Page 1

C360SM (10/99)

PS30A and PS30-24

Scanners

®

300 W. Pontiac Way,

Clovis, CA 93612-5699

USA

In North America & Canada:

Tel (800) 289-9100

FAX (800) 289-9150

DataFAX (800) 289-9108

International Customers:

Tel +1 (559) 292-1981

FAX +1 (559) 348-1120

DataFAX +1 (559) 292-0435

Pelco Online

http://www.pelco.com

This maintenance/service manual consists of an exploded assembly diagram and parts lists. Use

this manual when ordering replacement parts for PS30A/PS30-24 Scanners.

MAINTENANCE

Under normal operating conditions and usage, maintenance of this equipment is not necessary.

The PS30A and PS30-24 Scanners require no lubrication, and the motors are both clutch and

impedance protected from overload. The outside of the scanner can be cleaned by wiping with a

dry cloth or spraying with clean air pressure. Do not use spray cleaners or water.

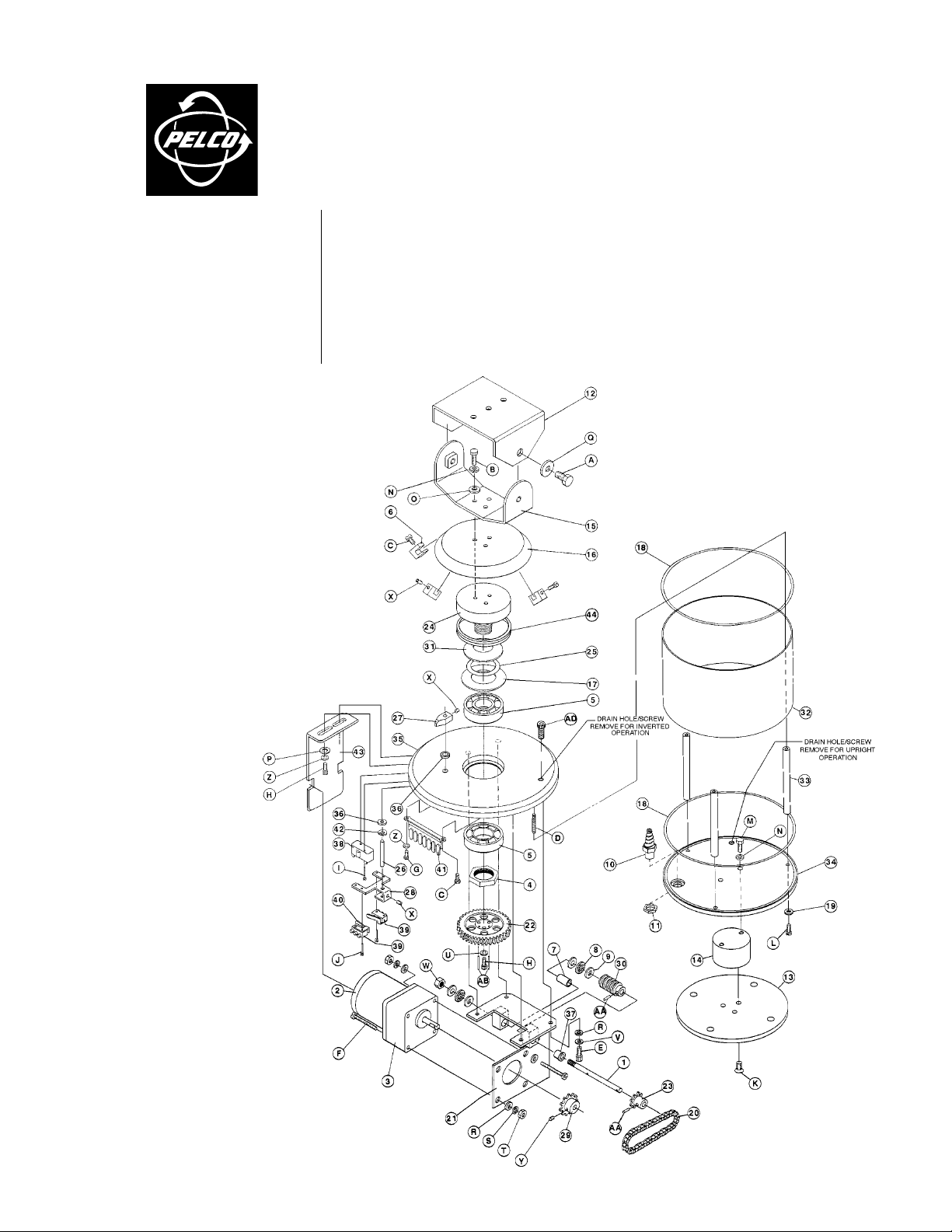

EXPLODED ASSEMBLY DIAGRAM

Figure 1. PS30A/PS30-24

Exploded Assembly Diagram

Page 2

Table A. Mechanical Parts List

Item Qty Description Part Number

1 1 Gear train shaft 1754064COMP

2 1 Motor, 24 VAC (PS30-24) 5708008

Motor, 120 VAC (PS30A) 1758008

3 1 Motor gear head 1758009

4 1 Spindle nut 2504012COMP

5 2 Pan spindle bearing 2506000

6 3 Limit stop 5801006

7 1 Bearing 5806005

8 2 Bearing cage 776001

9 4 Bearing washer 776002

10 1 Gland EH300010003

11 1 Nut for EH300010003 gland EH300010004

12 1 Top bracket EM224168COMP

13 1 Flange PM102A4196COMP

14 1 Mounting block PS204153COMP

15 1 Lower tilt bracket PS204160COMP

16 1 Dust cover PS204162COMP

17 1 Drag disk PS3010000

18 2 O-ring PS3010001

19 5 Thread sealing washer PS3010002

20 1 Drive chain PS301005COMP

21 1 Motor plate weld assembly PS301007WA

22 1 Worm gear PS304001COMP

23 1 Gear shaft sprocket PS304005COMP

24 1 Spindle PS304006COMP

25 1 Spindle spacer PS304008COMP

26 1 Limit switch shaft PS304009COMP

27 1 Limit arm PS304010COMP

28 1 Limit switch bracket PS304011COMP

29 1 Motor shaft sprocket PS304012COMP

30 1 Worm PS304013COMP

31 1 Spring washer PS304015COMP

32 1 Cover PS304102COMP

33 3 Spacer PS304103COMP

34 1 Bottom plate PS304104COMP

35 1 Top plate PS304110COMP

36 2 Friction disk limit PS710001

37 1 Bushing, 1/4-inch PT250010005

38 1 Switch SWI11-314

39 2 Switch SWI1SM1

40 2 Switch actuator with insulator SWIJS138B

41 1 Terminal strip, 7-pin TRS2007

42 1 Spring washer TV10000

43 1 Heat sink (PS30-24 only) PS304016COMP

44 1 Spindle seal PS3010003

Page 3

T able B. Hardware Parts List

Item Qty Description Part Number

A 2 Bolt, 3/8-16 x .625-inch ZH3/816X.625CH

B 3 Bolt, 1/4-20 x .625-inch ZH1/420X.625CH

C 3 Screw, 6-32 x .375-inch, pan head, Phillips ZH6-32X.375SPP

D 3 Set screw, 10-32 x .75-inch ZH10-32X.750S

E 4 Allen screw, 10-32 x .5-inch ZH10-32X.500CS

F 4 Screw, 8-32 x 2.25-inch, pan head ZH8-32X2.25CRS

G 1 Screw, 6-32 x .25-inch, pan head, Phillips ZH6-32X.250SPP

H 5 Allen screw, 6-32 x .375-inch ZH6-32X.375CS

I 2 Screw, 2-56 x .75-inch, pan head, Phillips ZH2-56X.750SPS

J 4 Screw, 2-56 x .437-inch, pan head, Phillips ZH2-56X.437SPP

K 3 Screw, 1/4-20 x .75-inch, flat head ZH1/4-20X.750CFS

L 3 Screw, 10-32 x .75-inch, pan head, Phillips ZH10-32X.750SPP

M 2 Allen bolt, 1/4-20 x .625-inch ZH1/420X.625CH

N 5 Split lock washer, .25-inch ZH1/4LWSSL

O 3 Flat washer, .1875-inch ZH260X562X65C

P 2 Flat washer, #8 ZH188X435X60C

Q 2 Flat washer, .375-inch ZH377X880X78

R 8 Flat washer, #10 ZH204X436X60C

S 4 Split lock washer, #8 ZH8LWSSL

T 4 Nut, 8-32 ZH8-32NUTSH

U 3 Split lock washer, #6, ZH6LWSSL

V 4 Split lock washer, #10 ZH10LWSSL

W 1 Nylon lock nut, 1/4-28 58010007

X 3 Set screw, 6-32 x .1875-inch ZH6-32X.187S

Y 1 Set screw, 10-32 x .1875-inch ZH10-32X.187S

Z 3 Internal tooth lock washer, #6 ZH6LWSIS

AA 2 Roll pin, .09375-inch x .5-inch ZHPIN3/32X1/2R

AB 2 Dowel pin .125-inch x .5-inch 15510003

AC 1 Connector mating assembly, 9-pin (not shown) 1751000COMP

AD 2 Allen screw, 10-32 x .375-inch ZH10-32X.375CS

WIRING DIAGRAMS AND SCHEMATICS

REMOTE CONTROL OPERATION

QTY SYMBOL DESCRIPTION PART NUMBER

1 C1 CAPACITOR, CAPU0001.8/250

1.8 µF/250V

2 C2-C4 CAPACITOR, CAPU000.05/500

.05 µF/500V

1 M1 MOTOR 1758008

1 R1 RESISTOR, RES012.0-8

12 OHM/8 W

CONTINUOUS-DUTY OPERATION

2 S1-S2 SWITCH SWI1SM1

1 S3 SWITCH SWI11-314

Figure 2. PS30A Schematic and Wiring Diagrams

Page 4

REMOTE CONTROL OPERATION

CONTINUOUS-DUTY OPERATION

Figure 3. PS30-24 Schematic and Wiring Diagrams

QTY SYMBOL DESCRIPTION PART NUMBER

2 C1-C2 CAPACITOR, CAPU0015.0/100N

15 µF/100V

2 C3-C4 CAPACITOR, CAPU000.05/500

.05 µF/500V

1 M1 MOTOR 5708008

1 R1 RESISTOR, RES010.0-.5

10 OHM, 1/2 W

2 S1-S2 SWITCH SWI1SM1

1 S3 SWITCH SWI11-314

WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or workmanship for a period of one year after the date of

shipment. Exceptions to this warranty are as noted below:

• Three years on Genex™ Series (multiplexers, server, and keyboard).

• Two years on all standard motorized and fixed focal length lenses.

• Two years on Esprit™, Legacy®, Intercept®, PV1000 Series, CM6700/

CM8500/CM9500/CM9750/CM9760 Matrix, Spectra®, DF5 Series and DF8

Fixed Dome products.

• Two years on WW5700 series window wiper (excluding wiper blades).

• Two years on cameras.

• Six months on all pan and tilts, scanners or preset lenses used in continuous

motion applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 da ys from the date

of Pelco shipment. All goods requiring warranty repair shall be sent freight

prepaid to Pelco, Clovis, California. Repairs made necessary by reason of

misuse, alteration, normal wear, or accident are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss

resulting from the specific use or application made of the Products. Pelco’s

liability for any claim, whether based on breach of contract, negligence, infringement of any rights of any party or product liability, relating to the Products shall not exceed the price paid by the Dealer to Pelco f or such Products .

In no event will Pelco be liable for any special, incidental or consequential

damages (including loss of use, loss of profit and claims of third parties) however caused, whether by the negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer

may also have additional rights, which are subject to variation from state to state.

REVISION HISTORY

Manual # Date Comments

C360SM 10/99 Original version.

If a warranty repair is required, the Dealer must contact Pelco at (800) 2899100 or (559) 292-1981 to obtain a Repair Authorization number (RA), and

provide the following information:

1. Model and serial number

2. Date of shipment, P .O. number , Sales Order n umber , or P elco inv oice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall

under the warranty conditions stated above, please include a written explanation with the product when returned.

Ship freight prepaid to: Pelco

Method of return shipment shall be the same or equal to the method by which

the item was received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please

call the factory at (800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned for credit, and RA number if returned for

repair). Goods returned for repair or credit should be clearly identified with

the assigned CA/RA number and freight should be prepaid. All merchandise

returned for credit may be subject to a 20% restocking and refurbishing charge.

Ship freight prepaid to: Pelco

300 West Pontiac Way

Clovis, CA 93612-5699

300 West Pontiac Way

Clovis, CA 93612-5699

®Pelco and the Pelco logo are registered trademarks of Pelco. © Copyright 1999, Pelco. All rights reserved.

Loading...

Loading...