Page 1

INSTALLATION

®

Endura

™

SP04-140 Dual-Input

Video Encoder

C613M-A (5/05)

Page 2

Contents

Regulatory Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Product Serial Number Label Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Equipment Placement and Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Desktop Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Pelco Badge Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Connecting Video Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Connecting Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connecting a PTZ Device, Relay, and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Connecting to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Connecting a PTZ Device (Pelco D Protocol) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Connecting a Relay Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connecting Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Front Panel Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuration/Reset Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

2 C613M-A (5/05)

Page 3

List of Illustrations

1 Product Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2 SP04-140 Desktop Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3 SP04-140 and WM5001-4U Wall Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4 Tighten the Thumbscrew to Secure the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

5 Multiple SP04-140 Units in an RK5000PS-5U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Tighten Thumbscrew to Secure the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7 Pelco Badge Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8 SP04-140 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

9 Video Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

10 SP04-140 Audio Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

11 SP04-140 Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

12 Connecting a Spectra Dome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

13 Connecting a Relay Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

14 Supervised Alarm Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

15 Supervised Alarm Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

16 Unsupervised Alarm Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

17 Unsupervised Alarm Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

18 Connecting Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

19 Connecting Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

20 SP04-140 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

List of Tables

A Video Coaxial Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

B PTZ, Relay, and Alarm Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

C Serial Port Options and Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

D Powering Multiple Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

E Recommended Wire Gauge and Maximum Wiring Distances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

F Configuration/Reset Button Functions and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

G Troubleshooting the SP04-140 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

C613M-A (5/05) 3

Page 4

Regulatory Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

RADIO AND TELEVISION INTERFERENCE

This equipment has been tested and found to comply with the limits of a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However there is no guarantee that the interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

You may also find helpful the following booklet, prepared by the FCC: “How to Identify and Resolve Radio-TV Interference Problems.” This

booklet is available from the U.S. Government Printing Office, Washington D.C. 20402.

Changes and Modifications not expressly approved by the manufacturer or registrant of this equipment can void your authority to operate this

equipment under Federal Communications Commission’s rules.

In order to maintain compliance with FCC regulations, shielded cables must be used with this equipment. Operation with non-approved

equipment or unshielded cables is likely to result in interference to radio and television reception.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

4 C613M-A (5/05)

Page 5

Description

The SP04-140 is a special version of the single-input NET5301T video encoder. It is a high-performance, dual-stream, dual-input video encoding

unit. Its main function is to convert live analog video from two cameras into dual MPEG-4 video streams. It transmits these streams over an

Ethernet network to other Endura

recorder or decoded by the following Endura components:

• NET5301R video decoder: Converts up to 4 video streams for display or recording on an analog device.

• WS5050 workstation: Converts up to 16 video streams for display on a computer monitor.

• VCD5000 video console display: Converts up to 64 video streams (depending on model) for display or recording on an analog device.

NOTE: The front panel of the SP04-140 shows NET5301T as the model. However, the special number appears on the product serial number label

on the unit’s bottom panel.

The SP04-140 incorporates EnduraView

product (decoder, workstation, console), all without affecting the system recording rate. For example, the unit selects a high rate and quality

setting for recording and alarm conditions; it selects a lower rate for simple monitoring.

The SP04-140 can be configured for three alarm inputs and one relay output. When an alarm event is triggered, the unit can send a message to

an operator, trigger a relay, and implement video recording.

The unit also supports activity detection. You can configure up to four activity zones. When the SP04-140 detects activity in any of these areas, it

can trigger an alarm event.

The video encoder supports half-duplex, bidirectional audio over the network. The system operator (security personnel) can see and hear the

person.

All Endura products support Pelco D and Coaxitron

(PTZ) cameras.

™

system components. Then these streams can be recorded on an Endura NVR5100 Series network video

™

video optimization technology to select the best image quality and frame rate for the target Endura

®

protocols. As a result, the SP04-140 supports control of remote peripherals such as pan/tilt/zoom

Before You Begin

Endura is a network system that requires a continuous amount of bandwidth to transmit true, live video. Therefore, always include your network

administrator when planning and installing Endura components.

You will also need the following:

• Pelco-approved Endura certification

• Power source

• One or two NTSC or PAL (fixed or PTZ) cameras

• Microphone and speaker (if using audio)

• Small flat-tip screwdriver (if connecting camera control, relay, or alarms)

• Access to an Endura network

NOTE: Since power requirements vary by installation, the SP04-140 does not include an individual power supply. You can purchase the optional

NET5301PS single-unit power supply from Pelco. Refer to Connecting Power for more information on supplying power to the SP04-140.

PARTS LIST

Qty Description

1 SP04-140 dual-input video encoder

1 16-pin terminal block

1Two-pin power terminal block

1 SP04-140 Installation manual

1 Pelco badge rotation sticker

C613M-A (5/05) 5

Page 6

PRODUCT SERIAL NUMBER LABEL PLACEMENT

Product serial number labels help Pelco’s Product Support identify your system and its factory configuration in case the SP04-140 or its

components require service.

A label citing your product’s serial number is attached to the bottom panel of the SP04-140. Because rack mounting or other installation options

may obscure the factory-applied label, two additional labels are provided. Attach one of them to your product documentation or another product

location that will not be obscured by installation. The second label is a spare.

To use these labels:

1. On the bottom panel of your SP04-140, locate two small labels, attached with a yellow sticker that reads, “Extra serial number labels:

remove prior to installation.”

2. Remove the yellow sticker and the labels.

3. Peel away the backing from one label and attach it to this installation manual, other product documentation, or an unobscured product

location.

Figure 1. Product Serial Number Label

6 C613M-A (5/05)

Page 7

Equipment Placement and Rack Mounting

The SP04-140 can be placed on a flat surface, such as a desktop; mounted to a wall; or mounted into an equipment rack.

DESKTOP MOUNTING

To place the SP04-140 on a flat surface, such as a desktop:

1. Make sure the rubber feet are installed on the unit to prevent surface damage.

2. Position the unit to allow for cable and power cord clearance at the front and rear panels.

WARNING: Do not place the SP04-140 unit on its side; the unit could fall over and cause damage.

Figure 2. SP04-140 Desktop Placement

C613M-A (5/05) 7

Page 8

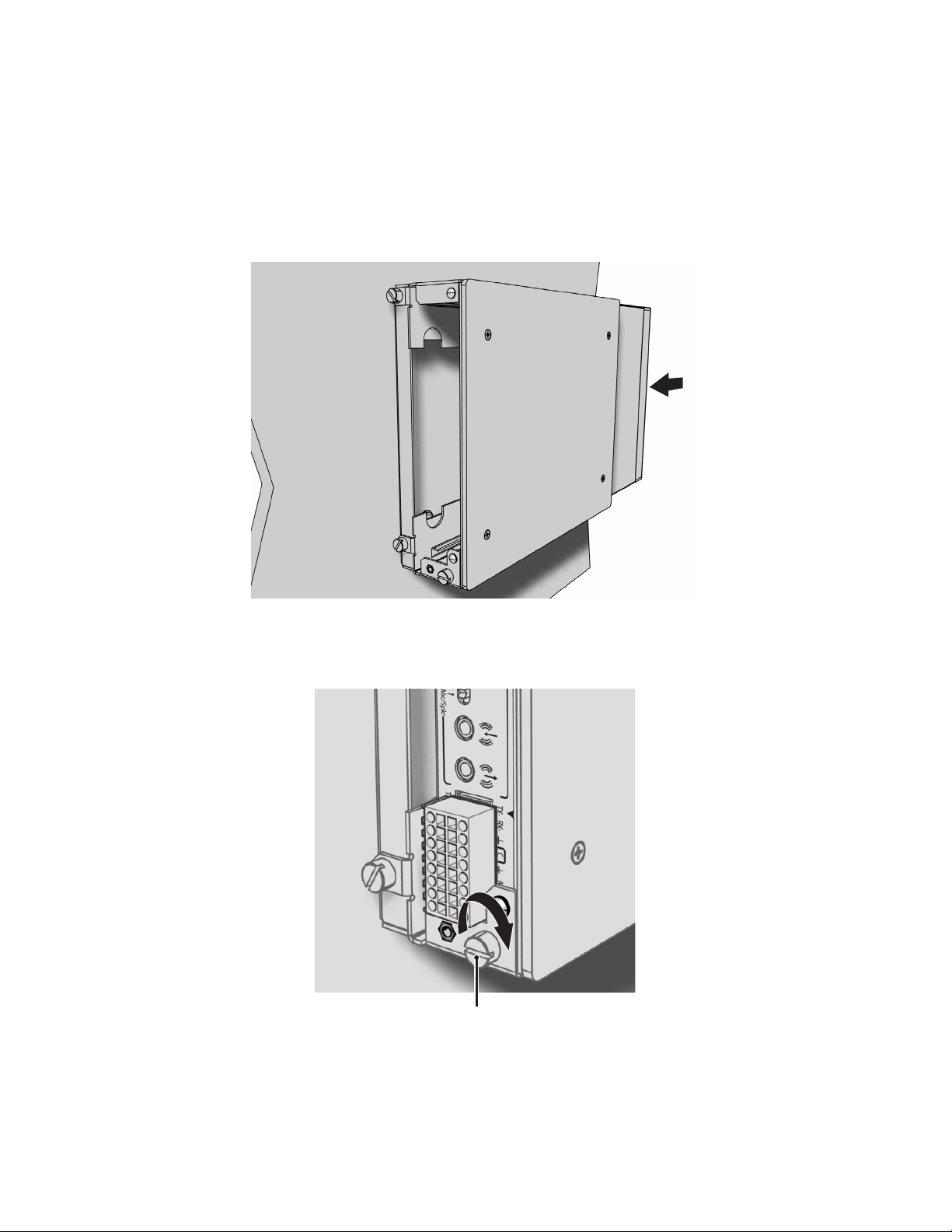

WALL MOUNTING

The SP04-140 can be mounted to a wall using the optional WM5001-4U wall mount system. You can mount up to four SP04-140, NET5301T, and

NET5301R units, in any combination, in a fully expanded WM5001-4U (one WM5001-4U with up to three WM5001-4UEXP expansion units).

To mount the SP04-140 to a wall using the WM5001-4U:

1. Install the WM5001-4U and any WM5001-4UEXP expansion units (refer to the WM5000 installation manual).

2. Insert the SP04-140 into the desired wall mount unit. Make sure all front and rear panel connectors are accessible.

Figure 3. SP04-140 and WM5001-4U Wall Mount

3. Tighten the thumbscrew on the wall mount to secure the unit (refer to Figure 4).

TIGHTEN

THUMBSCREW

Figure 4. Tighten the Thumbscrew to Secure the Unit

8 C613M-A (5/05)

Page 9

RACK MOUNTING

Any combination of SP04-140, NET5301T, and NET5301R units can be mounted together in the optional RK5000PS-5U rack mount kit, up to 12

units. Each unit plugs directly into a power connector in the rack and is powered by the rack.

NOTE: The RK5000PS-5U only supplies power. It does not provide a dock for any other unit connectors.

To install the SP04-140 into a rack mount kit:

1. Install the RK5000PS-5U rack mount kit into the rack (refer to the RK5000PS-5U installation manual).

2. Insert the SP04-140 into the desired slot.

Figure 5. Multiple SP04-140 Units in an RK5000PS-5U

3. Tighten the thumbscrew on the rack mount to secure the unit into the rack (refer to Figure 6).

TIGHTEN

THUMBSCREW

Figure 6. Tighten Thumbscrew to Secure the Unit

C613M-A (5/05) 9

Page 10

PELCO BADGE ORIENTATION

The Pelco badge on the front panel of the SP04-140 can be rotated in quarter turns. If you install the unit on a flat surface, the Pelco badge will

be turned the wrong way.

To rotate the Pelco badge:

1. Use the Pelco badge rotation sticker that came with the unit.

2. Attach the middle portion of the rotation sticker to the badge.

3. Press firmly with your thumb and rotate the badge to its correct position.

4. Remove the rotation sticker from the badge.

PELCO BADGE

Figure 7. Pelco Badge Orientation

10 C613M-A (5/05)

Page 11

Connections

Familiarize yourself with the SP04-140 rear panel before connecting any equipment to the unit.

FOUR-PIN

POWER

TWO-PIN

POWER

CONNECTING VIDEO INPUTS

The SP04-140 offers two analog video inputs. The unit automatically detects the video standard (PAL or NTSC) and accepts both color and

black-and-white analog video at both inputs.

The Video In (2) connector also supports PTZ operation using the following protocols:

• Coaxitron: When the SP04-140 receives a camera control command, it transmits that command up the coaxial cable to the PTZ device.

Since Coaxitron is a single-direction protocol, the PTZ device cannot return any data to the unit. By default, Coaxitron is disabled.

• Pelco D (RS-422): When the SP04-140 receives a camera control command, it transmits that command via the serial wires to the PTZ

device. Pelco D is a bidirectional protocol.

TERMINATION SWITCH AUDIO SWITCH RELAY CONTROL

VIDEO IN (1) VIDEO IN (2)

AUDIO IN AUDIO OUT

PTZ CONTROL (RS-422)

Figure 8. SP04-140 Rear Panel

ALARM

INPUT

CAMERA 1 (FIXED)

VIDEO IN (1)

CAMERA 2

(FIXED OR PTZ)

VIDEO IN (2)

Figure 9. Video Inputs

C613M-A (5/05) 11

Page 12

Before installing the SP04-140, make sure the distance from the unit to the video device is less than the maximum distance for the coaxial cable.

Refer to Table A for maximum video coaxial cable distances.

Table A. Video Coaxial Cable Requirements

Cable Type* Maximum Distance

RG59/U 750 ft (229 m)

RG6/U 1,000 ft (305 m)

RG11/U 1,500 ft (457 m)

*Cable requirements:

75-ohm impedance

All-copper center conductor; steel-center conductor cable may result in poor performance

All-copper braided shield with 95% braid coverage

NOTE: Make sure the termination switch is set to 75 Ω to enable termination. This is the default.

To connect a fixed camera:

1. Connect a coaxial cable to the camera device.

2. Connect the coaxial cable to the video in (1) connector on the rear panel.

To connect a second fixed camera:

1. Connect a coaxial cable to the camera device.

2. Connect the coaxial cable to the video in (2) connector on the rear panel.

To connect a PTZ device:

1. Connect a coaxial cable to the PTZ device.

2. Connect the coaxial cable to the video in (2) connector.

3. Pelco D only: Wire the TX and RX leads from the encoder to the PTZ device. Refer to Connecting a PTZ Device (Pelco D Protocol) .

12 C613M-A (5/05)

Page 13

CONNECTING AUDIO

The SP04-140 supports half-duplex, bidirectional audio (one direction at a time). It transmits audio and video signals simultaneously. This lets

you control a loudspeaker or other audio equipment, such as a door intercom system, at the monitored location.

The unit supports both microphone and line input levels. Microphones are usually not powered; they have weaker signals that must be amplified.

Line inputs usually have stronger, powered signals that have already been amplified.

NOTE: Use either microphone/speaker or line in/line out. The SP04-140 does not support mixed audio signal inputs and outputs.

MIC/SPKR

LINE

AUDIO PREAMP

Figure 10. SP04-140 Audio Connections

To implement audio:

1. Select the type of audio signal:

Mic/Spkr

Switch to Mic/Spkr if you are connecting a microphone or a speaker. The microphone input level is 5 mVp-p. The speaker

output level is 2.5 Vp-p.

Line

Switch to Line if you are connecting a powered audio input or output device. The line input and output level is 1 Vp-p.

By default, the switch is set to Line.

NOTE: If the switch setting does not match your audio equipment, audio distortion problems may occur.

2. Make sure the input and output audio connectors are wired as follows:

Connector Tip

Signal high

Connector Sleeve Common

3. Connect a line input device or microphone to the blue 3.5 mm audio in monaural connector. A preamplified microphone is recommended.

4. Connect a line output device or speaker to the green 3.5 mm audio out monaural connector.

NOTE: Audio out is not supported at this time.

C613M-A (5/05) 13

Page 14

CONNECTING A PTZ DEVICE, RELAY, AND ALARMS

The SP04-140 incorporates a 16-pin terminal block to support the following:

• PTZ device, such as a dome camera, using the Pelco D protocol (RS-422)

• Relay control, either normally open or normally closed

• Up to three alarm inputs, supervised or unsupervised, using any combination of high and low signals

The terminal block has tension clamps instead of screw terminals. Use a small screwdriver to open the clamp for a particular lead. Figure 11

shows how to wire the terminal block and connect it to the SP04-140.

NOTE: The terminal block is keyed. It attaches only one way to the video encoder.

PIN 1 PIN 1

PIN 9

PIN 16

Figure 11. SP04-140 Terminal Block

Table B identifies the pin assignments for the terminal block. An arrow on the rear panel identifies pin 1; on the terminal block, pin 1 is the

leftmost lead on the top row (refer to Figure 11).

Table B. PTZ, Relay, and Alarm Pin Assignments

Top Row Bottom Row

Pin Label Lead Pin Label Lead

1 TX- RS-422 Data TX- 9 TX+ RS-422 Data TX+

2 RX- RS-422 Data RX- 10 RX+ RS-422 Data RX+

3 Ground 11 NC Relay Normally Closed

4CRelay Common 12 NO Relay Normally Open

5 Ground 13 Ground

1

6A

7A

8A

Alarm 1 14 Ground

2

Alarm 2 15 Ground

3

Alarm 3 16 Ground

14 C613M-A (5/05)

Page 15

CONNECTING A PTZ DEVICE (PELCO D PROTOCOL)

NOTE: To connect a Coaxitron PTZ device, refer to Connecting Video Inputs

The SP04-140 supports camera control using Pelco D protocol (RS-422) for a PTZ device. You can connect only one serial PTZ device to a video

encoder. The default Pelco D device address is 0.

When the SP04-140 receives a camera control command, it transmits that command to the PTZ device. In four-wire installations, the encoder

also receives data from the PTZ device, including camera status and alarm states. It then transmits that data to the command center.

®

Figure 12 shows how to wire the SP04-140 to a Spectra

NOTE: When connecting a PTZ device to the SP04-140, connect the TX+ and TX- leads to the RX+ and RX- leads between the encoder and the

PTZ device.

By default, the encoder identifies any PTZ device as a fixed camera. You must configure the encoder before you can use the PTZ device (refer to

the WS5000 operation manual).

dome (refer to Table B for the specific connector pin assignments).

TX+

TX-

RXRX+

1VIDEO IN ( )

COAXIAL CABLE

VIDEO IN (2)

TRANSMIT

TO SPECTRA

RECEIVE

FROM SPECTRA

TX-TX+ RX+

RX-

SPECTRA

Figure 12. Connecting a Spectra Dome

C613M-A (5/05) 15

Page 16

Refer to Table C when installing the PTZ device. It lists the serial port settings that the SP04-140 supports.

Table C. Serial Port Options and Defaults

Setting Options Default

Data rate (bits per

second)

110, 300, 1200, 2400, 4800, 9600, 19200, 38400, 57600,

115200, 230400

2400

Data bits 5, 6, 7, 8 8

Parity None, Odd, Even None

Stop bits 1, 2 1

CONNECTING A RELAY DEVICE

The SP04-140 has an output for triggering an external device. It supports both momentary and continuous relay operation.

You can operate the relay interactively, during an active connection, or automatically to coincide with certain events. Typical applications include

activating a door, gate or lock, or switching on lights or other electrical devices.

WARNING: Do not exceed the maximum rating of 30 VDC, 1 A.

Figure 13 shows how to wire the relay with its power source to the video encoder (refer to Table B for the specific connector pin assignments).

NO

EXTERNAL

C

FUSE

MAX 30 VDC, 1 A

LIGHT/SIREN

POWER

Figure 13. Connecting a Relay Device

LOAD:

16 C613M-A (5/05)

Page 17

CONNECTING ALARMS

The SP04-140 offers three alarm inputs for external signaling devices, such as door contacts or motion detectors. Each encoder supports either

all normally open or all normally closed devices. If your installation requires mixed devices, install another SP04-140, NET5301T, or a NET5301R

video decoder. Then connect the normally open devices to one unit and the normally closed devices to the other unit.

Once configured, an alarm input can invoke many different activities, including triggering a relay device, sending an alert to a security office,

changing the video recording settings, and storing pre-alarm video to an NVR5100 Series recorder. You can connect switches or contacts directly

to the unit without a separate power supply.

Each encoder supports either all supervised or all unsupervised alarms. If your installation requires mixed alarm types, install another SP04-140,

NET5301T, or a NET5301R video decoder. Then connect the supervised alarm inputs to one unit and the unsupervised alarm inputs to the other

unit.

Supervised Alarms

When an alarm is configured as a supervised alarm, the SP04-140 maintains a constant electrical current through the alarm circuit (3.3 VDC,

1 k Ω ). If the alarm circuit length changes, due to an electrical short or a bypass, the voltage fluctuates from its normal state. Therefore, the unit

triggers an alarm.

NOTE: Install the 1 k Ω resister as close to the switch as possible.

Figure 14 illustrates the alarm and no alarm conditions of a supervised alarm input. Whether the alarm is normally closed or normally open,

neither a cut nor a bypass can defeat these alarms.

NORMALLY CLOSED

NO ALARM

GND

ALARM

GND

ALARM

GND

ALARM

GND

1 K

1 K

1 K

1 K

+V

+V

+V

CUT

+V

BYPASS

NO ALARM

ALARM

ALARM

ALARM

Figure 14. Supervised Alarm Conditions

NORMALLY OPEN

GND

GND

GND

CUT

GND

1 K

1 K

1 K

1 K

BYPASS

+V

+V

+V

+V

C613M-A (5/05) 17

Page 18

Figure 15 illustrates the wiring configuration for supervised alarm inputs.

NORMALLY CLOSED

1 KΩ

1 KΩ

1 KΩ

UNUSED

INPUTS

MUST ALSO

BE WIRED

NORMALLY OPEN

1 KΩ

1 KΩ

1 K

Ω

UNUSED

INPUTS

MUST ALSO

BE WIRED

Figure 15. Supervised Alarm Input Wiring

Unsupervised Alarms

When an alarm is configured as an unsupervised alarm, the SP04-140 only triggers an alarm when the normal alarm state (open or closed)

changes.

Figure 16 illustrates the alarm and no alarm conditions of an unsupervised alarm input. A normally closed alarm input can be defeated with a

bypass. A normally open input can be defeated with a cut.

NORMALLY CLOSED

NO ALARM

GND

ALARM

GND

ALARM

GND

NO ALARM

GND

CUT

+V

+V

+V

+V

NO ALARM

GND

ALARM

GND

NO ALARM

GND

ALARM

GND

NORMALLY OPEN

CUT

+V

+V

+V

+V

BYPASS

Figure 16. Unsupervised Alarm Conditions

Figure 17 illustrates the wiring configuration for unsupervised alarm inputs.

NORMALLY CLOSED

UNUSED

INPUTS

MAY BE

SHORTED

Figure 17. Unsupervised Alarm Input Wiring

BYPASS

NORMALLY OPEN

UNUSED

INPUTS

MUST BE LEFT

UNWIRED

18 C613M-A (5/05)

Page 19

Alarm Connections

Figure 18 shows how to wire the video encoder to an alarm (refer to Table B for the specific connector pin assignments).

Figure 18. Connecting Alarms

CONNECTING POWER

The SP04-140 video encoder is designed to operate from either a 12 VDC or a 24 VAC power supply. It automatically senses power type and

polarity (DC).

The SP04-140 can be powered from many sources:

• NET5301PS power supply connects directly to the four-pin connector on the SP04-140 rear panel.

• The RK5000PS-5U rack mount kit supplies power through the four-pin connector on the SP04-140 rear panel as soon as the unit slides into

place.

• The Pelco MCS (B model), WCS (B model), and TF Series power supplies provide power through a two-pin terminal block (supplied) that

plugs into the two-pin connector on the SP04-140 rear panel.

• Other UL Listed direct plug-in power units marked “Class 2” and rated for 12 VDC +10%/-15% or 24 VAC +10%/-15% provide power

through a two-pin terminal block (supplied) that plugs into the two-pin connector on the SP04-140 rear panel.

The power consumption of the SP04-140 is eight watts (13.3 VA).

Use Table D to estimate your power requirements when installing multiple SP04-140, NET5301T, and NET5301R units. This table is based on a

24 VAC power supply.

Model

NET5301T

SP04-140

NET5301R 1 2 2 4 5 11 24

Table D. Powering Multiple Units

Units Powered

at 20 VA at 48 VA at 50 VA at 100 VA at 120 VA at 240 VA at 480 VA

133 7 9 18 36

C613M-A (5/05) 19

Page 20

Use Table E to help identify the necessary wire gauge and maximum cable distance. This table applies to two-conductor solid copper wire.

(Reduce distance by 10% for stranded copper wire.) These maximum distances are based on a maximum allowable voltage drop of 10%.

Table E. Recommended Wire Gauge and Maximum Wiring Distances

Wire Gauge

20 AWG (0.5 mm

18 AWG (1.0 mm

16 AWG (1.5 mm

14 AWG (2.5 mm

12 AWG (4.0 mm

10 AWG (6.0 mm

2

) 89 ft (27 m) 356 ft (108 m)

2

) 141 ft (42 m) 566 ft (172 m)

2

) 224 ft (68 m) 899 ft (274 m)

2

) 357 ft (108 m) 1,428 ft (435 m)

2

) 566 ft (172 m) 2,267 ft (690 m)

2

) 900 ft (274 m) 3,600 ft (1,097 m)

Maximum Distance

12 VDC 24 VAC

Connect power to the SP04-140. The Pelco badge (blue) and the status light (green) on the front panel should glow.

CONNECTING TO THE NETWORK

When using one or more network switches with the Endura system, make sure you enable auto negotiation on all switches.

Connect the SP04-140 video encoder to your network:

1. Connect a 10/100/1000BaseT network Cat5e (or better) cable to the RJ-45 network connector on the front panel. The encoder

automatically searches the network for other Endura components.

2. Check the indicators on the front panel. They show network connection speed and status (refer to Front Panel Indicators ).

FOUR-PIN OR TWO-PIN

Figure 19. Connecting Power

20 C613M-A (5/05)

Page 21

Operation

Refer to the WS5000 operation manual for details on how to access and configure the SP04-140 video encoder.

FRONT PANEL INDICATORS

NETWORK CONNECTOR

Pelco badge (power)

The Pelco badge glows blue when the unit has power.

NETWORK STATUS

NETWORK ACTIVITY

UNIT STATUS

Figure 20. SP04-140 Front Panel

VIDEO

PRESENCE

CONFIGURATION/

RESET BUTTON

Unit status

Unit status is indicated by one of the following three colors:

Green

Amber

Red

Whenever the unit status indicator is flashing, the unit is in one of three system modes (refer to Configuration/Reset Button ).

The unit is functioning normally.

The unit is in configuration mode.

The unit is in an error condition.

Network status

Network status (connection and speed) is indicated by one of the following conditions:

Off

Solid Amber The unit is connected to the network using the 100BaseT standard.

Solid Red The unit is connected to the network using the 10BaseT standard.

NOTE: For optimum performance, Pelco recommends using the 100 BaseT standard.

The unit is not connected to the network.

Network activity

The network activity indicator flashes whenever the video encoder is sending or receiving network data.

Video presence

Video presence is indicated by one of the following conditions:

Green

Red Camera video is present at the video in (1) connector. The indicator is also red if there is no video to both video connectors.

Camera video is present at the video in (2) connector, or both video in connectors.

C613M-A (5/05) 21

Page 22

CONFIGURATION/RESET BUTTON

Use the recessed configuration/reset button at the top of the front panel to access the following modes:

Table F. Configuration/Reset Button Functions and Indicators

Mode Function Unit Status Indicator Light

Configuration Initiates system configuration.

Reboot Restarts the unit.

Reset

Cancel Cancels any configuration or reset action. • No light

To access one of these modes:

1. Use a probe or paper clip to press and hold the configuration/reset button . The unit starts cycling through the four modes

(configuration, reboot, reset, and cancel), holding each mode for five seconds. The unit status indicator flashes the color for the current

mode.

2. When the color of the desired mode appears, release the button.

NOTE: If there is no configuration activity for 15 minutes, the SP04-140 automatically exits configuration/reset mode.

Resets unit to factory default settings and then

restarts unit.

• Flashing amber when entering this mode

• Solid amber when selected

• Flashing green when entering this mode

• Flashing green when selected and during restart

• Flashing red when entering this mode

• Flashing red when selected, then flashing green during

restart

22 C613M-A (5/05)

Page 23

Troubleshooting

If the following instructions fail to solve your problem, contact Pelco Product Support at 1-800-289-9100 or 1-559-292-1981 for assistance.

Access the properties windows for the SP04-140 video encoder on the WS5050 workstation (refer to the WS5000 operation manual). Then note

the following before calling Pelco:

• Unit serial number: located on the Properties window and on the product label

• Unit firmware version: located on the Advanced Properties window, listed for the Encoder Device

Do not try to repair the unit yourself. Opening it immediately voids any warranty. Leave maintenance and repairs to qualified technical personnel.

Exchange the defective unit and return it for repair.

Problem Possible Causes Suggested Remedy

No video transmission Power turned off Check that the SP04-140 is switched on and

No audio transmission to receiver Faulty cable connection Check all leads, plugs, contacts, and

Cannot control PTZ cameras or other

devices

The unit is not ready for operation after

firmware upload

Table G. Troubleshooting the SP04-140

the power indicator is lit.

Faulty cable connections Check all leads, plugs, contacts, and

connections.

Defective camera Connect local monitor and check camera

function.

Defective encoder Check camera on a different encoder.

Network connectivity issues Contact your network administrator.

connections.

Defective hardware Check functioning of all connected audio

devices.

Connection in use by another receiver Wait until the connection is free and try again.

Faulty cable connection Check all cable connections and ensure all

plugs are properly plugged in.

Network connectivity issues Contact your network administrator.

Incorrect PTZ settings Change the camera settings on the WS5050

workstation.

PTZ camera connected to the video in (1)

connector

Voltage failure during programming of update

file

Connect the PTZ camera to the video in (2)

connector.

Replace the device and have it checked by

Pelco.

C613M-A (5/05) 23

Page 24

Specifications

MODEL NUMBER

SP04-140 Dual-input network video server that encodes video, audio, and control data for transmission over an

SUPPLIED ACCESSORIES

Mating Connectors One 16-pin, one 2-pin

SYSTEM

Processor PowerPC

Operating System Linux

User Interface Remote operation via WS5050 or VCD5000

VIDEO/AUDIO

Video Standards NTSC/PAL/EIA/CCIR composite

Video Coding MPEG-4

Video Streams 2, simultaneous

Video Resolutions NTSC

4CIF 704 x 480 704 x 576

2CIF 704 x 240 704 x 288

CIF 352 x 240 352 x 288

QCIF 176 x 120 176 x 144

Video Inputs/Connectors 2, BNC, 75 Ω, 1 Vp-p

Video Switch Hi-Z, 75Ω

Audio Encoding G.711 speech codec

Audio Bit Rate 64 kbps

Audio Levels

Line In/Line Out 1 Vp-p, 10 kΩ

Microphone 5 mVp-p, approximately 40 kΩ

Speaker 2.5 Vp-p, 30 mW, minimum 16 Ω

Audio Connectors Two 3.5 mm monaural

Connector Tip Signal high (input and output)

Connector Sleeve Common

Audio Inputs Microphone or line in

Audio Outputs Speaker or line out

Audio Switch Line, microphone/speaker

IP network

®

®

405EP

PAL

PTZ CONTROL

PTZ Interface RS-422, video in

PTZ Protocols Pelco D (RS-422), Coaxitron

ALARMS/RELAYS

Alarm Inputs 3, programmable, 3.3 VDC, 1 kΩ, triggered; uses 6 of 16 pins on terminal block connector

Relay Output 1, form-C relay, 30 VDC, 1 A; uses 3 of 16 pins on terminal block connector

24 C613M-A (5/05)

Page 25

VIDEO ACTIVITY DETECTION

Zones 3 plus background zone

Zone Types Any shape, user-definable in 16 x 16 pixel blocks

Sensitivity Adjustable

AUXILIARY INTERFACES

Serial Pelco D (RS-422); uses 4 of 16 pins on terminal block connector

Terminal Block Connector 16-pin: Pelco D (RS-422), 3 alarm inputs, 1 relay output

FRONT PANEL INDICATORS/FUNCTIONS

Network RJ-45, 10/100 BaseT

Power Blue

Status Green, amber, red

Network Link/Speed Amber, red

Network Activity Green

Video Green, red

Configuration/Reset Recessed button, 4 states

POWER

Power Consumption 8 watts, 28 BTU/H

Power Input 12 VDC +10%/-15%, 24 VAC +10%/-15%

Power Connectors

4-Pin For RK5000PS-5U or NET5301PS

2-Pin For user-supplied power supply

ENVIRONMENTAL

Operating Temperature 32˚ to 122˚F (0˚ to 50˚C)

Storage Temperature -40˚ to 149˚F (-40˚ to 65˚C)

Operating Humidity 20% to 80%, noncondensing

Maximum Humidity Gradient 10% per hour

Operating Altitude -50 ft to 10,000 ft (-16 m to 3,048 m)

Operating Vibration 0.25 G at 3 Hz to 200 Hz at a sweep rate of 0.5 octave/minute

PHYSICAL

Construction Sheet metal

Finish Gray metallic with black end caps, black matte finish

Dimension 8.75" (D) x 6.5" (W) x 1.2" (H)

(22.2 x 16.5 x 3.0 cm)

Mounting Desktop (feet), wall, or rack via options

Unit Weight 2.0 lb (0.9 kg)

OPTIONAL ACCESSORIES

RK5000PS-5U Rack mount with power supply (12 units)

WM5001-4U Wall mount without power supply (1 unit)

WM5001-4UEXP Wall mount expansion (1 unit)

NET5301PS Power supply (1 unit)

C613M-A (5/05) 25

Page 26

STANDARDS/ORGANIZATIONS

• Pelco is a member of the MPEG-4 Industry Forum

• Pelco is a member of the Universal Plug and Play (UPnP) Forum

• Pelco is a member of the Universal Serial Bus (USB) Implementers Forum

• Pelco is a contributor to the International Standards for Organization/Electrotechnical Commission (ISO/IEC) Joint Technical Committee 1

(JTC1), “Information Technology,” Subcommittee 29, Working Group 11

• Compliance, ISO/IEC 14496 standard (also known as MPEG-4)

• Compliant with International Telecommunication Union (ITU) Recommendation G.711, “Pulse Code Modulation (PCM) of Voice Frequencies

(Design and product specifications subject to change without notice.)

26 C613M-A (5/05)

Page 27

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or

workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

• Five years on FT/FR8000 Series fiber optic products and the following fixed camera models:

CC3701H-2, CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2, and CC3651H-2X.

• Three years on all other fixed camera models (including Camclosure® Integrated Camera

Systems) and Genex

®

Series (multiplexers, server, and keyboard).

•Two years on all standard motorized or fixed focal length lenses.

•Two years on Legacy

®

, CM6700/CM6800/CM8500/CM9500/CM9700 Series Matrix, DF5

and DF8 Series Fixed Dome products.

®

•Two years on Spectra

, Esprit®, and PS20 Scanners, including when used in continuous

motion applications.

®

•Two years on Esprit

• Eighteen months on DX Series digital video recorders, NVR300 Series network video

recorders, and all Endura

and WW5700 Series window wiper (excluding wiper blades).

™

Series distributed network-based video products.

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion

applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco

shipment. All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis,

California. Repairs made necessary by reason of misuse, alteration, normal wear, or accident

are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from

the specific use or application made of the Products. Pelco’s liability for any claim, whether

based on breach of contract, negligence, infringement of any rights of any party or product

liability, relating to the Products shall not exceed the price paid by the Dealer to Pelco for

such Products. In no event will Pelco be liable for any special, incidental or consequential

damages (including loss of use, loss of profit and claims of third parties) however caused,

whether by the negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have

additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or

(559) 292-1981 to obtain a Repair Authorization number (RA), and provide the following

information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the

warranty conditions stated above, please include a written explanation with the product

when returned.

Method of return shipment shall be the same or equal to the method by which the item was

received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at

(800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned

for credit, and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing

charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA

number and freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico, send goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico and are

instructed to return goods to the USA, you may do one of the following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

If the goods are to be sent by a FREIGHT FORWARDER, send the goods to:

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

REVISION HISTORY

Manual # Date Comments

C613M 12/04 Original version.

C613M-A 5/05 New labeling and specifications. General minor modifications.

Pelco, the Pelco logo, Spectra, Genex, Esprit, Camclosure, Coaxitron, and Legacy are registered trademarks of Pelco. © Copyright 2005, Pelco. All rights reserved.

Endura is a trademark of Pelco.

PowerPC is a registered trademark of International Business Machines Corporation.

Linux is a registered trademark of Linus Torvalds.

Page 28

®

Worldwide Headquarters

3500 Pelco Way

Clovis, California 93612 USA

USA & Canada

Tel: 800/289-9100

Fax: 800/289-9150

International

Tel: 1-559/292-1981

Fax: 1-559/348-1120

www.pelco.com

ISO9001

United States | Canada | United Kingdom | The Netherlands | Singapore | Spain | Scandinavia | France | Middle East

Loading...

Loading...