimal gap between

the ceiling and faceplate trim. Loosen the 1/4-20

hardware in the sides of the back box and make

adjustments as required. Insure that the face of the

back box is level with the ceiling.

9. Attach the lens and camera head to the tilt table

(hardware not supplied), if not factory pre-assembled,

using the camera/lens position template supplied

as a guide (see Figure 3). Locate the lens and camera so that when the notched area in the template

is fitted under the tilt table, the lens and camera do

not project further out from the tilt table than allowed by the template. Also, the lens must not

project higher than the long end of the template.

NOTE: If the camera and lens do not fit within

the boundaries of the template, they will not fit

inside the dome and need to be replaced with

smaller units.

10. Mount the camera power supply onto the bracket

provided, if not factory pre-assembled. (Screws to

mount the camera power supply and lens are not

provided with the pan/tilt.)

NOTE: For PC1804B and PC900U cameras,

remove the mounting bracket with the two 1/420 holes in it from the camera’s power supply,

align the camera power supply so that the two

(2) threaded holes in the power supply align

over two of the round holes in the camera power

supply bracket on the pan/tilt, and attach it with

the screws provided with the camera.

11. Hook up camera power, video, and lens with the

connectors supplied, if not factory pre-assembled.

Coil the excess camera cable and tie it down with

tie-wraps to the pan/tilt body.

NOTE: To insert or remove the drive unit from

the back box, the drive unit may need to be rotated 90° so that the wiring cover and/or camera power supply does not interfere with the

side of the back box. If difficulty inserting or

removing the drive unit is experienced, slowly

and gently rotate the drive unit 90°.

12. Engage the connector of the coil cord into the connector of the pan/tilt and attach the safety clamp;

then insert the pan/tilt into the back box, feeding

the coil cord back through the opening in the top

of the back box. Position the pan/tilt in the back

box so that the horizontal studs in the pan/tilt mount

bracket align with the slots in the back box mount

bracket. Lift the pan/tilt until it reaches its stop,

then slide it to one side while letting it drop about

1/4 inch (see Figure 4).

LENS

3.25

(8.26)

MAX

TILT TABLE

.875

(2.22)

MAX

GENERAL LENS MAXIMUM EXTENSIONS

PAST EDGES OF TILT TABLE

NOTE: VALUES IN PARENTHESE ARE CENTIMETERS;

ALL OTHERS ARE IN INCHES

6.5

(16.51)

MAX

CAMERA

1.625

(4.13)

MAX

SUPPLIED

TEMPLATE

Figure 3. Camera/Lens Mounting Dimensions

Pelco Manual C467M-D (5/95) 5

Page 8

13. Attach the dome to the pan/tilt by aligning the two

ball studs protruding through the flange of the dome

with the two holes in the dome attachment brackets and engaging the studs.

14. Attach the safety chain on the side of the back box

to the short 4-40 threaded screw in the 12.5" round

faceplate trim with the provided hardware.

15. Attach the faceplate trim to the back box by aligning the two serrated studs with two of the holes in

the edges of the back box and engaging the studs.

16. Operate the pan/tilt to verify that there are no obstructions or dragging cables within the back box

or dome.

UPPER MOUNTING PLATE

INSIDE BACK COVER

SAFETY SPRING CLIP

ATTACHED TO COIL CORD

(CAN BE POSITIONED

180° FROM SHOWN)

LOWER MOUNTING PLATE

ATTACHED TO PAN AND TILT

Figure 4. Pan/Tilt Mounting Detail

6 Pelco Manual C467M-D (5/95)

Page 9

4.3.1.2 Suspended Ceiling Tile

Replacement Mounting

template. Also, the lens must not project higher than

the long end of the template.

To mount the enclosure into a suspended ceiling grid

where the tile is replaced, perform the following steps.

1. Determine the location for mounting the enclosure

and remove the appropriate ceiling tile.

IMPORTANT: When installing the enclosure in a 2' x 4' ceiling grid, cut the ceiling tile

in half and install an additional “T” rail for

support.

2. Angle the 23.75" back box mounting plate (part

number APSB19, which must be ordered separately) through the grid opening and set the plate

into the grid. Attach the back box mount rails with

1/4-20 nuts (provided) to two opposite sides of the

mounting plate (see Figure 2). Use these mount

rails to secure the back box in place so that it can’t

move when inserting or removing the dome drive

unit, and so that all of the weight of the unit is not

on the ceiling tile, per local code.

3. Remove the factory assembled 12.5" round face-

plate from the back box by disengaging the serrated studs.

4. Remove the factory assembled 14.5" square mount-

ing plate by removing the four (4) 1-4/20 bolts.

5. Slide the back box through the mounting plate and

replace the four (4) 1/4-20 bolts and tighten to secure the back box to the mounting plate.

NOTE: If the camera and lens do not fit within

the boundaries of the template, they will not fit

inside the dome and need to be replaced with

smaller units.

8. Mount the camera power supply onto the bracket

provided, if not factory pre-assembled. (Screws to

mount the camera power supply and lens are not

provided with the pan/tilt.)

NOTE: For PC1804B and PC900U cameras,

remove the mounting bracket with the two 1/420 threaded holes in it from the camera’s power

supply, align the camera power supply so that

the two (2) threaded holes in the power supply align over two of the round holes in the

camera power supply bracket on the pan/tilt,

and attach it with the screws provided with

the camera.

9. Hook up camera power, video, and lens with the

connectors supplied, if not factory pre-assembled.

Coil the excess camera cable and tie it down with

tie-wraps to the pan/tilt body.

NOTE: To insert or remove the drive unit from

the back box, the drive unit may need to be rotated 90° so that the wiring cover and/or camera power supply does not interfere with the

side of the back box. If difficulty inserting or

removing the drive unit is experienced, slowly

and gently rotate the drive unit 90°.

6. Check the alignment of the back box to the mounting plate by attaching the 12.5" round faceplate

trim to the bottom of the back box, aligning the

two studs with two of the holes in the flanges of

the back box and engaging the studs. The studs

should engage, while leaving a very minimal gap

between the ceiling and faceplate trim. Loosen the

1/4-20 hardware in the sides of the back box and

make adjustments as required. Insure that the face

of the back box is level with the ceiling.

7. Attach the lens and camera head to the tilt table (hardware not supplied), if not factory pre-assembled, using the camera/lens position template supplied as a

guide (see Figure 3). Locate the lens and camera so

that when the notched area in the template is fitted

under the tilt table, the lens and camera do not project

further out from the tilt table than allowed by the

Pelco Manual C467M-D (5/95) 7

10. Engage the connector of the coil cord into the connector of the pan/tilt and attach the safety clamp;

then insert the pan/tilt into the back box, feeding

the coil cord back through the opening in the top

of the back box. Position the pan/tilt in the back

box so that the horizontal studs in the pan/tilt mount

bracket align with slots in the back box mount

bracket. Lift the pan/tilt until it reaches its stop,

then slide it to one side while letting it drop about

1/4 inch (see Figure 4).

11. Attach the dome to the pan/tilt by aligning the two

ball studs protruding through the flange of the dome

with the two holes in the dome attachment brackets and engaging the studs.

Page 10

12. Attach the safety chain on the side of the back box

to the short 4-40 threaded screw in the 12.5" round

faceplate trim with the provided hardware.

13. Attach the faceplate trim to the back box by aligning the two serrated studs with two of the holes in

the edges of the back box and engaging the studs.

14. Operate the pan/tilt to verify that there are no obstructions or dragging cables within the back box

or dome.

4.3.2 Hard Ceiling Mounting

To mount the enclosure into a hard ceiling, perform the

following steps.

1. Determine the location and direction of the enclosure. Ideally, the enclosure cutout should be parallel and adjacent, or perpendicular, to any ceiling

structure. Cut an opening (refer to Figure 8 for dimensions).

2. Remove the factory assembled 12.5" round faceplate from the back box by disengaging the serrated studs.

3. Remove the factory assembled 14.5" square mounting plate by removing the four (4) 1/4-20 bolts and

place it over the opening. Attach the back box

mount rails to the mounting plate with 1/4-20 nuts

(provided) to two opposite sides of the mounting

plate (see Figure 2). Use these mount rails to secure the back box in place so that it can’t move

when inserting or removing the dome drive unit,

and so that all of the weight of the unit is not on

the ceiling tile, per local code.

4. Slide the back box through the mounting plate and

replace the four (4) 1/4-20 bolts and tighten to secure the back box to the mounting plate.

5. Check the alignment of the back box to the ceiling

by attaching the 12.5" round faceplate trim to the

bottom of the back box, aligning the two studs with

two of the holes in the flanges of the back box and

engaging the studs. The studs should engage, while

leaving a very minimal gap between the ceiling

and faceplate trim. Loosen the 1/4-20 hardware in

the sides of the back box and make adjustments

are required. Insure that the face of the back box is

level with the ceiling.

6. Attach the lens and camera head to the tilt table

(hardware not supplied), if not factory pre-assembled,

using the camera/lens position template supplied

as a guide (see Figure 3). Locate the lens and camera so that when the notched area in the template

is fitted under the tilt table, the lens and camera do

not project further out from the tilt table than allowed by the template. Also, the lens must not

project higher than the long end of the template.

NOTE: If the camera and lens do not fit within

the boundaries of the template, they will not fit

inside the dome and need to be replaced with

smaller units.

7. Mount the camera power supply onto the bracket

provided, if not factory pre-assembled. (Screws to

mount the camera power supply and lens are not

provided with the pan/tilt.)

8. Hook up camera power, video, and lens with the

connectors supplied, if not factory pre-assembled.

Coil the excess camera cable and tie it down with

tie-wraps to the pan/tilt body.

NOTE: To insert or remove the drive unit from

the back box, the drive unit may need to be rotated 90° so that the wiring cover and/or camera power supply does not interfere with the

side of the back box. If difficulty inserting or

removing the drive unit is experienced, slowly

and gently rotate the drive unit 90°.

9. Engage the connector of the coil cord into the connector of the pan/tilt and attach the safety clamp;

then insert the pan/tilt into the back box, feeding

the coil cord back through the opening in the top

of the back box. Position the pan/tilt in the back

box so that the horizontal studs in the pan/tilt mount

bracket align with slots in the back box mounting

bracket. Lift the pan/tilt until it reaches its stop,

then slide it to one side while letting it drop about

1/4 inch (see Figure 4).

10. Attach the dome to the pan/tilt by aligning the two

ball studs protruding through the flange of the dome

with the two holes in the dome attachment brackets and engaging the studs.

11. Attach the safety chain on the side of the back box

to the short 4-40 threaded screw in the 12.5" round

faceplate trim with the provided hardware.

8 Pelco Manual C467M-D (5/95)

Page 11

12. Attach the faceplate trim to the back box by aligning the two serrated studs with two of the holes in

the edges of the back box and engaging the studs.

13. Operate the pan/tilt to verify that there are no obstructions or dragging cables within the back box

or dome.

2. Pan to the desired left position, remove the drive

unit from the back box and adjust the pan limit

stop until the actuator clicks, and lock into position. Replace the drive unit.

3. Pan to the right and left to verify the exact positioning.

4.4 CONNECTOR ASSEMBLY

To install and test the SB1900 Series enclosures you

may need to fabricate the interconnecting cable as outlined below. (Pretested wire harnesses, WH1900-06 and

WH1900-25, are optional cables for the SB1900 Series dome enclosures).

1. Strip back the cable jacket approximately 2 inches

and separate the individual conductors.

2. Attach spade lugs to each wire and mate BNC to

coax and camera sync.

3. Pop out a knock-out in one of the ends of the J-box

(on top of back box). Thread cable into J-box

through knock-out and attach each wire to the terminal block, as marked beside terminal block, and

engage BNC connectors or video and camer sync.

4.5 ADJUSTMENTS

To adjust the pan/tilt limits, perform the following steps.

Refer to Figure 5 for limit stop locations.

CAUTION: Do not attempt to adjust limit

stops when the pan/tilt is in operation. Damage

to the equipment can result. Also, do not operate equipment without limit stops. Note that SL

models are supplied without pan limit stops,

therefore, no adjustments are necessary.

4. The tilt limit is factory set at 0 to -90° travel (hori-

zontal to vertical). The tilt can be adjusted to any

point between horizontal and vertical; however,

under normal conditions the tilt limits should not

require adjustment.

5. To alter the factory set tilt limit*, bend the actuator stops on the microswitches (see Figure 6).

Move the tilt table to the desired position and adjust the actuators until the switch clicks; lock into

position.

6. Tilt up and down to verify exact positioning.

* It should be emphasized that only very minor adjustments should be made by bending the actuator attached

to the microswitch; and then, only for the reason of

bringing it within factory specifications.

LIMIT STOP LEFT

LIMIT STOP RIGHT

LIMIT STOP FIXED

LIMIT ACTUATOR

Factory pan limits are set to 0-355° and tilt limits are to

0-90° (horizontal to vertical). Under normal conditions,

the tilt limits should not have to be reset.

To adjust limit stops, perform the following steps:

1. Pan to the right using the joystick control until the

desired pan limit is reached. Remove the drive unit

from the back box and adjust the pan limit stop

until the actuator clicks. Lock the limit into position. Replace the drive unit.

NOTE: FIGURE IS A REPRESENTATION OF AN ACTUAL UNIT

WITH SOME PARTS NOT SHOWN TO PROVIDE

CLARITY OF LIMIT STOP LOCATIONS

Figure 5. Limit Stop Locations

Pelco Manual C467M-D (5/95) 9

Page 12

5.0 CARE AND MAINTENANCE

Regularly scheduled maintenance will prolong the operational life and appearance of the equipment.

If dust or other debris accumulates on the inside of the

lower dome, remove with clean air pressure only. Compressed air cans are available from commercial photographic equipment and supply dealers.

IMPORTANT: The lower dome of the enclosure is an optical surface. When cleaning the

inner surface of the dome and viewing window,

treat as carefully as you would a fine camera

lens. Do not use water, liquid or spray cleaners

of any kind on coated inner surface of dome.

Clean the outer surface of the dome and the inner surface of the viewing window with a non-abrasive cleaning cloth and anti-static cleaner that is safe for use on

acrylic plastic. Do not use kerosene or similar substances that can scratch the surface.

LOCKING SCREW

FRONT

LIMIT ACTUATOR

DOWN UP

UP

DOWN

Figure 6. Tilt Limit Stop Modification

10 Pelco Manual C467M-D (5/95)

Page 13

6.0 EXPLODED ASSEMBLY DIAGRAM

Refer to Figure 7 for an exploded assembly diagram of the SB19 enclosure.

PP ONLY

*

NON SL ONLY

**

EXPASB1900

EXPASB1900PP

Figure 7. SB19 Exploded Assembly Diagram

Pelco Manual C467M-D (5/95) 11

Page 14

7.0 EXPLODED ASSEMBLY MECHANICAL PARTS LIST

Item Qty Description Pelco Part Number

1 1 UL, Pad, camera, black .062" thick EH200010004

2 1 PCB assembly, pan/tilt PCB3000100ASSY

3 1 Bushing, 3/8" tilt shaft PT180010001

4 1 Shaft, tilt table PT18004002COMP

5 1 Sprocket .25" bore with pin and SS PT18004003COMP

6 2 Ball stud receiver PT180410001

7 Not used

8 1 Tilt Chain assembly PT18041006ASSY

9 1 Pan Chain assembly PT18041007ASSY

10 1 Tilt shaft, motor side PT18041011WA

11 1 Frame body, weld assembly PT18041012WA

12 2 Dome attachment bracket PT18044002COMP

13 1 Spindle, pan PT18044055COMP

14 1 Mount, lower pan and tilt PT18044006COMP

15 1 Bracket, PC1804-B power supply PT18044009COMP

16 1 Pan motor heat sink mount PT1804410COMP

17 1 Pan motor heat sink PT18044011COMP

18 1 Connector spacer, spindle mount PT18044014COMP

19 1 Bushing PT250010004

20 1 Bushing, 1/4", tilt shaft PT250010005

21 1 Sprocket, pan spindle PT25004104COMP

22 1 Tilt table PT25004106COMP

23 1 Tilt limit actuator PT25004108COMP

24 1 Collar, tilt table switch shaft PT25004121COMP

25 1 Spricket, 1/4" with SS and pilot PT25004125COMP

26 1 Bearing, flange PT350010000

27 2 UL, motor, 4 rpm, 24VAC PT350010010

28 1 Plate, bearing PT35001060COMP

29 1 Collar, tilt table motor side PT89104001COMP

30 4 NP spacer, 1/4" OD x .125, #6 clear SPA8500

31 2 Switch SWI1SM1

32 2 Switch actuator with insulator SWIJS138B

33 6 NP cable, S/S x inch E70810001

34 2 Connector ring, 14-wire #4 stud E70810002

35 1 Coil cord PT180410002

36 1 Black box assembly, 10.9" octagon SB10841010ASSY

37 1 Trim ring assembly SB18044100COMP

38 1 Mount, upper pan/tilt SB18044105COMP

39 2 J-box end SB18044105COMP

40 1 J-box cover SB18044006COMP

41 1 Boack box mount plate SSB18044007COMP

42 2 BNC panel mount bracket SB18044009COMP

43 1 8" dome camera/lens position template SB184220COMP

44 Not used

45 4 Back box mount rail SB194002COMP

46 2 Terminal block, 10-position PC mount TRB-2MV-10

47 1 Black opaque dome with smoked viewing window SB194200COMP

and mounting studs

1 Black opaque dome with clear viewing window SB194300COMP

and mounting studs

12 Pelco Manual C467M-D (5/95)

Page 15

7.0 EXPLODED ASSEMBLY MECHANICAL PARTS LIST (continued)

Item Qty Description Pelco Part Number

48 Not used

49 Not used

50 Not used

51 1 Slip ring, 24 circuit for presets 250010000

52 Not used

53 Not used

54 Not used

55 1 Bracket, tilt pot PT18044012COMP

56 1 Bracket, LPP lens connector PT18044013COMP

57 1 Gear, 1.875 plastic PT250010002

58 2 Gear, 1.5 plastic PT250010006

59 2 Pot, precision 10K POTP010.0K

60 1 Gear, spindle feedback, non-SL PT25004114COMP

61 1 Pan feedback pot PT25004116COMP

62 thru 70 Not used

71 2 Ring snap 15510000

72 1 Bracket, pan limit 2704051COMP

73 3 Limit stop, pan univ 5804006COMP

74 Not used

75 1 Grommet, neoprene GRO2172N

76 Not used

77 Not used

78 1 Pan limit stop ring PT18044018COMP

79 1 Bracket, pan limit mount PT18044019COMP

80 1 Pan limit actuator pin PT18044020COMP

Pelco Manual C467M-D (5/95) 13

Page 16

8.0 MODELS

DD1900 Dome drive unit for SB1900. (UL)

SB1900-PP Same as the SB1900, except this

package features the factory installed

preset (PP) option.

DD1900-PP Dome drive unit for SB1900-PP.

DD1900-SL Dome drive unit for SB1900-SL.

(UL)

DD1900SL-PP Dome drive unit for SB1900SL-PP.

SB19 Drop ceiling discreet surveillance

enclosure with black opaque lower

dome with less than 1 f-stop light attenuation and all aluminum back box

which mounts above the ceiling.

(Camera mount supplied.) (UL)

SB19-1 Same as SB19 except supplied with

clear viewing slot in the dome for

virtually zero light loss. (UL)

SB1900 This system package includes the

SB19 black opaque dome enclosure

plus a 24 VAC pan/tilt factory assembled inside the back box. It provides factory pre-wired feedthrough

for all control functions (i.e., pan/tilt,

motorized zoom lens, camera power

(24 VAC) and video). All connections

are made at the terminal blocks on

top of the back box, eliminating wiring harnesses made in the field. This

feature significantly reduces installation time while increasing the reliability and serviceability of the system.

(UL)

SB1901 Same as SB1900 except supplied

with clear viewing slot in the dome

for virtually zero light loss. (UL)

SB1900-SL Same as the SB1900, except this

package features 360° continuous

pan rotation. (UL)

SB1901-SL Same as SB1900-SL except supplied

with clear viewing slot in the dome

for virtually zero light loss. (UL)

SB1901-PP Same as SB1900-PP except supplied

with clear viewing slot in the dome

for virtually zero light loss.

SB1900SL-PP Same as the SB1900-SL with the

addition of the preset (PP) option.

SB1901SL-PP Same as SB1900SL-PP except sup-

plied with clear viewing slot in the

dome for virtually zero light loss.

9.0 RECOMMENDED CONTROLS

The following controls are recommended for use with

the SB1900 Series enclosures.

9.1 MODELS SB1900 AND SB1900-SL

Hardwire Short-Distance Controls

for 24 VAC Operation

MPT24DT Desk top joystick control module for

24 VAC pan/tilts.

MPTA24DT Same as MPT24DT except with auto/

random scan operation.

MLZ6DT Desk top zoom lens control module

with auto/manual iris control.

MEH24DT Desk top enclosure control module

for 24 VAC camera on/off.

Coaxitron System 2000

MPT9000CZ Desk top Coaxitron transmitter/control

with pan/tilt joystick, zoom lens, and

four accessory function controls.

CX9024RXI Desk top Coaxitron receiver for 24

VAC pan/tilts, zoom lens, 24 VAC

camera power and optional four accessory functions. Indoor use.

A9000 Auto/random scan plug-in module

for all Coaxitron receivers.

CX900TLC System test and receiver manual con-

trol board for Coaxitron receivers

(plug-in module).

14 Pelco Manual C467M-D (5/95)

Page 17

9.2 MODELS SB1900, SB1900-SL,

SB1900-PP AND SB1900SL-PP

IOP19B1C B/W NTSC 6X camera and lens pkg.

with preset positioning.

CM7500 Series Coaxitron Matrix Switcher/Control

System rack mount card cage with

CPU and power supply. Capable of

up to 64 inputs and up to 4 monitor

outputs. (See C584 product specification sheet for details).

CM8500 Series Matrix Switcher/Control System ca-

pable of up to 32 inputs and 16

monitor outputs. (See C501 product

specification sheet for details).

CM9500 Series Coaxitron Matrix Switcher/Control

System rack mount card cage with

CPU and power supply. Capable of

up to 96 inputs and 16 monitor outputs. (See C500 product specification

sheet for details).

CX9024RXI-PP Coaxitron indoor receiver for 24 VAC

pan/tilts, zoom lens, 24 VAC camera

power and optional four accessory

functions, with preset option (PP) for

pan/tilt and lenses (use with models

SB1900-PP and SB1900SL-PP).

(Must be used with CM7500/CM9500

series controls only.)

CX900TLC System test and receiver manual con-

trol board for Coaxitron receivers

(plug-in module).

MPT9500 Desktop controller (coaxitron com-

patible) with full PTZ, joy stick, 8

auxiliary functions.

10.0 OPTIONS

RB24 Relay box for 24 VAC pan/tilts and

scanners. Extends operating distance

(control to relay box) up to a maximum of 14,500 feet utilizing 16 Awg.

APSB19 23.75" square faceplate for suspended

ceiling applications.

APSB19-1 Same as APSB19 except black finish.

IOP19B1B B/W NTSC 6X camera and lens pkg.

IOP19B1G B/W NTSC 10X camera/lens pkg.

IOP19C1B Color NTSC 6X camera and lens pkg.

IOP19C1C Color NTSC 6X camera and lens

pkg. with preset positioning.

IOP19C1G Color NTSC 10X camera and lens pkg.

WH1900-06 6 foot wire harness with bare wire on

one end (for connection to the terminal blocks in the junction box on top

of the back box) and a 37 position connector on the other end (for connection to Coaxitron receiver).

WH1900-25 Same as WH1900-06, except 25 feet

long.

11.0 SPECIFICATIONS

MECHANICAL

Construction:

Pan/tilt Aluminum

Back box Aluminum

Lower dome Acrylic hemisphere with a clear,

distortion-free viewing window

with no light attenuation factor

(SB1901 Series) or smoked, distortionfree viewing window with less than

1 f-stop light attenuation (SB1900 Series); rotates with the pan/tilt/camera/

lens

Maximum

Camera/Lens

Size: 6.5" L x 4.5" W x 3.25" H, including

BNC (16.51 cm x 11.43 cm x 8.25 cm);

maximum camera head width is

2.50" (6.35 cm) (see Figure 3)

Max. Camera

Power Supply

Size: 2.5" x 5.0" x 2.5"

(6.35 cm x 12.7 cm x 6.35 cm)

Pan: 0-355° movement in horizontal

plane (Models SB1900, SB1900-PP)

360° continuous rotation (Models

SB1900-SL, SB1900SL-PP)

Pelco Manual C467M-D (5/95) 15

Page 18

Pan Speed: 24°/sec ± 1°

Tilt: -90° movement from horizontal plane

Tilt Speed: 12°/sec ± .5°

Maximum Load: 10 lbs (4.6 kg)

Lens Connector: Hirchmann 6100 type (mate supplied)

for non-PP models

AMP CPC type (mate supplied) for

PP models

Motors: Synchronous type, continuous duty,

instantaneous reversing

Gearing: Chain drive

Bearings:

Pan Heavy duty ball bearing and Oilite

bronze bushing

Tilt Oilite bronze bushing

Braking: Friction

ELECTRICAL

Input Voltage: 24 VAC required for pan/tilt

Power

Requirements:

Pan .31 amp (7.5 vA)

Tilt .31 amp (7.5 vA)

Connectors: Terminal strips inside J-box on the top of

the back box (all functions except video:

camera power, lens, pan/tilt and presets).

Video

Connector: BNC

Camera Power: Spade lugs, 24 VAC

Limit Switches:

Pan 5 amp, 10 million cycle rating (ex-

ternal adjustment) on non-SL

Tilt 5 amp, 10 million cycle rating (factory

set)

Conductor

Requirements:

Non-PP

models Pan/tilt (5 plus ground), Lens (4),

Camera AC (2), Video (coax), Camera Sync (coax)

PP models Pan/tilt (9 plus ground), Lens (6),

Camera AC (2), Video (coax), Camera Sync (coax)

GENERAL

Environment: Indoor

Temperature

Range: 14°F to 122°F (-10°C to +50°C)

Dimensions: See Figure 8

9.25

1.65

(4.19)

11.00

(27.94)

NOTE: VALUES IN PARENTHESES ARE CENTIMETERS; ALL OTHERS ARE INCHES.

(23.50)

3.10

(7.87)

8.50

(21.59)

12.50

(31.75)

A

B

C

WHERE:

A 10.90 (27.69)

B 7.70 (19.56)

C 3.20 (8.13)

1.80

(4.58)

7.93

(20.14)

C

B

A

Figure 8. SB19 Dimension Drawing

16 Pelco Manual C467M-D (5/95)

Page 19

12.0 WARRANTY AND RETURN

INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved

defective in material or workmanship for a period of one year after the date

of shipment.

Exceptions to this warranty are as noted below:

• Five years on FT/FR8000 Series fiber optic products.

• Three years on Genex

keyboard).

• Three years on Camclosure

CC3701H-2, CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2,

and MC3651H-2X camera models, which have a five-year warranty.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy®, CM6700/CM6800/CM9700 Series matrix, and

DF5/DF8 Series fixed dome products.

• Two years on Spectra

ing when used in continuous motion applications.

• Two years on Esprit

wiper blades).

• Eighteen months on DX Series digital video recorders, NVR300

Series network video recorders, and Endura

network-based video products.

• One year (except video heads) on video cassette recorders (VCRs).

Video heads will be covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in

continuous motion applications (that is, preset scan, tour and auto scan

modes).

Pelco will warrant all replacement parts and repairs for 90 days from the

date of Pelco shipment. All goods requiring warranty repair shall be sent

freight prepaid to Pelco, Clovis, California. Repairs made necessary by

reason of misuse, alteration, normal wear, or accident are not covered

under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or

loss resulting from the specific use or application made of the Products.

Pelco’s liability for any claim, whether based on breach of contract,

negligence, infringement of any rights of any party or product liability,

relating to the Products shall not exceed the price paid by the Dealer to

Pelco for such Products. In no event will Pelco be liable for any special,

incidental or consequential damages (including loss of use, loss of profit

and claims of third parties) however caused, whether by the negligence

of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The

Dealer may also have additional rights, which are subject to variation from

state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800)

289-9100 or (559) 292-1981 to obtain a Repair Authorization number

(RA), and provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice

number

3. Details of the defect or problem If there is a dispute regarding the

warranty of a product which does not fall under the warranty conditions

stated above, please include a written explanation with the product

when returned.

Method of return shipment shall be the same or equal to the method by

which the item was received by Pelco.

®

Series products (multiplexers, server, and

®

and fixed camera models, except the

®

, Esprit®, ExSite™, and PS20 scanners, includ-

®

and WW5700 Series window wiper (excluding

™

Series distributed

RETURNS

In order to expedite parts returned to the factory for repair or credit, please

call the factory at (800) 289-9100 or (559) 292-1981 to obtain an

authorization number (CA number if returned for credit, and RA number

if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking

and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the

assigned CA or RA number and freight should be prepaid. Ship to the

appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto

Rico, send goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto

Rico and are instructed to return goods to the USA, you may do one of the

following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

If the goods are to be sent by a FREIGHT FORWARDER, send the goods

to:

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

This equipment contains electrical or electronic components that must be recycled properly to comply with Directive 2002/96/EC of the European Union

regarding the disposal of waste electrical and electronic equipment (WEEE). Contact your local dealer for procedures for recycling this equipment.

Pelco Manual C467M-D (5/95) 17

Page 20

Pelco

3500 Pelco Way • Clovis, CA 93612-5699

(559) 292-1981 • (800) 289-9100

FAX (800) 289-9150 or (559) 292-3827

International customers call 1-559-292-1981 or FAX 1-559-348-1120

(Product specifications subject to change without notice.)

18 Pelco Manual C467M-D (5/95)

Loading...

Loading...