Page 1

®

MC3810-2

1/3-Inch

Monochrome

Camera

Installation/

Operation Manual

C1905M (10/99)

Pelco • 3500 Pelco Way • Clovis, CA 93612-5699 USA • www.pelco.com

In North America and Canada: Tel (800) 289-9100 or FAX (800) 289-9150

International Customers: Tel +1 (559) 292-1981 or FAX +1 (559) 348-1120

Page 2

CONTENTS

LIST OF ILLUSTRATIONS

Section Page

DESCRIPTION...................................................................................................................3

LOCATION AND FUNCTION OF PARTS...........................................................................3

TOP/FRONT/SIDE .....................................................................................................3

REAR .........................................................................................................................4

INSTALLATION...................................................................................................................5

BACKFOCUS ADJUSTMENT....................................................................................6

VERTICAL PHASE ADJUSTMENT ...........................................................................6

INCIDENT LIGHT LEVEL ADJUSTMENT .................................................................6

BACKLIGHT CONTROL ADJUSTMENT ...................................................................6

TROUBLESHOOTING .......................................................................................................6

SPECIFICATIONS..............................................................................................................7

REGULATORY NOTICES ..........................................................................................8

WARRANTY AND RETURN INFORMATION ....................................................................8

Figure Page

1 Location of Top, Front, and Side Parts ...............................................................3

2 Location of Rear Parts .......................................................................................4

3 Lens Mounting Dimensions................................................................................5

4 Replacing Lens Plug ..........................................................................................5

2 Pelco Manual C1905M (10/99)

Page 3

DESCRIPTION

The MC3810-2 is a black and white video camera that is designed for use in a monitoring

system.

Features

High resolution and high sensitivity with a 1/3-inch CCD imager

CCD iris function

AGC (Automatic Gain Control)

AC line lock

C or CS lens mount

Compatibility with auto iris lenses that are controlled by either DC or video signals

Level and backlight control adjustments for various lighting conditions

Isolated power circuit

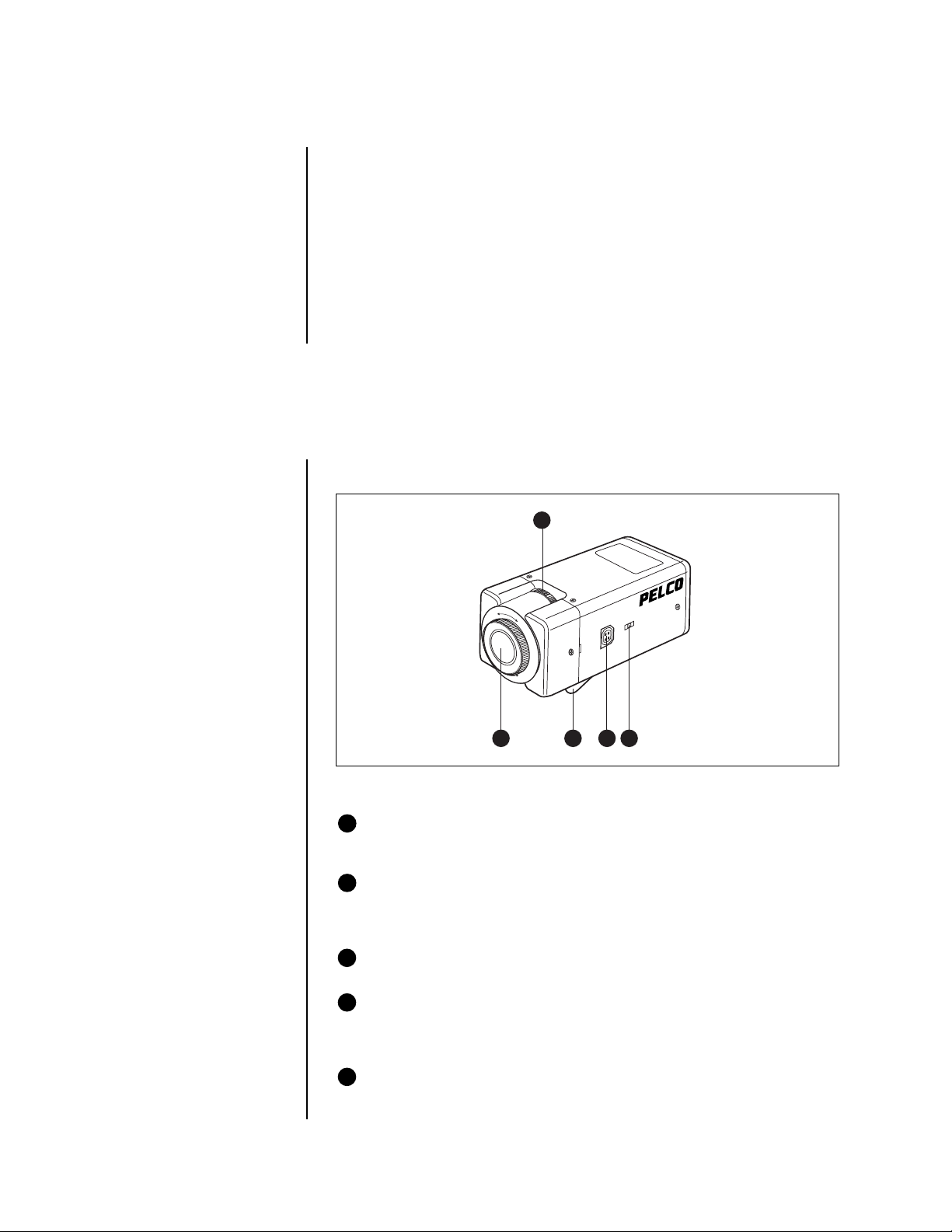

LOCATION AND FUNCTION OF PARTS

TOP/FRONT/SIDE

Refer to Figure 1 for parts on the top, front, and side of the camera.

1

NOTE:

When the auto iris

lens selection switch is set

to VIDEO, “hunting” may

occur. If this occurs, use the

LEVEL L/H adjustment

screw on the lens to change

the incident light level. When

adjusting the incident light

level, set the ALC (Automatic Light Control)

adjustment screw to AV.

C

CS

C

AUTO-IRIS

VIDEO IDC

LENS

LOCK

B&W VIDEO CAMERA

45 3 2

Figure 1. Location of Top, Front, and Side Parts

1 Focal length adjustment ring and locking screw

Use this ring to adjust the focal length (the distance between the lens mounting plane

and the image plane). Use the locking screw to lock the focal length.

2 Auto iris lens selection switch (DC/VIDEO)

Use to select the control signal for the auto iris lens.

DC: For auto iris lenses controlled by DC signals.

VIDEO: For auto iris lenses controlled by video signals.

3 Lens connector

This four-pin socket supplies power and control signals to an auto iris lens.

4 Tripod adapter

The tripod adapter can be attached to either the top or bottom of the camera using the

three attached screws (UNC 1/4-20). The adapter is attached at the factory to the bottom of the camera.

5 Lens mount

Use to attach a C- or CS-mount lens. To attach a lens, turn the focal length adjustment

ring to the appropriate position. The factory setting is CS mount.

Pelco Manual C1905M (10/99) 3

Page 4

REAR

Refer to Figure 2 for parts on the rear of the camera.

NOTE:

The BLC screw

cannot be used when the

camera has an auto iris lens

that is controlled by a video

signal.

7

CCD-IRIS

V-PHASE

+-

ONOFF

GND

BLC

AV P K

LEVEL

LH

AC 24V

96 8

VIDEO OUT

101112

Figure 2. Location of Rear Parts

6 V-PHASE adjustment screw

Use to adjust the vertical phase of cameras synchronized by line lock.

7 CCD-IRIS ON/OFF switch

When using a manual iris lens, set the switch ON to automatically adjust the sensitivity

according to the incident light conditions. When using an auto iris lens, set the switch

OFF.

8 BLC (Backlight Control) adjustment screw

Use to compensate for backlight conditions when using a manual iris lens (when CCDIRIS switch is set to ON) or a DC-controlled auto iris lens.

NOTE:

The LEVEL screw

cannot be used when the

camera has an auto iris lens

that is controlled by a video

signal.

9 VIDEO OUT connector

This is a BNC-type connector.

10 Screw terminals for power

Connect an external Class 2 power supply of 24 VAC.

11 LEVEL adjustment screw

Use to compensate for the video level when using a manual iris lens (when the CCDIRIS is set to OFF) or a DC-controlled auto iris lens.

12 Ground terminal

This is a screw-type terminal.

4 Pelco Manual C1905M (10/99)

Page 5

INSTALLATION

The lens must be either a C- or CS-mount type of less than 2.2 pounds (1 kg). The protrusion behind the mounting surface must be within the limits as shown in Figure 3.

The camera is supplied with a lens connector for inserting the power and control cable of

an auto iris lens. Before connecting an auto iris lens, however, you first have to replace the

lens cable plug with the one supplied with this camera. To replace the plug:

a. Detach the old plug from the lens cable.

b. Solder the wires to the pins of the new plug (refer to Figure 4). For cable pin as-

1

1)

1 C-mount lens 0.35-inch (9 mm) or less

2 CS-mount lens 0.16-inch (4 mm) or less

2)

Figure 3. Lens Mounting Dimensions

signments, refer to the instruction manual for the lens.

2

1Cover

2 Lens cable (not supplied)

3 Rib (If the cable is thick, cut this off.)

4 Plug (supplied)

5 Pin 4 Video signal control: Ground

DC control: DRV-

6 Pin 2 Video signal control: Not used

DC control: CONT+

7 Pin 1 Video signal control: Power supply (9 VDC, 50 mA maximum)

DC control: CONT-

8 Pin 3 Video signal control: Video signal (0.7 Vp-p)

DC control: DRV+

Figure 4. Replacing Lens Plug

1. Unscrew the lens mount cap.

CAUTION:

Keep

the lens mount cap

2. Loosen the locking screw. According to the type of lens, adjust the focal length by turning the focal length adjustment ring. Re-tighten the locking screw.

on the camera

when a lens is not attached.

3. Screw in the lens, and turn it until it is secure.

4. Insert the lens plug in the LENS connector. Skip this step if you are installing a manual

iris lens.

5. Mount the camera.

2

1

3

8

7

6

5

4

6. Connect a 75-ohm coaxial cable from the VIDEO OUT connector on the camera to the

VIDEO IN connector on a video monitor or other video input.

7. Connect the camera to a 24 VAC, 60 Hz, Class 2 power supply.

Pelco Manual C1905M (10/99) 5

Page 6

BACKFOCUS ADJUSTMENT

1. Set the CCD-IRIS switch on the rear of the camera OFF.

2. Set the iris wide open and the focus on infinity or a distant object. If you have an auto

iris lens, use a neutral density filter or other means to decrease the amount of light so

that the iris will open as wide as possible.

3. Turn the focal length adjustment ring for the best picture.

4. If you have a zoom lens, zoom to a close object and adjust the lens controller or focus

for the best picture. Repeat steps 2-4 until the lens remains in focus throughout the

zoom range.

5. If you have a lens with a manual iris, set the CCD-IRIS switch ON.

VERTICAL PHASE ADJUSTMENT

The vertical phase adjustment is used only when using more than one camera. If cameras

are not synchronized to the AC line, switching between cameras may produce what appears to be roll on the monitor.

To adjust the vertical phase, turn the V-PHASE screw on the rear of the camera (while

switching as rapidly as possible between two camera views) until the switching is clean and

there is no vertical roll or flip.

INCIDENT LIGHT LEVEL ADJUSTMENT

If the picture is too dark or if the picture’s highlights are extremely overexposed, adjust the

LEVEL adjustment on the rear of the camera. The adjustment can only be used for a

manual iris lens (CCD-IRIS switch is ON) or DC-controlled auto iris lens.

1. Turn toward L (low) to make the picture darker.

2. Turn toward H (high) to make the picture brighter.

BACKLIGHT CONTROL ADJUSTMENT

You can compensate for backlight conditions by turning the BLC (Backlight Control) adjustment screw on the rear of the camera. When using this unit under backlight conditions, turn

the BLC adjustment screw toward AV. The adjustment can only be used for a manual iris

lens (CCD-IRIS switch is ON) or DC-controlled auto iris lens.

TROUBLESHOOTING

The following conditions may be observed and are not necessarily a fault of the camera.

Vertical smear

This may occur when viewing a bright object or an intense reflection.

Patterned noise

A fixed pattern may appear over the entire monitor screen when the camera is operated at

a high temperature.

Jagged picture

This becomes noticeable when viewing stripes, straight lines, or similar patterns.

6 Pelco Manual C1905M (10/99)

Page 7

SPECIFICATIONS

GENERAL

Image Device 1/3-inch interline transfer CCD

Picture Elements 510 (H) x 492 (V)

Sensing Area 3.3 mm (H) x 4.4 mm (V)

Scanning System 525 lines, 2:1 interlace

Sync System AC line lock

Horizontal

Resolution 380 TV lines

Minimum

Illumination 0.06 lux at f1.2 (30 IRE, AGC on)

Signal-to-Noise

Ratio More than 45 dB (AGC off)

Automatic Gain Control AGC on

Phase Control V-phase control (±90°)

CCD Iris Control On/off switchable

Backlight

Compensation Pk/Av pot

Video Out 1.0 Vp-p, 75 ohms, sync negative, BNC type

Acceptable Lens

Mass 2.2 lb (1 kg) maximum

Auto Iris Lens Video- or DC-driven type (non-EE amplifier/non-ALC type), selectable

ELECTRICAL

Power

Requirements 24 VAC, 60 Hz (screw terminals)

Power

Consumption 2.5W

Connectors Video out (BNC)

1/60 to 1/100,000 second

by switch on side of camera

Lens (4-pin)

GND terminal

24 VA C terminals

MECHANICAL

Lens Mount C/CS mount (back-focus adjustable)

Camera Mount Removable mounting plate fits either top or bottom of camera housing;

ENVIRONMENTAL

Operating

Temperature 14° to 122°F (-10° to 50°C)

Storage

Temperature -40° to 140°F (-40° to 60°C)

Humidity 20 to 80%

PHYSICAL

Construction Aluminum case

Finish Light gray

Dimensions 2.31 (W) x 2.25 (H) x 4.49 (L) inches (5.87 x 5.72 x 12.99 cm)

Unit Weight 11 oz. (0.32 kg)

Shipping Weight 1 lb (0.45 kg)

ACCESSORIES

Supplied

Accessories Lens mount cap 4-pin plug for lens cable

uses 1/4-inch UNC-20 screw

(Design and product specifications subject to change without notice.)

Pelco Manual C1905M (10/99) 7

Page 8

REGULATORY NOTICES

NOTE: This equipment has been tested and found to comply with the limits of a Class B

digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. However there is no guarantee that the interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged

to try and correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or

workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

• Five years on FT/FR8000 Series fiber optic products.

®

• Three years on Genex

• Three years on Camclosure

CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2, and MC3651H-2X camera models,

which have a five-year warranty.

•Two years on standard motorized or fixed focal length lenses.

•Two years on Legacy

fixed dome products.

•Two years on Spectra

continuous motion applications.

•Two years on Esprit

• Eighteen months on DX Series digital video recorders, NVR300 Series network video

recorders, and Endura

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion

applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco

shipment. All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis,

California. Repairs made necessary by reason of misuse, alteration, normal wear, or accident

are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from

the specific use or application made of the Products. Pelco’s liability for any claim, whether

based on breach of contract, negligence, infringement of any rights of any party or product

liability, relating to the Products shall not exceed the price paid by the Dealer to Pelco for

such Products. In no event will Pelco be liable for any special, incidental or consequential

damages (including loss of use, loss of profit and claims of third parties) however caused,

whether by the negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have

additional rights, which are subject to variation from state to state.

Series products (multiplexers, server, and keyboard).

®

and fixed camera models, except the CC3701H-2,

®

, CM6700/CM6800/CM9700 Series matrix, and DF5/DF8 Series

®

, Esprit®, ExSite™, and PS20 scanners, including when used in

®

and WW5700 Series window wiper (excluding wiper blades).

™

Series distributed network-based video products.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or

(559) 292-1981 to obtain a Repair Authorization number (RA), and provide the following

information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the

warranty conditions stated above, please include a written explanation with the product

when returned.

Method of return shipment shall be the same or equal to the method by which the item was

received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at

(800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned

for credit, and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing

charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA

number and freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico, send goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico and are

instructed to return goods to the USA, you may do one of the following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

If the goods are to be sent by a FREIGHT FORWARDER, send the goods to:

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

REVISION HISTORY

Manual # Date Comments

C1905M 10/99 Original version.

Pelco, the Pelco logo, Camclosure, Esprit, Genex, Legacy, and Spectra are registered trademarks of Pelco. ©Copyright 1999, Pelco.

Endura and ExSite are trademarks of Pelco. All rights reserved.

8 Pelco Manual C1905M (10/99)

Loading...

Loading...