INSTALLATION

ExSite®/ExSite IP Series Explosionproof Pan/Tilt System

C1302M-H (2/11)

Contents

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Methods of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the Camera Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the Pan/Tilt Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Installing the Sun Shroud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Camera Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Camera/Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

List of Illustrations

1 Methods of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

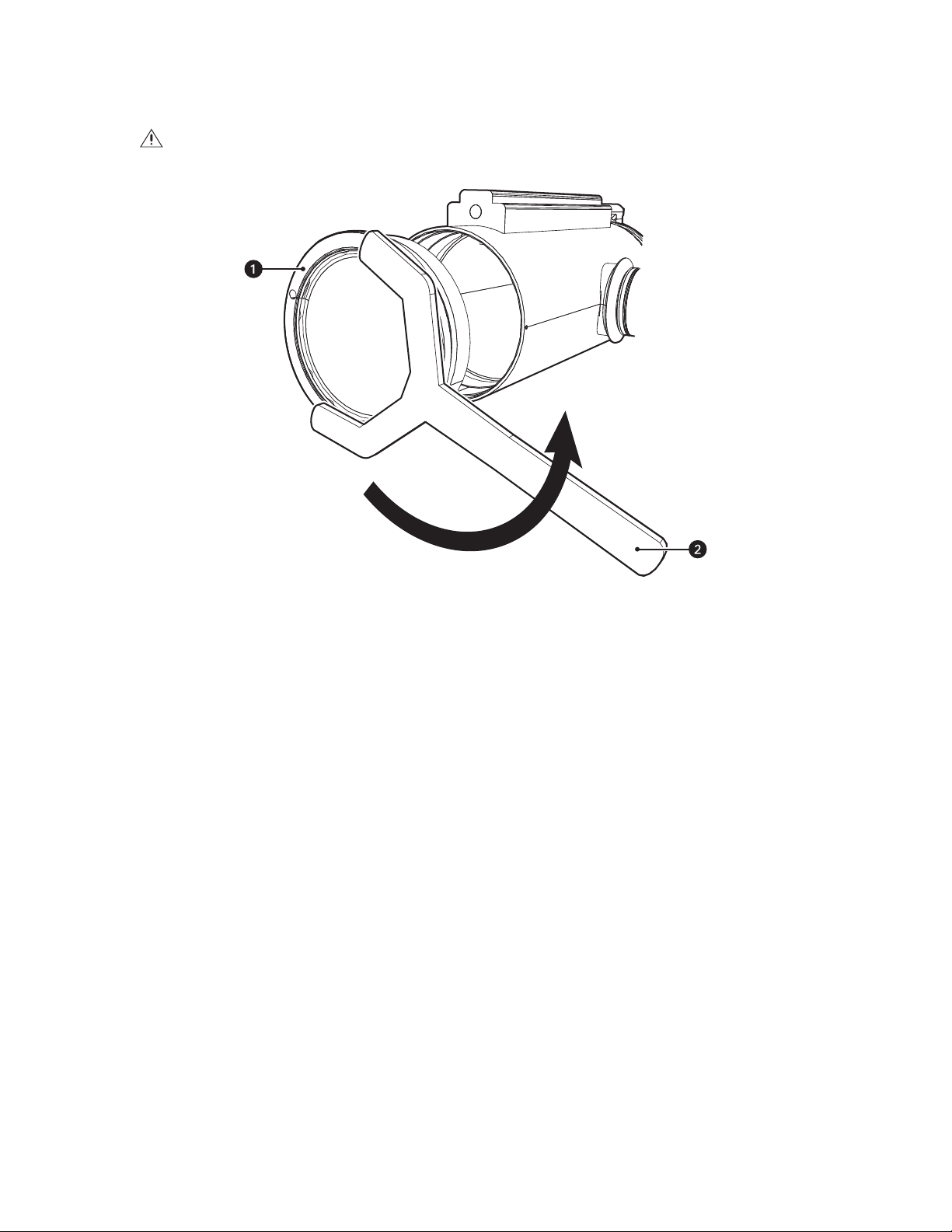

2 Loosen the Setscrew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Remove the Back Cap of the Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Install the Camera Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Center the Wiper Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

6 Install the Wiper Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7 Factory-Installed Power Module Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8 Attach the Pan/Tilt to the Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

9 Install the Sun Shroud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10 Remove the Back Cap of the Camera Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

11 Remove/Install the Camera Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

12 Install the Camera Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

13 Center the Wiper Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 C1302M-H (2/11)

Important Safety Instructions

CAUTION:

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

6. To reduce the risk of ignition of hazardous atmospheres, disconnect the equipment from the supply circuit before opening. Keep assembly

tightly closed when in operation.

7. The maximum ambient temperature range is -76° to 140°F (-60° to 60°C).

8. Only use attachments/accessories specified by the manufacturer.

9. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in any way, such as powersupply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus, the apparatus has been exposed to rain or

moisture, does not operate normally, or has been dropped.

10. Installation should be done only by qualified personnel and conform to all local codes.

11. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is designed for indoor use only and it must not

be installed where exposed to rain and moisture.

12. Use only installation methods and materials capable of supporting four times the maximum specified load.

13. Use stainless steel hardware to fasten the mount to outdoor surfaces.

14. AN ALL-POLE MAINS SWITCH with a contact separation of at least 3 mm in each pole shall be incorporated in the electrical installation of

the building.

15. A readily accessible disconnect device shall be incorporated in the building installation wiring.

16. CAUTION: These servicing instructions are for use by qualified service personnel only. To reduce the risk of electric shock do not perform

any servicing other that contained in the operating instructions unless you are qualified to do so.

17. Only use replacement parts recommended by Pelco.

18. A certified flameproof, "d," sealing device such as a stopping box with setting compound shall be provided, either in the flameproof

enclosure or immediately at the entrance thereto.

19. For ambient temperatures below 14°F ( -10°C) use field wiring suitable for both minimum and maximum ambient temperature.

The product and/or manual may bear the following marks:

WARNING: This symbol indicates that dangerous voltage constituting a risk of electric shock

is present within this unit.

This symbol indicates that there are important operating and maintenance instructions in the

literature accompanying this unit.

WARNING: HAZARDOUS MOVING PARTS. KEEP FINGERS AND OTHER BODY PARTS AWAY.

WARNING: To reduce the risk of ignition of hazardous atmospheres, disconnect the

equipment from the supply circuit before opening. Keep assembly tightly closed when

operating.

C1302M-H (2/11) 3

WARNING: To reduce the risk of ignition of hazardous atmospheres, conduit runs must have

a sealing fitting connected within 2 inches of the enclosure.

TO REDUCE THE RISK OF IGNITION DO NOT OPEN WHEN AN EXPLOSIVE GAS ATMOSPHERE

MAY BE PRESENT.

Description

ExSite®/ExSite IP Series are innovative integrated positioning systems that meet stringent explosionproof requirements, combining a receiver,

pan/tilt, and camera in a single, easy-to install package.

The ExSite IP Series system has all of the features and functionality of the analog ExSite Series and includes a built-in 100Base-TX network

interface for live streaming using a standard Web browser.

Both analog and network systems are available with a choice of power module: input voltage of 24 VAC or 100 to 240 VAC.

This manual includes instructions for installing the camera and pan/tilt unit.

WARNING: Install the ExSite IP Series power module before you install the camera and pan/tilt. For instructions on how to install the

power module, refer to the manual included with the power module .

Once the system installation is complete, refer to the operation manual available on the resource disc for instructions on how to operate and your

system.

PARTS LIST

PAN/TILT SYSTEM

Qty Description

1 Enclosure (with or without wiper)

1 Camera module

1 Sun shroud

1 Sun shroud hardware pack

2 Screws, 6-32 Phillips, pan head

2Nylon washers

1 Spanner wrench

2 Allen wrench, 1.5 mm

2 Allen wrench, 2 mm

MODELS WITH A WIPER

Qty Description

1 Wiper arm

1 Green bushing

1 Screw, 8-32 Phillips, flat head

4 C1302M-H (2/11)

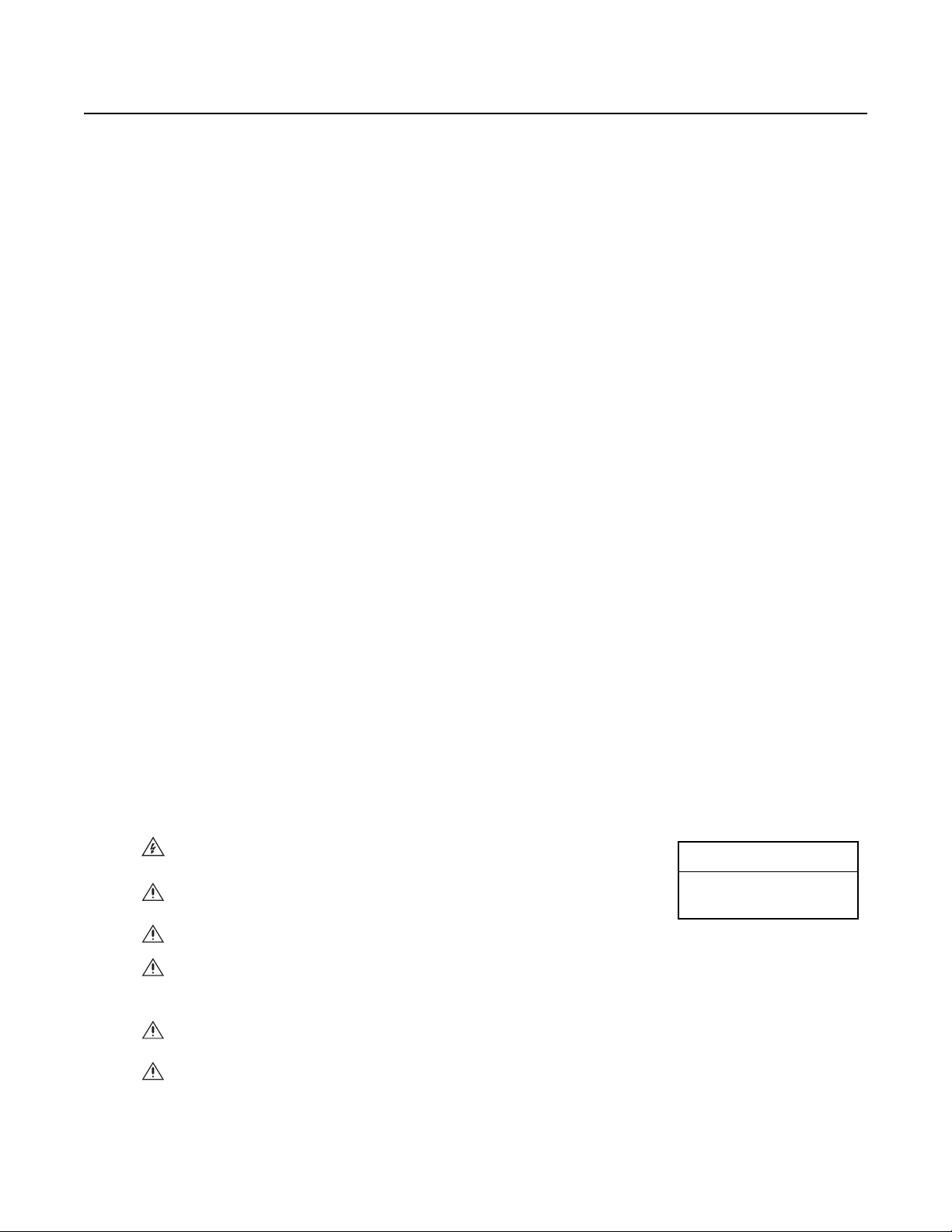

METHODS OF INSTALLATION

The system can be installed in a standard or inverted position. When installed for inverted operation, the camera oriention and controller

functions are reconfigured for normal operation through the system’s software. Hardware adjustment is not required for inverted operation.

STANDARD

INSTALLATION

Figure 1. Standard and Inverted Installations

WARNING: The total weight of the pan/tilt component is 25 kg (55 lb). Use caution when lifting and assembling the pan/tilt component on

the power module. It is recommended that non-slip gloves be worn during installation.

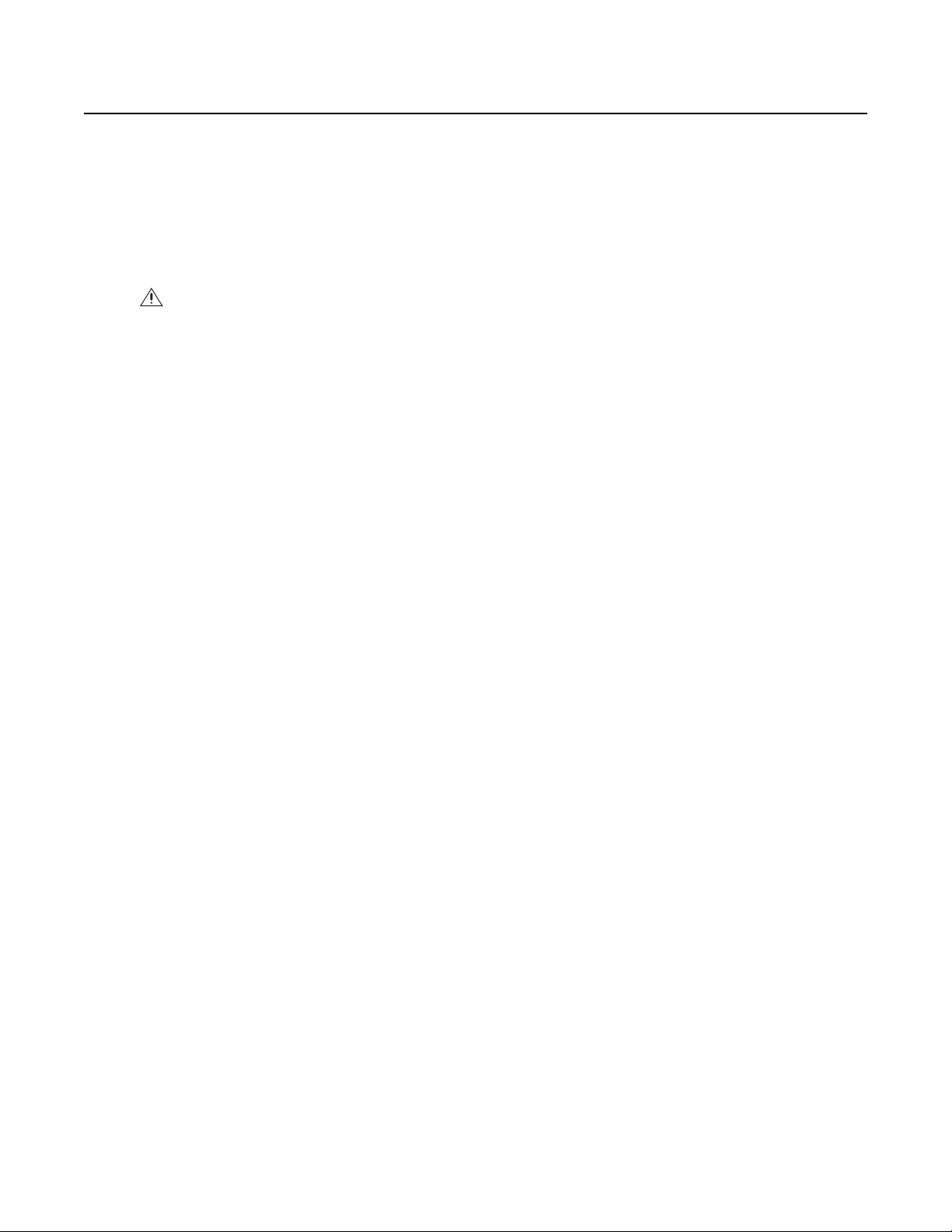

Installing the Camera Module

1. Loosen the setscrew at the back of the enclosure with the 1.5 mm Allen wrench (supplied).

INVERTED

INSTALLATION

Figure 2. Loosen the Setscrew

ì

Setscrew

C1302M-H (2/11) 5

2. Use the spanner wrench (supplied) to loosen the back of the camera enclosure (refer to Figure 3). Once the back is loose, use your hands to

continue to loosen it until it can be removed.

WARNING: To avoid thread damage, carefully remove the back of the camera enclosure. Never use force to remove the back of the

camera enclosure.

Figure 3. Remove the Back Cap of the Enclosure

ì

Back Cap of Enclosure

î

Spanner Wrench

6 C1302M-H (2/11)

3. Slide the camera module into the enclosure. Refer to Figure 4 to position the camera module properly in the enclosure.

(Models with a wiper) The tab located inside the enclosure must be pointing down before installing the camera module (refer to Figure 4). To

position the tab, place the wiper blade (located at the front of the enclosure) in the center of the viewing window (refer to Figure 5).

WARNING: Do not force the camera module into the enclosure.

4. Carefully mate the camera’s power connector to the mating connector located inside the enclosure.

ì

Camera Module

î

Center Notches

Figure 4. Install the Camera Module

ï

Enclosure Tab

ñ

Camera Enclosure

Figure 5. Center the Wiper Blade

ì

Wiper Blade

C1302M-H (2/11) 7

5. (Models with a wiper) Install the wiper arm (refer to Figure 6).

a. Place the green bushing (supplied with wiper models) on the stud located behind the handle of the camera module. The bushing

should be in the same orientation as shown in Figure 6.

b. Place the ridge of the wiper arm in the notch of the enclosure tab, and then place the slot of the wiper arm over the green bushing.

6. Secure the wiper arm with the 8-32 Phillips flat head screw (supplied with wiper models).

Figure 6. Install the Wiper Arm

ì

Enclosure Tab

î

8-32 Phillips Flat Head Screw

ï

Wiper Arm

ñ

Camera Module Handle

ó

Green Bushing

r

Stud

WARNINGS:

• To avoid thread damage, carefully install the back cap on the enclosure.

• Never force the back cap onto the end of the enclosure.

• When installation is completed, there should be no gap between the back cap and the enclosure.

7. Reinstall the back cap on the enclosure:

a. Using your hands, turn the back cap clockwise until you can no longer turn it. The back cap should turn easily until it comes in contact

with the O-ring. If it does not turn easily, the threads are not aligned and thread damage will occur.

b. Continue tightening the back cap with the spanner wrench (supplied). There should be no gap between the back cap and the enclosure

when the back cap is tightened and properly installed.

c. Once the back cap is installed, secure the back cap with the setscrew using the 1.5 mm Allen wrench (supplied).

8 C1302M-H (2/11)

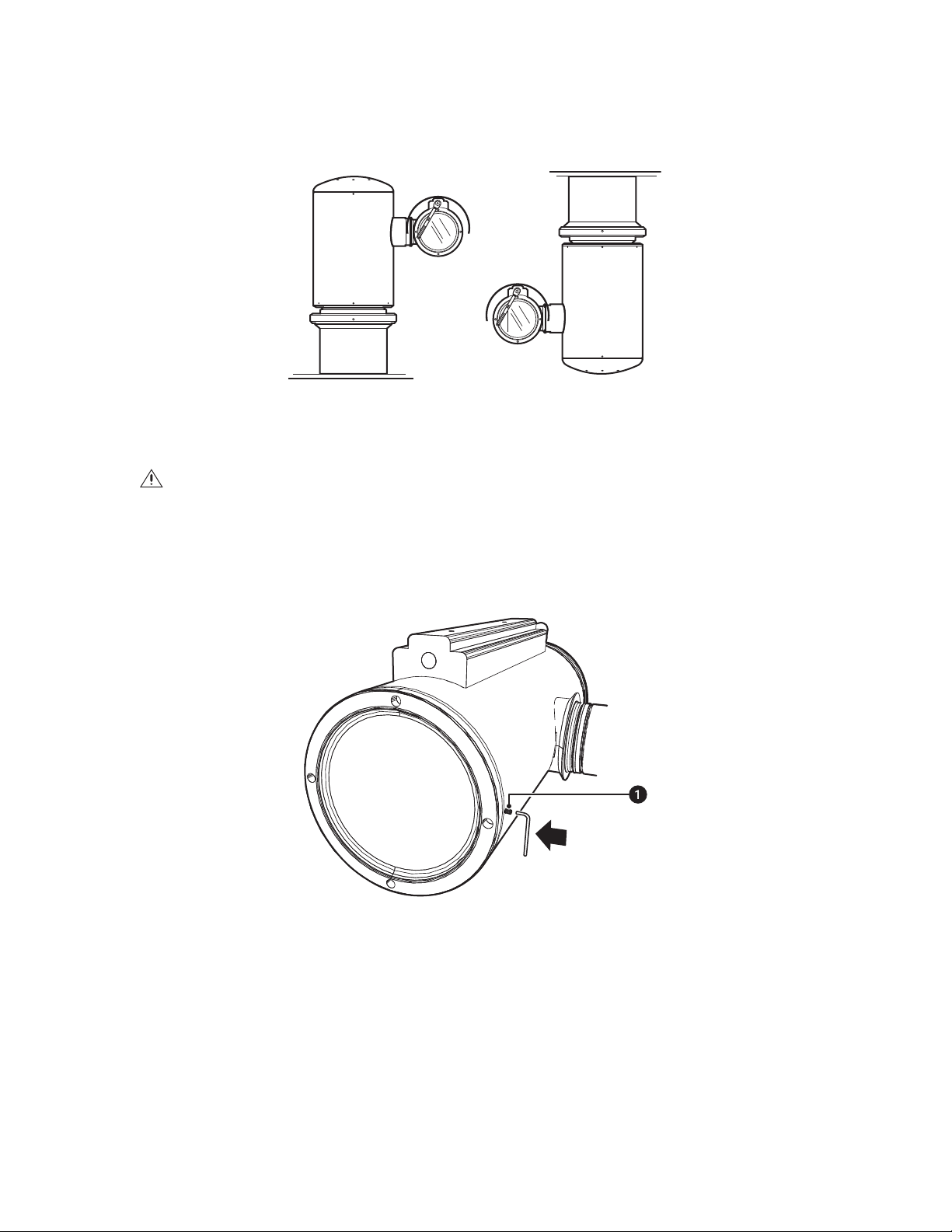

Installing the Pan/Tilt Unit

1. Verify that the power module seal is properly seated in the groove on the top of the power module.

Figure 7. Factory-Installed Power Module Seal

WARNING: Use caution when attaching the enclosure unit to the power module. If the grooves on the top of the power module are

damaged, the integrity of the unit could be compromised.

2. Attach the pan/tilt unit to the power module.

a. Align the pins on the pan/tilt unit with the holes on the power module.

b. Carefully mate the pan/tilt connector to the power module connector.

ì

Power Module Seal

î

Power Module

Figure 8. Attach the Pan/Tilt to the Power Module

ì

Locking Ring

î

Pins

ï

Holes

C1302M-H (2/11) 9

WARNINGS:

• Total weight of the pan/tilt component is 25 kg (55 lb). Use caution when lifting and assembling the pan/tilt component on the power

module.

• The weight of the pan/tilt unit must be safely supported during installation.

• It is recommended that non-slip gloves be worn during installation.

• Avoid thread damage. Never use force when assembling and tightening the threaded components of the system.

3. Using your hands, carefully thread the pan/tilt locking ring onto the threads of the power module until the threads are completely engaged

and can no longer be tightened by hand.

4. Using the spanner wrench (supplied), continue to tighten the locking ring.

5. Tap the spanner wrench handle with a hammer or the palm of your hand to ensure a secure fit.

6. Tighten the locking ring setscrew with the 2 mm Allen wrench (supplied) to secure the assembly.

10 C1302M-H (2/11)

Installing the Sun Shroud

1. Align the mounting holes on the sun shroud with the holes on top of the enclosure.

2. Insert the the nylon washers (supplied with sun shroud hardware pack) and the 6-32 Phillips pan head screws (supplied with sun shroud

hardware pack) into the mounting holes (refer to Figure 9).

3. Tighten the screws to secure the sun shroud to the enclosure.

Figure 9. Install the Sun Shroud

ì

Sun Shroud

î

Nylon Washers

ï

6-32 Phillips Pan Head Screws

C1302M-H (2/11) 11

Maintenance

CAMERA MODULE REPLACEMENT

WARNING: To reduce the risk of ignition of hazardous atmospheres, disconnect the equipment from the power supply before opening.

Keep the assembly tightly closed when operating.

To replace the camera module:

1. Remove the back cap of the camera enclosure (refer to Figure 10).

a. Loosen the setscrew with a 1.5 mm Allen wrench (supplied).

b. Use the spanner wrench (supplied) to loosen the back cap of the camera enclosure. Once the back cap is loose, use your hands to

continue to loosen it until it can be removed.

Figure 10. Remove the Back Cap of the Camera Enclosure

ì

Back Cap of Enclosure

î

Spanner Wrench

ï

Setscrew

12 C1302M-H (2/11)

2. (Models with wiper) Remove the 8-32 Phillips flat head screw (supplied with wiper models) that secures the wiper inside the enclosure.

3. (Models with wiper) Remove the wiper arm and the green bushing (supplied with optional wiper kit) from the unit.

4. Slide the camera module out of the enclosure.

Figure 11. Remove/Install the Camera Module

ì

Enclosure Tab

î

8-32 Phillips Flat Head Screw

ï

Wiper Arm

ñ

Camera Module Handle

ó

Green Bushing

r

Stud

C1302M-H (2/11) 13

5. Slide the replacement camera module into the enclosure (refer to Figure 12).

WARNING: Never force the camera module into the enclosure.

(Models with a wiper) The tab located inside the enclosure must be pointing down before installing the camera module (refer to Figure 12).

To position the tab, place the wiper blade (located at the front of the enclosure) in the center of the viewing window (refer to Figure 13).

6. Carefully mate the camera’s power connector to the mating connector located inside the enclosure.

ì

Camera Module

î

Center Notches

Figure 12. Install the Camera Module

ï

Enclosure Tab

ñ

Camera Enclosure

Figure 13. Center the Wiper Blade

ì

Wiper Blade

14 C1302M-H (2/11)

7. (Models with a Wiper) Reinstall the wiper arm (refer to Figure 11 on page 13).

a. Reinstall the green bushing on the stud located behind the handle of the camera module.

b. Place the ridge of the wiper arm in the notch of the enclosure tab, and then place the slot of the wiper arm over the green bushing.

8. Secure the camera module and the wiper arm with the 8-32 Phillips flat head screw (refer to Figure 11 on page 13).

WARNINGS:

• To avoid thread damage, carefully install the back cap on the enclosure.

• Never force the back cap onto the end of the enclosure.

• When installation is completed, there should be no gap between the back cap and the enclosure.

9. Reinstall the back cap on the enclosure:

a. Using your hands, turn the back cap clockwise until you can no longer turn it. The back cap should turn easily until it comes in contact

with the O-ring. If it does not turn easily, the threads are not aligned and thread damage will occur.

b. Continue tightening the back cap with the spanner wrench (supplied). There should be no gap between the back cap and the enclosure

when the back cap is tightened and properly installed.

c. After the back cap is installed, secure the back cap with the setscrew using a 1.5 mm Allen wrench (supplied).

C1302M-H (2/11) 15

Specifications

14.07

(5.54)

42.01

(16.54)

29.21 (11.5)

18.08

(7.12)

12.47

(4.91)

13.03

(5.13)

33.37 (13.14)

1.91 NPT

(0.75)

ELECTRICAL

Input Voltage 24 VAC or 100 to 240 VAC, 50/60 Hz

Input Voltage Range ±10%

Power Consumption Maximum 60 W (120 VA) per system

Electrical Connections 6-foot wire harness with connections for power, video, data control, alarm inputs, and auxiliary outputs

MECHANICAL

Cable Entry One 1.91 cm (0.75-inch) NPT threaded opening

Pan Movement 360° continuous pan rotation

Vertical Tilt Unobstructed +90° to –90°

Variable Speeds

Pan 0.1° to 40°/sec variable-speed operation

Tilt 0.1° to 40°/sec variable-speed operation

Preset Speeds

Pan 40°/sec

Tilt 40°/sec

GENERAL

Construction 316L stainless steel

Finish Electropolish

Viewing Window 12.7 mm (0.50-inch) thick, soda-lime tempered glass

Operating Temperature –60° to 60°C (–76° to 140°F)

Unit Weight 25 kg (55 lb)

Effective Projected Area (EPA) 40.8 square inches

NOTE: VALUES IN PARENTHESES ARE INCHES; ALL OTHERS ARE CENTIMETERS.

CS. TYP.

4 PL

10MM - 1.5MM X 14MM

ON A 4.75-INCH DIA. B.C.

EQUALLY SPACED

8.52

(3.354)

16 C1302M-H (2/11)

CAMERA/OPTICS

Camera Day/Night (23X) Color LowLight™ (22X) Color

Signal Format NTSC, PAL NTSC, PAL

Scanning System 2:1 Interlace 2:1 Interlace

Image Sensor 1/4-inch progressive scan CCD 1/4-inch EXview HAD

Effective pixels

NTSC

PAL

Horizontal Resolution

NTSC

PAL

768 (H) x 494 (V)

752 (H) x 582 (V)

540 TV lines

540 TV lines

768 (H) x 494 (V)

752 (H) x 582 (V)

>470 TV lines

>460 TV lines

Lens f/1.6 (focal length, 3.6 ~ 82.8 mm optical) f/1.6 (focal length, 4 ~ 88 mm optical)

Zoom 23X optical, 12X digital 22X optical, 12X digital

Zoom Speed 2.9/4.2/5.8 seconds 2.4/3.9/6.3 seconds

Horizontal 54° at 3.6 mm wide zoom 47° at 4 mm wide zoom

Angle of view 2.5° at 82.8 mm telephoto zoom 2.2° at 88 mm telephoto zoom

Focus Automatic with manual override Automatic with manual override

Maximum Sensitivity

at 35 IRE

NTSC

0.025 lux at 1/2 sec shutter (color)

0.02 lux at 1/2 sec shutter

0.1 lux at 1/60 sec shutter (B-W)

0.004 lux at 1/2 sec shutter (B-W)

PAL

0.025 lux at 1/1.5 sec shutter (color)

0.02 lux at 1/1.5 sec shutter

0.1 lux at 1/50 sec shutter (B-W)

0.004 lux at 1/1.5 sec shutter (B-W)

Sync System

Internal/AC line lock, phase adjustable using

remote control, V-Sync*

Internal/AC line lock, phase adjustable using

remote control, V-Sync*

White Balance Automatic with manual override* Automatic with manual override*

Shutter Speed

NTSC

PAL

Automatic (electronic iris)/Manual

1/2 ~ 1/30,000*

1/1.5 ~ 1/30,000*

Automatic (electronic iris)/Manual

1/2 ~ 1/30,000*

1/1.5 ~ 1/30,000*

Iris Control Automatic Iris Control with manual override* Automatic Iris Control with manual override*

Gain Control Automatic/OFF* Automatic/OFF*

Video Output 1 Vp-p, 75 ohms 1 Vp-p, 75 ohms

Video Signal to Noise >50 dB >50 dB

™

CCD

*(Analog Models only) Manual control of camera setup functions can be done with CM6700, CM6800, CM8500, CM9500, CM9740,

CM9760, CM9770, CM9780, KBD200A, KBD300A, and MPT9500 controllers. It cannot be done with CM7500, MPT9000, or KBD9000

controllers.

C1302M-H (2/11) 17

VIDEO (ExSite IP Models Only)

Video Encoding H.264 base profile, MPEG-4, and MJPEG

Video Streams Up to 2 simultaneous streams; the second stream is variable based on the setup of the primary stream

Frame Rate Up to 30, 25, 24, 15, 12.5, 12, 10, 8, 7. 5, 6, 5, 4, 3, 2.5, 2, 1

(dependent upon coding, resolution, and stream configuration)

Available Resolutions

Resolution

Width Height Format

704 480 NTSC 30 ips 5.4 Mbps 30 ips 1.9 Mbps 30 ips 2.0 Mbps

352 240 NTSC 30 ips 1.3 Mbps 30 ips 0.5 Mbps 30 ips 0.6 Mbps

704 576 PAL 25 ips 5.4 Mbps 25 ips 1.9 Mbps 25 ips 2.0 Mbps

Supported Protocols TCP/IP, UDP/IP (Unicast, Multicast IGMP), UPnP, DNS, DHCP, RTP, RTSP, NTP, IPv4, SNMP, QOS, HTTP,

HTTPS, LDAP (client), SSH, SSL, SMTP, FTP, mDNS (Bonjour

MJPEG H.264 Base Profile MPEG-4

Maximum

IPS

Recommended

Bit Rate

Maximum

IPS

®

), and 802.1x (EAP)

Recommended

Bit Rate

Maximum

IPS

Recommended

Bit Rate

Users

Unicast Up to 20 simultaneous users depending on resolution settings (2 guaranteed streams)

Multicast Unlimited users H.264 or MPEG-4

Security Access Password protected

Software Interface Web browser view and setup, up to 16 cameras

Pelco System Integration Endura

®

1.5 or later (MPEG-4) or Endura 2.0 or later (H.264); Digital Sentry® 4.2 IP bundle 3 or later;

DX8100 Series 2.0 or later; and DVR5100 version 1.5.4 or later

Open IP Integration Pelco IP camera API

Minimum System Requirements

Processor Intel

®

Pentium® 4 microprocessor, 1.6 GHz

Operating System Microsoft® Windows® XP, Windows Vista®, Windows 7® or Mac® OS X 10.4 (or later)

Memory 512 MB RAM

Network Interface Card 100 megabits (or greater)

Monitor Minimum of 1024 x 768 resolution, 16- or 32-bit pixel color resolution

Web Browser* Internet Explorer® 7.0 (or later) or Mozilla® Firefox® 3.0 (or later)

Media Player

†

Pelco Media Player or QuickTime® 7.6.5 for Windows XP, Windows Vista, or

QuickTime 7.6.4 for Mac OS X 10.4

*Internet Explorer is not supported by Mac OS X 10.4.

†

This product is not compatible with QuickTime version 7.6.4 for Windows XP or Windows Vista. If you have this version installed on your PC, you

will need to upgrade to QuickTime version 7.6.5.

18 C1302M-H (2/11)

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in

material or workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

• Five years:

– Fiber optic products

– Unshielded Twisted Pair (UTP) transmission products

– CC3701H-2, CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2, and

MC3651H-2X camera models

• Three years:

– Pelco-designed fixed network cameras and network dome cameras with

™

technology.

Sarix

– Pelco-branded fixed camera models (CCC1390H Series, C10DN Series,

C10CH Series, and IP3701H Series)

– EH1500 Series enclosures

– Spectra

– Camclosure

– DX Series digital video recorders (except DX9000 Series which is covered

– Endura

– Genex

– PMCL200/300/400 Series LCD monitors

– PMCL5xx Series FHD monitors

• Two years:

– Standard varifocal, fixed focal, and motorized zoom lenses

– DF5/DF8 Series fixed dome products

– Legacy

– Spectra III

– Esprit Ti and TI2500 Series thermal imaging products

– Esprit and WW5700 Series window wiper (excluding wiper blades).

– CM6700/CM6800/CM9700 Series matrix

– Digital Light Processing (DLP

– Intelli-M

• One year:

– Video cassette recorders (VCRs), except video heads. Video heads will be

®

IV products (including Spectra IV IP)

®

Series (IS, ICS, IP) integrated camera systems

for a period of one year), DVR5100 Series digital video recorders, Digital

®

Sentry

Series hardware products, DVX Series digital video recorders, and

NVR300 Series network video recorders

®

Series distributed network-based video products

®

Series products (multiplexers, server, and keyboard)

®

Series integrated positioning systems

™

, Spectra Mini, Spectra Mini IP, Esprit®, ExSite®, and PS20

scanners, including when used in continuous motion applications.

®

) displays (except lamp and color wheel). The

lamp and color wheel will be covered for a period of 90 days. The air filter is

not covered under warranty.

®

eIDC controllers

covered for a period of six months.

•Six months:

– All pan and tilts, scanners, or preset lenses used in continuous motion

applications (preset scan, tour, and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of

Pelco shipment. All goods requiring warranty repair shall be sent freight prepaid

to a Pelco designated location. Repairs made necessary by reason of misuse,

alteration, normal wear, or accident are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss

resulting from the specific use or application made of the Products. Pelco’s liability

for any claim, whether based on breach of contract, negligence, infringement of

any rights of any party or product liability, relating to the Products shall not exceed

the price paid by the Dealer to Pelco for such Products. In no event will Pelco be

liable for any special, incidental, or consequential damages (including loss of use,

loss of profit, and claims of third parties) however caused, whether by the

negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may

also have additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or

(559) 292-1981 to obtain a Repair Authorization number (RA), and provide the

following information:

1. Model and serial number

2. Date of shipment, P.O. number, sales order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product that does not fall under

the warranty conditions stated above, please include a written explanation with

the product when returned.

Method of return shipment shall be the same or equal to the method by which the

item was received by Pelco.

RETURNS

To expedite parts returned for repair or credit, please call Pelco at (800) 289-9100

or (559) 292-1981 to obtain an authorization number (CA number if returned for

credit, and RA number if returned for repair) and designated return location.

All merchandise returned for credit may be subject to a 20 percent restocking and

refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned

CA or RA number and freight should be prepaid.

2-10-10

The materials used in the manufacture of this document and its components are compliant to the requirements of Directive 2002/95/EC.

This equipment contains electrical or electronic components that must be recycled properly to comply with Directive 2002/96/EC of the European Union

regarding the disposal of waste electrical and electronic equipment (WEEE). Contact your local dealer for procedures for recycling this equipment.

REVISION HISTORY

Manual # Date Comments

C1302M 11/04 Original version.

C1302M-A 2/05 Added 24 VAC power supply information per ECO 04-10256. Added maintenance section for camera module replacement.

C1302M-B 5/05 Changed wire color for Alarm COM per ECO 05-11019. Added warning to provide access to TX+ and TX- wires for software upgrade.

C1302M-C 7/05 Revised dimension drawing per ECO 05-11303.

C1302M-D 7/06 Updated for new factory-installed power module seal (ECO 06-14300). Revised power module installation instructions. Removed Figure 3.

C1302M-E 10/06 Removed color reference to power module seal (ECO 06-14300). Added power module warning. Added Figure 9.

C1302M-F 11/08 Changed camera specs per CN22046.

C1302M-G 7/09 Updated Important Safety Instructions section and added product certifications; UL certification requirement. Reference CN22827.

C1302M-H 2/11 Updated manual for ExSite IP release. Removed power module installation information. Created separate power module installation manuals: one for ExSite analog

Pelco, the Pelco logo, and other trademarks associa ted with Pelco products referred to in this publication are trademarks of Pelco, Inc. or its affilia tes. © Copyright 2011, Pelco, Inc.

All other product names and services are the property of their respective companies. All rights reserved.

Product specifications and availability are subject to change without notice.

models and one for ExSite IP models.

www.pelco.com

Pelco by Schneider Electric 3500 Pelco Way Clovis, California 93612-5699 United States

USA & Canada Tel (800) 289-9100 Fax (800) 289-9150

International Tel +1 (559) 292-1981 Fax +1 (559) 348-1120

Loading...

Loading...