Page 1

ADDENDUM

Addendum No.: C1577M-A

Date: August 4, 2004

Manuals Affected: CM9760 Series Manuals – C538M-A, C539M-A, C540M-B, C541M-C, C542M-B,

C543M-A, C544M, C549M-A, C572M, C573M-D, C578M, C579M, C1501M, C1503M,

C1510M-QS, C1510M-A, C1520M-B, C1528M-D, C1940M, C1941M, C1942M, and

C1943M

Manual Update: The CM9760-CC1 has been replaced with the CM9700-CC1 and the CM9760-MGR manage-

ment software has been replaced with the CM9700-MGR management software.

Keep the following in mind when referring to the instructions contained in these manuals:

• The CM9700-CC1 contains the latest CC1 software (version 9.01 or higher), and is

programmed with the new CM9700-MGR management software.

• Despite the difference in model numbers, the CM9700-CC1 functions the same as the

CM9760-CC1 and most of the information in these manuals applies to version 9.01 (or

higher) CPU.

•You can add the CM9700-CC1 to an existing CM9760 system if you upgrade the existing

CM9760-CC1 units with the current software (version level 9.01 or higher).

Software version 9.01 requires a minimum of 16 MB of RAM in the CPU. If required, you

can upgrade the RAM in older CM9760-CC1 units using the software upgrade kit

appropriate for your CPU.

• Do not use the CM9760-MGR instructions contained in these manuals. Refer to the

CM9700-MGR Getting Started Software Guide, on-screen help, or Online Help for

instructions.

Pelco World Headquarters • 3500 Pelco Way, Clovis, California 93612-5699 USA • www.pelco.com

USA & Canada: Tel: 800/289-9100 • Fax: 800/289-9150

®

International: Tel: 1-559/292-1981 • Fax: 1-559/348-1120

Page 2

®

CM9760-VCRC

VCR Controller

Installation/

Operation Manual

C1941M (7/98)

Pelco • 3500 Pelco Way • Clovis, CA 93612-5699 USA • www.pelco.com

In North America and Canada: Tel (800) 289-9100 • FAX (800) 289-9150

International Customers: Tel +1(559) 292-1981 • FAX +1(559) 348-1120

Page 3

CONTENTS

Section Page

1.0 GENERAL..................................................................................................5

1.1 IMPORTANT SAFEGUARDS AND WARNINGS ...............................5

1.2 REGULATORY NOTICES ..................................................................5

2.0 DESCRIPTION ..........................................................................................6

2.1 MODELS............................................................................................6

2.2 CERTIFICATIONS .............................................................................6

2.3 OPTIONS...........................................................................................6

3.0 PRE-INSTALLATION INFORMATION........................................................7

3.1 FRONT VIEW.....................................................................................7

3.1.1 DIP Switches .........................................................................8

3.1.1.1 DIP Switch Locations..............................................8

3.1.1.2 DIP Switch Functions .............................................8

3.1.2 LEDs ......................................................................................8

3.2 REAR VIEW .......................................................................................9

3.2.1 Input VCR Connectors ..........................................................10

3.2.2 Relay Output Connector .......................................................11

3.2.3 Communication Connectors .................................................11

3.2.3.1 DB-9 Connector Pin-outs.......................................12

3.2.3.2 RJ-45 Connector ...................................................12

3.2.4 Power Connections...............................................................13

3.3 SETUP ..............................................................................................14

3.3.1 Preliminary Discussion .........................................................14

3.3.2 DIP Switch Settings ..............................................................14

3.3.3 Software Setup–Using the MGR Program to Configure

VCRC Operation...................................................................16

4.0 INSTALLATION .........................................................................................19

4.1 DIRECT RACK-MOUNT HOOK-UP .................................................19

4.2 REMOTE OPERATION .....................................................................19

4.3 DAISY-CHAINING .............................................................................20

5.0 OPERATIONAL OVERVIEW.....................................................................21

5.1 FUNCTIONAL BLOCK DIAGRAM ....................................................21

5.2 OPERATING THE CM9760-VCRC FROM THE CM9760-KBD ........22

6.0 SPECIFICATIONS ....................................................................................23

7.0 WARRANTY AND RETURN INFORMATION ...........................................24

2 Pelco Manual C1941M (7/98)

Page 4

LIST OF ILLUSTRATIONS

Figure Page

1 Front View of CM9760-VCRC ............................................................7

2 Front Panel Removal..........................................................................7

3 DIP Switch Location...........................................................................8

4 Rear View of CM9760-VCRC.............................................................9

5 VCR Input Plugs ...............................................................................10

6 Relay Output Connector ...................................................................11

7 RJ-45 Pin-outs ..................................................................................12

8 RJ-45 Connector Pin-out Geometry .................................................12

9 Power Input Fuse Replacement........................................................13

10 DIP Switch Functions........................................................................ 15

11 Configuring MGR Camera File for VCRC Operation......................... 16

12 Configuring the GPI SETUP file for VCRC Operation.......................17

13 Configuring the COMMS file for VCRC Operation ............................18

14 CM9760-VCRC Rack-Mount Installation ..........................................19

15 Daisy-Chain Configuration ................................................................20

16 Daisy-Chain Multi-Buss Configuration ..............................................20

17 VCRC Functional Block Diagram...................................................... 21

18 CM9760-KBD VCR Control Functions ..............................................22

REVISION HISTORY

Manual # Date Comments

C1941M 7/98 Original version.

Pelco Manual C1941M (7/98) 3

Page 5

(This page intentionally left blank.)

4 Pelco Manual C1941M (7/98)

Page 6

1.0 GENERAL

1.1 IMPORTANT SAFEGUARDS AND WARNINGS

Prior to installation and use of this product, the following WARNINGS should be

observed.

1. Installation and servicing should only be done by qualified service personnel

and conform to all local codes.

2. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X ,6 or

6P enclosure, it is designed for Indoor use only and it must not be installed

where exposed to rain and moisture.

3. Only use replacement parts recommended by Pelco.

4. After replacement/repair of this unit’s electrical components, conduct a resistance measurement between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage constituting a

risk of electric shock is present within this unit.

This symbol indicates that there are important operating and

maintenance instructions in the literature accompanying this unit.

Please thoroughly familiarize yourself with the information in this manual

prior to installation and

operation.

CAUTION:

RISK OF

ELECTRIC SHOCK.

DO NOT OPEN.

CAUTION:

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

DO NOT REMOVE COVER. NO USER-

SERVICEABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

1.2 REGULATORY NOTICES

NOTE: This equipment has been tested and found to comply with the limits of a

Class B digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However there is no guarantee that

the interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try and correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Pelco Manual C1941M (7/98) 5

Page 7

2.0 DESCRIPTION

The CM9760-VCRC is another optional accessory of the System 9760™. This VCRC

gives security and surveillance operators the ability to automatically or manually

control appropriate VCRs from the 9760 matrix system. It is designed to remotely

control seven basic VCR functions using two different control methods; resistive

ladder remote control and S-Link remote control.

Currently , it supports Sanyo and Sony model resistive ladder VCRs and Sony model

S-Link VCRs.

Some of the more important features of the VCR unit are as follows:

• Each unit can handle up to 64 VCRs.

• Controls seven VCR functions: play, stop, fast forward, rev erse , pause, record

and eject.

• Up to 11 units can be chained together giving a total of up to 700 VCRs controllable from a single Sercom port on the CM9760-CC1.

• VCR inputs can be configured in blocks of 16 for use by specific VCR type.

• There is one relay output per unit.

• The unit is powered by an auto-ranging power supply.

• Unique, one rack-unit chassis (1.75 inches or 4.45 cm) accommodates multiple types of mounting.

• Transparent system software operates with the CM9760-IRC as well as the

future CM9760-REL.

2.1 MODELS

CM9760-VCRC VCR control unit capable of controlling 64 VCRs per unit. VCR

control is specific to Sanyo and Sony VCRs.

2.2 CERTIFICATIONS

The products identified below have been tested and certified for agency compliance as noted.

Model CE FCC UL CSA/cUL

CM9760-VCRC X X

Applicable CE, FCC, UL, and CSA/cUL directives/standards:

• 93/68/EEC–CE Mark Directive

89/336/EEC, 92/31/EEC–Electromagnetic Compatibility (EMC) Directives

EN 55022: 1984 Class B–Radio-frequency emissions limits

EN 50082-2: 1992–Immunity standard

IEC 801-2: 1984–ESD immunity

IEC 801-3: 1984–Radiated field immunity

IEC 801-4: 1988–Electrical transients

• FCC–47 CFR, Part 15, Subpart B, Class B

Additional applicable standards:

• NEMA Type 1

• IP 20

2.3 OPTIONS

Agency Compliance Certification

CM9760-VCRC-TX A 20-foot (61 cm) VCR control cable with 1/8" jack on one end

(for connecting to VCR) and cord/shield (signal/ground) bare

wires at the opposite end for connection to input mating plugs

located on rear of VCRC.

6 Pelco Manual C1941M (7/98)

Page 8

3.0 PRE-INSTALLATION INFORMATION

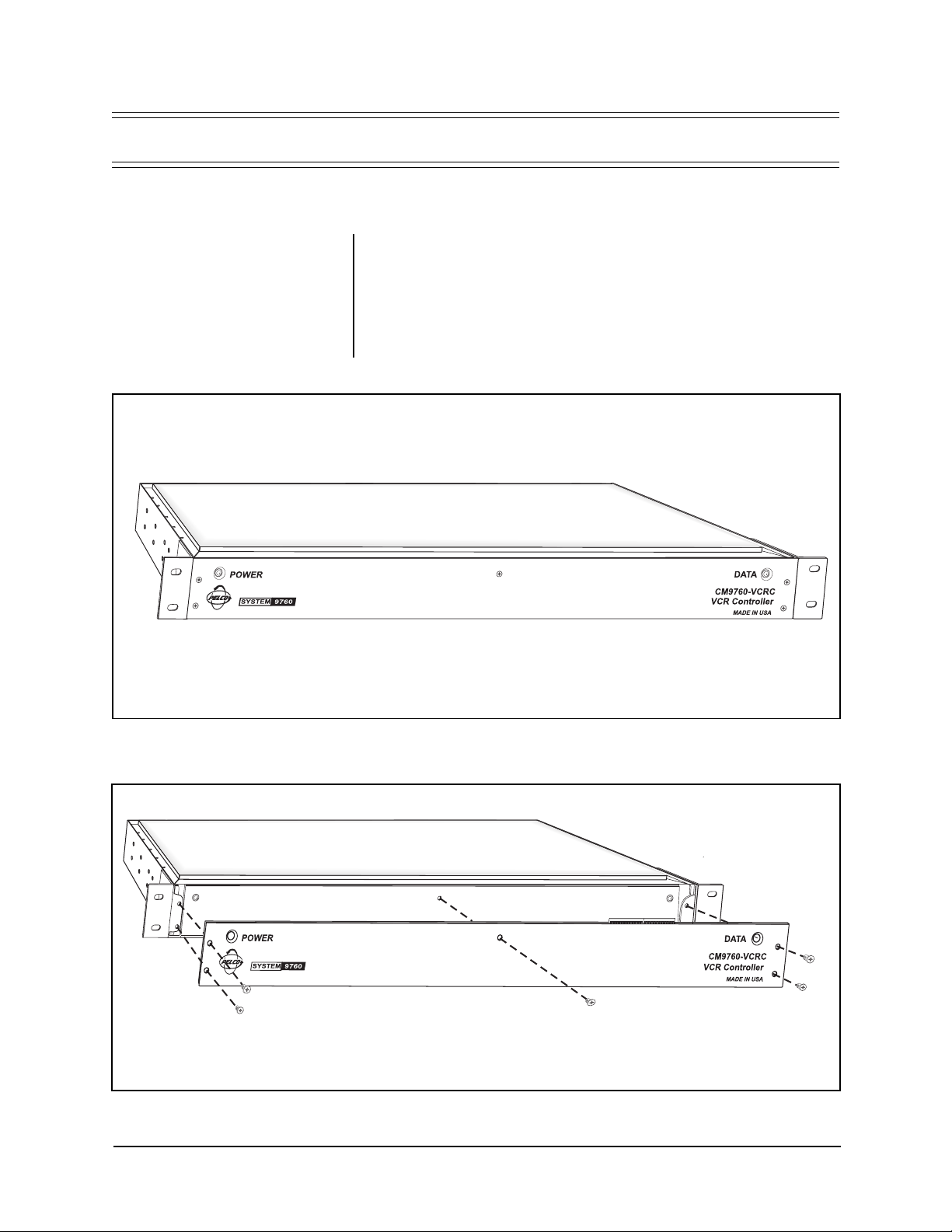

3.1 FRONT VIEW

Figure 1 illustrates the front view of the unit. P ower and data LEDs occup y opposite

ends of the front panel. The pow er LED on the left is green and the data LED on the

right is red. All other connectors, s witches, inputs and outputs are on the rear of the

unit except for two DIP switches and a reset switch located behind the front panel

cover plate.

The DIP switches can be accessed easily by removing the five flat-head Phillips

screws that hold the front panel in place as illustrated in Figure 2.

Figure 1. Front View of CM9760-VCRC

Figure 2. Front Panel Removal

Pelco Manual C1941M (7/98) 7

Page 9

3.1.1 DIP Switches

With the front panel removed, DIP switch 1 and DIP s witch 2 are visib le . These two

ten-position DIP switches configure and define many functions of the CM9760VCRC.

3.1.1.1 DIP Switch Locations

Figure 3 identifies the relative locations of DIP switches 1 and 2.

3.1.1.2 DIP Switch Functions

DIP switch functions are discussed in Section 3.3, SETUP.

3.1.2 LEDs

The green POWER LED located on the left front panel of the unit comes ON at

power up.

The red DATA LED located on the right side of the front panel continually flashes on

and off at a regular rate (about 1/2 second intervals) until the first valid command is

received. The LED will not flash again until another valid command is received.

Also, in cascaded situations, if a command is meant for a VCRC further down the

chain, the command will be relayed down the chain and the LED will not come on

until the appropriate VCRC processes the command. In other words, LED activity is

address specific. Additionally, if power is cycled, or if the DIP switch slide positions

are moved, or if a front panel reset occurs, then the LED will again flash intermittently until the first valid command is received.

Figure 3. DIP Switch Location

8 Pelco Manual C1941M (7/98)

Page 10

3.2 REAR VIEW

The rear of the unit is illustrated in Figure 4. From left to right are the following:

1. The four 16-input blocks of VCR connectors in the f orm of screw-type connectors with associated mating plugs (one shown in Block 1) running from the left

rear to middle right of the unit

NOTE:

VCR b loc k ranges are assigned specific VCR type via slide

switches 7 through 10 on DIP

switch 2.

2. The VCRC output relay (one per unit)

3. RS-422 input/output communication connectors (RJ-45 type)

4. One DB-9 type connector for factory use only

5. The grouped input power functions, consisting of input power terminals, a

fuse and an ON/OFF switch

5

Figure 4. Rear Vie w of CM9760-VCRC

Pelco Manual C1941M (7/98) 9

Page 11

IMPORTANT:

Control cable

length should not be extended further than the supplied 20 feet because resistive ladder input circuits

are very susceptible to additional

line impedance. It is also recommended that shielded cable be used

to minimize external electrical interference with VCRC control signals .

See important note in Figure 9 regarding power hookup and interference.

3.2.1 Input VCR Connectors

Physically , each of the f our VCRC input connectors consists of the same n umber of

input screw-type terminals. Each input group uses a dual-row removable plug and

each plug is associated with 8 VCR inputs.

For example, ref er to the leftmost group represented in Figure 5, which sho ws VCR

inputs 1-16. Of these VCR inputs, 1-8 are wired using the top 16 screw terminal

positions. VCR inputs on this connector physically alter nate with their associated

GND connection for a total of 8 available VCR/GND connections: that is, pin 1 is

VCR input 1 and pin 2 is the GND connection associated with VCR input 1; pin 3 is

VCR input 2 and pin 4 is VCR input 2’s associated GND connection, and so on.

The same explanation applies to the lower plug for VCR inputs 9-16, starting with

VCR input 9 which is associated with physical pin 17 on the mating plug.

In a similar manner, the remaining plug (upper/lower) combinations accommodate

the three remaining VCR input blocks: that is, inputs 17-32 are handled by header

two, inputs 33-48 by header three, and inputs 49-64 by header four.

IS SHOWN IN THE TABLE BELOW.

Figure 5. VCR Input Plugs

10 Pelco Manual C1941M (7/98)

Page 12

3.2.2 Relay Output Connector

Figure 6 illustrates the relay output connector and its relative port pin assignments.

The connector is a three-position plug with screw-type contacts similar in operation

to the mating connectors just discussed.

By default, the relay is in its normal state at power up of the unit as shown in Figure

6. During operation, the relay may be toggled by controlling the 64th VCR on the

VCRC by entering VCR number 64 on the keypad, then pressing the Camera button which brings up the VCR control functions and then pressing the blue button

under the PLA Y control icon. Similarly , performing the abov e but pressing the STOP

VCR control command instead of the PLA Y command will deactiv ate the rela y. Refer to Section 5.2, OPERATING THE CM9760-VCRC FROM THE CM9760-KBD,

for more details on the operational use of the VCRC from the CM9760-KBD.

3.2.3 Communication Connectors

Communication to and from the unit is provided through two RJ-45 ports on the

rear of the CM9760-VCRC. The ports are referenced as serial port 0 and serial port 1

(refer to the functional block diagram in Figure 17).

Serial Port 0 is associated with the RJ-45 IN female connector and is configured for

RS-422 operation by default. In the configuration, the RJ-45 IN connector allows

the VCRC unit to be connected to an appropriate Sercom port on the rear of a

CM9760-CC1 controller.

Serial port 1, associated with the RJ-45 OUT connector, is always configured as

RS-422 and is used for daisy-chaining subsequent VCRC units (see Section 4.2,

REMOTE OPERATION).

Individual connector pin-outs of the communication channels are discussed next.

Figure 6. Relay Output Connector

Pelco Manual C1941M (7/98) 11

Page 13

3.2.3.1 DB-9 Connector Pin-outs

The DB-9 connector is reserved for factory use only.

3.2.3.2 RJ-45 Connector

The RJ-45 connector pin-outs are illustrated in Figure 7.

Because both RJ-45 connectors have the same wiring pin-outs, they require the

same “flipped” cab le . In other words, the IN connector requires a “flipped” cable for

connecting the first unit to the CC1, and the OUT connector requires a “flipped” for

cascading other units. A “flipped” cable is as follows: Pin 1 of the cable at one end

becomes pin 8 at the other end. Refer to Figure 8.

Note that the active pin-outs are associated with the outer four pins; namely, 1, 2, 7

and 8. All accessories on the System 9760™ require the “flipped” cable to be used

to attach peripheral equipment. This presently pertains to the KBD, MXB, CXT,

ALM, MDA, CDU-T and now the VCRC unit.

TO INTERFACE THE VCRC UNIT TO ANY SERCOM PORT ON

OR BETWEEN ONE VCRC UNIT AND ANOTHER,

Figure 7. RJ-45 Pin-outs

THE REAR OF THE CM9760-CC1

FOLLOW THE DIAGRAM BELOW:

Figure 8. RJ-45 Connector Pin-out Geometry

12 Pelco Manual C1941M (7/98)

Page 14

3.2.4 Power Connections

The CM9760-VCRC utilizes an auto-ranging internal transformer circuit that allows

the input power to range from 100-240 VAC @ 50/60 Hz. Associated with the input

power is the power ON/OFF s witch and the input power fuse. The fuse is easily changed

as illustrated in Figure 9.

IMPORTANT: IT IS IMPORTANT TO ACTIVELY

AVOID INTRODUCING CURRENT GROUND

LOOPS IN YOUR CONFIGURATIONS WHEN

HOOKING UP A VCRC AND ITS ASSOCIATED

VCRs TO POWER SOURCES. IF POSSIBLE,

HOOK EVERYTHING TO THE SAME POWER

SOURCE. SOME VCR MODELS ARE

SUSCEPTIBLE TO NOISE INTERFERENCE IN

THE LOW mV RANGE. (SEE THE IMPORTANT

NOTE ASSOCIATED WITH FIGURE 5)

SPARE FUSE

Figure 9. Pow er Input Fuse Replacement

Pelco Manual C1941M (7/98) 13

Page 15

3.3 SETUP

3.3.1 Preliminary Discussion

NOTE:

It is highly recommended

that VCRC address # 1 (F rame Address 0) be used first, VCRC address # 2 second, and so on, to

minimize programming confusion.

NOTE:

GPIs are programmed using the 9760 System Manager program. See Section 3.3.3, Software

Setup–Using the MGR Program to

Configure VCRC Operation, f or introductory instructions. For detailed

programming instructions, refer to

the Systems Manager manual.

The VCR controller (VCRC) enables automatic control (via macro execution) or

manual control (from the CM9760-KBD) of seven predefined VCR functions. Each

VCRC can control up to 64 VCRs.

VCR control is implemented by associating System 9760™ GPIs to VCRs. When a

GPI is used for VCR control, its first seven auxiliary relays are used to control the

seven most common VCR control functions. The se ven auxiliary relay numbers and

their associated VCR functions are listed below.

1. Play

2. Stop

3. Rewind

4. Fast Forward

5. Pause

6. Record

7. Eject

T wo k ey setup procedures are required in order to accomplish VCR control from the

System 9760 ™. The Frame Address Table in Figure 10 can be used as an aid to

implement both procedures.

(1) The VCR controller must be assigned an address (1 of 11) that corresponds to

a sequential range of 64 GPIs (VCRs).

Use the Frame Address Table to determine the DIP switch settings for assigning an

appropriate VCRC address setting.

(2) GPIs must be programmed in order of the 9760 CPU to communicate with the

VCRC.

Each physical GPI # corresponds to an individual VCR and its terminal connection

point on the VCRC . Theref ore , 64 GPIs must be programmed in order to control 64

VCRs from one VCRC controller.

(Figure 18 shows the relationship of these relay

numbers and the associated VCR control function

as seen on the CM9760-KBD LCD screen)

How the physical GPI # is associated with the VCRC is as follows:

• Physical GPI # 1 corresponds to the first VCR control terminal on the VCRC

that is addressed as controller # 1 (Frame Address # 0). Likewise, physical

GPI # 64 corresponds to the 64th control terminal on VCRC # 1.

• The next GPI # (the 65th) corresponds to the 1st control terminal on VCRC # 2

(Frame Address # 2). This scheme continues until the last GPI is associated

with the appropriate control terminal on the last VCRC used, which, in this

case, would be controller # 11 (Frame Address # 20).

3.3.2 DIP Switch Settings

DIP switch settings are illustrated in Figure 10.

14 Pelco Manual C1941M (7/98)

Page 16

NOTES: ANY OF THE 11 VCRCS MAY BE

ASSIGNED ANY OF THE USEABLE EVEN FRAME

ADDRESSES IN ANY ORDER YOU WISH (KEEP

IN MIND THE SPECIFIC RECOMMENDATION

MADE IN THE NOTES ON THE PREVIOUS

PAGE). JUST REMEMBER THAT THE FRAME

ADDRESS USED IS ASSOCIATED WITH A

SPECIFIC VCR RANGE. IF YOU TRY TO

CONTROL A VCR THAT DOESN'T FALL WITHIN

THE VCR RANGE, NOTHING WILL HAPPEN.

Figure 10. DIP Switch Functions

Pelco Manual C1941M (7/98) 15

Page 17

3.3.3 Software Setup–Using the MGR Program to Configure VCRC Operation

The VCRC unit controls up to 64 VCRs per unit and pro vides sev en basic functions

of VCR control direct from the CM9760 keyboard. These controls include Stop,

Pause, Play, Eject Fast Forward, Rewind and Record.

The VCRC accepts GPI commands issued under call functions of VCR control via

direct key entry or through properly prepared Macros. Access to GPI functionality is

setup in the MGR program in the following manner . What follows is a brief introduction to just those files which need to be programmed for successful VCRC operation and does not address other items that might be needed for your particular

system operation. Consult your MGR manual and associated software for other

specific or more detailed information.

On a separate PC and monitor start the 9760-MGR Setup program and access the

Camera File (.CAM file). Refer to Figure 11.

NOTE:

It is a good idea to use the

same number for the assigned GPI

as is used for the camera (VCR).

This leads to less confusion later

when calling up the camera (VCRs)

from the keyboard that are associated here with a GPI. In other

words, associate camera #1 with a

GPI connect of 1, camera #2 with

a GPI connect of 2 and so on. Also

set the logical and physical numbers for cameras (VCRs) equal to

each other.

1. Select the desired physical camera input that will be associated as a VCR.

2. Program a logical input number, title identification (Ident), and operator access (Oper Acc) for the associated VCR selected in the previous step.

3. Access the tab labeled “Type” and select VCR as the input type.

4. Highlight the GPI box and input a GPI number that corresponds to a specific

VCR control signal on the VCR controller.

5. Continue to program all desired inputs as VCRs b y repeating steps 1-4. Up to

700 VCRs can be defined.

6. When all cameras (VCRs) are defined and associated “Connect GPIs” are

assigned, save the camera file and click on the GPI tab in the main menu of

the MGR program.

Figure 11. Configuring MGR Camera File for VCRC Oper ation

16 Pelco Manual C1941M (7/98)

Page 18

NOTE:

When writing macros to

control VCR operation, keep in

mind the following:

The macro must reflect your actual

equipment configuration; if you

change the configuration, you must

adjust the macro accordingly. For

example, if a macro were written

to control VCRs attached to three

VCRCs in a daisy-chained configuration and one of the VCRCs was

subsequently removed, then any

previously written macro that included these three VCRCs would

have to be rewritten to reflect that

change. Similarly, changing the

frame address setting via SW2 on

any of the three VCRCs w ould have

the same effect as physically removing the unit from the configuration (as far as the macro is concerned) and, as before, the macro

must be edited or rewritten to reflect any changes made.

7. This brings up the GPI SETUP file dialog box (.GPI file). Refer to Figure 12.

8. Program logical GPI numbers for all the physical numbers that will be used.

The physical GPI numbers correspond to a specific VCR control signal on the

VCR controller. Also, these GPI numbers correspond with the “Connect GPI”

numbers entered previously in the camera file.

9. For each associated GPI defined here, make sure none of the relay boxes

have been checked. In other words, define all relays as momentary.

Figure 12. Configuring the GPI SETUP file for VCRC Oper ation

Pelco Manual C1941M (7/98) 17

Page 19

10. Define operator access, save the GPI file, return to the MGR main menu screen

and press the tab to bring up the COMMS file (.SCP file). Refer to Figure 13.

11. In the COMMs file assign an equipment number “17” to the port on the CC1

that will be used for communicating to the VCRC. Also, set communication

settings for 9600 baud and even parity. Save the COMMs file, back out of the

MGR program and transfer all appropriate configuration files to disk and load

these files onto the CC1 to which your VCRC configuration is attached. You

should now be ready to operate your VCR via direct control from the CM9760KBD.

Figure 13. Configuring the COMMS file for VCRC Operation

18 Pelco Manual C1941M (7/98)

Page 20

Physical installation of the VCRC unit is relatively simple, although v arious configurations are possible.

4.1 DIRECT RACK-MOUNT HOOK-UP

Regardless of the location of a VCRC unit, it will more than likely be installed in a

rack (refer to Figure 14). The VCRC unit mounts in a standard 19-inch (48.26 cm)

rack and occupies only one RU (1.75" or 4.45 cm) of rack space.

4.2 REMOTE OPERATION

If it is desired or necessary to place the VCRC unit some distance from the controller (CM9760-CC1), the wiring run from the CC1 to the RJ-45 IN port should not

exceed 4,000 feet (1,219 m).

4.0 INSTALLATION

Figure 14. CM9760-VCRC Rack-Mount Installation

Pelco Manual C1941M (7/98) 19

Page 21

4.3 DAISY-CHAINING

Up to eleven VCRCs may be daisy-chained together. This enables the system to

support up to 700 VCRs. Figure 15 illustrates the required wiring connections for

daisy-chaining.

Note that the remarks made in the previous section regarding RS-422 wiring run

distances also applies here when considering cables distance runs between daisychained units.

Since the VCRC units utilize the same protocol as that f or GPIs, they can be b ussed

together with CM9760-IRCs, and in the future with CM9760-RELs. Figure 16 illustrates this configuration.

ANY OF THE ELEVEN UNITS REFERENCED BELOW CAN BE ASSIGNED ANY OF THE 11 FRAME

ADDRESS RANGES AVAILABLE. FRAME ADDRESSES DO NOT HAVE TO BE SEQUENTIAL. THIS

MEANS UNIT 11 IN THE DIAGRAM BELOW, FOR EXAMPLE, CAN BE ASSIGNED FRAME ADDRESS 2,

WHILE UNIT 3 IS ASSIGNED FRAME ADDRESS 10.

Figure 15. Daisy-Chain Configuration

CM9760-IRC CM9760-REL

Figure 16. Daisy-Chain Multi-Buss Configuration

20 Pelco Manual C1941M (7/98)

Page 22

5.0 OPERATIONAL OVERVIEW

The basic function of the VCRC unit is to act as an interface between the user/

operator of the system and any connected VCRs. Each VCRC processes and executes only commands with addresses that match the controller address. When a

VCRC receives a command with an inappropriate address it passes it on to the

next unit (if applicable) via its OUT port.

When power is first applied to the unit, RAM is cleared and initialization routines are

called. The power LED is lit, operational chips are configured, interrupt priorities are

set and the activity LED on the front panel of the unit flashes on and off at about

1/2 second intervals. LED activity is detailed in Section 3.1.2, LEDs. The unit is

waiting for its first valid command.

5.1 FUNCTIONAL BLOCK DIAGRAM

The block diagram below represents a combination of internal circuitry as well as

software controlled hardware within the CM9760-VCRC unit.

Figure 17. VCRC Functional Bloc k Diag ram

Pelco Manual C1941M (7/98) 21

Page 23

5.2 OPERATING THE CM9760-VCRC FROM THE CM9760-KBD

Direct control operation of VCRs attached to VCRCs from a CM9760-KBD is relatively straightforward. Once the system is running and the keyboard is on-line, direct control of a VCR is as follows:

1. Select an input (camera) that was programmed as a VCR on the keyboard.

This will cause the keyboard’s LCD to change to the VCR control menu illustrated in Figure 18.

2. Activate a VCR function b y pressing the blue b utton directly below the desired

function’s icon. All VCR functions require only a momentary ke y press for activation.

3. Control additional VCRs by repeating steps 1 and 2.

Figure 18. CM9760-KBD VCR Control Functions

22 Pelco Manual C1941M (7/98)

Page 24

6.0 SPECIFICATIONS

Electrical

Input Voltage: Auto-ranging 100-240 VAC, 50/60 Hz

Power: Consumption: 30 vA

Data Ports

Input: RS-422, RJ-45 connector

DIP switch selectable baud rate

Output: RS-422, RJ-45 connector.

Output: DB-9 connector

Indicators: 2 power LEDs, green

Fusing: 500 mA, 250 V

Relay Out: Load rating for relay contacts:

General

Dimensions 19.37" W x 1.73" H x 8.15" D (49.2 cm x 4.4 cm x 20.7 cm)

Operating

Temperature: 32°F to 158°F (0°C to 70°C)

Weight: 7 lb (3.17 kg)

Mechanical

Connectors

VCRC Input: Four dual-header, 32 input connectors with mating plugs

Power: 3-wire, #18 AWG

RS-422: Two RJ-45 connectors

RS-232: One DB-9 connector

Relay Out: One 3-pin header with mating plug

DIP switch selectable baud rate

Factory use only

1 activity LED, red

0.50 A at 125 VAC or 1 A at 24 VDC

(Design and product specifications subject to change without notice.)

Pelco Manual C1941M (7/98) 23

Page 25

7.0 WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or

workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

Pelco, the Pelco logo, Camclosure, Esprit, Genex,

Legacy, Spectra, CM9760, and PelcoVision are

registered trademarks of Pelco.

Endura and ExSite are trademarks of Pelco.

© Copyright 1998, Pelco. All rights reserved.

• Five years on FT/FR8000 Series fiber optic products.

• Three years on Genex

• Three years on Camclosure

2X, CC3751H-2, CC3651H-2X, MC3651H-2, and MC3651H-2X camera models, which have

a five-year warranty.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy

dome products.

• Two years on Spectra

continuous motion applications.

• Two years on Esprit

• Eighteen months on DX Series digital video recorders, NVR300 Series network video

recorders, and Endura

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion

applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco shipment.

All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis, California.

Repairs made necessary by reason of misuse, alteration, normal wear, or accident are not

covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from the

specific use or application made of the Products. Pelco’s liability for any claim, whether based

on breach of contract, negligence, infringement of any rights of any party or product liability,

relating to the Products shall not exceed the price paid by the Dealer to Pelco for such Products.

In no event will Pelco be liable for any special, incidental or consequential damages (including

loss of use, loss of profit and claims of third parties) however caused, whether by the negligence

of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have

additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or (559) 2921981 to obtain a Repair Authorization number (RA), and provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the warranty

conditions stated above, please include a written explanation with the product when returned.

Method of return shipment shall be the same or equal to the method by which the item was

received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at (800)

289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned for credit,

and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA number

and freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico, send goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico and are instructed

to return goods to the USA, you may do one of the following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

If the goods are to be sent by a FREIGHT FORWARDER, send the goods to:

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

®

Series products (multiplexers, server, and keyboard).

®

and fixed camera models, except the CC3701H-2, CC3701H-

®

, CM6700/CM6800/CM9700 Series matrix, and DF5/DF8 Series fixed

®

, Esprit®, ExSite™, and PS20 scanners, including when used in

®

and WW5700 Series window wiper (excluding wiper blades).

™

Series distributed network-based video products.

24 Pelco Manual C1941M (7/98)

Loading...

Loading...