Page 1

®

PT550P Series

PT570 Series

PT573 Series

PT680-24 Series

Medium Duty Pan/Tilt

Maintenance/

Service Manual

C325SM (3/99)

U

®

L

LISTED

Pelco • 300 W. Pontiac Way, Clovis • CA 93612-5699 USA • Pelco Online @ http://www.pelco.com

In North America and Canada: Tel (800) 289-9100 or FAX (800) 289-9150 • DataFAX (800) 289-9108

International Customers: Tel (1-559) 292-1981 or FAX (1-559) 348-1120 • DataFAX (1-559) 292-0435

Page 2

CONTENTS

Section Page

1.0 GENERAL ..................................................................................................3

1.1 IMPORTANT SAFEGUARDS AND WARNINGS ...............................3

2.0 DESCRIPTION ..........................................................................................4

2.1 MODELS ............................................................................................4

2.2 OPTIONS........................................................................................... 5

3.0 MAINTENANCE .........................................................................................6

3.1 SERVICING DRIVE CHAIN ASSEMBLIES ....................................... 6

3.1.1 Tightening Drive Chains ..........................................................6

3.1.2 Chain Drive Lubrication ...........................................................6

3.2 RESETTING POTENTIOMETERS ....................................................7

4.0 EXPLODED ASSEMBL Y DIAGRAMS .......................................................8

5.0 WIRING DIAGRAMS ................................................................................22

6.0 WARRANTY AND RETURN INFORMATION ...........................................32

LIST OF ILLUSTRATIONS

Figure Page

1 Servicing the Pan/Tilt .........................................................................6

2 Sealant Locations ..............................................................................7

3 PT550P Series Exploded Assembly Diagram....................................8

5 PT573 Series Exploded Assembly Diagram .....................................14

6 PT680-24P and PT680-24P/PP Exploded Assembly Diagram.........17

7 PT680-24SL and PT680-24SL/PP Exploded Assembly Diagram .....18

8 PT550P Wiring Diagram ...................................................................22

9 PT550P/PP Wiring Diagram .............................................................23

10 PT570P/PT570-24P Series Wiring Diagram..................................... 24

11 PT573 Series Wiring Schematic ....................................................... 25

12 PT680-24P Wiring Schematic........................................................... 26

13 PT680-24SL Wiring Schematic.........................................................27

14 PT680-24P/PP Wiring Schematic .....................................................28

15 PT680-24SL/PP Wiring Schematic ...................................................29

16 PT680-24P/HB Wiring Schematic..................................................... 30

17 PT680-24SL/HB Wiring Schematic................................................... 31

LIST OF TABLES

Figure Page

A PT550P Series Parts List...................................................................9

B PT570P/PT570-24P Series Mechanical Parts List ...........................12

C PT570P/PT570-24P Series Hardware List .......................................13

D PT573 Series Parts List.................................................................... 15

E PT680-24P and PT680-24P/PP MechanicalParts List .....................19

F PT680-24SL and PT680-24SL/PP Mechanical Parts List ................20

G PT680-24 Series Hardware List........................................................21

H PT550P Electrical Parts List .............................................................22

I PT550P/PP Electrical Parts List .......................................................23

J PT570P Series Electrical Parts List ..................................................24

K PT570-24P Series Electrical Parts List.............................................24

L PT573 Series Electrical Parts List ....................................................25

REVISION HISTORY

Manual # Date Comments

C323SM 10/98 Original version.

3/99 Revised Figure 3 preset pinouts, pins 2 and 9, for up/

down and right/left functions.

2 Pelco Manual C325SM (3/99)

Page 3

1.0 GENERAL

1.1 IMPORTANT SAFEGUARDS AND WARNINGS

Prior to installation and use of this product, the following WARNINGS should be

observed.

1. Installation and servicing should only be done by qualified service personnel

and conform to all local codes.

2. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or

6P enclosure, it is designed for indoor use only and it must not be installed

where exposed to rain and moisture.

3. The weight of the camera, lens, and enclosure shall not exceed 40 lb (18.16 kg)

for the PT550, PT570, and PT573 Series or 50 lb (22.7 kg) for the PT680

Series.

4. Only use replacement parts recommended by Pelco.

5. After replacement/repair of this unit’s electrical components, conduct a resistance measurement between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

6. The installation method and materials should be capable of supporting four

times the weight of the enclosure, pan/tilt, camera and lens combination.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage constituting a

risk of electric shock is present within this unit.

This symbol indicates that there are important operating and

maintenance instructions in the literature accompanying this

unit.

CAUTION:

RISK OF

ELECTRIC SHOCK.

DO NOT OPEN.

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

DO NOT REMOVE COVER. NO USER-

SERVICEABLE P ARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

CAUTION:

Please thoroughly familiarize yourself with the information

in this manual prior to installation and operation.

Pelco Manual C325SM (3/99) 3

Page 4

2.0 DESCRIPTION

Pan/tilts in the PT550P Series are designed to remotely position a TV camera in

both the horizontal and vertical attitudes. Pan (horizontal) and tilt (vertical) movements are caused by activating small DC motors in the pan/tilt unit. All Pelco units

are equipped with adjustable limits for both pan and tilt, and all motors are equipped

with electrical filtering circuits to suppress RF interference.

The PT573R and the PT573-24R are medium duty, indoor/outdoor pan/tilts designed for V330APT retrofit applications. Both units feature rugged worm gear final

drives to minimize backlash and prevent wind drift, and are fully adjustable for wear.

The PT570P Series and the PT570-24P Series have been engineered to provide

medium duty, indoor/outdoor pan and tilt operation. All units feature rugged worm

gear final drives to minimize backlash and prevent wind drift, and are fully adjustable for wear.

The pan/tilt units of the PT680-24 Series are designed for medium-duty, indoor/

outdoor use. They are factory pre-wired for pan and tilt control functions, motorized

zoom lens operation, camera power, and video. All connections are made at the

input/output connectors, eliminating the need for wiring harnesses. This greatly reduces installation time, while increasing reliability and serviceability.

2.1 MODELS

PT550P Medium duty pan/tilt, 115 VDC

PT550P/FGP Medium duty pan/tilt, 115 VDC, with special speed gearing for

pan (9°/sec pan speed)

PT550P/HB Medium duty pan/tilt, 115 VDC, with blanket heater in cover. 75

watts total. 120 VAC.

PT550P/PP Medium duty pan/tilt, 115VDC, with position feedback modifi-

cation. Requires preset control or control having AZL option

(position indication meter).

PT550P/RAD Medium duty pan/tilt, 115 VDC, with radiation resistant wiring

and white epoxy paint. Low level radiation resistant up to 10

rads

PT570P Medium duty pan/tilt, 120 VAC operation.

PT570P/PP Medium duty pan/tilt, 120 VAC operation with preset position

option (PP).

PT570P/RAD Same as PT570P except supplied with radiation resistant white

epoxy paint (resistant up to 10

6

rads)

PT570-24P Medium duty pan/tilt, 24 VAC operation.

PT570-24P/PP Medium duty pan/tilt, 24 VAC operation with preset position

option (PP)

PT570P-24P/RAD Same as PT570-24P except supplied with radiation resistant

white epoxy paint (resistant up to 10

6

rads)

PT573R Medium-duty, indoor/outdoor, 120 V AC.

PT573-24R Medium-duty , indoor/outdoor , 24 V AC.

6

PT680-24P Medium-duty, indoor/outdoor, 24 VAC.

PT680-24P/PP PT680-24P with preset positioning capabilities.

PT680-24SL PT680-24P with 360° pan rotation.

PT680-24SL/PP PT680-24SL with preset positioning capabilities.

4 Pelco Manual C325SM (3/99)

Page 5

2.2 OPTIONS

FG/570 Special high speed gears — 9°/4.5° per sec pan/tilt speed.

FGP/570 Special high-speed gearing for pan — 9°/sec pan speed.

FGT/570 Special high-speed gearing for tilt — 4.5°/sec tilt speed. (Re-

HB/570 Blanket heater in cover. Allows operation to -50°F (-46°C). 75

HB/680 Blanket heater in cover. Allows operation to -50°F (-46°C). 75

(Reduces load to 20 lb or 9.08 kg)

duces load to 20 lb or 9.08 kg)

watts total. 120 VAC, 50/60 HZ.

watts total. 120 VAC, 50/60 HZ.

Pelco Manual C325SM (3/99) 5

Page 6

3.0 MAINTENANCE

3.1 SERVICING DRIVE CHAIN ASSEMBLIES

Inspect the pan/tilt unit every six months to ensure trouble-free operation and an

extended product life. Harsh environments and/or continuous motion applications

may require more frequent maintenance.

Please read all of the instructions that follow before servicing the pan/tilt.

To begin, remove the three screws on the front of the pan/tilt housing and lift the

cover to gain access to the pan and tilt motor assemblies.

3.1.1 Tightening Drive Chains

Check the pan and tilt drive chains for tension. A movement of 1/32 of an inch to 3/32

of an inch in the chains is acceptable. If the movement of a chain exceeds 3/32 of an

inch, adjust the chain as follows:

1. Loosen the screws securing the motor to the mounting frame.

2. Pry on the motor to apply tension to the chain. Do not over-tension the drive

chain.

3. Keep tension on the chain while tightening the screws.

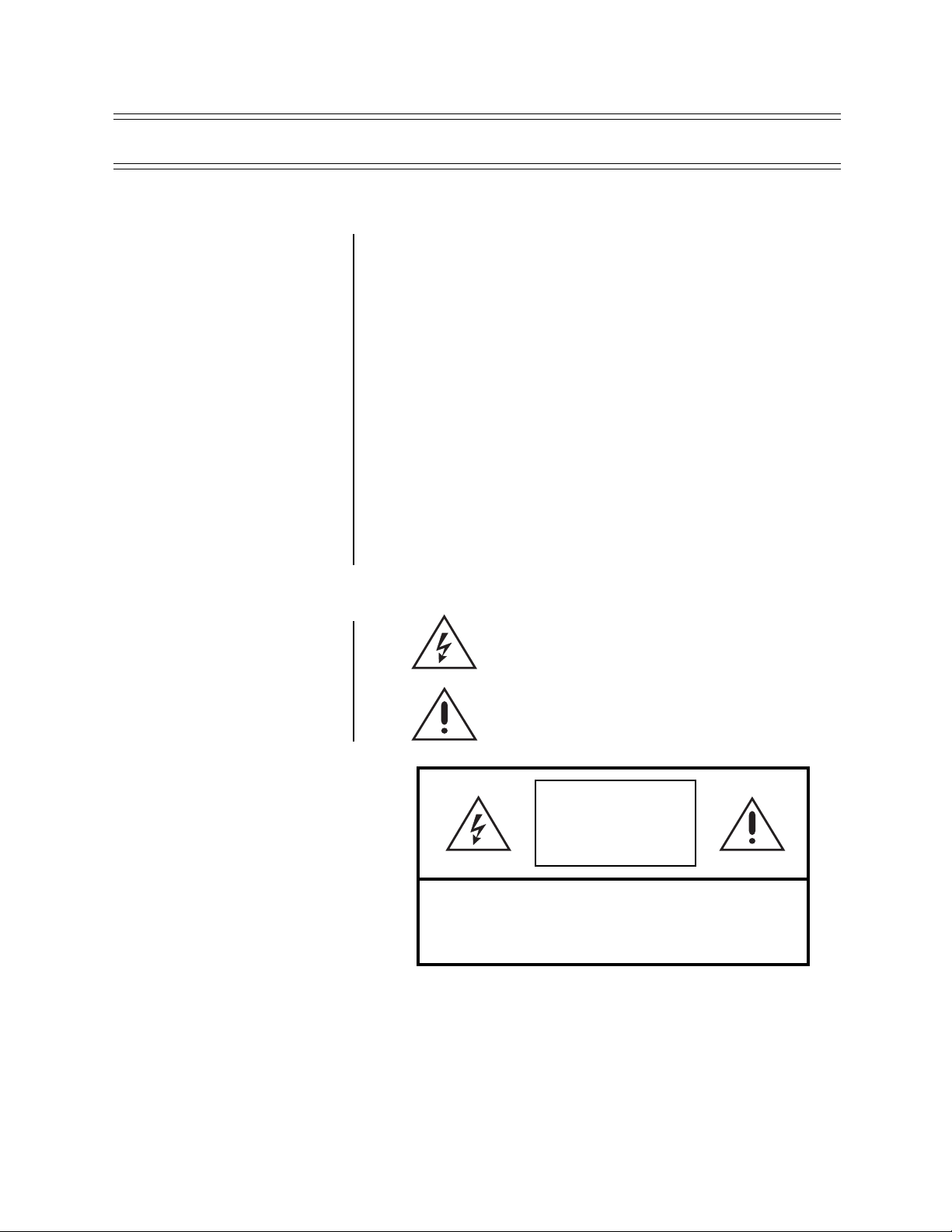

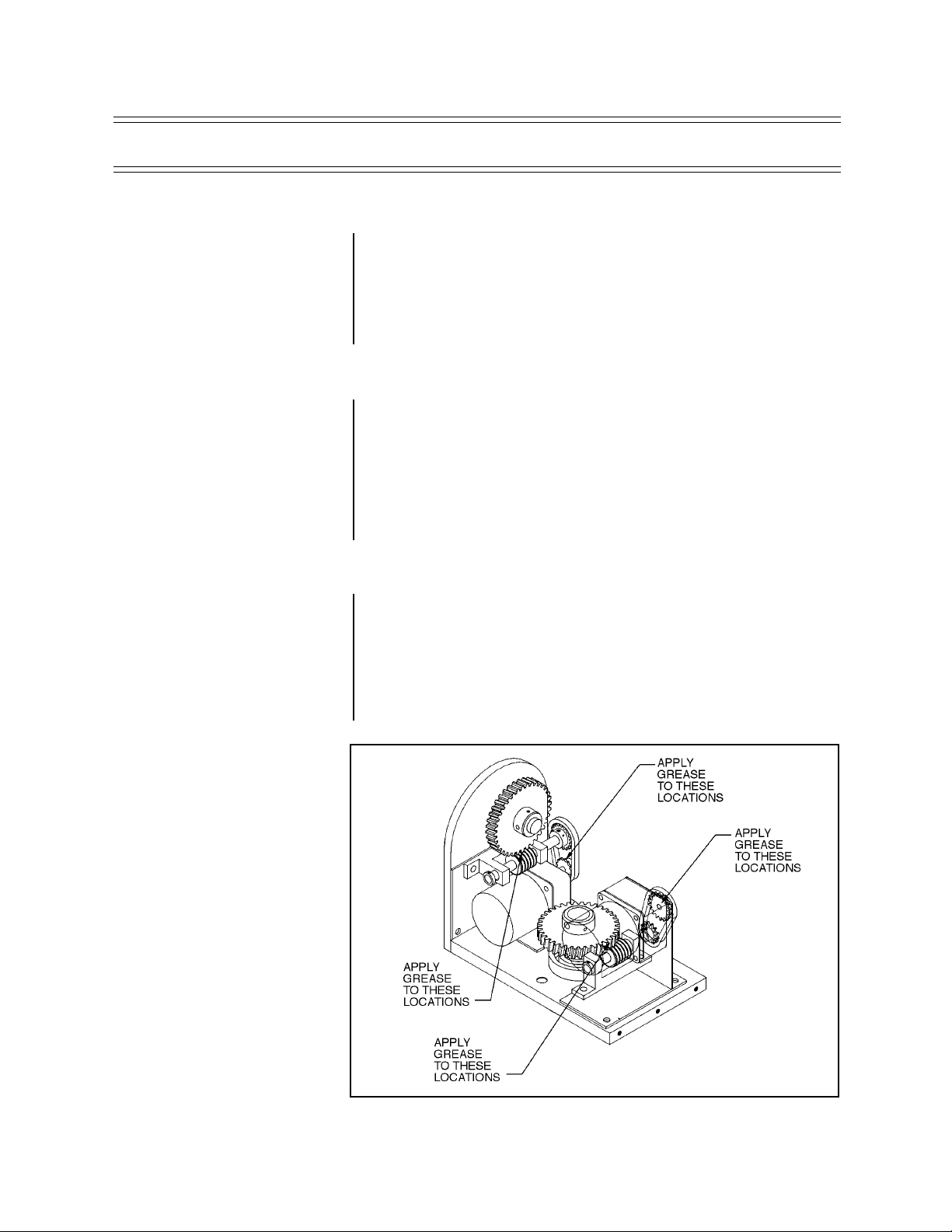

3.1.2 Chain Drive Lubrication

Sprockets, chains, and gears should be well greased. If necessary, lubricate the

pan and tilt gears, sprockets, and chains as follows with a high-quality grease capable of withstanding temperatures from -50° to 170°F (-46° to 77°C). Do the following:

1. Liberally apply grease to the pan and tilt gears, chains, and sprockets (refer to

Figure 1).

2. Operate the pan and tilt motors to spread the grease across the parts.

Figure 1. Servicing the Pan/Tilt

6 Pelco Manual C325SM (3/99)

Page 7

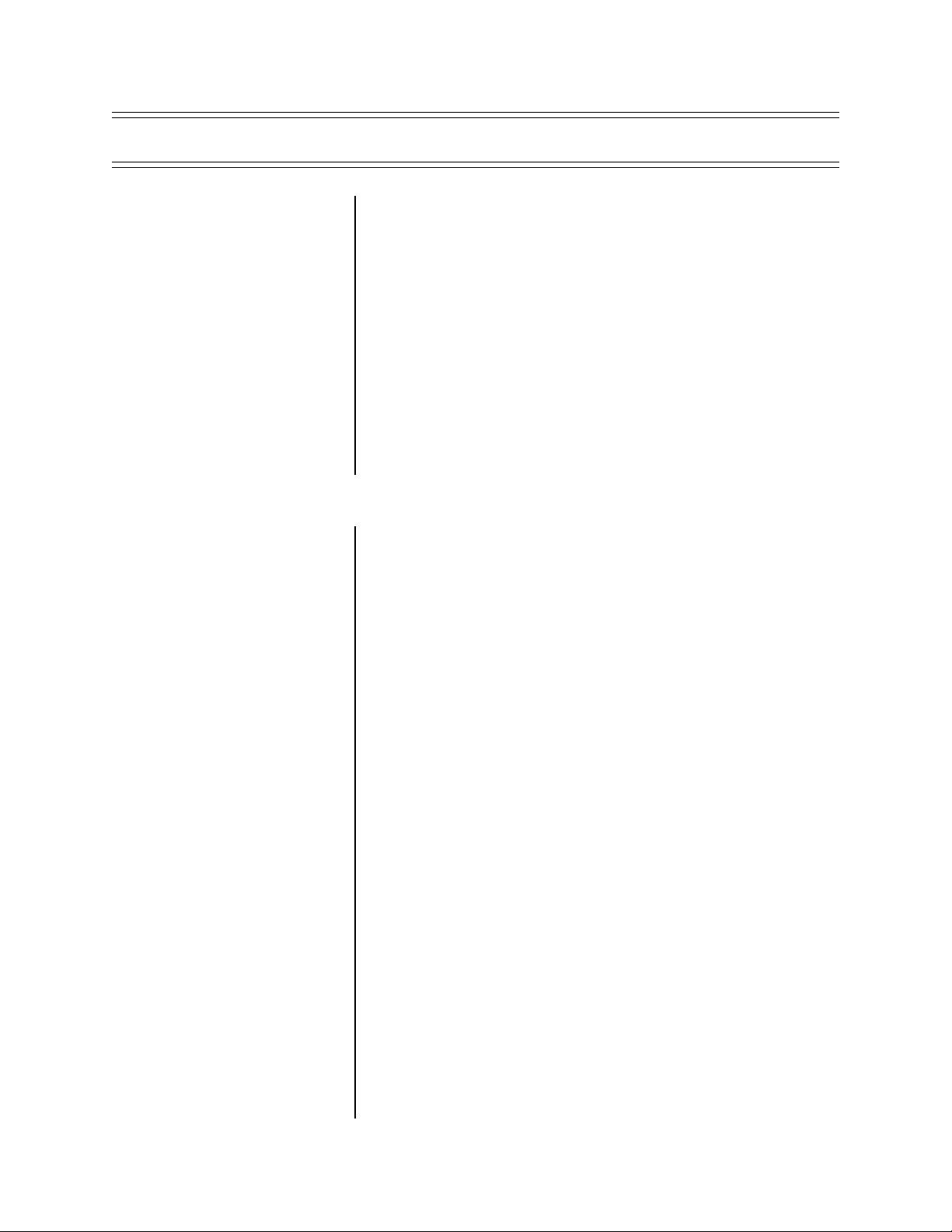

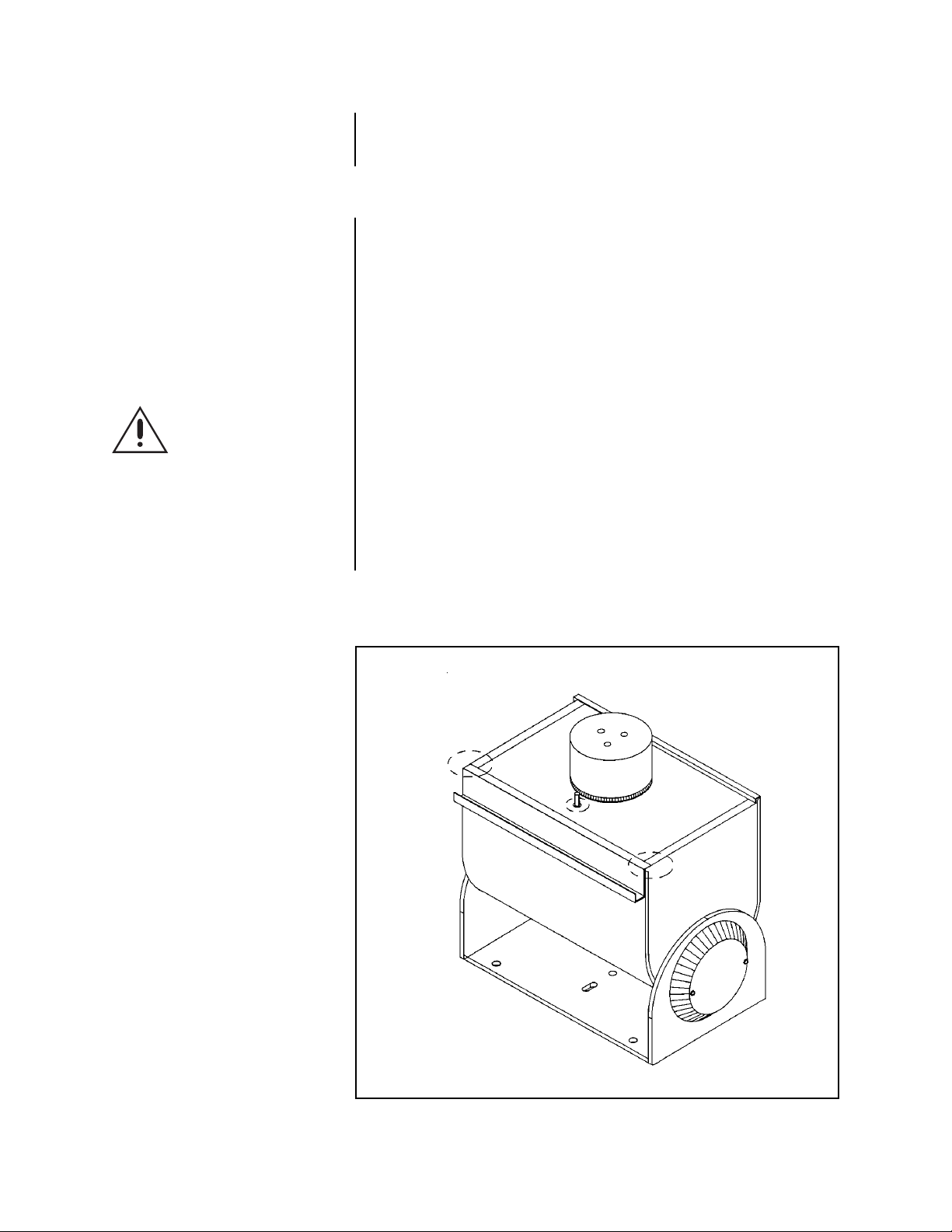

3. Apply additional grease if necessary.

4. Reinstall the cover. If the pan/tilt is installed outdoors in an inverted position,

apply RTV silicone sealant as shown in Figure 2.

3.2 RESETTING POTENTIOMETERS

IMPORTANT:

Be very careful

when resetting potentiometer

switches. Be sure that the pan/tilt

has been centered between maximum pan and tilt travel, regardless

of the adjustable limit stops. Failure to observe caution when resetting potentiometers could result in

damage to the preset positioning

ability of the pan/tilt.

WARNING:

NEVER

reposition the pan fixed

limit stop. Doing so

WILL DAMAGE the

wiring harness and, if

the pan/tilt has preset

positioning, COULD

cause the pan potentiometer to BREAK.

Models with Preset Positioning (PP)

Models with preset positioning (PP) use potentiometer switches that are factory set

to the full range of pan and tilt travel. Under normal operating conditions and at

routine service intervals they do not need adjusting.

Should your pan/tilt require any work on the drive mechanism other than routine

maintenance, perform the following procedure to reset the potentiometers.

To begin, remove the three screws on the front of the pan/tilt housing and lift the

cover to gain access to the pan and tilt motor assemblies.

1. Remove the potentiometer gears and position the pan/tilt to the middle of its

maximum pan and tilt travel, regardless of the position of the adjustable limit

stops. That is, the tilt table should be level and the fixed limit stop should be

opposite the limit switch.

2. Turn a potentiometer all the way in one direction until it stops, then observing

the number of turns, turn it back the other way until it stops. Rotate the potentiometer half the number of turns the other way to reach the center.

3. Replace the potentiometer gear.

4. Perform steps 2 and 3 for the other potentiometer.

➛

➛

➛

Figure 2. Sealant Locations

Pelco Manual C325SM (3/99) 7

Page 8

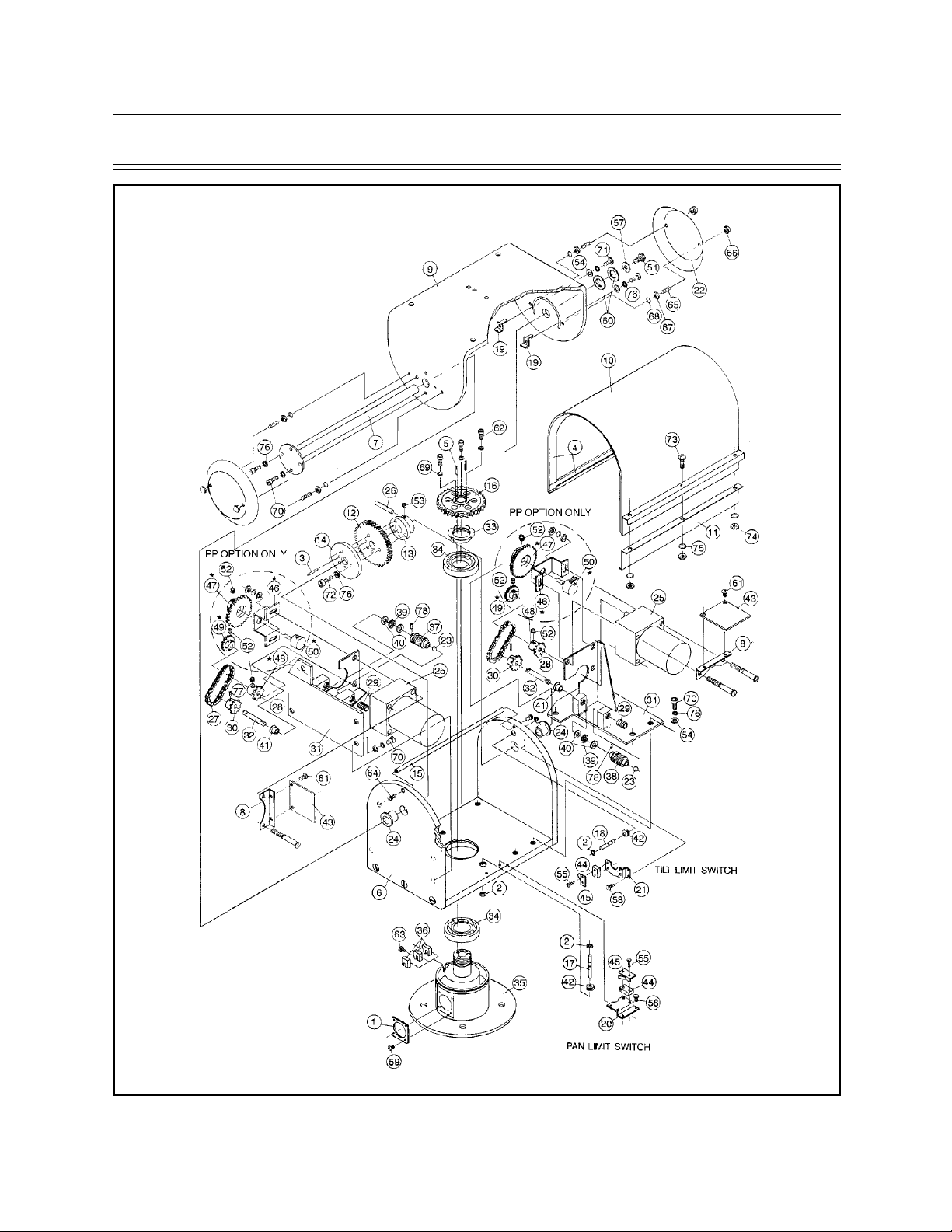

4.0 EXPLODED ASSEMBLY DIAGRAMS

Figure 3. PT550P Series Exploded Assembly Diagram

8 Pelco Manual C325SM (3/99)

Page 9

Table A. PT550P Series Parts List

Item Qty Description Part Number

1 1 Gasket Conn PT1000L-1 105010010

2 4 Ring, Snap #Q2-18 15510000

3 2 Pin Dowel 1/8" x 5/8" Hardened Steel 15510001

4 4 Gasket 1/8" x 1/2" #G207N x Feet 15510002

5 2 Pin Dowel 1/8" x 1/2" Hardened Steel 15510003

6 1 Body assembly 1551008COMP

7 1 Tilt shaft assembly 1551009COMP

8 2 Bracket, PC board filter 1554000COMP

9 1 Tilt table 1554037COMP

10 1 Cover 1554041COMP

11 1 Pull up bar 1554042COMP

12 1 Gear, tilt 1554044COMP

13 1 Hub tilt gear 1554045COMP

14 1 Plate backup, tilt gear 1554046COMP

15 1 Spacer, body sides 1554047COMP

16 1 Gear, pan 1554048COMP

17 1 Pin, pan limit 1554049COMP

18 1 Pin, tilt limit 1554049TCOMP

19 2 Tilt limit stop 1554050COMP

20 1 Bracket, pan limit 1554051COMP

21 1 Bracket, tilt limit 1554052COMP

22 2 Cover plate, tilt shaft 1554053COMP

23 2 Bearing, ball, 5/16 dia. 1556000

24 2 Bearing 1556004

25 2 Motor, gearhead, 115 VDC 1558004A

26 1 Pin, #3 Taper x 1 1/4" 17510001

27 2 Chain motor assembly 1751002COMP

28 2 Sprocket 17512004

29 2 Screw, worm shaft thrust adjust 1754005COMP

30 2 Sprocket 1754022COMP

31 2 Plate, motor 1754062COMP

32 2 Shaft, worm gear 1754063COMP

33 1 Locknut, No. 5 2504012COMP

34 2 Bearing, pan spindle 2506000

35 1 Spindle, base assembly 5501021COMP

36 3 Limit stop, pan 58010006

37 1 Gear, tilt 7712006

38 1 Gear, pan 7712007

39 2 Bearing, cage only 776001

40 4 Bearing, washer only 776002

41 2 Bearing 776003

42 2 Grommet, neoprene GRO2172N

43 2 PC Board pan/tilt filter PCB5500126B

44 4 Switch SWI1SM1

45 4 Switch actuator with insulator SWIJS138B

46 2 Bracket, AZL pot (PT550P/PP only) 1754000COMP

47 2 Gear, PP pot shaft (PT550P/PP only) 1754003COMP

48 2 Sprocket, motor (PT550P/PP only) 1754004COMP

49 2 Gear (PT550P/PP only) 1754006COMP

50 2 Pot, Model 534, 5K ohm POT005.0K10534

51 1 Bolt, 1/4 - 20 x 5/8" hex cad ZH1/420X.625CH

52 6 Set screw , 10-32 x 5/16" soc knur black ZH10-32X.187S

53 1 Set screw , 10-32 x 5/16" soc knur black 10-32X.312S

54 10 Washer, flat #10 ZH204X436X60

55 8 Screw, 2.56 x 1/2" pan phil SS ZH2-56X.500SPP

56 Not Used

57 1 Washer, flat 3/16" VSS SPL - size plt D ZH260X562X65C

58 4 Screw 4-40 x 3/8" pan phil SS ZH4-40X.250SPP

59 4 Screw 4-40 x 3/8" pan phil SS ZH4-40X.375SPP

60 2 Washer, flat 1/2 AN - 960-816 ZH515X.875X62

61 4 Screw, 6-32 x 1/4" pan phil SS ZH6-32X.250SPP

Continued on next page

Pelco Manual C325SM (3/99) 9

Page 10

Table A. PT550P Series Parts List (continued)

Item Qty Description Part Number

62 3 Screw, 6-32 x 3/8" soc cad ZH6-32X.375CS

63 3 Screw, 6-32 x 3/8" pan slot SS ZH6-32 X.375SPS

64 2 Screw, 6-32 x 5/8" flat slot SS ZH6-32X.625SFS

65 4 Set screw, 6-32 x 3/4" SS ZH6-32X.750SS

66 4 Nut, 6-32 a corn brass chrome ZH6-32XNUTCA

67 4 Nut, hex 6-32 SS ZH6-32XNUTSH

68 4 Washer, internal star #6 SS ZH6LWSIS

69 3 Washer, split lock #6 SS ZH6LWSSL

70 12 Screw, 8-32 x 1/2" soc cad ZH8-32X.500CS

71 2 Screw, 8-32 x 1/2" pan slot SS ZH8-32X.500SPS

72 3 Screw, 8-32 x 5/8" soc cad ZH8-32X.625CS

73 3 Screw, 8-32 x 3/4" pan slot SS ZH8-32X.750SPS

74 3 Nut, Hex 8-32 SS ZH8-32XNUTSH

75 3 Washer, internal #8" SS ZH8LWSIS

76 15 Washer, split lock #8" SS ZH8LWSSL

77 2 Pin, roll 3/32 x 1/2" ZHPIN3/32X1/2R

78 2 Pin, roll 3/32 x 3/8" ZHPIN3/32X3/8R

10 Pelco Manual C325SM (3/99)

Page 11

Figure 4. PT570P/PT570-24P Series Exploded Assembly Diagram

Pelco Manual C325SM (3/99) 11

Page 12

Table B. PT570P/PT570-24P Series Mechanical Parts List

Item Qty Description Part Number

1 4 Ring, snap 15510000

2 4 NP Gasket, Poron 1/8" x 1/2", Blk, x ft EH550010030

3 2 Pin, dowel 1/8" x 1/2", hardened steel 15510003

4 1 Plate, side tilt 1554038COMP

5 1 Plate, side pan 1554039COMP

6 1 Bottom plate 1554055COMP

7 1 Tilt shaft assembly 1551009COMP

8 2 Pin, dowel 1/8" x 5/8", hardened steel 15510001

9 1 Gear tilt 1554144COMP

10 1 Hub tilt gear 6804049COMP

11 1 Plate, backup tilt gear 1554046COMP

12 1 Tilt table 1554037COMP

13 1 Cover 1554041COMP

14 1 Pull up bar 1554042COMP

15 1 Spacer, body sides 1554047COMP

16 1 Pin, pan limit 1554049COMP

17 1 Pin, tilt limit 1554049TCOMP

18 2 Tilt limit stop 1554050COMP

19 2 Cover plate, tilt shaft 1554053COMP

20 1 Spindle 1554054ACOMP

21 2 Bearing 1556004

22 1 Gasket 105010010

23 1 Flange PM102A4196COMP

24 1 Pin #3, taper x 1-1/4" 17510001

25 1 Spring, tilt 17510040

26 1 Bracket, pan limit 1554051COMP

27 1 Bracket, tilt limit 1554052COMP

28 4 Switch SWI1SM1

29 4 Switch actuator with insulator SWIJS138B

30 1 Term strip, 9 pin (not shown) TRS2009

31 1 Bracket, spring 1754061COMP

32 2 Bearing, #B46-2 5806005

33 2 Chain assembly 1751002COMP

34 1 Collar, spring 1754020COMP

35 2 Sprocket 17512004

36 2 Sprocket 1754022COMP

37 2 Motor plate 1751062WA

38 2 Shaft gear train 1754064COMP

39 2 Motor, gear head 1758006

40 2 Motor only, 120 VAC 1758005

41 1 Worm tilt 7712006

42 4 Bearing, cage only 776001

43 4 Bearing, washer only 776002

44 2 Bushing, 1/4" tilt shaft PT250010005

45 1 Gear pan 1554048COMP

46 1 Worm pan 7712007

47 1 Nut spindle 25010002

49 2 Bearing, pan spindle 2506000

52 3 Limit stop, pan 58010006

54 2 Cap, 60MF 200V Ax Bulk (not shown) CAPU0060.0/200N

55 1 Conn, 9 Pos Recp (not shown) CON206705-1

56 9 Conn, CPC Pin Crimp (not shown) CON66103-2

57 2 Grommet, neoprene GRO2172N

60 2 Bracket, AZL pot 1754000COMP

61 2 Gear, PP pot shaft 1754003COMP

62 2 Sprocket, motor, PP 1754004COMP

63 2 Gear, PP 1754006COMP

64 2 Pot, 5K ohm POT005.0K10534

Motor only, 24 V AC 5708007

12 Pelco Manual C325SM (3/99)

Page 13

Table C. PT570P/PT570-24P Series Hardware List

Item Qty Description Part Number

A 4 Nut, 6-32, acorn brass chrome ZH6-32NUTCA

B 4 Screw, 8-32 x 1/2", soc cad ZH8-32X.500CS

C 10 Washer, split lock, #8 ZH8LWSSL

D 4 Set screw, 6-32 x 3/4", SS ZH6-32X.750SS

E 4 Nut, hex 6-32, SS ZH6-32NUTSH

F 4 Washer, internal star, #6 ZH6LWSIS

G 2 Screw, 6-32 x 1/2", pan phil, SS ZH8-32X.500SPP

H 10 Washer, flat, #10, AN960C-10X064SS ZH204X436X60C

I 2 Washer, flat, 1/2 AN960-816 cad ZH515X875X62

K 1 Washer, split lock, 1/4", SS ZH1/4LWSSL

L 1 Bolt, 1/4 - 20 x 5/8", hex cad ZH1/420X.625CH

M 3 Screw, 8-32 x 5/8", soc cad ZH8-32X.625CS

N 3 Screw, 6-32 x 3/8", soc cad ZH6-32X.375CS

O 5 Washer, internal star, #8, SS ZH8LWSIS

P 1 Washer, flat 3/16", VSS ZH260X562X65C

Q 1 Washer, internal star 1/4", SS ZH1/4LWSIS

R 6 Nut, hex, 8-32, SS ZH8-32NUTSH

S 3 Screw, 8-32 x 3/4", pan phil, SS ZH8-32X.750SPP

T 3 Washer, split lock, #6, SS ZH6LWSSL

U 9 Washer, split lock, #10, SS ZH10LWSSL

V 10 Screw, 10-32 x 1/2", soc cad ZH10-32X.500CS

W 2 Screw, 6-32 x 3/4", flat slot, SS ZH6-32X.750SFS

X 8 Screw, 2.56 x 7/16", pan phil, SS ZH2-56X.437SPP

Y 4 Screw, 4-40 x 3/8", pan phil, SS ZH4-40X.375SPP

Z 6 Bolt, 1/4-20 x 3/4", flat slot, SS ZH1/420X.750SFS

AA 1 Pin, spring roll, 3/32" x 3/8" ZHPIN3/32X3/8R

BB 4 Washer, internal star, #4, SS ZH4LWSIS

CC 2 Screw , 6-32 x 3/8", pan phil, SS ZH6-32X.375SPP

DD 1 Set screw, 6-32 x 3/16", soc, knurl blk ZH6-32X.187S

EE 4 Screw, 4-40 x 3/8", pan phil, SS ZH4-40X.375SPP

FF 3 Screw, 8-32 x 2 1/4", round slot ZH8-32X2.25CRC

Pelco Manual C325SM (3/99) 13

Page 14

Figure 5. PT573 Series Exploded Assembly Diagram

14 Pelco Manual C325SM (3/99)

Page 15

Table D. PT573 Series Parts List

Item Qty Description Part Number

1 1 Gasket 105010010

2 1 Frame scan circuit board (Model PT573R) 12501007ACOMP

3 4 Snap ring 15510000

4 2 Dowel pin, 1/8" x 5/8" 15510001

5 2 Dowel pin, 1/8" x 1/2" 15510003

6 1 Plate, tilt side 1554038COMP

7 1 Plate, pan side 1554039COMP

8 1 Bottom plate 1554055COMP

9 1 Tilt shaft assembly 1551009COMP

10 1 Tilt table 1554037COMP

11 1 Pull-up bar 1554042COMP

12 1 Back-up plate, tilt side 1554046COMP

13 1 Spacer 1554047COMP

14 1 Pan gear 1554048COMP

15 1 Pan limit pin 1554049COMP

16 1 Tilt limit pin 1554049TCOMP

17 2 Tilt limit stop 1554050COMP

18 1 Pan limit bracket 1554051COMP

19 1 Tilt limit bracket 1554052COMP

20 2 Tilt shaft cover plate 1554053COMP

21 1 Spindle 1554054ACOMP

22 1 Cover 1554056BWA

23 1 Tilt gear 1554144COMP

24 2 Bearing 1556004

25 1 Taper pin 17510001

26 2 Chain assembly 1751002COMP

27 1 Tilt spring 17510040

28 2 Motor plate 1751062WA

29 2 Sprocket 17512004

30 1 Collar spring 1754020COMP

31 2 Sprocket 1754022COMP

32 1 Bracket spring 1754061COMP

33 2 Gear train shaft 1754064COMP

34 2 120 VAC motor (Model PT573R) 1758005

35 2 Motor gearhead 1758006

36 1 Spindle nut 25010002

37 2 Pan spindle bearing 2506000

38 1 Plastic protector for circuit board 57310001

39 1 Mounting flange 5734000COMP

40 1 Bottom bracket for circuit board 5734001COMP

41 1 Side bracket for circuit board 5734002COMP

42 3 Pan limit stop 58010006

43 2 Bearing 5806005

44 1 Tilt gear hub 6804049COMP

45 1 Tilt worm 7712006

46 1 Pan worm 7712007

47 4 Bearing cage 776001

48 8 Bearing washer 776002

49 2 Capacitor, 60 MFD, 200 V (PT573-24R) (not shown) CAPU0060.0/200N

50 8 Crimp pin (not shown) CON66400-1

51 4 Gasket, 1/8" x 1/2" x foot EH550010030

52 2 Neoprene grommet GRO2172N

53 2 Tilt shaft bushing PT250010005

54 8 PVC sleeving in inches (not shown) SLV16105N

55 4 Switch SWI1SM1

56 4 Switch actuator with insulator SWIJS138B

57 1 7-pin terminal strip TRS2007

Frame scan circuit board (Model PT573-24R) 12501007BCOMP

24 V AC motor (Model PT573-24) 5708007

2 Capacitor, 1.8 MFD, 250 V (PT573R) (not shown) CAPU0001.8/250

1 Capacitor, 1.0 MFD, 600 V (PT573R) (not shown) CAPU0001.0/600

Continued on next page

Pelco Manual C325SM (3/99) 15

Page 16

Table D. PT573 Series Parts List (continued)

Item Qty Description Part Number

A 1 Bolt, 1/4-20 x 5/8-inch ZH1/420X.625CH

B 9 Screw, 1/4-20 x 3/4-inch, flat head, Phillips ZH1/420X.750SFS

C 1 Internal star washer, 1/4-inch ZH1/4LWSIS

D 1 Split lock washer, 1/4-inch (not shown) ZH1/4LWSSL

E 3 Set screw, 10-32 x 3/16-inch ZH10-32X.187S

F 10 Allen screw, 10-32 x 1/2-inch ZH10-32X.500CS

G 9 Split lock washer, #10 ZH10WSSL

H 10 Flat washer, #10 ZH204X436X60C

I 1 Flat washer, 3/16-inch ZH260X562X65C

J - Not used

K 8 Screw, 2-56 x 7/16-inch, pan head, Phillips ZH2-56X.437SPP

L 18 Screw, 4-40 x 3/8-inch, pan head, Phillips ZH4-40X.375SPP

M 3 Hex nut, 4-40 (not shown) ZH4-40NUTSH

N 4 Internal star washer, #4 ZH4LWSIS

O 2 Flat washer ZH515X875X62

P 1 Set screw, 6-32 x 3/16-inch ZH6-32X.187S

Q 3 Allen screw, 6-32 x 3/8-inch ZH6-32X.375CS

R 2 Screw, 6-32 x 3/8-inch, pan head, Phillips ZH6-32X.375SPP

S 2 Screw, 6-32 x 3/4-inch, flat head ZH6-32X.750SFS

T 4 Set screw, 6-32 x 3/4-inch ZH6-32X.750SS

U 4 Acorn nut, 6-32 ZH6-32NUTCA

V 4 Hex nut, 6-32 ZH6-32NUTSH

W 4 Internal star washer, #6 ZH6LWSIS

X 3 Split lock washer, #6 ZH6LWSSL

Y 4 Allen screw , 8-32 x 1/2-inch ZH8-32X.500CS

Z 2 Screw, 8-32 x 1/2-inch, pan head, Phillips (not shown) ZH8-32X.500SPP

AA 1 Allen screw, 8-32 x 5/8-inch ZH8-32X.625CS

BB 3 Screw, 8-32 x 3/4-inch, pan head, Phillips ZH8-32X.750SPP

CC 3 Screw, 8-32 x 2.25-inch, round head ZH8-32X.2.25CRC

DD 6 Hex nut, 8-32 ZH8-32NUTSH

EE 5 Internal star washer, #8 ZH8LWSIS

FF 10 Split lock washer, #8 ZH8LWSSL

GG 2 Roll pin ZHPIN3/32x1/2R

HH 2 Spring roll pin ZHPIN3/32X3/8R

16 Pelco Manual C325SM (3/99)

Page 17

Figure 6. PT680-24P and PT680-24P/PP Exploded Assembly Diagram

Pelco Manual C325SM (3/99) 17

Page 18

Figure 7. PT680-24SL and PT680-24SL/PP Exploded Assembly Diagram

18 Pelco Manual C325SM (3/99)

Page 19

Table E. PT680-24P and PT680-24P/PP Mechanical Parts List

Item Qty Description Part Number

1 2 Neoprene grommet GRO2172

2 4 Snap ring 15510000

3 1 Tilt shaft 1551009COMP

4 1 Tilt table 1554037COMP

5 1 Cover 1554056BWA

6 4 Gasket, 1/8" x 1/2" x foot EH550010030

7 1 Pull-up bar 1554042COMP

8 1 Spacer 1554047COMP

9 2 Tilt limit stop 1554050COMP

10 1 Pan limit bracket 1554051COMP

11 1 Tilt limit bracket 1554052COMP

12 2 Tilt shaft cover plate 1554053COMP

13 2 Bearing 1556004

14 1 Taper pin 17510001

15 2 Dowel pin 15510001

16 2 Sprocket 1754022COMP

17 1 Pan chain assembly 2701004COMP

18 1 24 VAC motor 5708007

19 1 Nut lock 58010001

20 - Not used

21 1 Bearing retainer ring 58010008

22 1 Pan spindle bearing with retainer ring 5806000

23 3 Pan limit stop 58010006

24 1 Sprocket 90010028

25 1 Sprocket 5804022COMP

26 1 Pan worm 5804040COMP

27 1 Pan motor gearhead 5804044COMP

28 1 Tilt motor gearhead 5804045COMP

29 1 Tilt gear 6804047COMP

30 1 Pan gear 5804048COMP

31 1 Tilt gear hub 6804049COMP

32 2 Gear train bracket 5804062COMP

33 2 Worm gear shaft 5804063COMP

34 1 Tilt limit pin 1554049TCOMP

35 1 Pan spindle bearing with retainer ring 5806000

36 4 Bearing 5806002

37 8 Bearing washer 5806003

38 8 Bearing 5806005

39 1 Motor 5808000

40 1 Tilt chain assembly 6801002COMP

41 1 Body, tilt side 6804038COMP

42 1 Body, pan side 6804039COMP

43 1 Bottom plate 6804055COMP

44 1 Motor plate 6804000COMP

45 1 Spindle mount strain relief 6804001COMP

46 1 Pan limit pin 1554049COMP

47 1 Spindle 6804007COMP

48 1 Spindle flange 6804008COMP

49 3 Gland EH400010003

50 1 Nut EH400010004

51 1 Circuit board PCB9000225ASSY

52 1 Worm PS304013COMP

53 4 Switch SWI1SM1

54 4 Switch actuator with insulator SWIJS138B

55 2* Gear 5804012COMP

56 2* Potentiometer mounting bracket 5804090COMP

57 2* Potentiometer, 5K ohm POT005.0K10534

58 2* Potentiometer gear PT350010002

* Model PT680-24PP only

Pelco Manual C325SM (3/99) 19

Page 20

Table F. PT680-24SL and PT680-24SL/PP Mechanical Parts List

Item Qty Description Part Number

1 1 Neoprene grommet GRO2172

2 2 Snap ring 15510000

3 1 Tilt shaft 1551009COMP

4 1 Tilt table 1554037COMP

5 1 Cover 1554056BWA

6 4 Gasket, 1/8" x 1/2" x foot EH550010030

7 1 Pull-up bar 1554042COMP

8 1 Spacer 1554047COMP

9 2 Tilt limit stop 1554050COMP

10 - Not used

11 1 Tilt limit bracket 1554052COMP

12 2 Tilt shaft cover plate 1554053COMP

13 2 Bearing 1556004

14 1 Taper pin 17510001

15 2 Dowel pin 15510001

16 2 Sprocket 1754022COMP

17 1 Pan chain assembly 2701004COMP

18 1 24 VAC motor 5708007

19 1 Nut lock 58010001

20 - Not used

21 1 Bearing retainer ring 58010008

22 1 Pan spindle bearing with retainer ring 5806000

23 - Not used

24 1 Sprocket 90010028

25 1 Sprocket 5804022COMP

26 1 Pan worm 5804040COMP

27 1 Pan motor gearhead 5804044COMP

28 1 Tilt motor gearhead 5804045COMP

29 1 Tilt gear 6804047COMP

30 1 Pan gear 5804048COMP

31 1 Tilt gear hub 6804049COMP

32 2 Gear train bracket 5804062COMP

33 2 Worm gear shaft 5804063COMP

34 1 Tilt limit pin 1554049TCOMP

35 1 Pan spindle bearing with retainer ring 5806000

36 4 Bearing 5806002

37 8 Bearing washer 5806003

38 8 Bearing 5806005

39 1 Motor 5808000

40 1 Tilt chain assembly 6801002COMP

41 1 Body, tilt side 6804038COMP

42 1 Body, pan side 6804039COMP

43 1 Bottom plate 6804055COMP

44 1 Motor plate 6804000COMP

45 - Not used

46 - Not used

47 1 Spindle 6804007COMP

48 1 Spindle flange (Model PT680-24SL) 6804008COMP

49 2 Gland EH400010003

50 - Not used

51 1 Circuit board PCB9000225ASSY

52 1 Worm PS304013COMP

53 2 Switch SWI1SM1

54 2 Switch actuator with insulator SWIJS138B

55 1* Gear 5804012COMP

56 1* Potentiometer mounting bracket 5804090COMP

57 1* Potentiometer, 5K ohm POT005.0K10534

58 2* Potentiometer gear PT350010002

59 1* Potentiometer, dual arm, 10K ohm POTDARM010.0K

60 1* Spacer 6804011COMP

1 Spindle flange (Model PT68024SL/PP) 6804010COMP

Continued on next page

20 Pelco Manual C325SM (3/99)

Page 21

Table F. PT680-24SL and PT680-24SL/PP Mechanical (continued)

Item Qty Description Part Number

61 1* Gear 6804012COMP

62 1* Potentiometer mounting bracket 6804300COMP

63 1 Slip ring (Model PT680-24SL) SR18

64 1 Neoprene grommet GRO2172

65 1 Hole plug ZH3091

66 1 Spacer 6804002COMP

*Model PT680-24SL/PP only

Slip ring (Model PT68024SL/PP) 250010000

Table G. PT680-24 Series Hardware List

Item Qty Description Part Number

A 4 Hex nut, 1/4-20 ZH1/420NUTCHN

B 2 Lock nut, 1/4 28 58010007

C 1 Bolt, 1/4-20 x 5/8-inch ZH1/420X.625CH

D 6 Screw, 1/4-20 x 3/4-inch, flat head, Phillips ZH1/420X.750SFS

E 2 Allen screw, 1/4-20 x 1.5-inch ZH1/420X1.50CX

F 2 Allen bolt, 1/4-20 x 1.75-inch ZH1/420X1.75CS

G 4 Allen screw, 1/4-20 x 2.25-inch, nylon ZH1/420X2.25BSN

H 1 Internal star washer ZH1/4LWSIS

I 4 Allen screw, 10-32 x 1/2-inch ZH10-32X.500CS

J 8 Screw, 2-56 x 7/16-inch, pan head, Phillips ZH2-56X.437SPP

K 10 Flat washer, #10 ZH204X436X60C

L 1 Flat washer, 3/16 ZH260X562X65C

M 8 Screw, 4-40 x 1/4-inch, pan head, Phillips ZH4-40X.250SPP

N 7 Screw, 4-40 x 3/8-inch, pan head, Phillips ZH4-40X.375SPP

O 15 Internal star washer, #4 ZH4LWSIS

P 2 Flat washer, 1/2 ZH515X875X62

Q 2 Screw, 6-32 x 3/8-inch, pan head, Phillips ZH6-32X.375SPP

R 2 Screw, 6-32 x 1/2-inch, flat head, Phillips ZH6-32X.500SFS

S 4 Set screw, 6-32 x 3/4-inch ZH6-32X.750SS

T 4 Acorn nut, 6-32 ZH6-32NUTCA

U 4 Hex nut, 6-32 ZH6-32NUTSH

V 4 Internal star washer, #6 ZH6LWSIS

W 6 Allen screw, 8-32 x 3/8-inch ZH8-32X.375CS

X 2 Screw, 8-32 x 3/8-inch, pan head, Phillips ZH8-32X.375SPP

Y 6 Allen screw, 8-32 x 1/2-inch ZH8-32X.500CS

Z 3 Screw, 8-32 x 3/4-inch, pan head, Phillips ZH8-32X.750SPP

a 4 Screw, 8-32 x 2.25-inch, pan head, Phillips ZH8-32X2.25CRS

b 4 Screw, 8-32 x 2.5-inch, pan head, Phillips ZH8-32X2.50CPS

c 8 Hex nut, 8-32 ZH8-32NUTSH

d 14 Split lock washer, #8 ZH8LWSSL

e 6 Roll pin, 3/32-inch x 1/2-inch ZHPIN3/32X1/2R

Pelco Manual C325SM (3/99) 21

Page 22

5.0 WIRING DIAGRAMS

Figure 8. PT550P Wiring Diagram

Table H. PT550P Electrical Parts List

Quantity Symbol Description Manufacturer Part Number

8 C1-8 Capacitor .0047/1kv CDE CAPU0.0047/1000

4 C9-12 Capacitor .1/400V Sprague CAPU0000.1/400

4 L1-4 Choke 100mh Miller CHO5250

2 M1-2 Motor w/Gear Head Pelco 1558004A

1 P1 Connector AMP CON206705-1

9 — Connector Pin AMP CON66103-2

4 R1-4 Resistor 47ohm 1/4W — RES047.0-.25

2 — P .C. Assembly Pelco 1551016COMP

1 — Mating Connector Assy. AMP 1751000COMP

4 S1-S4 Switch — SWI1SM1

22 Pelco Manual C325SM (3/99)

Page 23

Figure 9. PT550P/PP Wiring Diagram

Table I. PT550P/PP Electrical Parts List

Quantity Symbol Description Part Number

8 C1-8 Capacitor .0047/1kv CAPU0.0047/1000

4 C9-12 Capacitor .1/400V CAPU0000.1/400

4 L1-4 Choke 100mh CHO5250

2 M1-2 Motor w/Gear Head 1558004A

1 P1 Connector CON206036-1

4 R1-4 Resistor 47 ohm 1/4W RES047.0-.25

2 R5-6 Pot 5K Ten Turn POT005.0K10534

2 — P .C. Assembly 1551016COMP

1 — Mating Connector Assy. CONA16S

4 S1-S4 Switch SWI1SM1

16 — Connector Pin CON66103-2

Pelco Manual C325SM (3/99) 23

Page 24

P1 CONNECTOR

COM

1

3

LEFT

RIGHT

7

BRN

RED

BLU

S1

C1

M1

H1

75W

S2

S3

S4

C2 C3

RIGHT

2

UP

2

1

R1

3

3

R2

1

M2

PT570P MODELS

ONLY

ALL

MODELS

MODELS

W/PRESETS (PP)

MODELS

W/HEATERS (HB)

UP

DOWN

GND

PAN PRESET

PRESET COM

TILT PRESET

AC NEUT

120 VAC

6

5

8

2

10

9

15

16

ORG

YEL

GRN

W/GREEN

W/BLK

W/BRN+5 VDC 11

W/VIO

WHT

BLK

T

Figure 10. PT570P/PT570-24P Series Wiring Diagram

Table J. PT570P Series Electrical Parts List

Quantity Symbol Description Manufacturer Part Number

2 C1, C2 Capacitor, NP 1.8 MFD 250V — CAPU0001.8/250

1 C3 Capacitor 1.0 MFD, 600 V — CAPU0001.0/600

1 P1 Connector AMP CON206705-1

4 S1-S4 Switch Microswitch SWI1SM1

4 — Actuator Microswitch SWIJS138B

2 M1, M2 Motor w/Gear Head Pelco 1758005/1758006

1 H1 Blanket Heater Benchmark EH6610054

1 T Thermostat Elmwood EH5510049A

2 R1, R2 POT 5K Ten Turn AMP POT005.0K10534

1 — 9-Pin Mating Connector Assy., or Spectrol 1751000COMP

— 16-Pin Mating Connector Assy. Spectrol CONA16S

9 (16) — Connector Pin AMP CON66399-1

Table K. PT570-24P Series Electrical Parts List

Quantity Symbol Description Manufacturer Part Number

2 C1, C2 Capacitor, NP 60 MFD 200V Sprague CAPU0060.0/200

1 P1 Connector AMP CON206063-1

4 S1-S4 Switch Microswitch SWI1SM1

4 — Actuator Microswitch SWIJS138B

2 M1, M2 Motor w/Gear Head Pelco 5708007/1758006

1 H1 Heater Blanket Benchmark EH110065A

1 T Thermostat Elmwood EH5510049A

2 R1, R2 POT 5K Ten Turn AMP POT005.0K10534

1 — 9-Pin Mating Connector Assy., or Spectrol 1751000COMP

9 (16) — Connector Pin AMP CON66399-1

— 16-Pin Mating Connector Assy. Spectrol CONA16S

24 Pelco Manual C325SM (3/99)

Page 25

AUTO

LEFT

P1

TO FRAME SCAN CIRCUIT BOARD

4 13 14 11 12 2 10 3 7

VIO

8

6

RED

S1

BLU/W

RIGHT

COM

UP

DOWN

COM

GND

AC NEUT

120 V AC

C1

5

BLU

BRN/W

1

2

ORG

3

YEL

BRN

4

12

GRN

15

16

T

S2

S3

S4

75W

C3

C2

M1

M2

Figure 11. PT573 Series Wiring Schematic

Table L. PT573 Series Electrical Parts List

Symbol Qty Description Part Number

- 1 Frame scan circuit board (Model PT573R) 12501007ACOMP

- Frame scan circuit board (Model PT573-24R) 12501007BCOMP

C1, C2 2 Capacitor, 1.8 MFD, 250 V (Model PT573R) CAPU0001.8/250

Capacitor , 60 MFD, 200 V (Model PT573-24R) CAPU0060.0/200N

C3 1 Capacitor, 1 MFD, 600 V (Model PT573R) CAPU0001.0/600

M1, M2 2 Motor (Model PT573R) 1758005

Motor (Model PT573-24R) 5708007

S1-S4 4 Switch SWI1SM1

- 4 Switch Actuator with Insulator SWIJS138B

- 1 Heater blanket EH110065A

T 1 Thermostat EH5510049A

Pelco Manual C325SM (3/99) 25

Page 26

Figure 12. PT680-24P Wiring Schematic

26 Pelco Manual C325SM (3/99)

Page 27

Figure 13. PT680-24SL Wiring Schematic

Pelco Manual C325SM (3/99) 27

Page 28

Figure 14. PT680-24P/PP Wiring Schematic

28 Pelco Manual C325SM (3/99)

Page 29

Figure 15. PT680-24SL/PP Wiring Schematic

Pelco Manual C325SM (3/99) 29

Page 30

Figure 16. PT680-24P/HB Wiring Schematic

30 Pelco Manual C325SM (3/99)

Page 31

Figure 17. PT680-24SL/HB Wiring Schematic

Pelco Manual C325SM (3/99) 31

Page 32

6.0 WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in

material or workmanship for a period of one year after the date of shipment. Exceptions to this warranty are as noted below:

• Three years on Genex™ Series (multiplexers, server, and keyboard).

• Two years on all standard motorized and fixed focal length lenses.

• Two years on Esprit™, Legacy®, Intercept®, PV1000 Series, CM6700/

CM8500/CM9500/CM9750/CM9760 Matrix, Spectra®, DF5 Series and DF8

Fixed Dome products.

• Two years on WW5700 series window wiper (excluding wiper blades).

• Two years on cameras.

• Six months on all pan and tilts, scanners or preset lenses used in continuous

motion applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of

Pelco shipment. All goods requiring warranty repair shall be sent freight prepaid to

Pelco, Clovis, California. Repairs made necessary by reason of misuse, alteration,

normal wear, or accident are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from the specific use or application made of the Products. Pelco’s liability for

any claim, whether based on breach of contract, negligence, infringement of any

rights of any party or product liability, relating to the Products shall not exceed the

price paid by the Dealer to Pelco for such Products. In no event will Pelco be liable

for any special, incidental or consequential damages (including loss of use, loss of

profit and claims of third parties) however caused, whether by the negligence of

Pelco or otherwise.

®Pelco and the Pelco logo are

registered trademarks of Pelco.

©Copyright 1999, Pelco. All rights

reserved.

The above warranty provides the Dealer with specific legal rights. The Dealer may

also have additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or

(559) 292-1981 to obtain a Repair Authorization number (RA), and provide the

following information:

1. Model and serial number

2. Date of shipment, P .O. number , Sales Order number , or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under

the warranty conditions stated above, please include a written explanation with the

product when returned.

Ship freight prepaid to: Pelco

300 West Pontiac Way

Clovis, CA 93612-5699

Method of return shipment shall be the same or equal to the method by which the

item was received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the

factory at (800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA

number if returned for credit, and RA number if returned for repair). Goods returned

for repair or credit should be clearly identified with the assigned CA/RA number and

freight should be prepaid. All merchandise returned for credit may be subject to a

20% restocking and refurbishing charge.

Ship freight prepaid to: Pelco

300 West Pontiac Way

Clovis, CA 93612-5699

32 Pelco Manual C325SM (3/99)

Loading...

Loading...