Page 1

INSTALLATION

IS210 Series

Camclosure

Integrated Camera System

®

C3428M-A (1/08)

Page 2

Page 3

Contents

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Regulatory Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Prepare Mounting Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Install Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Without Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

With Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Reinstall Camera Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Adjust Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Replace Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DN/CH Series Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Auto Iris Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Vertical Phase Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Blemish Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Day/Night Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

DW/CW Series (Wide Dynamic Range) Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Auto Iris Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Vertical Phase Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Blemish Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Service Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

C3428M-A (1/08) 3

Page 4

Important Safety Instructions

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

6. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus

(including amplifiers) that produce heat.

7. Only use attachments/accessories specified by the manufacturer.

8. Use only with the cart, stand, tripod, bracket, or table specified by the manufacturer, or sold with the

apparatus. When a cart is used, use caution when moving the cart/apparatus combination to avoid

injury from tip-over.

9. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been

damaged in any way, such as power-supply cord or plug is damaged, liquid has been spilled or

objects have fallen into the apparatus, the apparatus has been exposed to rain or moisture, does not

operate normally, or has been dropped.

10. Installation should be done only by qualified personnel and conform to all local codes.

11. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is

designed for indoor use only and it must not be installed where exposed to rain and moisture.

12. Use only installation methods and materials capable of supporting four times the maximum

specified load.

13. Use stainless steel hardware to fasten the mount to outdoor surfaces.

14. To prevent damage from water leakage when installing a mount outdoors on a roof or wall, apply

sealant around the bolt holes between the mount and mounting surface.

15. CAUTION: These servicing instructions are for use by qualified service personnel only. To reduce

the risk of electric shock do not perform any servicing other that contained in the operating

instructions unless you are qualified to do so.

16. Only use replacement parts recommended by Pelco.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage

constituting a risk of electric shock is present within

this unit.

This symbol indicates that there are important

operating and maintenance instructions in the

literature accompanying this unit.

CAUTION:

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

4 C3428M-A (1/08)

Page 5

REGULATORY NOTICES

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

RADIO AND TELEVISION INTERFERENCE

This equipment has been tested and found to comply with the limits of a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However there is no guarantee that the interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

You may also find helpful the following booklet, prepared by the FCC: “How to Identify and Resolve

Radio-TV Interference Problems.” This booklet is available from the U.S. Government Printing Office,

Washington D.C. 20402.

Changes and modifications not expressly approved by the manufacturer or registrant of this equipment can

void your authority to operate this equipment under Federal Communications Commission’s rules.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

C3428M-A (1/08) 5

Page 6

Description

The IS210 Series Camclosure® is a wedge-style integrated camera system that is quick and easy to install.

The system is designed to mount directly to a wall or ceiling, or to a corner with the IS210-CM corner

mount.

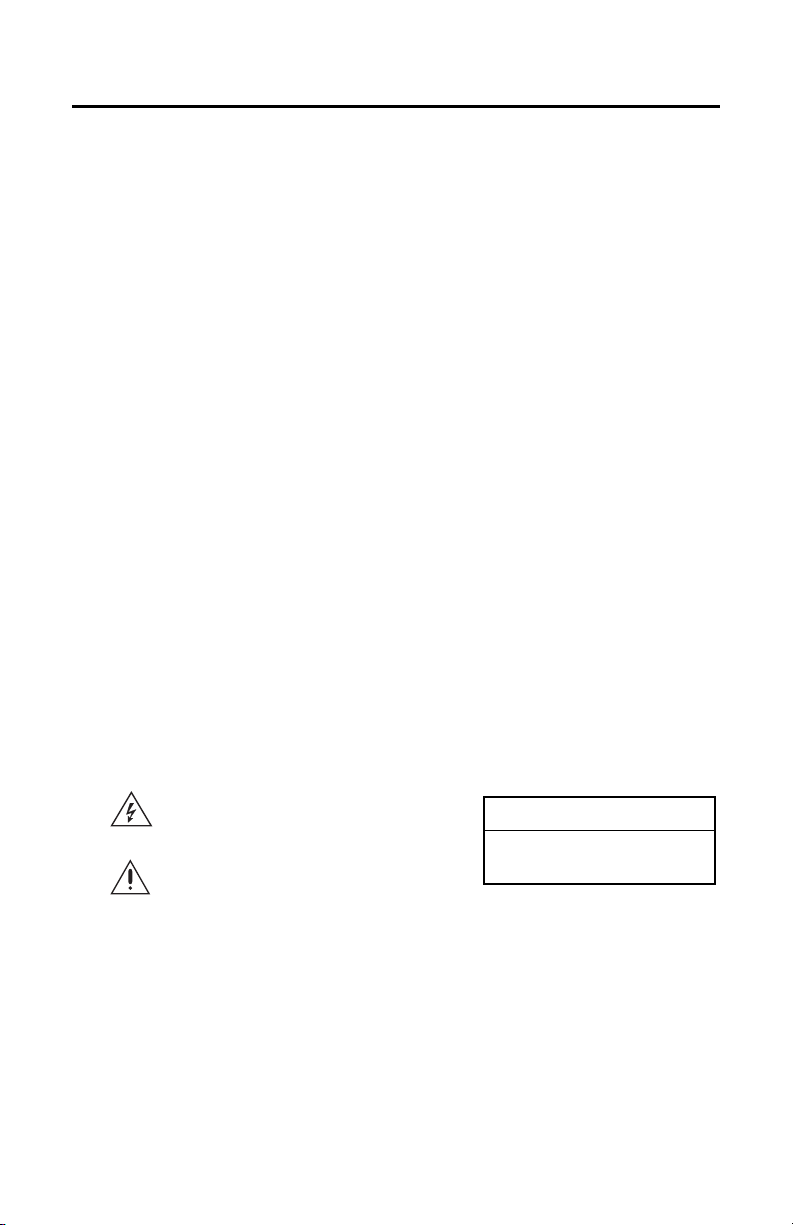

The IS210 system is shipped fully assembled. System components include a cover, base with camera and

lens, and a mounting plate (refer to Figure 1).

PARTS LIST

Qty Description

1 Camclosure integrated camera system

1 Hole plug

1 Hollow screwdriver bit (1/8-inch)

COVER

BASE

MOUNTING PLATE

Figure 1. Exploded View of System Components

6 C3428M-A (1/08)

Page 7

Installation

PREPARE MOUNTING SURFACE

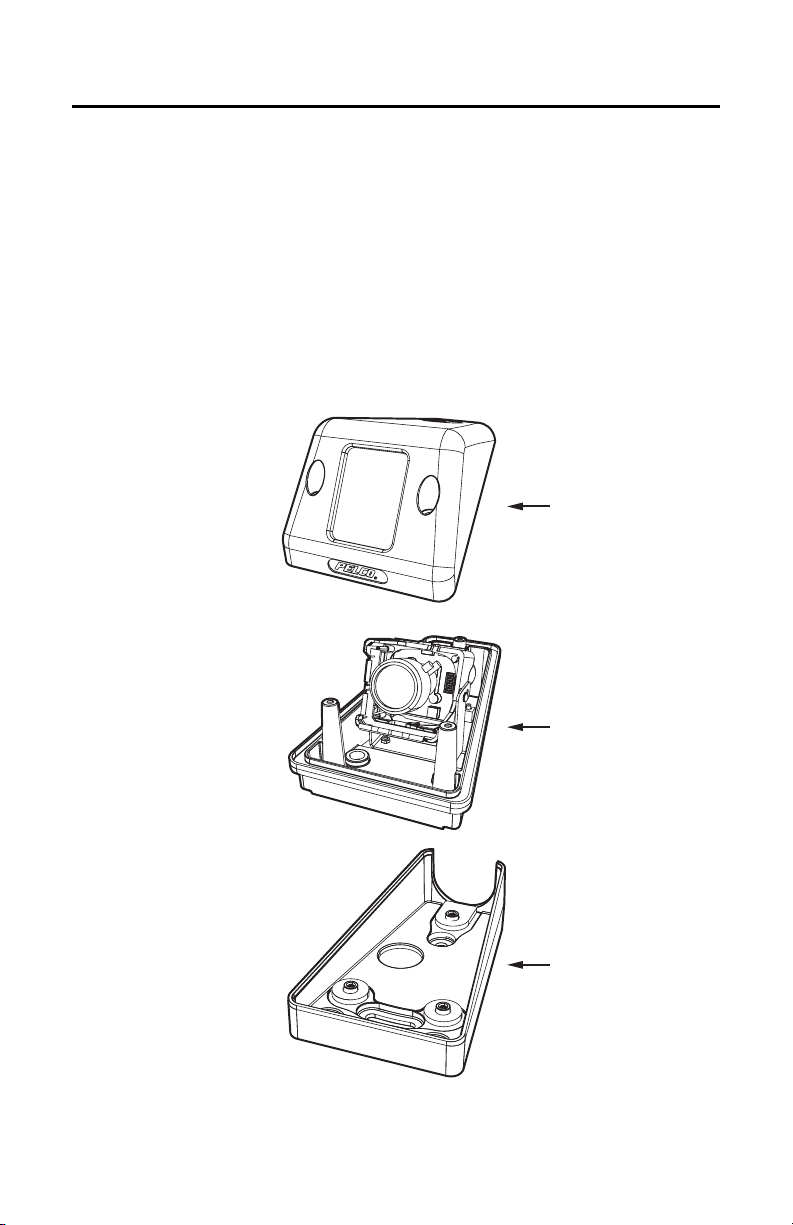

1. Remove the cover of the IS210. Use the screwdriver bit (supplied) to loosen the three tamperproof

screws, and then lift the cover from the base.

2. Remove the camera assembly from the base by removing the Phillips screws on each side of the

camera assembly (refer to Figure 2).

CAMERA ASSEMBLY

Figure 2. Removing Camera Module

PHILLIPS

SCREW

3. Remove the base from the mounting plate by removing the three 8-32 x 0.375-inch screws and

washers. Lift the base from the mounting plate and set aside the base, screws, and washers.

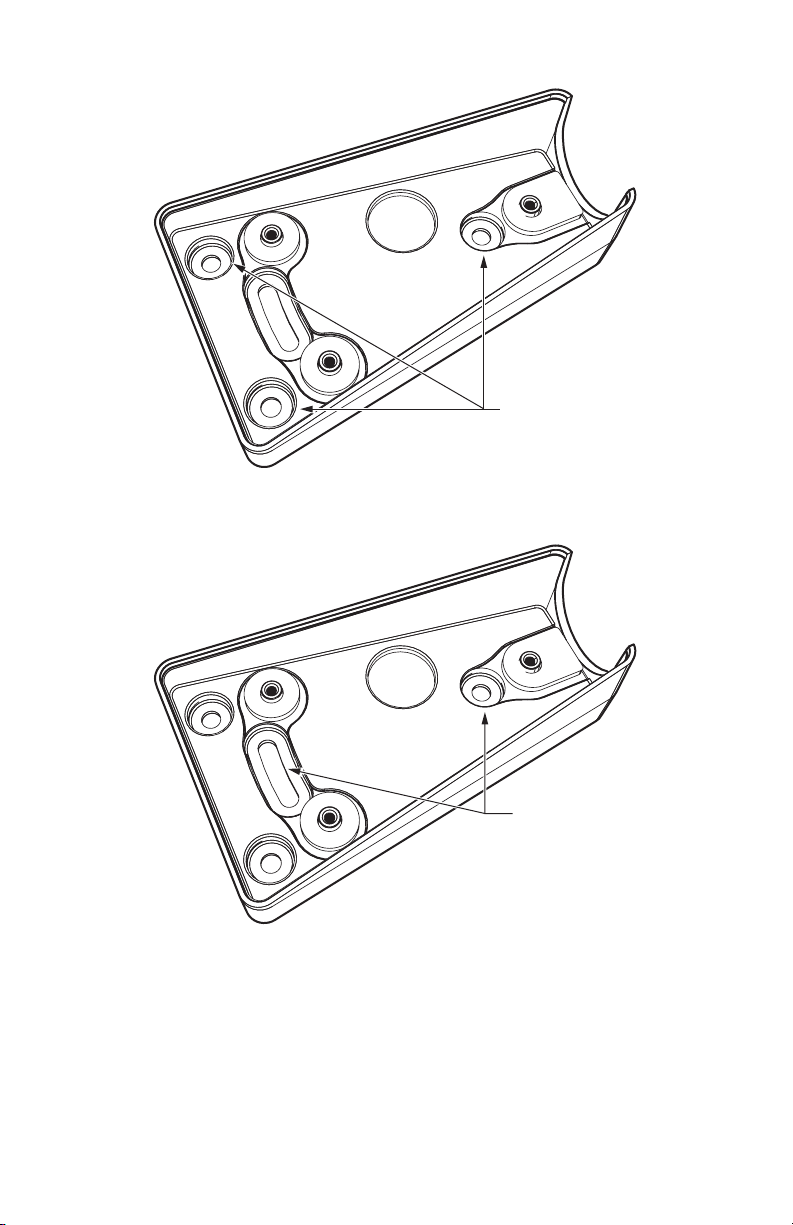

4. Select a fixed or adjustable mounting pattern (refer to Figure 3 and Figure 4 on page 8). Using the

mounting plate as a template, mark the wire feedthrough and fastener hole positions on the

mounting surface. Prepare the holes for the installation.

C3428M-A (1/08) 7

Page 8

Figure 3. Fixed Mounting Pattern

Figure 4. Adjustable Mounting Pattern

FIXED MOUNTING

PATTERN

ADJUSTABLE

MOUNTING

PATTERN

8 C3428M-A (1/08)

Page 9

INSTALL BASE

WITHOUT CONDUIT

1. Pull the power and video wiring for the camera through the mounting surface and then through the

wiring hole in the mounting plate. Fasten the mounting plate to the mounting surface with #8

stainless steel screws (not supplied) of the appropriate length.

Adjustable mounting pattern only: Adjust the angle of the base before tightening the mounting

hardware.

2. Connect the power input wires to the power wires located on the bottom of the IS210 base. Refer to

Table A to connect the power wires:

Tab le A . Power Input

Voltage Red Wire Black Wire

12 VDC + Ground

24 VAC ~ ~

3. Connect the video cable/wires:

• BNC: Connect the BNC connector from the unit to a mating BNC connector.

• UTP: Connect the blue wire to Video +; connect the gray wire to Video -.

4. Push the power wires and video cable back, through the mounting surface. Align the mounting holes

in the base with the mounting holes of the mounting plate. Attach the base to the mounting plate

with the three 8-32 x 0.375-inch screws and washers previously removed.

WITH CONDUIT

1. Prepare the conduit for the installation.

2. Fasten the mounting plate to the mounting surface with #8 stainless steel screws (not supplied) of

the appropriate length.

Adjustable mounting pattern only: Adjust the angle of the base before tightening the mounting

hardware.

3. Using a blunt tool, push out the wiring plug located in the bottom of the base (refer to Figure 5 on

page 10). Pull the wiring inside the base.

C3428M-A (1/08) 9

Page 10

Figure 5. Removing the Wiring Plug

4. Insert the hole plug (supplied) into the hole in the base of the Camclosure (refer to Figure 6).

HOLE PLUG

Figure 6. Installing the Hole Plug

5. Pull the wiring through the conduit opening (refer to Figure 7 on page 11):

a. Use a 1/16-inch hex head wrench to loosen the hex head set screw.

b. Use a screwdriver to remove the conduit cover.

c. Pull the power wires and video cable through the conduit opening.

10 C3428M-A (1/08)

Page 11

CONDUIT COVER

HEX HEAD INSET

SCREW

1/16-INCH HEX HEAD

WRENCH

Figure 7. Removing the Conduit Cover

6. Install a 0.75-inch (1.91 cm) conduit connector in the conduit opening. Line up the mounting holes in

the base with the mounting holes of the mounting plate. Attach the base to the mounting plate with

the three 8-32 x 0.375-inch screws and washers previously removed.

7. Attach the base to the conduit and then connect the power input wires to the power wires of the

IS210 Camclosure. Refer to the following to connect the power wires:

Tab le B . Power Input

Voltage Red Wire Black Wire

12 VDC + Ground

24 VAC ~ ~

8. Connect the video cable/wires:

• BNC: Connect the BNC connector from the unit to a mating BNC connector.

• UTP: Connect the blue wire to Video +; connect the gray wire to Video -.

C3428M-A (1/08) 11

Page 12

REINSTALL CAMERA MODULE

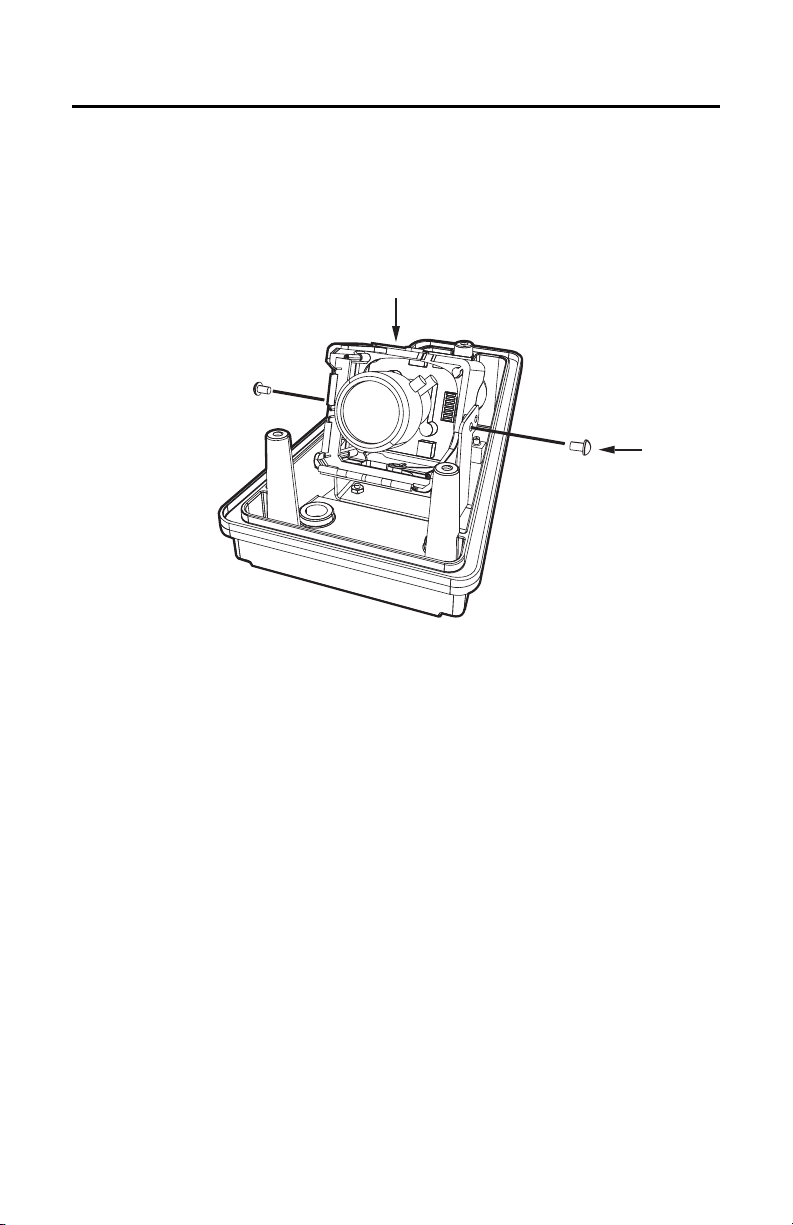

Reinstall the camera module (refer to Figure 8). Make sure the top of the camera is oriented properly; the

lens housing contains a label that reads TOP.

NOTE: To prevent damage to the camera or lens, install the camera in the correct hole positions of the

mounting bracket.

MOUNT CAMERA HERE

Figure 8. Camera Installation

DO NOT USE

ADJUST POSITION

1. Turn on power to the camera and monitor.

WARNING: Heater elements could be hot! When camera power is on, use caution when

adjusting the camera. This applies to all models.

2. Varifocal lens only: Loosen the focal length and focus locking screws (refer to Figure 9). Adjust

the lens according to scene detail. Retighten the screws.

VARIFOCAL LENS

LOCKING

SCREWS

Figure 9. Varifocal Lens Adjustment

3. Adjust the position of the camera.

REPLACE COVER

Place the cover of the IS210 onto the base of the unit. Using the screwdriver bit (supplied), tighten the

three tamperproof screws.

NOTE: Remove the foam from the inside of the cover before installing the cover.

12 C3428M-A (1/08)

Page 13

DN/CH SERIES ADJUSTMENTS

Refer to Figure 10 to adjust the IS210-DN or IS210-CH model.

Figure 10. Adjusting the IS210-DN/CH Series Camclosure

SWITCH SETTINGS

Locate the DIP switch. Then set the switches for your installation.

SW4-1: Automatic Gain Control

The automatic gain control (AGC) adjusts the image automatically to compensate for changes in light

levels.

Set SW4-1 to ON to enable AGC. Set it to OFF to disable AGC. The default setting is ON.

SW4-2: Backlight Compensation

The backlight compensation (BLC) feature compensates for backlit scenes by enhancing objects in the

center of the scene.

Set SW4-2 to ON to enable BLC. Use this setting if a bright backlight is present and the subject in

the center of the picture appears dark or as a silhouette. Set it to OFF to disable backlight compensation.

This is the default setting.

SW4-3: Line Sync

When multiple cameras are connected to the same switching device, vertical roll may occur on the

monitor. AC line lock eliminates vertical roll by locking the frame rate to the power supply frequency. Each

camera output is synchronized to the power supply frequency. Refer to Vertical Phase Adjustment on

page 14 for more information.

Internal line sync disables the line lock and synchronizes cameras internally.

Set SW4-3 to OFF to use AC line lock. Set it to ON to use internal line sync. The default setting is OFF.

C3428M-A (1/08) 13

Page 14

SW4-4: Flickerless

In certain lighting conditions, a flicker in the light source may affect camera operation. Flickering can be

caused by a number of conditions, including the quality of the source power and the age and type of

fluorescent bulbs and ballasts.

Set SW4-4 to enable flickerless operation. The camera removes the effects of flickering and the shutter

speed is set to 1/120 (NTSC) or 1/100 (PAL).

Set SW4-4 to disable flickerless operation. This is the default setting.

NOTE: If you enable flickerless operation, you should use AC line lock for best results.

SW4-5: Auto White Balance/Manual White Balance

Auto white balance (AWB) is enabled by default (OFF).

To manually set and lock the white balance:

1. Set SW4-5 to OFF.

2. Hold a white background in front of the lens until the video is all white.

3. While holding the background in place, set SW4-5 to ON. A blue blinking block appears on the video

image for a few seconds. When the block changes to solid green, the manual white balance (MWB)

process is complete.

SW4-6: Reserved

Do not change SW4-6 from its factory setting. SW4-6 must be set to OFF for Varifocal models; it must be

set to ON for fixed iris lenses.

AUTO IRIS LEVEL ADJUSTMENT

To adjust the auto iris DC drive level (refer to Figure 10 on page 13):

1. Tilt or rotate the camera module until you can access the auto iris level control (R19).

2. Turn the screw clockwise to increase the brightness level or counterclockwise to decrease the

brightness level.

VERTICAL PHASE ADJUSTMENT

NOTE: Use this procedure for 24 VAC operation only.

When using more than one camera power supply, a brief vertical roll may occur on the monitor when

switching from one camera to another.

To eliminate vertical roll, reverse the 24 VAC connections on one camera. If both cameras are connected to

the same transformer, this should solve the problem. If the problem continues, adjust the phase control by

synchronizing, or line locking, the cameras to one another.

NOTE: When adjusting vertical phase, line sync (SW4-3) must be set to OFF for AC line lock.

14 C3428M-A (1/08)

Page 15

Adjusting Vertical Phase

You may need two people when synchronizing the cameras: one at the camera, the other at the monitor to

observe the vertical roll and the effect of any camera adjustments.

To synchronize the cameras:

1. Choose a reference camera to which all other cameras will be phased.

2. Select the camera to synchronize. Use buttons SW1 and SW2 to synchronize the camera to the

reference camera (refer to Figure 10 on page 13). SW1 increases vertical phase; SW2 decreases

vertical phase.

3. Each time an adjustment is made, switch back and forth between the camera you are adjusting and

the reference camera. Repeat this process as many times as necessary until the roll between the

cameras is no longer noticeable.

4. Adjust the phase of all other cameras by repeating steps 2 and 3. Always adjust to the reference

camera selected in step 1.

NOTE: The preferred method for camera phase adjustment is to use a dual trace oscilloscope to align the

vertical sync pulses of the reference camera to the selected camera(s).

BLEMISH DETECTION

If small white or colored spots appear in the video image, one or more pixels on the camera imager may be

defective. (This condition is common for both CCD and CMOS imagers.)

DN and CH Series cameras with auto iris lenses automatically detect and correct defective pixels during

startup. Video turns on, then off, and then on again. If white or colored spots still appear, you can correct

the defective pixels manually.

CH Series cameras with fixed iris lenses do not automatically detect and correct defective pixels. You can

correct the defective pixels manually.

To manually correct defective pixels (refer to Figure 10 on page 13):

1. Cover the lens completely. Make sure no light can enter the lens.

NOTE: The mechanical iris lens aperture does not completely block the light.

2. Press and hold button SW3 for one second. The camera will find and correct defective pixels.

NOTE: Any defective pixels that cannot be completely corrected may still appear.

3. Release button SW3.

4. Uncover the lens for normal camera operation.

C3428M-A (1/08) 15

Page 16

DAY/NIGHT OPERATION

NOTE: This section only applies to DN model cameras.

DN model cameras regularly check the brightness level of the field of view to determine when to switch

between day (color) and night (black-white) operation.

Actual brightness threshold levels are affected by camera angle, amount of zoom, field of view, lens, and

type of lighting. The switching process lasts from 7 to 10 seconds.

Figure 10 on page 13 and Table A on page 9 show how the camera switches between color and

black-white operation.

MODE

COLOR

MODE

3.0 lux

COLOR

FALLING LIGHT LEVEL

B-W

MODE

1.5 lux

B-W

MODE

RISING LIGHT LEVEL

Figure 11. DN Models Threshold Switching Levels

Table C. DN Models Switching Thresholds

Color to B-W 1.5 lux ±1.0 lux

B-W to Color 3.0 lux ±1.0 lux

NOTE: These switching thresholds are approximate. Use the thresholds in Table A as a guide when

installing the unit.

16 C3428M-A (1/08)

Page 17

DW/CW SERIES (WIDE DYNAMIC RANGE) ADJUSTMENTS

Refer to Figure 12 to adjust the IS210-DW or IS210-CW model.

SW1

DEFAULT SWITCH POSITION

Figure 12. Adjusting the IS210-DW/CW Series Camclosure

R7

SWITCH SETTINGS

Locate the DIP switch. Then set the switches for your installation.

SW1-1: Video Format

Set SW1-1 to ON for NTSC. Set it to OFF for PAL. The default setting is ON.

SW1-2: Line Sync

When multiple cameras are connected to the same switching device, vertical roll may occur on the

monitor. AC line lock eliminates vertical roll by locking the frame rate to the power supply frequency.

Each camera output is synchronized to the power supply frequency. Refer to Vertical Phase Adjustment on

page 20 for more information.

Internal line sync disables line lock and synchronizes cameras internally.

Set SW-1 to ON to use AC line lock. Set it to OFF for internal line sync. The default setting is ON.

SW1-3: Interlaced Scanning/Progressive Scanning

Interlaced scanning is the standard for analog recording installations. Each frame contains one odd and

one even field, each processed separately.

Progressive scanning is better for digital recording installations. Each frame is processed as a whole,

which results in less blurring and cleaner digital conversion. It also saves storage space on digital video

recorders.

Set SW1-3 to ON to select interlaced scanning. Set it to OFF to select progressive scanning. The default

setting is ON.

C3428M-A (1/08) 17

Page 18

SW1-4: Auto White Balance/Manual White Balance

Auto white balance (AWB) is enabled by default (ON).

To manually set and lock the white balance:

1. Set SW1-4 to ON.

2. Hold a white background in front of the lens until the video is all white.

3. While holding the background in place, set SW1-4 to OFF. A green block and a white block alternate

briefly on the video image until the manual white balance (MWB) process is complete.

SW1-5: Fluorescent/General

Enable this option to adjust the camera for best operation under fluorescent lighting.

Set SW1-5 to OFF for fluorescent lighting. Set it to ON for general lighting. The default setting is ON.

NOTE: If you use fluorescent operation, you should use AC line lock for best results.

SW1-6: General WDR/Maximum WDR

Maximum wide dynamic range (WDR) supports about 36 dB of additional dynamic range over a standard

camera. Use it for installations that require the maximum WDR.

General WDR supports about 20 dB of additional dynamic range over a standard camera. Use it for

installations that do not require the maximum WDR.

Set SW1-6 to ON to select maximum WDR. Set it to OFF to select general WDR. The default setting is ON.

SW1-7: Digital Slow Shutter

The default shutter speed for NTSC is 30 frames per second (fps). It is 25 fps for PAL. This is also known as

SENS 2X.

You can decrease the shutter speed to 7.5 fps (NTSC) or 6.25 fps (PAL). This is known as SENS 8X, which

improves low light sensitivity.

Set SW1-7 to ON to select SENS 2X. Set it to OFF to select SENS 8X. The default setting is ON.

18 C3428M-A (1/08)

Page 19

SW1-8: Day/Night Operation (DW models only)

NOTE: On CW models, SW1-8 is unused and does not affect camera operation.

DW model cameras regularly check the brightness level of the field of view to determine when to switch

between day (color) and night (black-white) operation. Use SW1-8 to set the general light levels at which

the camera will automatically switch.

Set SW1-8 to ON (dark) to use standard thresholds to switch between color and black-white operation.

This is the default setting.

Set SW1-8 to OFF (dusk) to use higher light thresholds to switch between color and black-white operation.

Actual brightness threshold levels are affected by camera angle, amount of zoom, field of view, lens, and

type of lighting. The switching process lasts from 7 to 10 seconds.

Figure 13 and Table D show how the camera switches between color and black-white operation for each

setting.

MODE

COLOR

B-W

MODE

RISING LIGHT LEVEL

FALLING LIGHT LEVEL

MODE

COLOR

B-W

MODE

3.0 lux

1.0 lux

MODE

COLOR

B-W

MODE

RISING LIGHT LEVEL

FALLING LIGHT LEVEL

MODE

COLOR

B-W

MODE

7.0 lux

4.0 lux

DARK

DUSK

Figure 13. DW Models Threshold Switching Levels

Tab le D . DW Models Switching Thresholds

Dark (ON) Dusk (OFF)

Color to B-W 1.0 lux 4.0 lux

B-W to Color 3.0 lux 7.0 lux

NOTE: These switching thresholds are approximate and were measured using a 3.0 mm to 9.5 mm lens at

f/1.0. Use the thresholds in Table D as a guide when installing the unit.

C3428M-A (1/08) 19

Page 20

AUTO IRIS LEVEL ADJUSTMENT

The electronics of the IS210-DW and IS210-CW Series Camclosures automatically adjust the camera to

the auto iris. Auto iris level adjustments are not necessary.

VERTICAL PHASE ADJUSTMENT

NOTE: Use this procedure for 24 VAC operation only.

When using more than one camera power supply, a brief vertical roll may occur on the monitor when

switching from one camera to another.

To eliminate vertical roll, reverse the 24 VAC connections on one camera. If both cameras are connected to

the same transformer, this should solve the problem. If the problem continues, adjust the phase control by

synchronizing, or line locking, the cameras to one another.

NOTE: When adjusting vertical phase, line sync (SW1-2) must be set to ON for AC line lock.

Adjusting Vertical Phase

You may need two people when synchronizing the cameras: one at the camera, the other at the monitor to

observe the vertical roll and the effect of any camera adjustments.

To synchronize the cameras:

1. Choose a reference camera to which all other cameras will be phased.

2. Select the camera to synchronize. Use the phase adjustment control (R7) to synchronize the camera

to the reference camera (refer to Figure 12 on page 17). Turn R7 clockwise to increase vertical

phase; turn R7 counterclockwise to decrease vertical phase.

3. Each time an adjustment is made, switch back and forth between the camera you are adjusting and

the reference camera. Repeat this process as many times as necessary until the roll between the

cameras is no longer noticeable.

4. Adjust the phase of all other cameras by repeating steps 2 and 3. Always adjust to the reference

camera selected in step 1.

NOTE: The preferred method for camera phase adjustment is to use a dual trace oscilloscope to align the

vertical sync pulses of the reference camera to the selected camera(s).

BLEMISH DETECTION

If small white or colored spots appear in the video image, one or more pixels on the camera imager may be

defective. (This condition is common for both CCD and CMOS imagers.)

DW and CW Series cameras have auto iris lenses and automatically detect and correct defective pixels

during startup. Manual pixel correction is not available.

20 C3428M-A (1/08)

Page 21

Service Connector

The IS210 Series Camclosure integrated camera system includes a service connector that outputs camera

video. Use it at the installation site to set up the field of view and focus the camera.

SERVICE

CONNECTOR

Figure 14. Service Connector

Pelco offers two optional items that plug directly into the service connector: CST150 compact field tool

and IS-SC cable.

• The optional CST150 has a 3-foot (0.9 m) cable and micro display for viewing camera video. Plug it

into the service connector and view the video.

NOTE: The three buttons on the CST150 are not used with the IS210 Series Camclosure.

• The optional IS-SC is a 4-foot (1.2 m) cable with a service connector and a BNC connector. Plug the

cable into the service connector on the IS210. Then connect the other end to any standard BNC

(VIDEO IN) connector on a monitor.

To assemble a longer service cable for the Camclosure integrated camera system, purchase the following

from a local electronics supply store:

Qty Description

1 2.5 mm monaural headphone plug

1 CPM 88 miniature coaxial connector

1 RG174/U coaxial cable

To assemble the cable:

1. Attach the CPM 88 miniature coaxial connector to one end of the cable. Follow the directions

supplied with the miniature coaxial connector.

2. Attach the 2.5 mm monaural plug to the other end of the coaxial cable (refer to Figure 15):

a. Remove the support sleeve from the plug. Slip the support sleeve over the end of the cable.

b. Prepare the cable. Solder the center connector of the cable to the center pin of the plug.

Thread the braid of the cable through the hole in the crimp pin.

c. Solder the braid to the top of the crimp pin. Crimp the end of the crimp pin around the cable.

Reassemble the support sleeve and the plug.

CENTER CONDUCTOR

COAXIAL

CABLE

BRAID (SHIELD)

2.5 MM MONAURAL

HEADPHONE PLUG

Figure 15. Attaching the 2.5 mm Monaural Headphone Plug

C3428M-A (1/08) 21

Page 22

Specifications

GENERAL

Pan/Tilt Adjustment Manual

Pan 180°

Tilt 180°

Construction Aluminum base and cover, steel camera mounting bracket

Finish Gray polyester powder coat

Environment Low temperature, indoor/outdoor

Operating Temperature -50° to 122°F (-46° to 50°C); de-ices to -10°F (-23°C)

Heater Turns on at 50°F (10°C) and off at 80°F (27°C)

Unit Weight 1.45 lb (6 kg)

ELECTRICAL

Input Voltage 12 VDC or 24 VAC, ±10%

Power Consumption 13 W or less

Video Connector BNC

(Design and product specifications subject to change without notice.)

3.84

(9.75)

UTP wires

2.14

(5.33)

3.80

(9.65)

3.43

(8.71)

3.83

(9.73)

1.51

(3.84)

1.37

(3.48)

NOTE: VALUES IN PARENTHESES ARE CENTIMETERS; ALL OTHERS ARE INCHES.

1.11

(2.82)

2.37

(6.02)

6.10

(15.27)

The materials used in the manufacture of this document and its components are compliant to the

requirements of Directive 2002/95/EC.

This equipment contains electrical or electronic components that must be recycled properly to

comply with Directive 2002/96/EC of the European Union regarding the disposal of waste electrical

and electronic equipment (WEEE). Contact your local dealer for procedures for recycling this

equipment.

22 C3428M-A (1/08)

Page 23

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, an y merchandise proved defective in material or workmanship for a period of one year after the date of

shipment.

Exceptions to this warranty are as noted below:

• Five years on fiber optic products and TW3000 Series unshielded twisted pair (UTP) transmission products.

• Three years on Spectra® IV products.

• Three years on Genex® Series products (multiplexers, server, and keyboard).

• Three years on DX Series digital video recorders, DVR5100 Series digital video recorders, DigitalSENTRY® Series hardware products, DVX Series

digital video recorders, NVR300 Series netwo rk video recorders, and Endura® Series distributed network-based video products.

• Three years on Camclosure® and Pelco-branded fixed camera models, except the CC3701 H-2, CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2,

and MC3651H-2X camera models, which ha ve a five-year warranty.

• Three years on PMCL200/300/400 Series LCD monit ors.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy®, CM6700/CM6800/CM9700 Series matrix, and DF5/DF8 Series fixed dome products.

• Two years on Spectra III™, Spectra Mini, Esprit®, ExSite®, and PS20 scanners, including when used in continuous motion applications.

• Two years on Esprit and WW5700 Series window wiper (excluding wiper blades).

• Two years (except lamp and color wheel) on Digital Light Processing (DLP®) displays. The lamp and color wheel will be covered for a period of

90 days. The air filter is not covered un der warranty.

• Two years on Intelli-M® eIDC controllers.

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be covered for a period of six months.

• Six months on all pan and tilts, scanners, or pre set lenses used in continuous motion applications (preset scan, tour, and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco shipment. All goods requiring warranty repair shall be sent

freight prepaid to a Pelco designated locatio n. Repairs made necessary by reason of misuse, alteration, normal wear, or accident are no t covered under

this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from the specific use or application made of the Products. Pelco’s

liability for any claim, whether based on breach of contract, negligence, infringement of any rights of any party or product liability, relating to the

Products shall not exceed the price paid by the Dealer to Pelco for such Products. In no event will Pelco be liable for any special, incidental, or

consequential damages (including loss of use, loss of profit, and claims of third parties) however caused, whether by the negligence of Pelco or

otherwise.

The above warranty provides the Dealer with spe cific legal rights. The Dealer may also have additional right s, which are subject to variation from state

to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or (559) 292-1981 to obtain a Repair Authorization nu mber (RA), and

provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, sales order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product that does not fall un der the warranty conditions stated above, please include a written

explanation with the product wh en returned.

Method of return shipment shall be the same or equal to the method by which the item was received by Pelco.

RETURNS

To expedite parts returned for repair or credit, please call Pelco at (800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if

returned for credit, and RA number if returned for repair) and designated return location.

All merchandise returned for credit may be subject to a 20 percent restocking and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA number and freight should be prepaid.

REVISION HISTORY

Manual # Date Comments

C3428M 12/07 Original version.

C3428M-A 1/08 Added Parts List.

Pelco, the Pelco logo, Camclosure, DigitalSENTRY, Endura, Esprit, ExSite, Genex, Intelli-M, Legacy, and Spectra are registered trademarks of Pelco, Inc.

Spectra III is a trademark of Pelco, Inc. ©Copyright 2008, Pelco, Inc. All rights reserved.

DLP is a registered trademark of Texas Instruments Incorporated.

Page 24

Worldwide Headquarters

3500 Pelco Way

Clovis, California 93612 USA

USA & Canada

Tel: 800/289-9100

Fax: 800/289-9150

International

Tel: 1-559/292-1981

Fax: 1-559/348-1120

www.pelco.com

ISO9001

Australia|Canada|Finland|France|Germany|Italy|Macau|The Netherlands|Russia|Singapore

South Africa

Spain|Sweden|United Arab Emirates|United Kingdom|United States

|

Loading...

Loading...