®

MPT9000CZ/

MPT9000PZ

Transmitter/

Control

(Coaxitron

®

System 2000)

Installation/

Operation Manual

C550M-E (8/97)

Pelco • 3500 Pelco Way, Clovis, CA 93612-5699 • USA • www.pelco.com

In North America and Canada: Tel (800) 289-9100 • FAX (800) 289-9150

International Customers: Tel (1-559) 292-1981 or FAX (1-559) 348-1120

TABLE OF CONTENTS

Section Page

1.0 WARNING ..........................................................................................................................................1

2.0 SCOPE ...............................................................................................................................................2

3.0 DESCRIPTION ...................................................................................................................................2

4.0 INSTALLATION ..................................................................................................................................2

4.1 RECEIVER POWER INPUT MODIFICATIONS ....................................................................... 2

4.1.1 24 VAC Input Conversion ............................................................................................ 2

4.2 CONNECTOR ASSEMBLY ......................................................................................................5

4.3 SYSTEM CONFIGURATIONS ................................................................................................. 7

5.0 OPERATIONS ..................................................................................................................................10

5.1 FUNCTIONAL CIRCUIT DESCRIPTION................................................................................ 10

5.2 TRANSMITTER ......................................................................................................................11

5.2.1 Controls .....................................................................................................................11

5.3 RECEIVER ............................................................................................................................. 11

5.4 RECEIVER/TRANSMITTER INPUTS AND OUTPUTS ..........................................................11

5.5 COAXITRON PREPOSITION RECEIVER ............................................................................. 12

5.5.1 Power-Up Routine .....................................................................................................13

5.5.2 Creating Presets ........................................................................................................13

5.6 AUXILIARY FUNCTIONS .......................................................................................................17

5.7 AUTO/RANDOM OPERATION............................................................................................... 21

5.8 CX900TLC MANUAL/TEST MODULE ................................................................................... 21

6.0 TROUBLESHOOTING GUIDELINES ..............................................................................................23

7.0 MAINTENANCE ............................................................................................................................... 23

8.0 MODEL NUMBERS ..........................................................................................................................24

8.1 OPTIONAL ACCESSORIES ..................................................................................................25

8.2 RECOMMENDED CABLES.................................................................................................... 25

9.0 SPECIFICATIONS ...........................................................................................................................25

10.0 WARRANTY AND RETURN INFORMATION ..................................................................................28

Pelco, the Pelco Logo, Camclosure, Coaxitron, Esprit, Genex, Legacy, and Spectra are registered trademarks of Pelco. © Copyright 1997, Pelco. All rights reserved.

Endura and ExSite are trademarks of Pelco.

ii Pelco Manual C550M-E (8/97)

LIST OF ILLUSTRATIONS

Figure Page

1 Coaxitron System 2000 Receiver ................................................................................................... 3

2 24 VAC Input Wiring Schematic ..................................................................................................... 3

3 AC Input and Fuse Values ............................................................................................................. 4

4 Connector Assembly ......................................................................................................................5

5 Receiver Control Output/Input Pin Assignments ............................................................................ 6

6 Basic Coaxitron System 2000 ........................................................................................................7

7 Coaxitron System 2000 with Manual Video Switcher and Multiple Cameras ................................. 7

8 Coaxitron System 2000 with Multiple Transmitters ........................................................................ 8

9 Coaxitron System 2000 with Multiple Transmitters and Receivers ................................................ 9

10 Coaxitron System 2000 Basic Interconnect Diagram ..................................................................... 9

11 Wiring Diagram for preposition Alarm Outputs ............................................................................. 13

12 SB1900, SS2000, SB2500 and SB2600 Series Preset Wiring Diagram ...................................... 14

13 PT280, PT520, PT550, PT570, PT680, PT1250,PT1280 and SB2800 Series Preset Wiring

Diagram ........................................................................................................................................ 15

14 Lens Preset Wiring Diagram ........................................................................................................ 16

15 Jumper Settings, Receiver/Driver Mother Board .......................................................................... 17

16 External Device Wiring Diagram .................................................................................................. 18

17 Auxiliary Functions Wiring Diagram ............................................................................................. 19

18 AI700/AI701 Wiring Diagram ........................................................................................................ 20

19 Coaxitron Receiver Assembly Layout (Top View) ........................................................................ 21

20 A9000 Wiring Schematic .............................................................................................................. 22

21 CX900TLC Test Module and Wiring Schematic ........................................................................... 23

Pelco Manual C550M-E (8/97) iii

REVISION HISTORY

Manual # Date Comments

C550M — Original version.

C550M 8/89 Rev. A. Manual revised to new format.

C550M 9/90 Rev. B. Manual revised to include 230 VAC, 12 V and

preset (PP) models. Sections 2.1-2.3, 4.1.1, 4.2 and 5.5-

5.6 revised.

C550M 5/91 Rev. C. New figure added for connector assembly (Fig.

2); Figure 16 revised.

C550M 6/92 Rev. D. Revised to 2-column format. Section 4.1.1 and

Figures 10-12 revised.

ADDENDUM to Rev. D created 6/93 for CX9024RX field

modification procedures. Pages 4, 18 and 19 revised;

pages 4-1 and 19-1 added. (Addendum was incorporated in reprint of manual as pages 4, 5, 5-1, 5-2, 18, 19,

19-1 and 19-2.)

C550M-E 11/94 Rev. E. Completely revised. Updated for PCB1500529

REV J and PCB1500529 REV K production models.

Incorporates update for fuse values per ECO 94-376.

8/96 Revised fusing values for fuse #F1, Figure 3.

10/96 Revised Figure 2, 24 VAC Input Wiring Schematic, per

ECO #96-278.

8/97 Revised fusing values for fuse #F2, Figure 3 per ECO#

96-362.

iv Pelco Manual C550M-E (8/97)

INSTALLATION/OPERATION MANUAL

COAXITRON SYSTEM 2000

1.0 WARNINGS

Prior to installation and use of this product, the following

WARNINGS should be observed.

1. Installation and servicing should only be done by

Qualified Service Personnel and conform to all

Local codes.

2. Unless the unit is specifically marked as a NEMA

Type 3-6P enclosure, it is designed for Indoor use

only and it must not be installed where exposed to

rain and moisture.

3. The product bears the following marks:

This symbol indicates that dangerous voltage

constituting a risk of electric shock is present

within this unit.

CAUTION:

TO REDUCE THE RISK OF ELECTRICAL

SHOCK, DO NOT REMOVE COVER. NO

USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

4. Only use replacement parts recommended by Pelco.

5. After replacement/repair of this unit’s electrical

components, conduct a resistance measurement

between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

This symbol indicates that there are important

operating and maintenance instructions in the

literature accompanying this unit.

CAUTION:

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

Please thoroughly familiarize yourself with the information in this manual

prior to installation and operation.

Pelco Manual C550M-E (8/97) 1

NOTE: This manual applies to those Coaxitron

systems using either PCB1500529 REV J or

PCB1500529 REV K boards. PCB board drawings were done from the REV J board perspective;

however, differences between the two boards that

affect function or operation are clearly pointed out.

2.0 SCOPE

Coaxitron System 2000 is an improved version of the

original Coaxitron. Improvements include the following features:

1. When used with an AI700 Auto Iris Servo, three

latching functions rather than two are available: (a)

auto scan, (b) camera power and (c) auto/manual

iris.

The information contained within this manual covers

the installation and operation of the Coaxitron System

2000 (transmitter control and receiver).

Installation should be in accordance with all applicable

local and national electric codes, utilizing approved

materials only.

Please thoroughly familiarize yourself with the information in this manual prior to installation and operation.

3.0 DESCRIPTION

The Coaxitron System 2000 control system provides up

to 16 remote control functions without the need for

control cables other than for a dedicated video cable for

the normal transmission of a remote camera signal to the

local monitoring and control position. The Coaxitron

Control System lends itself to application in situations

where short-to-medium distances are involved and where

equalization of cable losses is not required.

Typically, these functions are:

1. Pan Left 9. Iris Open

2. Pan Right 10. Iris Close

3. Tilt Up 11. Camera Power On/Off

4. Tilt Down 12. Auto/Manual Scan

5. Zoom In 13. AUX 1 (Manual Iris)

6. Zoom Out 14. AUX 2 (Auto Iris)

7. Focus Near 15. AUX 3

8. Focus Far 16. AUX 4

Functions 1 through 10, 15 and 16 are momentary; that

is , they are only actuated while the associated control

switch located on the Coaxitron transmitter or front

panel is operated. Functions 11, 12, 13 and 14 are

latching; that is, camera power, auto scan, and auto/

manual iris are latching functions and remain on until

turned off. The latching iris function is not dedicated,

and with proper interfacing, it can be used for some

other latching function. Alternately, AUX 1, 2, 3 and 4

may be used as momentary functions to control such

things as lights or gates with proper external interfacing.

Up to ten functions can be operated simultaneously.

Functions 11 through 16 must be used individually;

although any one of these functions may be used simultaneously with functions 1 through 10.

2. When used with a CX900TLC Local Test Board

Plug-in Module, manual control of functions from

the receiver location plus the ability to check for the

valid reception of a given command from the

transmitter.

3. Pan/tilt, zoom lens and camera power control are

included on the main (video and logic) receiver

board, which eliminates malfunctions due to

miswiring or broken wires.

Coaxitron System 2000 provides the following standard functions on a single circuit board and chassis with

integral power supply:

1. Pan/Tilt (24 VAC or 120 VAC as ordered from the

factory)

2. Zoom Lens — Zoom, iris, and focus with adjustable speed (speed not remote controllable)

3. Camera power (24 VAC or 120 VAC as ordered

from the factory)

4. An open collector transistor output (latching) intended for use in manual override of an automatic

iris control.

4.0 INSTALLATION

Coaxitron System 2000 installation includes the connection of all coaxial cable to the proper connectors,

depending on your system configuration. Various connector assembly pin-out geometries are shown in Figure

4. Connector location and pin assignments are illus-

trated in Figure 5.

For optional auxiliary functions, consult the factory to

make the proper connections between the receiver, pan/

tilt and camera/enclosure.

4.1 RECEIVER POWER INPUT

MODIFICATIONS

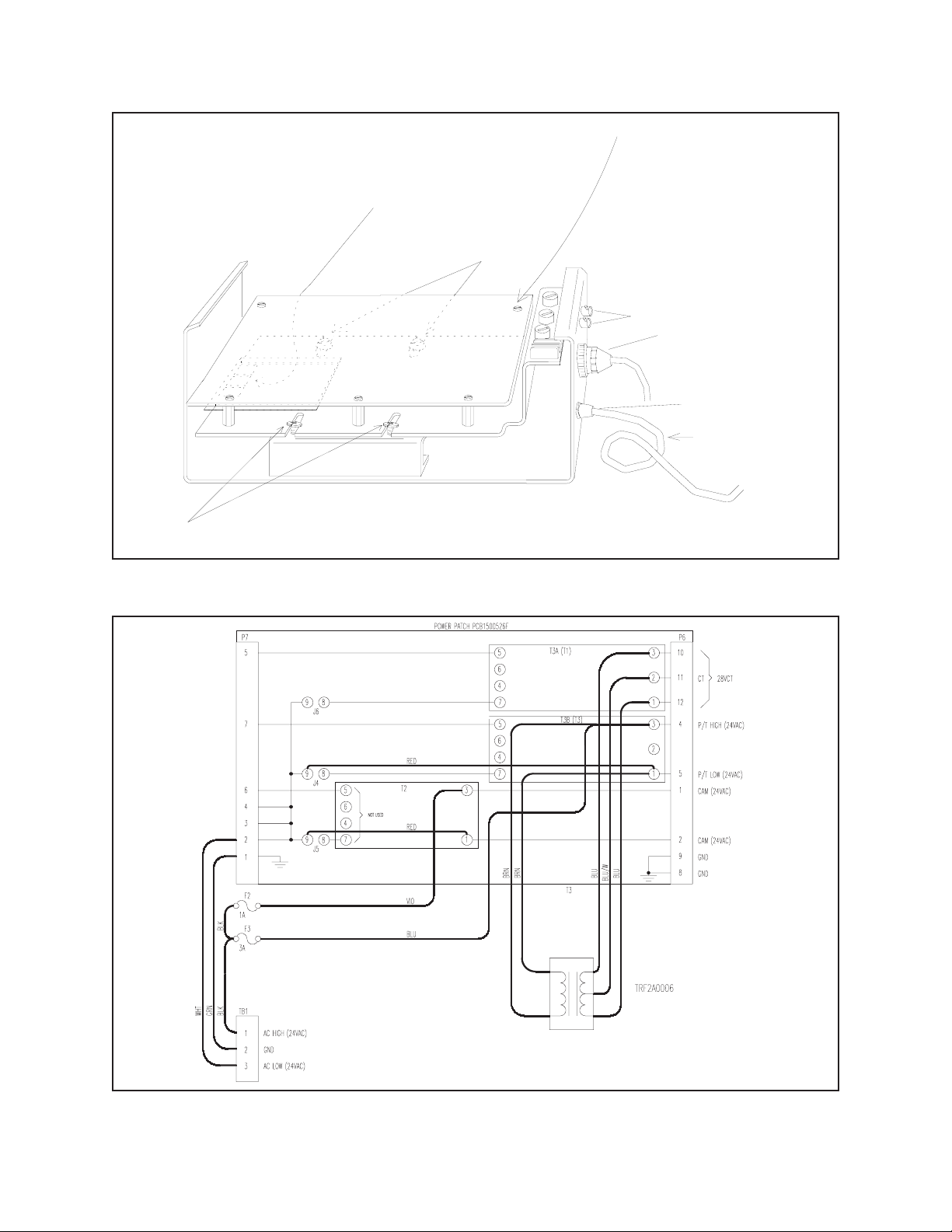

4.1.1 24 VAC Input Conversion

The CX9024RX series receivers can be converted to

operate with a 24 VAC input. If desired (see Figure 2).

Please contact factory for more information. For AC

input and fuse values, refered to Figure 3.

2 Pelco Manual C550M-E (8/97)

T1

T2

T3

Remove or loosen the four patch panel mounting

screws indicated below to gain access to patch

panels T1, T2, and T3.

SCREWS

PC BOARD

Remove PC board mounting screws

and remove the PC board.

If necessary, tag and remove

any affected cables attached to

the PC board.

BNC

CONNECTORS

37-PIN

AMP CONNECTOR

POWER INPUT

REMOVE POWER

CORD

SCREWS

COAXITRON SYSTEM 2000

RECEIVER

Figure 1. Coaxitron System 2000 Receiver

COAXITRON II POWER PATCH

(24 VAC INPUT/24 VAC OUT)

Figure 2. 24 VAC Input Wiring Schematic

Pelco Manual C550M-E (8/97) 3

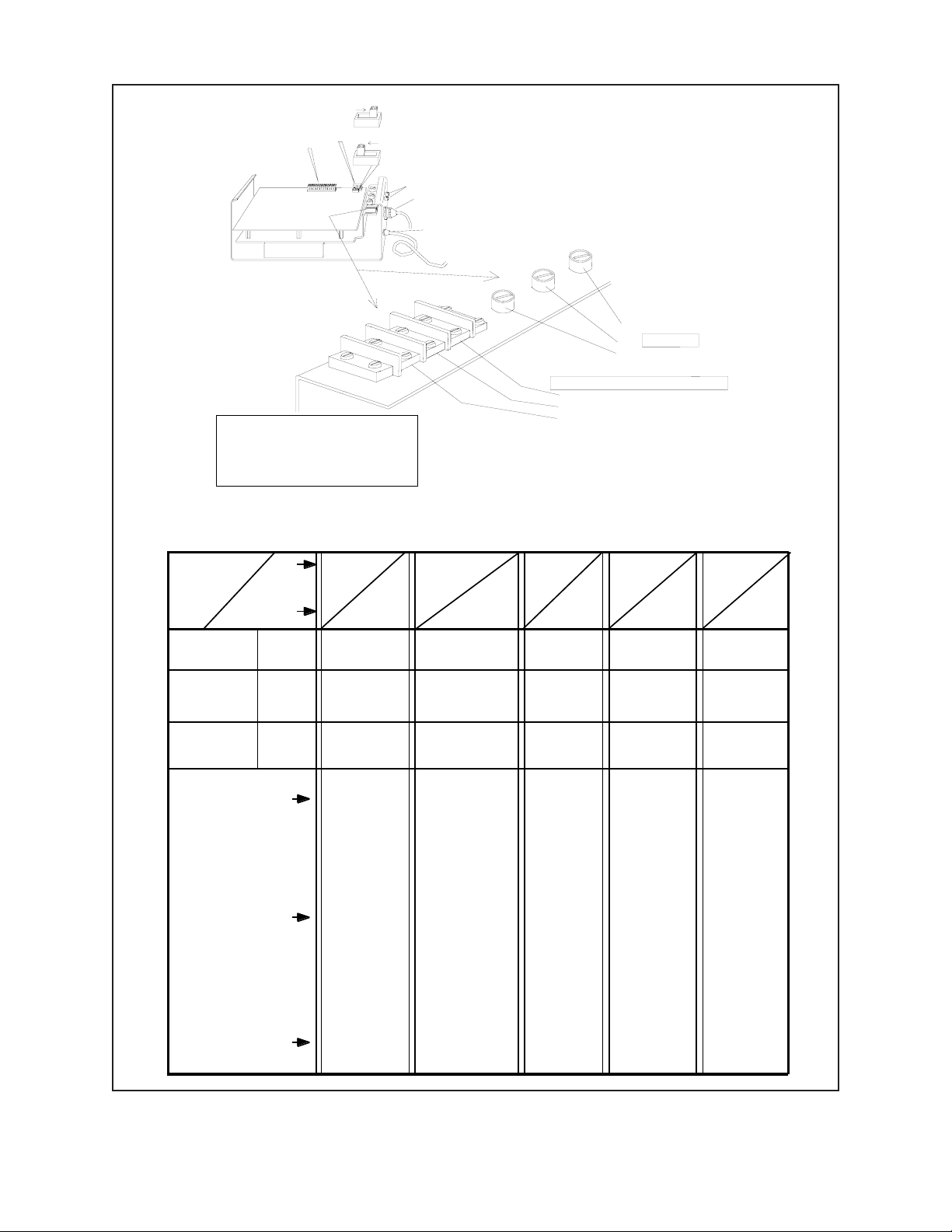

SW 1

P2

P1

PC BOARD

**

For REV K boards, the SW1

switch positions shown above

are just reversed; i.e., "Short"

is "Long" and "Long" is "Short".

SW 1

shown in the

"Long" position

shown in the

"Short" position

BNC

CONNECTORS

37-PIN

AMP CONNECTOR

POWER INPUT

**

**

TRANSMITTER: F1 2/10 ASB, 3AG

RECEIVER FUSE VALUES: SHOWN BELOW

F1

FUSES

F2

F3

AC INPUT DESIGNATIONS

1. AC HIGH

2. GROUND

3. AC LOW

NOTE:

For this manual, ignore references to “WX” type models in the table below.

These are “Wiretron” equipment models.

POWER OUTPUT

INPUT P/T

VAC VAC

P/T

CAMERA

PC BOARD

F3

F2

F1

Additional

combinations

of equipment options

are possible

depending

on customer need &

availability.

This listing

covers the

most used

and/or the

most available

type units &

A P P L I C A B L E M O D E L S

their options.

120VAC

IN

24VAC

P/T OUT

1ASB

2/10ASB

*1/2ASB

NOT

USED

CX9024RX

CX9024RXI

*12VDC Camera

options use a

1/2ASB fuse

value in this

position in place

of the 2/10’s

value.

*CX9024RXI-12V

*CX9024RX-12V

CX9024RX-PP

CX9024RXI-PP

WX8024RX

WX8024RXI

230VAC

IN

24VAC

P/T OUT

1/2ASB

1/10ASB

*1/4ASB

NOT

USED

CX9024RX/220

CX9024RXI/220

CX9024RXI-PP/22

CX90224RX-PP220

*CX9024RX-12V220

CX9024RXI-12V220

*12VDC camera

option uses a

1/4ASB fuse

value in place of

the 1/10’s value.

WX8024RX/220

WX8024RXI/220

230VAC

IN

230VAC

P/T OUT

1/2ASB

1/10ASB

1/10ASB

CX9220RX

CX9220RX-PP

CX9220RXI

CX9220RXI-PP

WX8220RX

24VAC

IN

24VAC

P/T OUT

3A

1A

NOT

USED

CX9224RX

CX9224RX-PP

CX9224RXI

CX9224RXI-PP

*CX9224RXI-12V

WX8224RX

WX8224RXI

*The CX9224

option w/ 12VDC

camera uses 1

(one) fuse in the

F3 position. It is

a 3A fuse, not a

3ASB fuse. Fuse

positions F1 and

F2 are not used.

120VAC

IN

120VAC

P/T OUT

1ASB

2/10ASB

2/10ASB

CX9115RX

CX9115RX-PP

CX9115RXI

CX9115RXI-PP

WX8115RX

Figure 3. AC Input and Fuse Values

4 Pelco Manual C550M-E (8/97)

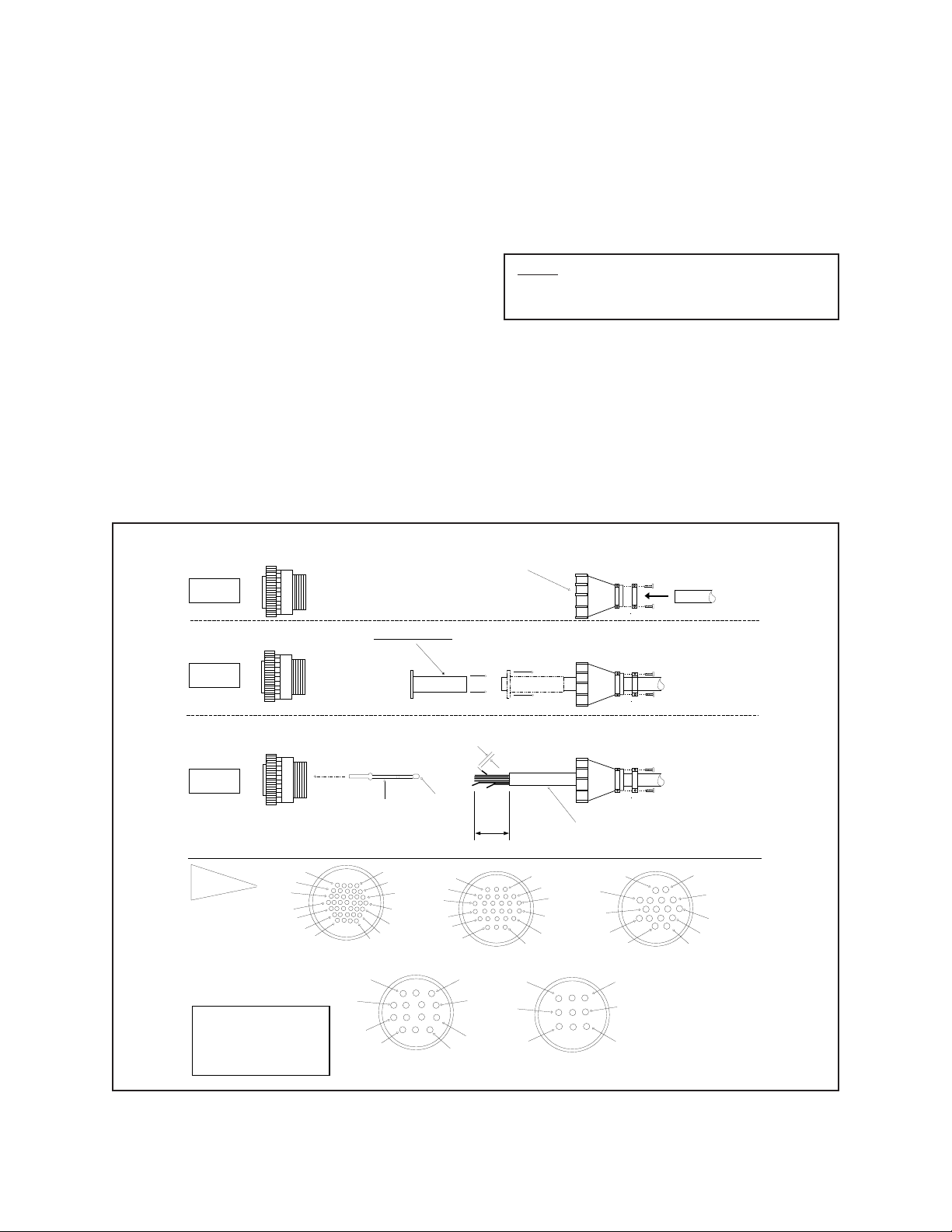

4.2 CONNECTOR ASSEMBLY

Installation and/or testing will require you to assemble

the connector parts provided. Fabricate the interconnecting cable according to the following steps (reference Figure 4).

1. Slide part A of the cable clamp (item 1) over

the end of the cable (item 1, part C) with the

threaded end of the cable clamp facing the connector (item 5).

4. The contact pins supplied with the mating connector are the “crimp” type which may also

be soldered if you so desired (item 4).

5. After crimping or soldering the contact pins

to the conductors, push them into the proper

holes in the connector until they snap in place.

Note: Contacts cannot be removed from the connector without the use of the appropriate AMP extraction tool which is available from PELCO.

2. If the cable has a diameter less than 1/2 inch

(1.3 cm), slide the rubber boot (item 2) over

the end of the cable and pull through the cable

clamp to so that the boot encases the cable and

forms a good seal.

3. Strip back the cable jacket approximately 11/4 inches (3.2 cm) and separate the individual

conductors (item 3).

5

STEP 1

FLEXIBLE RUBBER BOOT

4

CRIMP

WIRE

1

29

34

3

7

11

14

14-PIN CONNECTOR

5

10

16

23

FRONT VIEW

CRIMP

INSULATION

14

20

STEP 2

STEPS 3-7

**

ITEM 5 DETAIL

THE MOST COMMONLY USED

CONNECTOR PIN-OUT CONFIGURATIONS ARE SHOWN HERE.

REFERENCE THE CONNECTOR

DRAWING APPLICABLE TO

YOUR SITUATION.

5 1

5 **

4

9

15

22

28

33

37

FRONT VIEW

37-PIN CONNECTOR

2

3

8

25

28

12

threaded end of

cable clamp

STRIP 1/8"

STRIP 1"

FRONT VIEW

28-PIN CONNECTOR

1

4

8

6. Slide part A of the cable clamp toward the connector and screw the parts together. Attach part

B (item 1) onto part A and connect both parts

with the screws provided.

7. Connect the cable assembly to the unit and

seat the connector by twisting the locking collar until it snaps into position (see Figure 5

and Figure 10).

1

A B C

A B

C

3

3

6

OUTSIDE

JACKET

OF CABLE

1

4

9

15

21

26

FRONT VIEW

9-PIN CONNECTOR

6

10

14

1

A B

2

16

FRONT VIEW

16-PIN CONNECTOR

1

4

79

C

1

3

7

11

15

Figure 4. Connector Assembly

Pelco Manual C550M-E (8/97) 5

shown in the

"Short" position

37-PIN

AMP CONNECTOR

POWER INPUT

PC BOARD

SW 1P2

P1

BNC

CONNECTORS

COAXITRON SYSTEM 2000

RECEIVER

RECEIVER CONTROL

INPUT PIN

ASSIGNMENTS

(P1 & P2 ARE

LOCATED ON

P1

THE COAXITRON

RECEIVER CARD)

3 BRN P/T COM 1

5 ORG LEFT 3

8 4

7 GRN DOWN 5

6 BLU UP 6

4 VIO RIGHT 7

9 GRAY GROUND 8

*

RECEIVER CONTROL

OUTPUT PIN

ASSIGNMENTS

(GOING TO THE

37-PIN AMP

CONNECTOR)

12 BLACK IRIS 10 1

11 W/BRN FOCUS 11 3 LENS

10 W/RED ZOOM 12 2 INPUT

14 W/ORG LENS COM 13 4

13 RED MAN IRIS 2 5

1 WHITE CAM AC HIGH 9 CAMERA

2 W/YEL CAM AC LOW 14 INPUT POWER

P2

10 BRN/W +21V 28

9 RED/W CAM ON 29

8 ORG/W AUX 1 30 AUXILIARY

7 YEL/W CAM OFF 31 WIRING

6 GRN/W AUX 4 32 PROVIDED IN

5 BLU/W AUX 3 33 OUTDOOR

4 VIO/W AUX 2 34 MODELS ONLY

3 GRY/W LOGIC RESET 35

2 W/GRY GROUND 36

1 BLK/W +10V 37

For REV K boards, the SW1 switch position is the reverse of that shown

*

above; i.e., "short" is "long" and "long" is "short". See page 8 for further details.

Figure 5. Receiver Control Output/Input Pin Assignments

NOTE: CONSULT

FACTORY BEFORE

ATTEMPTING TO USE

AUX FUNCTIONS.

EXTERNAL REQUIREMENTS ARE NEEDED.

6 Pelco Manual C550M-E (8/97)

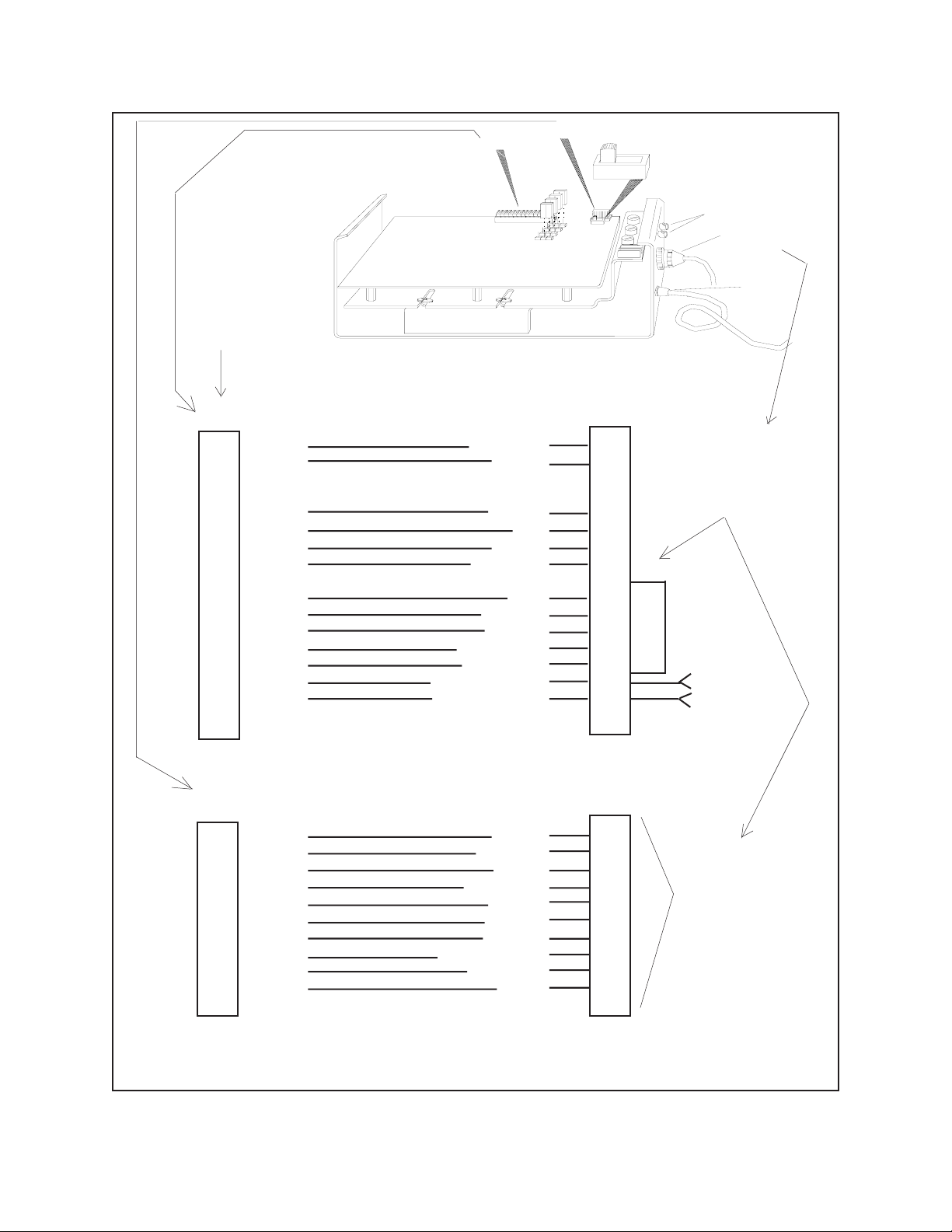

4.3 SYSTEM CONFIGURATIONS

Figure 6 shows the simplest system configuration utilizing the Coaxitron System 2000. This system consists of

the control transmitter, coax cable and receiver/camera.

This basic Coaxitron system is flexible in that it can be

expanded to control multiple camera sites when a hard

contact switching device is added.

COAXITRON

TRANSMITTER

COAXITRON

TERMINATE MONITOR

Figure 7 shows the addition of a manual video switcher

and one receiver/camera. In this example, the active

coaxial cable is terminated in the transmitter and the

inactive cables are terminated in the switcher. The

selected camera signal is fed to the Coaxitron transmitter, which then feeds the monitor. When a camera

selection is made, that video line is dedicated to the

transmitter that allows the associated Coaxitron receiver to be controlled. Functions such as auto/random

are latching and will remain on until turned off by the

transmitter.

VIDEO

COAXITRON

RECEIVER

SIGNAL

MULTI-CONDUCTOR

CABLE

TERMINATE MONITOR

Figure 6. Basic Coaxitron System 2000

COAXITRON

TRANSMITTER

COAXITRON

MANUAL

SWITCHER

COAXITRON

RECEIVER

COAXITRON

RECEIVER

VIDEO

SIGNAL

MULTI-CONDUCTOR

CABLE

VIDEO

SIGNAL

MULTI-CONDUCTOR

CABLE

Figure 7. Coaxitron System 2000 with Manual Video Switcher and Multiple Cameras

Pelco Manual C550M-E (8/97) 7

A more complex system is shown in Figure 8. Here,

several control locations can serve a single camera

system.

Note: All transmitters, except the last one, must

be looping (unterminated) rather than terminating.

This monitor may also be used for sequential switching.

As in the previous configuration, any one transmitter

can assume control. If two or more control units are

activated simultaneously, erroneous responses are prevented by error detection circuitry in the associated

receiver.

In a system of this type, any one of the transmitters can

assume control because there is no priority provision. If

two or more transmitters are activated simultaneously,

error detection circuitry in the receiver will cause multiple commands to be ignored.

Figure 9 shows an even more complex system. In this

example, multiple transmitters are controlling multiple

receivers.

Note: All but the last transmitter and associated

switcher must be looping (unterminated). Transmitters and associated switchers should be physically adjacent to insure against signal deterioration

due to cable mismatch.

Video cables from the receivers are looped through the

first control station to the second. At the first control

station, a bridging-looping type sequential switcher

(except VA500 series) is used. The Monitor 2 output is

a hard contact switch, otherwise known as the bridged

output for continuous viewing or control selection.

The switchers depicted in Figure 10 are hard contact

devices and do not have isolation or bridging amplifiers.

In each case, the Coaxitron transmitter acts as the

isolation or bridging amplifier. Do not use VA500

series switchers with Coaxitron systems.

Note: For configurations where RG59 cable

length between the transmitter and receiver exceeds 750 feet, it is necessary to reset switch SW1

on the receiver board (PCB1500529) from SHORT

to LONG. The switch should be left in the SHORT

position when using shorter lengths of RG59 cable

or when using RG11 cable (see Figure 5). For

RG11 cable, the upper limit is 1800 ft. In any case,

these operating distances can be extended by using

the EA2000. See the table on page 26.

Coaxitron System 2000 basic interconnections between

the transmitter and receiver are shown in Figure 10. If

you have chosen a configuration that includes a switching device, refer to the manual provided with the switcher

for the appropriate connections.

TERMINATE MONITOR

VIDEO

SIGNAL

MULTI-CONDUCTOR

CABLE

TERMINATE MONITOR

TERMINATE MONITOR

COAXITRON

TRANSMITTER

UNTERMINATED

TRANSMITTER

COAXITRON

TRANSMITTER

UNTERMINATED

TRANSMITTER

COAXITRON

TRANSMITTER

COAXITRON

RECEIVER

Figure 8. Coaxitron System 2000 with Multiple Transmitters

8 Pelco Manual C550M-E (8/97)

COAXITRON

TRANSMITTER

COAXITRON

TRANSMITTER

COAXITRON

LOOPING

SWITCHER

TERMINATING

SWITCHER

COAXITRON

RECEIVER

COAXITRON

RECEIVER

VIDEO

SIGNAL

MULTI-CONDUCTOR

CABLE

VIDEO

SIGNAL

MULTI-CONDUCTOR

CABLE

Figure 9. Coaxitron System 2000 with Multiple Transmitters and Receivers

RECEIVER VIDEO CABLE

RECEIVER

INPUT FROM CAMERA

RECEIVER

VIDEO CABLE

OUTPUT TO

TRANSMITTER

RECEIVER

CONTROL OUTPUT

TO PAN AND TILT/

LENS

24/120/230 VAC

(AMP SERIES CPC

OUTPUT CONNECTOR)

VIDEO CABLE

TRANSMITTER

AC INPUT

120 VAC

230 VAC

F1

.2 ASB

LOOPING

OUTPUT

J8 J7 J6

VIDEO

INPUT FROM

RECEIVER

OUTPUT TO

MONITOR

TO ADDITIONAL

CONTROL TRANSMITTERS

OR TERMINATE

Figure 10. Coaxitron System 2000 Basic Interconnect Diagram

Pelco Manual C550M-E (8/97) 9

5.0 OPERATION

In general, all operating controls on the transmitter are

self explanatory. With the exception of the ON/OFF

power switch and the 8-position joystick, all controls

are center-off, spring return paddle switches (momentary on-off-on).

5.1 FUNCTIONAL CIRCUIT DESCRIPTION

The basic functional concept of the Coaxitron system is

that 15 control pulses are fed in a reverse direction from

the control transmitter to the receiver located near each

camera station. These control pulses do not interfere

with the video monitor presentation because they occur

during the vertical blanking interval of the video signal.

The equipment is designed to operate with video cable

lengths up to 750 feet of RG59B/U (or equivalent), or up

to 1,800 feet of RG11. The SW1 switch prominently

located on the receiver board (PCB1500529), should be

moved to the LONG position when RG59B/U cable of

greater than 750 feet is used (see Figure 3).

Cable impedance matching is insured by the video

amplifier in the control receiver. Proper receiving

and termination impedance is likewise insured by the

terminating resistor in the control transmitter.

Any equipment placed between the remote and local

locations must be of the “loop-through” or “bridging”

type; power splitter or line amplifiers cannot be tolerated.

Response time of the system is normally less than 30

ms. Error detection circuitry is incorporated to immunize the system from externally generated noise. Under

extremely adverse environmental noise conditions response time may increase, and in the limit, control

functions can fail. Under such extreme conditions,

however, provision is made to inhibit all momentary

functions.

The proper function of the Coaxitron system depends

on the compatibility of two signals simultaneously

traveling in opposite directions in the same coaxial

cable. If the control signal is made large, compared to

the video signal, there is the risk that associated equipment will be adversely affected. If the control signal is

made small, compared to the video signal, it becomes

difficult to separate it from the video signal (and any

incumbent noise or hum). Therefore, the Coaxitron

system is designed to function with video and control

signals nominally equal.

Under such circumstances, reliable performance can be

predicted with cable lengths of 1,500 feet or more.

Beyond this distance, the control signal amplitude can

become attenuated sufficiently to make performance

marginal. Marginal performance is also approached if

the video signal is allowed to become excessive — the

dynamic range of the receiver video amplifier is one

limitation. Sending end distortion produced by the

coaxial cable is typically the major contributor to the

malfunctioning of a Coaxitron system. The amplitude

of distortion products is proportional to video signal

amplitude and is a non-linear function of cable length.

The influence of these distortion products upon system

performance is difficult to predict if signal amplitude is

allowed to exceed specifications.

Normally, auto-target or auto-iris functions will maintain a video level well within reasonable limits and

insure reliable performance. Often, however, automatic

or manual level settings may be made abnormally high

(perhaps to compensate for long cable losses or to

produce a picture with more contrast). An excessively

high video level setting can cause the Coaxitron control

system to fail completely — with all control functions

disabled. In order to prevent system failures due to

excessively high video levels, it is recommended that

cameras be powered by the receiver.

The Coaxitron System 2000 is designed to combat

prolonged loss of control due to the conditions described above by providing the following protective

functions:

1. Simultaneous commands from two different

sources are processed to insure that manual iris

control cannot be inadvertently selected in

place of automatic control.

2. A sustained (20 to 40 second) illegal command

condition results in (a) camera off,

(b) automatic iris, or (c) manual pan.

These functions greatly reduce the possibility of loss of

control and usually eliminate the need for service.

10 Pelco Manual C550M-E (8/97)

As an example, assume that the operator switches to

manual iris control and proceeds to open the iris excessively. The result can be a complete loss of control.

Within 20 to 40 seconds, camera power is automatically

removed (assuming this feature exists) and auto iris is

reinstated. Thus, distortion products are eliminated if

the camera power function is incorporated in the system

or reduced to a tolerable level if only the AUTO/

MANUAL iris function is incorporated.

5.2 TRANSMITTER

The transmitter is housed in a 1-3/4" high enclosure,

supplied as a desk top unit (rack mount available). Three

video connectors (J6, J7, J8) are located on the rear rail

(see Figure 10). J8 allows the user to loop the camera

signal from one transmitter to another, or to terminate

the signal by installing the appropriate resistor. Connector J7 accepts the camera signal from the receiver, and

J6 provides an output for monitoring equipment.

5.2.1 Controls

Power ON/OFF Rocker switch

Pan/Tilt 8-position joystick

Zoom Paddle switch Tele/Wide

Focus Paddle switch Near/Far

Iris Paddle switch Open/Close

Aux 1,2 Paddle switch Auto/Manual

Iris (latching function)

Camera Power Paddle switch On/Off (latching

function)

Pan Auto/Man Paddle switch Manual/Auto

(latching function)*

surface for entry of AC power line (120/230/24 VAC).

(See Figure 10.)

The INPUT video connector accepts the signal from the

camera and provides a 75 ohm termination.

The OUTPUT video connector is connected to the

transmitter input connector (J7) via a dedicated and

continuous coaxial cable. Proper termination of this

cable is vital to the operation of the equipment. Although loop-through connections in this cable are permissible, power splitter or line amplifiers cannot be

tolerated.

5.4 RECEIVER/TRANSMITTER

INPUTS AND OUTPUTS

The Receiver/Transmitter inputs and outputs are described as follows:

• Receiver Video Input

Normally, this is the video signal from the camera serviced by the receiver. The receiver provides a 75 ohm cable termination and an isolation

amplifier to prevent the control pulse train from

being fed to the camera. (See Figure 10.)

• Receiver Video Output

This output is fed to the transmitter video input

(J7) via 75 ohm coaxial cable. Active elements

or “splitters” in this cable run cannot be tolerated. (See Figure 9.)

• Receiver Power Input

All Coaxitron receivers may be powered by 24/

120/230 VAC as ordered from the factory.

The AC power input for 24 VAC operation must

be changed as described in Section 4.1.

Aux 3, 4 Paddle switch (momentary

functions)*

*External requirements are needed for operation

5.3 RECEIVER

The receiver and control function assemblies are contained in a “J-Box” housing. One end of the J-Box has

two video connectors (input and output) and CPC-type

control cable connector. Provision is made on this same

Pelco Manual C550M-E (8/97) 11

• Receiver Control Output

All control signals from the receiver are available from an AMP Series CPC output connector,

except for optional auxiliary functions. (See

Figure 10.)

• Receiver Control Output for 12 VDC Camera

Option

The usual output for camera power is 24 VAC

accessed at pins 9 and 14 of the 37-pin AMP

connector (see Fig. 5) where CAM AC HIGH

and AC LOW emerge as CAMERA INPUT

POWER. The output pin assignments remain the

same for 12 VDC camera power options, only

now pin 9 (WH) is positive (+) and pin 14 (WH/

YEL) is negative (-).

• Transmitter Video Input

The transmitter usually provides for the 75 ohm

termination of the cable from the receiver. However, the user may alter this termination in order

to loop through and terminate further downstream. (See Figure 10.)

WARNING: Power for enclosure models utilizing heater/blowers cannot be tapped off the secondary of the Coaxitron receiver transformer or off

of camera AC power (see Figure 5, Pins 9 and 14).

Instead,for example, enclosure power for these

purposes could be run off of the primary of the

Coaxitron transformer and routed to the enclosure

via unused Pins 15 and 16 of the 37-Pin connector.

Although the Coaxitron control system is immune to

transient or surge disturbances, its performance can be

impaired by the presence of large ground loop voltages

between the transmitter and the receiver. The amplitude

of ground loop potential that can be tolerated varies as

a complex function of cable center conductor resistance, video signal amplitude, and cable length. However, ground loop voltages that induce less than 0.5 volt

p-p into the video output of the receiver should not cause

the system to malfunction.

Factors that limit the distance over which the Coaxitron

can be used are transmission line attenuation and transmission line signal distortion

When signal attenuation becomes large due to excessive cable length, the differential amplifier in the

Coaxitron receiver can no longer detect the presence of

a control pulse train. The limitation can be overcome by

increasing the amplitude of the pulses generated by the

transmitter. This is not done without danger, however,

because associated equipment may be over-driven by

the larger signal. (Note that the presence of the control

signal is not restricted to the cable between the transmitter and receiver, but will be on all signal cables downstream from the receiver.)

It has been stipulated that loop-through connections are

permissible in the control link, and distribution or

equalizing amplifiers are not because of their

undirectional characteristics.

Pre-equalization of the camera signal prior to feeding to

the Coaxitron receiver is generally not practical because

of the dynamic limits in the receiver video amplifier.

Post equalization of the signal (transmitter output signal) is permissible, but probably not practical. It should

be kept in mind that although the camera signal has been

deteriorated by the transmission line, the control signal

has not. Therefore, the equalized control pulses will be

extremely large and probably cause an overload in some

part of the system downstream from the equalizing

amplifier.

In the absence of an assertive control command, the

transmitter is inactive. Thus, it is possible to control one

receiver from more than one control.

5.5 COAXITRON PREPOSITION

RECEIVER

In general, ground loop problems will seldom be encountered. However, potentials as high as 10 volts p-p

between ground connections within a single building

are not unheard of. If such circumstances arise, Pelco

recommends the use of its Model GIT100 Ground

Isolation Transformer. When inserted in the cable run

between two points of different ground potential, the

effect of this potential difference on the video signal is

reduced by more than 100 times with 200 feet, and more

than 20 times with 1,500 feet of RG59 type cable. More

than one GIT100 can be utilized in situations where the

common mode voltage (CMV) exceeds 10 volts p-p.

This transformer is passive and can easily be inserted

where required at any time.

12 Pelco Manual C550M-E (8/97)

Note: The Coaxitron preposition receiver is

designed for use with Coaxitron Matrix controls

only.

The Coaxitron System utilizes linear taper precision

potentiometers as the position feedback sensors. This

feedback voltage is digitized and stored in the receiver.

The storage of the presets is held in EEPROM and is

therefore nonvolatile.

Up to 32 presets can be stored in each receiver. Up to 8

T

presets can be activated by alarm contacts connected to

the receiver. There is also an open collector output from

the receiver to activate an external device (such as the

CSA764) when the alarm contacts are activated. Figure

11 shows the wiring for alarmed presets.

The pan/tilt will “nod yes” if the receiver reads the

feedback voltages (preposition lens) or “nod no” if it

does not read any feedback voltages (manual lens).

This routine is a good troubleshooting indicator of

incorrect wiring of the control cable.

If multiple alarms are activated, the receiver will sequence between the alarm presets at a 5 second dwell

time per preset.

Figures 12 through 14 provide pin-to-pin connections

for preset domes, pan/tilts and lenses to the Coaxitron

receiver that are available at this revision manual.

5.5.1 Power-up Routine

When a preposition receiver is first powered up, it has

a routine that it goes through to orient itself to the pan/

tilt and lens connected to it.

The routine first automatically operates the lens “zoom”

and “focus” functions.

NOTE: ALARM OUTPUT MUST RETURN TO

THE CSA764 FOR THE ALARM CONDITION

TO BE SWITCHED TO THE MONITOR 1

OUTPUT OF THE MATRIX

OAXITRON RECEIVER

37 PIN CONNECTOR

17

ALARM INPUT 1

18

ALARM INPUT 2

19

ALARM INPUT 3

20

ALARM INPUT 4

21

ALARM INPUT 5

22

ALARM INPUT 6

23

ALARM INPUT 7

24

ALARM INPUT 8

25

ALARM OUTPUT

26

ALARM COMMON

ALARM CONTACTS NORMALLY OPEN

The second part of the routine will operate the “pan left”

and “pan right” functions. The pan/tilt will “nod yes” if

it reads only one feedback voltage (pan/tilt with limit

stops) or “nod no” if it reads two feedback voltages (SL

pan/tilt).

The total routine takes approximate 45 seconds to

complete.

5.5.2 Creating Presets

At the present time the only Coaxitron system transmitters capable of creating presets are the CM7500, the

CM9500 Matrix and the MPT9500. Refer to the instructions in the product manuals (C584M, dated 2/90 or

later for CM7500 matrix, or C500M for CM9500 matrix

or C535M for the MPT9500) to create presets, if necessary.

ALARM CONDITION

OPEN COLLECTOR OUTPUT

BACK TO CSA764 ALARM INPU

ALARM COMMON

BACK TO CSA764

Figure 11. Wiring Diagram for Preposition Alarm Outputs

Pelco Manual C550M-E (8/97) 13

Function

SB1900-PP, SB1900SL-PP,

SS2000-PP and SS2000SL-PP

28-pin

Connector

Function

SB2500-PP, SB2500SL-PP,

SB2600-PP and SB2600SL-PP

37-pin

Connector

Function

Preset Unit Only

Coaxitron Receiver

1 Pan/Tilt Common 1 Pan/Tilt Common 1 Pan/Tilt Common

2 Manual Iris 2 Not Used 2 Video Core

3 Pan Left 3 Pan Left 3 Pan Left

4 Video Shield 4 Video Shield 4 Video Shield

5 Tilt Down 5 Tilt Down 5 Tilt Down

6 Tilt Up 6 Tilt Up 6 Tilt Up

7 Pan Right 7 Pan Right 7 Pan Right

8 Ground 8 Ground 8 Ground

9 Camera AC (High) 9 Camera AC (High) 9 Camera AC (High)

11 Focus 11 Focus 11 Focus

10 Iris 10 Iris 10 Iris

12 Zoom 12 Zoom 12 Zoom

13 Lens Common 13 Lens Common 13 Lens Common

14 Camera AC (Low) 14 Camera AC (Low) 14 Camera AC (Low)

15 Not Used 15 Not Used 15 Not Used

16 Not Used 16 Not Used 16 Not Used

17 Alarm Input 1 17 Not Used 17 Preset +5V

18 Alarm Input 2 18 Not Used 18 Preset Ground

19 Alarm Input 3 19 Not Used 19 Cam Sync-C

20 Alarm Input 4 20 Not Used 20 Preset Zoom

21 Alarm Input 5 21 Not Used 21 Preset Focus

22 Alarm Input 6 22 Not Used 22 Preset Pan

23 Alarm Input 7 23 Not Used 23 Preset Tilt

24 Alarm Input 8 24 Not Used 24 Preset Pan (SL models only)

25 Alarm Output 25 Not Used 25 Not Used

26 Ground 26 Not Used 26 Not Used

27 Video Core 27 Video Core 27 Not Used

28 Preset Ground 28 Preset Ground 28 Not Used

29 Preset +5 V 29 Preset + 5V

30 Not Used 30 Cam Sync - C

31 Not Used 31 Not Used

32 Not Used 32 Not Used

33 Pan B Preset 33 Preset Pan

34 Preset Focus 34 Preset Focus

35 Preset Zoom 35 Preset Zoom

37-pin

Connector

14 Pelco Manual C550M-E (8/97)

36 Preset Tilt 36 Preset Tilt

Figure 12. SB1900, SS2000, SB2500 and SB2600 Series Preset Wiring Diagram

37 Pan A Preset (360) 37 Preset Pan (SL models only)

Function

28-pin

Series Domes/ PT1280P/PP and PT1280SL/PP

Connector

Preposition Pan/Tilts PT280, PT680 Series and SB2800

Function

Preposition Pan/Tilts

PT520, PT550, PT570 and PT1250 Series

37-pin

Connector

Function

Preset Unit Only

Coaxitron Receiver

1 Pan/Tilt Common 1 Pan/Tilt Common 1 Pan/Tilt Common

2 Manual Iris 2 Preset Pan 2 Video Core

3 Pan Left 3 Pan Left 3 Pan Left

4 Video Shield 4 Video Shield 4 Video Shield

5 Tilt Down 5 Tilt Down 5 Tilt Down

6 Tilt Up 6 Tilt Up 6 Tilt Up

7 Pan Right 7 Pan Right 7 Pan Right

8 Ground 8 Ground 8 Ground

9 Camera AC (High) 9 Preset Tilt 9 Camera AC (High)

11 Focus 11 Preset +5 V 11 Focus

10 Iris 10 Preset Ground 10 Iris

12 Zoom 12 Not Used 12 Zoom

13 Lens Common 13 Not Used 13 Lens Common

14 Camera AC (Low) 14 Not Used 14 Camera AC (Low)

15 Not Used 15 Not Used 15 Not Used

16 Not Used 16 Not Used 16 Not Used

17 Alarm Input 1 17 Preset Ground

18 Alarm Input 2 18 Preset + 5 V

19 Alarm Input 3 19 Preset Pan

20 Alarm Input 4 20 Preset Tilt

21 Alarm Input 5 21 Not Used

22 Alarm Input 6 22 Not Used

23 Alarm Input 7 23 Preset Zoom

24 Alarm Input 8 24 Preset Focus

25 Alarm Output 25 Preset Pan (SL models only)

26 Ground 26 Not Used

27 Video Core 27 Not Used

28 Preset Ground 28 Not Used

29 Preset +5 V

30 Not Used

31 Not Used

32 Not Used

33 Pan B Preset

34 Preset Focus

35 Preset Zoom

37-pin

Connector

Pelco Manual C550M-E (8/97) 15

36 Preset Tilt

Figure 13. PT280, PT520, PT550, PT570, PT680, PT1250, PT1280 and SB2800 Series Preset Wiring Diagram

37 Pan A Preset (360)

Coaxitron Receiver

Preset Unit Only

37-pin 9-pin

Connector Function Connector Function

1 Pan/Tilt Common 1 Iris

2 Manual Iris 2 Zoom

3 Pan Left 3 Focus

4 Video Shield 4 Lens Common

5 Tilt Down 5 Ground

6 Tilt Up 6 Preset +5V

7 Pan Right 7 Preset Zoom

8 Ground 8 Preset Ground

9 Camera AC (High) 9 Preset Focus

10 Iris

11 Focus

12 Zoom

13 Lens Common

14 Camera AC (Low)

15 Not Used

16 Not Used

17 Alarm Input 1

18 Alarm Input 2

19 Alarm Input 3

20 Alarm Input 4

21 Alarm Input 5

22 Alarm Input 6

23 Alarm Input 7

24 Alarm Input 8

25 Alarm Output

26 Ground

27 Video Core

28 Preset Ground

29 Preset +5 V

30 Not used

31 Not used

32 Not used

33 Pan B Preset

34 Preset Focus

35 Preset Zoom

36 Preset Tilt

37 Pan A Preset (360)

Preposition Lenses

Figure 14. Lens Preset Wiring Diagram

16 Pelco Manual C550M-E (8/97)

5.6 AUXILIARY FUNCTIONS

The Coaxitron receiver is capable of operating up to

four (4) remotely activated auxiliary functions. Each

auxiliary output may be individually converted at the

receiver for momentary or latching operation. Refer to

Figure 15 for the desired jumper location. When in the

latching mode, activating the same AUX function will

toggle the function from on to off.

The AUX outputs are buffered to provide a continuous

10 VDC at 25 mA to drive small relays, lamps or some

other external device. Refer to Figures 16 and 17 for

examples of typical circuits used for auxiliary functions.

Note: The preceding two paragraphs pertain to

Revision J or newer Receiver/Driver Mother boards.

Figure 18 shows a typical connection using the latching

command to operate an AI700 or AI701 for auto iris or

manual iris operation. AUX 1 latches manual iris; AUX

2 latches auto iris.

Latching

**

For Revision K (REVK)

boards, SW1 positions are

reversed; i.e., the position

shown above is the "Long"

position for REVK boards.

AUXILLARY JUMPER

SETTINGS ON THE

COAXITRON RECEIVER

BOARD. JUMPERS ARE

SHOWN IN THE

MOMENTARY "POSITION"

OR "MODE".

JP4

JP3

JP1

JP2

AUX 4

AUX 1

AUX 2

AUX 3

Momentary

P1

PC BOARD

P2

"Short" position

BNC

CONNECT ORS

shown in the

SW1

COAXITRON SYSTEM 2000

37-PIN

AMP CONNECTOR

POWER INPUT

**

RECEIVER

Figure 15. Jumper Settings, Receiver/Driver Mother Board

Pelco Manual C550M-E (8/97) 17

COAXITRON

RECEIVER/DRIVER

37-PIN CONNECTOR

1

+ 12 VDC

1N4005

NORMALLY-OPEN

CONTACTS

10 VDC RELAY

25 mA COIL

CURRENT MAXIMUM

2

MANUAL IRIS

NOTE: CUSTOMER SUPPLIES PARTS AND 12 VDC

POWER SUPPLY

3

8

GROUND

Figure 16. External Device Wiring Diagram

CONNECT TO NEGATIVE

SIDE OF 12 VDC SUPPLY

18 Pelco Manual C550M-E (8/97)

30

34

33

32

36

RECEIVER/DRIVER

AUXILIARY FUNCTIONS

TYPICAL WIRING CONNECTIONS

10 VDC RELAY

25 mA COIL

CURRENT MAXIMUM

10 VDC RELAY

25 mA COIL

CURRENT MAXIMUM

10 VDC RELAY

25 mA COIL

CURRENT MAXIMUM

1N4005

1N4005

1N4005

10 VDC RELAY

25 mA COIL

CURRENT MAXIMUM

AUX 1 CONTACTS

AUX 2 CONTACTS

AUX 3 CONTACTS

AUX 4 CONTACTS

NOTE: CUSTOMER MUST SUPPLY PARTS

Pelco Manual C550M-E (8/97) 19

Figure 17. Auxiliary Functions Wiring Diagram

1

2

3

10

11

12

13

MANUAL IRIS

37 PIN CONNECTOR

IRIS

FOCUS

ZOOM

LENS COMMON

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

LENS CABLE

LENS CABLE

TO COAXITRON RECEIVER

COAX COAX

AUX 1 COMMAND LATCHES MANUAL IRIS CONTROL

AUX 2 COMMAND LATCHES AUTO/IRIS CONTROL

CAMERA

LENS

AI700 OR AI701 WIRING CONNECTION

TO THE COAXITRON RECEIVER

LENS CABLE

AI700 OR AI701

20 Pelco Manual C550M-E (8/97)

Figure 18. AI700/AI701 Wiring Diagram

5.7 AUTO/RANDOM OPERATION

The A9000 Auto/Random Scan module is a plug-in

P.C. board option (See Fig. 19 for board location) for all

Coaxitron receivers. This module provides two modes

for automatically controlling pan and tilts within preset

limits — Auto Scan and Random Scan. The Random

Scan and Auto Scan functions are controlled by the

same momentary switch on the control panel labeled

AUTO and MAN. The first activation of the switch to

the AUTO position will put the pan/tilt into Random

Scan. In Random Scan operation the pan/tilt will travel

between the preset limits with a random scan period of

about 0 to 60 seconds, and a random dwell period of

between about 4 seconds and a programmable 60 to 900

seconds. At the completion of a dwell period, another

random scan period is started. The direction of this scan

period is also randomly determined. When a pan limit is

reached, scan direction is reversed automatically. A

second activation of the AUTO switch will put the pan/

tilt into continuous duty Auto Scan. After approximately 1/2 hour of auto scan, the circuit will reset to

random scan. Commanding AUTO while in Random

mode causes a shift to Auto mode and starts the halfhour timer. Similarly, commanding AUTO while in

Auto mode causes a shift to the Random mode and zeros

the half-hour timer.

Advantages of random scan:

1. Because scan direction, scan period and dwell

period are unpredictable, unauthorized activities or intrusions are discouraged.

2. Because of the reduced duty cycle, gear train

wear, cable fatigue, drive motor wear and

temperature rise are reduced. These factors all

contribute to higher system reliability and increased equipment life.

2. Insert spacers into appropriate holes in the

motherboard and snap firmly into place.

5.8 CX900TLC MANUAL/TEST MODULE

The CX900TLC Manual/Test Board is a dual purpose

plug-in module (See Fig. 19 for board location) which

permits local operation of all functions directly from the

receiver unit, and also serves to verify that the receiver

and accessories are operating properly by providing

visual confirmation. This module also aids in troubleshooting receiver or transmitter operational problems.

See Figure 21 for module functions and wiring schematic.

P3

1

TEST

MODULE

CX900TLC

22

AUTO/RANDOM SCAN MODULE

AC

LOW

A9000

AC

GRN

HIGH

RECEIVER BOARD

RX90001000ASSY (24 VAC)*

RX90001007ASSY (120/220 VAC)*

(*VOLTAGES REFER TO

OUTPUT (P/T), CAMERA.)

8

J2

1

P5

F2 F1F3

14

1

P1

P2

1

10

The A9000 auto/random scan plug-in module comes

equipped with an 8-pin male connector and two nylon

spacers factory installed. To install the module perform

the following steps:

3 2 1

A.C. INPUT

VIDEOINVIDEO

OUT

OUTPUT

WARNING: Power must be removed from receiver prior to installing A9000. Destructive fail-

CAUTION: HAZARDOUS VOLTAGE MAY EXIST.

ure of A9000 may result if it is plugged into a

powered motherboard.

1. Locate the 8-pin female connector (J2) on the

motherboard and insert the 8-pin male connector (P5). See Figure 20 for wiring schematic.

Figure 19. Coaxitron Receiver Assembly Layout

(Top View)

Pelco Manual C550M-E (8/97) 21

Figure 20. A9000 Wiring Schematic

U1

1N914

1

2

8

3

R1

100K

+10

GND

ACTIVE

14

15

U1

CD4049

U1

U1

U1

U1

R2

820

LED 1

12

10

6

4119

7

5

AUTO

SCAN

CAM

ON

AUX 4

AUTO

IRIS

AUX 2

IRIS

CLOSE

FOCUS

NEAR

ZOOM

WIDE

DOWN

RIGHT

LEFT

UP

ZOOM

TELE

FOCUS

FAR

IRIS

OPEN

AUX 1

MAN

IRIS

AUX 3

CAM

OFF

MAN

SCAN

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S16

S17

S18

S19

RIGHT

DOWN

ZOOM

WIDE

FOCUS

NEAR

IRIS

CLOSE

AUX 2

AUTO

IRIS

AUX 4

CAM ON

AUTO

SCAN

LEFT

UP

ZOOM

TELE

FOCUS

FAR

IRIS

OPEN

AUX 1/MAN IRIS

AUX 3

CAM

OFF

MAN

SCAN

20

21

22

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

U1

R1

CR1

R2

CR2

LED

INDICATOR

7

8

1

2

3

4

5

6

9

10

11

12

14

15

16

17

18

1913INTERCONNECT TO RECEIVER

BOARD PCB1500529

P3

22 Pelco Manual C550M-E (8/97)

LEFT

UP

1

2

ZOOM

3

TELE

4

5

6

FOCUS

7

FAR

8

9

IRIS

10

OPEN

11

12

13

AUX 1/MAN IRIS

14

15

16

17

18

19

AUX 3

20

21

22

CAM

OFF

MAN

SCAN

U1

INTERCONNECT TO RECEIVER

BOARD PCB1500529

P3

1

2

3

RIGHT

DOWN

4

5

6

7

10

12

11

13

14

15

8

9

ZOOM

WIDE

FOCUS

NEAR

IRIS

CLOSE

AUX 2

AUTO

IRIS

16

17

18

19

ACTIVE

20

21

+10

22

LED

INDICATOR

GND

R1

CR1

R2

AUX 4

CAM ON

AUTO

SCAN

CR2

S1

S2

S3

S4

S5

S6

S7

S8

S9

1N914

3

U1

S10

LEFT

UP

ZOOM

TELE

FOCUS

FAR

IRIS

OPEN

AUX 1

MAN

IRIS

AUX 3

CAM

OFF

MAN

SCAN

1

2

8

S11

S12

S13

S14

S15

S16

S17

S18

S19

R1

100K

RIGHT

DOWN

ZOOM

WIDE

FOCUS

NEAR

IRIS

CLOSE

AUX 2

AUTO

IRIS

AUX 4

CAM

ON

AUTO

SCAN

11

U1

9

U1

7

U1

5

U1

14 15

U1

CD4049

12

10

6

R2

820

4

LED 1

Figure 21. CX900TLC Test Module and Wiring Schematic

6.0 TROUBLESHOOTING GUIDELINES

If you experience operating problems with either the

receiver or transmitter, first check all fuses and voltage

readings to make sure they are in working order. The

CX900TLC can be utilized to verify receiver functions

and accessories are operational.

7.0 MAINTENANCE

The Coaxitron System 2000 is engineered to provide

years of reliable service. The Coaxitron System 2000

has very few operator serviceable parts and we recommend that system components be serviced by a trained

technician or returned to the factory for repair.

There is little that can be done without the aid of an

oscilloscope. We recommend you contact your local

dealer or our Customer Service Department for assistance.

Copies of the Coaxitron System 2000 Maintenance

Manual (document number C550SM) are available on

request.

Pelco Manual C550M-E (8/97) 23

24 Pelco Manual C550M-E (8/97)

8.0 MODEL NUMBER

TRANSMITTER

WEATHER-PROOF?

INDOOR USE?

24VAC PAN/TILT?

120VAC PAN/TILT?

230VAC PAN/TILT?

Receiver in weatherproof box,

120VAC power input, 24VAC

pan/tilts with power supply

for pan/tilt, zoom lens,

and 4 accessory functions (3

latching, 1 momentary).

CX9024RX

24VAC POWER INPUT?

CX9224RX

Same as CX9024RX except

with 24 VAC power input.

.

PRESETS?

CX9224RX-PP

Same as CX9224RX except

with up to 32 presets for pan/tilt,

zoom and focus functions.

For use with Coaxitron Matrix

controls only.

CX9115RX

PRESETS?

CX9115RX-PP

Same as CX9115RX except

with up to 32 presets for pan/

tilt, zoom and focus functions.

For use with Coaxitron Matrix

Controls only.

12VDC CAMERA POWER?

CX9024RX-12V

PRESETS?

CX9024RX-PP

Same as CX9024RX except with up to 32

presets for pan/tilt, zoom and focus functions.

For use with Coaxitron Matrix controls only.

CX9024RX/220

Same as CX9024RX except 230

VAC operation.

120VAC PAN/TILT?

230VAC PAN/TILT?

CX9024RXI

24VAC POWER INPUT?

CX9224RXI

Same as CX9024RXI except

with 24 VAC power input.

.

PRESETS?

CX9224RXI-PP

Same as CX9224RXI except

with up to 32 presets for pan/tilt,

zoom and focus functions.

For use with Coaxitron Matrix

controls only.

CX9115RXI

PRESETS?

CX9115RXI-PP

Same as CX9115RXI except

with up to 32 presets for pan/

tilt, zoom and focus functions.

For use with Coaxitron Matrix

Controls only.

12VDC CAMERA POWER ?

CX9224RXI-12V

Same as CX9024RXI except

supplied with 12 VDC camera

power.

PRESETS?

CX9024RXI-PP

Same as CX9024RXI except with

up to 32 presets for pan/tilt, zoom

and focus functions. For use with

Coaxitron Matrix controls only.

CX9024RXI-PP/22

Same as CX9024RXI-PP except 230

VAC operation.

Same as CX9024RX except

for indoor use.

24VAC PAN/TILT?

Same as CX9115RX except

for indoor use.

DESK TOP MOUNTED?

RACK MOUNTED?

MPT9000CZ

MPT9000PZ

Transmitter/control with pan/tilt

joystick, zoom lens control, and

4 accessory functions.

Transmitter/control with pan/tilt

joystick, zoom lens control, and

4 accessory functions.

12VDC CAMERA POWER ?

CX9024RXI-12V

Same as CX9024RXI except

supplied with 12 VDC camera

power.

CX9024RXI/220

Same as CX9024RXI except 230

VAC operation.

230VAC PAN/TILT?

230VAC POWER INPUT?

CX9220RX

Same as CX9024RX/220 except

230 VAC power input.

230VAC POWER INPUT?

Same as CX9024RXI/220 except

230 VAC power input.

CX9220RXI

NOTE: Additional combina-

tions of equipment options

are possible depending on

customer need and avail-

ability. This list covers the

most used and/or most

most available type units &

their options.

RECEIVER

TREE LIST

Receiver in weatherproof box,

120VAC power input, 120VAC

pan/tilts with power supply

for pan/tilt, zoom lens,

and 4 accessory functions

(3 latching, 1 momentary).

Same as CX9024RX except

supplied with 12 VDC camera

power.

8.1 OPTIONAL ACCESSORIES

A9000 Auto/random scan, plug-in mod-

ule.

AUX2000 Auxiliary function relay box for

control of wiper/washer functions.

C6806/PP Same as C6806 except for use

with preset pan/tilts.

C6825 Pretested 25 foot (8 m) cable for

use with PT680-24P/PT68024SL pan/tilts. Not for inverted

operation.

AUX9000 Auxiliary function wiring harness.

Required for use with AUX2000

and all indoor Coaxitron/Wiretron

receivers (supplied with outdoor

receivers).

CX900TLC Local test board, plug-in module.

EA2000 Coaxitron equalizing video/con-

trol amplifier. This unit is highly

effective in maintaining picture

quality. See Section 9.0 for specific distances.

8.2 RECOMMENDED CABLES

C1906 Pretested 6 foot (2 m) cable for

use with ED2820, ED2920,

SB2800, SS2000, and SS3000

series enclosures and inverted

PT180-24P, PT280-24P pan/

tilts.

C1906/PP Same as C1906 except for use

with preset pan/tilts.

C1925 Pretested 25 foot (8 m) cable for

use with ED2820/ED2920,

SB2800, SS2000 and SS3000

series enclosures and inverted

PT180-24P, PT280-24P pan/

tilts.

C1925/PP Same as C1925 except for use

with preset pan/tilts.

C2506 Pretested 6 foot (2 m) cable for use

with SB2500 series enclosures.

C2525 Pretested 25 foot (8 m) cable for

use with SB2500 series enclosures.

C6806 Pretested 6 foot (2 m) cable for

use with PT680-24P/PT68024SL pan/tilts. Not for inverted

operation.

C6825/PP Same as C6825 except for use

with preset pan/tilts.

WH1900-06 6 foot (2 m) wire harness pre-

assembled with bare wire and

37-pin connector for use with

SB1900 series enclosures.

WH1900-25 Same as WH1900-06 except 25

feet (8 m) long.

9.0 SPECIFICATIONS

ELECTRICAL

Input Voltage: 120 VAC, 60 Hz Transmitter

and Receiver (strapable for 230

VAC, 50 Hz)

Power

Consumption:

Transmitter 2.5vA

Receiver 5vA (120 VAC or 24 VAC)

Pan/Tilt Supply 140vA Max. (120 VAC)

50vA Max. (24 VAC)

Lens Supply 0-4vA Max.

Camera Supply 15vA (typical)

Control Method: 15-pulse train (pulse width

modulated) superimposed on the

video signal during the vertical

blanking interval by the control

transmitter. Pulse train occupies

1 TV line period.

Pulse Amplitude: Approximately 1V p-p added to

video signal, 333 kHz nominal

Connectors:

Control

Transmitter 3 BNC connectors

Receiver 2 BNC connectors for video in-

put and output

37-pin AMP CPC for control

output (mate supplied)

Pelco Manual C550M-E (8/97) 25

Input Video Level: 1V p-p nominal; 2V p-p maxi-

mum at less than 75% APL;

1.5V p-p maximum at 90% APL

System

Bandwidth: Less than 2 dB down at 10 MHz

(exclusive of cable)

Fuse Protection: 3 AG type

Power Cord: 3-wire grounded #18 AWG,

Transmitter and Receiver

Operating

Distance: Cable distances are approximate

according to cable type used. 75

ohm coax required.

Distance

Cable Type Distance Using EA2000

RG59U 750 ft (229 m) 3,000 ft (914 m)

RG6 1,500 ft (457 m) 4,500 ft (1372 m)

RG11 1,800 ft (549 m) 6,000 ft (1829 m)

RG15 — 8,000 ft (2438 m)

GENERAL

Ambient

Temperature: -4°F to +140°F (-20°C to +60°C)

26 Pelco Manual C550M-E (8/97)

NOTES:

Pelco Manual C550M-E (8/97) 27

10.0 WARRANTY AND RETURN

INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved

defective in material or workmanship for a period of one year after the date

of shipment.

Exceptions to this warranty are as noted below:

• Five years on FT/FR8000 Series fiber optic products.

• Three years on Genex

keyboard).

• Three years on Camclosure

CC3701H-2, CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2,

and MC3651H-2X camera models, which have a five-year warranty.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy®, CM6700/CM6800/CM9700 Series matrix, and

DF5/DF8 Series fixed dome products.

• Two years on Spectra®, Esprit®, ExSite™, and PS20 scanners, includ-

ing when used in continuous motion applications.

• Two years on Esprit® and WW5700 Series window wiper (excluding

wiper blades).

• Eighteen months on DX Series digital video recorders, NVR300

Series network video recorders, and Endura

network-based video products.

• One year (except video heads) on video cassette recorders (VCRs).

Video heads will be covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in

continuous motion applications (that is, preset scan, tour and auto scan

modes).

Pelco will warrant all replacement parts and repairs for 90 days from the

date of Pelco shipment. All goods requiring warranty repair shall be sent

freight prepaid to Pelco, Clovis, California. Repairs made necessary by

reason of misuse, alteration, normal wear, or accident are not covered

under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or

loss resulting from the specific use or application made of the Products.

Pelco’s liability for any claim, whether based on breach of contract,

negligence, infringement of any rights of any party or product liability,

relating to the Products shall not exceed the price paid by the Dealer to

Pelco for such Products. In no event will Pelco be liable for any special,

incidental or consequential damages (including loss of use, loss of profit

and claims of third parties) however caused, whether by the negligence

of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The

Dealer may also have additional rights, which are subject to variation from

state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800)

289-9100 or (559) 292-1981 to obtain a Repair Authorization number

(RA), and provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice

number

3. Details of the defect or problem If there is a dispute regarding the

warranty of a product which does not fall under the warranty conditions

stated above, please include a written explanation with the product

when returned.

Method of return shipment shall be the same or equal to the method by

which the item was received by Pelco.

®

Series products (multiplexers, server, and

®

and fixed camera models, except the

™

Series distributed

RETURNS

In order to expedite parts returned to the factory for repair or credit, please

call the factory at (800) 289-9100 or (559) 292-1981 to obtain an

authorization number (CA number if returned for credit, and RA number

if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking

and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the

assigned CA or RA number and freight should be prepaid. Ship to the

appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto

Rico, send goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto

Rico and are instructed to return goods to the USA, you may do one of the

following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

If the goods are to be sent by a FREIGHT FORWARDER, send the goods

to:

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

This equipment contains electrical or electronic components that must be recycled properly to comply with Directive 2002/96/EC of the European Union

regarding the disposal of waste electrical and electronic equipment (WEEE). Contact your local dealer for procedures for recycling this equipment.

28 Pelco Manual C550M-E (8/97)

Loading...

Loading...