Page 1

WARNING!

Warning! When lifting, transporting, or unpacking the PT7700 Series pan/tilt systems,

DO NOT use the camera enclosure as a

handle. Severe damage to the unit can occur.

C997M

®

3500 Pelco Way, Clovis, CA 93612-5699 • (559) 292-1981 • (800) 289-9100

• FAX (800) 289-9150

Page 2

®

PT7700 Series

Pan and Tilt

Systems

Installation/

Operation Manual

C397M (4/98)

Pelco • 3500 Pelco Way • Clovis, CA 93612-5699 • USA • www.pelco.com

In North America and Canada: Tel (800) 289-9100 • FAX (800) 289-9150

International Customers: Tel (1-559) 292-1981 or FAX (1-559) 348-1120

Pelco Manual C397M (4/98) 1

Page 3

CONTENTS

Section Page

1.0 GENERAL .................................................................................................. 3

1.1 IMPORTANT SAFEGUARDS AND WARNINGS ...............................3

2.0 DESCRIPTION ..........................................................................................4

2.1 MODELS ............................................................................................ 4

2.2 CERTIFICATIONS ............................................................................. 4

3.0 INSTALLATION ..........................................................................................5

3.1 MOUNTING ....................................................................................... 5

3.2 CAMERA/LENS INSTALLATION .......................................................5

3.3 WIRING ............................................................................................. 7

3.4 TESTING SYSTEM AND ADJUSTING LIMIT STOPS ...................... 10

4.0 OPERATION .............................................................................................11

5.0 TROUBLESHOOTING ..............................................................................12

6.0 MAINTENANCE ........................................................................................13

7.0 EXPLODED ASSEMBLY DIAGRAMS ...................................................... 15

8.0 SPECIFICATIONS ....................................................................................20

9.0 WARRANTY AND RETURN INFORMATION ........................................... 24

LIST OF ILLUSTRATIONS

Figure Page

1 PT7700 Series Input Wiring Diagram ................................................ 8

2 PT7700 Series Connector ................................................................. 9

3 Tilt Limit Stop Adjustment ................................................................. 10

4 Pan Adjustments and Lubrication ..................................................... 14

5 Tilt Adjustments and Lubrication ....................................................... 14

6 Exploded Assembly Diagram for Blower and Circuit Board ..............15

7 Exploded Assembly Diagram for Heaters and Circuit Board ............ 17

8 Wiring Diagram for Enclosure Circuit Board ..................................... 18

9 Component Locations for Enclosure Circuit Board ...........................19

10 Layout of Traces on Enclosure Circuit Board ................................... 19

11 Dimension Drawing ...........................................................................23

LIST OF TABLES

Table Page

A Parts List (Figure 6) .......................................................................... 16

B Parts List (Figure 7) .......................................................................... 17

REVISION HISTORY

Manual # Date Comments

C397M 8/96 Original version

C397M 8/97 Completely revised manual. Added models and revised

4/98 Removed options. Added certifications. Changed pagination.

pin assignments in Figure 2 per ECR #0927.

2 Pelco Manual C397M (4/98)

Page 4

1.0 GENERAL

1.1 IMPORTANT SAFEGUARDS AND WARNINGS

Prior to installation and use of this product, the following WARNINGS should be

observed.

1. Installation and servicing should only be done by Qualified Service Personnel

and conform to all Local codes.

2. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or

6P enclosure, it is designed for indoor use only and it must not be installed

where exposed to rain and moisture.

3. The weight of the camera/lens and enclosure shall not exceed 75 lbs.

(34.02 kg).

4. Only use replacement parts recommended by Pelco.

5. After replacement/repair of this unit’s electrical components, conduct a resistance measurement between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

6. The installation method and materials should be capable of supporting four

(4) times the weight of the enclosure, pan/tilt, camera and lens combination.

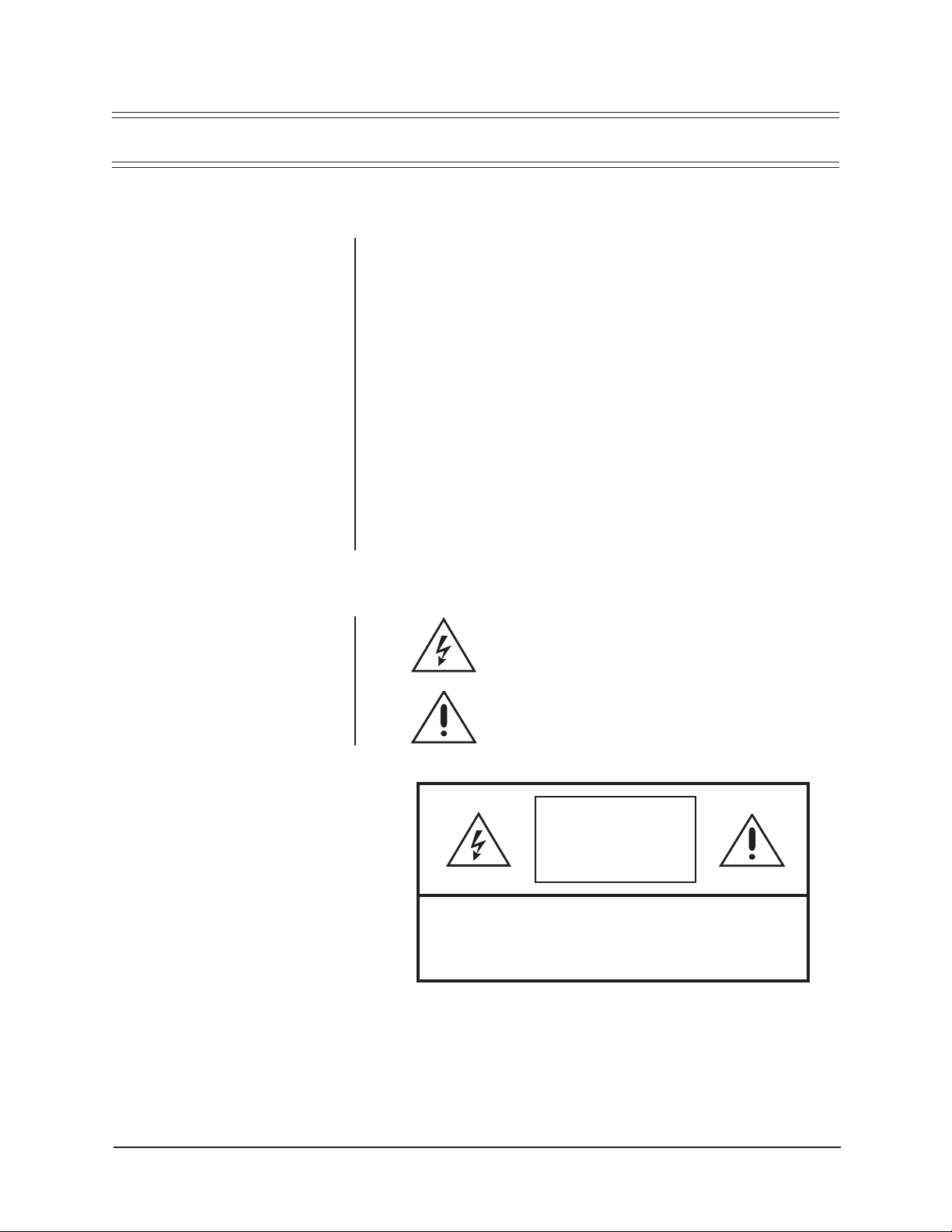

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage constituting a

risk of electric shock is present within this unit.

This symbol indicates that there are important operating and

maintenance instructions in the literature accompanying this

unit.

CAUTION:

RISK OF

ELECTRIC SHOCK.

DO NOT OPEN.

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

DO NOT REMOVE COVER. NO USER-

SERVICEABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

CAUTION:

Please thoroughly familiarize yourself with the information

in this manual prior to installation and operation.

Pelco Manual C397M (4/98) 3

Page 5

2.0 DESCRIPTION

The PT7700 systems combine an environmental camera enclosure, pan/tilt assembly, and receiver/driver into a single unit that you can install indoors or outdoors. You can install 2/3-inch (1.69 cm) and 1-inch (2.54 cm) format cameras with

either fixed focal length lenses or motorized zoom lenses. An adjustable camera

sled will accommodate different sizes of cameras and lenses.

2.1 MODELS

PT7723RX-1 Pan/tilt, CX9115RX Coaxitron® receiver/driver, and EH5723-1

PT7723RX-1/PP PT7723RX-1 with preset positioning capabilities and alarm

PT7723RX-3 Pan/tilt, CX9115RX Coaxitron® receiver/driver, and EH5723-1

PT7723RX-3/PP PT7723RX-3 with preset positioning capabilities and alarm

PT7729RX Pan/tilt, CX9115RX Coaxitron

PT7729RX-1 PT7729RX with thermostatically controlled heater and blower.

PT7729RX-1/PP PT7729RX-1 with preset positioning capabilities and alarm

PT7729RX-1/SL PT7729RX-1 with 360° pan rotation.

PT7729RX-3 Pan/tilt, CX9220RX Coaxitron® receiver/driver, and EH5729-3

PT7729RX-3/PP PT7729RX-3 with preset positioning capabilities and alarm

PT7723WX-1 Pan/tilt, WX8115RX Wiretron receiver/driver, and EH5723-1

PT7729WX Pan/tilt, WX8115RX Wiretron receiver/driver, and EH5729

PT7729WX-1 PT7729WX with thermostatically controlled heater and blower.

PT7729WX-3 Pan/tilt, WX8220RX Wiretron receiver/driver, and EH5729-3

23-inch (54 cm) enclosure. 120 VAC input. Thermostatically

controlled heater and blower.

outputs.

23-inch (54 cm) enclosure. 230VAC input. Thermostatically

controlled heater and blower.

outputs.

29-inch (74 cm) environmental camera enclosure. 120 VAC input.

outputs.

29-inch (74 cm) enclosure. 230 VAC input. Thermostatically

controlled heater and blower.

outputs.

23-inch (54 cm) enclosure. 120 VAC input. Thermostatically

controlled heater and blower.

29-inch (74 cm) environmental camera enclosure. 120 VAC input.

29-inch (74 cm) enclosure. 230 VAC input. Thermostatically

controlled heater and blower.

®

receiver/driver, and EH5729

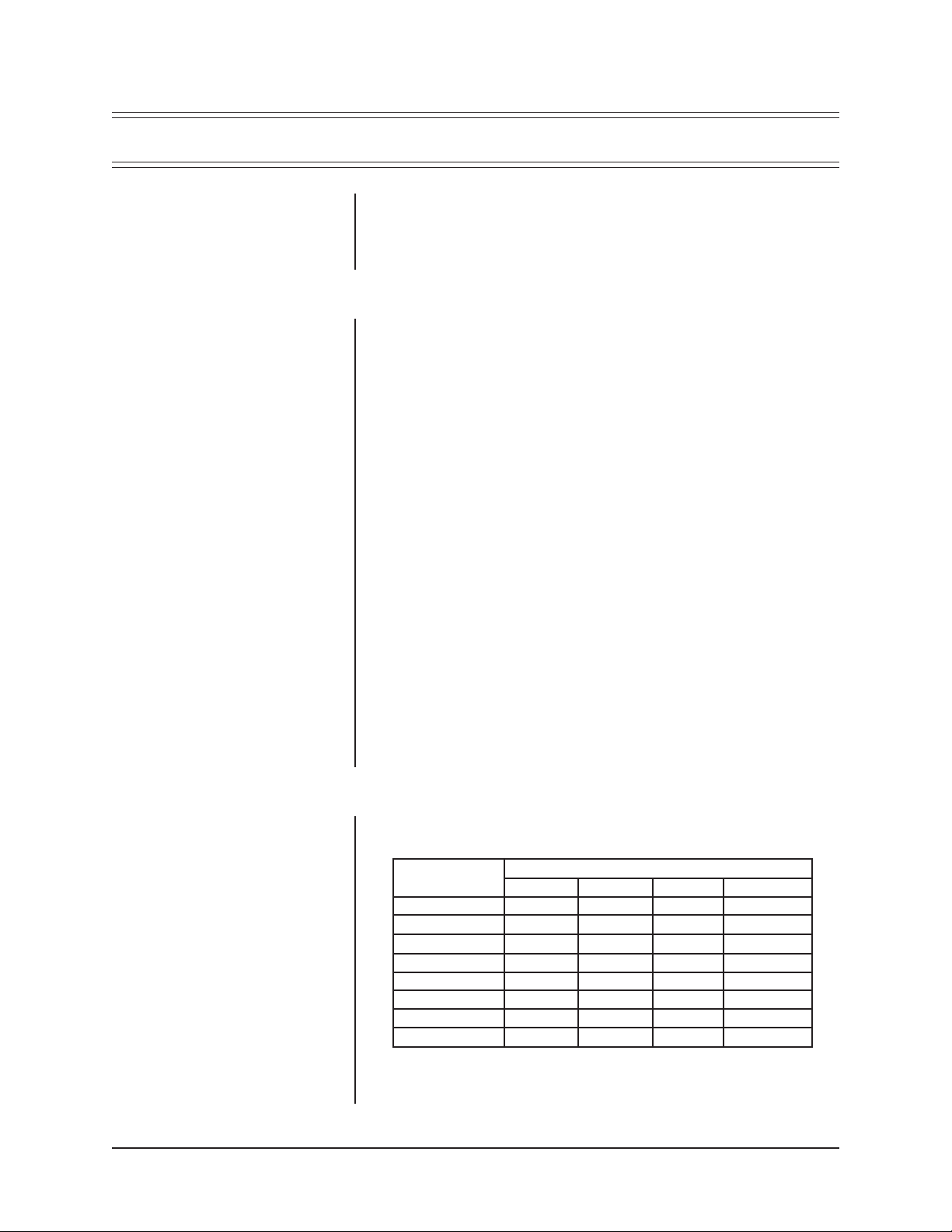

2.2 CERTIFICATIONS

The products identified below have been tested and certified for agency compliance as noted.

Agency Compliance Certification

Model CE FCC UL CSA/cUL

PT7723RX-1 X

PT7723RX-1/PP X

PT7729RX-1 X

PT7729RX-1/PP X

PT7729RX-1/SL X

PT7723WX-1 X

PT7729WX X

PT7729WX-1 X

Applicable CE, FCC, UL, and CSA/cUL directives/standards:

• UL Listed to UL2044

4 Pelco Manual C397M (4/98)

Page 6

3.0 INSTALLATION

CAUTION:

When unpacking, transporting, or lifting the PT7700 Series systems, DO NOT use

the camera enclosure as a handle. Severe damage to the unit can occur.

NOTE:

To insure proper wiring and operation of your equipment, it is recommended that you test the PT7700

system and its controller in your facility before installing them in the field. Refer to Sections 3.2 through 3.4.

3.1 MOUNTING

CAUTION:

The PT7700

systems are designed to operate in an upright position

only. Do not mount the systems horizontally or in an in-

Attach the base of the pan/tilt system to a flat surface. If you use a wall or pedestal

mount, follow the instructions that are provided with the mount.

Make sure the mounting surface can support four (4) times the weight of the pan/tilt

system. Refer to section 8.0, “Specifications,” for unit weights (excluding camera/

lens).

verted position.

Proceed to Section 3.2, CAMERA/LENS INSTALLATION.

3.2 CAMERA/LENS INSTALLATION

1. Open the enclosure lid and remove the camera sled from the rail:

a. Loosen the screws.

b. Slide the sled so that the screws are in the large part of the mounting

slots.

c. Remove the sled.

d. Remove the parts tied to the sled.

2. All Models Except the PT7729RX and PT7729WX - If you are installing the

pan/tilt system in a marine or high-moisture environment, make the following

modifications to your enclosure:

Refer to Figure 6 in Section 7.0, “Exploded Assembly Diagram,” for an exploded assembly diagram of the blower assembly.

a. Remove the plastic cover over the power supply section of the circuit

board.

b. Disconnect the electrical plug from the fan.

c. Remove the three screws that secure the fan plate and fan to the enclosure.

d. Remove the four screws that secure the fan to the fan plate.

e. Turn the fan around so that it blows toward the viewing window (refer to

the arrows on the fan).

f. Reinstall the fan on the fan plate.

g. Reinstall the fan plate and fan in the enclosure.

h. Reconnect the electrical plug on the fan.

i. Replace the plastic cover.

Pelco Manual C397M (4/98) 5

Page 7

j. On the bottom of the enclosure, remove the vent grill and filters at the

front of the enclosure. Replace the grill with one of the vent cover plates

that was attached to the camera sled as loose equipment.

k. On the bottom of the enclosure, attach the other vent cover plate over

the grill at the rear of the enclosure.

3. Mount the camera/lens to the sled with the 1/4-20 Phillips-head screws that

are provided in the parts bag. You can mount the camera to either side of the

sled for proper elevation of the camera inside the enclosure.

4. Install the sled and camera/lens in the enclosure:

a. If the camera’s lens is adjustable, extend the lens to its maximum length.

b. Place the sled over the mounting screws in the enclosure.

c. Slide the sled forward until the camera’s lens almost touches the window.

d. Tighten the screws to secure the camera sled to the enclosure.

5. Connect the video cable in the enclosure to the video output connection on

the camera.

6. If your camera has a motorized zoom lens control, connect or wire the camera’s

lens control to the LENS or LENS CONTROL connector on the circuit board.

Refer to Figure 1 to see where to connect different lens connector options.

NOTE:

If the AC power input to your

PT7700 unit is 120 VAC, the camera

must use 120 VAC. If the power input is 230 VAC, the camera must use

230 VAC.

7. Wire power from the circuit board to the camera. There are two ways to connect power (refer to Figure 1):

a. A three-pin plug with leads is supplied as loose equipment. Connect the

leads from the plug to the camera as follows:

Brown - AC HI

Blue - AC NT

Green - Ground

Remove the plastic cover over the power supply section of the circuit

board.

Connect the plug to the CAM1 socket on the circuit board.

Replace the plastic cover.

or

b. If your pan/tilt system uses 120 VAC and you ordered the optional 120 VAC

electrical outlet accessory (O/I-OUTLET), connect the 120 VAC plug to the

camera. Connect the three-pin plug to CAM1 (remove the plastic cover over

the circuit board and replace the cover after you plug in the connector).

8. Adjust the focus and iris on the camera, if necessary.

9. Close the enclosure lid.

Proceed to Section 3.3, WIRING.

6 Pelco Manual C397M (4/98)

Page 8

3.3 WIRING

1. Route the six-foot power/video/control cable through the wall or pedestal mount

if applicable.

2. Connect the end of the cable with the 16-pin connector to the mating connector in the base of the pan/tilt unit.

3. Connect the other end of the cable as follows:

a. Connect the coax cable to the video input of the controller.

b. For models PT7729WX, PT7729WX-1, PT7723WX-1 and PT7729WX-3,

c. For models PT7729RX-1/PP and PT7729RX-3/PP, connect the alarm

d. Plug the power cord into either 120 VAC or 230 VAC, depending on your

Proceed to Section 3.4, TESTING SYSTEM AND ADJUSTING LIMIT STOPS.

connect the Wiretron control wires (refer to Figure 2).

outputs (cable not supplied). Refer to Figure 2.

model.

Pelco Manual C397M (4/98) 7

Page 9

Figure 1. PT7700 Series Input Wiring Diagram

8 Pelco Manual C397M (4/98)

Page 10

PT7729RX

PT7723RX-1

PT7729RX-1

PT7729RX-3

PT7729RX-1/SL

Base Connector

Pin Assignments

PT7729WX

PT7723WX-1

PT7729WX-1

PT7729WX-3

Base Connector

Pin Assignments

PIN FUNCTION COLOR

2 COAX CORE RED

4 COAX SHIELD BLK

8 GROUND GRN

10 AUX COMMON WHT/GRN

11 AUX1 ORG

12 AUX2 YEL

13 AUX3 BLU

15 AC NEUTRAL WHT (2X)

16 AC HIGH BLK (2X)

PIN FUNCTION COLOR

2 COAX CORE RED

4 COAX SHIELD BLK

8 GROUND GRN

9 WIRETON INPUT SIGNAL HIGH BRN/WHT

10 AUX COMMON WHT/GRN

11 AUX1 ORG

12 AUX2 YEL

13 AUX3 BLU

14 WIRETRON INPUT SIGNAL LOW BLK/WHT

15 AC NEUTRAL WHT (2X)

16 AC HIGH BLK (2X)

PIN FUNCTION COLOR

2 COAX CORE RED

4 COAX SHIELD BLK

8 GROUND GRN

15 AC NEUTRAL WHT (2X)

PT7729RX-1/PP

PT7729RX-3/PP

With Alarm Outputs

Base Connector

Pin Assignments

16 AC HIGH BLK (2X)

1 ALARM #1

3 ALARM #2

5 ALARM #3

6 ALARM #4

7 ALARM #5

10 ALARM #6

11 ALARM #7

12 ALARM #8

13 EXTERNAL ALARMING OUTPUT (ACTIVE LO)

ALARM COMMON IS CHASSIS GROUND

Figure 2. PT7700 Series Connector

Pelco Manual C397M (4/98) 9

Page 11

3.4 TESTING SYSTEM AND ADJUSTING LIMIT STOPS

WARNING:

Never remove

the limit stops. Do not adjust the limit stops while the

unit is moving. You may injure yourself or damage the

unit.

NOTE:

The tilt limit stops are factory

set for 0° and -90° from the horizon.

To test the system and adjust the limit stops:

1. Loosen the two pan limit stops at the base of the pan/tilt.

2. Turn on power.

3. Test the system by moving the pan/tilt to the left, right, up and down. Do not

move the pan/tilt very far as the limit stops are not set yet. All you want to do is

verify that the motors work. Also verify that the camera functions properly.

4. Pan the unit to the right to the desired right pan limit.

5. Move the right pan limit stop until it touches the pan limit switch actuator.

Continue pushing the stop until the actuator clicks, indicating the switch has

opened. Lock the stop in place.

6. Pan the unit to the left to the desired left pan limit.

7. Move the left pan limit stop until it touches the pan limit switch actuator. Continue pushing the stop until the actuator clicks, indicating the switch has opened.

Lock the stop in place.

8. Remove the four screws from the right side cover of the pan/tilt.

9. Refer to Figure 3 and loosen the recessed set screws on the up and down

limit stop collars attached to the tilt shaft.

10. Tilt the unit up to the desired upward limit.

11. Turn the up limit stop collar until it touches the tilt limit switch actuator. Continue turning the stop until the actuator clicks, indicating the switch has opened.

Lock the collar in place.

12. Tilt the unit down to the desired downward limit.

13. Turn the down limit stop collar until it touches the tilt limit switch actuator.

Continue turning the stop until the actuator clicks, indicating the switch has

opened. Lock the collar in place.

14. Replace the side cover.

15. The installation is complete.

Figure 3. Tilt Limit Stop Adjustment

10 Pelco Manual C397M (4/98)

Page 12

4.0 OPERATION

Refer to the manual for your control equipment for operating the pan/tilt system.

If your enclosure has a thermostatically controlled blower, the thermostat is set to

turn the fan on between 77° and 93°F (25° and 34°C) and to turn the fan off between 62° and 78°F (17° and 26°C).

If your enclosure has thermostatically controlled heaters or defroster, the thermostat is set to turn them on between 42° and 58°F (6° and 14°C) and to turn them off

between 72° and 88°F (22° and 31°C).

Pelco Manual C397M (4/98) 11

Page 13

5.0 TROUBLESHOOTING

Fuses are located inside the left cover of the pan/tilt unit. Fuses F1 (mother board)

and F2 (camera) are 2/10-ampere, slow-blow fuses. F3 (pan/tilt) is a 1-ampere,

slow-blow fuse. To order fuses F1 and F2, specify the part number FUS2/10SB. To

order fuse F3, specify the part number FUS1SB.

If you need to return the pan/tilt system and you can not place the camera enclosure in a horizontal position, remove three of the four Allen bolts that attach the

enclosure to the tilt shaft. This will allow movement without damage to the gear

train assembly components.

Figures 6-7 and Tables A-B show exploded assembly diagrams and parts lists for

the blower and heaters, if your model is equipped with them.

Figures 8-10 show the wiring, component locations, and layout of traces for the

circuit board in the enclosure.

12 Pelco Manual C397M (4/98)

Page 14

6.0 MAINTENANCE

Perform the following maintenance at six-month (or more often in harsh environments) intervals to prolong the operational life and appearance of the equipment.

Window and Filters

1. Clean the window with a mild nonabrasive detergent in water and a soft cloth

to maintain picture clarity.

2. If your enclosure has a blower, clean the foam filters as follows:

a. On the bottom front of the enclosure, remove the two screws in the vent grill.

b. Remove the vent grill and take out the filters.

c. Clean the filters with warm water and mild detergent, dry thoroughly, and

replace them in the grill.

d. Reinstall the vent grill.

To order replacement filters, use the part number EH550010045.

Pan Adjustments and Lubrication

3. Tilt the enclosure so that the front points downward.

4. Remove the four screws at the rear, just above the base, of the pan/tilt unit.

5. Lift up the lid slightly and push it forward to free the lip at the front of the lid.

6. Check the tension of the pan drive chain. A movement of 1/32" to 3/32" in the

chain is acceptable. To adjust the chain:

a. Refer to Figure 4. Loosen the four screws (A - two shown) that secure the

motor/gearbox to the mounting frame.

b. Use a screwdriver to pry at B to apply tension to the chain.

c. Tighten the screws.

7. If necessary, tighten the nut at C to remove any endplay in the worm (E).

8. Lubricate the pan gears and chain assembly with a high quality grease capable of withstanding temperatures from -50° to 170° F (-46° to 77° C):

a. Liberally apply grease to the chain and sprockets (D), worm (E), and

worm gear (behind worm).

b. Pan the unit to spread the grease uniformly on the parts.

c. Apply additional grease if necessary.

9. Replace the lid over the pan housing.

Pelco Manual C397M (4/98) 13

Page 15

Tilt Adjustments and Lubrication

10. Remove the plastic cover on the right side of the pan/tilt unit.

11. Refer to Figure 5. Verify that the worm (B) is fully seated in the worm gear (A).

If it is not, turn the two nuts (C) to lift the worm. Tighten the two nuts at (D).

12. If necessary, tighten the nut at E to remove any endplay in the worm (B).

13. If you can move the enclosure up and down, but the worm gear (A) does not

move, push pin H further into the tilt shaft to eliminate movement.

14. Lubricate the tilt gears and chain assembly with a high quality grease capable

of withstanding temperatures from -50° to 170° F (-46° to 77° C):

a. Liberally apply grease to the chain and sprockets (J), worm (B), and worm

gear (A).

b. Tilt the unit to spread the grease uniformly on the parts.

c. Apply additional grease if necessary.

15. Replace the cover over the tilt housing.

Figure 4. Pan Adjustments and Lubrication

H

E

D

C

G

F

Figures 5. Tilt Adjustments and Lubrication

A

B

D

C

J

14 Pelco Manual C397M (4/98)

Page 16

7.0 EXPLODED ASSEMBLY DIAGRAMS

B

11

C

10

9

E

C

B

A

A

2

1

SCREWS COME WITH

BLANKING PLATE

B

8

B

F

G

H

12

7

6

5

4

Figure 6. Exploded Assembly Diagram for Blower and Circuit Board

Pelco Manual C397M (4/98) 15

Page 17

Table A. Parts List (Figure 6)

Item Qty Description Part Number

1 1 Vent Grill 57004005COMP

2 2 Foam Filter EH550010045

4 1 Circuit Board Insulator EH450010256

5 1 Circuit Board PCB9000276ASSY

6 2 Power Supply Barrier EH47004029COMP

7 1 Power Supply Barrier Cover EH470010019

8 1 Fan Wire Cord with Plug WIR432000

9 1 Fan Tube, 230 VAC ED210015

1 Fan Tube, 120 VAC EH18013

10 1 Fan Plate 57004010COMP

11 1 Standoff, 3.375" Length 570010007

12 1 Connector Plug CON1-480318-0

A 3 Screw, 6-32 x 3/8", Pan Head, Phillips ZH6-32X.375SPP

B 8 Internal Tooth Lock Washer, #6 ZH6LWSIS

C 2 Flat Washer, #6 ZH148X375X32

E 4 Cap Screw, 6-32 x 3/8", Allen Socket Head ZH6-32X.375CS

F 2 Screw, 4-40 x 1/4", Pan Head, Phillips ZH4-40X.250SPP

G 2 Split Lock Washer, #4 ZH4LWSSL

H 2 Circuit Board Grounding Clip 570010004

16 Pelco Manual C397M (4/98)

Page 18

Figure 7. Exploded Assembly Diagram for Heaters and Circuit Board

Table B. Parts List (Figure 7)

Item Qty Description Part Number

1 1 Bracket/Heater Sink 57004020COMP

2 2 Heater, 230 VAC HTR40220

2 Heater, 120 VAC HTR50120

3 1 Connector Plug CON1-480424-0

4 1 Power Supply Barrier Cover EH470010019

5 2 Power Supply Barrier EH47004029COMP

6 1 Circuit Board PCB9000276ASSY

7 1 Circuit Board Insulator EH450010256

A 2 Spacer, .375" Length SPA8422

B 4 Internal Tooth Lock Washer, #4 ZH4LWSIS

2 Internal Tooth Lock Washer, #4 ZH4LWSIS

C 4 Screw 4-40 x 1/4", Pan Head, Phillips ZH4-40X.250SPP

2 Screw 4-40 x 1/4", Pan Head, Phillips ZH4-40X.250SPP

D 2 Grounding Clip 570010004

E 2 Screw, 6-32 x 1/4", Pan Head, Phillips ZH6-32X.250SPP

F 2 Internal Star Washer, #6 ZH6LWSIS

Pelco Manual C397M (4/98) 17

Page 19

Figure 8. Wiring Diagram for Enclosure Circuit Board

18 Pelco Manual C397M (4/98)

Page 20

Figure 9. Component Locations for Enclosure Circuit Board

Figure 10. Layout of Traces on Enclosure Circuit Board

Pelco Manual C397M (4/98) 19

Page 21

8.0 SPECIFICATIONS

SYSTEM

Input Voltage: 120 or 230 VAC, 50/60 Hz

Power Requirements:

PT7729RX,

PT7729WX 0.35 A (42 vA)

PT7729RX-1,

PT7723RX-1,

PT7729RX-1/PP,

PT7729RX-1/SL,

PT7729WX-1,

PT7723WX-1 1.7 A (204 vA)

PT7729RX-3,

PT7729RX-3/PP,

PT7729WX-3 1.9 A (437 vA)

Power/Control Cables

All Models: Power - 3-wire grounded, 18 AWG, 6 ft (1.83 m)

Video - RG59, 6 ft (1.83 m)

PT7729WX,

PT7729WX-1,

PT7723WX-1,

PT7729WX-3 Wiretron Control - 2-conductor, 18 AWG, 6 ft (1.83 m)

NEMA Rating: 3R

Environment: Indoor/outdoor -10° to 120° F (-23° to 49° C)

Dimensions: See Figure 11

Unit Weight

PT7723RX-1,

PT7723WX-1 48 lbs (21.77 kg)

PT7729RX,

PT7729WX 49 lbs (22.23 kg)

PT7729RX-1,

PT7729RX-1/PP,

PT7729RX-3,

PT7729RX-3/PP,

PT7729RX-1/SL,

PT7729WX-1,

PT7729WX-3 53 lbs (24.04 kg)

20 Pelco Manual C397M (4/98)

Page 22

PAN/TILT

Construction

Body: Aluminum plate

Side Covers: Vacuum-formed ABS plastic, UV protected

Pan: 0-355° movement in horizontal plane, except PT7729RX-1/SL,

Pan Speed: 9°/sec ±1° (no load condition)

Tilt: +15° movement in vertical plane from horizon

Tilt Speed: 3°/sec ±5° (no load condition)

Torque

Pan: 10 ft lbs with specified voltage

Tilt: 20 ft lbs with specified voltage

Gearing: Adjustable worm-gear final drive to prevent drift and minimize

Bearings: Heavy-duty ball bearings on all rotating surfaces

Motors: Instantaneous reversing

Limit Switches: Pan and tilt - 5 A each

RECEIVER/DRIVER

Coaxitron® Receiver/Driver

Fuses: One 1 A, 3 AG type

Control Method: 15-pulse train (pulse width modulated) superimposed on the

which has 360° pan rotation

-90° movement in vertical plane from horizon

backlash

Two 2/10 A, 3 AG type

video signal during the vertical interval by the control transmit-

ter. Pulse train occupies one (1) TV line period.

Pulse Amplitude: Approximately 1 V p-p added to video signal; 333 KHz nominal

Input Video: 1 V p-p nominal; 2 V p-p maximum at less than 75% APL; 1.5

System Bandwidth: Less than 2 dB down at 10 MHz (exclusive of cable)

Maximum Operating

Distance: 750 ft (229 m) on RG59

V p-p maximum at 90% APL

1000 ft (305 m) on RG6

1500 ft (457 m) on RG1

(cables above are 75-ohm coax)

Pelco Manual C397M (4/98) 21

Page 23

Wiretron Receiver/Driver

Fuses: One 1 A, 3 AG type

Control Method: 15 pulse train (pulse width modulated)

Pulse Amplitude: 35 mA current loop

Cable

Requirements: Twisted pair, unshielded

Two 2/10 A, 3 AG type

Operating Distance: 22 AWG - 5 miles (8 km)

ENCLOSURE

Construction: Aluminum

Finish: Gray polyester powder coat

Window: Glass, 0.25-inch (0.64 cm) thick

Window Viewing

Area: 3.8" H x 4.8" W (9.65 x 12.19 cm)

Camera Mounting: Removable camera than can be inverted to accommodate

Maximum

Camera/Lens Size:

EH5723 22" L x 7.5" W x 5.5" H (55.88 x 19.05 x 13.97 cm)

EH5723-1,-2,-3 15.5" L x 6.25" W x 5.5" H (39.37 x 15.88 x 13.97 cm)

EH5729 28" L x 7.5" W x 5.5" H (71.12 x 19.05 x 13.97 cm)

EH5729-1,-2,-3 21.5" L x 6.25 W x 5.5" H (54.61 x 15.88 x 13.97 cm)

Electrical

Connections: One each of the following:

20 AWG - 10 miles (16 km)

various heights of cameras and lenses

3-connector terminal block for power input

6-pin lens connector

9-connector terminal block for lens wiring

10-connector terminal block for camera/lens wiring

3-pin socket for camera power input

2-pin socket for blower

2-pin socket for defroster

4-pin socket for heaters

4-pin socket for wiper

2-pin socket for wiper control

BNC for video

Accessory

Input Power: Heater (120 VAC models) 90 watts

Heater (230 VAC models) 70 watts

Defroster (all models) 30 watts

Blower (all models) 15 watts

Wiper (all models) 15 watts

(Design and product specifications subject to change without notice.)

This equipment contains electrical or electronic components that must be recycled properly to comply with Directive 2002/96/EC of the European Union

regarding the disposal of waste electrical and electronic equipment (WEEE). Contact your local dealer for procedures for recycling this equipment.

22 Pelco Manual C397M (4/98)

Page 24

MODEL “A” “B”

PT7729RX 32.50 (82.55) 29.00 (73.66)

PT7729RX-1

PT7729RX-1/SL

PT7729RX-1/PP

PT7729RX-3

PT7729RX-3/PP

PT7729WX

PT7729WX-1

PT7729WX-3

PT7723RX-1 26.50 (67.31) 23.00 (58.42)

PT7723RX-1/PP

PT7723RX-3

PT7723RX-3/PP

PT7723WX-1

Figure 11. Dimension Drawing

Pelco Manual C397M (4/98) 23

Page 25

9.0 WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or

workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

• Five years on FT/FR8000 Series fiber optic products.

• Three years on Genex

• Three years on Camclosure

CC3751H-2, CC3651H-2X, MC3651H-2, and MC3651H-2X camera models, which have a fiveyear warranty.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy

dome products.

• Two years on Spectra

continuous motion applications.

• Two years on Esprit

• Eighteen months on DX Series digital video recorders, NVR300 Series network video

recorders, and Endura

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion applications

(that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco shipment.

All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis, California. Repairs

made necessary by reason of misuse, alteration, normal wear, or accident are not covered under

this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from the

specific use or application made of the Products. Pelco’s liability for any claim, whether based on

breach of contract, negligence, infringement of any rights of any party or product liability, relating

to the Products shall not exceed the price paid by the Dealer to Pelco for such Products. In no event

will Pelco be liable for any special, incidental or consequential damages (including loss of use, loss

of profit and claims of third parties) however caused, whether by the negligence of Pelco or

otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have

additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or (559) 292-1981

to obtain a Repair Authorization number (RA), and provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the warranty

conditions stated above, please include a written explanation with the product when returned.

Method of return shipment shall be the same or equal to the method by which the item was received

by Pelco.

®

Series products (multiplexers, server, and keyboard).

®

and fixed camera models, except the CC3701H-2, CC3701H-2X,

®

, CM6700/CM6800/CM9700 Series matrix, and DF5/DF8 Series fixed

®

, Esprit®, ExSite™, and PS20 scanners, including when used in

®

and WW5700 Series window wiper (excluding wiper blades).

™

Series distributed network-based video products.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at (800)

289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned for credit,

and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA number

and freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico, send goods to:

Service Department

Pelco

3500 Pelco Way

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico and are instructed

to return goods to the USA, you may do one of the following:

Clovis, CA 93612-5699

If the goods are to be sent by a COURIER SERVICE, send the goods to:

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

Pelco, the Pelco logo, Camclosure, Esprit,

Genex, Legacy, and Spectra are registered

trademarks of Pelco.

Endura and ExSite are trademarks of Pelco.

© Copyright 1998, Pelco. All rights reserved.

If the goods are to be sent by a FREIGHT FORWARDER, send the goods to:

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

24 Pelco Manual C397M (4/98)

Loading...

Loading...