Page 1

INSTALLATION/OPERATION

REL2064

®

Relay Interface Unit

C1518M-A (11/02)

Page 2

CONTENTS

Section Page

IMPORTANT SAFEGUARDS AND WARNINGS .................................................................................................................................................................. 3

OVERVIEW .......................................................................................................................................................................................................................... 4

DESCRIPTION ............................................................................................................................................................................................................ 4

FRONT VIEW ..............................................................................................................................................................................................................4

REAR VIEW ................................................................................................................................................................................................................ 5

INSTALLATION ....................................................................................................................................................................................................................6

MOUNTING ............................................................................................................................................................................................................... 6

WIRING RELAYS ........................................................................................................................................................................................................6

CONNECTING TO THE CM6800 ................................................................................................................................................................................ 9

SETTING THE DIP SWITCHES .................................................................................................................................................................................. 10

OPERATION........................................................................................................................................................................................................................ 12

MEMORY FEATURE .................................................................................................................................................................................................. 12

OPERATING RELAYS FROM THE KBD960 ................................................................................................................................................................13

ACTIVATING RELAYS USING F12 ....................................................................................................................................................................13

ACTIVATING RELAYS FROM THE GPI MENUS................................................................................................................................................ 13

MOMENTARY .........................................................................................................................................................................................13

LATCHING ...............................................................................................................................................................................................13

TROUBLESHOOTING ..........................................................................................................................................................................................................15

APPENDIX A ...................................................................................................................................................................................................................... 16

SPECIFICATIONS................................................................................................................................................................................................................ 18

REGULATORY NOTICES ..................................................................................................................................................................................................... 19

WARRANTY AND RETURN INFORMATION ...................................................................................................................................................................... 19

LIST OF ILLUSTRATIONS

Figure Page

1Front View with Panel Removal ....................................................................................................................................................................... 4

2 Rear View of the REL2064 ................................................................................................................................................................................5

3 Rack-Mount Installation ................................................................................................................................................................................... 6

4 Relay Interface Contact Configuration ............................................................................................................................................................. 7

5 Wiring Relays to Peripheral Equipment ........................................................................................................................................................... 8

6 Connection to the CM6800 .............................................................................................................................................................................. 9

7 SW1 DIP Switches .......................................................................................................................................................................................... 11

8 SW2 DIP Switches .......................................................................................................................................................................................... 11

9 SW3 DIP Switches .......................................................................................................................................................................................... 11

10 Power Input Fuse Replacement .......................................................................................................................................................................15

11 REL2064 Dimension Diagram .......................................................................................................................................................................... 18

LIST OF TABLES

Table Page

A Switch 1........................................................................................................................................................................................................... 10

B Switch 2........................................................................................................................................................................................................... 10

C Switch 3........................................................................................................................................................................................................... 10

D Relay Unit 1 ..................................................................................................................................................................................................... 14

E Relay Unit 2 ..................................................................................................................................................................................................... 14

2 C1518M-A (11/02)

Page 3

IMPORTANT SAFEGUARDS AND WARNINGS

1. Read, keep, and follow these instructions.

2. Heed all warnings.

3. There are no user-serviceable parts inside this unit. Only authorized service personnel may open the unit.

4. Installation and servicing should only be done by qualified service personnel and conform to all local codes.

5. WARNING: To reduce the risk of fire or electric shock, do not expose this unit to rain or moisture if this unit is designed for indoor

use only.

6. Unless this unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6 or 6P enclosure, it is designed for indoor use only and it

must not be installed where exposed to rain or moisture.

7. Do not expose this unit to dripping or splashing. Do not place objects filled with liquids, such as vases, on this unit.

8. Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

9. The installation method and materials should be capable of supporting four times the weight of the unit and equipment.

10. Do not install near any heat source.

11. Only use attachments/accessories specified by the manufacturer.

12. Clean only with dry cloth.

13. Do not defeat the safety purpose of the polarized or grounding-type plug.

14. Protect the power cord from being walked on or pinched, particularly at plugs, convenience receptacles, and the point where they

exit from the unit.

15. Unplug this unit during lightning storms or when unused for long periods of time.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage constituting a risk

of electric shock is present within this unit.

This symbol indicates that there are important operating and

maintenance instructions in the literature accompanying this unit.

Please thoroughly familiarize yourself with the information in this manual prior to installation and operation.

FOR QUALIFIED SERVICE PERSONNEL ONLY

1. Only use replacement parts recommended by Pelco.

2. After replacement/repair of this unit’s electrical components, conduct a resistance measurement between line and exposed parts to

verify the exposed parts have not been connected to line circuitry.

CAUTION:

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

C1518M-A (11/02) 3

Page 4

OVERVIEW

DESCRIPTION

The REL2064 Relay Interface Unit provides up to 64 single-pole, single-throw (SPST) dry contact outputs for direct or automatic control of

peripheral equipment. Using Pelco’s proprietary M protocol, the relay unit communicates with Pelco’s CM6800 matrix switcher via an RS-485

communication interface. The relay unit can be located remotely from the system controller and still communicate back to the central system

when an alarm occurs.

Other features include the following:

• Multiple units can be cascaded to provide multiple relay contact points on a single M port connection.

• Relay output contacts can be configured for normally open (N.O.) or normally closed (N.C.) operation.

• With the memory feature, relay groups can retain their contact position in the event of a power failure or front panel reset.

• The unit is powered by an auto-ranging power supply.

• The unit occupies one rack unit (1.75 inches or 4.45 cm), accommodating multiple types of mounting.

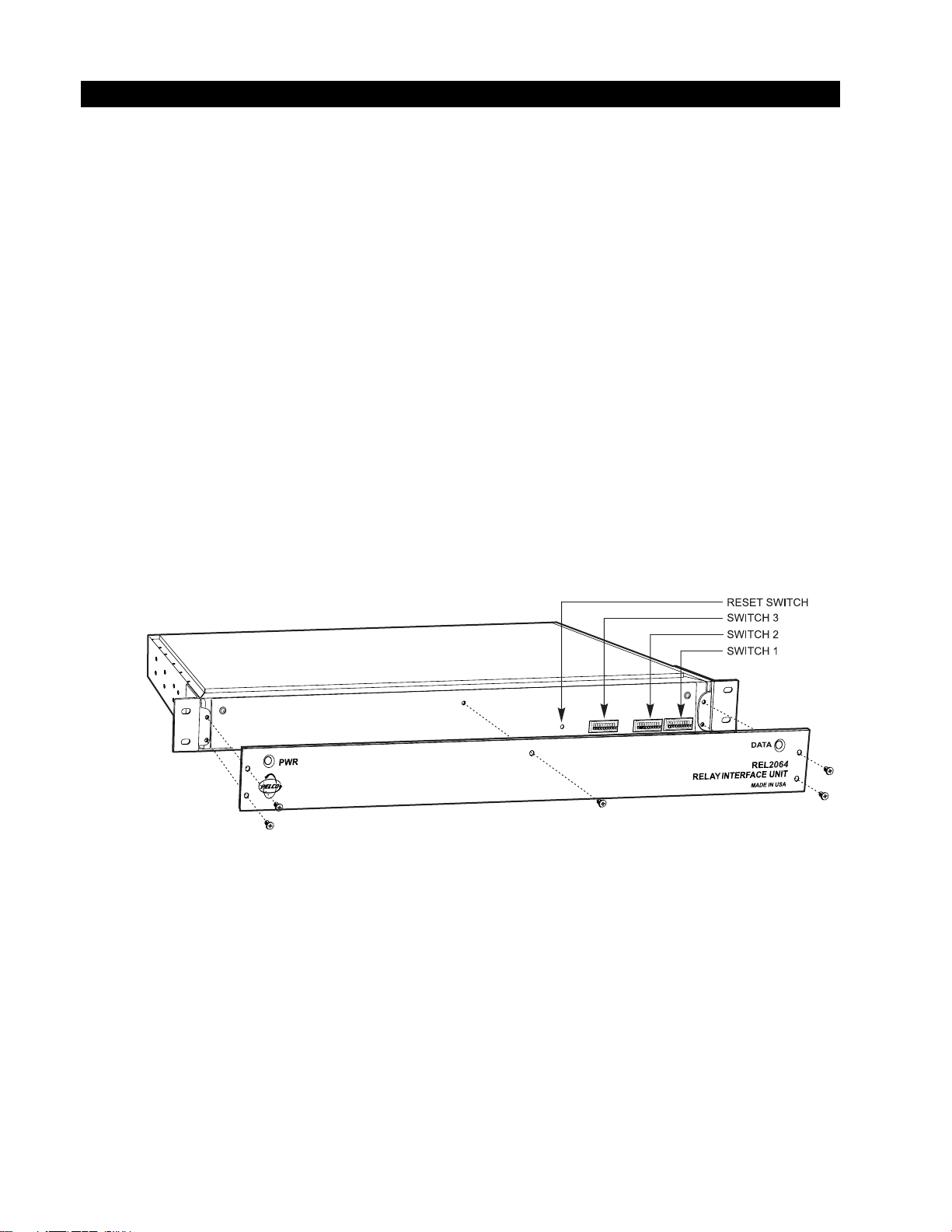

FRONT VIEW

The left side of the front panel includes the green power LED light. This light comes on at power-up.

The right side of the front panel includes the red data LED light. This light continually flashes on and off at a regular rate (about one-second

intervals) until the unit is online and communicating with the CM6800. Once online, the LED remains ON. If for any reason communication is

lost, the LED flashes again until communication is re-established.

When you remove the front panel, you have access to a reset button and configuration DIP switches.

00696

Figure 1. Front View with Panel Removal

4 C1518M-A (11/02)

Page 5

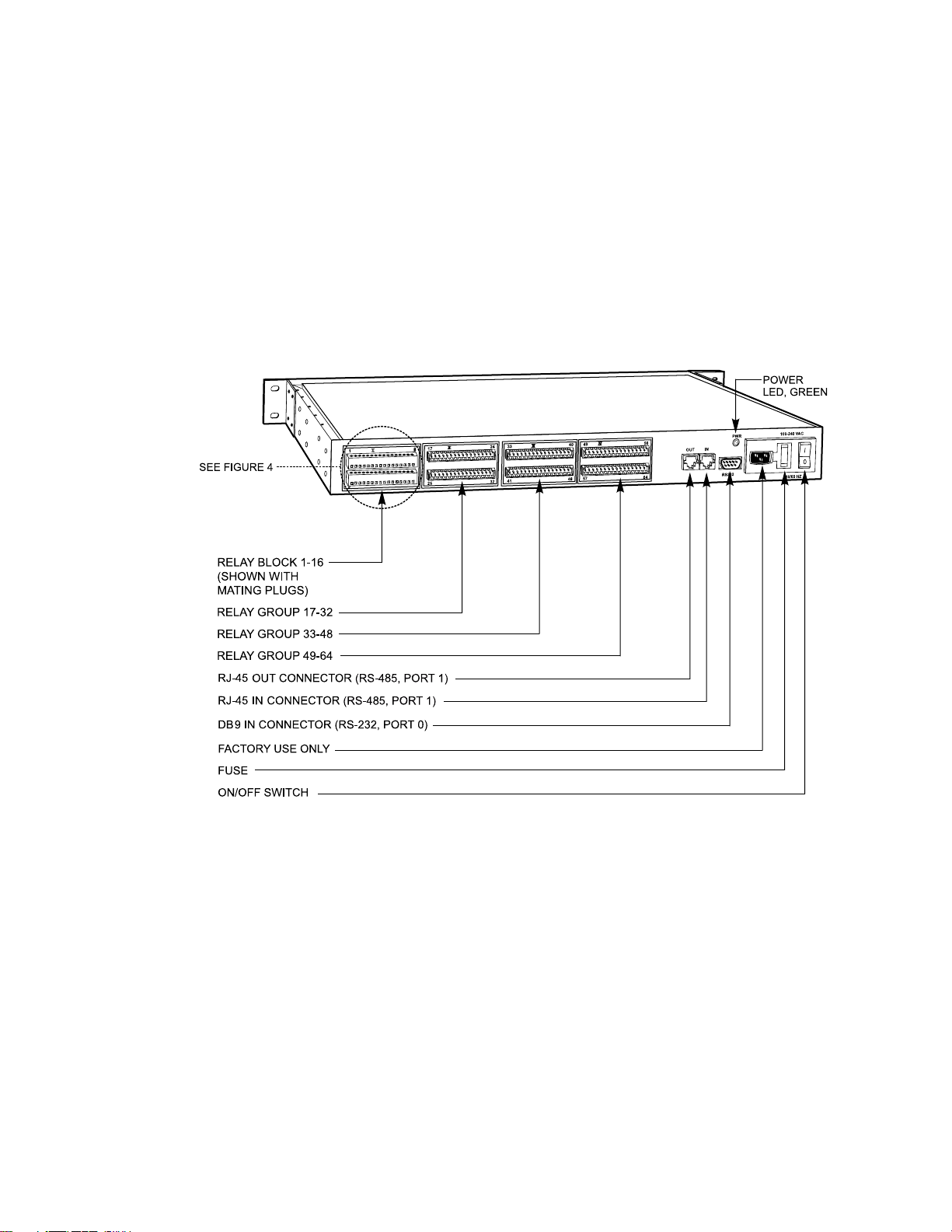

REAR VIEW

The rear of the REL2064 unit consists of the following:

1. Four groups of 16 contact pairs, each with mating plugs for the attachment of peripheral equipment; only the group for the first 16

2. One RS-485 output communication port (RJ-45 type connector)

3. One RS-485 input communication port (RJ-45 type connector)

4. One RS-232 diagnostic communication port (DB9 type connector)

5. The grouped input power functions consisting of input power terminals, a fuse, and an on/off switch

contact pairs is shown in Figure 2 with mating plugs

00700

Figure 2. Rear View of the REL2064

C1518M-A (11/02) 5

Page 6

INSTALLATION

The following items are supplied:

• REL2064 Relay Interface Unit

• 120 VAC power cord

• 220 VAC power cord

• Pelco screwdriver

• 10-foot (3 m) straight RJ-45 cable (8-conductor)

•4 #10 screws with nylon washers

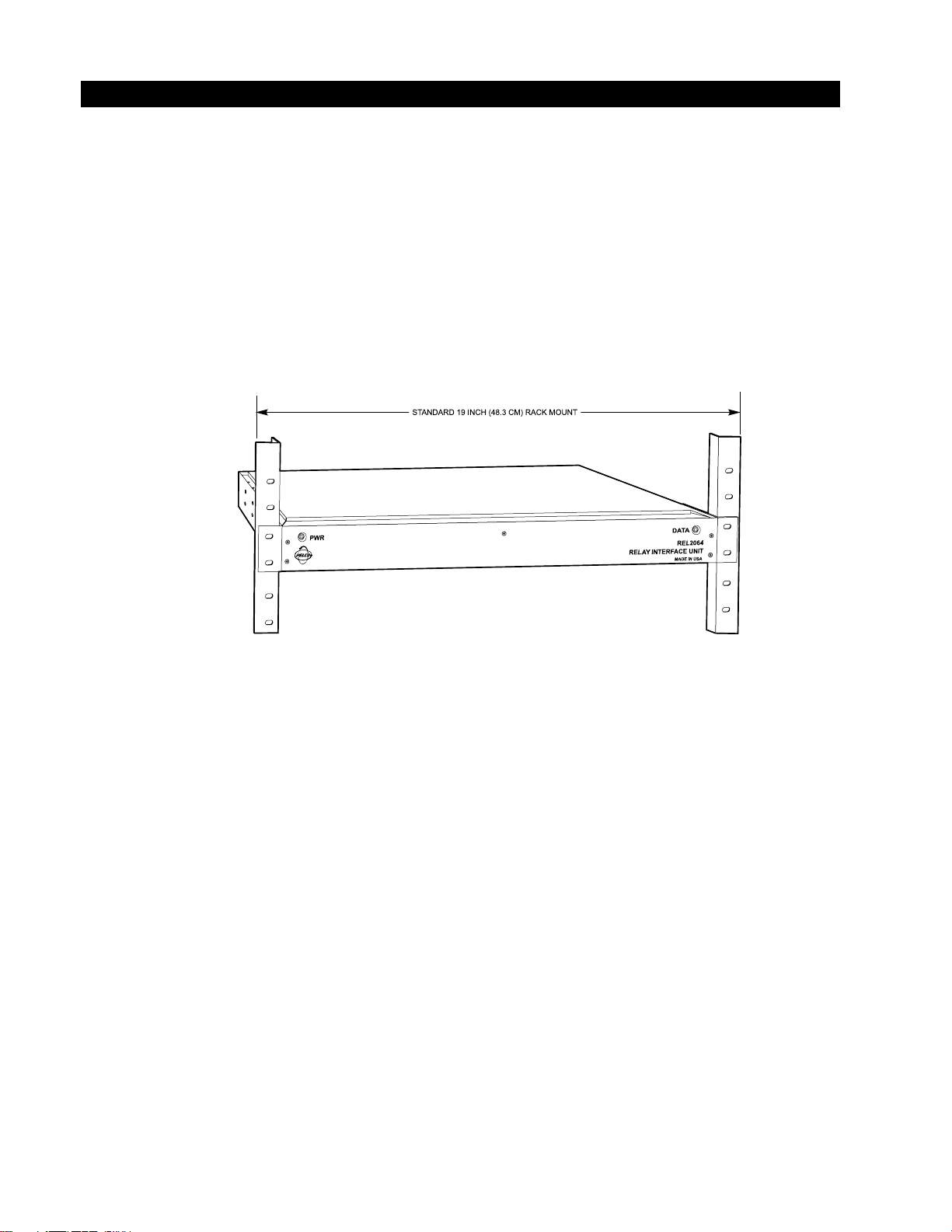

MOUNTING

Install the relay unit in a 19-inch rack. The unit occupies one rack unit (1.75 inches or 4.45 cm) of space. You can mount the relay unit to

something other than a standard 19-inch rack by relocating the rack ears to another location.

WIRING RELAYS

The relay unit has four groups of relay contacts. Each group represents 16 pairs of relay contacts:

• Group I – 1-8, 9-16

• Group II – 17-24, 25-32

• Group III – 33-40, 41-48

• Group IV – 49-56, 57-64

Each of the four groups contains two connectors with input mating plugs. The top connector is for the first eight pairs of relay contacts

and the bottom connector is for the last eight pairs of relay contacts. Each mating plug has 16 screw terminals and 16 pins. When you

place a wire into a pin, tighten the screw to secure it.

Refer to Figure 4 to determine the screw terminal number for a particular contact. The numbers that appear on the mating plugs in Figure

4 are for illustration only. The terminal positions on the actual physical plugs are not numbered.

Refer to Figure 5 for wiring the relays to peripheral equipment.

00701

Figure 3. Rack-Mount Installation

6 C1518M-A (11/02)

Page 7

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

00702

Figure 4. Relay Interface Contact Configuration

C1518M-A (11/02) 7

Page 8

9

WARNING:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

WARNING:

+

—

Figure 5. Wiring Relays to Peripheral Equipment

32-122F (0-50C)

00703

8 C1518M-A (11/02)

Page 9

CONNECTING TO THE CM6800

Connect the supplied RJ-45 straight cable from the REL2064 OUT port to the CM6800 COM 3 port. The active pin-outs are associated with

the four outer pins: 1, 2, 7, and 8. Refer to Figure 6.

If you want to place the relay unit some distance from the CM6800, the RS-485 communication from the relay unit to the controller should

not exceed 4,000 feet (1,219 m). You need an RJ-45 wall-block terminal (part number CON12J008Z03G0Z) if operating from a remote site.

To cascade two relay units, connect a straight cable from the OUT port of the second relay unit to the IN port of the first relay unit. The

first unit is the one you connect to the CM6800.

Figure 6. Connection to the CM6800

00704

C1518M-A (11/02) 9

Page 10

SETTING THE DIP SWITCHES

The positioning of the DIP switches on the front of the relay unit determines how the relay unit operates. You must recycle power whenever

you make changes to the DIP switches.

1. Remove the front panel by unscrewing the five flat-head Phillips screws. You see three switches.

Baud Relay Range GPI Contacts

1200 Off Off Off 1-64 Off Off Off 1

2400 On Off Off 65-128 On Off Off 9

4800 Off On Off 129-192 Off On Off 17

9600 On On Off 193-256 On On Off 25

19200 Off Off On 257-320 Off Off On 33

38400 On Off On 321-384 On Off On 41

57600 Off On On 385-448 Off On On 49

115200 On On On 449 On On On 57

DIP Switch 1 2 3 4 5 6 7 8 9 10

Table A. Switch 1

SW1 – Communications/Relay Type Selection

Table B. Switch 2

Norm

Open

(N.O.)

Norm

Closed

(N.C.)

1-16 17-32 33-48 49-64

Off Off Off Off

On On On On

Address SW2 – Address

1 Off Off Off Off Off Off Off Off Off Off

2 On Off Off Off Off Off Off Off Off Off

3 Off On Off Off Off Off Off Off Off Off

4 On On Off Off Off Off Off Off Off Off

5 Off Off On Off Off Off Off Off Off Off

6 On Off On Off Off Off Off Off Off Off

7 Off On On Off Off Off Off Off Off Off

8 On On On Off Off Off Off Off Off Off

9 Off Off Off On Off Off Off Off Off Off

10 On Off Off On Off Off Off Off Off Off

11 Off On Off On Off Off Off Off Off Off

12 On On Off On Off Off Off Off Off Off

13 Off Off On On Off Off Off Off Off Off

14 On Off On On Off Off Off Off Off Off

15 Off On On On Off Off Off Off Off Off

16 On On On On Off Off Off Off Off Off

DIP Switch 1 2 3 4 5 6 7 8 9 10

Table C. Switch 3

SW3 – Power-On Initialization

N/A Initialization Relay Relay Relay Relay

State 1-16 17-32 33-48 49-64

Off

DIP Switch 1, 2 3 4 5 6 7-10

Initialize Off Off Off Off

Maintain Last State On On On On

Off

10 C1518M-A (11/02)

Page 11

2. Set the DIP switches.

)

5

1

ON

2

BAUD RATE

1200: OFF, OFF, OFF

2400: ON, OFF, OFF

4800: OFF, ON , OFF

9600: ON, ON, OFF

19200: OFF, OFF, ON

38400: ON, OFF, ON

57600: OFF, ON, ON

115200: ON, ON, ON

N.O. = NORMALLY OPEN

N.C. = NORMALLY CLOSED

SUP = SUPERVISED

UNSUP = UNSUPERVISED

DEFAULT SETTINGS: BAUD 19200, RELAY RANGE 1-64,

NOTE: REFER TO APPENDIX A FOR EACH LOCAL DEVICE

ADDRESS (1-253).

4

3

6

7

BEGIN RELAY RANGE/BEGIN GPI

1-64/1: OFF, OFF, OFF

65-128/9: ON, OFF, OFF

129-192/17: OFF, ON, OFF

193-256/25: ON, ON, OFF

257-320/33: OFF, OFF, ON

321-384/41: ON, OFF, ON

385-448/49: OFF, ON, ON

449/57: ON, ON, ON

RELAY CONTACT GROUPS

7 (1-16): OFF (N.O.) ON (N.C.)

8 (17-32): OFF (N.O.) ON (N.C.)

9 (33-48): OFF (N.O.) ON (N.C.)

10 (49-64): OFF (N.O.) ON (N.C.

RELAY CONTACT GROUPS N.O.

Figure 7. SW1 DIP Switches

5

ON

1

2

4

3

6

7

9

8

8

10

9

10

LOCAL DEVICE ADDRESS

DEFAULT SETTINGS: LOCAL DEVICE ADDRESS 1,

DIP SWITCH 9 OFF,

DIP SWITCH 10 ON

NOT USED:

OFF

DIAGNOSTICS:

OFF

Figure 8. SW2 DIP Switches

5

1

ON

NOT USED:

OFF

2

4

3

6

MEMORY (MEM) CONTACTS

1-16: OFF OR ON

17-32: OFF OR ON

7

33-48: OFF OR ON

49-64: OFF OR ON

MEM ON: SETTINGS REMAIN IN MEMORY IN CASE OF POWER

FAILURE OR ACCIDENTAL RESET

MEM OFF: SETTINGS GO BACK TO THE FACTORY DEFAULT IN

CASE OF POWER FAILURE OR ACCIDENTAL RESET

DEFAULT SETTINGS: MEMORY FEATURE DISABLED,

DIP SWITCHES 1, 2, AND 7-10 OFF

9

8

10

NOT CONNECTED:

OFF

Figure 9. SW3 DIP Switches

00697

00698

3. Replace the front panel.

C1518M-A (11/02) 11

Page 12

OPERATION

The function of the relay unit is to operate relays to control peripheral equipment. Each relay unit processes and executes only commands with

addresses that match those of the relay units.

When power is turned on, the green power LEDs on the front and back of the unit light. The red data LED light on the front continually

flashes on and off at a regular rate (about one-second intervals) until the unit is online and communicating with the CM6800. Once online,

the LED remains ON. If for any reason communication is lost, the LED flashes again until communication is re-established.

MEMORY FEATURE

Although relay groups retain their contact position in the event of a power failure, the unit does not report relay status when requested

after power is recycled. Since the firmware has no battery backed up memory, it does not know the state of the relays and may report

them incorrectly. If a KBD960 keyboard is present on the system, it can contain inaccurate information in the GPI menu.

If the memory feature is disabled, the relays are all placed in a known state at startup. Under these conditions, the state of the relays are

all known and are reported when requested. True relay status shows up on the keyboard display.

12 C1518M-A (11/02)

Page 13

OPERATING RELAYS FROM THE KBD960

To operate relays from a KBD960 keyboard, you must know which GPI to call, and which auxiliary (AUX) to select on the keyboard.

You can cascade two relay units. Each relay unit has eight GPIs. Relay Unit 1 has a GPI range of 1-8, and Relay Unit 2 has a GPI range of

9-16. Refer to Tables C and D.

There are two ways you can operate relays from the KBD960.

ACTIVATING RELAYS USING F12

NOTE: You hear a brief click from the relay unit whenever you activate a momentary or latching relay contact.

Follow these steps to activate a momentary relay:

1. Go to Main Menu 1.

2. Enter a logical relay contact number (1-128).

3. Press F12.

A momentary relay does not remain on. Only a latched relay remains on. If you want a latched relay, you must activate it from the GPI

Menus.

ACTIVATING RELAYS FROM THE GPI MENUS

You can activate relays from the GPI Menus as momentary or latching. A momentary relay goes on briefly and then turns off. A latched

relay remains on until you turn it off.

Momentary

To activate relay contact 4, for example, follow these steps:

1. Go to Main Menu 1 and enter 1 (GPI). GPI 1 is associated with relay contact 4. Refer to Table C.

2. Select

GPI

to bring up GPI Menu 1. This menu displays auxiliaries 1-4. Make sure

MTRY

is highlighted. When

relay you activate becomes momentary.

3. Select 4.

Latching

To activate the same relay as latching, follow these steps:

1. Go to Main Menu 1 and enter 1 (GPI).

GPI

2. Select

3. Select

4. Select

5. Select

to bring up GPI Menu 1.

MTRY

so that it is not highlighted. When

4

. This icon becomes highlighted.

MTRY

and then the highlighted auxiliary icon to turn off the latched relay.

MTRY

is not highlighted, any relay you activate latches (remains on).

MTRY

is highlighted, any

C1518M-A (11/02) 13

Page 14

Table D. Relay Unit 1

GPI Relay Contacts

1 12345678

291011 12 13 14 15 16

31718192021222324

42526272829303132

53334353637383940

64142434445464748

74950515253545556

85758596061626364

Associated Aux 12345678

Table E. Relay Unit 2

GPI Relay Contacts

96566676869707172

10 73 74 75 76 77 78 79 80

11 81 82 83 84 85 86 87 88

12 89 90 91 92 93 94 95 96

13 97 98 99 100 101 102 103 104

14 105 106 107 108 109 110 111 112

15 113 114 115 116 117 118 119 120

16 121 122 123 124 125 126 127 128

Associated Aux 12345678

NOTE: In Relay Unit 2, GPIs 9-16 are associated with the physical relays (1-64) on the back of the unit.

However, GPIs 9-16 are also associated with logical relays 65-128. For example, the physical relays for

GPI 9 are 1-8 and the logical relays are 65-72.

14 C1518M-A (11/02)

Page 15

TROUBLESHOOTING

Problem

Why were the contact positions lost when

there was a power failure?

Why is the unit not operating as it should?

What is the DB9 port used for?

Solution

Make sure DIP switches 3-6 of SW3 are enabled so that your settings remain in

memory.

Make sure the power cord is plugged in and the power switch is turned on. If the unit

still fails to operate, remove the front panel and press the reset button. This initializes

the unit to its start-up settings. Make sure the DIP switch settings and software

settings are correct. Check the input power fuse. You may need to replace it. Refer to

Figure 10.

This port is used for diagnostics. A technical support representative may ask you to

enable this feature should a problem arise with the unit. This port is not needed for the

everyday operation of the REL2064.

00699

Figure 10. Power Input Fuse Replacement

C1518M-A (11/02) 15

Page 16

APPENDIX A

Address 12345678

1 00000000

2 10000000

3 01000000

4 11000000

5 00100000

6 10100000

7 01100000

8 11100000

9 00010000

10 10010000

11 01010000

12 11010000

13 00110000

14 10110000

15 01110000

16 11110000

17 00001000

18 10001000

19 01001000

20 11001000

21 00101000

22 10101000

23 01101000

24 11101000

25 00011000

26 10011000

27 01011000

28 11011000

29 00111000

30 10111000

31 01111000

32 11111000

33 00000100

34 10000100

35 01000100

36 11000100

37 00100100

38 10100100

39 01100100

40 11100100

41 00010100

42 10010100

43 01010100

44 11010100

45 00110100

46 10110100

47 01110100

48 11110100

49 00000100

50 10001100

51 01001100

52 11001100

53 00101100

54 10101100

55 01101100

56 11101100

57 00011100

58 10011100

59 01011100

60 11011100

61 00111100

62 10111100

DIP Switch

Address 12345678

63 01111100

64 11111100

65 00000010

66 10000010

67 01000010

68 11000010

69 00100010

70 10100010

71 01100010

72 11100010

73 00010010

74 10010010

75 01010010

76 11010010

77 00110010

78 10110010

79 01110010

80 11110010

81 00001010

82 10001010

83 01001010

84 11001010

85 00101010

86 10101010

87 01101010

88 11101010

89 00011010

90 10011010

91 01011010

92 11011010

93 00111010

94 10111010

95 01111010

96 11111010

97 00000110

98 10000110

99 01000110

100 11000110

101 00100110

102 10100110

103 01100110

104 11100110

105 00010110

106 10010110

107 01010110

108 11010110

109 00110110

110 10110110

111 01110110

112 11110110

113 00001110

114 10001110

115 01001110

116 11001110

117 00101110

118 10101110

119 01101110

120 11101110

121 00011110

122 10011110

123 01011110

124 11011110

0 = OFF

1 = ON

16 C1518M-A (11/02)

DIP Switch

(Continued on next page)

Page 17

Address 12345678

DIP Switch

125 00111110

126 10111110

127 01111110

128 11111110

129 00000001

130 10000001

131 01000001

132 11000001

133 00100001

134 10100001

135 01100001

136 11100001

137 00010001

138 10010001

139 01010001

140 11010001

141 00110001

142 10110001

143 01110001

144 11110001

145 00001001

146 10001001

147 01001001

148 11001001

149 00101001

150 10101001

151 01101001

152 11101001

153 00011001

154 10011001

155 01011001

156 11011001

157 00111001

158 10111001

159 01111001

160 11111001

161 00000101

162 10000101

163 01000101

164 11000101

165 00100101

166 10100101

167 01100101

168 11100101

169 00010101

170 10010101

171 01010101

172 11010101

173 00110101

174 10110101

175 01110101

176 11110101

177 00001101

178 10001101

179 01001101

180 11001101

181 00101101

182 10101101

183 01101101

184 11101101

185 00011101

186 10011101

187 01011101

188 11011101

189 00111101

Address 12345678

190 10111101

191 01111101

192 11111101

193 00000011

194 10000011

195 01000011

196 11000011

197 00100011

198 10100011

199 01100011

200 11100011

201 00010011

202 10010011

203 01010011

204 11010011

205 00110011

206 10110011

207 01110011

208 11110011

209 00001011

210 10001011

211 01001011

212 11001011

213 00101011

214 10101011

215 01101011

216 11101011

217 00011011

218 10011011

219 01011011

220 11011011

221 00111011

222 10111011

223 01111011

224 11111011

225 00000111

226 10000111

227 01000111

228 11000111

229 00100111

230 10100111

231 01100111

232 11100111

233 00010111

234 10010111

235 01010111

236 11010111

237 00110111

238 10110111

239 01110111

240 11110111

241 00001111

242 10001111

243 01001111

244 11001111

245 00101111

246 10101111

247 01101111

248 11101111

249 00011111

250 10011111

251 01011111

252 11011111

253 00111111

DIP Switch

0 = OFF

1 = ON

C1518M-A (11/02) 17

Page 18

SPECIFICATIONS

ELECTRICAL

Input Voltage: 100-240 VAC, 50/60 Hz, auto-ranging

Power: 30 VA

Data Ports

Diagnostic: RS-232, DB9 connector

Input: RS-485, RJ-45 connector

Output: RS-485, RJ-45 connector

Indicators: Two green power LEDs

Fusing: 500 mA, 250V

Relay Contacts

Type: Normally open

Max. Switching Capacity: 60 watts

Max. Operating Voltage: 125 VAC/VDC

Maximum Current: 2 amps

Contact Resistance: 75 milliohms

Rated Load Parameters: .5A @ 125 VAC; 2A @ 30 VDC

Relay Output: Load rating for relay contacts: 0.50A at 125 VAC or 1A at 25 VAC

GENERAL

Dimensions: See Figure 11.

Operating Temperature: 32° to 122°F (0° to 50°C)

Unit Weight: 8 lb (3.63 kg)

MECHANICAL

Connectors

Relay Inputs: Screw terminals

Power: 3-wire receptacle, #18 AWG

RS-485: Two RJ-45 connectors

RS-232: One DB9 connector (factory use only)

One data LED

(Design and product specifications subject to change without notice.)

8.15

(20.70)

1.75

(4.45)

PWR

NOTE: VALUES IN PARENTHESES ARE CENTIMETERS;

ALL OTHERS ARE INCHES

Figure 11. REL2064 Dimension Diagram

19.00 (48.26)

17.40 (44.20)

ALARM

Relay Interface Unit

REL2064

Made in USA

00695

18 C1518M-A (11/02)

Page 19

REGULATORY NOTICES

This equipment has been tested and found to comply with the limits of a Class B digital device, pursuant to part 15 of the FCC rules. These

limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However there is no guarantee that the interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on,

the user is encouraged to try and correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or

workmanship for a period of one year after the date of shipment. Exceptions to this warranty are

as noted below:

• Five years on Pelco manufactured cameras (CC3500/CC3600/CC3700 and MC3500/MC3600

Series); two years on all other cameras.

• Three years on Genex® Series (multiplexers, server, and keyboard) and 090 Series Camclosure

Camera System.

•Two years on 100/150, 200, and 300 Series Camclosure Camera Systems.

•Two years on all standard motorized or fixed focal length lenses.

•Two years on Legacy®, CM6700/CM6800/CM8500/CM9500/CM9740/CM9760 Matrix, DF5

and DF8 Series Fixed Dome products.

•Two years on Spectra®, Esprit®, and PS20 Scanners, including when used in continuous

motion applications.

•Two years on Esprit and WW5700 series window wiper (excluding wiper blades).

• Eighteen months on DX Series digital video recorders.

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco

shipment. All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis,

California. Repairs made necessary by reason of misuse, alteration, normal wear, or accident

are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from the

specific use or application made of the Products. Pelco’s liability for any claim, whether based on

breach of contract, negligence, infringement of any rights of any party or product liability, relating

to the Products shall not exceed the price paid by the Dealer to Pelco for such Products. In no

event will Pelco be liable for any special, incidental or consequential damages (including loss of

use, loss of profit and claims of third parties) however caused, whether by the negligence of

Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have

additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or (559) 292-1981 to

obtain a Repair Authorization number (RA), and provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

®

If there is a dispute regarding the warranty of a product which does not fall under the warranty conditions

stated above, please include a written explanation with the product when returned.

Method of return shipment shall be the same or equal to the method by which the item was received by

Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at (800) 2899100 or (559) 292-1981 to obtain an authorization number (CA number if returned for credit, and RA

number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA number and

freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico:

Intermediate Consignee Ultimate Consignee

American Overseas Air Freight Pelco

320 Beach Road 3500 Pelco Way

Burlingame, CA 94010 Clovis, CA 93612-5699

USA USA

REVISION HISTORY

Manual # Date Comments

C1518M 5/01 Original version.

C1518M-A 11/02 Updated manual to new format. Revised Table A and updated Table B.

® Pelco, the Pelco logo, Spectra, Genex, Esprit, Camclosure, and Legacy are registered trademarks of Pelco. © Copyright 2002, Pelco. All rights reserved.

C1518M-A (11/02) 19

Page 20

®

World Headquarters

3500 Pelco Way

Clovis, California 93612 USA

USA & Canada

Tel: 800/289-9100

Fax: 800/289-9150

International

Tel: 1-559/292-1981

Fax: 1-559/348-1120

www.pelco.com

ISO9001

Orangeburg, New York Las Vegas, Nevada Eindhoven, The Netherlands Wokingham, United Kingdom Montreal, Canada

Loading...

Loading...