Page 1

®

PT1250 Series

PT1250DC Series

PT1253R

PT1250 EX/AMS

PT1260EX Series

PT1280 Series

Heavy-Duty Pan/Tilts

Maintenance/

Service Manual

C373SM-A (8/01)

Pelco • 3500 Pelco Way, Clovis • CA 93612-5699 USA • www.pelco.com

In North America and Canada: Tel (800) 289-9100 or FAX (800) 289-9150

International Customers: Tel +1 (559) 292-1981 or FAX +1 (559) 348-1120

Page 2

CONTENTS

LIST OF ILLUSTRATIONS

Section Page

IMPORTANT SAFEGUARDS AND WARNINGS................................................................4

DESCRIPTION...................................................................................................................5

MODELS ....................................................................................................................5

OPTIONS ...................................................................................................................6

MAINTENANCE .................................................................................................................7

TIGHTENING DRIVE CHAINS ..................................................................................7

CHAIN DRIVE LUBRICATION ...................................................................................7

Resetting Potentiometers ...................................................................................................8

MOTOR BRAKE REPLACEMENT.............................................................................8

EXPLODED ASSEMBLY DIAGRAMS................................................................................9

WIRING DIAGRAMS.........................................................................................................34

WARRANTY AND RETURN INFORMATION....................................................................48

Figure Page

1 Servicing the Pan/Tilt .........................................................................................7

2 Sealant Locations ..............................................................................................8

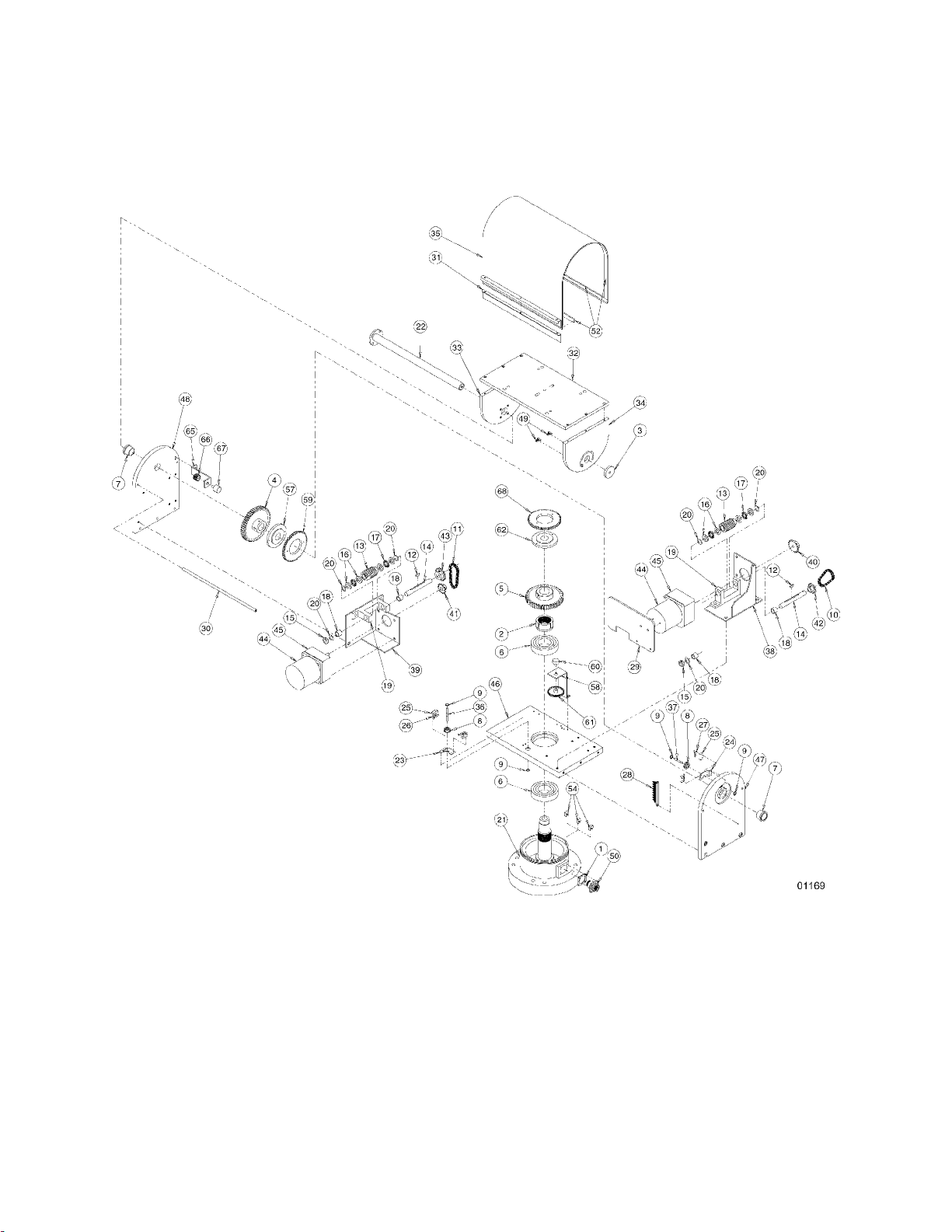

3 PT1250 Series Exploded Assembly Diagram (Mechanical Parts) .....................9

4 PT1250 Series Exploded Assembly Diagram (Hardware) ................................12

5 PT1250DC Series Exploded Assembly Diagram ..............................................14

6 PT1253R Exploded Assembly (Mechanical Parts) ...........................................16

7 PT1253R Exploded Assembly (Hardware) ....................................................... 18

8 PT1250EX/AMS Exploded Assembly Diagram.................................................20

9 PT1260EX and PT1260EX/PP Exploded Assembly Diagram (Mechanical

Parts) ................................................................................................................23

10 PT1280P and PT1280SL Exploded Assembly (Mechanical Parts)...................26

11 PT1280P and PT1280SL Exploded Assembly (Hardware)...............................28

12 PT1280P/PP and PT1280SL/PP Exploded Assembly Diagram (Mechanical

Parts) ................................................................................................................30

13 PT1280P/PP and PT1280SL/PP Exploded Assembly (Hardware) ...................32

14 PT1250 Series Wiring for P, FG, FGP, HB and 220 Models .............................34

15 PT1250 Series Wiring for RAD Model ..............................................................35

16 PT1250 Series Wiring for PP and WT Models ..................................................35

17 PT1250DC Wiring Diagram ..............................................................................36

18 PT1250DC/PP Wiring Diagram.........................................................................37

19 PT1253R Schematic Diagram ..........................................................................38

20 12501007ACOMP Frame Scan Schematic.......................................................39

21 PT1250EX/AMS Wiring Diagram ......................................................................41

22 PT1260EX Wiring Schematic............................................................................42

23 PT1260EX/220 Wiring Diagram ........................................................................42

24 PT1260EX/PP and PT1260EX/PP/230 Wiring Schematic................................43

25 PT1280P/PT128SL Wiring Diagram .................................................................44

26 PT1280P/HB Wiring Diagram ...........................................................................45

27 PT1280P/PP Wiring Diagram............................................................................46

28 PT1280Sl/PP Wiring Diagram...........................................................................47

2 Pelco Manual C373SM-A (8/01)

Page 3

LIST OF TABLES

Table Page

A PT1250 Series Mechanical Parts List ...............................................................10

B PT1250 Series Hardware List ...........................................................................13

C PT1250DC Series Parts List .............................................................................15

D PT1253R Mechanical Parts List ........................................................................17

E PT1253R Hardware List....................................................................................19

F PT1250EX/AMS Parts List................................................................................21

G PT1260EX Series Mechanical Parts List ..........................................................24

H PT1260EX Series Hardware List ......................................................................25

I PT1280P and PT1280SL Mechanical Parts List ...............................................27

J PT1280P and PT1280SL Hardware List ...........................................................29

K PT1280P/PP and PT1280SL/PP Mechanical Parts List ...................................31

L PT1280P/PP and PT1280SL/PP Hardware List ...............................................33

M PT1250 Series Electrical Parts List...................................................................34

N PT1250DC Electrical Parts List .........................................................................36

O PT1250DC/PP Electrical Parts List ...................................................................37

P 12501007ACOMP Frame Scan Parts List ........................................................40

Q PT1250EX/AMS Electrical Parts List ................................................................41

Pelco Manual C373SM-A (8/01) 3

Page 4

IMPORTANT SAFEGUARDS AND WARNINGS

Prior to installation and use of this product, the following WARNINGS should be observed.

1. Installation and servicing should only be done by qualified service personnel and

conform to all local codes.

2. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6 or 6P

enclosure, it is designed for indoor use only and it must not be installed where

exposed to rain and moisture.

3. Only use replacement parts recommended by Pelco.

4. The installation method and materials should be capable to supporting four times the

weight of the enclosure, camera and lens combination.

5. The total load on tilt table shall not exceed 100 lb (45 kg) with the center of gravity at

5 inches above the tilt table surface. The weight and stiffness of explosion-proof

cabling must be included in this weight calculation.

6. PT1250EX/AMS, PT1260EX Series Only–If used in marine applications, the

installation shall be in accordance with the Electrical Engineering Regulations of the

U.S.C.G., Subpart J, C.G. 259 (46 CFR Parts 110-113).

7. After replacement/repair of this unit’s electrical components, conduct a resistance

measurement between line and exposed parts to verify the exposed parts have not

been connected to line circuitry.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous

voltage constituting a risk of electric shock

is present within this unit.

This symbol indicates that there are

important operating and maintenance

instructions in the literature accompanying

this unit.

Please thoroughly familiarize yourself with the information in this manual prior to installation

and operation.

CAUTION:

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

4 Pelco Manual C373SM-A (8/01)

Page 5

DESCRIPTION

All heavy duty pan/tilts can operate with loads up to 100 pounds (45.4 kg). Rugged hightorque motors with adjustable worm-gear final drives ensure long operational life and driftfree operation. All models are manufactured from cast and/or plate aluminum with all

internal parts corrosion-protected steel or aluminum.

The PT1250 Series and PT1280 Series are capable of auto/random scan operation with

the addition of the Pelco solid-state auto/random scan joystick control.

The PT1253R is equipped with variable frame scan capabilities (adjustable from 2-9

seconds) and interfaces with other manufacturers' control systems for frame scan operation. This pan/tilt can be used in place of the Vicon V390APT pan/tilt.

The PT1250EX/AMS meets the rigorous requirements for weather and dust-proof electrical

equipment for installations in salt-air environments.

Pan/tilts in the PT1260EX Series meet the rigorous requirements of explosion-proof and

dust-ignition-proof electrical equipment for installation and use in hazardous locations.

PT1260EX Series units are suitable for use in salty conditions such as aboard ships and on

sea coasts.

MODELS

PT1250 Series

PT1250P Heavy-duty, indoor/outdoor pan/tilt, 120 VAC

PT1250P/220 Same as PT1250P except 230 VAC input

PT1250P/FG Same as PT1250P except supplied with high-speed gears (12°/6° per

PT1250P/FGP Same as PT1250P except supplied with special pan-speed gearing

PT1250P/HB Same as PT1250P except supplied with spot heaters in base, blanket

PT1250P/HB/FG Combination of PT1250P/HB and PT1250P/FG

PT1250P/PP Same as PT1250P except supplied with preset positioning option.

PT1250P/PP/WT Same as PT1250P/PP except white epoxy polyester powder coat finish

PT1250P/RAD Same as PT1250P except supplied with radiation-resistant wiring and

PT1250DC Series

PT1250DC Heavy duty, indoor/outdoor pan/tilt, 115 VDC

PT1250DC/FG Same as PT1250DC except supplied with special high-speed gears

PT1250DC/HB Same as PT1250DC except supplied with spot heater in base, blanket

sec pan/tilt speed). Reduces load to 50 lb (22.68 kg)

(12°/sec pan speed)

heater in cover. Heaters are 120 VAC, 50/60 Hz, 230 watts total, and

allow operation to -50°F (-46°C)

Requires preset control or control with AZL option (position-indication

meter)

white epoxy paint. Low-level radiation resistancy

(12°/6° per second pan/tilt speed). Reduces total load rating to 50 lb

(22.68)

heater in cover, 120 VAC (230 watts total). Allows operation to

-50°F (-46°C)

Pelco Manual C373SM-A (8/01) 5

Page 6

PT1250DC/PP Same as PT1250DC except supplied with position feedback

modification. Requires preset control or control with AZL option (panel

readout meters)

PT1250DC/RAD Same as PT1250DC except supplied with radiation resistant wiring and

PT1253R

PT1253R Heavy duty, indoor/outdoor pan/tilt, 120 VAC. Equipped with variable

PT1250EX/AMS

PT1250EX/AMS Heavy duty, indoor/outdoor pan/tilt, 120 VAC, Weather and dust-proof

PT1260EX Series

PT1260EX Explosion-proof, 120 VAC operation pan/tilt for loads up to 100 lb (45 kg).

PT1260EX/220 Same as PT1260EX except 230 VAC operation

PT1260EX/PP Same as PT1260EX except supplied with preset position modification

PT1260EX/PP/230 Same as PT1260EX/PP except 230 VAC operation

PT1280 Series

PT1280P Heavy duty indoor/outdoor pan/tilt, 120 VAC

PT1208P/HB Same as PT1280P except supplied with spot heaters in base, blanket

white epoxy paint. Low level radiation resistant up to 106 rads

frame scan

construction for installation in salt-air environments.

(PP)

heater in cover, 230 watts total. 120 VAC, 50/60 Hz

PT1280P/PP Same as PT1280P except with presets

PT1280SL Heavy duty indoor/outdoor pan/tilt with SL option (360° pan rotation)

PT1280SL/PP Same as PT1280SL except with presets

OPTIONS

FGT/1250 Special tilt speed gearing: 6°/sec tilt speed. Reduces load to 50 lb

FG/1250P High speed gears: 12°/sec pan, 6°/sec tilt. Reduces load to 50 lb

FGP/1250P High speed gearing for pan: 12°/sec

FGT/1250P High speed gearing for tilt: 6°/sec tilt. Reduces load to 50 lb (22.68 kg)

SEC Sector scan modification allows pan/tilt to auto-scan and manually

HB/1250 Spot heaters in base, blanket heater in cover. 230 watts total. 120

(22.68 kg)

(22.68 kg)

override in present sector (PT1280P)

VAC, 50/60Hz allows operation to -50°F (-45.56°C)

6 Pelco Manual C373SM-A (8/01)

Page 7

MAINTENANCE

Inspect the pan/tilt unit every six months to ensure trouble-free operation and an extended

product life. Harsh environments and/or continuous motion applications may require more

frequent maintenance.

Please read all of the instructions that follow before servicing the pan/tilt.

To begin, remove the three screws on the front of the pan/tilt housing and lift the cover to

gain access to the pan and tilt motor assemblies.

TIGHTENING DRIVE CHAINS

Check the pan and tilt drive chains for tension. A movement of 1/32 of an inch to 3/32 of an

inch in the chains is acceptable. If the movement of a chain exceeds 3/32 of an inch, adjust

the chain as follows:

1. Loosen the screws securing the motor to the mounting frame.

2. Pry on the motor to apply tension to the chain. Do not over-tension the drive chain.

3. Keep tension on the chain while tightening the screws.

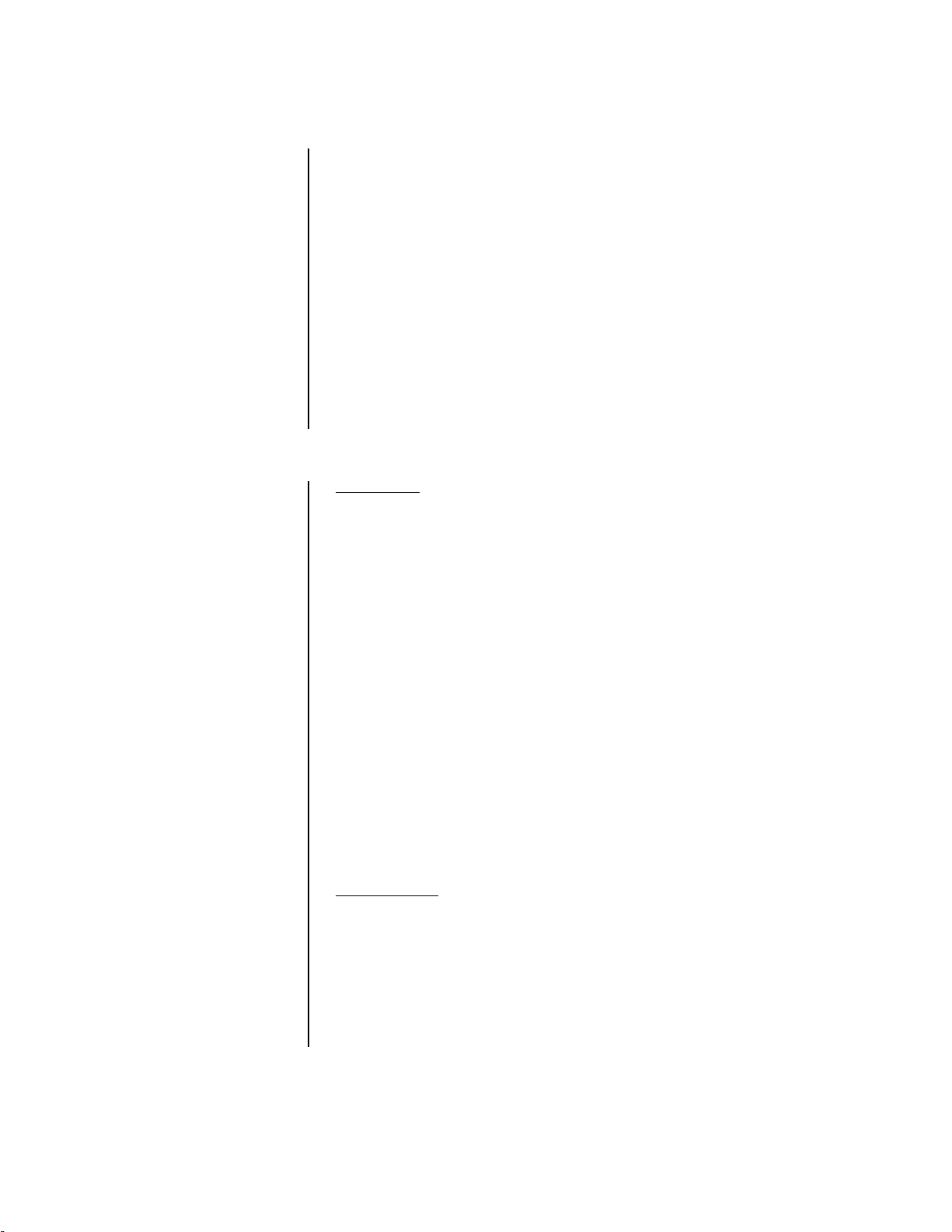

CHAIN DRIVE LUBRICATION

Sprockets, chains, and gears should be well greased. If necessary, lubricate the pan and tilt

gears, sprockets, and chains as follows with a high-quality grease capable of withstanding

temperatures from -50° to 170°F (-46° to 77°C). Do the following:

1. Liberally apply grease to the pan and tilt gears, chains, and sprockets (refer to Figure 1).

2. Operate the pan and tilt motors to spread the grease across the parts.

3. Apply additional grease if necessary.

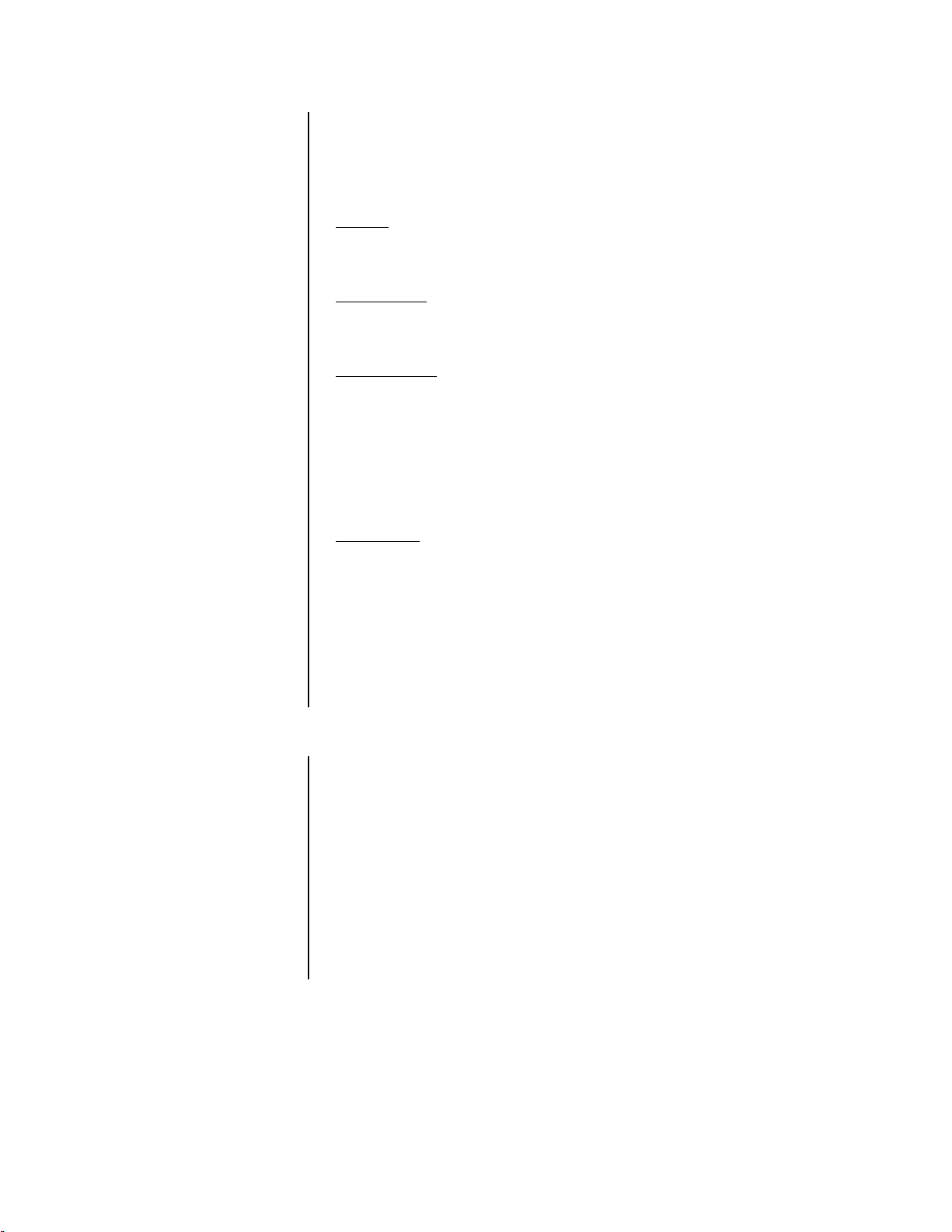

4. Reinstall the cover. If the pan/tilt is installed outdoors in an inverted position, apply

RTV silicone sealant as shown in Figure 2 (except PT1250EX/AMS and PT1260EX

Series).

Figure 1. Servicing the Pan/Tilt

Pelco Manual C373SM-A (8/01) 7

Page 8

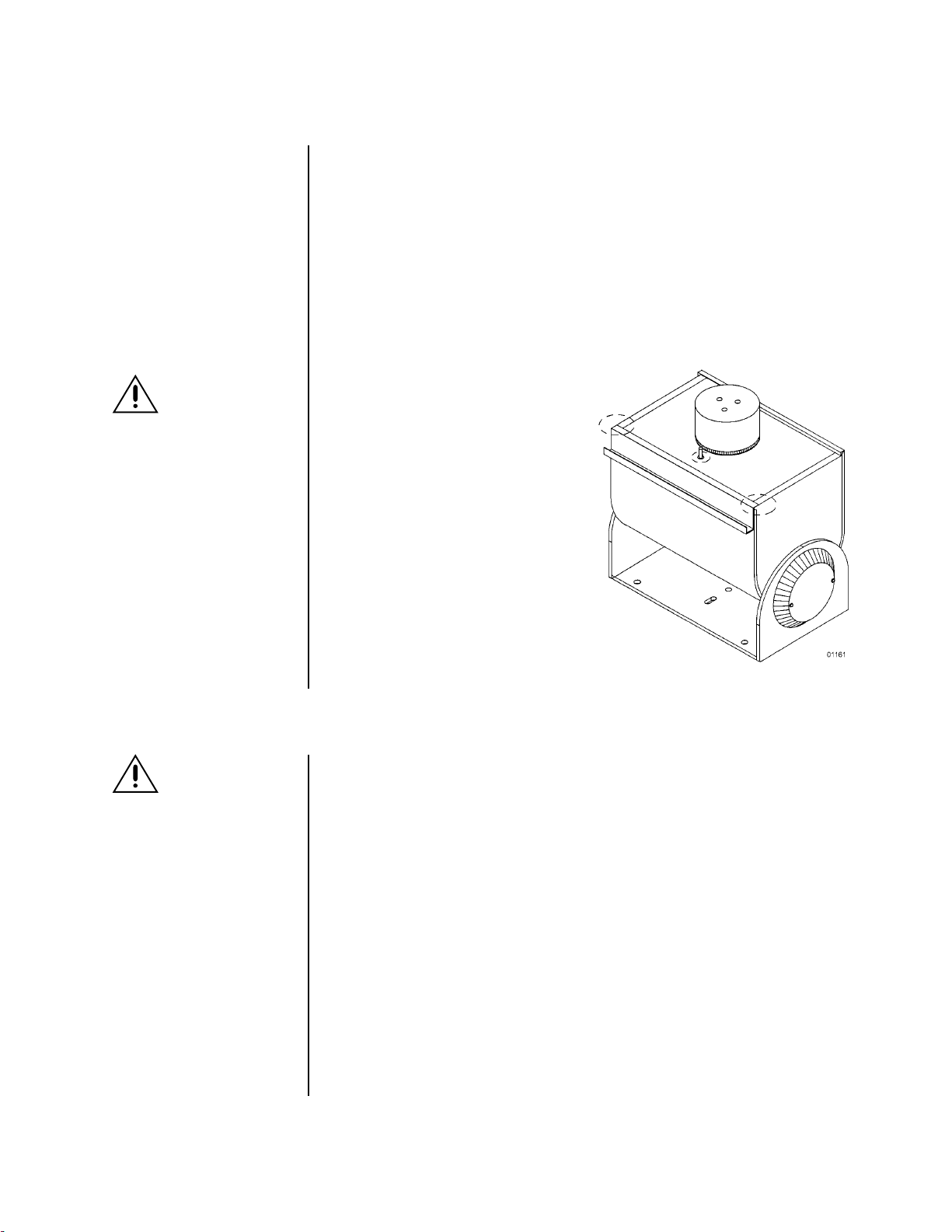

RESETTING POTENTIOMETERS

IMPORTANT:

Be very

careful when resetting potentiometer switches. Be

sure that the pan/tilt has

been centered between

maximum pan and tilt travel,

regardless of the adjustable

limit stops. Failure to observe caution when resetting potentiometers could

result in damage to the

preset positioning ability of

the pan/tilt.

WARNING:

NEVER reposition

the pan fixed limit

stop. Doing so WILL DAMAGE the wiring harness

and, if the pan/tilt has preset

positioning, COULD cause

the pan potentiometer to

BREAK.

Models with Preset Positioning (PP)

Models with preset positioning (PP) use potentiometer switches that are factory set to the

full range of pan and tilt travel. Under normal operating conditions and at routine service

intervals they do not need adjusting.

Should your pan/tilt require any work on the drive mechanism other than routine maintenance, perform the following procedure to reset the potentiometers.

To begin, remove the cover to gain access to the pan and tilt motor assemblies.

1. Remove the potentiometer gears and position the pan/tilt to the middle of its maximum

pan and tilt travel, regardless of the position of the adjustable limit stops. That is, the

tilt table should be level and the fixed limit stop should be opposite the limit switch.

2. Turn a potentiometer all the way in

one direction until it stops, then

observing the number of turns, turn it

back the other way until it stops.

Rotate the potentiometer half the

number of turns the other way to

reach the center.

3. Replace the potentiometer gear.

4. Perform steps 2 and 3 for the other

potentiometer.

➛

➛

➛

WARNING

: The

knife-blade included in the brake

kit is very sharp. It should be

handled carefully and disposed of properly after use.

NOTE

: This section does

not apply to the PT1250DC

Series.

Figure 2. Sealant Locations

MOTOR BRAKE REPLACEMENT

To order replacement motor brakes, specify part number 1250BRAKE. The kit consists of

four springs, four Teflon pads, two screws, and a small knife-blade for removing the old

brake pads.

1. Remove the large rectangular heat sink from the back of the pan motor. Remove the

four springs. Do not disturb the silicone heat sink compound. It ensures the transfer of

heat to the heat sink and MUST be present when the heat sink is replaced.

2. Use the knife blade to remove the worn pads, as follows:

a. Insert the knife blade into the opening and press firmly into the brake pad.

b. Before trying to remove the brake pad, twist the knife-blade. This will loosen the

worn pad and make removal easier.

c. Gently twist the blade as you pull the worn pad out.

3. Insert the four new brake pads and four springs. Replace the heat sink using the new

screws.

Reinstall the cover. If your pan/tilt is installed outdoors in an inverted position, apply RTV

silicone sealant to the areas circled in Figure 2 (except PT1250EX/AMS and PT1260EX

Series).

8 Pelco Manual C373SM-A (8/01)

Page 9

EXPLODED ASSEMBLY DIAGRAMS

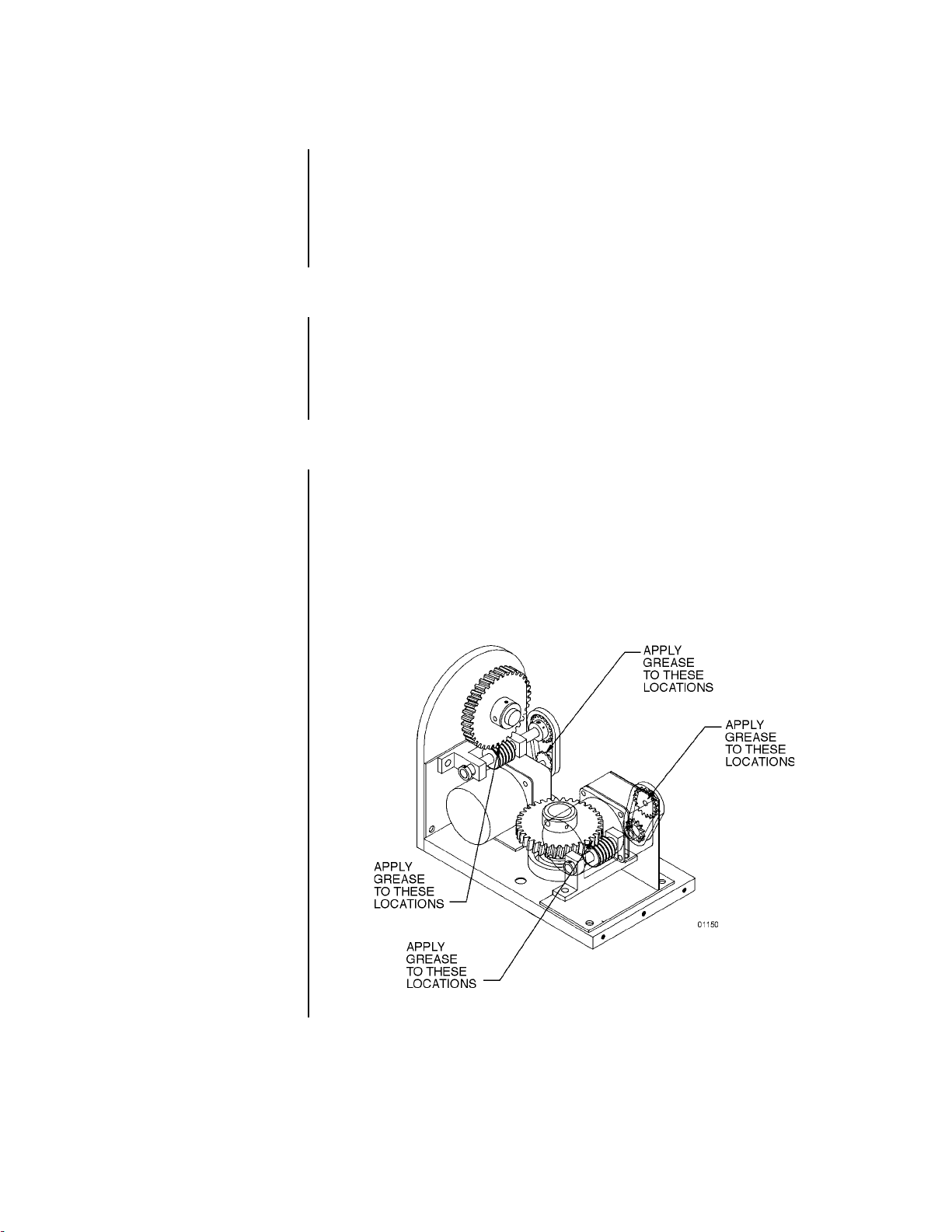

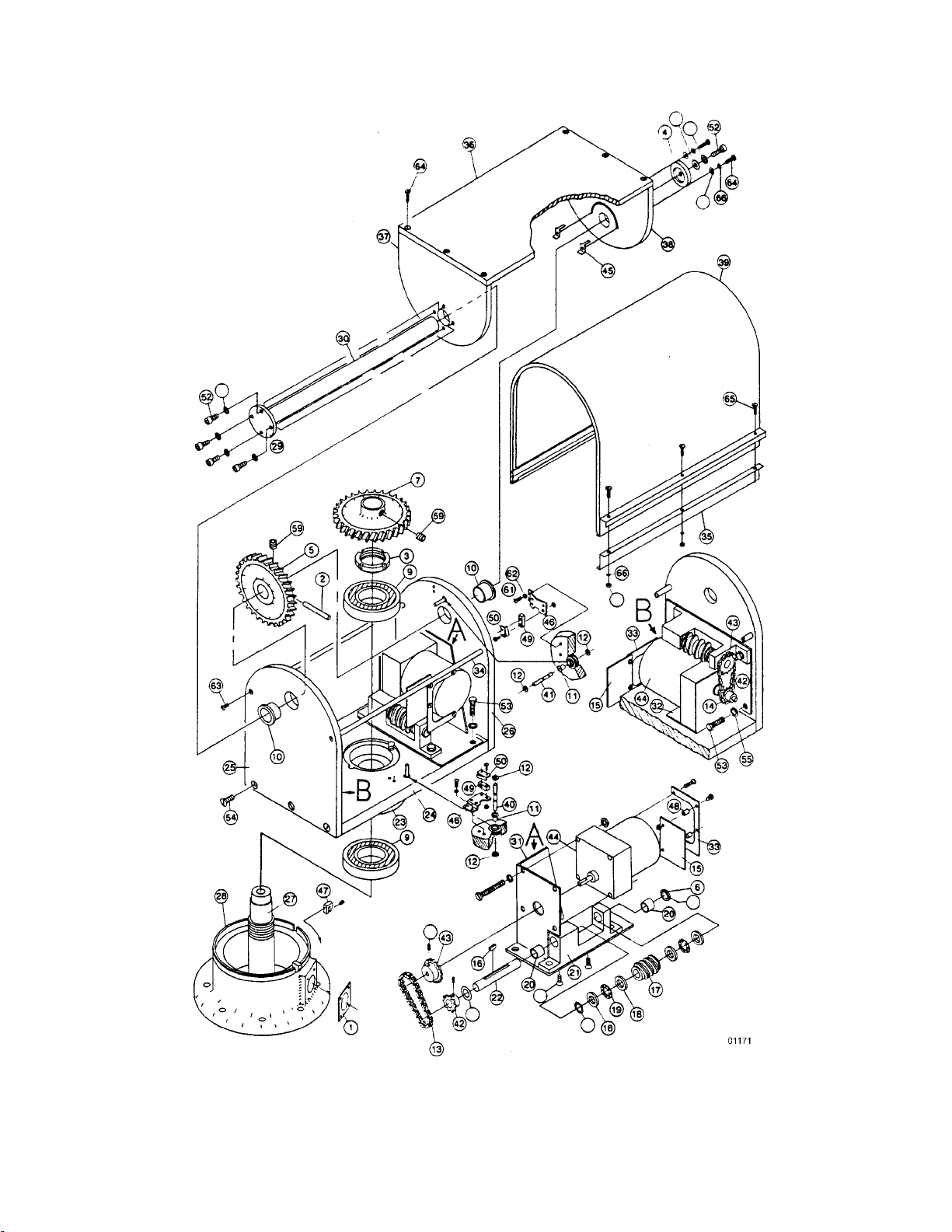

Figure 3. PT1250 Series Exploded Assembly Diagram (Mechanical Parts)

Pelco Manual C373SM-A (8/01) 9

Page 10

Table A. PT1250 Series Mechanical Parts List

Item Qty Description Part Number

11Gasket 105010010

21Pan spindle nut 10504017COMP

31Thrust cap (except WT, RAD models) 10504076COMP

41Tilt gear 10504084COMP

51Pan gear 10504089COMP

62Bearing 10506009

72Bearing 10506010

82Grommet 125010000

94Retainer clip 125010001

10 1 Pan chain assembly (except 220, FG, FGP models) 12501010COMP

11 1 Tilt chain assembly (except 220 , FG, FGP models) 12501011COMP

12 2 Key 105010015

13 2 Worm gear 105012010

14 2 Shaft (except 220 model) 10504078COMP

15 2 Thrust collar 10504085COMP

16 8 Bearing washer 10506005

17 4 Bearing cage 10506006

18 4 Bearing 10506007

19 2 Gear train bracket 12504079COMP

20 8 Arbor shim ZHSHIM.004

21 1 Spindle base assembly (except WT, RAD models) 12501041ACOMP

22 1 Tilt shaft assembly 12501043COMP

23 1 Pan limit bracket 12504100COMP

24 1 Tilt limit bracket 1554052COMP

25 4 Switch SWI1SM1

26 2 Pan switch actuator with insulation SWIJS221

27 2 Tilt switch actuator with insulation SWIJS138B

28 1 9-pin terminal strip TRS2009

29 1 Heat sink (except 220, RAD models) 12504010ACOMP

30 2 Spacer rod 12504110COMP

31 1 Pull-up bar (except WT, RAD models) 12504111COMP

32 1 Tilt table top (except WT , RAD models) 12504116COMP

33 1 Tilt table side (except WT, RAD models) 12504117COMP

34 1 Tilt table side (limit stops) (except WT, RAD models) 12504118COMP

35 1 Cover (except WT, RAD models) 12504119BWA

36 1 Pan limit pin 12504120ACOMP

37 1 Tilt limit pin 12504121ACOMP

38 1 Pan motor plate (except 220 model) 12504123COMP

39 1 Tilt motor plate (except 220 model) 12504123TCOMP

40 1 Pan motor sprocket (except 220, FG, FGP models) 12504124COMP

41 1 Tilt motor sprocket (except 220, FG models) 12504125COMP

42 1 Pan sprocket 12504126COMP

1 Thrust cap (WT and RAD only) 10504076WCOMP

1 Pan chain assembly (FG and FGP only) 12501020COMP

1 Pan chain assembly (220 only) 12501221COMP

1 Tllt chain assembly (FG and FGP only) 12501001COMP

1 Tilt chain assembly (220 only) 12501220COMP

2 Shaft (220 only) 20004110COMP

1 Spindle base assembly (WT and RAD only) 12501041AWCOMP

1 Pull-up bar (WT and RAD only) 12504111WCOMP

1 Tilt table top (WT and RAD only) 12504116WCOMP

1 Tilt table side (WT and RAD only) 12504117WCOMP

1 Tilt table side (limit stops) (WT and RAD only) 12504118WCOMP

1 Cover (WT and RAD only) 12504119WA

1 Pan motor plate (220 only) 12504220COMP

1 Tilt motor plate (220 only) 12504221COMP

1 Pan motor sprocket (FG and FGP only) 1504016 COMP

1 Pan motor sprocket (220 only) 12504226COMP

1 Tilt motor sprocket (220 only) 28012011

1 Tilt motor sprocket (FG only) 12504124COMP

Continued on next page

10 Pelco Manual C373SM-A (8/01)

Page 11

Table A. PT1250 Series Mechanical Parts List (Continued)

Item Qty Description Part Number

43 1 Tilt sprocket (except 220, FG models) 12504127COMP

44 2 Motor, 120 VAC (except 220 model) 12508110

45 2 Gear head (except 220 model) 12508111

46 1 Bottom plate 12504112ACOMP

47 1 Side plate, tilt side (except WT , RAD models) 12504115COMP

48 1 Side plate, pan side (except WT, RAD models) 12504114ACOMP

49 2 Tilt limit stop 1554055COMP

50 1 7-pin male connector (RAD model) MS3102E16S1P

51 Not used

52 7 Gasket, 1/8" x 1/2" x feet (except FG, FGP models) EH550010030

53 Not used

54 3 Pan limit stop 58010006

55 Not used

56 Not used

57 1 Collar, tilt AZL gear 12504020COMP

58 1 AZL potentiometer bracket 12504003COMP

59 1 Gear, AZL collar 12504104

60 1 Potentiometer, 5K ohm POT005.0K10534

61 1 Gear potentiometer TV12000

62 1 Collar, pan AZL gear 12504001COMP

63 Not used

64 Not used

65 1 AZL potentiometer bracket 12504003COMP

66 1 Gear TV12000

67 1 Potentiometer, 5K ohm POT005.0K10534

68 1 Gear, AZL collar 12504104

1 Tilt sprocket (220 only) 12504227COMP

1 Tilt sprocket (FG only) 12504126COMP

2 Motor, 230 VAC (220 only) 12508115

2 Gear head (220 only) 12508114

1 Side plate, tilt side (WT and RAD only) 12504115WCOMP

1 Side plate, pan side (WT and RAD only) 12504114AWCOMP

1 9-pin male connector (P, 220, FG, FGP models) CON206705-1

1 16-pin male connector (PP, WT, HB models) CON206036-1

2 Gasket, 1/8" x 1/2" x feet (FG and FGP only) EH550010030

The following items are for the PP and WT models only:

The following items are for the HB model only but are

not shown:

1Cover heater blanket, 120 VAC 105010000

2 Base heater blanket, 120 VA C EH110065A

1 Thermostat EH5510049A

Pelco Manual C373SM-A (8/01) 11

Page 12

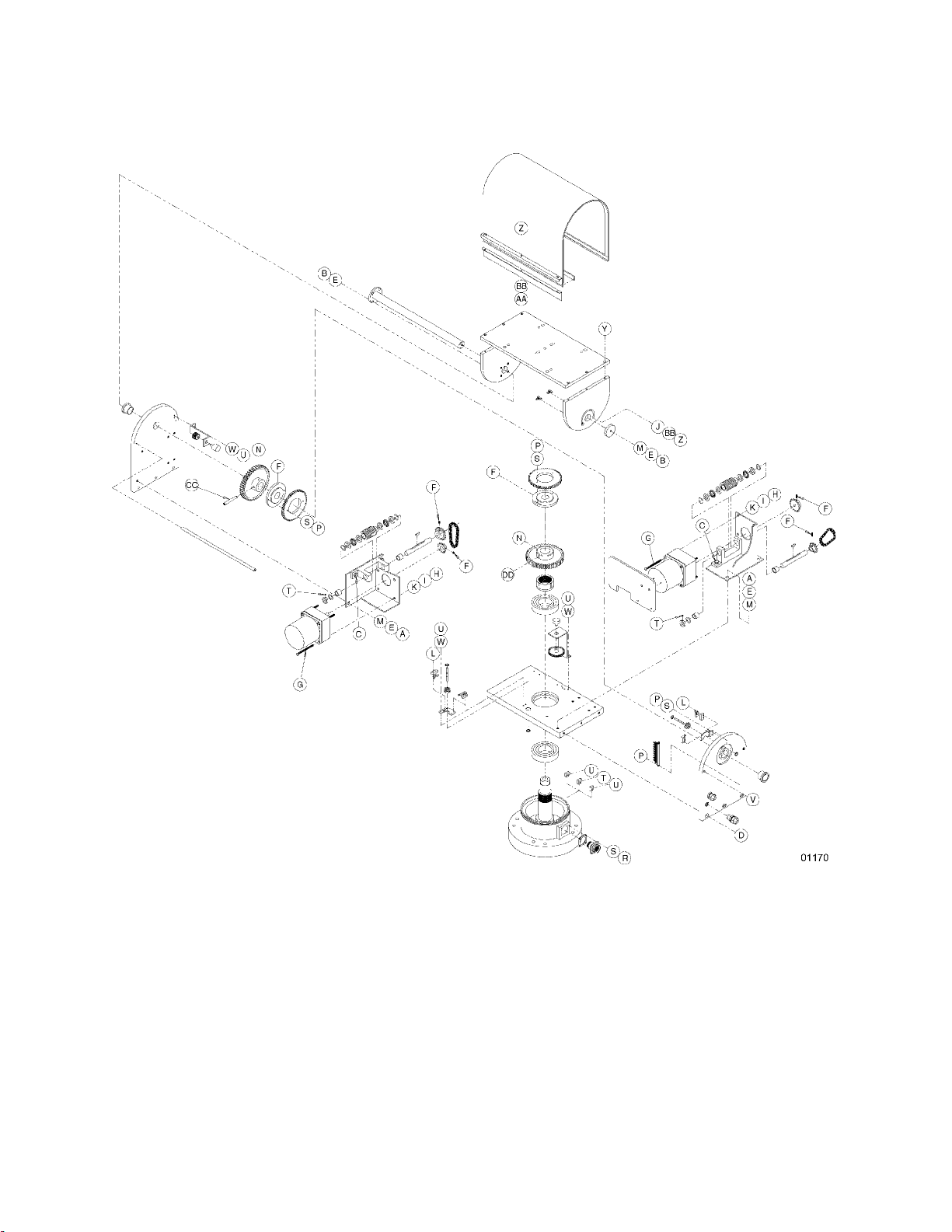

Figure 4. PT1250 Series Exploded Assembly Diagram (Hardware)

12 Pelco Manual C373SM-A (8/01)

Page 13

Table B. PT1250 Ser ies Hardware List

Item Qty Description Part Number

A4Screw, 1/4-20 x 1/2" ZH1/420X.500CH

B5Allen bolt, 1/4-20 x 5/8" ZH1/420X.625CS

C4Bolt, 1/4-20 x 3/4" ZH1/420X.750CH

D6Screw 1/4-20 x 1", flat-head, Phillips ZH1/420X1.00SFS

E9Split lock washer, 1/4" ZH1/4LWSSL

F4Set screw, 10-32 x 3/16" (except PP, WT models) ZH10-32X.187S

G8Screw, 10-32 x 2 1/4", pan head, Phillips ZH10-32X2.25SPS

H8Nut, 10-32 ZH10-32NUTSH

I8Split lock washer, #10 ZH10LWSSL

J2Flat washer, #8 ZH188X435X60C

K8Flat washer, #10 ZH204X436X60C

L8Screw, 2-56 x 7/16", pan head, Phillips ZH2-56X.437SPP

M5Flat washer, 3/16" ZH260X562X65C

N2Set screw, 3/8-24 x 3/8" ZH3/8-24X.375S

P4

R4Screw, 4-40 x 3/8", pan head, Phillips ZH4-40X.375SPP

S6Internal tooth lock washer, #4 (except PP, WT) ZH4LWSIS

T3Set screw, 6-32 x 3/16" ZH6-32X.187S

U4

V4Screw, 6-32 x 3/4" flat head, Phillips ZH6-32X.750SFS

W2Split lock washer, #6 (except PP, WT) ZH6LWSIS

X Not used

Y6Allen screw, 8-32 x 1/2" ZH8-32X.500CS

Z5Screw, 8-32 x 5/8", pan head, Phillips ZH8-32X.625SPP

AA 3 Nut, 8-32 ZH8-32NUTSH

BB 5 Internal star washer, #8 ZH8LWSIS

CC 1 Tapered pin, #5 x 2 1/2" 105010017

DD 1 Dowel pin, 3/16" x 5/8" ZHPIN3/16X5/8

6 Set screw, 10-32 x 3/16" (PP and WT only) ZH10-32X.187S

8 Screw, 4-40 x 1/4", pan head, Phillips (PP, WT only) ZH4-40X.250SPP

Screw, 4-40 x 1/4", pan head, Phillips (except PP, WT

10 Internal tooth lock washer, #4 (PP and WT only) ZH4LWSIS

Screw, 6-32 x 3/8", pan head, Phillips (except PP, WT

6 Screw, 6-32 x 3/8", pan head, Phillips (PP, WT only) ZH6-32X.375SPP

6 Split lock washer, #6 (PP and WT only) ZH6LWSIS

) ZH4-40X.250SPP

) ZH6-32X.375SPP

Pelco Manual C373SM-A (8/01) 13

Page 14

Figure 5. PT1250DC Series Exploded Assembly Diagram

14 Pelco Manual C373SM-A (8/01)

Page 15

Table C. PT1250DC Series Parts List

Item Qty Description Part Number

11Gasket connector 105010010

21Pin tapper #5 x 2" 105010017

31Nut, pan spindle 10504017COMP

41Thrust cap 10504076COMP

51Gear tilt 10504084COMP

62Thrust collar 10504085COMP

71Gear, pan 10504089COMP

8–(Not used)

92Bearing 10506009

10 2 Bearing 10506010

11 2 Mount limit pin 125010000

12 4 Clip retainer 125010001

13 1 Chain assembly, pan motor 12501000COMP

14 1 Chain assembly, tilt motor 12501001COMP

15 2 PC board assembly filter 12501003COMP

16 2 Key, Woodruff #3 105010015

17 2 Gear, worm pan/tilt 105012010

18 8 Bearing, A016 washer only 10506005

19 4 Bearing, A016C cage only 10506006

20 6 Bearing 10506007

21 2 Bracket, gear train 12504079COMP

22 2 Shaft, gear train 20004110COMP

23 1 Bearing, boss 10504069COMP

24 1 Bottom plate 12504113ACOMP

25 1 Pan side plate 12504114ACOMP

26 1 Tilt side plate 12504115ACOMP

27 1 Spindle 10504074COMP

28 1 Base 12504112ACOMP

29 1 Flange, tilt 10504077COMP

30 1 Shaft, tilt (less flange) 12504122COMP

31 1 Plate, pan motor 12504006COMP

32 1 Plate, tilt motor 12504007COMP

33 2 Bracket, circuit board 12504009COMP

34 2 Spacer, rod 12504110COMP

35 1 Pull-up bar 12504111COMP

36 1 Tilt table top 12504116COMP

37 1 Table, side tilt 4H 12504117COMP

38 1 Table, side tilt 1H 12504118COMP

39 1 Cover 12504119BWA

40 1 Pin limit, pan 12504120ACOMP

41 1 Pin limit, tilt 12504121ACOMP

42 2 Sprocket, pan gear train 12504126ACOMP

43 2 Sprocket, tilt gear train 12504127ACOMP

44 2 Motor MR02-0002-3104

45 2 Tilt limit stop 1554050COMP

46 2 Bracket, tilt limit 1554052COMP

47 3 Limit stop pan, univ pan/tilt 58010006

48 4 Spacer, 1/4 O.D. x .375 ##6, clear SPA2101

49 4 Switch SWI1SM1

50 2 Pan switch actuator w/insulator SWIJS138B

51 4 Screw, 1/4-20 x 1/2" Hex CAD ZH1/4-20X.500CH

52 5 Bolt, 1/4-20 x 5/8" SOC SS ZH1/420X.625CS

53 4 Bolt, 1/4-20 x 3/4" Hex CAD ZH1/420X.750CH

54 6 Screw, 1/4-20 x 1" Flat slot SS ZH1/420X1.00SFS

2 Tilt switch actuator w/insulator SWIJS221

Pelco Manual C373SM-A (8/01) 15

Page 16

35

31

22

33

48

4

7

20

18

20

15

30

45

44

20

17

13

16

12

18

19

25

26

23

11

43

14

41

39

49

5

2

6

46

9

36

8

9

6

52

32

34

3

20

17

13

16

20

19

45

44

29

9

28

54

18

20

15

37

8

27

25

24

9

47

40

12

10

42

14

18

38

7

21

1

50

01172

Figure 6. PT1253R Exploded Assembly (Mechanical Parts)

16 Pelco Manual C373SM-A (8/01)

Page 17

Table D. PT1253R Mechanical Parts List

Item Qty Description Part Number

11Gasket, connector 105010010

21Nut, pan spindle black no. 8 10504017COMP

31Thrust cap 10504076COMP

41Gear, tilt 10504084COMP

51Gear, pan 10504089COMP

62Bearing 6208-ZZ 10506009

72Bearing FB1416-6 10506010

82Mount grommet LOR00 125010000

94Clip retainer 125010001

10 1 Chain, assy pan 12501010COMP

11 1 Chain, assy tilt 12501011COMP

12 2 Key, Woodruff #3 alloy 105010015

13 2 Gear, worm pan 105012010

14 2 Pan shaft 10504078COMP

15 2 Thrust collar 10504085COMP

16 8 Bearing AO16, washer only 10506005

17 4 Bearing AO16C, cage only 10506006

18 4 Bearing B810-4 10506007

19 2 Bracket, gear train 12504079COMP

20 6 Shim arbor ZHSHIM.004

21 1 Base, spindle assy 12501041ACOMP

22 1 Tilt, shaft assy 12501043COMP

23 1 Pan limit bracket 12504100COMP

24 1 Tilt limit bracket 1554052COMP

25 4 Switch SWI1SM1

26 2 Switch actuator w/ insulation SWIJS138B

27 2 Switch actuator, long w/insulation SWIJS221

28 1 Terminal strip, 9 position TRS2009

29 1 Heat sink 12504010ACOMP

30 2 Spacer rod 12504110COMP

31 1 Pull up bar 12504111COMP

32 1 Tilt table, top 12504116COMP

33 1 Table, side tilt 4H 12504117COMP

34 1 Table, side tilt 1H 12504118COMP

35 1 Cover 12504119BWA

36 1 Pin, limit pan 12504120ACOMP

37 1 Pin, limit tilt 12504121ACOMP

38 1 Plate, motor pan 12504123COMP

39 1 Plate, motor tilt 12504123TCOMP

40 1 Sprocket, 25B18-5/16" W/SS 12504124COMP

41 1 Sprocket, motor tilt 12504125COMP

42 1 Sprocket, 25B13 1/2" bore w/ set screw 12504126COMP

43 1 Sprocket, 25B18 1/2" bore w/ set screw 12504127COMP

44 2 Motor, 120V 12508110

45 2 Gear head 12508111

46 1 Bottom plate assy 12504112ACOMP

47 1 Tilt, side plate 12504115COMP

48 1 Pan, side plate 12504114ACOMP

49 2 Tilt, limit stop 1554050COMP

50 1 Conn CPC 16 pos pin recp CON206036-1

51 1 PCB Assy, Frame Scan (not shown) 12501007ACOMP

52 7 ft. Gasket, poron 1/8 x 1/2, black EH550010030

53 Not Used

54 3 Limit stop, pan 58010006

Pelco Manual C373SM-A (8/01) 17

Page 18

Z

B

E

CC

N

F

T

K

M

E

A

C

G

F

H

I

U

W

L

BB

AA

Y

J

BB

Z

M

E

B

N

DD

G

T

C

H

I

K

A

E

M

F

F

P

L

S

P

U

T

U

S

R

V

D

01173

Figure 7. PT1253R Exploded Assembly (Hardware)

18 Pelco Manual C373SM-A (8/01)

Page 19

Table E. PT1253R Hardware List

Item Qty Description Part Number

A4Screw, 1/4-20 x .500 soc ZH1/420X.500CS

B5Bolt, 1/4-20 x 5/8" sock SS ZH1/420X.625CS

C4Bolt, 1/4-20 x 3/4" hex SS ZH1/420X.750CH

D6Screw, 1/4-20 x 1" flat phil SS ZH1/420X1.00SFS

E9Washer, split lock 1/4" SS ZH1/4LWSSL

F4Set screw, 10-32 x 3/16" soc knur blk ZH10-32X.187S

G8Screw, 10-32 x 2 1/4" phil pan SS ZH10-32X2.25SPS

H8Nut, hex 10-32 SS ZH10-32NUTSH

I8Washer, split lock #10 SS ZH10LWSSL

J2Washer, flat #8 SS ZH188X435X60C

K8Washer, flat #10 ZH204X436X60C

L8Screw, 2-56 x 7/16" pan phil SS ZH2-56X.437SPP

M5Washer, flat 3/16" SS ZH260X562X65C

N2Set screw, 3/8-24 x 3/8" soc knur blk ZH3/8-24X.375S

P4Screw, 4-40 x 1/4" pan phil SS ZH4-40X.250SPP

R4Screw, 4-40 x 3/8" pan phil SS ZH4-40X.375SPP

S6Washer, lock #4 internal tooth SS ZH4LWSIS

T3Set screw, 6-32 x 3/16" soc knur blk ZH6-32X.187S

U6Screw, 6-32 x 3/8" pan phil SS ZH6-32X.375SPP

V4Screw, 6-32 x 3/4" flat phil SS ZH6-32X.750SFS

W4Washer, split lock #6 ZH6LWSIS

X3Screw, 8-32 x 3/8" pan phil SS ZH8-32X.375SPP

Y6Screw, 8-32 x 1/2" soc SS ZH8-32X.500CS

Z5Screw, 8-32 x 5/8" pan phil SS ZH8-32X.625SPP

AA 3 Nut, hex 8-32 SS ZH8-32NUTSH

BB 5 Washer, internal star #8 SS ZH8LWSIS

CC 1 Taper pin, #5 x 2 1/2" ZHPIN#5X21/2

DD 1 Pin, dowel 3/16" x 5/8" ZHPIN3/16X5/8

Pelco Manual C373SM-A (8/01) 19

Page 20

20 Pelco Manual C373SM-A (8/01)

Figure 8. PT1250EX/AMS Exploded Assembly Diagram

Page 21

Table F. PT1250EX/AMS Parts List

Item Qty Description Part Number

1 Not used

21Pan spindle nut 10504017COMP

31Thrust cap 10504076WCOMP

41Tilt gear 10504084COMP

51Pan gear 10504089COMP

61Upper pan shaft bearing 10506009

71Lower pan shaft bearing 10506012

81Pan chain assembly 12501010COMP

91Tilt chain assembly 12501011COMP

10 2 Key 105010015

11 2 Worm gear 105012010

12 2 Worm gear shaft 10504078COMP

13 2 Thrust collar 10504085COMP

14 8 Bearing washer 10506005

15 4 Bearing cage 10506006

16 4 Bearing 10506007

17 2 Gear train bracket 12504079COMP

18 8 Arbor shim ZHSHIM.004

19 1 Tilt shaft 12501043SSCOMP

20 1 Heat sink 12504010ACOMP

21 2 Tilt collar 12504020COMP

22 1 Mounting for pan limit ring and preset position gear 12504101COMP

23 2 Preset position gear 12504104

24 1 Tilt table top 12504116WCOMP

25 1 Pan motor plate 12504123COMP

26 1 Sprocket 12504124COMP

27 1 Sprocket 12504125COMP

28 1 Sprocket 12504126COMP

29 1 Sprocket 12504127COMP

30 2 120 VAC motor 12508110

31 2 Gear head 12508111

32 1 Spindle base 1250EX1043COMP

33 1 Body 1250EX1141WCOMP

34 1 Potentiometer bracket 12550EX4003WA

35 2 Limit stop ring 1250EX4005COMP

36 1 Tilt switch bracket 1250EX4006COMP

37 1 Pan switch bracket 1250EX4007COMP

38 1 Heat sink bracket 1250EX4008COMP

39 1 Tilt table side plate, tilt side 1250EX4213WCOMP

40 1 Tilt table side plate, pan side 1250EX4116WCOMP

41 1 Tilt motor plate 1250EX4123TCOMP

42 2 Bushing 1250EX6000

43 4 Retainer clip 125010001

44 Not used

45 6 Limit stop 58010006

46-48 Not used

49 2 Grommet GRO2172N

50 2 Potentiometer, 5K ohm POT005.0K10534

51 2 Actuator pin PT18044020COMP

52 4 Switch SWI1SM1

53 4 Actuator with insulator SWIJS138B

54 Not used

55 1 Terminal strip TRS2009

56 2 Gear TV12000

57 2 Cover 1250EX4218WCOMP

2 Cover gasket (not shown) 1250EX10002

Continued on next page

Pelco Manual C373SM-A (8/01) 21

Page 22

Table F. PT1250EX/AMS Parts List (Continued)

Item Qty Description Part Number

A Not used

B6Allen screw, 8-32 x 1/2" ZH8-32X.500CS

C-E Not used

F6Internal star lock washer, #6 ZH6LWSIS

G Not used

H8Flat washer, #10 ZH204X436X60C

I-J Not used

K12Split lock washer, 1/4" ZH1/4LWSSL

L-M Not used

N3Allen screw, 6-32 x 3/8" ZH6-32X.375CS

O Not used

P9Flat washer, 3/16" ZH260X562X65C

Q1Internal star lock washer, 1/4" ZH1/4LWSIS

R-S Not used

T3Split lock washer, #6 ZH6LWSSL

U8Split lock washer, #10 ZH10LWSSL

V-W Not used

X8Screw, 2-56 x 7/16", pan head ZH2-56X.437SPP

Y8Screw, 4-40 x 3/8", pan head ZH4-40X.375SPP

Z-AA Not used

BB 4 Internal star lock washer, #4 ZH4LWSIS

CC 5 Screw, 6-32 x 3/8", pan head ZH6-32X.375SPP

DD 3 Set screw, 6-32 x 3/16" ZH6-32X.187S

EE 2 Screw, 4-40 x 1/4", pan head ZH4-40X.250SPP

FF Not used

GG 5 Allen bolt, 1/4-20 x 5/8" ZH1/420X.625CS

HH 2 Set screw, 3/8-24 x 3/8" ZH3/8-24X.375S

II 9 Set screw, 10-32 x 3/16" ZH10-32X.187S

JJ 6 Screw, 6-32 x 1/4", pan head ZH6-32X.250SPP

KK 4 Bolt, 1/4-20 x 1/2" ZH1/4-20X.500CH

LL 24 Allen bolt, 1/4-20 x 3/4" ZH1/4-20X.750CS

MM 4 Bolt, 1/4-20 x 3/4" ZH1/420X.750CH

NN 2 Nut, 4-40 ZH4-40NUTSH

OO Not used

PP 9 Nut, 10-32 ZH10-32NUTSH

QQ 2 Screw, 10-32 x 1/2", pan head ZH10-32X.500SPP

RR 8 Screw, 10-32 x 2-1/4", pan head ZH10-32X2.25SPS

SS 1 Tapered pin, #5 x 2" 105010017

TT 2 Dowel pin, 3/16” x 5/8" ZHPIN3/16X5/8

UU 8 Nylon washer ZH131X361X62N

22 Pelco Manual C373SM-A (8/01)

Page 23

Figure 9. PT1260EX and PT1260EX/PP Exploded Assembly Diagram (Mechanical Parts)

Pelco Manual C373SM-A (8/01) 23

Page 24

Table G. PT1260EX Series Mechanical Parts List

Item Qty Description Part Number

1—Not used —

21Nut, pan spindle 10504017COMP

31Thrust cap 10504076COMP

41Gear, tilt 10504084COMP

51Gear, pan 10504089COMP

62Bearing, pan shaft 10506012

7—Not used —

81Chain assembly, pan 12501010COMP

91Chain assembly, tilt 12501011COMP

10 2 Key, Woodruff #3 105010015

11 2 Gear, worm 105012010

12 2 Shaft, worm gear 10504078COMP

13 2 Collar, thrust 10504085COMP

14 8 Bearing, washer only 10506005

15 4 Bearing, cage only 10506006

16 4 Bearing 10506007

17 2 Bracket, gear train 12504079COMP

18 8 Shim, arbor ZHSHIM.004

19 1 Shaft, tilt 12501043SSCOMP

20 1 Heat sink 12504010ACOMP

21 1 Collar, tilt (non-preset models) 12504020COMP

22 1 Mount, pan limit ring 12504101COMP

23 2 Gear, AZL collar (preset models only) 12504104

24 1 Tilt table 12504116COMP

25 1 Plate, motor pan 12504123COMP

26 1 Sprocket, with set screw 12504124COMP

27 1 Sprocket, with set screw 12504125COMP

28 1 Sprocket, with set screw 12504126COMP

29 1 Sprocket, with set screw 12504127COMP

30 2 Motor only: 120 VAC 12508110

31 2 Gear head only: 120 VAC 12508111

32 1 Spindle base 1260EX1042COMP

33 1 Body 1250EX1141COMP

34 1 Bracket, AZL pots (preset models only) 1250EX4003WA

35 2 Ring, limit stop 1250EX4005COMP

36 1 Bracket, tilt switch 1250EX4006COMP

37 1 Bracket, pan switch 1250EX4007COMP

38 1 Bracket, heat sink 1250EX4008COMP

39 1 Side plate, tilt table, tilt side 1250EX4213COMP

40 1 Side plate, tilt table, pan side 1250EX4116COMP

41 1 Plate, motor tilt 1250EX4123TCOMP

42 2 Bushing 1250EX6000

43 4 Retainer, clip 125010001

44 — Not Used

45 6 Limit stop universal 58010006

46 1 Plate, UL label (not Shown) 1260EX4000COMP

47 — Not used —

48 — Not used —

49 2 Grommet (special) GRO2172N

50 2 Potentiometer, 5K ohm (preset models only) POT005.0K10534

51 2 Pin, actuator PT18044020COMP

52 4 Switch SWI1SM1

53 4 Actuator with insulator SWIJS138B

54 — Not used —

55 1 Terminal Strip TRS2009

56 2 Gear, AZL (preset models only) TV12000

57 2 Cover, front/rear 1250EX4218COMP

58 1 Pipe nipple 1/2" x 4" galv. 1250EX10000

59 1 Gland, explosion proof EHX82410084

2 Collar, tilt (preset models) 12504020COMP

Motor only: 230 VAC 12508115

Gear head only: 230 VAC 12508114

UL Label (not shown) ULBL02

2 Gasket, cover (not shown) 1250EX10002

24 Pelco Manual C373SM-A (8/01)

Page 25

Table H. PT1260EX Ser ies Hardware List

Item Qty Description Part Number

A—Not used —

B6Screw, 8-32 x 1/2" Hex socket head ZH8-32X.500CS

C—Not used —

D—Not used —

E—Not used —

F6Lockwasher #6 internal star ZH6LWSIS

G—Not used —

H8Flat, washer #10 ZH204X436X60C

I—Not used —

J—Not used —

K12Washer, split lock 1/4" ZH1/4LWSSL

L—Not used —

M—Not used —

N3Screw, 6-32 x 3/8", socket head (preset models only) ZH6-32X.375CS

O—Not used —

P9Washer, flat 3/16" special ZH260X562X65C

Q1Lockwasher, 1/4" internal star ZH1/4LWSIS

R—Not used —

S—Not used —

T3Split lock washer, #6 (preset models only) ZH6LWSSL

U8Washer, #10 split lock ZH10LWSSL

V—Not used —

W—Not used —

X8Screw 2-56 x 7/16" pan head ZH2-56X.437SPP

Y4Screw 4-40 x 3/8" pan head (non-preset models) ZH4-40X.375SPP

Z—Not used —

AA — Not used —

BB 4 Lockwasher #4 internal star ZH4LWSIS

CC 5 Screw 6-32 x 3/8" pan head ZH6-32X.375SPP

DD 3 Set screw 6-32 x 3/16" socket head knur black ZH6-32X.187S

EE 2 Screw 4-40 x 1/4" pan head ZH4-40X.250SPP

FF — Not used —

GG 5 Bolt 1/4-20 x 5/8" hex socket head ZH1/420X.625CS

HH 2 Set screw 3/8-24 x 3/8" hex socket knur black ZH3/8-24X.375S

II 7 Set screw 10-32 x 3/16" hex socket knur black (non-preset models) ZH10-32X.187S

JJ 6 Screw 6-32 x 1/4" pan head ZH6-32X.250SPP

KK 4 Bolt 1/4-20 x 1/2" hex head ZH1/4-20X.500CH

LL 24 Bolt 1/4-20 x 3/4" hex socket head ZH1/420X.750CS

MM 4 Bolt 1/4-20 x 3/4" hex head ZH1/420X.750CH

NN 2 Nut, Hex 4-40 ZH4-40NUTSH

OO — Not used —

PP 9 Nut, Hex 10-32 ZH10-32NUTSH

QQ 2 Screw 10-32 x 1/2" pan head ZH10-32X.500SPP

RR 8 Screw 10-32 x 2-1/4" pan head ZH10-32X2.25SPS

SS 1 Pin, taper #5 x 2" 105010017

TT 2 Pin, dowel 3/16" x 5/8" ZHPIN3/16X5/8

UU 8 Washer, nylon ZH131X361X62N

8 Screw 4-40 x 3/8" pan head (preset models) ZH4-40X.375SPP

9 Set screw 10-32 x 3/16" hex socket knur black (preset models) ZH10-32X.187S

Pelco Manual C373SM-A (8/01) 25

Page 26

35

31

7

*PT1280P ONLY

**PT1280SL ONLY

22

33

48

4

20

17

13

16

20

18

18

20

30

15

45

44

19

25

*

26

*

23

*

11

43

14

12

41

39

49

56

**

55

**

5

2

6

53

46

9

*

36

*

8

*

9

*

6

21

52

32

34

3

20

17

13

16

20

19

45

44

29

9

54

28

*

18

20

15

37

8

27

25

24

9

47

40

12

10

42

14

18

38

7

1

50

51

01151

Figure 10. PT1280P and PT1280SL Exploded Assembly (Mechanical Parts)

26 Pelco Manual C373SM-A (8/01)

Page 27

Table I. PT1280P and PT1280SL Mechanical Parts List

Item Qty Description Part Number

11Gasket, connector 105010010

21Nut, pan spindle black no.8 10504017COMP

31Thrust cap 10504076COMP

41Gear, tilt 10504084COMP

51Gear, pan 10504089COMP

62Bearing 6208-ZZ 10506009

72Bearing FB1416-6 10506010

82 (1) Mount grommet LOR00 125010000 (SL)

94 (2) Clip retainer 125010001 (SL)

10 1 Chain, assy pan 12501010COMP

11 1 Chain, assy tilt 12501011COMP

12 2 Key, Woodruff #3 alloy 105010015

13 2 Gear, worm pan 105012010

14 2 Pan shaft 10504078COMP

15 2 Thrust collar 10504085COMP

16 8 Bearing AO16, washer only 10506005

17 4 Bearing AO16C, cage only 10506006

18 4 Bearing B810-4 10506007

19 2 Bracket, gear train 12504079COMP

20 6 Shim arbor ZHSHIM.004

21 1 Base, spindle assy 12501041ACOMP

22 1 Tilt, shaft assy 12501043COMP

23 1 Pan limit bracket 12504100COMP

24 1 Tilt limit bracket 1554052COMP

25 4 (2) Switch SWI1SM1 (SL)

26 2 Switch actuator w/insulation SWIJS138B

27 2 Switch actuator, long w/insulation SWIJS221

28 1 Terminal strip, 9 position TRS2009

29 1 Heat sink 12504010ACOMP

30 2 Spacer rod 12504110COMP

31 1 Pull up bar 12504111COMP

32 1 Tilt table, top 12504116COMP

33 1 Table, side tilt 4H 12504117COMP

34 1 Table, side tilt 1H 12504118COMP

35 1 Cover 12504119BWA

36 1 Pin, limit pan 12504120ACOMP

37 1 Pin, limit tilt 12504121ACOMP

38 1 Plate, motor pan 12504123COMP

39 1 Plate, motor tilt 12504123TCOMP

40 1 Sprocket 25B18-5/16" W/SS 12504124COMP

41 1 Sprocket, motor tilt 12504125COMP

42 1 Sprocket, 25B13 1/2" bore w/set screw 12504126COMP

43 1 Sprocket, 25B18 1/2" bore w/set screw 12504127COMP

44 2 Motor 115V 12508110

45 2 Gear head 12508111

46 1 Bottom plate 12504112ACOMP

47 1 Tilt, side plate 12504115COMP

48 1 Pan, side plate 12804114COMP

49 2 Tilt, limit stop 1554050COMP

50 1 Conn CPC 16 pos pin recp CON206036-1

51 2 UL, gland, SL-9 EH400010003

52 7 FT Gasket poron 1/8 x 1/2, black EH550010030

53 1Term strip, 11 pin TRS2011

54 3 Limit, stop pan 58010006 (P ONLY)

55 1 Bracket, slip ring 12804002COMP (SL ONLY)

56 1 Ring, slip #AC4023-18A 28010000 (SL ONLY)

Pelco Manual C373SM-A (8/01) 27

Page 28

CC

Z

B

E

N

F

T

K

M

E

C

A

G

F

H

I

U

*

W

*

L

*

DD

BB

AA

Y

J

BB

X

**

U

**

W

**

N

U

G

Z

M

E

B

C

T

H

I

K

A

E

M

F

F

P

L

S

*PT1280 Only

**PT1280SL Only

*

U

P

*

T

*

U

S

R

V

D

Figure 11. PT1280P and PT1280SL Exploded Assembly (Hardware)

28 Pelco Manual C373SM-A (8/01)

01152

Page 29

Table J. PT1280P and PT1280SL Hardware List

Item Qty Description Part Number

A4Screw, 1/4-20 x .500 soc ZH1/420X.500CS

B5Bolt, 1/4-20 x 5/8" sock SS ZH1/420X.625CS

C4Bolt 1/4-20 x 3/4" hex SS ZH1/420X.750CH

D6Screw 1/4-20 x 1" flat phil SS ZH1/420X1.00SFS

E9Washer, split lock 1/4" SS ZH1/4LWSSL

F4Set screw 10-32 x 3/16" soc knur blk ZH10-32X.187S

G8Screw 10-32 x 2 1/4" phil pan SS ZH10-32X2.25SPS

H8Nut, hex 10-32 SS ZH10-32NUTSH

I8Washer, split lock #10 SS ZH10LWSSL

J2Washer, flat #8 SS ZH188X435X60C

K8Washer, flat #10 ZH204X436X60C

L8 (4) Screw 2-56 x 7/16" pan phil SS ZH2-56X.437SPP (SL ONLY)

M5Washer, flat 3/16" SS ZH260X562X65C

N2Set screw 3/8-24 x 3/8" soc knur blk ZH3/8-24X.375S

P4Screw 4-40 x 1/4" pan phil SS ZH4-40X.250SPP

R4Screw 4-40 x 3/8" pan phil SS ZH4-40X.375SPP

S6Washer lock #4 internal tooth SS ZH4LWSIS

T3Set screw 6-32 x 3/16" soc knur blk ZH6-32X.187S

U6 (4) Screw 6-32 x 3/8" pan phil SS ZH6-32X.375SPP (SL ONLY)

V4Screw 6-32 x 3/4" flat phil SS ZH6-32X.750SFS

W2 (2) Washer, split lock #6 ZH6LWSIS (SL ONLY)

X3Screw 8-32 x 3/8" pan phil SS ZH8-32X.375SPP

Y6Screw 8-32 x 1/2" soc SS ZH8-32X.500CS

Z5Screw 8-32 x 5/8" pan phil SS ZH8-32X.625SPP

AA 3 Nut, hex 8-32 SS ZH8-32NUTSH

BB 5 Washer, internal star #8 SS ZH8LWSIS

CC 1 Taper pin #5 x 2 1/2" ZHPIN#5X21/2

DD 1 Pin, dowel 3/16" x 5/8" ZHPIN3/16X5/8

Pelco Manual C373SM-A (8/01) 29

Page 30

35

31

22

33

48

65

66

67

7

30

4

57

59

20

18

20

15

45

44

* PT1280P/PP Only

** PT1280SL/PP Only

20

17

13

16

18

19

25

*

26

*

23

*

11

43

14

12

41

39

49

68

*

62

*

64

**

63

**

5

2

6

53

46

9

*

36

*

8

*

9

*

6

52

32

34

3

20

17

13

16

20

19

45

44

60

29

58

61

54

*

9

28

18

20

15

37

8

27

25

38

24

9

47

**

56

**

55

40

12

10

42

14

18

7

21

1

50

51

01153

Figure 12. PT1280P/PP and PT1280SL/PP Exploded Assembly Diagram (Mechanical Parts)

30 Pelco Manual C373SM-A (8/01)

Page 31

Table K. PT1280P/PP and PT1280SL/PP Mechanical Parts List

Item Qty Description Part Number

11Gasket, connector 105010010

21Nut, pan spindle, black no.8 10504017COMP

31Thrust cap 10504076COMP

41Gear, tilt 10504084COMP

51Gear, pan 10504089COMP

62Bearing 6208-ZZ 10506009

72Bearing FB1416-6 10506010

82 (1) Mount grommet Loroo 125010000 (SL/PP)

94 (2) Clip retainer 125010001 (SL/PP)

10 1 Chain assy, pan 12501010COMP

11 1 Chain assy, tilt 12501011COMP

12 2 Key, Woodruff #3 alloy 105010015

13 2 Gear, worm pan 105012010

14 2 pan shaft 10504078COMP

15 2 Thrust collar 10504085COMP

16 8 Bearing, AO16, washer only 10506005

17 4 Bearing, A016C, cage only 10506006

18 4 Bearing B810-4 10506007

19 2 Bracket, gear train 12504079COMP

20 6 Shim arbor ZHSHIM.004

21 1 Base spindle assy 12501041ACOMP

22 1 Tilt shaft assy 12501043COMP

23 1 Pan limit bracket 12504100COMP

24 1 Tilt limit bracket 1554052COMP

25 4 (2) Switch SWI1SM1 (SL/PP)

26 2 (0) Switch actuator, long w/insulation SWIJS221 (SL/PP)

27 2 Switch actuator w/insulation SWIJS138B

28 1 Terminal strip, 9 pin TRS2009

29 1 Heat sink 12504010ACOMP

30 2 Spacer rod 12504110COMP

31 1 Pull up bar 12504111COMP

32 1 Tilt table top 12504116COMP

33 1 Table, side tilt 4H 12504117COMP

34 1 Table, side tilt 1H 12504118COMP

35 1 Cover 12504119BWA

36 1 (0) Pin, limit pan 12504120ACOMP (SL/PP)

37 1 Pin, limit tilt 12504121ACOMP

38 1 Plate, motor pan 12504123COMP

39 1 Plate, motor tilt 12504123TCOMP

40 1 Sprocket 25B18-5/16" W/SS 12504124COMP

41 1 Sprocket, motor tilt 12504125COMP

42 1 Sprocket, 25B13, 1/2" bore w/set screw 12504126COMP

43 1 Sprocket, 25B18, 1/2" bore w/set screw 12504127COMP

44 2 Motor, 115V 12508110

45 2 Gear head 12508111

46 1 Bottom plate 12504112ACOMP

47 1 Tilt side plate 12504115COMP

48 1 Pan side plate 12804114COMP

49 2 Bottom plate 1554055COMP

50 1 Conn 28 pos pin recp CON205840-3 (SL/PP, P/PP)

51 2 UL, gland, SL-9 EH400010003

52 7 FT Gasket, Poron 1/8 x 1/2, blk EH550010030

53 1Term strip, 11 pin TRS2011

54 3 Limit stop, pan 58010006 (P/PP only)

55 1 Bracket, slip ring 12804003COMP (SL/PP only)

56 1 Slip ring, 24 circuit 250010000

57 1 Collar, tilt AZL gear 12504020COMP

58 1 Bracket, AZL pot 12504003COMP (P/PP only)

59 1 Gear, AZL collar, polycarb 12504104

Bracket, pot (pan) 12804004COMP (SL/PP only)

Pelco Manual C373SM-A (8/01) 31

Page 32

Table K. PT1280P/PP and PT1280SL/PP Mechanical Parts List (Continued)

Item Qty Description Part Number

60 1 Pot model 534 5K OHM POT005.0K10534 (P/PP only)

Pot, dual arm pre res POTDARM01.0K (SL/PP only)

61 1 Gear potentiometer TV12000 (P/PP only)

Gear 1.875 plastic PT250010002 (SL/PP only)

62 1 Collar, pan AZL gear 12504001COMP

63 1 Hub, PP pan gear 12804005COMP

64 1 Gear, pan spindle feedback SL PT25004122COMP

65 1 Gear, polycarb TV12000

66 1 Bracket, AZL potentiometer 12504003COMP

67 1 Pot, model 534 5K OHM POT005.0K10534

68 1 Gear, AZL collar, polycarb 12504104

Z

B

E

BB

AA

Y

CC

J

BB

P

W

N

U

F

F

S

P

F

H

I

T

C

G

* PT1280P/PP Only

** PT1280SL/PP Only

K

M

E

U

A

*

W

*

L

*

*

S

*

F

*

N

F

**

DD

U

W

U

*

*

U

T

*

U

S

R

Z

M

E

B

G

P

C

T

P

L

S

X

**

H

**

I

H

I

K

A

E

M

V

D

F

F

01154

Figure 13. PT1280P/PP and PT1280SL/PP Exploded Assembly (Hardware)

32 Pelco Manual C373SM-A (8/01)

Page 33

Table L. PT1280P/PP and PT1280SL/PP Hardware List

Item Qty Description Part Number

A4Screw 1/4-20 x .500 soc ZH1/420X.500CS

B5Bolt 1/4-20 x 5/8" soc SS ZH1/420X.625CS

C4Bolt 1/4-20 x 3/4" hex SS ZH1/420X.750CH

D6Screw 1/4-20 x 1" flat phil SS ZH1/420X1.00SFS

E9Washer split lock 1/4" SS ZH1/4LWSSL

F6Set screw 10-32 x 3/16" soc knur blk ZH10-32X.187S

G8Screw 10-32 x 2 1/4" phil pan SS ZH10-32X2.25SPS

H8 (10) Nut hex 10-32 SS ZH10-32NUTSH (SL/PP)

I8 (10) Washer split lock #10 SS ZH10LWSSL (SL/PP)

J2Washer, flat #8 SS ZH188X435X60C

K8Washer, flat #10 ZH204X436X60C

L8 (4) Screw 2-56 x 7/16" pan phil ZH2-56X.437SPP (SL/PP)

M5Washer flat 3/16" SS ZH260X562X65C

N2Set screw 3/8-24 x 3/8" soc knur black ZH3/8-24X.375S

P8Screw 4-40 x 1/4" pan phil SS ZH4-40X.250SPP

R4Screw 4-40 x 3/8" pan phil SS ZH4-40X.375SPP

S10Washer lock #4, internal tooth SS ZH4LWSIS

T3Set screw 6-32 x 3/16" soc knur black ZH6-32X.187S

U 10 (6) Screw 6-32 x 3/8" pan phil SS ZH6-32X.375SPP (SL/PP)

V4Screw 6-32 x 3/4" flat phil SS ZH6-32X.750SFS

W6 (2) Washer split lock #6 ZH6LWSIS

X3Screw 8-32 x 3/8" pan phil SS ZH8-32X.375SPP

Y6Screw 8-32 x 1/2" soc SS ZH8-32X.500CS

Z5Screw 8-32 x 5/8" pan phil SS ZH8-32X.625SPP

AA 3 Nut hex 8-32 SS ZH8-32NUTSH

BB 5 Washer internal star #8 SS ZH8LWSIS

CC 1 Taper pin #5 x 2 1/2" ZHPIN#5X21/2

DD 2 Pin dowel 3/16" x 5/8" ZHPIN3/16X5/8

Pelco Manual C373SM-A (8/01) 33

Page 34

WIRING DIAGRAMS

Table M. PT1250 Series Electrical Parts List

Parts are for all models unless specified otherwise

Symbol Description Part Number

C1, C2 Capacitor, 6 MFD, 250 VAC (except 220 model) CAPU0006.0/250N

C3 Capacitor, 1 MFD, 600 V (except 220 model) CAPU0001.0/600

M1, M2 Pan and tilt motors (except 220 model) 12508110

— Motor gearhead (except 220 model) 12508111

— Motor gearhead (220 model only) 12508114

R1, R2 Potentiometer, 5K ohm (PP, WT models only) POT005.0K10534

S1-S4 Switch SWI1SM1

S1-S4 Pan switch actuator SWIJS221

S1-S4 Tilt switch actuator SWIJS138B

— Cover heater blanket, 80 watts (HB model only) 10501000

— Base heater blanket, 75 watts each (HB model only) EH110065A

— Thermostat (HB model only) EH5510049A

— 7-pin female mating connector assy (RAD model only) MS3106E16S1S

— 9-pin female connector assy (P, 220, FG, FGP models only) 1751000COMP

— 16-pin female connector assy (PP, WT, HB models only) CONA16S

Capacitor, 1.5 MFD, 400 V (220 model only) 12508016

Not used (220 model only)

Pan and tilt motors (220 model only) 12508115

Figure 14. PT1250 Series Wiring for P, FG, FGP, HB and 220 Models

34 Pelco Manual C373SM-A (8/01)

Page 35

Figure 15. PT1250 Series Wiring for RAD Model

Figure 16. PT1250 Series Wiring for PP and WT Models

Pelco Manual C373SM-A (8/01) 35

Page 36

Figure 17. PT1250DC Wiring Diagram

Table N. PT1250DC Electrical Parts List

Quantity Symbol Description Manufacturer Part Number

8 C1-8 Capacitor .0047/1kv CDE CAPU0.0047/1000

4 C9-12 Capacitor .1/400V Sprague CAPU0000.1/400

4 L1-4 Choke 100mh Miller CHO5250

2 M1-2 Motor Pelco MR02-0002-3104

1P1 Connector AMP CON206705-1

9— Connector Pin AMP CON66103-2

4 R1-4 Resistor 47ohm 1/4W — RES047.0-.25

2— P.C. Assembly Pelco 1551016COMP

1—Mating Connector Assy. AMP 1751000COMP

4 S1-S4 Switch — SWI1SM1

36 Pelco Manual C373SM-A (8/01)

Page 37

Figure 18. PT1250DC/PP Wiring Diagram

Table O. PT1250DC/PP Electrical Parts List

Quantity Symbol Description Part Number

8 C1-8 Capacitor .0047/1kv CAPU0.0047/1000

4 C9-12 Capacitor .1/400V CAPU0000.1/400

4 L1-4 Choke 100mh CHO5250

2 M1-2 Motor MR02-0002-3104

1P1 Connector CON206036-1

4 R1-4 Resistor 47 ohm 1/4W RES047.0-.25

2 R5-6 Pot 5K Ten Turn POT005.0K10534

2— P.C. Assembly 1551016COMP

1— Mating Connector Assy. CONA16S

4 S1-S4 Switch SWI1SM1

16 — Connector Pin CON66103-2

Pelco Manual C373SM-A (8/01) 37

Page 38

Figure 19. PT1253R Schematic Diagram

38 Pelco Manual C373SM-A (8/01)

Page 39

01162

Figure 20. 12501007ACOMP Frame Scan Schematic

Pelco Manual C373SM-A (8/01) 39

Page 40

Table P. 12501007ACOMP Frame Scan Parts List

Schematic Quantity Component Description Part Number

C7 1 CAP 500PF 600V radial CAPP0500.0/500

C2 1 CAP .022MF 100V AZ CAPU00.022/100

C4A, C6A 2 CAP .01M 1000V radial disc CAPU000.01/1000

C3, C4 2 CAP .01MF 16V radial CAPU000.01/16

C1A, C7A 2 CAP .1M 400V axial CAPU0000.1/400

C5, C10 2 CAP .1M 50V rad CAPU0000.1/50

C6 1 CAP 1M 35V TNTDP CAPU0001.0/35TD

C1 1 CAP 1MF AX CAPU0001.0/400

C8 1 NP CAP 22M 15VAX CAPU0022.0/15T

C9 1 CAP 470M 35V RAD CAPU470.0/35

M4610 2 Choke, 6.2 microhenrys CHO4610

Input Connector 1 CONN MTA HDR LK 14-pos PC MT CON1-640388-4

CR4, CR5, CR6, CR7 4 NP diode 600V 1A 1N4005 DIO4005

CR3 1 Diode 10V 1W ZENNER 1N470A DIO4740

CR1, CR2 2 NP diode 1A UNITRODE 1N914 DIO914

4011 1 IC MC14011BCP ICO4011

4027 1 IC CD4027BCN ICO4027

4060 1 IC binary CT DIV OS HCF4060BE IOC4060

4093 1 IC GN NAND SCHMTRIG CD4093BE IOC4093

R17 1 POT 20K OHM POT20.0K0191BR

K1, K2 2 Relay 120 VAC SPST MP120D4 REL120A01MP

R5A, 10R4, 11R3 3 NP RES 4.7K OHM 1/4W RES004.7K.25

R9, R13A, R13B, R15A 4 NP RES 10 OHM 1/2W RES010.0-.5

R1 1 NP RES 10K OHM 1/4W RES010.0K.25

R2 1 NP RES 5.1K OHM 1/4W RES005.1K.25

R12 1 Resistor 22K OHM 1W RES022.0K1

R13 1 Resistor 22K OHM 2W RES022.0K2

R6, R7, R8 3 NP RES 47K OHM 1/4W RES047.0K.25

R5, R10, R14 3 NP RES 100K OHM 1/4W RES100.0K.25

R11, R15 2 Resistor 270K OHM 1/4W RES270.0K.25

40 Pelco Manual C373SM-A (8/01)

Page 41

Figure 21. PT1250EX/AMS Wiring Diagram

Table Q. PT1250EX/AMS Electrical Parts List

Symbol Description Part Number

C1, C2 Capacitor, 6 MFD, 250 VAC CAPU0006.0/250N

C3 Capacitor, 1 MFD, 600 V CAPU0001.0/600

M1, M2 Pan and tilt motors 12508110

— Motor gearhead 12508111

—Potentiometer, 5K ohm POT005.0K10534

S1-S4 Switch SWI1SM1

S1-S4 Switch actuator SWIJS138B

— Heater blanket, 40 watts each EHWD10087

T Thermostat EH5510049A

— Mating connector assembly CONMS3406D20-27

Pelco Manual C373SM-A (8/01) 41

Page 42

BRN

RED

BLUE

S1

C1 M1

S2

S3

ORG

YEL

C2 C3 M2

S4

GRN

Quantity Symbol Description Part Number

1 C1, C2 Capacitor, 6 MFD 250 VAC CAPU0006.0/250N

1C3Capacitor, 1 MF 600V CAPU0001.0/600

1M1Pan Motor 12508110

1M2Tilt Motor 12508110

2—Motor Gearhead 12508111

4 S1–S4 Switch SWI1SM1

Figure 22. PT1260EX Wiring Schematic

COMMON

BRN

S1

LEFT

RIGHT

RED

BLUE

C1 M1

S2

S3

UP

DOWN

ORG

YEL

C2 M2

S4

GROUND

Quantity Symbol Description Part Number

1 C1, C2 Capacitor, 1.5 MF 400V 12508116

1M1Pan Motor 12508115

1M2Tilt Motor 12508115

2—Motor Gearhead 12508114

4 S1–S4 Switch SWI1SM1

GRN

Figure 23. PT1260EX/220 Wiring Diagram

42 Pelco Manual C373SM-A (8/01)

Page 43

S1

PRESET COMMON

PAN PRESET

TILT PRESET

PRESET +5V

PT1260EX/PP

LEFT

RIGHT

UP

DOWN

COMMON

GROUND

RED

BLUE

W/BLK

W/GRN

W/VIO

W/BRN

ORG

YEL

BRN

GRN

S2

S3

S4

C1

C2 C3

RIGHT

LEFT

3

PAN

R1

5K

1

M1

M2

DOWN

UP

1

TILT

R2

5K

3

01164

Quantity Symbol Description Part Number

2 C1, C2 Capacitor, 6 MF 250V CAPU0006.0/250N

1C3Capacitor, 1 MF 600V CAPU0001.0/600

4 S1–S4 Switch SWI1SM1

1M1Pan Motor 12508110

1M2Tilt Motor 12508110

2—Gear Head 12508111

2 R1, R2 Pot POT005.0K10534

PT1260EX/PP/230

Quantity Symbol Description Part Number

1 C1, C2 Capacitor, 1.5 MF 400V 12508016

—C3Not Used —

1M1Pan Motor 12508115

1M2Tilt Motor 12508115

2—Motor Gearhead 12508114

4 S1–S4 Switch SWI1SM1

Figure 24. PT1260EX/PP and PT1260EX/PP/230 Wiring Schematic

Pelco Manual C373SM-A (8/01) 43

Page 44

CAMERA ENCLOSURE

T

MOUNTED HERE

OTHER CONTROL

SIGNAL FEED-THRU

FEED-THROUGHS

GO TO THE

CAMERA ENCLOSURE

BOTH OF THESE

COAX VIDEO

FEED-THRU

(THIS REPRESENTS ONLY A

PORTION OF THE WIRING

THAT ENTERED THE PAN/TIL

HOUSING VIA THE P1

CONNECTOR)

P1

CONNECTOR FROM

CONTROLLER

(ALL CONTROL AND POWER FUNCTIONS ENTER

THE PAN/TILT HOUSING THROUGH THIS CONNECTOR).

01165

Qty Sym Description Mfr Part Number

1 C1,C2 Capacitor 6MFD, 250VAC — CAPU0006.0/250N

1C3Capacitor, 1MF 600VAC CDE CAPU0001.0/600

1M1Pan Motor Pelco 12508110

1M2Tilt Motor Pelco 12508110

1P1Connector AMP CON206036-1

4 S1-S4 Switch Microswitch SWI1SM1

16 — Connector Pins AMP CON66103-2

Figure 25. PT1280P/PT128SL Wiring Diagram

44 Pelco Manual C373SM-A (8/01)

Page 45

CAMERA ENCLOSURE

T

MOUNTED HERE

OTHER CONTROL

SIGNAL FEED-THRU

FEED-THROUGHS

GO TO THE

CAMERA ENCLOSURE

BOTH OF THESE

COAX VIDEO

FEED-THRU

(THIS REPRESENTS ONLY A

PORTION OF THE WIRING

THAT ENTERED THE PAN/TIL

HOUSING VIA THE P1

CONNECTOR)

P1

CONNECTOR FROM

CONTROLLER

(ALL CONTROL AND POWER FUNCTIONS ENTER

THE PAN/TILT HOUSING THROUGH THIS CONNECTOR).

01166

Qty Sym Description Mfr Part Number

1 C1,C2 Capacitor 6MFD 250VAC — CAPU0006.0/250N

1C3 Capacitor 1MF 600VAC CDE CAPU0001.0/600

1M1 Pan Motor Pelco 12508110

1M2 Tilt Motor Pelco 12508110

1P1 Connector AMP CON206036-1

4 S1-S4 Switch Microswitch SWI1SM1

28 — Connector Pins AMP CON205840-3

Figure 26. PT1280P/HB Wiring Diagram

Pelco Manual C373SM-A (8/01) 45

Page 46

CAMERA ENCLOSURE

T

MOUNTED HERE

OTHER CONTROL

SIGNAL FEED-THRU

FEED-THROUGHS

GO TO THE

CAMERA ENCLOSURE

BOTH OF THESE

COAX VIDEO

FEED-THRU

(THIS REPRESENTS ONLY A

PORTION OF THE WIRING

THAT ENTERED THE PAN/TIL

HOUSING VIA THE P1

CONNECTOR)

P1

CONNECTOR FROM

CONTROLLER

(ALL CONTROL AND POWER FUNCTIONS ENTER

THE PAN/TILT HOUSING THROUGH THIS CONNECTOR).

01167

Qty Sym Description Mfr Part Number

1 C1, C2 Capacitor 6MFD 250VAC — CAPU0006.0/250N

1C3 Capacitor 1MF 600VAC CDE CAPU0001.0/600

1M1 Pan Motor Pelco 12508110

1M2 Tilt Motor Pelco 12508110

1P1 Connector AMP CON206036-1

4 1-S4 Switch Microswitch SWI1SM1

28 — Connector Pins AMP CON205840-3

Figure 27. PT1280P/PP Wiring Diagram

46 Pelco Manual C373SM-A (8/01)

Page 47

CAMERA ENCLOSURE

T

MOUNTED HERE

OTHER CONTROL

SIGNAL FEED-THRU

FEED-THROUGHS

GO TO THE

CAMERA ENCLOSURE

BOTH OF THESE

COAX VIDEO

FEED-THRU

(THIS REPRESENTS ONLY A

PORTION OF THE WIRING

THAT ENTERED THE PAN/TIL

HOUSING VIA THE P1

CONNECTOR)

P1

CONNECTOR FROM

CONTROLLER

(ALL CONTROL AND POWER FUNCTIONS ENTER

THE PAN/TILT HOUSING THROUGH THIS CONNECTOR).

01168

Qty Sym Description Mfr Part Number

1 C1, C2 Capacitor 6MFD 250VAC — CAPU0006.0/250N

1C3 Capacitor 1MF 600VAC CDE CAPU0001.0/600

1M1 Pan Motor Pelco 12508110

1M2 Tilt Motor Pelco 12508110

1P1 Connector AMP CON206036-1

4 1-S4 Switch Microswitch SWI1SM1

28 — Connector Pins AMP CON205840-3

Figure 28. PT1280Sl/PP Wiring Diagram

Pelco Manual C373SM-A (8/01) 47

Page 48

WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material

or workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

• Five years on FT/FR8000 Series fiber optic products.

• Three years on Genex® Series products (multiplexers, server, and keyboard).

• Three years on Camclosure® and fixed camera models, except the CC3701H-2,

CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2, and MC3651H-2X camera

models, which have a five-year warranty.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy®, CM6700/CM6800/CM9700 Series matrix, and DF5/DF8 Series

fixed dome products.

• Two years on Spectra®, Esprit®, ExSite™, and PS20 scanners, including when used in

continuous motion applications.

• Two years on Esprit® and WW5700 Series window wiper (excluding wiper blades).

• Eighteen months on DX Series digital video recorders, NVR300 Series network video

recorders, and Endura™ Series distributed network-based video products.months on DX

Series digital video recorders, NVR300 Series network video recorders, Endura™ Series

distributed network-based video products, and TW3000 Series twisted pair transmission

products.

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion

applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco

shipment. All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis,

California. Repairs made necessary by reason of misuse, alteration, normal wear, or

accident are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting

from the specific use or application made of the Products. Pelco’s liability for any claim,

whether based on breach of contract, negligence, infringement of any rights of any party

or product liability, relating to the Products shall not exceed the price paid by the Dealer to

Pelco for such Products. In no event will Pelco be liable for any special, incidental or

consequential damages (including loss of use, loss of profit and claims of third parties)

however caused, whether by the negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also

have additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800)289-9100 or

(559) 292-1981 to obtain a Repair Authorization number (RA), and provide the following

information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the

warranty conditions stated above, please include a written explanation with the product

when returned.

Method of return shipment shall be the same or equal to the method by which the item

was received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory

at (800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if

returned for credit, and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing

charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA

number and freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico, send goods

to:

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico and are

instructed to return goods to the USA, you may do one of the following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

If the goods are to be sent by a FREIGHT FORWARDER, send the goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

REVISION HISTORY

Manual # Date Comments

C373SM 1/99 Original version.

C373SM-A 8/01 Revised description of PT1260EX Series and changed part numbers for the pan shaft bearings and the tilt shaft in the parts list.

Reference ECO #01-7128.

® Pelco, the Pelco logo, Spectra, Esprit, Genex, Legacy, and Camclosure are registered trademarks of Pelco.

™ Endura and ExSite are trademarks of Pelco. © Copyright 2001, Pelco. All rights reserved.

48 Pelco Manual C373SM-A (8/01)

Loading...

Loading...