Pelco DSSRV2-040-D, DSSRV2-040-US, DSSRV2-040DV-D, DSSRV2-040DV-US, DSSRV2-080-D User Manual

...Page 1

Digital Sentry Hardware

For DSSRV2 and DS-CPPC Models

INSTALLATION MANUAL

C4693M-D | 7/15

Page 2

Contents

Important Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Regulatory Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warranty Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Legal Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Video Quality Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

KCC Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Korean Class A EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Tools and Parts Required for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Product Overview: Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Product Overview: Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Placing on a Desktop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Product Serial Number Label Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

IP Camera License Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Attaching the Third Set of Serial Number Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing a DSSRV-RAID Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Disabling UEFI Booting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Re-Imaging the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Installing the SCSI Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Preparing the Unit for the SCSI Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Opening the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Installing an ENC5400 Capture Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mounting in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Installing the Drive Array . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Connecting an ENC5516 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting an Uninterruptible Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Connecting to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Connecting the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Starting Up the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Shutting Down the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Orderly Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Immediate Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Enabling SNMP Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Page 3

Enabling Serial Ports in the BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Digital Sentry Port Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Page 4

Important Notices

Regulatory Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Radio and Television Interference

This equipment has been tested and found to comply with the limits of a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

Changes and modifications not expressly approved by the manufacturer or registrant of this equipment can void your authority to operate

this equipment under Federal Communications Commission’s rules.

CAN ICES-3 (A)/NMB-3(A) OR CAN ICES-3 (B)/NMB-3(B)

Warranty Statement

For information about Pelco’s product warranty and thereto related information, refer to www.pelco.com/warranty.

Legal Notice

SOME PELCO EQUIPMENT CONTAINS, AND THE SOFTWARE ENABLES, AUDIO/VISUAL AND RECORDING CAPABILITIES, THE

IMPROPER USE OF WHICH MAY SUBJECT YOU TO CIVIL AND CRIMINAL PENALTIES. APPLICABLE LAWS REGARDING THE USE OF

SUCH CAPABILITIES VARY BETWEEN JURISDICTIONS AND MAY REQUIRE, AMONG OTHER THINGS, EXPRESS WRITTEN CONSENT

FROM RECORDED SUBJECTS. YOU ARE SOLELY RESPONSIBLE FOR INSURING STRICT COMPLIANCE WITH SUCH LAWS AND FOR

STRICT ADHERENCE TO ANY/ALL RIGHTS OF PRIVACY AND PERSONALTY. USE OF THIS EQUIPMENT AND/OR SOFTWARE FOR ILLEGAL

SURVEILLANCE OR MONITORING SHALL BE DEEMED UNAUTHORIZED USE IN VIOLATION OF THE END USER SOFTWARE AGREEMENT

AND RESULT IN THE IMMEDIATE TERMINATION OF YOUR LICENSE RIGHTS THEREUNDER.

Video Quality Caution

Frame Rate Notice Regarding User Selected Options

Pelco systems are capable of providing high quality video for both live viewing and playback. However, the systems can be used in lower

quality modes, which can degrade picture quality, to allow for a slower rate of data transfer and to reduce the amount of video data

stored. The picture quality can be degraded by either lowering the resolution, reducing the picture rate, or both. A picture degraded by

having a reduced resolution may result in an image that is less clear or even indiscernible. A picture degraded by reducing the picture

rate has fewer frames per second, which can result in images that appear to jump or move more quickly than normal during playback.

Lower frame rates may result in a key event not being recorded by the system. Judgment as to the suitability of the products for users'

purposes is solely the users' responsibility. Users shall determine the suitability of the products for their own intended application,

picture rate and picture quality. In the event users intend to use the video for evidentiary purposes in a judicial proceeding or otherwise,

users should consult with their attorney regarding any particular requirements for such use.

KCC Certification

If you know the product is being submitted for KCC certification, add one of the following KCC statements and the respective heading to

the Important Notices page of your English document. If the KCC mark is not required, do not add this information. The statement should

4

Page 5

follow the French FCC translation in the Regulatory Notices section. When the document is translated, this text will already be included

and translated per the requirements.

The Korean Class A statement applies to business/commercial product use. This notice indicates that the equipment has acquired electromagnetic conformity registration, so sellers and users are required to use caution.

The Korean Class B statement applies to residential product use. This notice indicates that the equipment has acquired electromagnetic

conformity registration, so it can be used in both residential and other areas.

Korean Class A EMC

5

Page 6

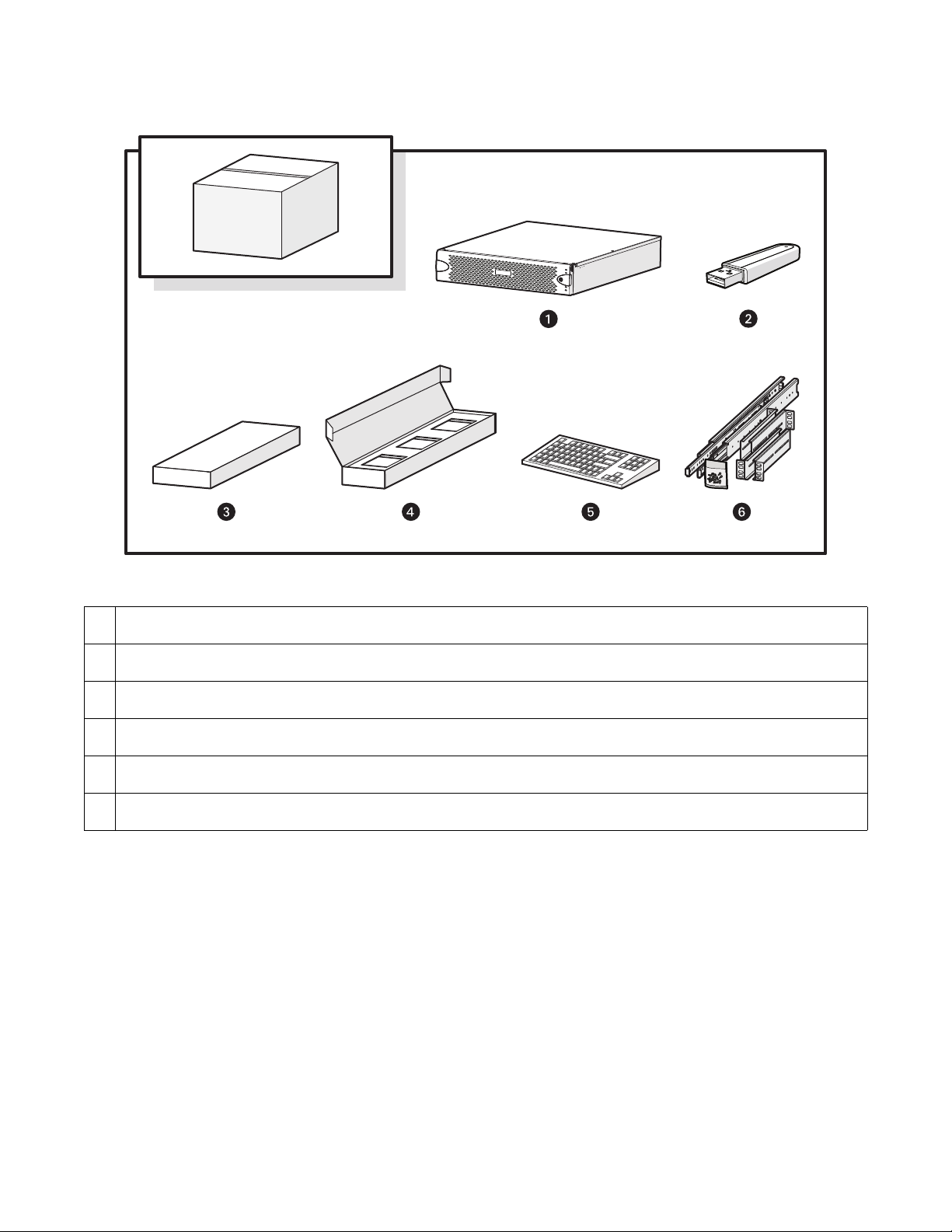

Package Contents

Figure 1: Package Contents

1 System Hardware

2 USB Key: may include applicable software, a recovery image, and the installation and operation manuals.

3 Accessory Pack

4 Hard Drive Pack (hard drives in carriers)

5 Standard USB Keyboard (1 ea. for workstation models only)

6 Rack Mount Kit (1 ea.)

6

Page 7

Figure 2: Accessory Pack Contents

1 Standard USB Mouse (1 ea.)

2 Bezel Keys (2 ea.)

3 Standard US Power Cord (1 ea.)

4 Power Cord (based on country designation, 1 ea.)

NOTE: Units shipped to China do not include power cords.

5 Chassis Handles (2 ea.); includes Phillips screws for installation.

6 Rubber Feet (4 ea.)

7

Page 8

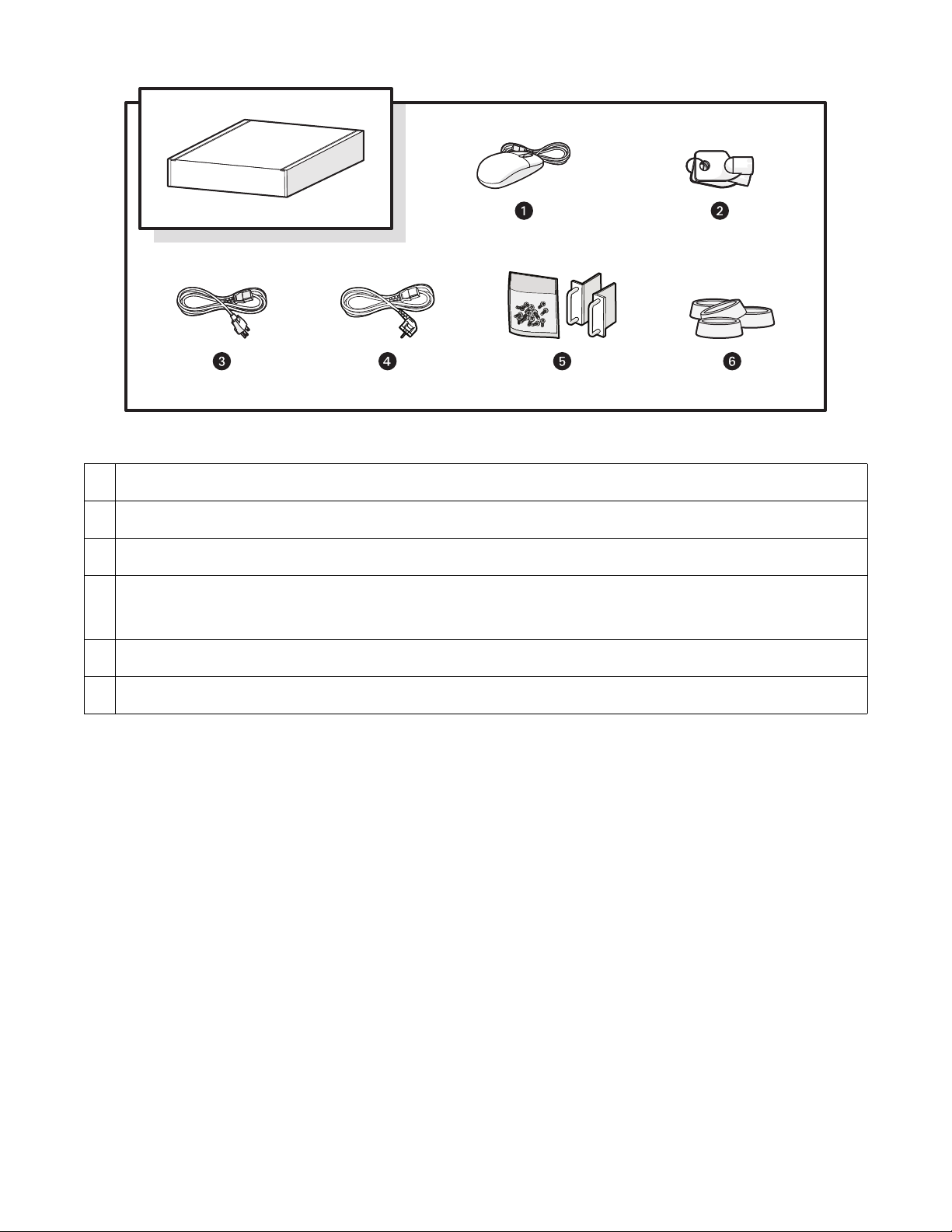

Figure 3: Rack Mount Kit Contents

1 Sliding Mounting Brackets (2 ea.)

2 Rear Mount Rails (2 ea.), Front Mount Rails (2 ea.)

3 L-Shaped Plate Nuts (4 ea.)

4 M5*8L-H2.5 Round Head Nickel Screws (18 ea.), M4*6L-H2.5 Round Head Nickel Screws (18 ea.), 4.2*11*0.8 Nickel Washers (10

ea.)

Tools and Parts Required for Installation

The following installation tools and parts are needed for installation, but are not supplied.

• Power source (110/220 VAC)

• Small Phillips screwdriver, if mounting the unit into a rack

8

Page 9

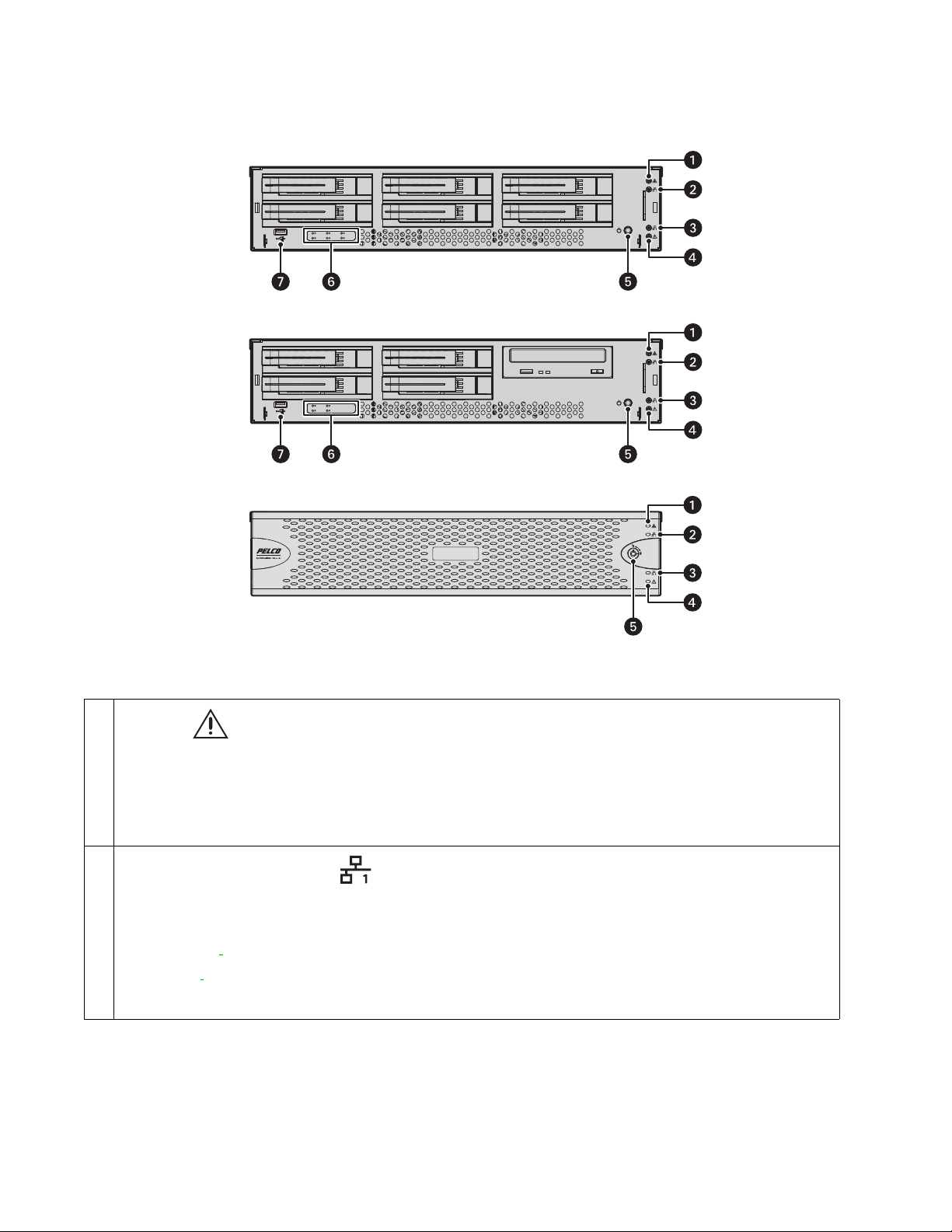

Product Overview: Front

NOTE: LED indicators might not be operational with out-of-box software.

Figure 1: Server Models: Front Panel Layout (Bezel Open)

Figure 2: Workstation Models with-DVD: Front Panel Layout (Bezel Open)

Figure 3: Front Bezel Indicators (Bezel Closed)

1

Unit Status

• Green: The unit is functioning normally.

• Flashing green: The unit is starting or shutting down.

• Amber: The unit is nearing operational thresholds; maintenance is recommended.

• Red: The unit is in an error condition.

2

Network Port 1 Speed and Activity

• Off: The unit is not connected to the network.

• Solid green: The unit is connected to the network using the 1000Base-T standard.

• Solid amber:

• Solid red:

NOTE: Use the 1000Base-T standard.

The unit is connected to the network using the 100Base-T standard.

The unit is connected to the network using the 10Base-T standard.

9

Page 10

3

Network Port 2 Speed and Activity

The unit is not connected to the network.

• Off:

• Solid green:

• Solid amber:

• Solid red:

NOTE: Use the 1000Base-T standard.

The unit is connected to the network using the 1000Base-T standard.

The unit is connected to the network using the 100Base-T standard.

The unit is connected to the network using the 10Base-T standard.

4

Software Status

• Green:

The software is operating normally.

• Amber: A minor software malfunction is detected (for example, an excessive network packet loss).

• Red:

5

Power Button

A fatal software error has occurred (for example, ceasing to record).

• Push the power button to turn the unit on or off.

• Push and hold the power button for a hard shutdown.

6 Drive Status

• Flashing green: The read or write activity on a specific hard drive.

• Solid red: A problem exists with the hard drive.

• Flashing green/red: The unit is initializing the hard drive

7 USB Ports

The unit has five USB ports: one on the front panel (USB 2.0 port) and four on the rear panel (two USB 3.0 and two USB 2.0

ports). Use these ports to connect a UPS unit, or conduct diagnostic and troubleshooting activities.

10

Page 11

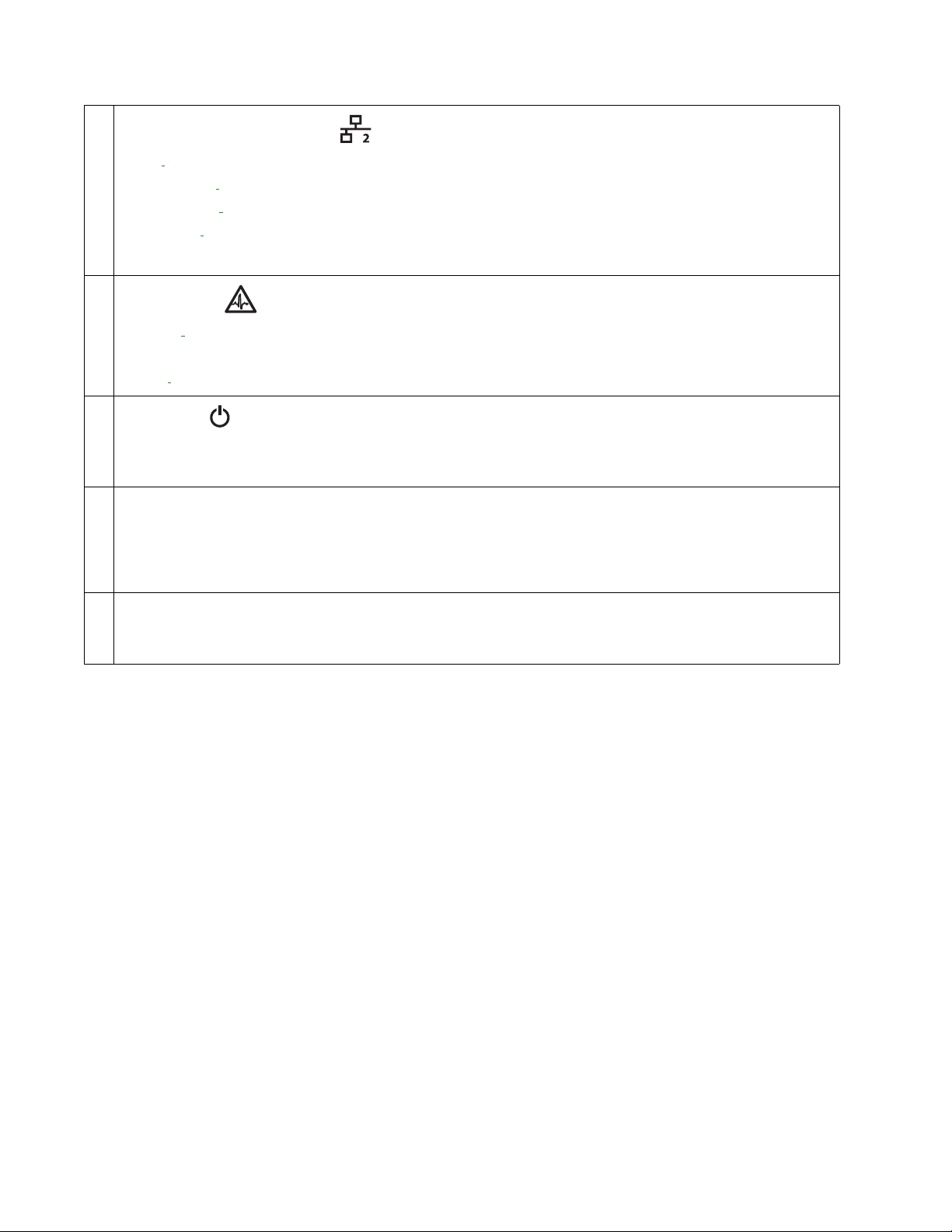

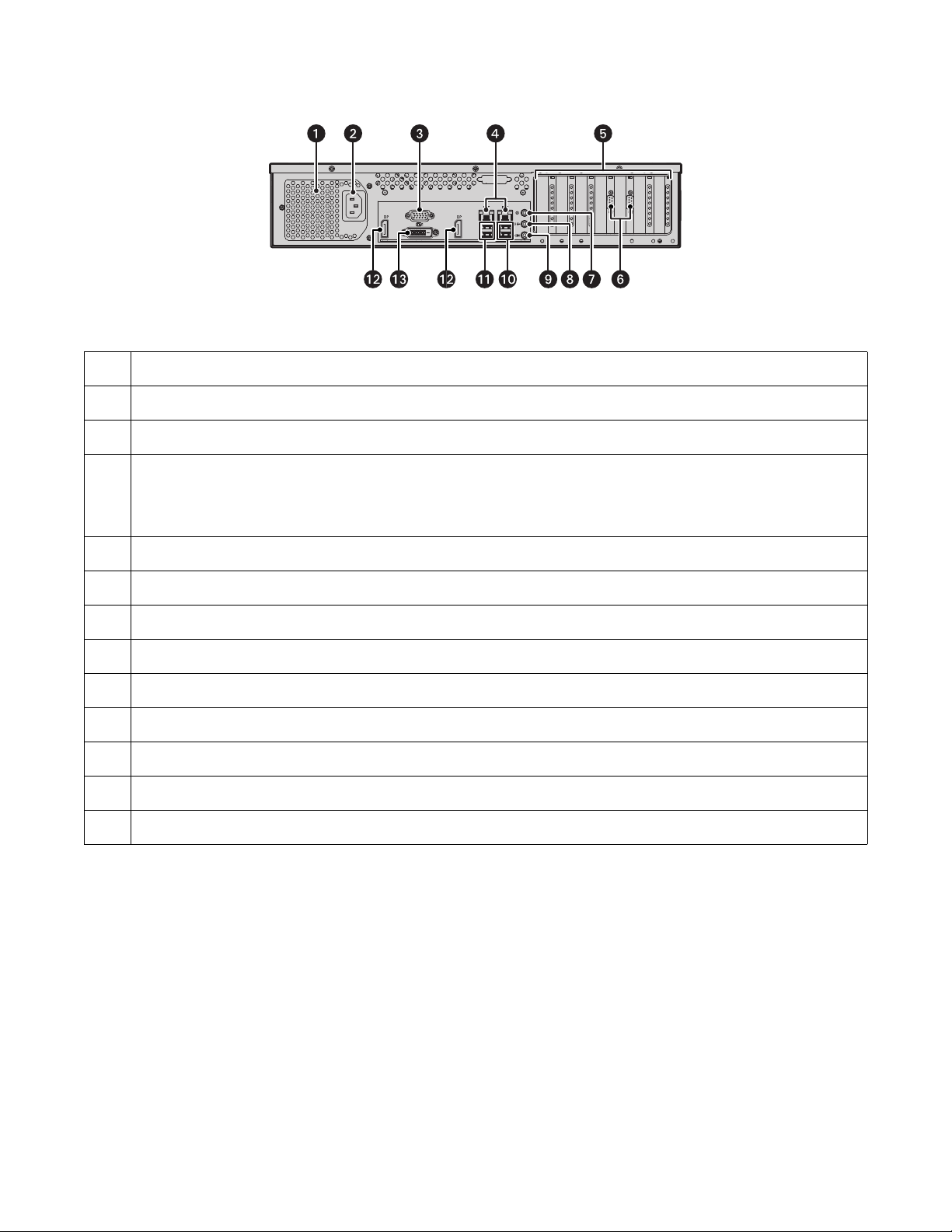

Product Overview: Rear

1 Rear Chassis Fan

2 Power Receptacle

3 VGA Port

4 Ethernet Ports

• Network Port 1 (left is primary)

• Network Port 2 (right is secondary)

Figure 1: Rear Panel Layout

5 Expansion Slots

6 Serial Ports

7 Reserved (do not use)

8 Audio Output

9 Audio Input

10 USB 3.0 Ports

11 USB 2.0 Ports

12 DisplayPort Connectors

13 Digital Visual Interface (DVI) Connector

11

Page 12

Placing on a Desktop

WARNING: Do not place the unit on its side; in this position, the unit is likely to fall over and may cause equipment damage or personal

injury.

1. Verify that the rubber feet are attached to the bottom of the unit. If not, secure the rubber feet to the bottom of the unit.

2. Position the unit to allow for cable and power cord clearance at the rear.

12

Page 13

Product Serial Number Label Placement

Product serial number labels identify a unit and its factory configuration if it should require service.

Three labels citing a serial number are attached to the unit.

• One label is attached to the upper-right corner of the rear of the unit.

• A second, smaller label is attached to the inside left of the bezel.

• A third set of labels is provided to attach to another product location that will not be obscured by installation. This is useful because

rack mounting and other installation options might obscure the factory-applied labels.

IP Camera License Label

If you ordered a license for additional IP cameras, locate the license label on the inside left of the bezel. This label contains a key you

can use to add IP cameras through DS Quick Setup.

Attaching the Third Set of Serial Number Labels

1. Locate the small label attached to the outside of the front bezel, attached with a yellow sticker that reads, “Extra serial number

label: remove prior to installation.”

2. Remove the yellow sticker.

3. Peel away the backing of the small label, and then attach it to this manual, other product documentation, or an unobstructed product

location.

13

Page 14

Installing a DSSRV-RAID Controller Card

The unit must be turned off, unplugged, and the chassis cover open before you can install hardware.

DSSRV-RAID is an internal controller card that can be installed in DSSRV2 and DSSRV2-DVD units to manage your video storage in a

RAID 5 array.

A RAID 5 array requires at least three drives. One drive in the array is used for parity, reducing net storage capacity by one drive. Installing

the RAID controller will cause your drives to go through a rebuild cycle, deleting all recorded video. Ensure that your video data is

backed-up before installing the RAID controller.

The RAID controller card does not support Unified Extensible Firmware Interface (UEFI) booting. If enabled, you must disable UEFI before

the unit will start up with a RAID controller installed.

1. With the chassis open, remove the SATA cable ties from the inside left of the unit.

2. Carefully disconnect the SATA cables from the motherboard.

Figure 1: Disconnecting SATA Cables from the Motherboard

3. Remove the drive carriers from the front of the unit.

a. Open each drive carrier’s latch by pulling the latch to the left.

b. Slide the drive carriers gently out of their bays.

4. Remove the top two screws on the backplanes.

Figure 2: Lifting the Backplanes

14

Page 15

5. Lift the backplanes, and disconnect the SATA cables from each backplane. Do not disconnect the power cables. Remove the SATA

cables from the chassis.

Figure 3: Disconnecting the SATA Cables

6. Connect the multilane SATA cables to the appropriate connectors on the backplanes (refer to Figure 4).

NOTE: Two sets of multilane SATA cables are supplied. The first set is numbered P1 to P4. The second set is numbered P5 to P6.

The P5 cable is attached to the backplane for the optical drive and the P6 cable is unattached. Each cable has a different length,

and the connectors are right-angle connectors for nesting. The multilane SATA cable lengths are as follows:

• P1: 317.5 mm (12.5 inches)

• P2: 330.0 mm (13.0 inches)

• P3: 444.5 mm (17.5 inches)

• P4: 457.0 mm (18.0 inches)

• P5: 571.5 mm (22.5 inches)

• P6: 585.0 mm (23.0 inches)

Table A: Multilane SATA Cable Connections (Sheet 1 of 2)

Connect To

First Set of Cables

P1 HD1

P2 HD2

P3 HD3

P4 HD4

Second Set of Cables

P5

P6

15

Page 16

Table A: Multilane SATA Cable Connections (Continued) (Sheet 2 of 2)

Connect To

*DSSRV2-DVD uses only P5 in the second set of cables for the optical drive.

7. Align each backplane with the two guide pins located at the bottom of the backplane slot. Ensure that all cables are cleared before

seating the backplane.

8. Insert and tighten the two screws on the top of each backplane.

9. Unscrew and remove the metal filler bracket for the PCIe x 16 slot.

Figure 4: Removing the PCIe x 16 Filler Bracket

10. Replace the RAID card’s high-profile bracket with the supplied low-profile bracket.

16

Page 17

11. Align the card with the PCIe x 16 slot. Gently press down on the card so that it is properly seated in the PCIe x 16 slot. Insert and

tighten the metal bracket screw to secure the card.

Figure 5: Removing the PCIe x 16 Filler Bracket

12. Run the multilane SATA cables through the slot on the inside left of the unit.

Figure 6: Running the Cables Through the Cable Slot

13. Connect the other end of the P5 cable to the motherboard for the optical drive on the DSSRV2-DVD.

17

Page 18

14. Connect the multilane SATA cable plugs to the 4-lane connectors on the card.

NOTE: The bottom DS-SRV-RAID connector (SAS_1) must be used for the first set of drives (HD1 to HD4). The top DS-SRV-RAID

connector (SAS_0) must be used for the second set of hard drives (HD5 and HD6). Only one plug is required for the DSSRV2-DVD.

Figure 7: Connecting the Cables to the RAID Controller Card

15. Secure the power and multilane SATA cables by bundling them with cable ties.

16. Close the chassis and insert the drive carriers to complete the installation process.

Disabling UEFI Booting

1. Restart the system.

2. Press Delete repeatedly while the system is starting up to access the BIOS.

3. Modify the boot order to ensure that the unit boots from a non-UEFI device.

Re-Imaging the Unit

A USB key containing the software image is shipped with the unit. You must re-image the unit after installing an optional DSSRV-RAID

controller card.

NOTE: If burning the ISO image to a DVD, you must use a dual-layer DVD. DS-SRV2-RD models have the RAID card installed. Use the

USB key packaged with the DS-SRV2 system to perform an image recovery.

1. Shut down the unit.

2. Insert the USB key.

3. Turn on the unit.

4. Depending on the system configuration, perform a RAID or Non-RAID recovery.

RAID Recovery

A warning dialog appears before the recovery process. If you have not backed up your video data, you might want to exit the recovery

dialog and back up your data before continuing with the recovery process.

18

Page 19

1. Press any key to continue with the factory restore. The RAID Operations dialog box appears.

Figure 8: RAID Operations Dialog Box

2. Select one of the following options:

• Press 1 to convert to a RAID 5 array.

• Press 2 to convert to a single-drive (JBOD) configuration.

• Press 3 to exit the recovery console.

3. Press y to confirm your selection. Press Enter to continue.

The RAID 5 configuration will take approximately one hour to complete.

Non-RAID Recovery

If recovering a unit that does not have a RAID controller installed, or you selected a single-drive configuration during the RAID recovery

process, the non-RAID recovery dialog appears.

1. Select one of the following options:

• Press 1 to restore the OS partition only, leaving video data intact.

• Press 2 to erase all system drives, including video data.

• Press 3 to exit the recovery console.

2. After selecting Option 1 or 2, type y, and then click the Enter key.

19

Page 20

Installing the SCSI Card

Disconnect the power source before opening the chassis and installing or removing any expansion cards or other hardware.

1. Unscrew and remove the bracket for the PCIe x 16 slot. Set the screw aside.

2. Replace the high-profile bracket connected to the card with the low-profile bracket (supplied).

3. Align the card with the PCIe x 16 slot and gently press down on the card until it is firmly seated in the slot.

Figure 1: Installing the SCSI Card

4. Insert and tighten the screw to secure the card.

Preparing the Unit for the SCSI Card

1. Shut down the unit.

2. Disconnect the power.

3. Disconnect any cables restricting access.

4. If mounted in a rack, unscrew the fasteners and carefully lift the unit out of the rack (two people may be required).

5. Place the unit on a flat surface with ample workspace.

6. Unlock and open the bezel.

7. Use a Phillips screwdriver to remove the case cover screws.

8. Remove the case cover by lifting it up. Set aside the case cover.

Opening the Chassis

When opening the chassis, ensure that the unit is turned off, disconnected from power, and you are wearing a properly grounded ESD

wrist strap.

1. Unlock and open the bezel.

20

Page 21

2. Use a Phillips screwdriver to remove the chassis cover screws. There are two screws on the top front, two screws on the left and

right sides, and three screws on the rear.

3. Carefully lift and remove the chassis cover.

21

Page 22

Installing an ENC5400 Capture Card

PCIe x16

PCIe x4

PCI

PCIe x16

The unit must be turned off, unplugged, and the chassis cover open before you can install the ENC5400 Capture Card.

The ENC5400 capture card consists of two pieces. The primary card fits the unit’s PCIe x16 slot, and the secondary card fits over the PCIe

x4 slot to the left of the PCIe x16 slot.

1. Unscrew and remove the metal filler bracket for the PCIe x16 slot.

2. Align the card with the PCIe x16 slot. Gently press down on the card so that it is properly seated in the PCIe x16 slot.

Figure 1: Installing a Primary Capture Card

3. Insert and tighten the metal bracket screw to secure the card.

4. Unscrew and remove the metal filler bracket for the PCIe x4 slot to the left of the PCIe x16 slot where the 2-port card is installed.

5. Align the secondary card with the PCIe x4 slot. Gently press down on the card so that it is properly seated over the PCIe slot.

22

Page 23

6. Connect the primary and secondary cards using the 20p flat cable (supplied).

PCIe x16

PCIe x4

PCI

PCIe x16

Figure 2: Installing a Secondary Capture Card

7. Insert and tighten the metal bracket screw to secure the card.

23

Page 24

Mounting in a Rack

Do not block slots and openings in the cabinet. These provide ventilation to prevent the unit from overheating. Never place the unit near

or over a radiator or heat register. When placing the unit in a rack, be sure to provide proper ventilation.

1. Install the chassis handles:

a. Align the screw holes on the chassis handles and the chassis.

b. Insert and tighten the four 10-32 x 0.5-inch Phillips flat head screws with a Phillips screwdriver.

2. Remove the chassis brackets from the sliding brackets:

a. Slide each chassis bracket away from the sliding bracket until it locks in place.

b. Press the release lever up or down (depending on the rail) to release the chassis bracket from the sliding bracket. Press down

on the release lever for the right set of rails and press up for the left set of rails.

Figure 1: Remove the Chassis Brackets from the Sliding Brackets

3. Attach one chassis bracket to each side of the unit. Use four M4*6L-H2.5 round head nickel screws for each bracket. Attach the

chassis brackets so that the slotted ends are positioned toward the rear of the unit.

Figure 2: Attach the Mounting Brackets

4. If necessary, remove the rubber feet from the underside of the unit.

5. Attach a front and rear L-shaped bracket to the left and the right sliding brackets using two M4*6L-H2.5 round head nickel screws.

Leave all eight of the screws untightened.

24

Page 25

Figure 3: Attach the L-Shaped Mounting Brackets

6. Attach the front and rear L-shaped brackets to the rack. Make sure the rails are mounted back to back. Use two M5*8L-H2.5 round

head nickel screws for each bracket.

The mounting brackets are identical and can be used on either side of the rack.

a. Position the ear of the front L-shaped bracket and an L-shaped plate nut against the inside front of the equipment rack. Align

the two center holes in the ear of the L-shaped bracket and L-shaped plate nut with the holes in the rack.

b. Using two M5*8L-H2.5 round head nickel screws, insert and tighten the screws from the outside of the rack, pointing toward

the back of the rack.

c. Adjust the rails to the correct depth of the equipment rack by sliding the rear-mount rail to the back of the equipment rack.

d. Repeat the previous steps to attach the rear L-shaped bracket and L-shaped plat nut to the rack.

Figure 4: Attach the Brackets to the Rack

7. Tighten the M4*6L-H2.5 round head nickel screws that are attached to the front- and rear-mount rails which were left untightened

earlier in the installation.

8. Place the unit onto the mount rails by sliding the chassis brackets onto the rails. Align the chassis brackets with the first slot on the

sliding brackets when installing the unit. This will ensure that the two brackets are aligned properly when sliding the unit in and

out of the rack. It might require two people to lift and slide the unit into place.

NOTE: To pull the unit completely out of the rack, pull the unit out of the sliding bracket until it locks into place, and then press the

release levers on either side of the chassis bracket to release the unit.

25

Page 26

Figure 5: Install the Unit in the Rack

Figure 6: Align the Chassis Bracket and the Sliding Bracket

9. Insert and tighten two M5*8L-H2.5 round head nickel screws above and below the chassis handles to secure the unit in the rack.

26

Page 27

Installing the Drive Array

After securely mounting the unit in the rack, install the drive array. Place the drives into the bays in the correct order.

When replacing a drive in a RAID array, you should rebuild the array before operating. If another drive fails before the array is rebuilt,

the array will go offline and data loss will occur.

WARNING: The drive parts and assemblies are susceptible to damage by Electrostatic Discharge (ESD).

Figure 1: Drive Bay Allocation

1 drive Bay 1: Install this drive first in a non-RAID 5 configuration

2 Drive Bay 2

3 Drive Bay 3

4 Drive Bay 4

5 Drive Bay 5

6 Drive Bay 6

Figure 2: Drive Bays with Optical DVD Drive

1 Drive Bay 1: Not hot-swappable; contains operating system, install first

2 Drive Bay 2

3 Drive Bay 3

4 Drive Bay 4

5 Drive Bay 5: Optical DVD drive

1. Unlock and open the bezel.

27

Page 28

2. Install the drive carriers:

a. Open the drive latch (grasp the latch right side and pull it to the left).

b. Slide the drive carrier into the drive bay.

c. Close the drive latch; ensure that the drive carrier locks into place.

3. After the drive carriers are inserted, close and lock the bezel.

28

Page 29

Connecting an ENC5516

DSSRV

ENC5516

ENC5516

1. Ensure the unit is powered off.

2. Connect the dual-connector end of the DSSRV Data cable (ordered separately) to the unit’s primary capture card.

3. For 4-port connections, connect the dual-connector end of the DSSRV data cable to the unit’s secondary capture card.

4. Connect the other end of the DSSRV Data cable to each ENC5516. Observe the port assignments as follows:

• Primary capture card: The top DSSRV data cable port on the primary capture card is for Encoder 1 (COM ports 3 and 4). The

bottom DSSRV data cable port is for Encoder 2 (COM ports 5 and 6). The primary capture card connects to the 20-pin ribbon

connector slot in 2-port kits.

• Secondary capture card: The top DSSRV data cable port on the secondary capture card is for Encoder 3 (COM ports 7 and

8). The bottom DSSRV data cable port is for Encoder 4 (COM ports 9 and 10). The secondary capture card is the daughter card

that connects to the 20-pin ribbon connector slot in 4-port kits.

Figure 1: Connecting the DSSRV and ENC5516(s)

5. When you have finished connecting the encoders, turn the unit on.

NOTE: Disconnecting an ENC5516 encoder from the unit while powered might cause the application or operating system to stop

responding. To recover from this error, restart the unit. Video will not record until the unit has restarted. Ensure the screws on the

data cables between the ENC5516 encoders and the unit are fastened to prevent encoders from disconnecting during use.

29

Page 30

Connecting an Uninterruptible Power Supply

UPS

POWER SOURCE

INPUT POWER

USB

OUTPUT POWER

While UPS units supply backup battery power, the unit works in conjunction with the SmartUPS from APC. The SmartUPS signals the

unit to begin a graceful shutdown if the UPS standby power falls below a specific threshold.

1. Shut down the unit.

2. Connect a power cord from the unit power supply to a standard wall outlet.

3. Connect a power cord from the UPS to a standard wall socket or other power source.

4. Connect a USB cable from the APC SmartUPS to the USB connector on the unit.

5. Turn on the UPS.

6. Turn on the unit.

Figure 1: Connecting a UPS

30

Page 31

Connecting to the Network

SECONDARY

NETWORK

The primary network interface card (NIC) must be active when using the License Key Entry program to add or update IP camera licenses.

1. Connect one end of an Ethernet cable one of the unit’s network interfaces.

2. Connect the other end of the cable to an available Gigabit Ethernet port.

Figure 1: Network Cable Connection

31

Page 32

Connecting the Power Supply

1. Connect the power cord to the unit’s power connector.

2. Connect the other end of the power cord to the appropriate power source.

32

Page 33

Starting Up the Unit

1. Unlock and open the bezel.

2. Press the power button.

3. Close and lock the bezel.

4. Log in to Windows. Your default user name is DSServiceUser and your default password is dsserviceuser.

Shutting Down the Unit

Use an orderly shutdown for the unit to close files and power down.

Use the immediate shutdown in an emergency or when there is not enough time for an orderly shutdown.

Orderly Shutdown

1. Click Start.

2. For servers, click Power Options.

3. Click Shut Down.

Immediate Shutdown

1. Unlock and open the bezel.

2. Press and hold the power button until the unit shuts down.

3. Close and lock the bezel.

33

Page 34

Enabling SNMP Services

The Windows SNMP service is turned off by default. You must enable the SNMP service to issue SNMP requests or receive traps from

the unit.

The Digital Sentry MIB files are located on the Digital Sentry recorder at C:\Program Files (x86)\Pelco\Health Monitor\MIB

• DigitalSENTRY-Base-MIB.MIB

• Integral-Tech-SMI.MIB

Consult the documentation for your SNMP manager for information about loading MIB files.

1. Click Start (Windows icon). Type “Turn Windows Features On or Off” in the Search Programs and Files field, and then click Enter.

2. Select the Simple Network Management Protocol (SNMP) and WMI SNMP Provider check boxes, and then click OK.

3. Click Start and type services.msc in the Search Programs and Files field, and then click Enter.

4. Right-click SNMP Service and select Properties.

5. Click the Security tab within the “Accepted community names” frame, and then click Add.

6. Ensure the “Community rights:” menu states READ ONLY. In the “Community Name:” field, type “Public”, and then click Add.

7. Click Apply.

8. Go to the Traps tab. Under “Trap destinations:” click Add, and type the IP address of your SNMP manager. Click Add.

9. Click OK to save and close the SNMP Service Properties dialog.

34

Page 35

Enabling Serial Ports in the BIOS

1. Turn the unit on. If the unit is already on, restart it.

2. Press the Delete key repeatedly to access the BIOS.

3. Go to the Advanced menu.

4. Select NCT6776F Super IO Configuration. Press Enter.

5. Select the serial port you want to enable. Press Enter.

6. Select Serial Port from the menu. Press Enter.

7. Select Enabled from the menu. Press Enter.

8. Press Esc, and repeat the steps above to enable other serial ports.

9. Press F4, select Yes, and then press Enter to save your changes and exit the BIOS.

35

Page 36

Digital Sentry Port Assignments

Table A: DS Port Assignments

Port Assignment

25 TCP SMTP: Used to send email; can be blocked if not using the

DSAdmin Email Notification feature

123 UDP NTP: Used by the Windows Time Service; can be blocked

137 TCP/UDP NETBIOS: Name Service

445 TCP/UDP Microsoft-DS: Used by the NET TIME/SET command; used in the

scheduled task setup by FLTime

1433 TCP Off-box SQL server

1434 UDP Off-box SQL server

2000 TCP Remotely anywhere: Can be blocked if not used

17772 TCP DS ControlPoint System Discovery/Diagnostics (VSS Utility)

18772 TCP Used to deliver DS Video Server to a network client

18776 TCP Transactional Data: Can be blocked if unused

18777 TCP Transactional Data: Can be blocked if unused

18778 TCP Transactional Data: Can be blocked if unused

18778 UDP Used to deliver live audio to a network client. A new port is used

whenever a client listens to live audio; for example, 18778, 18779,

and 18780. Ports will also be re-used. These ports can be blocked

if audio is not used.

36

Page 37

Troubleshooting

If the following instructions fail to solve your problem, contact Pelco Product Support at 1-800-289-9100? (USA and Canada)

or+1-559-292-1981 (international) for assistance. Be sure to have the serial number available when calling.?Do not try to repair the unit

yourself. Leave maintenance and repairs to qualified technical personnel only.

Table A: Troubleshooting

Problem Possible Causes Suggested Solutions

The unit is not ready. Power turned off. Check that the power indicator is lit

Faulty cable connections. Check all leads, plugs, contacts, and

connections.

Network connectivity issues. Contact your network administrator.

The unit is not ready for operation after

software/firmware upload.

The unit status indicator is red. Power supply failure. Temperature

The unit status indicator is red and the

power supply alarm sounds.

The unit status and hard drive indicators

are red and the unit alarm sounds.

Voltage failure during programming of

update file.

Unit fan failure. Replace the failed fan.

exceeds specifications (internal or

external).

Power loss to either power supply. Check each power supply, line voltage,

Power supply module failure. Replace the failed power supply.

Hard drive failure. Replace the failed hard drive.

Replace the unit and have Pelco check it.

Check power supplies. Check all fans;

check the external temperature.

and the UPS.

37

Page 38

Technical Specifications

Hardware Specifications

Processor

Internal Memory 8 GB DDR3 non-ECC RAM; 16 GB DDR ECC RAM for DSSRV2-RD models

Operating System Windows 7 Ultimate 64-bit SP1

User Interface Graphical User Interface, DS ControlPoint

Internal Storage

DSSRV2 500 GB, 4 TB, 8 TB, 12 TB, 16 TB, or 20 TB

DSSRV2-DVD 500 GB, 4TB, 8 TB, 12 TB, or 16 TB

DSSRV2-RD 12 TB, 16 TB, 20 TB, or 24 TB

DS-CPPC 4 TB

Optical Drive DVD±RW (DSSRV2-DV models only)

USB Ports 3 USB 2.0 ports (1 front, 2 rear), 2 USB 3.0 ports (rear)

Video

Video System Intel HD Graphics P4700 (shared memory)

Max Resolution 3840 x 2160 per DisplayPort output (2X)

Video Outputs Supports up to 3 simultaneous displays using any combination of the four outputs

Video Standards 60 Hz capable for NTSC

Video Decoding Supported MPEG-4 ASP; H.264 Baseline, Main, and High profiles

Decoding Performance

DS-CPPC Models 10X H.264 streams at 1920 x 1080, 100 image quality, 30 frames per second, averaging 3.5 Mbps; 54X

®

Intel

Xeon® E3-1275 v3

1920 x 1200 @ 60 Hz on DVI-D output

1920 x 1200 @ 60 Hz on VGA output

75 Hz capable for PAL

H.264 streams at 1280 x 720, 100 image quality, 12.5 frames per second, averaging 3 Mbps

Audio

Audio Decoding G.711 speech codec

Audio Bit-rate 64 kbps

Audio Levels

Input Electret microphone

Output Up to 3 Vp-p, adjustable, minimum load of 8 ohms

Audio Connectors 2, 3.5 mm stereo jacks

Connector Tip Signal left (input and output)

Connector Ring Signal right (input and output)

Connector Sleeve Common

Audio Inputs Microphone

Audio Outputs Speaker or line out

38

Page 39

Network

Interface 2 Gigabit Ethernet RJ-45 port (1000Base-T)

Front Panel

Buttons

Indicator

Unit Status Green, amber, red

Primary Network Green, amber, red

Secondary Network Green, amber, red

Software Status Green, amber, red (based on diagnostics)

Hard Disk Status Green, red, off (behind bezel)

Power

Power Input 100 to 240 VAC, 50/60 Hz, autoranging

Power Supply Internal

Power Consumption Operating Maximum

100 VAC 160 W, 1.60 A, 547 BTU/H

115 VAC 160 W, 1.39 A, 547 BTU/H

220 VAC 160 W, 0.72 A, 547 BTU/H

Environmental

Operating Temperature 10° to 35°C (50° to 95°F) at unit air intake (front of unit)

Storage Temperature –40° to 65°C (–40° to 149°F)

Operating Humidity 20% to 80%, noncondensing

Maximum Humidity Gradient 10% per hour

Operating Altitude –15 to 3,048 m (–50 to 10,000 ft)

Operating Vibration 0.25 G at 3 Hz to 200 Hz at a sweep rate of 0.5 octave/minute

NOTE: The temperature at the unit air intake can be significantly higher than room temperature. Temperature is affected by rack configura-

tion, floor layout, air conditioning strategy, and other issues. To prevent performance failure and unit damage, make sure the temperature

at the unit is continuously within the operating temperature range.

Physical

Construction Steel cabinet

Finish

Front Panel Gray metallic with black end caps

Chassis Black matte finish

Dimensions 50.8 x 43.4 x 8.9 cm (20" D x 17.1" W x 3.5" H)

Mounting Desktop (feet) or rack (2 RU per unit)

Unit Weight 13.06 kg (28.8 lb)

39

Page 40

Models

The following table describes DSSRV2 and DS-CPPC model numbers. For example, a 12 TB DSSRV2 unit with a power cord for the United

Kingdom is DSSRV2-120-UK.

Model Storage Country Code

NVR Without Optical Disc Drive

DSSRV2-005 500 GB

DSSRV2-040 4 TB

DSSRV2-080 8 TB

DSSRV2-120 12 TB

DSSRV2-160 16 TB

DSSRV2-200 20 TB

NVR With RAID Configuration

DSSRV2-120RD 12 TB

DSSRV2-160RD 16 TB

DSSRV2-200RD 20 TB

US = North America, AU = Australia, AR = Argentina, EU = Europe, UK =

United Kingdom, CN = China

DSSRV2-240RD 24 TB

NVR With Optical Disc Drive

DSSRV2-005DV 500 GB

DSSRV2-040DV 4 TB

DSSRV2-080DV 8 TB

DSSRV2-120DV 12 TB

DSSRV2-160DV 16 TB

Workstation Running DS ControlPoint

DS-CPPC 4 TB

Supplied Accessories

Keyboard (USB) 1

Mouse (USB) 1

USB-DS Includes recovery image and documentation

Bezel Key 2

Rack Mount Kit 1

Power Cord 1

NOTE: Units shipped to China do not include power cords.

Optional Accessories

DS-SW-CAM DSSRV2 models include licenses for 8 IP cameras; additional DS-SW-CAM license can be purchased separately

ENC5516 Direct-attached analog encoder

ENC5400-4PORT 4-port host card (analog); allows for connection of up to 4 ENC5516 encoders

DSSRV-RAID LSI 3Ware 9750-8i RAID controller card

DSSRV-SCSI

Adaptec

®

SCSI card 29320LPE

DSHDD-005 500 GB upgrade/replacement drive

DS-EN-HDD-040 4 TB upgrade/replacement drive

40

Page 41

Certifications

CE, Class A

FCC, Class A

UL/cUL Listed

S-Mark for Argentina

CCC

C-Tick

Standards/Organizations

Pelco is a member of the MPEG-4 Industry Forum

Pelco is a member of the Universal Plug and Play (UPnP) Forum, Steering Committee

Pelco is a member of the Universal Serial Bus (USB) Implementers Forum

Pelco is a contributor to the International Standards for Organization / Electrotechnical Commission (ISO/IEC) Joint Technical Committee 1

(JTC1), “Information Technology,” Subcommittee 29, Working Group 11

Compliance, ISO/IEC 14496 standard (also known as MPEG-4)

Compliance, International Telecommunication Union (ITU) Recommendation G.711, “Pulse Code Modulation (PCM) of Voice Frequencies”

41

Page 42

Pelco by Schneider Electric

3500 Pelco Way Clovis, California 93612 USA

(800) 289-9100 Tel (800) 289-9150 Fax

+1 (559) 292-1981 International Tel

+1 (559) 348-1120 International Fax

www.pelco.com

Pelco, the Pelco logo, and other trademarks associated with Pelco products referred to in this publication are trademarks of Pelco, Inc. or its affiliates. © Copyright 2015, Pelco, Inc.

ONVIF and the ONVIF logo are trademarks of ONVIF Inc. All other product names and services are the property of their respective companies. All rights reserved.

Product specifications and availability are subject to change without notice.

Loading...

Loading...