Pelco IPSXME136-2, IPSXME136-7, IPSXM3136-2, IPSXME036-7 User Manual

INSTALLATION

ExSite®/ExSite IP Series Explosionproof Pan/Tilt System

C1302M-H (2/11)

Contents

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Methods of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the Camera Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the Pan/Tilt Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Installing the Sun Shroud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Camera Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Camera/Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

List of Illustrations

1 Methods of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

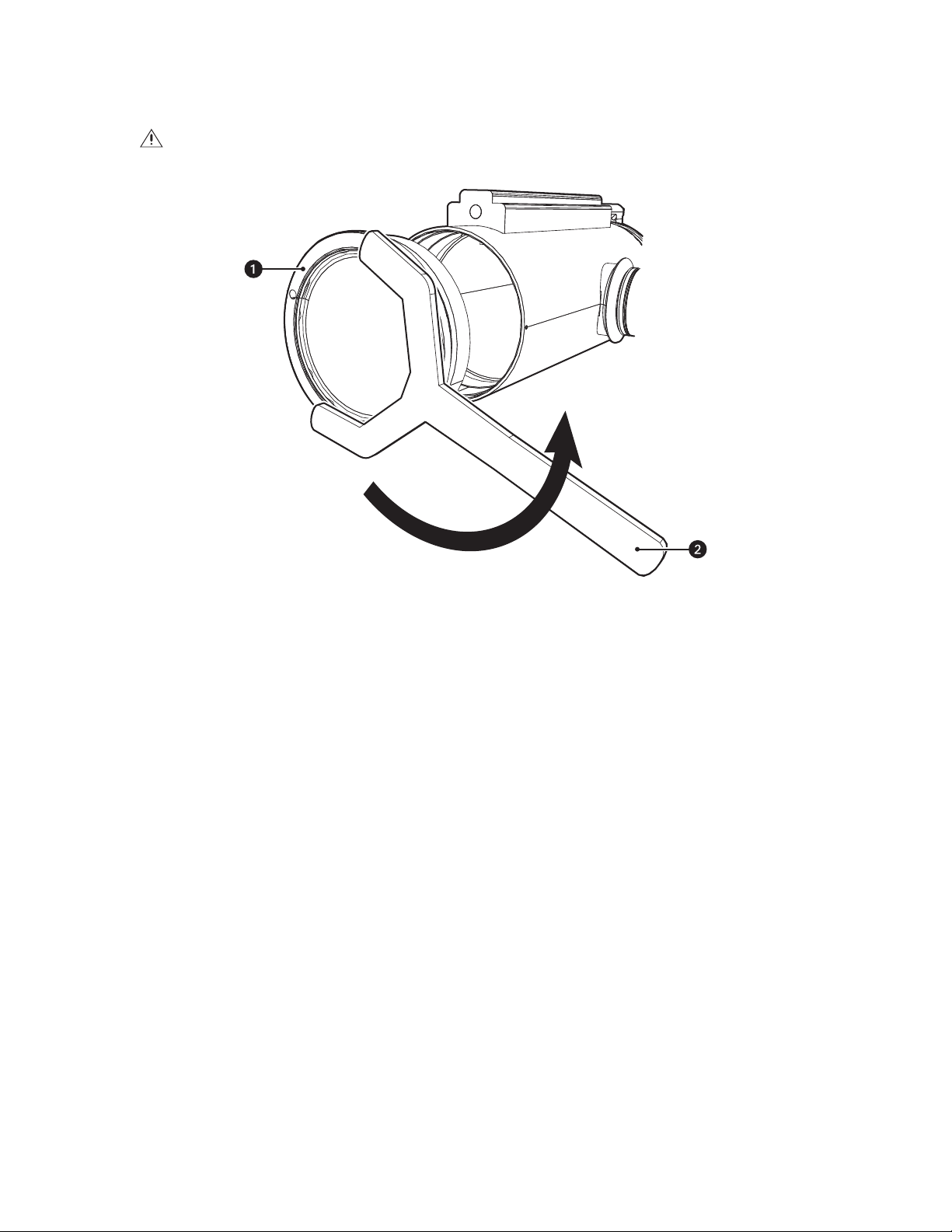

2 Loosen the Setscrew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Remove the Back Cap of the Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Install the Camera Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Center the Wiper Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

6 Install the Wiper Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7 Factory-Installed Power Module Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8 Attach the Pan/Tilt to the Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

9 Install the Sun Shroud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10 Remove the Back Cap of the Camera Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

11 Remove/Install the Camera Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

12 Install the Camera Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

13 Center the Wiper Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 C1302M-H (2/11)

Important Safety Instructions

CAUTION:

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

6. To reduce the risk of ignition of hazardous atmospheres, disconnect the equipment from the supply circuit before opening. Keep assembly

tightly closed when in operation.

7. The maximum ambient temperature range is -76° to 140°F (-60° to 60°C).

8. Only use attachments/accessories specified by the manufacturer.

9. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in any way, such as powersupply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus, the apparatus has been exposed to rain or

moisture, does not operate normally, or has been dropped.

10. Installation should be done only by qualified personnel and conform to all local codes.

11. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is designed for indoor use only and it must not

be installed where exposed to rain and moisture.

12. Use only installation methods and materials capable of supporting four times the maximum specified load.

13. Use stainless steel hardware to fasten the mount to outdoor surfaces.

14. AN ALL-POLE MAINS SWITCH with a contact separation of at least 3 mm in each pole shall be incorporated in the electrical installation of

the building.

15. A readily accessible disconnect device shall be incorporated in the building installation wiring.

16. CAUTION: These servicing instructions are for use by qualified service personnel only. To reduce the risk of electric shock do not perform

any servicing other that contained in the operating instructions unless you are qualified to do so.

17. Only use replacement parts recommended by Pelco.

18. A certified flameproof, "d," sealing device such as a stopping box with setting compound shall be provided, either in the flameproof

enclosure or immediately at the entrance thereto.

19. For ambient temperatures below 14°F ( -10°C) use field wiring suitable for both minimum and maximum ambient temperature.

The product and/or manual may bear the following marks:

WARNING: This symbol indicates that dangerous voltage constituting a risk of electric shock

is present within this unit.

This symbol indicates that there are important operating and maintenance instructions in the

literature accompanying this unit.

WARNING: HAZARDOUS MOVING PARTS. KEEP FINGERS AND OTHER BODY PARTS AWAY.

WARNING: To reduce the risk of ignition of hazardous atmospheres, disconnect the

equipment from the supply circuit before opening. Keep assembly tightly closed when

operating.

C1302M-H (2/11) 3

WARNING: To reduce the risk of ignition of hazardous atmospheres, conduit runs must have

a sealing fitting connected within 2 inches of the enclosure.

TO REDUCE THE RISK OF IGNITION DO NOT OPEN WHEN AN EXPLOSIVE GAS ATMOSPHERE

MAY BE PRESENT.

Description

ExSite®/ExSite IP Series are innovative integrated positioning systems that meet stringent explosionproof requirements, combining a receiver,

pan/tilt, and camera in a single, easy-to install package.

The ExSite IP Series system has all of the features and functionality of the analog ExSite Series and includes a built-in 100Base-TX network

interface for live streaming using a standard Web browser.

Both analog and network systems are available with a choice of power module: input voltage of 24 VAC or 100 to 240 VAC.

This manual includes instructions for installing the camera and pan/tilt unit.

WARNING: Install the ExSite IP Series power module before you install the camera and pan/tilt. For instructions on how to install the

power module, refer to the manual included with the power module .

Once the system installation is complete, refer to the operation manual available on the resource disc for instructions on how to operate and your

system.

PARTS LIST

PAN/TILT SYSTEM

Qty Description

1 Enclosure (with or without wiper)

1 Camera module

1 Sun shroud

1 Sun shroud hardware pack

2 Screws, 6-32 Phillips, pan head

2Nylon washers

1 Spanner wrench

2 Allen wrench, 1.5 mm

2 Allen wrench, 2 mm

MODELS WITH A WIPER

Qty Description

1 Wiper arm

1 Green bushing

1 Screw, 8-32 Phillips, flat head

4 C1302M-H (2/11)

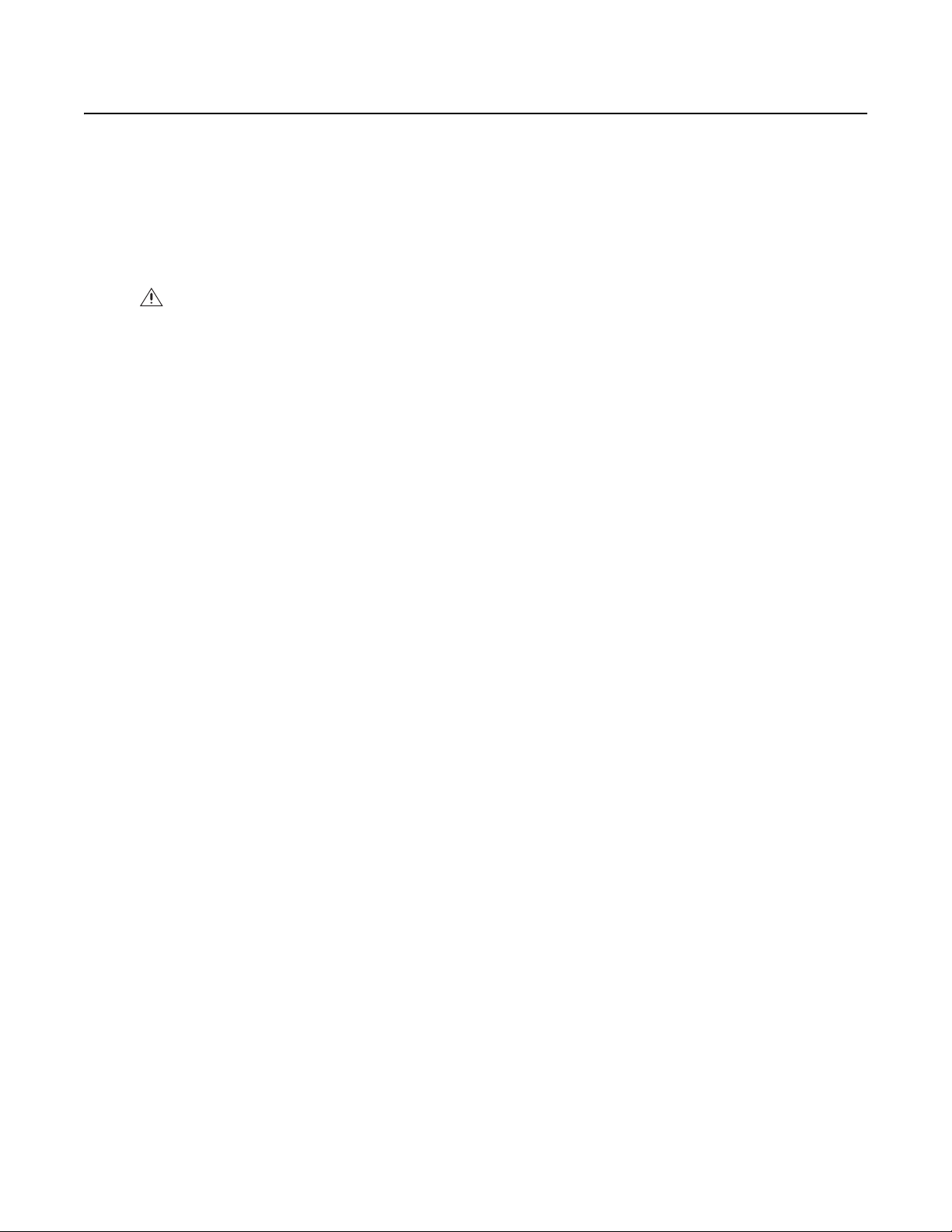

METHODS OF INSTALLATION

The system can be installed in a standard or inverted position. When installed for inverted operation, the camera oriention and controller

functions are reconfigured for normal operation through the system’s software. Hardware adjustment is not required for inverted operation.

STANDARD

INSTALLATION

Figure 1. Standard and Inverted Installations

WARNING: The total weight of the pan/tilt component is 25 kg (55 lb). Use caution when lifting and assembling the pan/tilt component on

the power module. It is recommended that non-slip gloves be worn during installation.

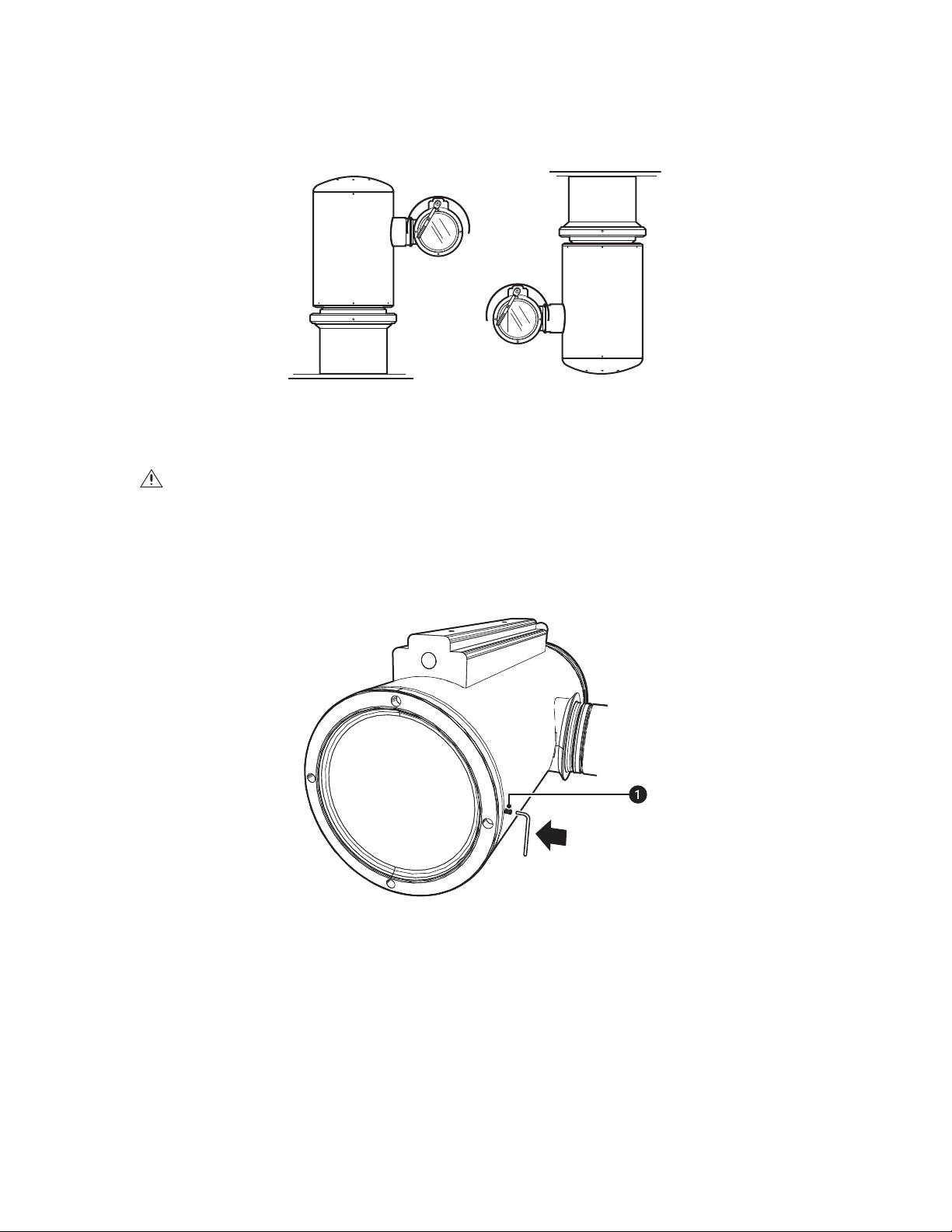

Installing the Camera Module

1. Loosen the setscrew at the back of the enclosure with the 1.5 mm Allen wrench (supplied).

INVERTED

INSTALLATION

Figure 2. Loosen the Setscrew

ì

Setscrew

C1302M-H (2/11) 5

2. Use the spanner wrench (supplied) to loosen the back of the camera enclosure (refer to Figure 3). Once the back is loose, use your hands to

continue to loosen it until it can be removed.

WARNING: To avoid thread damage, carefully remove the back of the camera enclosure. Never use force to remove the back of the

camera enclosure.

Figure 3. Remove the Back Cap of the Enclosure

ì

Back Cap of Enclosure

î

Spanner Wrench

6 C1302M-H (2/11)

Loading...

Loading...