Page 1

INSTALLATION

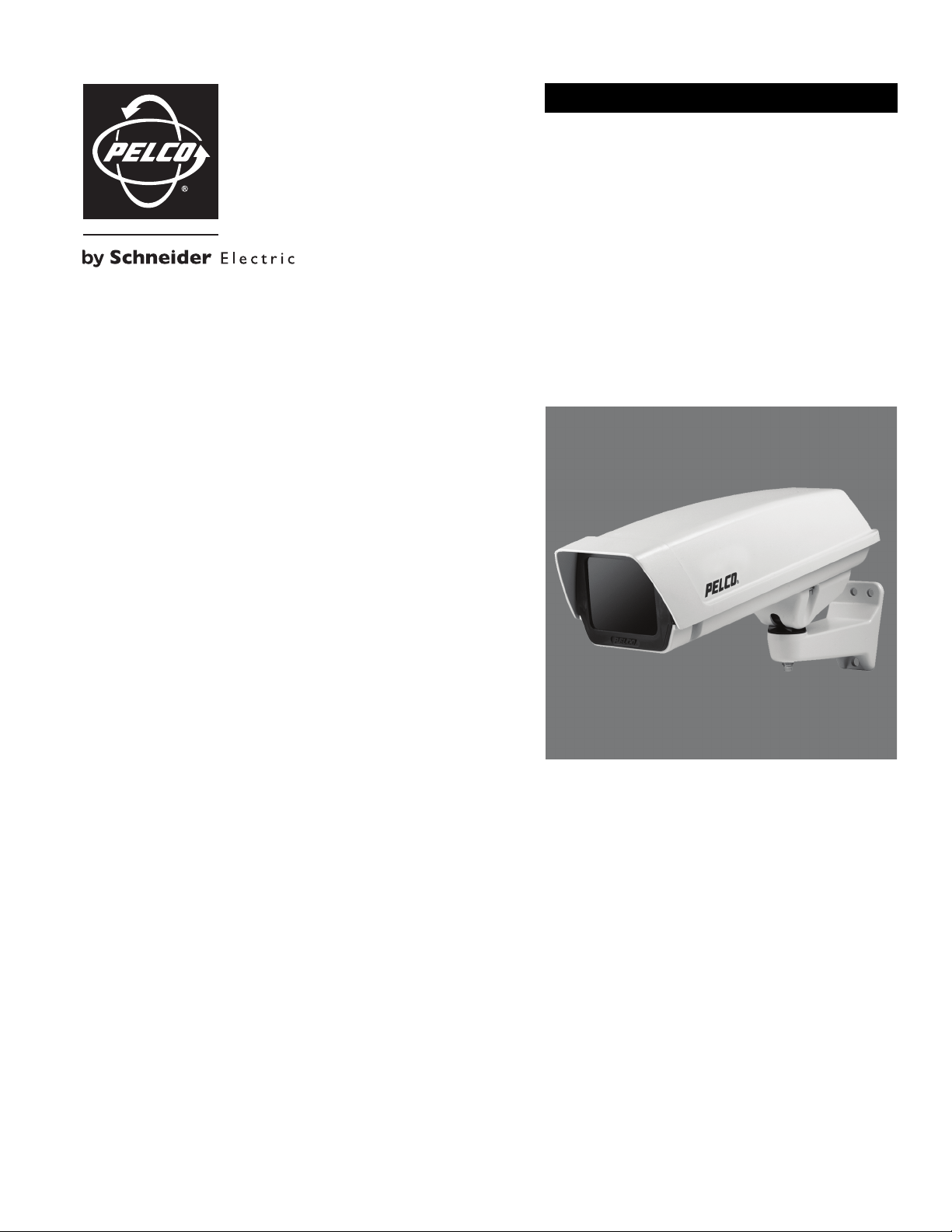

EH1512 Series Enclosures

EH1512 Enclosure with EM1512 Mount

C3453M-C (5/09)

Page 2

Contents

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing the Optional Security Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing the Camera and Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing the Sun Shroud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 C3453M-C (5/09)

Page 3

Important Safety Instructions

CAUTION:

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with dry cloth.

7. Do not block any ventilation openings. Install in a

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus (including amplifiers) that pr

9. Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized plug has two blades with one blade wider tha

other. A grounding plug has two blades and a third grounding prong. The wide blade or the third prong are provided for your safety. If the

provided plug does not fit into your outlet, consult an electrician for replacement of the obsolete outlet.

10. Protect the power cord from being walked on or pinched particula

the apparatus.

11. Only use attachments/accessories specified by the manufacturer.

12. Only use with the cart, stand, tripod, bracket, or table specified by the manufacturer, or sold with the apparatus. When a cart is used, use

caution when moving the cart/apparatus combination to avoid injury from tip-over.

13. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in any way, such

supply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus, the apparatus has been exposed to rain or

moisture, does not operate normally, or has been dropped.

14. Unplug the apparatus during lightning storms or when unused for long periods of time.

15. Apparatus shall not be exposed to dripping or splashing and no objects filled with liquids, such as vases shall be placed on the apparatus.

16. WA

17. Installation should be done only by qualified personnel and conform to all local codes.

18. Unless this unit is specifically marked as NEMA Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is designed for indoor use only and it must not

RNING: To reduce the risk of fire or electric shock, do not expose this apparatus to rain or moisture.

be installed where exposed to rain and moisture.

ccordance with the manufacturer’s instructions.

oduce heat.

n the

rly at plugs, convenience receptacles, and the points where they exit from

as power-

19. Only use installation methods and materials capable of supporting four times the maximum specified load.

20. Only use replacement parts recommended by Pelco.

21. Do not use attachments, such as mounts, that are not recommended by Pelco. They may be hazardous.

22. A CCC-approved power cord must be used to power this equipment when used in China.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage constituting a risk of electric shock is

present within this unit.

This symbol indicates that there are important operating and maintenance instructions in

the literature accompanying this unit

C3453M-C (5/09) 3

Page 4

Description

The EH1512 Series indoor/outdoor enclosures are designed for use with small- to medium-sized analog and IP cameras. They will accommodate

both fixed and variable focal length lenses (with or without auto-iris operation). They can be wall mounted using either Pelco’s EM1512

(feedthrough wall mount) or any light to medium duty mount.

The tethered, removable enclosure lid provides easy access during installation and when camera and lens adjustments are necessary. Power and

video cabling is brought into the enclosure through two adjustable glands (PG9 and PG11) on the bottom of the enclosure, allowing for easy

installation.

Field-installed options include a heater/blower or blower with a 24 VAC camera power supply and sun shroud. The enclosures can also be

ordered from the factory with a 24 VAC, 120 VAC, or 230 VAC heater/blower or blower with a 24 VAC camera power supply. If your enclosure has

a thermostatically controlled heater, the thermostat is set to turn on at 50°F (10°C) and turn off at 80°F (27°C). The blower operates continuously.

An optional security kit that prevents opening the enclosure is available.

NOTE: A metric Allen wrench (5 mm) and a Phillips screwdriver are required for installation but are not included. A flat head screwdriver might

also be needed for all models except the EH1512 and EH1512MT. The Allen wrench is needed to secure the enclosure to all mounts. It is also

needed to open and close the enclosure and to secure the pan/tilt (swivel head) on the EM1512 mount.

MODELS

EH1512 Enclosure, indoor/outdoor.

EH1512MT Same as EH1512 with an EM1512 feedthrough wall mount.

EH1512-1 Same as EH1512 with a 120 VAC heater/blower with 24 VAC camera power (includes the 4-inch wire tie); 12 W enclosure

EH1512-2 Same as EH1512 with a 24 VAC heater/blower with 24 VAC camera power; 12 W enclosure power consumption*.

EH1512-3 Same as EH1512 with a 230 VAC heater/blower with 24 VAC camera power (includes the 4-inch wire tie); 12 W enclosure

EH1512-1MT Same as EH1512 with a 120 VAC heater/blower with 24 VAC camera power and an EM1512 feedthrough wall mount

EH1512-2MT Same as EH1512 with a 24 VAC heater/blower with 24 VAC camera power and an EM1512 feedthrough wall mount; 12 W

EH1512-3MT Same as EH1512 with a 230 VAC heater/blower with 24 VAC camera power and an EM1512 feedthrough wall mount

EH1512-1MTS Same as EH1512 with a 120 VAC heater/blower with 24 VAC camera power, an EM1512 feedthrough wall mount (includes

EH1512-2MTS Same as EH1512 with a 24 VAC heater/blower with 24 VAC camera power, an EM1512 feedthrough wall mount, and an

EH1512-3MTS Same as EH1512 with a 230 VAC heater/blower with 24 VAC camera power, an EM1512 feedthrough wall mount (includes

power consumption*; 25 W maximum power consumption capacity.

power consumption*; 25 W maximum power consumption capacity.

(includes the 4-inch wire tie); 12 W enclosure power consumption*; 25 W maximum power consumption capacity.

enclosure power consumption*.

(includes the 4-inch wire tie); 12 W enclosure power consumption*; 25 W maximum power consumption capacity.

the 4-inch wire tie), and an SS1512 sun shroud; 12 W enclosure power consumption*; 25 W maximum power consumption

capacity.

SS1512 sun shroud; 12 W enclosure power consumption*.

the 4-inch wire tie), and an SS1512 sun shroud; 12 W enclosure power consumption*; 25 W maximum power consumption

capacity.

*Enclosure power consumption does not include camera wattage.

4 C3453M-C (5/09)

Page 5

OPTIONAL ACCESSORIES

Blower Kit

EH1512-1BKIT Continuous duty, 120 VAC, 1 W, 1.45 cfm

EH1512-2BKIT Continuous duty, 24 VAC, 1 W, 1.45 cfm

EH1512-3BKIT Continuous duty, 230 VAC, 1 W, 1.45 cfm

Heater/Blower Kit

EH1512-1HBKIT 120 VAC, 11 W, 1.45 cfm

EH1512-2HBKIT 24 VAC, 11 W, 1.45 cfm

EH1512-3HBKIT 230 VAC, 11 W, 1.45 cfm

NOTE: Heaters are thermostatically controlled to turn on at 50°F (10°C) and turn off at 80°F (27°C). The blower operates continuously.

Sun Shroud SS1512

Marine Kit EH-MKIT (requires EM1512 or EM1450 wall mount)

Security Kit EH-SKIT for EH1512 (three tamper-resistant screws and one 1/8-inch hollow screwdriver bit)

Wall Mount EM1512 with feedthrough for EH1512 (tilt angle of +20° to -70°; sustains wind velocity up to 90 mph)

C3453M-C (5/09) 5

Page 6

PACKAGE CONTENTS

NOTE: A metric Allen wrench (5 mm) is required for installation but is not included. A Phillips screwdriver, flat head screwdriver, or 1/4-inch nut

driver is needed for the EH1512-1 and EH1512-3 only. The Allen wrench is needed to open and close the enclosure and to secure the enclosure to

all mounts. It is also needed to secure the pan/tilt (swivel head) on the EM1512 mount.

The following items are supplied:

Qty Description

1 EH1512 Series enclosure

1 Screw, 1/4-20 x 3/8-inch, Phillips

1 Washer, 1/4-inch split lock

2 Screws, M6 x 1.0 P x 12 mm, hex socket cap

2 Washers, 6 mm split lock

1 Gland and nut, PG9 cable

1 Gland and nut, PG11 cable

1 Wire tie, 4-inch (EH1512-1 and EH1512-3 only)

1 Installation manual

1 EM1512 mount (optional)

1 SS1512 sun shroud (optional)

WIRE

TIE

1 EA.

SHIPPING BOX

HEX SOCKET

CAP SCREW

2 EA.

MOUNT

1 EA.

(OPTIONAL)

6MM

SPLIT

WASHERS

2 EA.

PHILLIPS

SCREW

1 EA.

EH1512 ENCLOSURE

1 EA.

1/4-INCH

SPLIT

WASHER

1 EA.

SUN SHROUD

1 EA.

(OPTIONAL)

GLANDS AND NUTS

2 EA.

Figure 1. Package Contents

6 C3453M-C (5/09)

Page 7

Installation

INSTALLING THE OPTIONAL SECURITY KIT

The optional security kit (EH-SKIT) contains three tamper-resistant screws and a 1/8-inch hollow screwdriver bit. To install the security kit:

1. Use a 5-mm Allen wrench (not sup

enclosure base. (Refer to Figure 2.)

plied) to remove the three 10-24 x 0.75-inch hex head screws (factory installed) that are located on the

2. Insert the three tamper-resistant screws i

3. Tighten the screws using the 1/8-inch hollow screwdriver bit (s

n the bottom of the enclosure.

INSTALLING THE CAMERA AND MOUNT

To install the enclosure, camera, and lens:

1. Use a 5-mm Allen wrench (not supplied) to loosen the three 10-24 x 0.75-inch hex head screws (factory installed) that are loca

enclosure base. If the security kit is installed, use the 1/8-inch hollow screwdriver bit (supplied with the kit) to loosen the three tamperresistant screws that are located on the enclosure base.

2. Lift up and remove the lid (refer to Figure 2). Hang the lid from the front of the enclosure base by the lanyards.

NOTE: The gasket can come loose when the lid is removed. Be sure to properly reseat the gasket when closing the lid, if necessary.

upplied). Ensure that the gasket is properly sealed.

ted on the

Figure 2. Removing the Lid

C3453M-C (5/09) 7

Page 8

3. Remove the camera sled from the enclosure rail (refer to Figure 3).

a. Squeeze the two plastic tabs (located near the front window) that hold the camera sled in place.

b. Pull up and slide the sled forward.

c. Remove the sled.

Figure 3. Removing the Sled

4. Remove the parts bag. This includes the screws, split washers, glands, and nuts.

5. Remove the glands and nuts from the parts bag.

6. Wire the enclosure:

• Without cond

uit (for example, the EM1512 mount): Install and tighten the glands and nuts in the bottom of the enclosure. Refer to

Table A on page 11 for allowable cable diameter for the glands.

NOTE: The PG11 gland might not accommodate RX11 coaxial cable because the coaxial diameter might be larger than the gland,

0.395 inches (0.10 cm).

Glands can be mounted either inside or outside of the enclosur

e. When using the EM1512 feedthrough mount, Pelco recommends

mounting the glands inside the enclosure with the nuts on the outside.

• With conduit:

Use a step drill to drill the larger hole to 0.875 inches (2.22 cm) for 1/2-inch conduit.

7. Steps 8, 9, and 10 contain instructions for installing the EM1512 mount. If you are using a mount other than the EM1512, refer t

specific mount manual for installation instructions, and then go to step 11.

o the

8 C3453M-C (5/09)

Page 9

8. (EM1512 mount only) Attach the mount to the wall:

a. Use the mount as a template to mark and drill holes in the mounting surface.

b. Pull the video and power cables from the wall through the mount. If wir

ing with conduit, use a step drill to drill a 0.875 inches (2.22 cm)

hole in one of the three knockout locations for 1/2-inch conduit. (Knockouts are indicated on the side and bottom of the mount arm.)

Refer to Tab le B on page 11 to determine the size of the power wire needed. Refer to Table D on page 12 to determine the type of video

coaxial cable needed.

c. Fasten the mount to the wall using a minimum of two flat washers (not supplied) and two 1/4-20 bolts (not supplied).

WARNINGS:

• If you install the mount outdoors, rainwater could leak through the mounting bolt holes and damage the wall. To prevent

water damage, seal the bolt holes with an appropriate sealant. Apply the sealant around the bolt holes between the mount

and the mounting surface.

• Use fasteners of a suitable size, and make sure the mounting surface can support the combined weight of the mount and

camera/enclosure.

d. Pull the cables through the glands in the enclosure. If the glands are mounted outside the enclosure, tighten the glands around the

cables. (If the glands are mounted inside the enclosure, do not tighten the glands around the cables until after you perform step 9.)

M1512 mount only) Attach the enclosure using the threaded mounting holes in the bottom of the enclosure. Use the M6 bolts and 6 mm

9. (E

split washer (supplied in the parts bag). Tighten the bolts to attach the enclosure body to the mount surface. Tighten the glands around the

cables.

10. (EM1512 mount

only) Adjust the enclosure position by loosening the M6 bolt at the bottom of the mount. Position the mount as desired, and

then tighten the M6 bolt.

11. (For

mounts other than EM1512) Perform the following steps:

a. Install the mount according to the specific installation instructions supplied with the mount.

b. Pull the video and power cables through the glands or conduit on the bottom of the enclosure. Refer to Ta bl e B on page 11 to

determine the size of power wire needed. Refer to Ta bl e D on page 12 to determine the type of video coaxial cable needed.

NOTE: Be sure to route all coaxial cable and wiring along the sides of the enclosure to avoid heating problems. Maintain separation be

120/230 VAC, 24 VAC, and video wiring.

12. Adjust the glands for a tight fit around the cables. If you are wiring the enclosure with conduit, install the fittings to con

nect the conduit to

the enclosure.

13. Attach the camera to the sled with the 1/4-20 x 3/8-inch Phillips screw (supplied) and the 1/4-inch split lock washerwasher. (Refer to

Figure 4.) Align the front of the lens with the front edge of the sled. Tighten the screw, and then reinsert the sled.

tween

Figure 4. Attaching the Camera to the Sle

d

14. Refer to Figure 5 on page 10 to connect power to the enclosure and the camera.

15. Attach the video cables to the camera.

16. If required, connect the ground wire to the ground screw boss an

d screw on the bottom of the enclosure, which is located in front of the PC

board. For EH1512-1 and EH1512-3, pass the supplied zip tie through the hole in the PCB cover to secure the input power wires to the PCB

cover.

C3453M-C (5/09) 9

Page 10

17. Adjust the camera focal length and focus, if necessary.

CAMERA

18. Position the enclosure lid and close it. If using the 10-24 x 0.75-inch hex head screws, tighten them using a 5-mm Allen wrench

supplied). If using the optional security kit, insert the three tamper-resistant screws (supplied) and tighten them using the 1/8-inch hollow

screwdriver bit (supplied). When tightening either kind of screw, ensure that the gasket is properly seated.

120 VAC MODEL WIRING

INPUT, AC LOW (NEUTRAL)

INPUT, AC HIGH

24 VAC CAMERA OUTPUT

AC IN

AC OUT

HI NT HI NT

HIGH

HI LOW

24 VAC

ZIP TIE HERE

120 VAC CAMERA OUTPUT, LOW (NEUTRAL)

120 VAC OUTPUT, HIGH

24 VAC CAMERA OUTPUT

LOW

0 - GROUND BOSS

24 VAC MODEL WIRING

INPUT, AC LOW (NEUTRAL)

INPUT, AC HIGH

(not

CAMERA OUTPUT, AC LOW (NEUTRAL)

CAMERA OUTPUT, AC HIGH

INPUT, AC LOW (NEUTRAL)

INPUT, AC HIGH

CAMERA

230 VAC MODEL WIRING

24 VAC CAMERA OUTPUT

AC IN

AC OUT

HI NT HI NT

ZIP TIE HERE

230 VAC CAMERA OUTPUT, LOW (NEUTRAL)

230 VAC OUTPUT, HIGH

LOW HI

AC AC

HIGH

HI LOW

24 VAC

0 - GROUND BOSS

24 VAC CAMERA OUTPUT

LOW

Figure 5. EH1512 Wiring Diagram

10 C3453M-C (5/09)

Page 11

INSTALLING THE SUN SHROUD

The optional sun shroud fits over the top of the EH1512 enclosure. Perform the following steps to install the sun shroud.

1. Position the front of the sun shroud above the front of the enclosure.

2. Press the sun shroud down and against the enclosure until the sun shroud snaps into place.

Table A. Allowable Cable

Gland Cable Diameter

PG9 0.181-inch to 0.312-inch

PG11 0.230-inch to 0.395-inch

NOTE: Conduit must be used if the cable diameter

is greater than 0.395 inches (1.00 cm). RG11 coaxial

might be greater than 0.395 inches.

Ta bl e B describes the minimum recommended cable sizes needed for use with the heater and blower combinations in the EH1512 enclosure.

WARNING: When using a single power source for both camera and accessories, consider the camera power consumption when

determining the wire gauge. Table B does not include camera power.

Table B. Enclosure Accessory Wiring Distances

Maximum Power

Model Number Input Voltage

EH1512-1 120 VAC 22 W

EH1512-2 24 VAC 22 W

Consumption Cable Size Cable Distance

Diameter

20 AWG

18

AWG

16 AWG

14 AWG

20 AWG

18 AWG

16 AWG

14 AWG

2,782 ft (848 m)

4,424 ft (1,348 m)

7,035 ft (2,144 m)

11,184 ft (3,409 m)

142 ft (43 m)

225 ft (69 m)

358 ft (109 m)

569 ft (173 m)

EH1512-3 230 VAC 22 W

EH1512-1MT,

EH1512-1MTS

EH1512-2MT,

EH

1512-2MTS

EH1512-3MT,

EH1512-3MTS

120 VAC 22 W

24 VAC 22 W

230 VAC 22 W

20 AWG

18 AWG

16 AWG

14 AWG

20 AWG

AWG

18

16 AWG

14 AWG

20 AWG

AWG

18

16 AWG

14 AWG

20 AWG

18

AWG

16 AWG

14 AWG

6,473 ft (1,973 m)

10,291 ft (2,137 m)

16,365 ft (4,988 m)

26,019 ft (7,931 m)

2,782 ft (848 m)

4,424 ft (1,348 m)

7,035 ft (2,144 m)

11,184 ft (3,409 m)

142 ft (43 m)

225 ft (69 m)

358 ft (109 m)

569 ft (173 m)

6,473 ft (1,973 m)

10,291 ft (2,137 m)

16,365 ft (4,988 m)

26,019 ft (7,931 m)

C3453M-C (5/09) 11

Page 12

Table C. 24 VAC Wiring Distances

Wire Gauge

Total VA 20 AWG (0.5 mm

10 283 ft (86 m) 451 ft (137 m) 716 ft (218 m) 1142 ft (348 m)

20 141 ft (42 m) 225 ft (68 m) 358 ft (109 m) 571 ft (174 m)

30 94 ft (28 m) 150 ft (45 m) 238 ft (54 m) 380 ft (115 m)

40 70 ft (21 m) 112 ft (34 m) 179 ft (54 m) 285 ft (86 m)

50 56 ft (17 m) 90 ft (27 m) 143 ft (43 m) 228 ft (69 m)

Ta bl e C describes the recommended maximum distances for 24 VAC applications, which are calculated with a 10 percent voltage drop.

(Ten percent is generally the maximum allowable voltage drop for AC-powered devices.)

For example, an enclosure that requires 30 VA and is installed 94 feet (28 m) from the transformer would require a minimum wire gauge of

20 AWG.

Table D. Video Coaxial Cable Wiring Distance

2

) 18 AWG (1.0 mm2) 16 AWG (1.5 mm2) 14 AWG (2.5 mm2)

Cable Type* Maximum Distance

Maintenance

Clean the window regularly to maintain picture clarity. Use a soft cloth and a mild, nonabrasive detergent and water.

RG59/U

RG6/U

RG11/U

*Minimum Cable Requirements:

75-ohm impedance

All-copper center conductor

All-copper braided shield with 95% braid coverage

750 ft (229 m)

1,000 ft (305 m)

1,500 ft (457 m)

12 C3453M-C (5/09)

Page 13

Specifications

†

Assumes the lens is fully extended.

‡

Check the environmental specification of your specific camera/lens.

MECHANICAL

Camera Mounting Single slot for adjustable camera positioning on snap-in camera sled

Camera and Lens Size Accepts camera and lens combinations† (including BNC connector) up to 9.00" L x 2.87" W x 3.00" H

Viewing Window 0.118-inch (3 mm) thick scratch-resistant Lexan

Viewing Area 2.81" W x 2.47" H (7.14 x 6.27 cm)

Cable Entry 1 x PG9 and 1 x PG11 compression glands on bottom; PG9 0.312-inch (0.8 cm) and PG11 0.395 (1.0 cm)

Cable Entry Holes 1 x 0.750-inch (1.91 cm) diameter and 1 x 0.630-inch (1.6 cm) diameter;

Lid Fastening 3 Allen-head screws

GENERAL

Construction Die-cast aluminum

Finish Alodine with gray polyester powder coat

Environment

Unit Length

Base 13.38 inches (33.99 cm)

Overall 14.39 inches (36.55 cm)

Unit Weight

EH1512 2.50 lb (1.13 kg)

EH1512MT 3.13 lb (1.42 kg)

EH1512-1 3.25 lb (1.47 kg)

EH1512-2 2.56 lb (1.16 kg)

EH1512-3 3.25 lb (1.47 kg)

EH1512-1MT 3.88 lb (1.76 kg)

EH1512-2MT 3.19 lb (1.45 kg)

EH1512-3MT 3.88 lb (1.76 kg)

EH1512-1MTS 4.76 lb (2.16 kg)

EH1512-2MTS 4.07 lb (1.85 kg)

EH1512-3MTS 4.76 lb (2.16 kg)

‡

(22.86

x 7.28 x 7.62 cm)

®

maximum cable diameters

0.750-inch hole will accept 1/2-inch NPT conduit fitting when enlarged to 0.875-inch;

0.630-inch hole will accept 1/4-inch NPT conduit fitting

Indoor/outdoor ambient temperature -10° to 120°F (-23° to 49°C)

RECOMMENDED MOUNTS

Wall

EM1512 Wall mount with feedthrough for EH1512 (tilt angle of +20° to -70°; sustains wind velocity up to 90 mph)

EM1450 Light duty wall mount; maximum load 20 lb (9.07 kg)

EM2400 Medium duty wall mount; maximum load 40 lb (18.14 kg) with feedthrough (tilt angle of ±90°)

EM1900U, EM22 Medium duty wall mount; maximum load 40 lb (18.14 kg)

Pedestal

EM1009U, EM1015U, MM22 Medium duty pedestal mount; maximum load 40 lb (18.14 kg)

Pipe/Pole

EM1109, EM2000, EM2200 Medium duty mounts for pipe/pole applications; maximum load 40 lb (18.14 kg); fits poles with

3-inch

(7.62 cm) to 8-inch (20.32 cm) diameter

Ceiling

EM3000 Light duty ceiling J-mount; maximum load 20 lb (9.07 kg); 360° pan rotation; ±75° tilt angle

C3453M-C (5/09) 13

Page 14

RECOMMENDED CAMERAS AND LENSES

3.80

(9.65)

4.94

(12.55)

14.00 (35.56)

16.01 (40.67)

2.64 (6.71)

3.27 (8.31)

4.47

(11.35)

3.78 (9.60)

14.39 (36.55)

13.38 (33.99)

Cameras C10CH-6, C10CH-6X, C10CH-7X, C10DN-6, C10DN-6X, C10DN-7X, CCC1390H-6, CCC1390H-6X,

IP3701H-2, IP3701H-2X, IXS0C, IXS0DN, IX10C, IX10DN, IXE20C, IXE20DN, IX30C, IX30DN

Lenses 13VD2.8-12, 13VD3-8, 13VD5-40, 13VD5-50, 13VDIR2.8-11, 13VDIR3-8.5, 13VDIR7.5-50

NOTE: These lenses are for use with all cameras except Pelco IP cameras with Sarix™ technology. Refer

to the specific camera specification sheet for information on recommended lenses.

(Design and product specifications subject to change without notice.)

SS1512 Sun Shroud

EH1512 Camera Enclosure

2.61

(6.63)

4.02

(10.21)

6.00

(15.24)

5.74

(14.58)

2.56

(6.50)

3.60

(9.14)

1.50

(3.81)

EM1512 Wall Mount

NOTE: VALUES IN PARENTHESES ARE CENTIMETERS; ALL OTHERS ARE INCHES.

0.75

(1.91)

2.84

(7.21)

14 C3453M-C (5/09)

Page 15

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in

material or workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

• Five years:

– Fiber optic products

– TW3000 Series unshielded twisted pair (UTP) transmission products

– CC3701H-2, CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2, and

MC3651H-2X camera models

• Three years:

– Pelco-branded fixed camera models (CCC1390H Series, C10DN Series,

C10CH Series, IP3701H Series, and IX Series)

– EH1500 Series enclosures

– Spectra

– Camclosure

– DX Series digital video recorders, DVR5100 Series digital video recorders,

– Endura

– Genex

– PMCL200/300/400 Series LCD monitors

• Two years:

– Standard varifocal, fixed focal, and motorized zoom lenses

– DF5/DF8 Series fixed dome products

– Legacy

– Spectra III

– Esprit Ti and TI2500 Series thermal imaging products

– Esprit and WW5700 Series window wiper (excluding wiper blades).

– CM6700/CM6800/CM9700 Series matrix

– Digital Light Processing (DLP

– Intelli-M

• One year:

– Video cassette recorders (VCRs), except video heads. Video heads will be

•Six months:

– All pan and tilts, scanners, or preset lenses used in continuous motion

®

IV products (including Spectra IV IP)

®

Series (IS, ICS, IP) integrated camera systems

®

Digital Sentry

recorders, and NVR300 Series network video recorders

®

Series hardware products, DVX Series digital video

®

Series distributed network-based video products

Series products (multiplexers, server, and keyboard)

®

Series integrated positioning systems

™

, Spectra Mini, Spectra Mini IP, Esprit®, ExSite®, and PS20

scanners, including when used in continuous motion applications.

®

) displays (except lamp and color wheel). The

lamp and color wheel will be covered for a period of 90 days. The air filter is

not covered under warranty.

®

eIDC controllers

covered for a period of six months.

applications (preset scan, tour, and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of

Pelco shipment. All goods requiring warranty repair shall be sent freight prepaid

to a Pelco designated location. Repairs made necessary by reason of misuse,

alteration, normal wear, or accident are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss

resulting from the specific use or application made of the Products. Pelco’s liability

for any claim, whether based on breach of contract, negligence, infringement of

any rights of any party or product liability, relating to the Products shall not exceed

the price paid by the Dealer to Pelco for such Products. In no event will Pelco be

liable for any special, incidental, or consequential damages (including loss of use,

loss of profit, and claims of third parties) however caused, whether by the

negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may

also have additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or

(559) 292-1981 to obtain a Repair Authorization number (RA), and provide the

following information:

1. Model and serial number

2. Date of shipment, P.O. number, sales order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product that does not fall under

the warranty conditions stated above, please include a written explanation with

the product when returned.

Method of return shipment shall be the same or equal to the method by which the

item was received by Pelco.

RETURNS

To expedite parts returned for repair or credit, please call Pelco at (800) 289-9100

or (559) 292-1981 to obtain an authorization number (CA number if returned for

credit, and RA number if returned for repair) and designated return location.

All merchandise returned for credit may be subject to a 20 percent restocking and

refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned

CA or RA number and freight should be prepaid.

12-23-08

The materials used in the manufacture of this document and its components are compliant to the requirements of Directive 2002/95/EC.

This equipment contains electrical or electronic components that must be recycled properly to comply with Directive 2002/96/EC of the European Union

regarding the disposal of waste electrical and electronic equipment (WEEE). Contact your local dealer for procedures for recycling this equipment.

REVISION HISTORY

Manual # Date Comments

C3453M 12/08 Original version.

C3453M-A 3/09 Updated the manual to describe the change in the lanyard position and the revised maximum power consumption and heater/blower kit power specifications.

C3453M-B 4/09 Added security kit EH-SKIT to the list of optional accessories.

C3453M-C 5/09 Added instructions for installing the security kit, removed the Models table, and moved optional accessories from the Specification section to the Description section.

Pelco, the Pelco logo, Camclosure, Digital Sentry, Endura, Esprit, ExSite, Genex, Intelli-M, Legacy, and Spectra are registered trademarks of Pelco, Inc. © Copyright 2009, Pelco, Inc. All rights reserved.

Sarix and Spectra III are trademarks of Pelco, In c.

DLP is a registered trademark of Texas Instruments Incorporated.

All product names and services identified t hroughout this document are trademarks or registered trademarks of their re spective companies.

The absence of a trademark or registered trademark from this document does not constitute a waiver of intellectual property rights.

A Phillips screwdriver is now required; a flat head screwdriver is required for certain models. A screw was added to the end of the enclosure. Revised figures 1

and 2, the enclosure specification drawing, the model table in the specification section, and added Sarix cameras to the recommended camera list.

Page 16

www.pelco.com

Pelco, Inc. Worldwide Headquarters 3500 Pelco Way Clovis, California 93612 USA

USA & Canada Tel (800) 289-9100 Fax (800) 289-9150

International Tel +1 (559) 292-1981 Fax +1 (559) 348-1120

Loading...

Loading...