Page 1

C421M-D (2/00)

HT10 Series

Liquid-Cooled Enclosure

®

300 W. Pontiac Way,

Clovis, CA 93612-5699

USA

In North America & Canada:

Tel (800) 289-9100

FAX (800) 289-9150

DataFAX (800) 289-9108

International Customers:

Tel +1 (559) 292-1981

FAX +1 (559) 348-1120

DataFAX +1 (559) 292-0435

Pelco Online

http://www.pelco.com

U

®

L

LISTED

IMPORTANT SAFEGUARDS AND WARNINGS

Prior to installation and use of this product, the following WARNINGS should be observed.

1. Installation and servicing should only be done by qualified service personnel and conform

to all local codes.

2. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X ,6 or 6P enclosure, it is designed for indoor use only and it must not be installed where exposed to rain

and moisture.

3. Only use replacement parts recommended by Pelco.

4. After replacement/repair of this unit’s electrical components, conduct a resistance measurement between line and exposed parts to verify the exposed parts have not been connected to line circuitry.

5. The installation method and materials should be capable of supporting four times the

weight of the enclosure, pan/tilt, camera and lens combination.

6. Use or mount this enclosure so that it is positioned not less than 91 degrees and not

more than 180 degrees when considering 12 o’clock to be 0 degrees and 6 o’clock to be

180 degrees.

7. Only Nema 3R liquid tight conduit should be used in all outdoor applications.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage constituting a risk of

electric shock is present within

this unit.

This symbol indicates that there

are important operating and maintenance instructions in the literature accompanying this unit.

Please thoroughly familiarize yourself with the information in this manual prior to installation

and operation.

CAUTION:

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

DESCRIPTION

The products in the HT10 Series are liquid-cooled enclosures designed for high temperature

applications.

The stainless steel enclosure features two separate double-walled cooling jackets that protect

the camera and lens and other sensing devices housed within the unit.

Models

HT10V High temperature enclosure with Vycor® window; window suitable in

temperatures up to 2500°F (1371°C)

HT10V/RC Same as the HT10V except Vycor window has an infrared reflective coating

for environments where high levels of radiant heat are encountered; window

suitable in temperatures up to 1832°F (1000°C)

Page 2

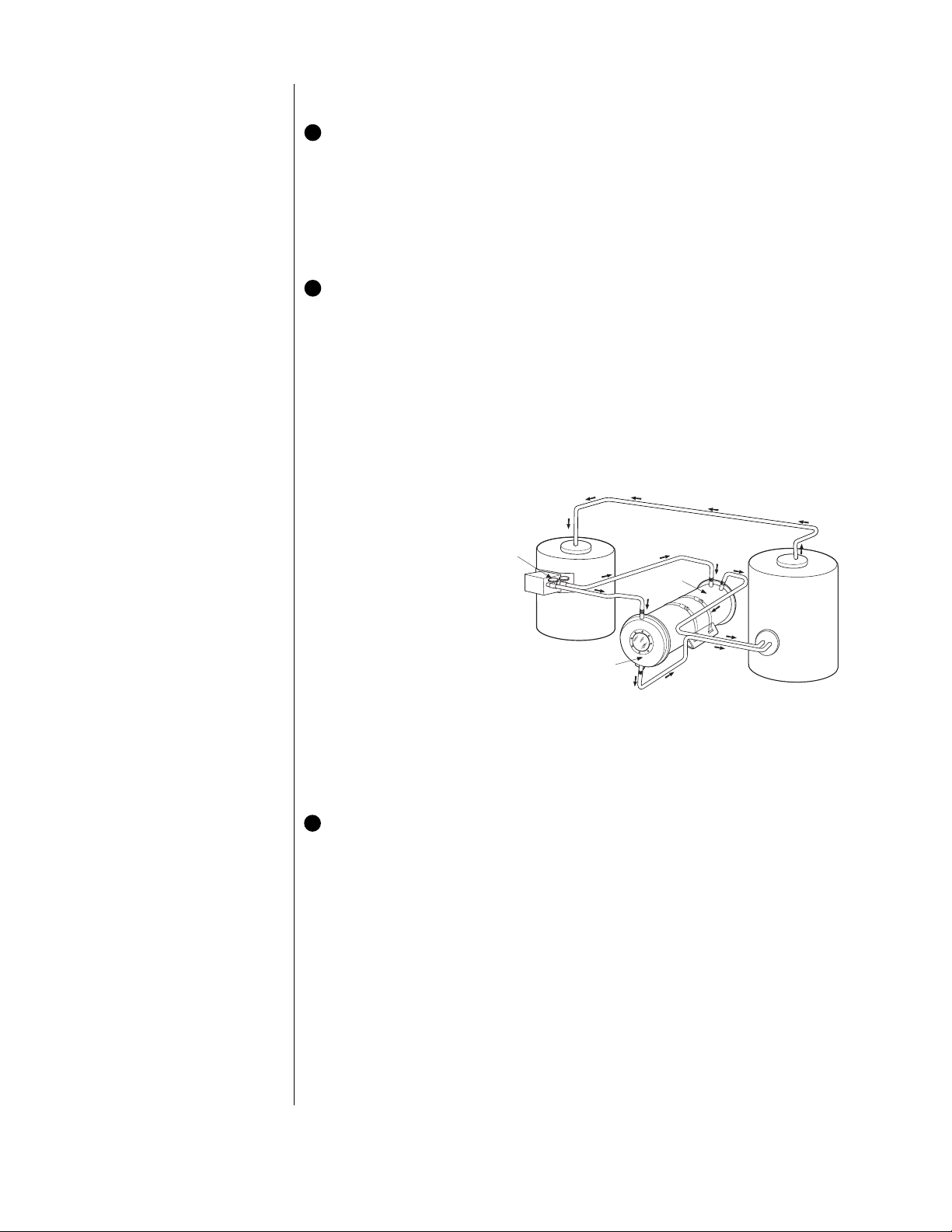

*RESERVOIR

*COOLING TANK

*SHUT OFF

VALVES

COOLING

JACKET

COOLING

JACKET

*LOCATION OF EQUIPMENT IS NOT INTENDED FOR ANY SPECIFIC APPLICATION.

NOTE:

GENERAL DIAGRAM - PUMP, INSULATION, CHECK VALVES AND TYPE OF

PLUMBING NOT SHOWN.

INSTALLATION

1 Mount the Enclosure

Determine the mounting location. Attach the enclosure as follows:

1. Remove the enclosure from the cradle by loosening the screw clamps on the stainless

steel straps.

2. Attach the cradle to the mounting surface (mount, pan/tilt, etc.).

3. Center the enclosure on the cradle and secure it with the stainless steel straps.

2 Connect Cooling Systems

The HT10 Series enclosure features two distinct cooling systems. One cooling jacket is located in the body of the unit and the other is strategically placed around the viewing window.

(Refer to Figure 1.)

To make cooling system connections:

1. Use hoses with a 3/8-inch NPT fitting (not supplied).

2. Connect the enclosure to a coolant reservoir. A shut-off valve should be installed in the

input line to regulate coolant flow.

3. Make input connections.

Input hoses are connected

to the IN line fittings

located at the top and

rear of the enclosure.

IMPORTANT:

Check coolant

flow rate periodically to ensure

that sediment or deposits are

not restricting flow. This will prevent heat from building up in the

enclosure, or steam from developing in the water jacket.

4. Make output connections.

Output hoses are connected to the OUT line

fittings located at the top

and rear of the enclosure.

The output line should not

be restricted, so that the 35

psi working pressure is not

exceeded. The liquid flow

rate is determined by the

temperature of the coolant

as it enters the enclosure

and the temperature gradient

in which the enclosure is

installed.

Figure 1. Coolant Hook-Up, General Installation

3 Install Camera

To mount the camera on the sled:

1. Remove the rear plate of the enclosure.

2. Remove the camera sled:

a. Loosen the 1/4-20 hex socket head screw with the 3/16-inch Allen wrench (supplied).

b. Slide the sled out of the enclosure.

3. Mount the camera and lens onto the sled:

a. Extend the lens to the maximum length before positioning the camera and lens.

b. Position the camera and lens so that they do not extend beyond the track.

c. Fasten the camera and lens to the sled with the two 1/4-20 x .375-inch Phillips

screws (supplied).

4. Reinstall the camera sled.

5. Feed the cable(s) through the feedthrough hole in the rear plate of the enclosure. Make

all equipment connections; refer to the installation manuals supplied with the equipment.

Page 3

SPECIFICATIONS

MECHANICAL

Cooling Pipe Connections: Standard 3/8-inch NPT pipe fittings

Suggested Operating

Pressure: 35 psi, approximately 2.3 gallons/minute

Cooling Jacket Volume: Approximately 3 gallons

GENERAL

Construction: Type 304 stainless steel

Finish: Silver-gray paint

Viewing Window

HT10V: .25-inch (6.35 mm) thick Vycor glass

HT10V/RC: .25-inch (6.35 mm) thick Vycor glass with infrared coating

Window

Temperature Range

HT10V: Up to 2500°F (1371°C)

HT10V/RC: Up to 1832°F (1000°C)

Maximum

Camera and Lens Size: Accepts camera and lens combinations (including BNC

connector) up to:

5.50 (H) x 5.00 (W) x 22.00 (L) inches

(13.97 x 12.70 x 55.88 cm) or

8 (D) x 22 (L) inches

(20.32 x 55.88 cm)

Weight

Dry: 50 lb (22.5 kg)

With coolant: 70 lb (31.5 kg) approx.

Rating: NEMA 1 (HT10V)

(Design and product specifications subject to change without notice.)

3/8” N.P.T.

I.D.

9.75

(24.76)

5.00 (12.70)

A

6.25 (15.88)

B

9.00 (22.86)

C

WATER INLET AND OUTLET

3/8” N.P.T.

25.31

(64.29)

DRAIN

Ø .31 (.79), 6X

7.00

(17.78)

9.12

(23.16)

WATER INLET

AND OUTLET

11.50

(29.21)

12.50

(31.75)

.75 (1.9)

NOTE: VALUES IN PARENTHESES ARE CENTIMETERS; ALL OTHERS ARE IN INCHES.

A

BASE

B

C

Figure 2. HT10 Series Dimension Drawing

Page 4

WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or workmanship for a period of one year after the date of

shipment. Exceptions to this warranty are as noted below:

®

• Three years on Genex

• Two years on all standard motorized and fixed focal length lenses.

• Two years on Esprit™, Legacy

CM8500/CM9500/CM9750/CM9760 Matrix, Spectra

Fixed Dome products.

• Two years on WW5700 series window wiper (excluding wiper blades).

• Two years on cameras.

• Six months on all pan and tilts, scanners or preset lenses used in continuous

motion applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date

of Pelco shipment. All goods requiring warranty repair shall be sent freight

prepaid to Pelco, Clovis, California. Repairs made necessary by reason of

misuse, alteration, normal wear, or accident are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss

resulting from the specific use or application made of the Products. Pelco’s

liability for any claim, whether based on breach of contract, negligence, infringement of any rights of any party or product liability, relating to the Products shall not exceed the price paid by the Dealer to Pelco for such Products.

In no event will Pelco be liable for any special, incidental or consequential

damages (including loss of use, loss of profit and claims of third parties) however caused, whether by the negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may

also have additional rights, which are subject to variation from state to state.

Series (multiplexers, server, and keyboard).

®

, Intercept®, PV1000 Series, CM6700/

®

, DF5 Series and DF8

REVISION HISTORY

Manual # Date Comments

C421M 3/91 Original version.

C421M-A 3/92 Warranty page added.

C421M-B 12/93 New format, dimension drawing; updated models, options, mounts.

C421M-C 2/95 WCAL instructions added. Figure 1 added. Per ECO94-198, changed part # for infrared coated glass.

C421M-D 2/00 Updated manual to new format. Created separate manual for WCAL.

If a warranty repair is required, the Dealer must contact Pelco at (800) 2899100 or (559) 292-1981 to obtain a Repair Authorization number (RA), and

provide the following information:

1. Model and serial number

2. Date of shipment, P .O. number, Sales Order number , or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall

under the warranty conditions stated above, please include a written explanation with the product when returned.

Ship freight prepaid to: Pelco

Method of return shipment shall be the same or equal to the method by which

the item was received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please

call the factory at (800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned for credit, and RA number if returned for

repair). Goods returned for repair or credit should be clearly identified with

the assigned CA/RA number and freight should be prepaid. All merchandise

returned for credit may be subject to a 20% restocking and refurbishing charge.

Ship freight prepaid to: Pelco

300 West Pontiac Way

Clovis, CA 93612-5699

300 West Pontiac Way

Clovis, CA 93612-5699

®Pelco, the Pelco logo, Spectra, Genex, Legacy, and Intercept are registered trademarks of Pelco. ™ Esprit is a trademark of Pelco.

® Vycor is a registered trademark of Corning Glass Works. © Copyright 1999, Pelco. All rights reserved.

Loading...

Loading...