Page 1

®

Inter-Check ICI1000S Series

Cash Register Interface System

®

™

Installation/Operation Manual

C1000M-B (1/96)

PELCO • 3500 Pelco Way, Clovis, CA 93612-5699 • USA • (800) 289-9100 or (1-559) 292-1981

FAX (800) 289-9150 or (1-559) 292-3827

Page 2

TABLE OF CONTENTS

Section Page

1.0 WARNINGS........................................................................................................................................1

2.0 SCOPE...............................................................................................................................................2

2.1 DESCRIPTION .........................................................................................................................2

3.0 INSTALLATION...................................................................................................................................3

3.1 INST ALLING INTERF ACE CABLE ...........................................................................................3

3.2 BASIC INST ALLA TIONS...........................................................................................................3

3.3 VIDEO ADJUSTMENTS ...........................................................................................................6

4.0 INTER-CHECK ON-BOARD KEYP AD OPERATION..........................................................................7

4.1 PROGRAMMING THE ICI1000SI .............................................................................................7

4.2 THE NV MEMORY WRITE PROTECT SWITCH......................................................................7

4.3 CHANNEL SETUP....................................................................................................................9

4.3.1 Communication Setup .................................................................................................9

4.3.2 Communication Parameters ........................................................................................9

4.3.3 Device Addresses ......................................................................................................10

4.4 DA T A FORMAT/COMMUNICATION PROTOCOL...................................................................10

4.5 VIDEO PARAMETERS ...........................................................................................................11

4.6 SYSTEM PARAMETERS........................................................................................................11

4.6.1 Alarm Output .............................................................................................................11

4.6.2 Carriage Return Control ............................................................................................12

4.6.3 Camera Screen Data Position ...................................................................................12

4.6.4 Printer Settings ..........................................................................................................12

4.6.5 Exception Alarm Settings ..........................................................................................13

4.6.6 Exception Alarm Text Edit ..........................................................................................14

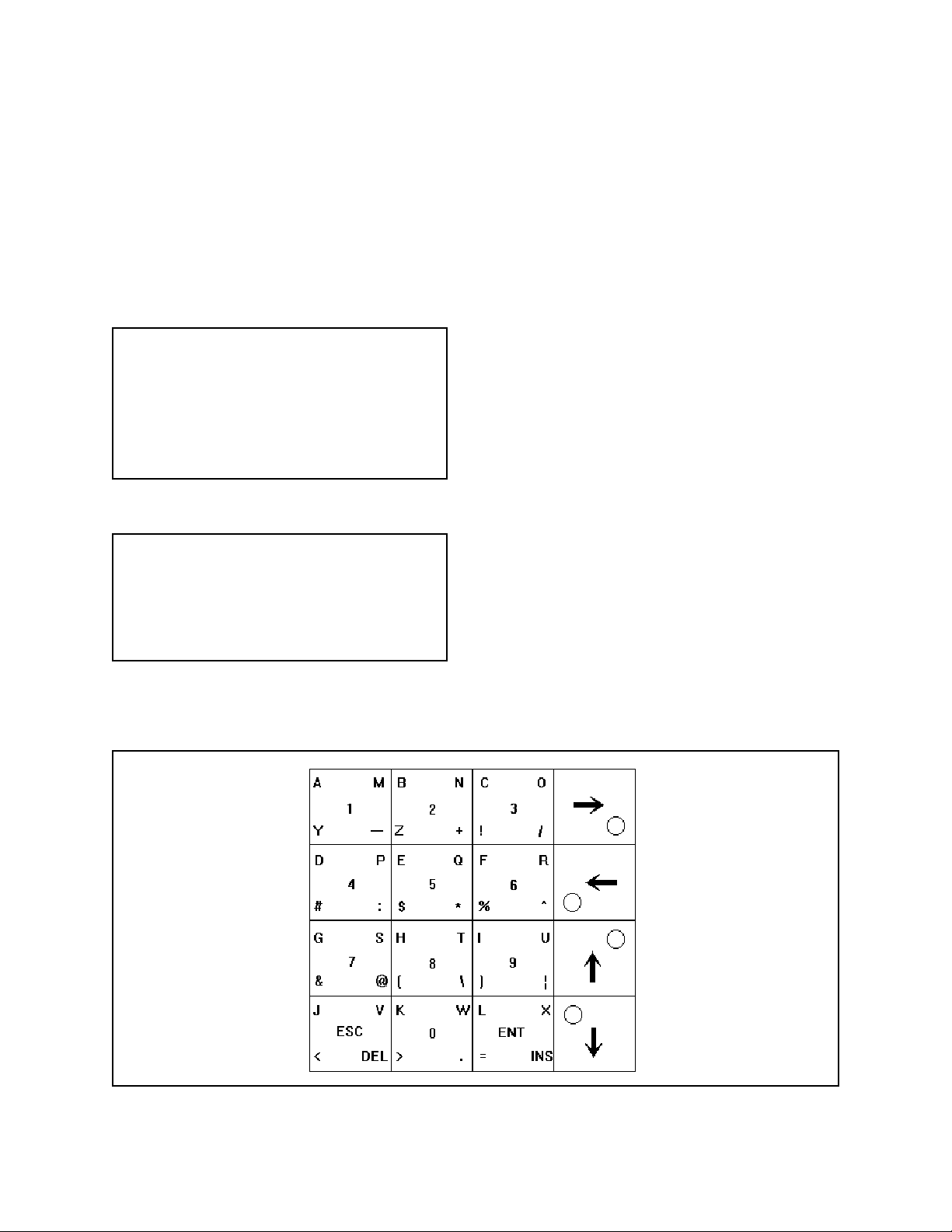

4.6.6.1 Keypad Definitions......................................................................................14

4.6.7 Programming Stratagies ............................................................................................15

4.6.8 Exception Column Line ..............................................................................................17

4.7 CLOCK SETUP ......................................................................................................................17

4.7.1 Set Clock ...................................................................................................................17

4.7.2 Clock ID On and Screen Position Set ........................................................................18

4.7.3 Clock ID Off ...............................................................................................................18

4.7.4 USA Standard Date ...................................................................................................18

4.7.5 European Date...........................................................................................................18

4.7.6 Auto Clock Set ...........................................................................................................18

Inter-Check® is a registered trademark of Pelco.

®Pelco and the Pelco logo are registered trademarks of Pelco.

©Copyright 1996, Pelco. All rights reserved.

ii Pelco Manual C1000M-B (1/96)

Page 3

TABLE OF CONTENTS (Continued)

Section Page

4.8 LOCA TION ID SETUP ............................................................................................................18

4.8.1 Location ID Program ..................................................................................................18

4.8.2 Location ID On and Screen Position Set ...................................................................19

4.8.3 Location ID Off ...........................................................................................................19

4.9 CUSTOMER HEADER ...........................................................................................................19

4.10 DIAGNOSTICS .......................................................................................................................19

4.10.1 Program Transfer .......................................................................................................20

4.10.2 (DL) Burn-In Test .......................................................................................................20

4.10.3 (DL) Input Channel Port T est .....................................................................................20

4.10.4 Memory Tests ............................................................................................................21

4.10.5 System Signals T est...................................................................................................21

4.10.6 Video Screen Test......................................................................................................21

4.10.7 Graphics Screen T est.................................................................................................21

4.10.8 (DL) Pelco PIM Default Load .....................................................................................22

4.11 ALARM INPUT........................................................................................................................23

4.11.1 Alarm Input On/Off.....................................................................................................23

4.11.2 Alarm Trigger Dwell....................................................................................................24

4.11.3 Screen Link ................................................................................................................24

4.11.4 Auxiliary Print Link .....................................................................................................24

4.11.5 Alarm Text ..................................................................................................................24

4.12 ALARM PROGRAMMING ......................................................................................................24

4.13 THE NV MEMORY WRITE PROTECT SWITCH.................................................................... 25

5.0 TROUBLESHOOTING .....................................................................................................................26

5.1 TROUBLESHOOTING FLOW CHART ...................................................................................27

6.0 SPECIFICA TIONS............................................................................................................................29

7.0 WARRANTY AND REPAIR INFORMATION.....................................................................................29

APPENDIX A. HEXADECIMAL, DECIMAL AND BINARY CONVERSION TABLES ................................. 30

APPENDIX B. ICI1000PIM SWITCH SETTINGS.......................................................................................33

Pelco Manual C1000M-B (1/96) iii

Page 4

LIST OF ILLUSTRATIONS

Figure Page

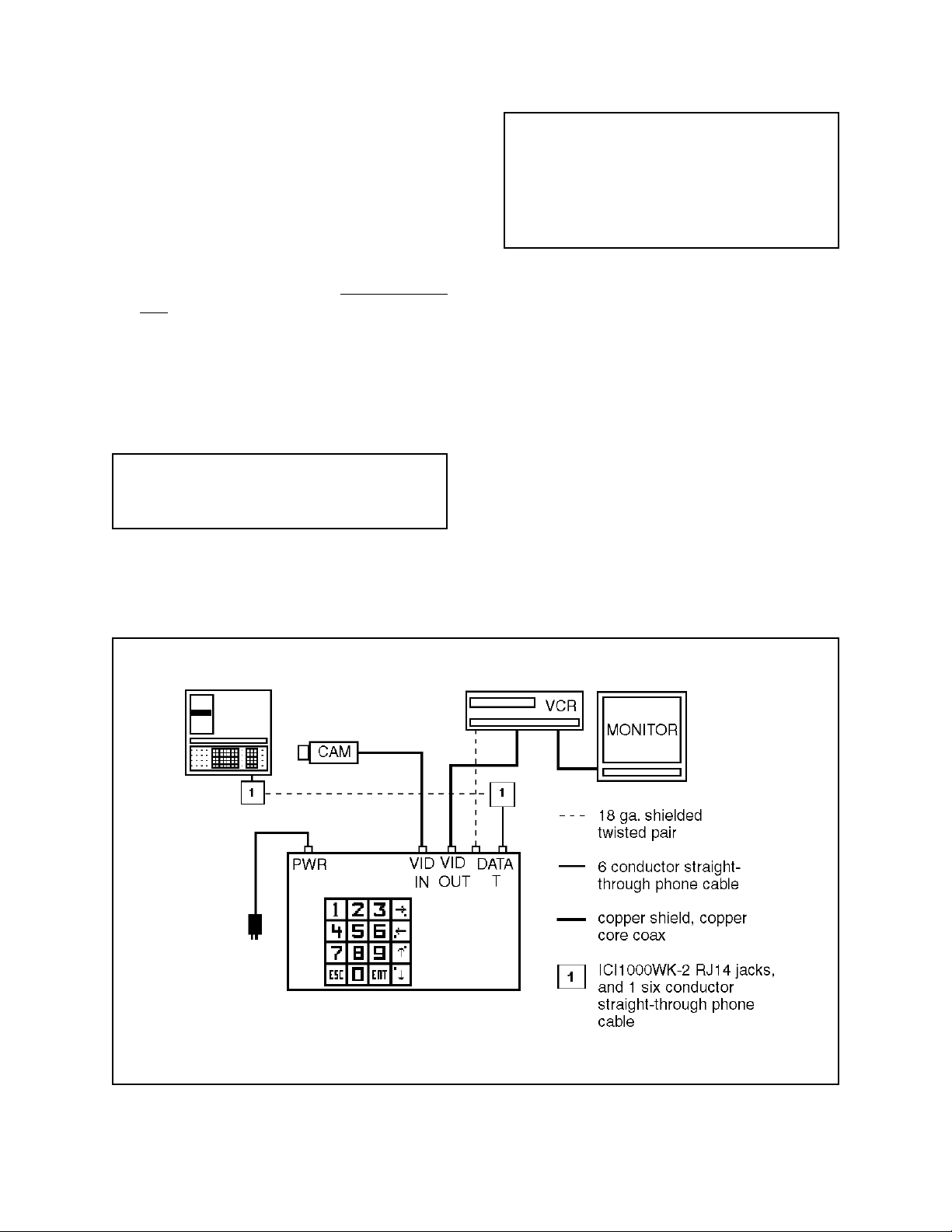

1 Basic ICI1000S Configuration Wiring Diagram ............................................................................3

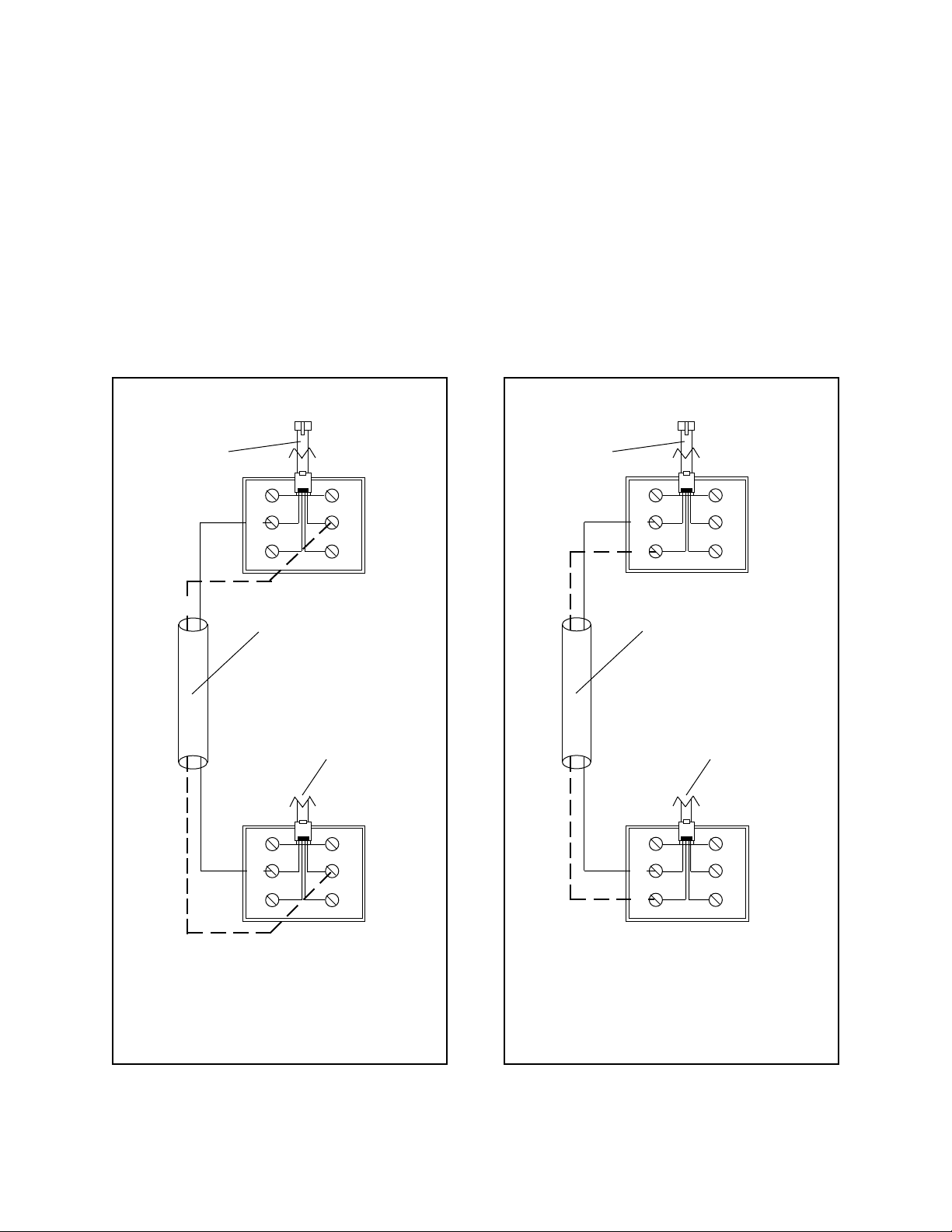

2 ICI1000PIM Wiring Configuration ................................................................................................4

3 Standard RS-232 Style Wiring Configuration...............................................................................4

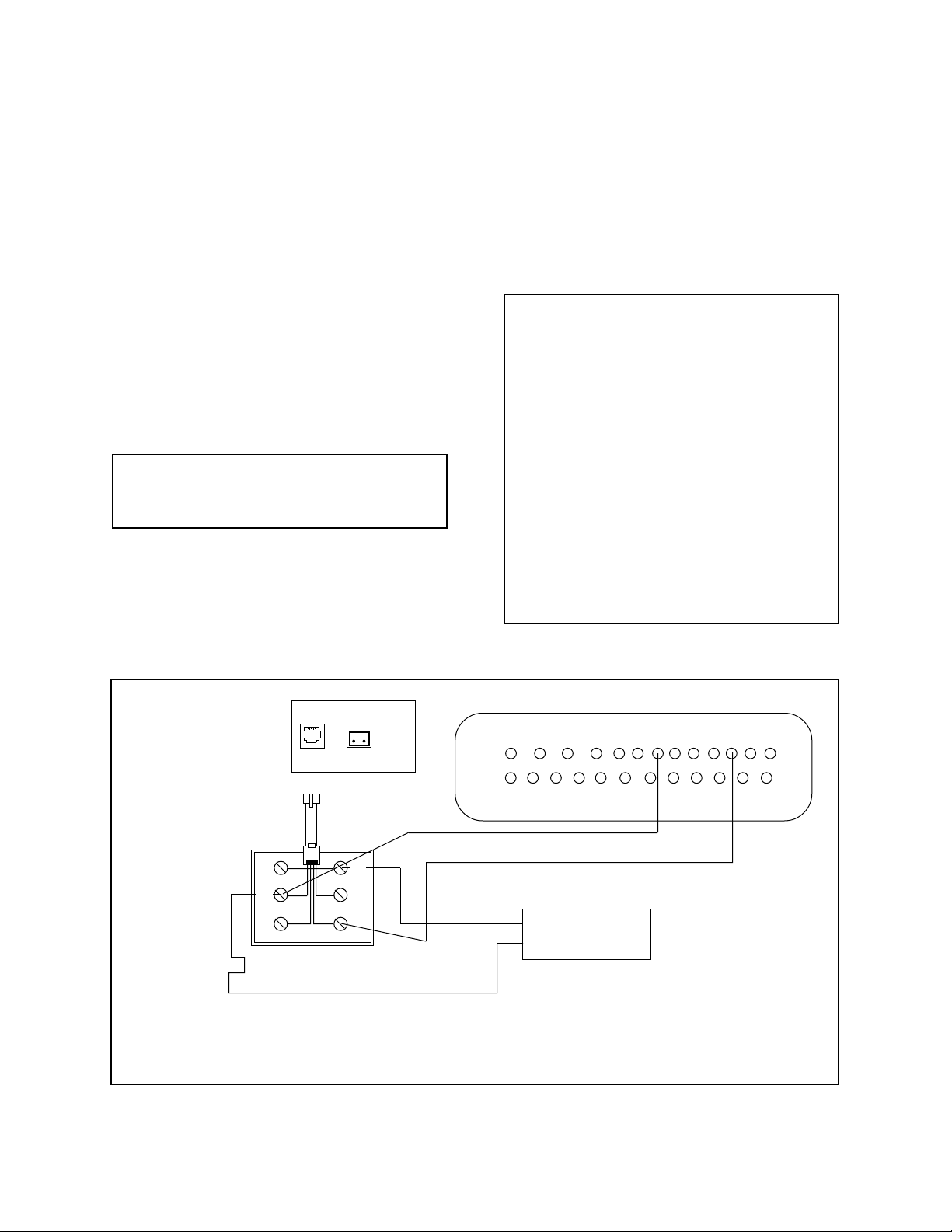

4 Printer Output and Alarm Input Wiring.........................................................................................5

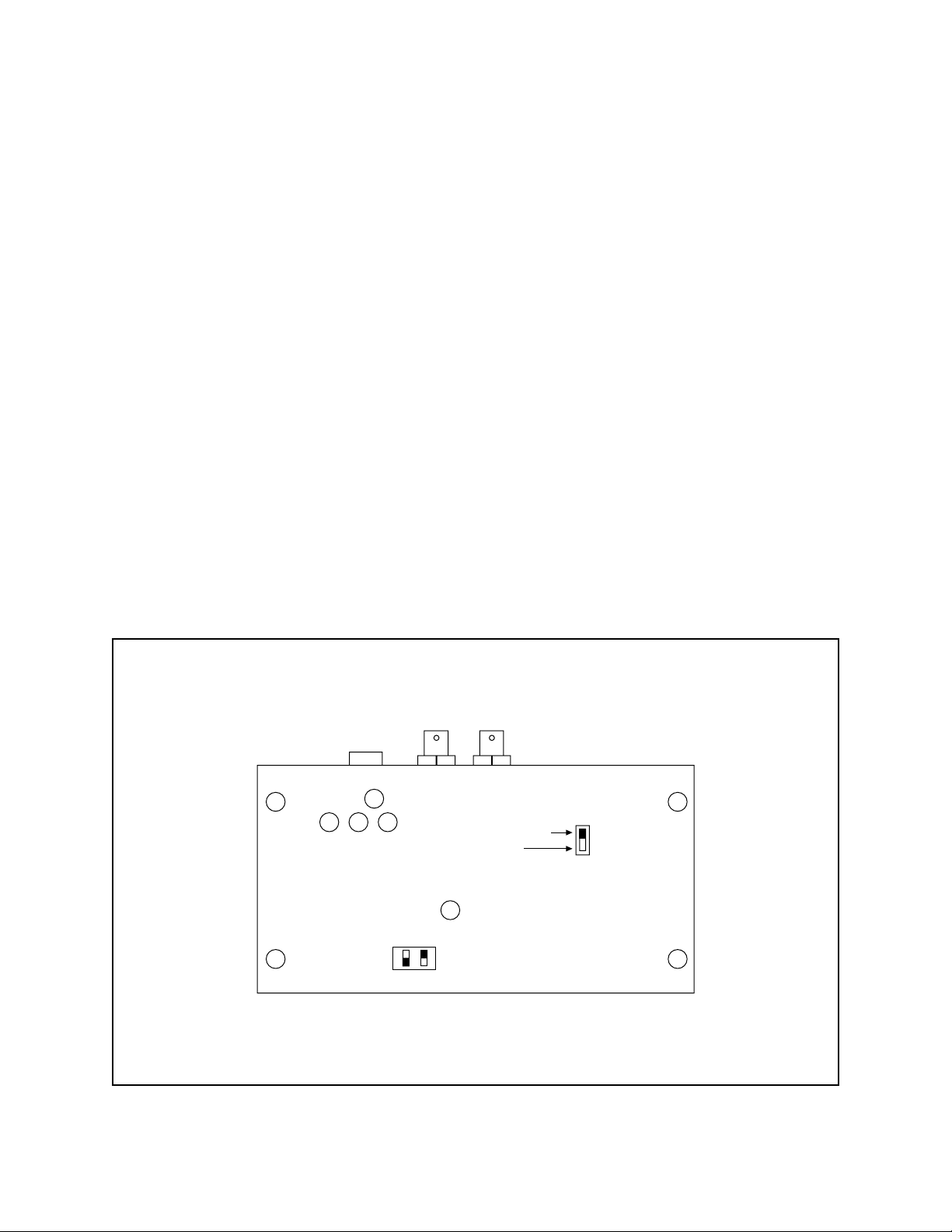

5 Video Adjustment Locations ........................................................................................................6

6 Keypad Layout ................................................................................................................. ............7

7 Program Transfer Wiring Diagram..............................................................................................20

8 Printer Output and Alarm Input Wiring.......................................................................................23

9 ICI1000PIM Switch Settings ......................................................................................................36

LIST OF TABLES

Table Page

1 Data Screen ID ..........................................................................................................................11

2 Label Descriptors.......................................................................................................................25

3 ICI1000S Series Pinouts............................................................................................................25

REVISION HISTORY

Manual # Date Comments

C1000M — Original version.

C1000M-A 11/95 Revised to incorporate Programming Menu Map, Section 4.0,

and Troubleshooting Flow Chart, Section 5.1.

C1000M-B 1/96 Revised to include Appendix B, ICI1000PIM Switch Settings.

iv Pelco Manual C1000M-B (1/96)

Page 5

INSTALLATION/OPERATION MANUAL

ICI1000S SERIES INTER-CHECK

®

CASH REGISTER INTERFACE SYSTEM

1.0 WARNINGS

Prior to installation and use of this product, the following

WARNINGS should be observed.

1. Installation and servicing should only be done by

qualified service personnel and conform to all local

codes.

2. Unless the unit is specifically marked as a NEMA

Type 3, 3R, 3S, 4, 4X, 6 or 6P enclosure, it is

designed for indoor use only and it must not be

installed where exposed to rain and moisture.

3. The product and/or manual may bear the following

marks:

This symbol indicates that dangerous voltage

constituting a risk of electric shock is present

within this unit.

CAUTION:

TO REDUCE THE RISK OF ELECTRICAL

SHOCK, DO NOT REMOVE COVER. NO

USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

4. Only use replacement parts recommended by Pelco.

5. After replacement/repair of this unit’s electrical

components, conduct a resistance measurement

between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

This symbol indicates that there are important

operating and maintenance instructions in the

literature accompanying this unit.

CAUTION:

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

Please thoroughly familiarize yourself with the information in this manual

prior to installation and operation.

Pelco Manual C1000M-B (1/96) 1

Page 6

2.0 SCOPE

The information contained within this manual covers

the installation and operation of the Inter-Check

ICI1000S Series cash register interface system.

Installation should be in accordance with all applicable

local and national electric codes, utilizing approved materials only.

Please familiarize yourself with the information in this

manual prior to installation and operation.

2.1 DESCRIPTION

The Inter-Check terminal monitor, or P.O.S., interfaces

with most ATM machines and popular cash registers. It

is compatible with most standard CCTV cameras, video

tape recorders and monitors. The Inter-Check is the heart

of a large family of Pelco products which are designed

to reduce losses in any financial institution.

In addition to the high performance and reliability

you’ve come to expect from Pelco products, the InterCheck ICI1000S Series offers the following MAIN

®

FEATURES:

• Monitors one device, cash register or ATM machine.

• Exception flagging for special alarm flags such as

VOID or REFUND.

• Exception flagging on numerical values such as

price and the manipulation of these values.

• 30 separate exceptions can be programmed.

• One programmable alarm output for VCR control.

• One programmable alarm input for sensing of any

closure.

• Completely programmable data channel.

• Self-diagnostics to check for proper operation.

• Easy on-screen, menu-driven programming.

• Non-volatile memory for program storage (no battery needed).

• Horizontal and vertical fine tune controls.

• Character size, intensity and video gain controls.

• Program transfer function between another InterCheck ICI1000S Series unit or Personal Computer

(PC).

• Program transfer between an Inter-Check ICI1000S

Series and a PC requires special software designed

by Pelco Systems. If interested in this option, contact a Pelco representative.

• Compact 64 function keypad used to program the

Inter-Check ICI1000S Series.

• The Inter-Check ICI1000S Series keypad can be

ordered for either external operation or hidden internal operation. Your choice must be specified

upon the initial order.

2 Pelco Manual C1000M-B (1/96)

Page 7

3.0 INSTALLATION

To begin installation, refer to the following instructions

and Figures 1 and 2.

3.1 INSTALLING INTERFACE CABLE

1. Install interface cable and PIM (if applicable) into

the cash register according to the instructions supplied with your interface cable. Do not power up

PIM .

NOTE: Do not mount the Inter-Check

ICI1000S Series unit until all connections are

made and programming is complete. V ideo adjustments on the bottom of the Inter-Check

ICI1000S Series may need to be accessible

during the initial set-up.

3.2 BASIC INSTALLATIONS

For basic installations, perform the following steps:

2 Install an 18 gauge, two-conductor shielded cable

between the interface cable/PIM and the ICI1000S

unit using the ICI1000WK (wiring kit) supplied

with your ICI1000S (refer to Figures 2 and 3). This

kit contains two RJ14 phone jacks and one straightthrough six conductor cable.

WARNINGS: Do not power up the InterCheck ICI1000S Series unit until all other connections have been made.

Only use the power supply supplied with the Inter-Check

ICI1000S Series unit. Other power supplies may damage

the unit.

1. Connect the cable from your video camera to the

BNC labeled “VIDEO IN” on the Inter-Check

ICI1000S (refer to Figure 1). This normally comes

from your camera, splitter, switcher or quad. For

Coaxitron matrix installations, connect the cable

from the desired MONITOR OUTPUT to the BNC

labeled “VIDEO IN” on the Inter-Check unit.

2. Connect a cable from the BNC labeled “VIDEO

OUT” on the Inter-Check ICI1000S Series to the

video input of your video cassette recorder or

monitor.

Figure 1. Basic ICI1000S Configuration Wiring Diagram

Pelco Manual C1000M-B (1/96) 3

Page 8

To Inter-Check Unit

To Inter-Check Unit

Straight through

phone cable

WH

BK

RD

BL

YL

GR

User-supplied cable.

18 AWG shielded wire is

suggested

From ICI1000PIM

WH

BK

BL

YL

Straight through

phone cable

WH

BK

RD

BL

YL

GR

User-supplied cable.

18 AWG shielded wire is

suggested

From RS-232 style input

WH

BK

BL

YL

RD

GR

RD

GR

NOTE: For RS-232 style applications only.

Figure 2. ICI1000PIM Wiring Configuration

Figure 3. Standard RS-232 Style

Wiring Configuration

4 Pelco Manual C1000M-B (1/96)

Page 9

3. Connect the data cable from the register interface

cable (or PIM) to “DATA IN” on the Inter-Check

ICI1000S, using the ICI1000WK and 18 gauge, 2conductor shielded cable (see Figure 1).

4. If using alarms, attach a 22-gauge, 2-conductor

shielded cable from the “ALARM OUT” of the

Inter-Check ICI1000S Series unit to your VCR,

switcher, or other alarmable device.

8. Plug the power supply for the ICI1000PIM into a

120 VAC outlet. The monitor should now display

the register model number.

9. If using the auxiliary print feature, and/or alarm

inputs, follow the wiring diagram in Figure 4 for

proper installation.

5. Plug the power supply for the Inter-Check

ICI1000S Series unit into a 120 VAC outlet.

6. Use the keypad on top of, or inside, the ICI1000S

chasis to set the standard PIM defaults. Press ENT ,

6, 8 and then ESC to return to monitoring mode.

This step is required for all ICI1000S systems (refer to Figure 4).

NOTE: ICI1000SI models have an internal

keypad; ICI1000SE models have an external

keypad.

7. Set the dip switches on the front of the ICI1000PIM

to match the setting for your register model number. Use the ICI1000PIM switch settings located

in the ICI1000PIM manual or Appendix B of this

manual. If your register does not require an

ICI1000PIM, disregard this step.

Alarm

Data

Out

In

NOTE: The monitor should now show the initialization message shown below .

Pelco

INTER-CHECK/S VER X.X

ROM CHECK = YYYY

CALC. ROM CHECK = YYYY

SYSTEM BEING INITIALIZED!

MM VER. Z.Z

(register model # displayed here)

NOTE: If you do not receive this message,

refer to the troubleshooting guide in Section 5.0.

If your installation does not require the use of

an ICI1000PIM, the register model number will

not appear.

13 12 11 10 9 8 7 6 5 4 3 2 1

25 24 23 22 21 20 19 18 17 16 15 14

WH

BK

RD

BL

YL

GR

Alarm

Contact

NOTE: A serial printer used with the Inter-Check ICI1000S

Series must be set at 1200 baud, 8 bits, no parity.

Figure 4. Printer Output and Alarm Input Wiring

Pelco Manual C1000M-B (1/96) 5

Page 10

3.3 VIDEO ADJUSTMENTS

All video adjustments are located on the bottom of

the Inter-Check unit (refer to Figure 5). Using a nonmetallic screwdriver, make any necessary adjustments

as follows:

• Horizontal Positioning adjusts the height of the

displayed text. To raise the text position, turn the

potentiometer labeled “H” slightly clockwise. This

adjustment will also correct double-sized characters appearing on the screen.

• V ertical Positioning adjusts the lateral position of

the displayed text. T o move the text to the left, turn

the potentiometer labeled “V” slightly clockwise.

This adjustment will also correct “jittering” text.

• Intensity adjusts the brightness of the text. To increase the intensity of the text, turn the potentiometer labeled “I” slightly clockwise.

• Gain adjusts the entire video screen. T oo much gain

will distort the video picture. T o reduce video gain,

turn the potentiometer labeled “G” slightly counterclockwise.

• Horizontal Size adjusts the width of the text. To

increase the text width, turn the potentiometer labeled “S” slightly clockwise.

• Character Size adjusts the size of the characters.

There are four selections. Set the switches marked

“C” in one of the following choices: both up, both

down, first switch up and second one down, or first

switch down and second one up.

G

VHI

UNLOCKED

LOCKED

NV MEMORY

SWITCH

S

C

Figure 5. Video Adjustment Locations

6 Pelco Manual C1000M-B (1/96)

Page 11

4.0 INTER-CHECK ON-BOARD

KEYPAD OPERATION

The Inter-Check ICI1000S Series features a compact,

64 function keypad used for all programming functions.

Refer to Figure 6. The keypad contains 16 keys. The

four keys on the right side of the keypad are used for

both cursor movement and “shift operations”. The remaining keys contain alpha, numeric, and other characters for editing your program. These keys each contain five functions when used with the shift keys.

To select: Press:

White Character Desired Key

Color Character Cursor key of matching color

and then desired key.

Cursor Movement Desired arrow key twice.

Main Menu Enter (ENT)

Exit Main Menu Escape (ESC)

4.1 PROGRAMMING THE ICI1000SI

NOTE: Please familiarize yourself with the

information in this manual prior to installation

and operation. Contact the customer's register

dealer/installer prior to installation and operation. Some warranties and/or service agreements may be affected.

If your Inter-Check unit is an ICI1000SI, it utilizes an

internal keypad for programming all parameters. Follow the steps below prior to programming.

1. Power down the Inter-Check ICI1000SI unit.

2. Remove the four cover screws with a Phillips

screwdriver and set the cover aside.

3. Power up the ICI1000SI unit.

4. Program the Inter-Check unit for your particular

application.

5. When finished programming, replace the cover and

screw down firmly.

4.2 THE NV MEMORY WRITE PROTECT

SWITCH

Your new Inter-Check ICI1000S Series incorporates a

Non-Volatile (NV) type memory. This type of memory

does not require a battery to operate. Refer to Figure 5

for the location of this switch and note the locked and

unlocked positions. This switch must be positioned in

the UNLOCKED position if you intend on programming the Inter-Check ICI1000S Series unit. If the switch

is in the LOCKED position and you try to enter programming data, an “ERROR IN WRITING NV

MEMORY !!!” warning will be displayed on the monitor screen. T o allow programming, simply position the

write protect switch to the UNLOCKED position. When

programming is complete, position the switch to the

LOCKED position. This will protect your programming

from possible errors that may occur during AC power

fluctuations or complete Inter-Check ICI1000S Series

power loss.

Figure 6. Keypad Layout

Pelco Manual C1000M-B (1/96) 7

Page 12

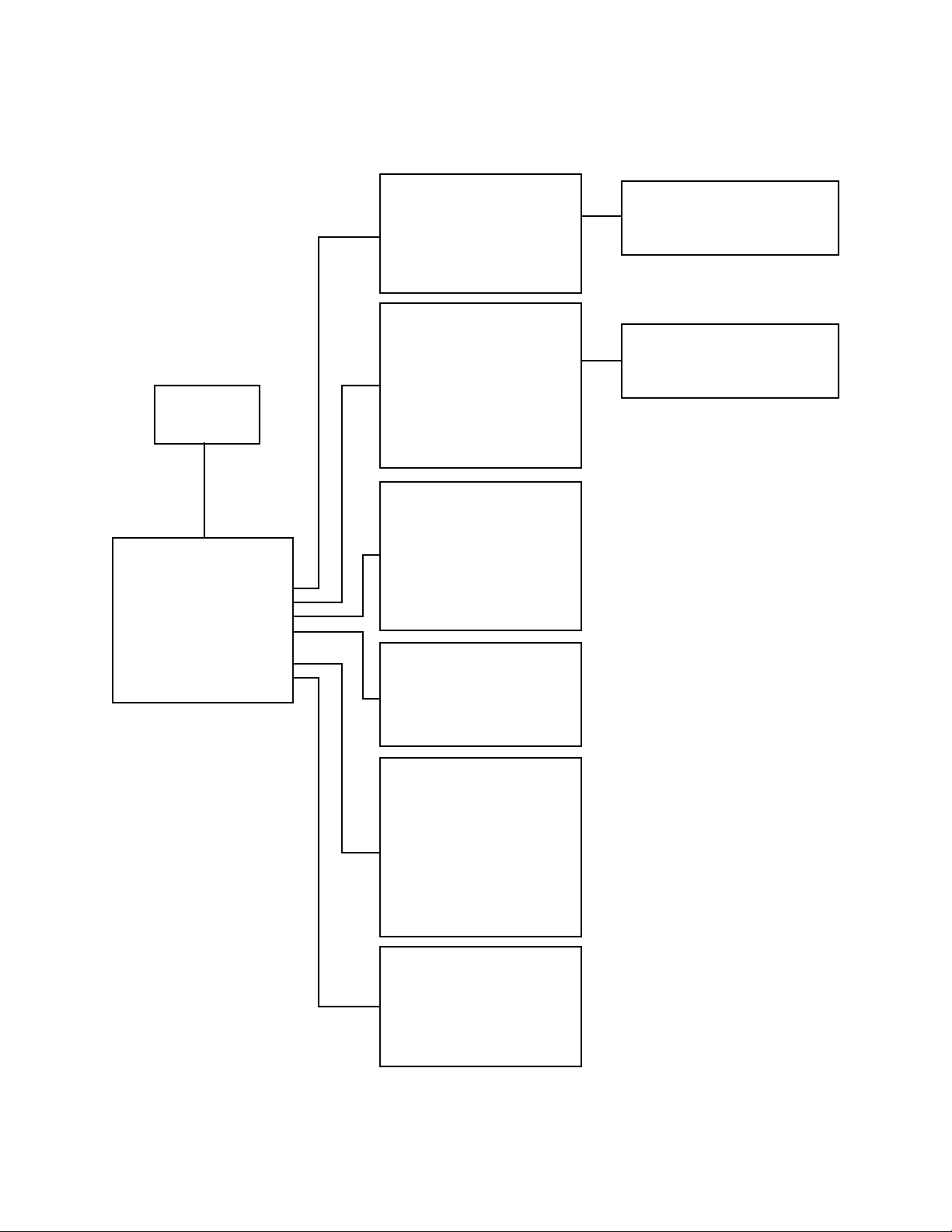

ICI1000S PROGRAMMING MENU TREE

Monitoring

Mode

↵ ENT

Main Program Menu

1. Channel 1 Setup

2. System Parameters

3. Clock Setup

4. Location ID Setup

5. Customer Header

6. Diagnostics

7. Alarm Inputs

Channel Program Menu

1. Communication Setup

2. Data Format/Communication Protocol

3. Video Parameters

4. A TM Line Select

System Program Menu

1. Alarm Outputs

2. Carriage Return Control

3. Channel Screen Data

Position

4. Printer Settings

5. Exception Alarm Settings

6. Exception Alarm Text Edit

7. Exception Column Line

Clock Program Menu

1. Set Clock

2. Clock ID On and Screen

Position Set

1

2

3

4

6

7

3. Clock ID Off

4. USA Standard Date

5. European Date

6. Auto Clock Set

Location ID Setup Menu

1. Location ID Program

2. Location ID on and

Screen Position Set

3. Location ID Off

Communication Setup Menu

1

1. Communication Parameters

2. Device Addresses

Carriage Return Menu

2

1. Exception Auto CR

2. End Of Line Stop

Diagnostics Selection Menu

1. Programm Transfer

2. (DL) Burn In Test

3. (DL) Input Channel Port

Test

4. Memory T ests

5. Signals T est

6. Screen T est

7. Graphics T est

8. (DL) PIM Default Load

Alarm Input Menu

1. Alarm Input On/Off

2. Alarm Trigger Dwell

3. Screen Link

4. Auxiliary Print Link

5. Alarm T ext

↵ ENT Key moves Inter-Check

into the programming

mode from the monitoring

mode

ESC Key returns to the

previous menu

Select catagories by

number

8 Pelco Manual C1000M-B (1/96)

Page 13

4.3 CHANNEL SETUP

There are two ways you can view your current channel

parameters:

1. Press the “1” key on your keypad while in the

monitoring mode.

NOTE: If the current settings are acceptable, press the ESC key which returns to the

CHANNEL PROGRAM SELECTION

MENU. If you wish to change the communication parameters, press “1”. To change the

device addresses press “2”.

2. Select CHANNEL SETUP (#1) in the MAIN PROGRAM MENU.

After executing one of these steps, an example of what

you might see is shown below:

SELECTED: CHANNEL

Pelco PIM STANDARD

9600 BAUD,8 BITS,OFF PARITY

NRZ,ASCII,DATA INVERT

DEVICE ADDRESS 1 = 00H 0

DEVICE ADDRESS 2 = 00H 0

NOR. VID,OFF ID.,30 CHARACTERS

18 LINES,DATA DWELL=0

ALARM DWELL : 6/D1

EALRM = ON/VP PNTR = OFF

CHANNEL PROGRAM SELECTION MENU

1. COMMUNICATION SETUP

2. DA T A FORMA T/COMMUNICATION PROTOCOL

3. VIDEO PARAMETERS

4.3.1 Communication Setup

This selection allows you to set COMMUNICATION

P ARAMETERS and DEVICE ADDRESSES. The communication parameters must be programmed correctly

in order for the Inter-Check ICI1000S Series to accept

data from your interface. Device addresses are used predominantly in ATM programming. Upon entering this

menu, you will notice that the channel’s current COMMUNICATION SETUP parameters are displayed as

shown below.

COMMUNICATION SETUP MENU

4.3.2 Communication Parameters

This menu enables you to program the data string format, baud rate, and character set into the Inter-Check

ICI1000S series.

NOTE: If you do not want to change items

within this menu, simply press ESC. The ESC

key will save the contents on the current line

and bring you to the prompt on the next line.

BAUD RATE =?

This prompt enables you to change the baud rate. Enter

the appropriate data and press ENT to save. Use 9600

when connecting to a PIM. Setting the baud to 0 will

turn off the data channel.

BITS (7 or 8) =?

Enter the appropriate number of data bits by pressing a

7 or 8 on your keypad. Use 8 when connecting to a

PIM.

PARITY = 1. ODD, 2. OFF, 3. EVEN

Enter the correct parity configuration of your device

by selecting 1, 2 or 3. Choose #2 for a PIM.

1=NRZ OR 2=NRZI

Choose the appropriate code transmission format by

selecting 1 or 2. NRZ is the most common format. An

exception to this is the SNA/SDLC type of communications. Select #1 for normal PIM applications.

SELECTED: 9600 BAUD,8 BITS,OFF PARITY

NRZ,ASCII,DATA INVERTED

DEVICE ADDRESS 1 = 00H 0

DEVICE ADDRESS 2 = 00H 0

1. COMMUNICATION PARAMETERS

2. DEVICE ADDRESSES

Pelco Manual C1000M-B (1/96) 9

Page 14

1=ASCII OR 2=EBCDIC

The fifth prompt sets up the character set for the InterCheck ICI1000S Series. Press a “1” to select ASCII

and “2” for EBCDIC. The ASCII character set is the

most common whereas EBCDIC is used predominantly

in IBM systems. Select ASCII when connecting to a

Pelco PIM.

1=DA TA NON INVER T OR 2=DA TA INVERT

This prompt sets up the Inter-Check ICI1000S series to

receive either inverted or non-inverted data. This selection varies from one register to the next. Choose

DATA INVERT in PIM applications.

After you have answered all of the prompts, the InterCheck ICI1000S Series will show you the changes (if

any) you have made. If the changes are correct, press

ESC. If the changes are incorrect, follow the same steps

just described. Again note that if you do not want to

edit a certain parameter you can skip and save the initial settings by pressing ESC.

4.3.3 Device Addresses

Select this menu by pressing #2 in the Communication Setup Menu. As mentioned earlier , DEVICE ADDRESSES are used in ATM installations. A device

address is the electronic address of the specific ATM

being monitored. The Inter-Check ICI1000S Series

allows you to enter two DEVICE ADDRESSES.

NOTE: Appendix A illustrates a Hexadecimal to Decimal conversion chart that you may

find helpful. Also, set the unused device address to 00H.

After pressing #2 the screen will display:

DEVICE ADDRESS -1 3 DECIMAL DIGITS (000-

255) = ?

This prompts you to enter the appropriate address up to

three digits in length. This address must also be between the specified boundaries, 000-255. If less than

three digits are used, you must press ENT to save. Pressing the ESC key will return you to the CHANNEL PROGRAM MENU.

The next prompt reads:

DEVICE ADDRESS -2 3 DECIMAL DIGITS (000-

255) = ?

Enter the appropriate address as explained above. After pressing ESC or entering an address you will be in

the CHANNEL PROGRAM MENU once again. The

current programmed addresses are displayed in both

Hexadecimal and Base 10 formats.

NOTE: If you are using SNA or SDLC formats, make both device addresses the same

value.

NOTE: Setting both addresses to 00 puts the

Inter-Check ICI1000S Series unit into diagnostics mode. In this mode the Inter-Check

ICI1000S Series unit will display all network

activity including the proper device address in

your installation.

4.4 DATA FORMAT/COMMUNICATION

PROTOCOL

Select this menu by pressing #2 in the CHANNEL

PROGRAM MENU. The menu allows you to choose

the type of device you are connecting to. After pressing

#2 the current settings will be displayed. An example

might be:

DATA PROTOCOL MENU

SELECTED: PIM STANDARD

To select the proper communication protocol for your

application, use the ENT key or the up and down cursor control keys to scroll through your options. When

you reach the device, save the selection by pressing

ESC.

Current options include:

• PIM STANDARD

• PIM GRAPHICS

• ICL PRINTER

• WAYNE-DRESSER PRINTER

• DIEBOLD 910/911 : NCR 751/279

• DIEBOLD 910/911 : TC 500/700

• DIEBOLD 910/911 : TC 500/700 SYNC

• DIEBOLD 910/911 : IBM 3275

• DIEBOLD 910/911 : IBM 2260

• DIEBOLD 910/911 : IBM 2265

• DIEBOLD 910/911 : SNA/SDLC

• IBM3624

• NCR NATIVE MODE

• IBM NATIVE MODE

• RS232 STANDARD PRINTER

10 Pelco Manual C1000M-B (1/96)

Page 15

4.5 VIDEO PARAMETERS

NUMBER OF LINES DISPLAYED (01-18)

To view the video parameters setting press #3 in the

CHANNEL PROGRAM MENU. The Inter-Check

ICI1000S Series will display the current settings. Pressing ESC will skip the current line and allow you to continue in the CHANNEL PROGRAM MENU.

VIDEO PARAMETER SETUP MENU

SELECTED: NOR VID, OFF ID., 30 CHARACTERS

18 LINES, 0 DATA DWELL

ENTER DATA OR ESC TO SKIP

REVERSE VIDEO = 1. REV, 2. OFF =?

You may find this feature very useful in bright lighting

conditions. When it is turned on it creates a dark background around the white text displayed on the monitor.

Reverse video is used for ease in readability. If you

want this feature turned on, press 1. For normal video

presentation press 2.

ID. VALUE 0 = OFF, (1-7) = “A” TO “G”

This second prompt enables you to identify the data

screen. This ID will remain on the screen at all times.

For example, you may want to label the data channel

“A” for ease in recognition while viewing the video

tape. This feature is very useful if two Inter-Check

ICI1000S Series are used together on a single VCR and/

or monitor. Refer to Table 1 for a cross-reference. If

you do not wish a screen ID value, press 0 or ESC.

Table 1. Data Screen ID

Selection Display

1A

2B

3C

4D

5E

6F

7G

MAX CHARACTERS PER LINE (01-80)

Selection #3 designates how many characters per line

you want displayed on the monitor. Simply press any

number from 1-80 that best suits your application. Default value is 30.

This selection specifies the number of lines you wish

to be displayed. Select the appropriate number of lines

for your application and press enter. The default value

is 18 lines.

DATA DWELL TIME IN SECONDS (000-255)

The data dwell time defines the duration of time the

data will stay on the screen. Simply enter the appropriate number of seconds that best suits your needs and

press ENTER. For example, if you want the data to stay

on the screen for 5 seconds after the last line is printed,

press 5 for the data dwell time. The default value is 0

which forces the data “on” at all times.

Example:

A five-second dwell is entered as 005 ENTER

4.6 SYSTEM PARAMETERS

(Selection #2 from the main menu)

4.6.1 Alarm Output

This selection allows you to set the alarming output

features. This output is a normally open closure used to

control external alarmable devices. This output can become active if:

• Data is present on the channel.

• Exception is met on the data channel.

• Closure is seen on the alarming input.

The first line in this menu is:

ALARM DWELL : 6/D1

(D1 = Data Alarm ON; E1 = Exception Alarm ON)

(I1 = Alarm Input On)

This line gives you the current status of the alarming

output. If, for example, the first line of this menu read

“ALARM DWELL : 30/D1E1” the alarm would remain

active for 30 seconds upon the occurrence of either data

or an exception on the data channel. 6/D1 is the default

factory setting.

Pelco Manual C1000M-B (1/96) 11

Page 16

The next prompt is:

ALARM DWELL TIME IN SECONDS

(001-255)=?

Selecting 1 in this menu turns off the auto carriage return feature and brings you back to the EXCEPTION

AUTO CR MENU. Selecting 2 in this menu will bring

up the next prompt:

Simply enter in the amount of time you wish the alarming output to remain active in seconds and press ENT.

The following prompts allow you to activate the alarming output upon the occurrence of data and/or an exception on the channel.

CHANNEL DATA ALARM ?

1=OFF 2=ON

CHANNEL EXCEPTION ALARM ?

1=OFF 2=ON

4.6.2 Carriage Return Control

The carriage return control feature allows you to use

your Inter-Check ICI1000S Series unit with devices that

do not execute a carriage return at the end of the data

lines or a device that has a scrolling message when transactions are not taking place. If a carriage return is not

found at the end of a line, the Inter-Check ICI1000S

Series unit cannot correctly place the text on the screen

or do exceptions on that line. This problem can be solved

with the EXCEPTION AUTO CR feature of this menu.

The END OF LINE STOP feature allows you to force

the Inter-Check ICI1000S Series to stop its display at

the end of the line when a carriage return is not received. This is useful when a device scrolls messages

when transactions are not taking place.

NOTE: The “end of the line” is dependent on

the MAXIMUM CHARACTERS PER LINE

setting in the VIDEO PARAMETERS menu.

The first prompt in this menu is:

1. EXCEPTION AUTO CR

2. END OF LINE STOP

Entering 1 for EXCEPTION AUTO CR will bring up

the following:

EXCEPTION AUTO CR MENU

EXC. CR

SELECTED: OFF

CR DWELL:1

ENTER DATA OR ESC TO SKIP

1=OFF 2=ON

CR DWELL TIME IN SECONDS (000-255)=?

At this prompt enter the amount of time in seconds you

wish to wait before the Inter-Check unit automatically

inserts a return. You will then return to the EXCEPTION AUTO CR MENU.

Entering 2 in the CARRIAGE RETURN MENU will

bring up:

END OF LINE STOP MENU

STOP

SELECTED: OFF

ENTER DATA OR ESC TO SKIP

1=OFF 2=ON

Enter your choice by pressing 1 or 2. Y ou will be brought

back to the CARRIAGE RETURN MENU.

4.6.3 Camera Screen Data Position

This option allows you to position the data anywhere

on the monitor’s screen. When this option is selected a

block of ones (1) is displayed on the monitor which

represents the current size and position of the displayed

data. Move the block by pressing the arrow keys twice

for each increment. After the block has been moved to

the desired position, press ENT to save.

4.6.4 Printer Settings

The PRINTER SETTINGS selection allows you to enable the auxiliary printer output port and select the data

being sent to the printer. The first thing displayed in

this menu is the current status of the AUX port.

CHANNEL DATA TO AUX PRINT ?

1=AUX 2=OFF

Pressing 1 will send the data received on the channel to

the auxiliary port.

Pressing 2 will turn off the auxiliary printer port.

NOTE: A serial printer used with the InterCheck ICI1000S Series must be set at 1200

baud, 8 bits, no parity .

12 Pelco Manual C1000M-B (1/96)

Page 17

4.6.5 Exception Alarm Settings

(Selection #5 in the System Program Menu)

Programming Exceptions

EXCEPTIONS are situations of special interest that you can program into your Inter-Check

ICI1000S Series unit. They are used to alarm

your VCR or other alarmable devices when a

certain condition has been met. Exceptions can

also be directly printed to an external printer.

Exception flagging will save you valuable time

reviewing VCR tapes because you have the

ability to view only events of specific interest.

Entering the Exception Menu

To select the Edit Exception Text menu while

in the monitoring mode, follow these steps:

Press the ENT key (you will hear one tone).

The MAIN PROGRAM MENU will be displayed.

MAIN PROGRAM MENU

1. CHANNEL SETUP

2. SYSTEM PARAMETERS

3. CLOCK SETUP

4. LOCATION ID. SETUP

5. CUSTOMER HEADER

6. DIAGNOSTICS

7. ALARM INPUTS

Press #2 (you will hear one tone) which corresponds to the SYSTEM PARAMETERS

MENU. The following text should appear:

NOTE: In order for the Inter-Check ICI1000S

Series to “capture” exception text you must turn

on the EXCEPTION ALARM SETTINGS. An

example is shown below:

CHANNEL : EALRM = ON / PNTR = ON

ESC TO EXIT OR ENTER TO EDIT?

The above example shows that Channel Exceptions are

turned ON and are being “sent” to an auxiliary printer.

Press ENT to edit; the prompt reads:

CHANNEL EXCEPTION FLAG ?

1=OFF 2=ON

Press 1 to turn channel exceptions OFF or 2 for ON.

CHANNEL EXCEPTION MARKER VIDEO

PRINT ?

1=OFF 2=ON

The Exception Marker Video Print displays asterisks

around an exception appearing on the monitor and/or

printer. It is designed to capture your attention when an

exception has occurred. Press 1 or 2 for your choice.

CHANNEL EXCEPTION MARKER AUX.

PRINT ?

1=AUX 2=OFF

This menu is used if you have an external serial printer.

This menu enables you to send data to the auxiliary

output port. If you do not utilize an external printer,

press #2.

SYSTEM PROGRAM MENU

1. ALARM OUTPUTS

2. CARRIAGE RETURN CONTROL

3. CHANNEL SCREEN DATA

POSITION

4. PRINTER SETTINGS

5. EXCEPTION ALARM SETTINGS

6. EXCEPTION ALARM TEXT EDIT

7. EXCEPTION COLUMN LINE

Pelco Manual C1000M-B (1/96) 13

Page 18

4.6.6 Exception Alarm Text Edit

(Selection #6 in the System Program Menu)

After Pressing #6 the following numbers will appear

across your monitor screen:

12345678901234567890123456789012345678901234567890

= =

This row of numbers is referred to as the Exception

Column Line. This will aid you in programming various parameters which will be covered later in this section. As mentioned earlier , the Exception Column Line

exactly matches the EXCEPTION COLUMN LINE in

the monitoring mode (when it is turned on).

ENT Saves changes to one line in the Text

Editor.

DEL Deletes a line.

ESC Saves any changes made in the edi-

tor and exits back to the SYSTEM

PROGRAM MENU.

(^) Wildcard or column specific charac-

ter. The caret (^) symbol is displayed

by pressing the right arrow key followed by a 6.

SPACE Inserts position spaces. To insert a

space, press the right arrow key.

The text editor has two prompts; == and =>.

The == prompt signifies that the edit mode has not been

entered on that line. Y ou may either edit the line or press

the ENT key to skip.

The => prompt signifies that the edit mode has been

entered on that line. You must view the whole line of

text before you press enter or the line will be deleted.

NOTES: The ENT and the INS key must be

used together to save all changes. If you make

changes within a line, move the cursor to the

end of the line with the RIGHT ARROW key

and press ENT. Pressing the ESC key deletes

all the changes and the text returns to its original settings.

Unlike the ICI2000D, the ICI1000S automatically converts all text into capital letters for comparison purposes. Therefore, when programming exceptions, you do not have to worry

about capital and lower-case designations.

4.6.6.1 Keypad Definitions

Listed below are the various keys you will be using

when programming exceptions on the Inter-Check

ICI1000S Series. Pelco suggests that you become familiar with the functions before attempting to use the

exception menus.

(\) The back-slash (\) is used to describe

a transaction. This symbol is created

by pressing the right arrow key, followed by an 8.

( ) The “double bar” ( ) is used in price

point formats to define and manipulate a string of numbers. This symbol is created by pressing the right

arrow key, followed by a 9.

NOTE: The next three symbols are used in

conjunction with the “double bar” described

above.

(=) Used to identify an equal compari-

son in the price point format.

(<) Enables you to flag on values less

than a specified number being defined with the double bar in the price

point format.

(>) Enables you to flag on values greater

than a specified number being defined with the double bar in the price

point format.

INS Saves all changes in Text Editor and

exits back to SYSTEM PROGRAM

MENU. The INS key is also used in

conjunction with the ENT key.

14 Pelco Manual C1000M-B (1/96)

Page 19

4.6.7 Programming Stratagies

Exceptions Using the GLOBAL Strategy

This is used to flag on any text regardless of placement

on the register ticket.

EXAMPLE: Flagging on any VOID within

your system.

Y ou must first enter into the Exception Alarm Text Edit

mode. To do this press #2 in the MAIN PROGRAM

MENU (SYSTEM PARAMETERS). Then press #6 in

the SYSTEM PROGRAM MENU (EXCEPTION

ALARM TEXT EDIT).

The display should now read:

Exceptions Using the COLUMN SPECIFIC

Strategy

This is used to flag on specific placement of text on

the register ticket. This type of exception uses the (^)

character on your keypad. It is used to capture text according to the position on the register ticket. When this

type of exception strategy is used, the Inter-Check

ICI1000S Series searches for specific column placement of data defined by the number of ^ symbols you

use. It may be useful for you to refer to the explanation of the EXCEPTION COLUMN LINE to ensure

proper positioning.

EXAMPLE: Flagging on department number 5200 but your register prints it as “ 5200

40.00 “

123456789012345678901234567890123456789012345678901234567890

= =

1. Type VOID to match the exact format it is printed

on the register ticket.

123456789012345678901234567890123456789012345678901234567890

=>VOID

2. Press ENT to save the exception.

3. Press INS to save the changes.

4. Turn on the EXCEPTION ALARM SETTINGS.

For further instructions, refer to EXCEPTION

ALARM SETTINGS previously described.

5. Press ESC three times to resume monitoring.

1. Turn on the exception column line by pressing selection #7 (EXCEPTION COLUMN LINE) in the

SYSTEMS PARAMETER MENU.

2. Press ESC three times to return to the monitoring

mode.

Let’s say the display read:

123456789012345678901234567890123456789012345678901234567890

5200 $40.00

3. Press ENT to access the MAIN MENU.

4. Press 2 to access the SYSTEMS PARAMETER

MENU.

5. Press 6 to edit exception text.

6. Key in the following:

123456789012345678901234567890123456789012345678901234567890

=>^^^^^5200

7. Press ENT to save the exception.

8. Press INS to save the changes.

9. Press ESC three times to return to the monitoring

mode.

Pelco Manual C1000M-B (1/96) 15

Page 20

Exception Flagging Using WILDCARDS

Used to flag on groups of transactions or departments.

This type of exception also uses the caret (^) character

and is usually used with the COLUMN SPECIFIC type

of exception. Again, it is suggested that you use the

EXCEPTION COLUMN LINE.

EXAMPLE: Flag any transaction in your jewelry department where the department number

is 5200-5299. Also, the register prints it out as

“ 5250 $40.00 “

1. Follow steps 1-5 in the previous example.

2. Key in the following:

123456789012345678901234567890123456789012345678901234567890

=>^^^^^52^^

3. Follow steps 7-9 in the previous example.

NOTE: When the ^ key is used as the first

character of exception text, it causes that line

to be Column Specific. Also, when the ^ is preceded by any other character it will then be read

as a W ildcard character.

Exception Marking Using the

DESCRIPTOR

The PRICE POINT Exception Flag

Strategy

The Double Bar character ( ) key enables you to flag

or compare any number that is equal to, greater than,

or less than a desired number.

EXAMPLE: Flagging on any price over

$40.00 in department 52XX and labeling the

exception with a descriptor of JEWELR Y DEP AR TMENT.

1. Select 7 in the SYSTEM PARAMETER MENU.

This turns on the Exception Column Line in the

monitoring mode.

2. Press ESC three times to return to the monitoring

mode.

Let’s say the screen read:

12345678901234567890123456789012345678901234567890

5248 $40.00

3. Press ENT.

4. Press 2 to access the SYSTEMS PARAMETER

MENU.

5. Press 6 to edit exception text.

The back-slash symbol (\) is used to describe a certain

transaction you are flagging. It is printed on the line

after the exception in the video or printer flag display.

EXAMPLE: Describe the department 52005299 in the above example with a descriptor of

JEWELRY DEP ARTMENT.

1. Follow the same programming steps used in the

previous example.

2. Key in the following:

123456789012345678901234567890123456789012345678901234567890

^^^^^52^^\JEWELRY DEPARTMENT

6. Key in the following:

12345678901234567890123456789012345678901234567890

=>^^^^^52^^ 40.00 >\JEWELRY DEPARTMENT

7. Press ENT to save the exception.

8. Press INS to save the changes and exit.

9. Turn on the Exceptions. Do this by pressing #5 in

the SYSTEM PROGRAM MENU and answering

the prompts. For a further explanation on how to

turn on exceptions refer to EXCEPTION ALARM

SETTINGS.

10. Press ESC three times to return to the monitoring

mode.

16 Pelco Manual C1000M-B (1/96)

Page 21

Notice that the second double bar is placed directly after the data you are interested in. This format holds true

for any transaction you wish to flag using the double

bar format. The first double bar has a leeway of 15 characters or spaces. In other words, in the previous example the first double bar could be placed at 15 spaces

to the left of the 4 in $40.00, but the second double bar

must be inserted directly after the last 0 in $40.00. Therefore, if your register prints negative numerical values

with a minus sign behind the text and you wish to flag

this type of transaction, you must insert the minus sign

in front (some registers record a refund with a minus

sign). For example, if the above example printed out a

refund of $40.00 as 40.00- you would capture this data

as an exception by programming the Inter-Check

ICI1000S Series in the following format:

4.7 CLOCK SETUP

The Inter-Check unit can be programmed to display

the time and date on the video monitor in any convenient location. The Inter-Check also accepts the USA

or European date structure. The AUTO CLOCK feature allows the Inter-Check unit to synchronize with

the cash register or ATM machine clock. If the register

or ATM has a clock that is displayed with the data, it is

suggested that the auto clock load feature be used. This

will remove the inaccuracy of using the Inter-Check’s

clock.

NOTE: The internal clock on the Inter-Check

ICI1000S Series is software generated and is

inaccurate.

-40.00 >\JEWELRY DEPARTMENT

4.6.8 Exception Column Line

(Selection #7 in the System Program Menu)

This selection proves to be a valuable tool when editing exceptions. When this function is turned on, a row

of numbers will appear across the screen in the monitoring mode. The row of numbers will exactly match

the row found in the EXCEPTION ALARM TEXT

EDIT menu (explained prior). This function will save

you time when you have a lot of text or multiple spaces

between numbers or characters and are using column

specific exceptions. Examples of this function are also

explained in the following pages.

Entering 4 in the main menu will bring up the CLOCK

PROGRAM menu:

CLOCK PROGRAM MENU

1. SET CLOCK

2. CLOCK ID. ON AND SCREEN POSITION SET

3. CLOCK ID. OFF

4. USA STANDARD DATE

5. EUROPEAN DATE

6. AUTO CLOCK SET

4.7.1 Set Clock

Entering 1 in this menu allows you to set the internal

clock. The following prompt will follow:

YR,MT,DY,HR,MN,SC,DW

XX XX XX XX XX

The cursor will start at the far left hand side and move

to the right as you enter the information. The backspace

key on the keyboard allows you to delete the previous

entry . The arrow keys allow you to move back and forth

without effecting the entered data. The DW position

indicates the day of the week, Sunday being the first

day. The clock uses the 24-hour system (military time)

so the hour is entered as a number from 01 to 24. The

day of the week is entered as a number from 01 to 07.

EXAMPLE: If the day is May 21, 1993 and

the time is 1:40:30 p.m. on a Monday, the following information would be entered:

YR,MT,DY,HR,MN,SC,DW

93 05 21 13 40 30 02

Pelco Manual C1000M-B (1/96) 17

Page 22

4.7.2 Clock ID On and Screen

Position Set

Selection 2 in the CLOCK PROGRAM MENU will

turn the clock on and allow positioning on the screen.

Press the arrow keys twice for each increment to move

the time and date to the preferred position and press

ENT to save.

4.7.3 Clock ID Off

The 3rd selection in the menu will turn off the time and

date video display.

4.7.4 USA Standard Date

Pressing 4 will set the date in the USA standard format

(month, day, year).

4.7.5 European Date

Pressing 5 will set the date in the European standard

format (day, month, year).

4.7.6 Auto Clock Set

Choosing selection 6 in the CLOCK PROGRAM

MENU permits the use of the AUTO CLOCK feature.

In order to use this function, the register’s clock must

be displayed on the monitor by the ICI1000S. Most

registers will display this information. The programming prompt begins:

DATE DELIMITER 1.(/) 2.(-)

Select 1 if the date displayed by the register uses (/) as

a delimiter.

Select 2 if the date displayed by the register uses (-) as

a delimiter.

TIME DELIMITER 1.(:) 2.(-)

Use the same procedure for selecting the time delimiter as the date delimiter.

NOTE: The Autoclock Load does not discriminate the seconds position. It will always

load in 30 seconds.

4.8 LOCATION ID SETUP

(Selection #4 from the main menu)

The LOCA TION ID is normally used to place the name

or location of the user’s store. The ID can be placed

anywhere on the screen and stays resident on the screen

at all times. This feature is useful when one party is

reviewing video tapes from multiple store locations.

Pressing 3 in the MAIN PROGRAM MENU will bring

you to the LOCATION ID SETUP menu:

LOCATION ID SETUP MENU

CHANNEL AUT OSET ?

1=OFF 2= ON

Pressing 1 will disable the AUTO CLOCK SET.

Pressing 2 will enable the AUTO CLOCK SET.

12 HOUR MODE LOOK ?

1=OFF 2=ON

Select 1 if the register displays the time in a 24-hour

format.

Select 2 if the register displays the time in a 12-hour

format.

NOTE: If the 12-hour mode is used the InterCheck looks for an “A” or a “P” designating

A.M. or P.M. In the 24-hour mode the InterCheck loads the time by numerical values.

18 Pelco Manual C1000M-B (1/96)

1. LOCATION ID PROGRAM

2. LOCA TION ID ON AND SCREEN POSITION SET

3. LOCATION ID OFF

4.8.1 Location ID Program

Number 1 in this menu allows you to program the text

for the ID:

ENTER DATA WANTED UP T O 12 CHARACTERS.

(ESC) TO SKIP, (ENTER) TO ENTER,

(BS) TO BACKSPACE

Enter the text you wish to have displayed, up to 12 characters long, and press ENT to save.

Page 23

4.8.2 Location ID On and Screen

Position Set

Pressing 2 in the LOCATION ID SETUP MENU will

turn the ID on at all times. It also allows you to position the ID with the cursor control keys to the desired

screen display position.

4.8.3 Location ID Off

Pressing 3 will turn off the ID display.

4.9 CUSTOMER HEADER

(Selection #5 from the main menu)

4.10.1 Program Transfer

The PROGRAM TRANSFER function is used for easy

duplication of the Inter-Check ICI1000S Series program.

This is especially useful for transferring exception programming to multiple Inter-Check ICI1000S Series units

within the same chain of stores. Programming can also

be transferred to an IBM compatible PC. This requires a

software program which must be ordered directly from

Pelco. To accomplish a program transfer a simple cable

can either be made or may be ordered from Pelco. Refer

to Figure 7 for proper wiring.

Upon entering 1 in the DIAGNOSTICS MENU the

following prompt appears:

The CUSTOMER HEADER is the message displayed

when the Inter-Check ICI1000S Series is being reset

and initialized. This text may be changed to reflect the

name of the customer’s store or company . Pressing 6 in

the MAIN PROGRAM MENU will allow changing the

customer header:

ENTER DATA WANTED UP TO 25 CHARACTERS

(ESC) TO SKIP, (ENTER) TO ENTER,

(BS) TO BACKSPACE

Enter the header desired up to 25 characters in length

and press ENTER to save.

NOTE: Performing a DEF AULT LOAD (DL)

in the Diagnostics Menu will return the customer header to the default setting.

4.10 DIAGNOSTICS

(Selection #6 from the main menu)

WARNING: Some of the tests selected in the

DIAGNOSTICS MENU will cause the programming in the Inter-Check ICI1000S Series

unit to be lost. These selections are preceded

by (DL) in the DIAGNOSTIC SELECTION

MENU.

1. SOURCE 2. DESTINATION

After connecting the cable between the two Inter-Check

units, enter #1 for SOURCE on the Inter-Check ICI1000S

Series that is sending the program. Then enter #2 on the

DESTINATION Inter-Check unit, or the one that is receiving the program data. The program will then be sent

automatically. Upon detection of an error in transmission,

the system will retry until the proper data is received or

until manually aborted by pressing ESC.

CAUTION: Both units must have the same

memory map version. The memory map is displayed upon completion of initialization.

MM VER. X.X

4.10.2 (DL) Burn-In Test

(Test performed by Pelco personnel only)

4.10.3 (DL) Input Channel Port Test

(Test performed by Pelco personnel only)

NOTE: Some of the tests in the DIAGNOSTICS MENU can only be performed by factory trained personnel.

Pelco Manual C1000M-B (1/96) 19

Page 24

Data

Alarm

Data

Alarm

Out

In

BL

BK

RD

WH

YL

GR

BL

BK

RD

Figure 7. Program Transfer Wiring Diagram

4.10.4 Memory Tests

By entering 4 in this menu the following sub-menu is

displayed:

MEMORY TEST MENU

1. RAM TEST

2. VIDEO RAM TEST

3. (DL) NV MEMORY TEST

4. ROM CRC TEST

By selecting 1, the unit will perform a self test on its

Random Access Memory. This test is used to verify

system RAM integrity. The system will display an OK

message if the test passes or an address and data if it

fails. ESC brings the Inter-Check ICI1000S Series back

to the DIAGNOSTICS MENU.

Selecting 2 in this menu will put the Inter-Check

ICI1000S Series into the VIDEO RAM TEST mode.

The video RAM is verified by a slotted, scrolling display in the upper left hand corner of the monitor. If an

error is detected an address and data will appear on the

screen. ESC brings the unit back to the DIAGNOSTICS MENU.

WARNING: When the NON-VOLATILE

MEMORY TEST is selected all programming

is lost.

The NV MEMORY TEST, (3rd selection), is used to

verify the NON-VOLATILE MEMORY integrity. The

system will display OK if the test passes. Upon error,

the Inter-Check ICI1000S Series will display an address

and the data that was written into the memory location.

Out

In

WH

YL

GR

NOTE: For complete pin-out

information, refer to Table 3.

NOTE: If the Inter-Check ICI1000S Series

displays the message “ERROR WRITING NV

MEMORY!!!!!!”, the write protect switch on

the bottom of the Inter-Check ICI1000S Series

unit is in the wrong position for this test. Refer

to Section 4.2 and Figure 5 for an explanation

of this error message.

Pressing #4 will allow the Inter-Check ICI1000S Series unit to perform a CRC test on the Read Only

Memory. While this test is running, verify that the ROM

CHECK and the CALC. ROM CHECK numbers match.

If there is an error the system will beep and display the

two different ROM numbers. If a failure occurs, unplug and retry.

4.10.5 System Signals Test

(Test performed by Pelco personnel only)

4.10.6 Video Screen Test

This test produces normal and reverse video images

covering the entire screen. It is used to verify video

character generation and system control.

4.10.7 Graphics Screen Test

The number 7 selection in the diagnostics menu is used

to test the video graphics mode available on the InterCheck ICI1000S Series unit.

20 Pelco Manual C1000M-B (1/96)

Page 25

4.10.8 (DL) Pelco PIM Default Load

The Pelco DEFAULT LOAD should be executed for

the following situations:

2. Press #6 (you will hear two tones). The following

text will appear:

DIAGNOSTICS SELECTION MENU

• Before doing any programming of the Inter-Check

ICI1000S Series upon initial installation.

• After a firmware update has been completed.

Performing a default load sets up all parameters of the

Inter-Check ICI1000S Series unit to the default settings.

This feature of the Inter-Check ICI1000S Series should

be used in normal PIM installations. After executing a

(DL) the Inter-Check ICI1000S Series communication

parameters are set up to receive data from a PIM. The

Inter-Check ICI1000S Series communication parameters are set to the following values:

9600 BAUD

8 BITS

OFF PARITY

NRZ

ASCII

DATA INVERTED

To execute a (DL), follow these steps:

1. Press ENT while in the monitoring mode (you will

hear one tone). The MAIN PROGRAM MENU

will be displayed.

MAIN PROGRAM MENU

1. CHANNEL SETUP

2. SYSTEM PARAMETERS

3. CLOCK SETUP

4. LOCATION ID. SETUP

5. CUSTOMER HEADER

6. DIAGNOSTICS

7. ALARM INPUTS

ESC TO QUIT OR SELECT # TO

PROGRAM

1. PROGRAM TRANSFER

2. (DL) BURN IN TEST

3. (DL) INPUT CHANNEL PORT TEST

4. MEMORY TESTS

5. SYSTEM SIGNAL TEST

6. VIDEO SCREEN TEST

7. GRAPHICS SCREEN TEST

8. (DL) Pelco PIM DEFAULT LOAD

ESC TO QUIT OR SELECT # TO

PROGRAM

3. Press #8 (you will hear two tones). The Inter-Check

ICI1000S Series will prompt you:

DEFAULTS BEING LOADED

The DIAGNOSTICS SELECTION MENU will be displayed again.

4. Press the ESC key (you will hear one tone). The

Inter-Check ICI1000S Series unit will return to the

monitoring mode and initialize again.

NOTE: Each time you enter the SYSTEM

MENUS and ESC back into the monitoring

mode, the initialization message will be displayed.

5. After executing a (DL) Pelco PIM DEFAULT

LOAD, the Inter-Check ICI1000S Series system

parameters are set to the following:

• Data channel: set for Pelco PIM STANDARD

• Data dwell time: continuous display

• Lines displayed: 18 lines

• Characters displayed: 30 characters

• Alarm output : set for six seconds dwell when data

is received.

• Data channel text positioning: column 1

• Exception alarm: OFF

• Auxiliary ports: OFF

• Exceptions: not programmed

• Location ID: not programmed

Pelco Manual C1000M-B (1/96) 21

Page 26

4.11 ALARM INPUT

(Selection #7 from the main menu)

The ALARM INPUT can be connected to any normally

open (open loop) alarm device that can trigger a closure for at least one-half second. Once an alarm is valid,

the trigger is reset to open and will not detect the next

alarm until timeout. For correct wiring, refer to Figure

8 and Table 3.

After selecting #7, the following text will be displayed:

ALARM DWELL : 6/D1

ALARM IN DWELL : 0/OFF/V1 = =>ALARM

IN

ALARM INPUT PROGRAM MENU

1. ALARM INPUT ON/OFF

2. ALARM TRIGGER DWELL

3. SCREEN LINK

4. AUXILIARY PRINT LINK

5. SCREEN HOMING

6. ALARM TEXT

NOTE: For a complete table of status label

descriptions used in the Inter-Check ICI1000S

Series menu system refer to Table 2.

4.11.1 Alarm Input On/Off

This selection enables you to turn the ALARM INPUT

on or off. You can also route an ALARM INPUT exception to the output port (i.e., VCR). After pressing

#1 you will see the following:

ALARM IN

1=OFF 2=ON

Press one (1) to turn the input off, or two (2) to turn the

input on. The next prompt will read:

TRIGGER ALARM OUT

1=OFF 2=ON

Select one (1) to not trigger the ALARM OUTPUT on

when an alarm from the input is received. Select two

(2) to trigger the ALARM OUTPUT when an alarm

from the input is received.

WH

BK

RD

Alarm

Data

13 12 11 10 9 8 7 6 5 4 3 2 1

Out

In

25 24 23 22 21 20 19 18 17 16 15 14

BL

YL

GR

NOTE: A serial printer used with the Inter-Check ICI1000S

Series must be set at 1200 baud, 8 bits, no parity.

Alarm

Contact

Figure 8. Printer Output and Alarm Input Wiring

22 Pelco Manual C1000M-B (1/96)

Page 27

4.11.2 Alarm Trigger Dwell

4.12 Alarm Programming

Selection #2 enables you to program the amount of time

that the ALARM INPUT closure must be present in

order for the Inter-Check ICI1000S Series to recognize

it as a valid alarm condition. To program this option,

simply enter a suitable value between 000-255 seconds

for the minimum duration the ALARM INPUT closure

is present. This ensures the Inter-Check ICI1000S Series unit will recognize it as a valid ALARM. The default value is set at 6 seconds.

4.11.3 Screen Link

Selection #3 allows you to program the ALARM INPUT TEXT to the video display. The ALARM INPUT

TEXT is surrounded by asterisks when this selection is

turned on. It captures your attention when an ALARM

INPUT condition has occurred. Simply select on or off

to display the text to the video screen.

4.11.4 Auxiliary Print Link

This selection allows you to program the auxiliary output to print the alarm text. Select either 1 to turn off the

printer to the alarm text, or select 2 to turn the printer

on.

4.11.5 Alarm Text

This last selection displays an associated descriptor to

a specified ALARM INPUT. The Inter -Check ICI1000S

Series allows you to program 12 characters including

spaces. This text will be displayed on the screen if the

SCREEN LINK is turned on and/or a printer if the

AUXILIARY PRINT LINK is turned on. As mentioned

earlier, the ALARM TEXT is surrounded by asterisks

on the printer or video screen.

NOTE: In the following examples, underlined

text designates the correct selection.

1. Since you want to turn ALARM INPUT “on”, select #1 under the ALARM INPUT PROGRAM

MENU.

2. Select #2 to turn this ALARM INPUT “on”

ALARM IN

1=OFF 2=ON

3. Since you want to “send” the ALARM INPUT to

the ALARM OUTPUT, you have to turn ALARM

OUTPUT “on”. This is done by selecting #2 at the

next prompt:

TRIGGER ALARM OUT

1=OFF 2=ON

4. Programming a 10 second closure time is done by

pressing #2 (ALARM TRIGGER DWELL) under

the ALARM INPUT PROGRAM MENU.

ALARM DWELL TIME IN SECONDS

(000-255) =?10

Press 10, the appropriate time period, then ENT to

save.

5. Now link your ALARM INPUT to screen #1. Do

this by selecting #3 (SCREEN LINK) under the

ALARM INPUT PROGRAM MENU.

SCREEN DISPLAY

1=OFF 2=ON

NOTE: Each time you change any of the parameters just mentioned, the Inter-Check

ICI1000S Series updates current settings automatically. The current settings can be viewed

by entering the ALARM INPUT PROGRAM

MENU.

Let’s say you want your Inter-Check ICI1000S Series

to activate an alarm condition when a cash register

drawer has been open for 10 seconds. After this alarm

has occurred, you want to print the text “REG. 1 OPEN”

on the screen as well as print this text on a printer via

the auxiliary port. You also wish to capture the action

on VCR tape.

Pelco Manual C1000M-B (1/96) 23

Page 28

6. Print the ALARM INPUT text via auxiliary port.

Do this by selecting #4 (AUXILIARY PRINT

LINK) in the ALARM INPUT PROGRAM

MENU.

AUX PRINT

1=OFF 2=ON

7. The descriptor will describe the type of action that

caused the alarm. T o program the descriptor “REG.

1 OPEN”, enter #5 (ALARM TEXT) in the

ALARM INPUT PROGRAM MENU.

ENTER DATA WANTED UP TO 12

CHARACTERS.

(ESC) TO SKIP, (ENTER) TO ENTER,

(BS) TO BACKSPACE

ALARM IN

REG.1 OPEN

Press ENTER

4.13 THE NV MEMORY WRITE

PROTECT SWITCH

Your new Inter-Check ICI1000S Series incorporates a

Non-Volatile (NV) type memory. This type of memory

does not require a battery to operate. Refer to Figure 5

for the location of this switch and note the locked and

unlocked positions. This switch must be positioned in

the UNLOCKED position if you intend on programming the Inter-Check ICI1000S Series unit. If the switch

is in the LOCKED position and you try to enter programming data, an “ERROR IN WRITING NV

MEMORY !!!” warning will be displayed on the monitor screen. T o allow programming, simply position the

write protect switch to the UNLOCKED position. When

programming is complete, position the switch to the

LOCKED position. This will protect your programming

from possible errors that may occur during AC power

fluctuations or complete Inter-Check ICI1000S Series

power loss.

8. The final display should look like this for ALARM

1 IN:

ALARM IN DWELL : 10/ON/V1A1

= =>REG. 1 OPEN

DESCRIPTION: The alarm input is ON and

is currently being “sent” to both the video and

an auxiliary printer. Alarm occurs after a closure of 10 SECONDS with a descriptor displaying REG.1 OPEN.

Table 2 is used to identify the descriptors used throughout the Inter-Check ICI1000S Series menu system.

Table 2. Label Descriptors

Descriptor Display

Data D1

Video V

Exception E

Auxiliary 1 A1

Printer PNTR

Exception Alarm EALRM

Table 3. ICI1000S Series Pinouts

Color Pin # Description

White 1 Program download input

Black 2 Signal ground

Red 3 RS232 current loop CHANNEL

INPUT

Green 4 TTL printer output

Yellow 5 ICI1000PIM input

Blue 6 Alarm input

24 Pelco Manual C1000M-B (1/96)

Page 29

5.0 TROUBLESHOOTING

Symptom: System does not receive register data.

1. Power down the PIM, then repower it. If you receive a display on your monitor with a register

model number, the unit is receiving data from the

PIM.

2. Make sure the register model matches the number

displayed on the monitor.

Symptom: Red power indicator light on back of

unit is not lit.

1. Make sure power supply is plugged in properly.

2. Make sure outlet is working properly.

3. Ensure power supply is good (measure 5 volt output).

4. Ensure that internal fuse is not blown.

3. Make sure the switch settings on your PIM are correct for your model register.

4. Verify that the communication setup and protocol

is accurate for your model register (non-PIM applications).

5. Check for proper wiring and hardware connections.

6. Refer to DEFAULT LOAD procedures in Section

4.10.8 of this manual.

7. Refer to PIM INSTALLATION procedures supplied with your ICI1000PIM or Appendix B of this

manual.

Symptom: No text is displayed on the monitor.

1. Check camera and monitor connections.

2. Verify that the Inter-Check’s power supply is connected.

3. Adjust potentiometers on bottom of the Inter-Check

unit.

Symptom: External serial printer not operating

properly.

1. Ensure proper wiring to the Inter-Check unit.

2. Set printer parameters at 1200 baud, 8 bits, no parity.

Symptom: ERROR IN NV MEMORY message

appears on the monitor.

1. NV MEMOR Y write protect switch on the bottom

of the unit is in the locked position. Move to other

setting. (Refer to Section 4.2 and Figure 5.)

Symptom: RECEIVE ERROR, PLEASE

CHECK PARAMETERS is displayed on monitor.

1. Usually an indication of incorrect baud rate.

2. Also check protocol selection and communication

parameters.

Symptom: Inter-Check unit displays strange

character.

1. Check communication parameters and protocol.

2. Make sure baud rate is correct.

Symptom: Text vibrates on the monitor.

1. Adjust Vertical (V) on the bottom of the InterCheck unit.

2. Adjust Gain (G) on the bottom of the Inter-Check

unit.

Pelco Manual C1000M-B (1/96) 25

Page 30

5.1 TROUBLESHOOTING FLOW CHART

26 Pelco Manual C1000M-B (1/96)

Page 31

6.0 SPECIFICATIONS

GENERAL

MODELS

ICI1000SI Single register interface with inter-

nal keypad for programming; one (1)

alarm output and thirty (30) programmable exceptions

ICI1000SE Same as ICI1000SI except with ex-

ternal keypad for programming

ELECTRICAL

Input Voltage: 5 VDC ±3%

Power Supply:

Input 120 VAC @ 15 watts, 60 Hz

Output 5 VDC @ 1 amp

Fuse Protection: 1 amp

Video Inputs: One 75 ohm NTSC/PAL

Video Outputs: One 75 ohm NTSC/PAL

Alarm Outputs: One open collector output optically

isolated to 3000V

Ambient Operating

Temperature: 35° to 95°F (12.725° to 35°C)

Dimensions: 1.5"H x 4.75"W x 8.75"L

(3.81 cm x 12.07 cm x 22.23 cm)

Weight: 2 lbs (.9 kg)

Construction: Steel, black enamel

Connectors:

Video 2 BNC

Alarm Out One open collector output

Rating: NEMA 1

Internal Composite

Synchronization:

Standard

NTSC Vertical 60 Hz @ 260 µs

Horizontal 15.36 KHz @ 4.38 µs

or

Optional PAL Vertical 50 Hz @ 260 µs

Horizontal 15.36 KHz @ 4.38 µs

Pelco Manual C1000M-B (1/96) 27

Page 32

7.0 WARRANTY AND RETURN

INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved

defective in material or workmanship for a period of one year after the date

of shipment.

Exceptions to this warranty are as noted below:

• Five years on FT/FR8000 Series fiber optic products.

• Three years on Genex

keyboard).

• Three years on Camclosure

CC3701H-2, CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2,

and MC3651H-2X camera models, which have a five-year warranty.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy

DF5/DF8 Series fixed dome products.

• Two years on Spectra

ing when used in continuous motion applications.

• Two years on Esprit

wiper blades).

• Eighteen months on DX Series digital video recorders, NVR300

Series network video recorders, and Endura

network-based video products.

• One year (except video heads) on video cassette recorders (VCRs).

Video heads will be covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in

continuous motion applications (that is, preset scan, tour and auto scan

modes).

Pelco will warrant all replacement parts and repairs for 90 days from the

date of Pelco shipment. All goods requiring warranty repair shall be sent

freight prepaid to Pelco, Clovis, California. Repairs made necessary by

reason of misuse, alteration, normal wear, or accident are not covered

under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or

loss resulting from the specific use or application made of the Products.

Pelco’s liability for any claim, whether based on breach of contract,

negligence, infringement of any rights of any party or product liability,

relating to the Products shall not exceed the price paid by the Dealer to

Pelco for such Products. In no event will Pelco be liable for any special,

incidental or consequential damages (including loss of use, loss of profit

and claims of third parties) however caused, whether by the negligence

of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The