Page 1

®

EH66/EH66X

Environmental Enclosures

Installation/Operation Manual

C411M-D (1/96)

Pelco • 3500 Pelco Way, Clovis, CA 93612-5699 • USA • www.pelco.com

(559) 292-1981 or (800) 289-9100 • FAX (559) 292-3827 or (800) 289-9150

Pelco Manual C411M-D (1/96) 17

Page 2

TABLE OF CONTENTS

Section Page

1.0 WARNINGS ........................................................................................................................................1

2.0 SCOPE ............................................................................................................................................... 2

3.0 DESCRIPTION ................................................................................................................................... 2

3.1 CERTIFICATIONS ....................................................................................................................2

4.0 INSTALLATION ..................................................................................................................................3

4.1 ELECTRICAL CONNECTIONS/BLOWER AND HEATER ........................................................ 3

4.2 INSTALLATION OF CAMERA/LENS ........................................................................................3

4.3 FIXED ENCLOSURE MOUNTING ...........................................................................................5

4.4 PAN/TILT ENCLOSURE MOUNTING ....................................................................................... 6

4.5 WINDOW WIPER INSTALLATION ............................................................................................8

4.6 B66KIT/E624HB/H66KIT INSTALLATION ................................................................................ 9

5.0 CARE AND MAINTENANCE ..............................................................................................................9

6.0 EXPLODED ASSEMBLY DIAGRAMS .............................................................................................. 10

7.0 MECHANICAL PARTS LISTS .......................................................................................................... 12

7.1 MECHANICAL PARTS LIST WW66 AND WW66-5/220 ASSEMBLY .....................................13

8.0 OPTIONAL ACCESSORIES ............................................................................................................ 14

9.0 SPECIFICATIONS ............................................................................................................................14

9.1 RECOMMENDED CABLE SIZE .............................................................................................15

9.2 POWER REQUIREMENTS FOR BLOWER, HEATER, ACCESSORIES ............................... 15

10.0 WARRANTY AND RETURN INFORMATION ...................................................................................16

ii PELCO Manual C411M-C (1/96)

Page 3

LIST OF ILLUSTRATIONS

Figure Page

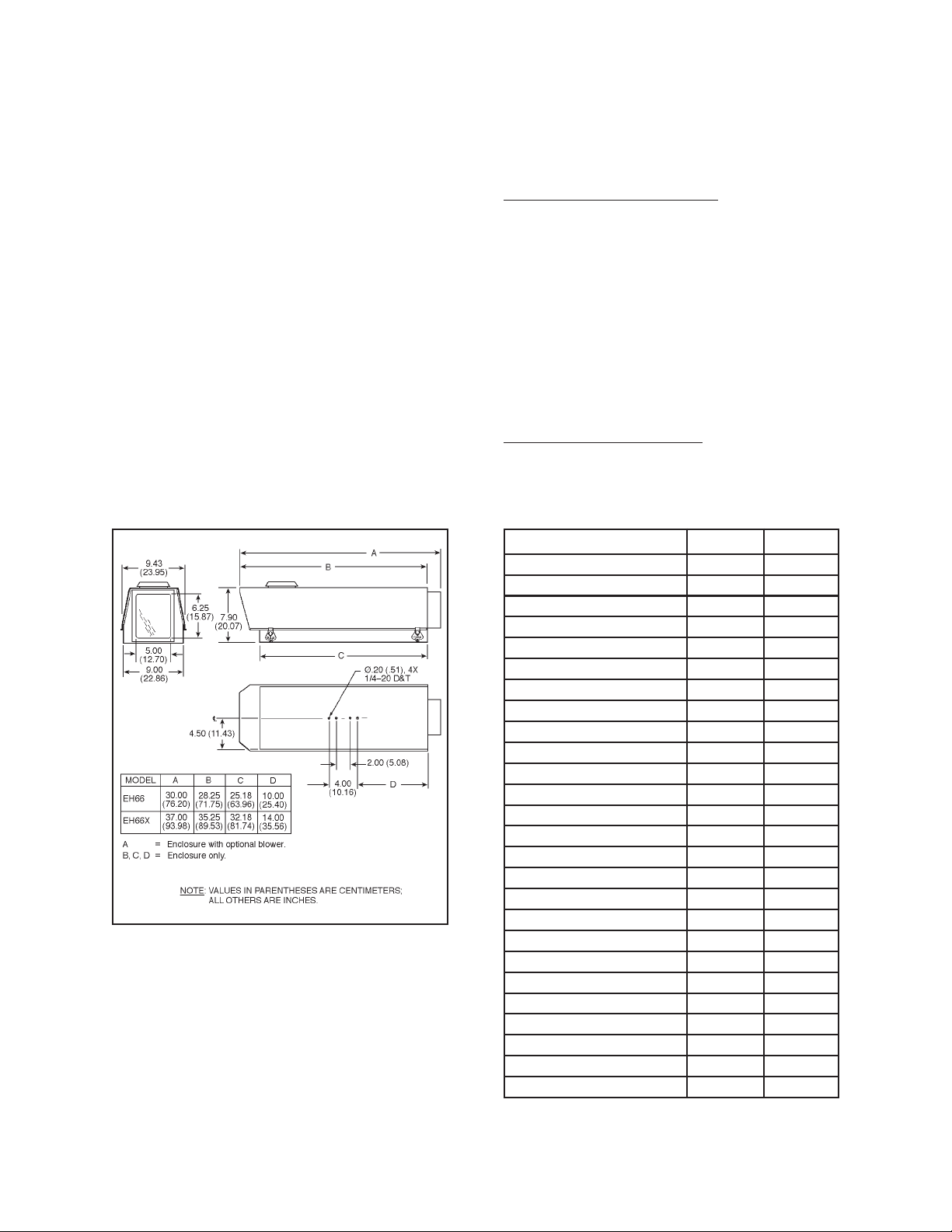

1 EH66/EH66X Dimension Drawing ................................................................................................. 2

2 Wiring Diagram for Window Defroster, Wiper/Washer and Blower/Heater Assemblies................. 4

3 EH66 Enclosure with Wall Mount .................................................................................................. 5

4 EH66 Enclosure with Pedestal/Ceiling Mount ............................................................................... 5

5 EH66 Enclosure with Pan/Tilt and Wall Mount .............................................................................. 6

6 EH66 Enclosure with Pan/Tilt and Pedestal/Ceiling Mount ........................................................... 6

7 Window Wiper Motor Installation ................................................................................................... 7

8 Mounting Hole Dimensions ........................................................................................................... 7

9 EH66 Enclosure Exploded Assembly Diagram ............................................................................. 9

10 WW66, WW66-5/220 Wiper Exploded Assembly Diagram ......................................................... 10

REVISION HISTORY

Manual # Date Comments

C411M 8/88 Original Manual

C411M 5/91 Revision A. Revised to include new series models; cable distance

information, and the addition of the WW66 installation information as well

as new manual format

C411M 11/92 Revision B. Revised to include new wiring diagram information for

accessory kits as well as WW66 motor installation/mounting information.

C411M-C 2/95 Revision C. Manual revised to include new dimension drawing; the addition

of rubber grommet to WW66 BOM as per ECO #94-091; changes to the

WW66 exploded view diagram as per ECO #94-233; installation instructions

incorporated as per ECO #92-129; completely new EH66 exploded assembly

drawing with new materials list; new mounting hole dimension drawing and

window wiper assembly drawing as per ECO # 93-200; and minor corrections

to wiring diagram.

C411M-D 1/96 Revision D. Manual revised to include new wiper/washer pump as per ECO

95-431.

Pelco, the Pelco logo, Camclosure, Esprit, Genex, Legacy, and Spectra are registered trademarks ofPelco. ©Copyright 1998, Pelco. All rights reserved.

Endura and ExSite are trademarks of Pelco.

Pelco Manual C411M-D (1/96) iii

Page 4

This page intentionally left blank.

iv Pelco Manual C411M-D (1/96)

Page 5

INSTALLATION/OPERATION MANUAL

MODEL EH66/EH66X SERIES

ENVIRONMENTAL ENCLOSURES

1.0 WARNINGS

Prior to installation and use of this product, the following

WARNINGS should be observed.

1. Installation and servicing should only be done by

Qualified Service Personnel and conform to all

local codes.

2. Unless the unit is specifically marked as a NEMA

Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is

designed for indoor use only and it must not be

installed where exposed to rain and moisture.

3. Only use replacement parts recommended by Pelco.

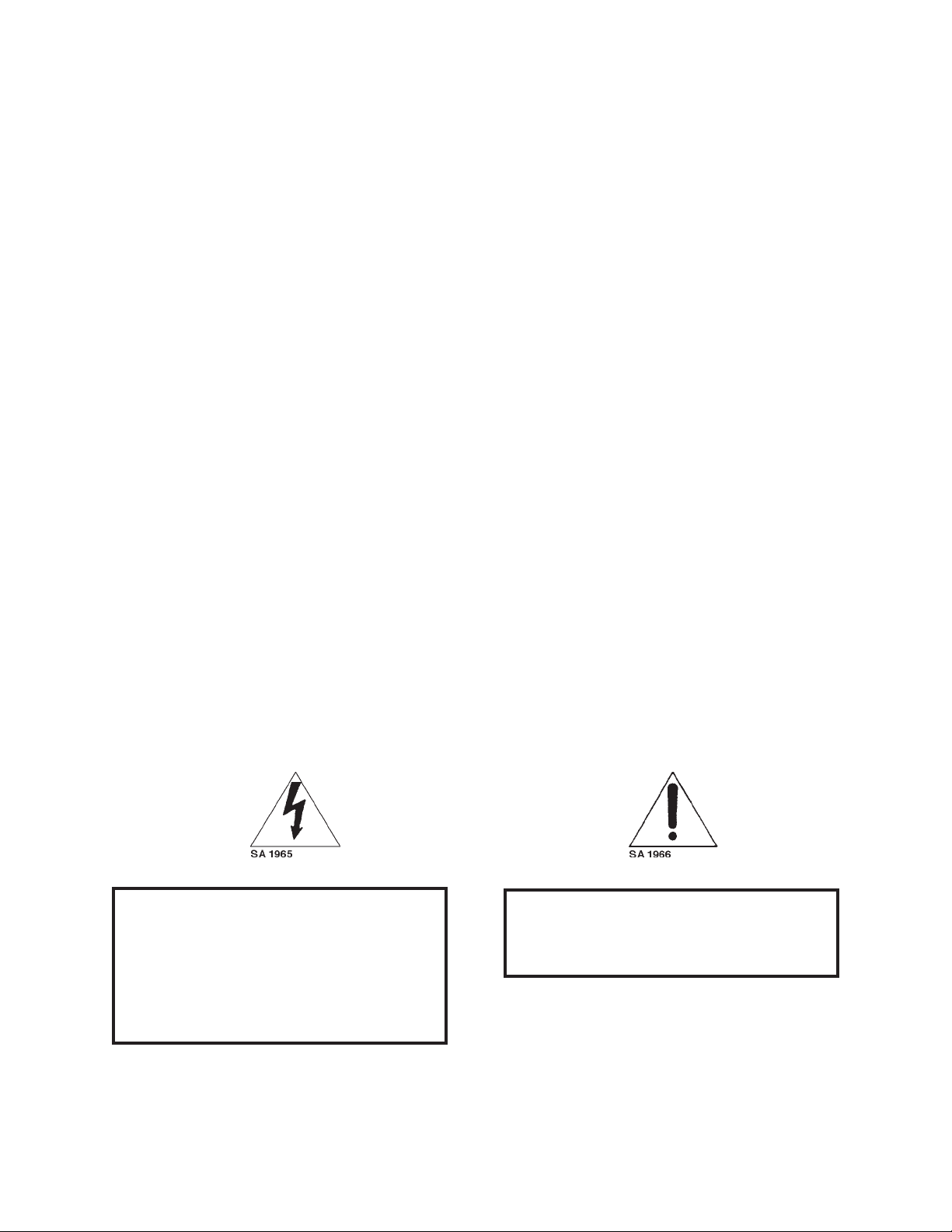

The product and/or manual may bear the

following marks:

This symbol indicates that dangerous voltage

constituting a risk of electric shock is present

within this unit.

4. After replacement/repair of this unit’s electrical

components, conduct a resistance measurement

between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

5. The installation method and materials should be

capable of supporting four times the weight of the

enclosure, pan/tilt, camera and lens combination.

This symbol indicates that there are important

operating and maintenance instructions in the

literature accompanying this unit.

CAUTION:

TO REDUCE THE RISK OF ELECTRICAL

SHOCK, DO NOT REMOVE COVER. NO

USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

RISK OF ELECTRIC SHOCK.

CAUTION:

DO NOT OPEN.

Please thoroughly familiarize yourself with the information in this manual

prior to installation and operation.

Pelco Manual C411M-D (1/96) 1

Page 6

2.0 SCOPE

The information contained within this manual covers

the EH66/EH66X Series environmental enclosure.

3.0 DESCRIPTION

The EH66 Series is an all-weather environmental enclosure for 2/3" and 1" cameras with a maximum camera/

lens size of 7" W x 7" H x 22" L (17.7 cm x 17.7 cm x

55.8 cm). Rugged all aluminum construction protects

the camera from adverse weather conditions. Built-in

sun visor shields the lens from direct sunlight, and a vent

cap allows heated air to escape from the interior. Removable lid with four secure latches provides convenient access. Camera is mounted on an adjustable rail/

sled. Two adjustable glands in the bottom of the enclosure permit easy cable entry.

The EH66X Series is the same as the EH66 Series

except the enclosures have extra length to accommo-

Figure 1. EH66/EH66X Dimension Drawing

date intensified cameras. The EH66X Series will accept

a maximum camera/lens size of 7" W x 7" H x 30" L

(17.7 cm x 17.7 cm x 76.2 cm).

Models With The Letters “HB” in the suffix come

equipped with a factory installed filtered blower and

wired blanket heater with thermostat controls. The

heater activates when the internal temperature falls

below 40° F (4.44° C). It is electrically insulated from

the enclosure and provides 160 watts of heat. The

blower provides 105 CFM and activates when the

internal temperature reaches approximately 100° F

(37.78° C). Internal temperature is reduced when the

blower draws ambient air from a filtered intake port,

circulates it through the enclosure, and exhausts it out

the vent cap.

Models With The Letter “L” in the suffix include

tamper resistant locks which are keyed alike.

3.1 CERTIFICATIONS

Model Number UL CE

EH66 X X

EH66/WW X

EH66B X

EH66B/WW X

EH66BL X

EH66H X

EH66HB X

EH66HB/WW X

EH66HB-3 X

EH66HBL X

EH66HBL/WW X

EH66HL X

EH66L X X

EH66L/WW X

EH66X X X

EH66X/WW X

EH66XB X

EH66XBL X

EH66XH X

EH66XHB X

EH66XHB/WW X

EH66XHBL X

EH66XHBL/WW X

EH66XHL X

EH66XL X X

EH66XL/WW X

2 Pelco Manual C411M-D (1/96)

Page 7

4.0 INSTALLATION

Please check the contents of your package(s) for the

following items before proceeding with the installation

of the equipment.

Quantity Item

2 1/4-20 x .500 hex head screws to mount

camera

1 5/32-inch Allen wrench for adjusting sled

1 Blower assembly (installed on models

with “HB” in suffix only)

1 Heater assembly (installed on models with

“HB” in suffix only)

NOTE: Cameras with a low optical centerline

or using a large diameter lens require an elevation block (1 inch or 2 inch) for proper positioning. See Section 8.0, Optional Accessories,

for the correct model number.

3. Replace the camera/sled assembly onto the rail and

slide along the rail to adjust the camera to maximum forward camera position; lock into place by

tightening the Allen head screws.

IMPORTANT: Set the focus for the shortest

distance to extend the lens to the maximum

length before positioning the camera/lens combinations. This will ensure that the lens has

enough clearance and will not hit the window

during focusing.

2 Keys (for models with “L” in suffix only)

4.1 ELECTRICAL CONNECTIONS –

ENCLOSURES WITH BLOWER AND

HEATER

Factory installed heater and blower assemblies are

factory pre-wired and only require connection of power

to the terminal block (see Figure 2). Refer to Section 4.6

for field installed heater/blower kits.

NOTE: In dusty locations, double filters can

be installed. Loosen the two Allen head screws

at the rear of the enclosure and pull the drawer

open. Remove the acorn nuts at the rear of the

housing and pull the end plate off for access to

the filters.

4.2 INSTALLATION OF CAMERA/LENS

To install the camera/lens, perform the following:

1. Remove the lid by unlatching the two latches on

each side.

4. Loosen the cable gland nuts on the back of the

enclosure (1/2-inch gland for video cable, 3/8-inch

gland for power cable). Route the camera cables

through the appropriate glands and connect to the

camera. Wire the enclosure per wiring diagram

provided (see Figure 2). Tighten the gland nuts for

a snug fit around the cables.

NOTE: The plate holding the two cable glands

on the bottom of the enclosure is removable,

which allows enough clearance for the connector assemblies to be inserted in or removed from

the enclosure. This permits the connectors (i.e.,

lens connector, video connector, etc.) to be assembled somewhere other than the field and

also allows the enclosure to be moved in the

field without disassembling all the connectors.

5. Replace the lid and secure the latches.

6. Attach the enclosure to the appropriate mount or

pan and tilt using the instructions provided with the

mounting equipment.

2. Remove the camera sled from the rail by loosening

the two Allen head screws and attach the camera/

lens with the 1/4-20 hex head screws provided.

Pelco Manual C411M-D (1/96) 3

Page 8

to control

Figure 2. Wiring Diagram for Window Defroster, Wiper/Washer and Blower/Heater Assemblies

4 Pelco Manual C411M-D (1/96)

Page 9

4.3 FIXED ENCLOSURE MOUNTING

3. Attach the adjustable head to the mount.

The are two types of mounts that can be used with the

EH66 enclosure: wall, or pedestal/ceiling (see Figures

3 and 4).

Instructions for mounting the enclosure are as follows:

1. Select the appropriate mount (WM2000 for wall

mounting or PM2000/PM2010 for pedestal mounting) for the application.

The mount must be equipped with the AH2000

adjustable head for precise positioning of the enclosure.

2. Secure the mount to a suitable load bearing

surface. Use fasteners with a minimum 1/4-inch

diameter.

4. Align the 1/4-20 threaded holes in the bottom of the

EH66 enclosure with the holes in the tilt table of the

adjustable head. Fasten the enclosure to the table

using 1/4-20 fasteners (not to exceed 5/8" in length,

minimum two (2).

5. If you have not already done so, install the camera/

lens according to the instructions in Section 4.2 of

this manual.

6. Make all necessary electrical connections.

7. Position the enclosure to the desired viewing angle

and tighten all fasteners.

Figure 3. EH66 Enclosure with Wall Mount

Pelco Manual C411M-D (1/96) 5

Figure 4. EH66 Enclosure with

Pedestal/Ceiling Mount

Page 10

4.4 PAN/TILT ENCLOSURE MOUNTING

The EH66 enclosure can also be mounted to a pan/tilt

assembly in addition to the wall or pedestal/ceiling

mount.

To include the pan/tilt assembly in your configuration,

perform the following steps:

4. Attach the pan/tilt to the mount. The pan/tilt control

connect should be positioned towards the building/

mounting location. Note the “front” label on the

pan/tilt.

5. If you have not already done so, install the

camera/lens according to the instructions in

Section 4.2 of this manual.

1. Select the appropriate mount (WM2000 for wall

mounting, PM2000/PM2010 for pedestal mount)

for the application.

2. Select the appropriate pan/tilt for the application.

Considerations must be made as to enclosure options, camera and lens selection, and environmental conditions. All of these will affect the pan/tilt

selection.

3. Secure the mount to a suitable load bearing surface.

Use fasteners with a minimum 1/4-inch diameter.

6. Balance the enclosure/camera/lens load on the tilt

table. Adjust the positioning as needed to align the

mounting holes. A minimum of two 1/4-20 x 5/8"

fasteners must be used. Secure the enclosure to the

tilt table.

7. Make all necessary electrical connections. Be sure

to leave an adequate loop of cables between the

enclosure and the pan/tilt, and the enclosure and the

rigid mount to prevent binding and/or strain on the

cables (see Figures 5 and 6).

Figure 5. EH66 Enclosure with Pan/Tilt and

Wall Mount

6 Pelco Manual C411M-D (1/96)

Figure 6. EH66 Enclosure with Pan/Tilt and

Pedestal/Ceiling Mount

Page 11

4.5 WINDOW WIPER INSTALLATION

To install the window wiper kit, perform the following

steps and refer to Figures 7 and 8:

1. Turn the EH66 enclosure over so the bottom is

facing up.

2. If necessary, lay out the locations of the four (4)

.171-inch diameter mounting holes using the dimensions given in Figure 8.

4. Attach the wiper box using the four (4) mounting

holes, inserting the wire leads through one of the

rubber grommets.

5. Adjust the force of the wiper blade against the

glass by applying force to the arms toward the

glass or away from glass.

6. Attach wiper wire leads inside the enclosure as

shown in Figure 2.

7. Connect cable to wiper box.

8. Attach the water reservoir bottle to the rear of the

EH66 enclosure by removing the two (2) top acorn

nuts.

9. Place the bottle mount on the protruding studs and

replace the acorn nuts.

10. Attach the water hose to the bottle from the wiper.

Figure 7. Window Wiper Motor Installation

Figure 8. Mounting Hole Dimensions

Pelco Manual C411M-D (1/96) 7

Page 12

4.6 B66KIT/E624HB/H66KIT

INSTALLATION

All heater and blower kits are supplied partially assembled. Install in the enclosure according to the following instructions:

1. Remove the round cap on the rear of the enclosure

and the two (2) 8-32 screws and nuts located on

each side of the opening above the horizontal line.

5.0 CARE AND MAINTENANCE

Maintenance performed at regularly scheduled intervals will help prolong the operational life and appearance of the equipment.

1. Clean the plexi-glass window with a mild nonabrasive detergent in water and a soft cloth regularly to

help maintain picture clarity. For a heavily soiled

window, use vinyl cleaner.

2. Remove the two (2) acorn nuts holding the air box

to the heater/blower assembly; remove the air box.

3. Install the assembly in the enclosure utilizing the

two (2) open holes for mounting; reinstall the air

box on the outside of the enclosure and secure the

assembly with the two (2) acorn nuts.

4. Mount the two (2) heater strips onto the sides of the

enclosure with the four (4) sheet metal screws

provided.

5. Wire input power to the terminal block on the top of

the heater/blower assembly as shown in Figure 2.

2. Clean or replace the fiberglass filter pad in the

blower assembly periodically. To replace or clean

the filter pad, perform the following steps:

a. Remove the two acorn nuts at the rear of the

housing and pull the end plate off for access to

the filter.

b. Remove the wire screen and filter pad. Clean

the pad with water and mild detergent, dry

thoroughly, and reinsert or replace with a new

pad. (Replacement pads, part number

EH14050COMP, are available from Pelco.)

NOTE: Pelco offers a 24-hour, seven-day-a

week Technical Assistance Program (TAP) designed to assist any customer with a technical

problem involving Pelco equipment whether it’s

the weekend or late at night. For technical assistance dial (800) 289-9100 and you will be

connected to a Pelco TAP member who is

trained to answer your questions.

Pelco also guarantees one-day turnaround on any Pelco

equipment sent in for repair. This includes warranty and

non-warranty items. Refer to the section on “Warranty

and Return Information” in this manual for the proper

procedure.

8 Pelco Manual C411M-D (1/96)

Page 13

6.0 EXPLODED ASSEMBLY DIAGRAMS

See Figures 9 and 10 for exploded assembly diagrams of the EH66 enclosure and WW66, WW66-5/220 wiper assembly.

Figure 9. EH66 Enclosure Exploded Assembly Diagram

Pelco Manual C411M-D (1/96) 9

Page 14

NOTE: FIGURE DOES NOT REPRESENT

CURRENT PUMP IN USE.

Figure 10. WW66, WW66-5/220 Wiper Exploded Assembly Diagram

10 Pelco Manual C411M-D (1/96)

Page 15

7.0 MECHANICAL PARTS LISTS

7.1 MECHANICAL AND ELECTRICAL PARTS LIST FOR EH66 ENCLOSURE

Item No. Qty Description Part Number

1 4 Gasket, Window Frame EH110042

2 1 Gasket, Cable Entry EH110072

3 1 Plate, Cable Entry EH14231COMP

4 2 Gasket, Rim EH450010000

5 2 Gland, UL, PG-13.5 black EH470010007B

6 2 Nut, UL Gland, 13.5 EH470010008B

7 4 Fastener, Lid Link Lock EH550010010B

8 8 Gasket, Poron EH550010030

9 1 Camera Sled EH55004100COMP

10 1 Body Weld Assy EH661000WA

1 Body Weld Assy (EH66X) EH66X1000WA

11 1 Glass 1/4 X 5-9/16 X 6-11/16 EH6610051

12 1 Screen Vent Cap EH664000COMP

13 1 Bar Vent Cap EH664001COMP

14 1 Lid EH664228COMP

1 Lid (EH66X) EH66X4228COMP

15 2*, 1** Vent Cap *, ** EH664229COMP

16 1 Frame, Window EH664230COMP

17 4 Lug, Spade 16-20AWG CON52929-1**

18 2 Heater Blanket, 1" X 17", 120VAC, 80W ED210048 **

19 1 Filter, Fiberglass Cut EH14050COMP **

20 1 Filter Screen EH14051COMP **

21 1 Air Box EH14242COMP **

22 1 Fan, Tube 120VAC EH18013 **

23 1 Gasket, Closed Cell EH5510042 **

24 1 Thermostat, SC-100-A EH5510045A **

25 1 Thermostat, OA-60 EH5510049A **

26 1 Bracket, Terminal Block EH664002COMP **

27 2 Bracket, Heater Strip EH664003COMP **

28 1 Terminal Block, 6-pos TRB6-141 **

29 2 Plate Block EH664104COMP **

A 2*, 1** Screw, 10-32 X 1.25 Pan Phil SS ZH10-32X1.25SPS

B 2 Screw, 10-32 X 2.00 Pan Phil SS ZH10-32X2.00SPP

C 10 Screw, 10-32 X 3/8 Pan Phil SS ZH10-32X.375SPP

D 2 Nut, Acorn, 10-32 SS ZH10-32NUTCA

E 6*, 8** Nut, Hex, 10-32 SS ZH10-32NUTSH

F 2 Washer, Split Lock Washer ZH10LWSSL

G 6 Washer, Nylon ZH200X.437X62N

H 2*, 3** Washer, Flat #10 ZH204X436X60C

I 6 Internal Tooth Lock Washer #10 ZH10LWSIS

J 4** Screw, 6-32 X 1/4 Pan Phil ZH6-32X.250SPP

K 4 Screw, 6-32 X 3/8 Truss SS ZH6-32X.375STS

L 8** Screw, 6-32 X 1/2 Pan Phil ZH6-32X.500SPP

M 8 Screw, 6-32 X 5/8 Pan Phil ZH6-32X.625SPP

N 4** Screw, 6-32 X 3/8 Type F, Pan Phil` ZH6-SFX/375SPP

O 4** Nut, Hex, 6-32 ZH6-32X.32NUTSH

P 12, 16** Internal Tooth Lock Washer, #6 ZH6LWSIS

Q 8 Screw, 4-40 X 3/8 Pan Phil ZH4-40X.375SPP

R 8 Nut, Hex, 4-40 ZH4-40NUTSH

S 8 Internal Tooth Lock Washer ZH4LWSIS

*EH66, EH66X

**EH66HB

***EH66L

Pelco Manual C411M-D (1/96) 11

Page 16

7.2 MECHANICAL PARTS LIST FOR WW66 AND WW66-5/220

WINDOW WIPER ASSEMBLY

Item No. Qty Description Part Number

1 3 Bearing 776003

2 1 Diode DIOPT40F

3 — Not used —

4 1 Switch SWIV3L

5 1 Spacer, 1/4" Hex x .6254-40 tap SPA8404

6 1 Transformer TRF21162.01.0CM

7 1 Pump WW6610031

8 12 Tubing, Vinyl, 1/8 ID x 1/4 OD x in. WW6610007

9 42 Tubing, Vinyl, 1/4 ID x 3/8 OD x in. WW6610005

10 1 Solenoid valve WW650010010

11 3 Spacer Shaft, #84-9 WW6610010

12 1 Roller Plate WW661006COMP

13 1 Follower Arm WW661011COMP

14 1 Wiper Washer Enclosure WW664000COMP

15 1 Bracket, Wiper Motor WW664001COMP

16 1 Motor, 120 VAC (model WW66) WW664017COMP

Motor, 230 VAC (model WW66-5/220) WW664020COMP

17 1 Wiper Arm WW664003COMP

18 1 Wiper Blade Clevis WW664204COMP

19 1 Wiper Idler Arm WW664005COMP

20 1 Bearing Block WW664010COMP

21 1 Wiper Blade WW664214COMP

22 1 Tube, Spray WW66 WW664015COMP

23 2 Fitting, BARBXMNPT WW650010020

24 1 Lid, Enclosure WW664016COMP

25 2 Fitting, BARB, 1/4 tube x 1/8 NPT WW6610008

26 1 4-position CPC pin receptacle CON206061-1

27 1 Cable, 4-position female WIRA220036

1 Bottle, cap, hanger WW6610004

1 Bottle cover WW664900COMP

12 Pelco Manual C411M-D (1/96)

Page 17

8.0 OPTIONAL ACCESSORIES

FACTORY INSTALLED

EHRC Relay module for low voltage control

of wiper/washer and camera on/off.

Requires MEH24DT control module.

TI66 Thermal insulation provides increased

thermal protection for enclosure and

contents at extreme temperatures (for

model EH66 series only).

T166X Thermal insulation for model EH66X

series.

H66KIT Heater kit, 120 VAC, for EH66/EH66X

enclosures. (For 230 VAC option, wire

heaters in series.)

L66KIT Tamper proof lock kit.

S66 Sun shroud, provides an air space be-

tween the sun shroud and the enclosure

to protect the enclosure from the direct

rays of the sun. Reduces internal temperature approximately 10-15° (for

model EH66 only).

S66X Sun shroud for model EH66X.

WD66 Window defroster and defogger, 120

VAC, 80 watt operation, prevents ice

buildup or condensation of moisture

on the window caused by temperature

and humidity. Must be used with heater/

blower assembly.

WD66/220 Same as WD66 except 230 VAC, 80

watt operation.

WW66 Window wiper and washer assembly,

120 VAC operation, designed to remove moisture and dirt from the window by remote control. The washer

enhances cleaning ability of wiper and

has a one quart reservoir for water or

antifreeze solution, which is recommended for low temperature applications.

WW66-5/220 Same as WW66 except 230 VAC, 50 Hz.

FIELD INSTALLED

B66KIT Blower kit, 105 CFM, 13.4 watts at 60

Hz, 120 VAC, for EH66/EH66X enclosures.

BK66KIT/220 Blower kit, 90 CFM, 15 watts at 50

Hz, 230 VAC, for EH66/EH66X enclosures.

E624HB Heater/blower kit, 24 VAC, for Mod-

els EH66/EH66X.

MISCELLANEOUS

EB1 Elevation block 1", required for cam-

eras having a low optical centerline or

using a large diameter lens.

EB2 Elevation block 2", same as EB1, ex-

cept 2" high.

NOTE: Fasteners to secure mounts are not supplied. (Minimum 1/4" diameter recommended.)

9.0 SPECIFICATIONS

ELECTRICAL

Input Voltage: 120 VAC, 60 Hz (230 VAC

optional)

Electrical

Connection: 6-pin terminal strip

GENERAL

Construction: 5052H32 aluminum

Finish: Polyester powder coat

Weight: EH66 — 11 lbs (4.98 kg)

EH66X — 14 lbs (6.34 kg)

Dimensions: See Figure 1

Cable Entry: Two adjustable 1/2" sealable

glands, mounted on removable

plate for ease of assembly.

EHCM Cradle mount for inverted mounting of

enclosure when used with PM2000/

AH2000 ceiling mount or pan and tilts.

Pelco Manual C411M-D (1/96) 13

Latches: Link lock fasteners

Window: 1/4" thick plate glass

Camera Mounting: Adjustable rail/sled

Page 18

9.1 RECOMMENDED CABLE SIZE

9.2 POWER REQUIREMENTS FOR

BLOWER, HEATER, ACCESSORIES

CAUTION: When a single power source is

used for both the camera and accessories, the

camera power consumption must be taken into

consideration when determining the wire gauge.

The following cable sizes are the minimum recommended for use with the combination of defroster/

blower/heater/camera. Cable distances specified assume a 10% line voltage loss:

Input

Voltage 22 Awg 20 Awg 18 Awg 16 Awg

The blower, heater and electrically powered accessories

use the following wattage when in operation:

Blower:

24 VAC: 7.2 watts (AC rectified)

120 VAC: 13.5 watts at 60 Hz

230 VAC: 15 watts at 50 Hz

Heater:

120 VAC or

230 VAC: 160 watts

24 VAC: 75 watts

Defroster

Assembly: 80 watts

Wiper/Washer

Assembly: 95 watts

Camera: Assuming 7 watts

Camera (7 w) 115 5,852' 9,306' 14,806' 23,498'

220 6,526 m 10,377 m 16,510 m 26,203 m

Cam/Wiper (102 w) 115 401' 638' 1,016' 1,612'

220 447 m 712 m 1,133 m 1,798 m

Cam/Wiper/Def (182 w) 115 225' 357' 569' 903'

220 251 m 399 m 635 m 1,007 m

Cam/Heater/Blower (177.5 w) 115 231' 368' 585' 929'

220 258 m 410 m 652 m 1,036 m

Cam/Heater/Blower/Def (257.5 w) 115 165' 263' 419' 665'

220 184 m 294 m 467 m 742 m

Cam/Heater/Blower/Wiper (272.5 w) 115 160' 255' 406' 645'

220 179 m 284 m 453 m 719 m

Cam/Heater/Blow/Def/Wiper (352.5 w) 115 119' 190' 303' 480'

220 133 m 212 m 337 m 536 m

14 Pelco Manual C411M-D (1/96)

Page 19

10.0 WARRANTY AND RETURN

INFORMATION

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or

workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

• Five years on FT/FR8000 Series fiber optic products.

®

• Three years on Genex

• Three years on Camclosure® and fixed camera models, except the CC3701H-2,

CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2, and MC3651H-2X camera models,

which have a five-year warranty.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy

fixed dome products.

• Two years on Spectra

continuous motion applications.

• Two years on Esprit

• Eighteen months on DX Series digital video recorders, NVR300 Series network video

recorders, and Endura

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion

applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco

shipment. All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis,

California. Repairs made necessary by reason of misuse, alteration, normal wear, or accident

are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from

the specific use or application made of the Products. Pelco’s liability for any claim, whether

based on breach of contract, negligence, infringement of any rights of any party or product

liability, relating to the Products shall not exceed the price paid by the Dealer to Pelco for

such Products. In no event will Pelco be liable for any special, incidental or consequential

damages (including loss of use, loss of profit and claims of third parties) however caused,

whether by the negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have

additional rights, which are subject to variation from state to state.

Series products (multiplexers, server, and keyboard).

®

, CM6700/CM6800/CM9700 Series matrix, and DF5/DF8 Series

®

, Esprit®, ExSite™, and PS20 scanners, including when used in

®

and WW5700 Series window wiper (excluding wiper blades).

™

Series distributed network-based video products.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or

(559) 292-1981 to obtain a Repair Authorization number (RA), and provide the following

information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the

warranty conditions stated above, please include a written explanation with the product

when returned.

Method of return shipment shall be the same or equal to the method by which the item was

received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at

(800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned

for credit, and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing

charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA

number and freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico, send goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico and are

instructed to return goods to the USA, you may do one of the following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

If the goods are to be sent by a FREIGHT FORWARDER, send the goods to:

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

This equipment contains electrical or electronic components that must be recycled properly to comply with Directive 2002/96/EC of the European Union

regarding the disposal of waste electrical and electronic equipment (WEEE). Contact your local dealer for procedures for recycling this equipment.

Pelco Manual C411M-D (1/96) 15

Page 20

®

Pelco

3500 Pelco Way, Clovis, CA 93612-5699 • (559) 292-1981 • (800) 289-9100

FAX (559) 292-3827 • (800) 289-9150 • www.pelco.com

International customers call 1-559-292-1981 or FAX 1-559-348-1120

(Product specifications subject to change without notice.)

C411M-D

16 Pelco Manual C411M-D (1/96)

Loading...

Loading...