Page 1

®

Coaxitron® Matrix

System 8500

Installation/

Operation Manual

C501M-B (10/97)

Pelco • 300 W. Pontiac Way, Clovis • CA 93612-5699 USA • Pelco Online @ http://www.pelco.com

In North America and Canada: Tel (800) 289-9100 or FAX (800) 289-9150 • DataFAX (800) 289-9108

International Customers: Tel (1-209) 292-1981 or FAX (1-209) 348-1120 • DataFAX (1-209) 292-0435

Page 2

REVISION HISTORY

Revision Level Date Description

1.0 7/93 Initial Issue, PRELIMINARY

1.1 9/93 Revised; Additional features added. All pages affected. PRELIMINARY

1.2 5/94 Revised; Additional features added. Major revisions

of sections 5 and 6. Minor revisions throughout.

A 9/95 Manual completely revised. New information through-

out. Updated to include CM9505J/CM9505UPS installation information, as well as CM8506/CM8507

Option Board installation information. New Card

Cage Exploded-view diagram included.

B 12/96 Manual revised to incorporate design changes (CE

compliance) to the hardware per ECO 96-225. Added

the following: Figure 2, note to Section 4.3 to remove

paper between battery contacts, step 11 to Section

5.5.2.11, Section 6.1.11.1, and Section 6.1.11.2.

1/97 Changed fuse values in Section 3.1.9.

10/97 Throughout the manual, added references to the

Spectra™ dome. Corrected Figure 9 per ECO #97-

440.

®Pelco and the Pelco logo are registered trademarks of Pelco.

©Copyright 1997, Pelco. All rights reserved.

ii Pelco Manual C501M-B (10/97)

Page 3

TABLE OF CONTENTS

Section Page

1.0 WARNINGS.................................................................................................................................... 1-1

1.1 IMPORTANT SAFEGAURDS ............................................................................................... 1-1

1.2 REGULATORY NOTICES .................................................................................................... 1-2

2.0 GENERAL DESCRIPTION............................................................................................................. 2-1

2.1 MODELS AND ASSOCIATED EQUIPMENT ........................................................................ 2-2

2.1.1 CPU/Card Cage/Power Supply................................................................................ 2-2

2.1.2 Video Input/Output Matrix Card ............................................................................... 2-2

2.1.3 Keyboard Controllers ............................................................................................... 2-2

2.1.4 Optional Feature Circuit Cards ................................................................................ 2-3

2.1.5 Receiver/Drivers ...................................................................................................... 2-3

2.1.5.1 Standard Receiver/Drivers ...................................................................... 2-3

2.1.5.2 Intercept®/Legacy® Receiver/Drivers ....................................................... 2-4

2.2 CERTIFICATIONS ................................................................................................................ 2-4

3.0 SPECIFICATIONS.......................................................................................................................... 3-1

3.1 CARD CAGE ........................................................................................................................ 3-1

3.1.1 General .................................................................................................................... 3-1

3.1.2 Video Inputs ............................................................................................................. 3-1

3.1.3 Video Outputs .......................................................................................................... 3-1

3.1.4 Video Specifications ................................................................................................ 3-1

3.1.5 Character Generator ................................................................................................ 3-1

3.1.6 Keyboard Interface .................................................................................................. 3-2

3.1.7 Alarm Interface Inputs.............................................................................................. 3-2

3.1.8 Relay Follow Outputs............................................................................................... 3-2

3.1.9 Power Supply........................................................................................................... 3-2

3.1.10 Physical Specifications ............................................................................................ 3-2

3.2 KEYBOARD.......................................................................................................................... 3-3

3.2.1 General .................................................................................................................... 3-3

3.2.2 Keyboard Electrical Specifications........................................................................... 3-3

3.2.3 Keyboard Communications...................................................................................... 3-3

3.2.4 Physical Specifications ............................................................................................ 3-3

4.0 INSTALLATION .............................................................................................................................. 4-1

4.1 INSTALLATION PREPARATION .......................................................................................... 4-1

4.2 MOUNTING .......................................................................................................................... 4-1

4.3 SYSTEM HOOKUP .............................................................................................................. 4-1

4.3.1 General .................................................................................................................... 4-1

4.3.2 Keyboard to CPU Hookup ....................................................................................... 4-2

4.3.2.1 CM9505UPS/CM9505J Installation......................................................... 4-3

4.3.2.2 Pin Configuration ..................................................................................... 4-3

4.3.2.3 CM9505J Wire/Pin Configuration ............................................................ 4-3

4.3.2.4 Cable Distances ...................................................................................... 4-3

4.3.2.5 Interfacing Keyboard to CPU Via Fiber, Modem or Microw ave ............... 4-6

4.3.2.6 Keyboard Self-Test .................................................................................. 4-6

4.3.3 CM8502-1/CM8503-1 Card Cage Configuration ..................................................... 4-6

4.3.3.1 Removal/Replacement of Individual Circuit Cards .................................. 4-7

4.3.3.1.1 Motherboard Access ............................................................ 4-7

4.3.3.1.2 Insertion/Extraction of the CM8504 I/O Card. ...................... 4-8

4.3.3.1.3 Insertion/Extraction of the CPU Card ................................... 4-8

4.3.3.1.4 Insertion/Extraction of the Buffer Card ................................. 4-8

4.3.3.1.5 Installing Option Boards ....................................................... 4-9

P elco Manual C501M-B (10/97) iii

Page 4

4.3.3.1.6 Option Board Receiver Connections .................................... 4-9

4.3.3.2 Setting Termination on Video Inputs..................................................... 4-10

4.3.3.3 Determining and Setting Monitor Output Assignments.......................... 4-10

4.3.3.4 Camera Location to Video Input Hookup............................................... 4-10

4.3.3.4.1 Cable Selection ................................................................... 4-11

4.3.3.4.2 Termination.......................................................................... 4-11

4.3.3.4.3 Ground Loops .................................................................... 4-13

4.3.3.4.4 Hookup ............................................................................... 4-13

4.3.4 Connecting Keyboard to the Data Monitor............................................................. 4-13

4.3.5 Connecting Other System Monitors ....................................................................... 4-13

4.3.6 Installation/Connection of CM8532 Alarm / Relay Interface .................................. 4-13

4.3.6.1 Alarm/Relay Interface Kit Installation..................................................... 4-13

4.3.7 Alarm Input Connection ......................................................................................... 4-13

4.3.7.1 Alarm Interface 37-Pin Sub “D” Connectors......................................... 4-14

4.3.8 Relay Output Connection....................................................................................... 4-14

4.3.8.1 Relay Interface Connector Pin Assignments ......................................... 4-15

4.3.9 2-wire control Output “D” Connector ...................................................................... 4-16

5.0 PROGRAMMING THE CM85OO ................................................................................................... 5-1

5.1 THE KEYBOARD/CONTROLLER........................................................................................ 5-1

5.1.1 General .................................................................................................................... 5-1

5.1.2 Joystick .................................................................................................................... 5-1

5.1.3 Numeric Keypad ...................................................................................................... 5-2

5.1.4 Selection Keys ......................................................................................................... 5-2

5.1.5 Lens Function Switches........................................................................................... 5-3

5.1.6 Keyboard Data Ports ............................................................................................... 5-3

5.2 FORMATS FOR KEYSTROKE ENTRIES ............................................................................ 5-3

5.3 INITIAL POWER-UP............................................................................................................. 5-4

5.3.1 Keyboard and Monitor Requirements ...................................................................... 5-4

5.3.2 Initial User ID Prompt............................................................................................... 5-4

5.4 MENU BAR........................................................................................................................... 5-5

5.4.1 MaIn Menu Bar and On-Screen Function Buttons ................................................... 5-5

5.4.1.1 System Menu........................................................................................... 5-6

5.4.1.2 Cam Menu............................................................................................... 5-7

5.4.1.3 Keybrd Menu ........................................................................................... 5-8

5.4.1.4 User Menu............................................................................................... 5-8

5.4.1.5 Seq Menu ................................................................................................ 5-9

5.4.1.6 Alarm Menu ............................................................................................. 5-9

5.4.1.7 Tour Menu.............................................................................................. 5-10

5.4.1.8 Event Menu ........................................................................................... 5-10

5.4.1.9 Logoff Menu............................................................................................5-11

5.4.1.10 On-Screen Function Buttons ..................................................................5-11

5.4.2 Exiting the Menu Programs ....................................................................................5-11

5.5 PROGRAMMING................................................................................................................ 5-12

5.5.1 Preprogramming Information ................................................................................. 5-12

5.5.1.1 Video Input Form ................................................................................... 5-12

5.5.1.2 User Profile Form .................................................................................. 5-14

5.5.1.3 Keyboard Access Form ......................................................................... 5-16

5.5.1.4 Preset Assignment Form ....................................................................... 5-17

5.5.1.5 P attern Assignment Form ...................................................................... 5-19

5.5.1.6 Zone Assignment Form ......................................................................... 5-20

5.5.1.7 Sequence Assignment Form ................................................................. 5-21

5.5.1.8 Alarm Assignment Form ........................................................................ 5-23

5.5.2 Programming Instructions ...................................................................................... 5-24

5.5.2.1 System Initialization............................................................................... 5-24

5.5.2.2 Programming System Time and Date.................................................... 5-24

iv Pelco Manual C501M-B (10/97)

Page 5

5.5.2.3 Programming Camera Labels................................................................ 5-25

5.5.2.4 Programming Receiver Types ............................................................... 5-26

5.5.2.5 Programming Presets............................................................................ 5-27

5.5.2.6 Programming Patterns........................................................................... 5-27

5.5.2.7 Programming Zones .............................................................................. 5-28

5.5.2.8 Programming Keyboard/Monitor Access............................................... 5-29

5.5.2.9 Programming User Profiles ................................................................... 5-30

5.5.2.10 Programming Sequences ...................................................................... 5-32

5.5.2.11 Programming Alarms ............................................................................. 5-34

5.5.2.12 Programming Relay Follow ................................................................... 5-36

5.5.2.13 Relay Manual Control ............................................................................ 5-37

5.5.2.14 Programming Tours ............................................................................... 5-37

5.5.2.14.1 Tour Keypad Control .......................................................... 5-38

5.5.2.15 Programming Event Schedules ............................................................. 5-39

5.5.2.16 Programming DayTypes ........................................................................ 5-39

5.5.2.17 Programming Schedules ....................................................................... 5-40

6.0 SYSTEM OPERATION, KEYBOARD COMMANDS ...................................................................... 6-1

6.1 SYSTEM OPERATION/KEYBOARD COMMANDS.............................................................. 6-1

6.1.1 Data Monitor ............................................................................................................ 6-1

6.1.2 Log On ..................................................................................................................... 6-2

6.1.3 Calling Up a Monitor ................................................................................................ 6-2

6.1.4 Calling Up a Camera ............................................................................................... 6-3

6.1.4.1 Camera Access Prompt........................................................................... 6-4

6.1.5 Controlling Camera Operation ................................................................................. 6-4

6.1.5.1 Manual Movement ................................................................................... 6-4

6.1.5.2 Controlling Lens Functions ...................................................................... 6-4

6.1.5.3 Flip Control Function ............................................................................... 6-4

6.1.5.4 Next and Previous Functions................................................................... 6-4

6.1.5.5 Calling Up a Preset Position.................................................................... 6-4

6.1.5.6 Adjusting Lens Zoom and Focus Speed.................................................. 6-5

6.1.6 Running a Sequence ............................................................................................... 6-5

6.1.6.1 Starting a Sequence ................................................................................ 6-5

6.1.6.2 Stopping a Sequence .............................................................................. 6-6

6.1.7 Running a Pattern.................................................................................................... 6-6

6.1.8 Running a Tour ........................................................................................................ 6-6

6.1.9 Acknowledging Alarms............................................................................................. 6-6

6.1.10 Energizing/De-energizing Relays Manually............................................................. 6-7

6.1.11 Activ ating Auxiliary Functions .................................................................................. 6-7

6.1.11.1 Intercept® Auto/Random/Frame Scan...................................................... 6-7

6.1.11.2 Legacy® Random/Auto Scan ................................................................... 6-7

6.1.12 Log Off ..................................................................................................................... 6-8

6.2 OPERATION QUICK REFERENCE GUIDE ......................................................................... 6-9

7.0 SCHEMATICS AND DRAWINGS ................................................................................................... 7-1

8.0 TROUBLESHOOTING ................................................................................................................... 8-1

8.1 INITIALIZATION.................................................................................................................... 8-1

8.2 OPERATIONAL PROBLEMS................................................................................................ 8-2

9.0 PROGRAMMING FORMS ............................................................................................................. 9-1

10.0 GLOSSARY OF TERMS .............................................................................................................. 10-1

11.0 WARRANTY AND RETURN INFORMATION.............................................................................. 11-1

P elco Manual C501M-B (10/97) v

Page 6

LIST OF ILLUSTRATIONS

Figure Page

1 CM8500 Configuration Diagram.................................................................................................. 2-1

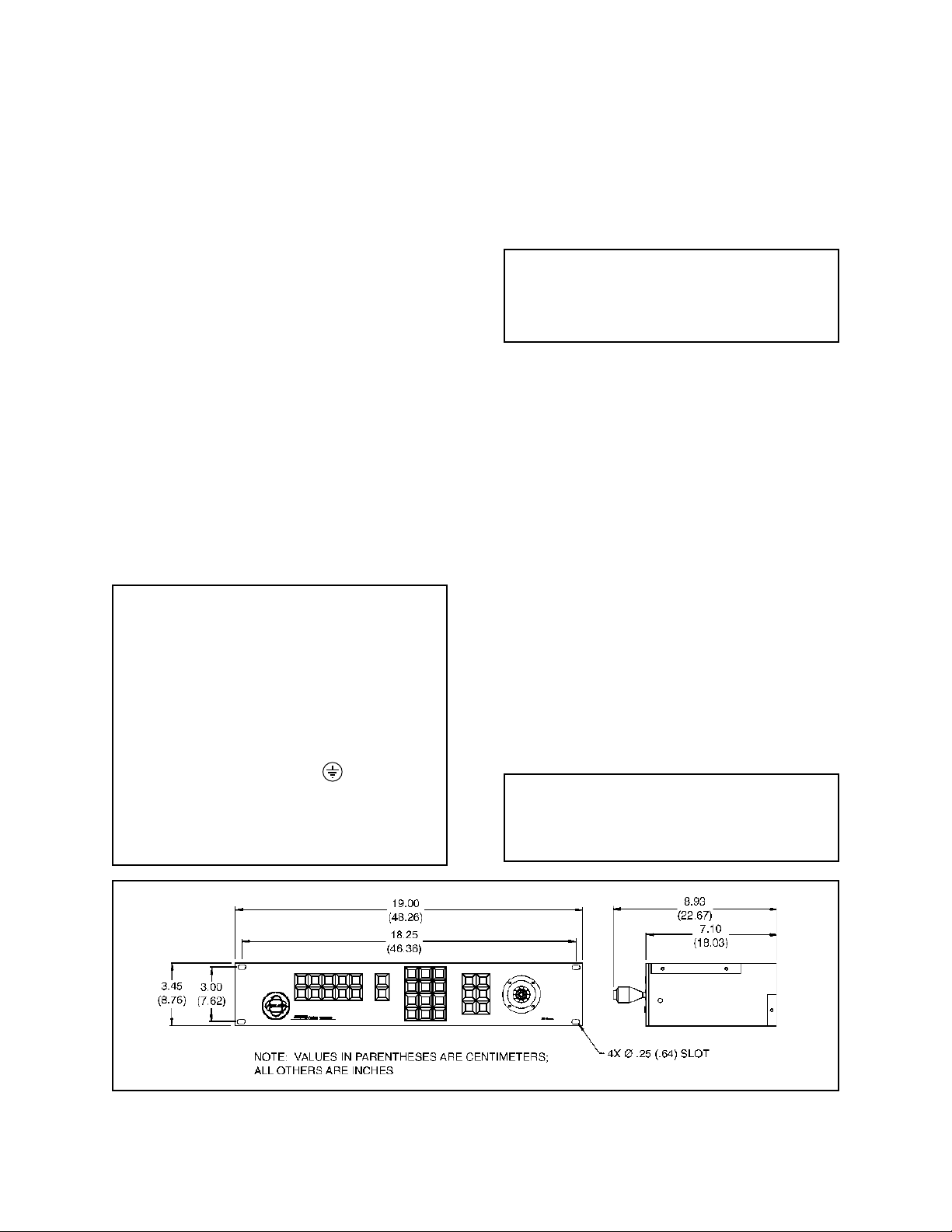

2 CM8505R Dimension Drawing.................................................................................................... 4-1

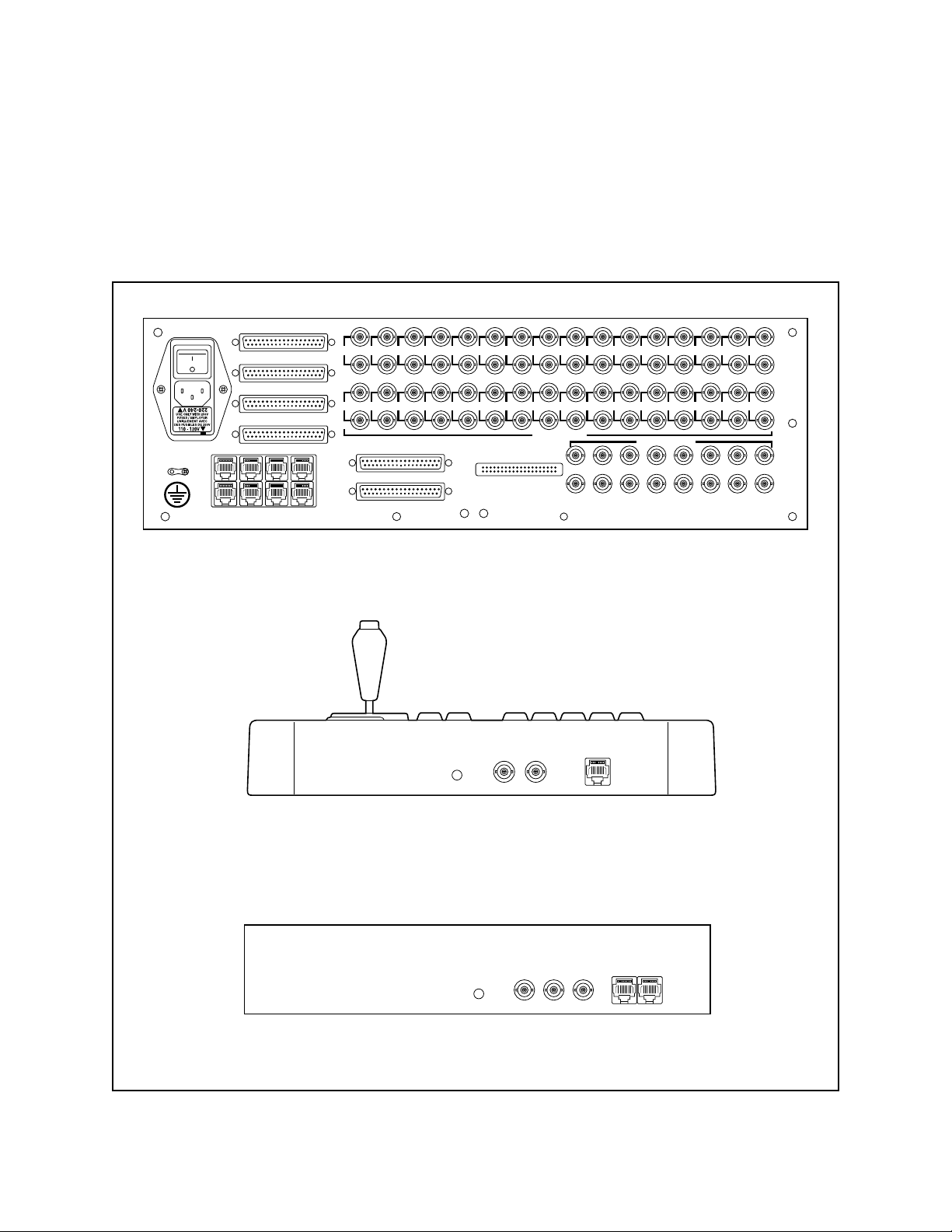

2A CM8503A-1 Card Cage and CM8505 Keyboard Back Panel Connector Layout ........................ 4-2

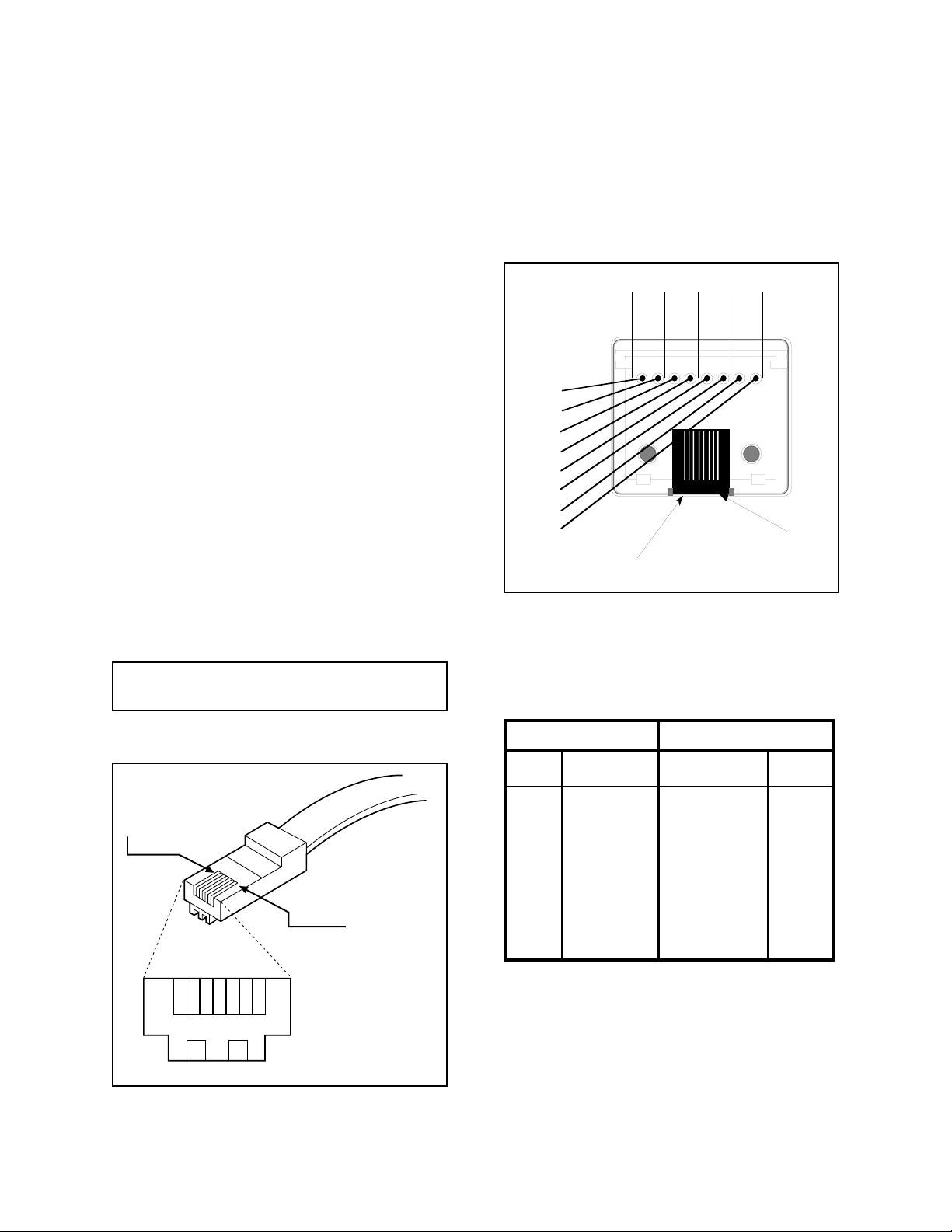

3 Data Cable Pin Assignments....................................................................................................... 4-3

4 Junction Box Pin Assignments .................................................................................................... 4-3

5 CM9505UPS/CM9505J Configuration ........................................................................................ 4-4

6 CM8503-1 Card Cage Top View.................................................................................................. 4-5

7 CM8502-1/CM8503-1 Card Cage Front View ............................................................................. 4-6

7a Slide-out Motherboard Access .................................................................................................... 4-7

8 CPU Card Component Location.................................................................................................. 4-8

9 Buffer Card and Jumper Locations ........................................................................................... 4-10

10 Data Monitor Hookup ................................................................................................................ 4-12

11 CM8505D Keyboard/Controller................................................................................................... 5-1

12 Numeric Keypad.......................................................................................................................... 5-2

13 Selection Switches ...................................................................................................................... 5-3

14 Lens Function Switches .............................................................................................................. 5-3

15 Log On Screen with On-Screen Keyboard.................................................................................. 5-4

16 Main Menu Bar ............................................................................................................................ 5-5

17 System Menu .............................................................................................................................. 5-6

18 Cam Menu................................................................................................................................... 5-7

19 Keyboard Menu ........................................................................................................................... 5-8

20 User Menu................................................................................................................................... 5-8

21 Sequence Menu .......................................................................................................................... 5-9

22 Alarm Menu ................................................................................................................................. 5-9

23 Tour Menu ................................................................................................................................. 5-10

24 Event Menu ............................................................................................................................... 5-10

25 Logoff Menu ...............................................................................................................................5-11

26 Clock Programming Screen ...................................................................................................... 5-24

27 Label Programming Screen ...................................................................................................... 5-25

28 Receiver Types Programming Screen ...................................................................................... 5-26

29 Keyboard/Monitor Access Programming Screen ...................................................................... 5-29

30 User Profiles Programming Screen........................................................................................... 5-31

31 Camera Access Programming Screen ...................................................................................... 5-31

32 Sequence Description Screen................................................................................................... 5-33

33 Sequence Programming Screen ............................................................................................... 5-33

34 Alarm Description Screen ......................................................................................................... 5-34

35 Monitor and Camera Definition Screen ..................................................................................... 5-35

36 Relay Follow Menu.................................................................................................................... 5-36

37 Relay Follow Assignments Menu .............................................................................................. 5-36

38 Relay Control Menu .................................................................................................................. 5-37

39 Tour “Pick” List Menu ................................................................................................................ 5-37

40 Tour Menu and Camer a “Pick” List ............................................................................................ 5-38

41 Tour Control Menu..................................................................................................................... 5-38

42 Event Editor Menu..................................................................................................................... 5-39

43 Event Editor and Tour “Pick” List Menus ................................................................................... 5-40

44 Event Editor Menu..................................................................................................................... 5-40

45 Schedule Editor Menu ............................................................................................................... 5-40

46 Data Monitor................................................................................................................................ 6-1

47 Monitor Selection Menu .............................................................................................................. 6-2

48 Camera Selection Menu.............................................................................................................. 6-3

49 Sequence Menu .......................................................................................................................... 6-5

50 CM8500 Series Card Cage Exploded View Diagram.................................................................. 7-2

vi Pelco Manual C501M-B (10/97)

Page 7

1.0 WARNINGS

1.1 IMPORTANT SAFEGUARDS

Before installing your equipment, please read the following important safeguards as outlined by Underwriters Laboratories Inc.

Read Instructions

All the safety and operating instructions should be read

before the appliance is operated.

Retain Instructions

The safety and operating instructions should be retained

for future reference.

Heed Warnings

All warnings on the appliance and in the operating instructions should be followed.

Follow Instructions

All operating and use instructions should be followed.

Cleaning

Do not use liquid cleaners or aerosol cleaners. Use a

Damp Cloth for cleaning.

Attachments

Do not use attachments not recommended by Pelco as

they may cause hazards.

V entilation

Slots and openings in the cabinet are provided for ventilation and to ensure reliable operation of the CCTV

product, and to protect it from overheating. These openings must not be blocked or covered. The openings

should never be blocked by placing the CCTV product

on furniture, carpet, or similar surfaces. The CCTV

product should never be placed near or over radiators

or heat registers. This CCTV product should not be

placed in a built-in installation, such as a book case or

rack unless proper ventilation is provided or Pelco’s

installation instructions are adhered to.

Power Sources

This CCTV product should only be operated from the

type of power source indicated on the marketing label.

If you are not sure of the type of power supply to your

installation location, consult your local electrical building official or power company. Refer to the operating

instructions for appliances intended to operate from

battery or other power sources.

Grounding

This CCTV product is equipped with a 3-wire “grounding” type plug, having a third (grounding) pin. This plug

will only fit into a “grounding” type power outlet. This

is a safety feature. If you are unable to insert the plug

into the outlet, contact your electrician to replace your

obsolete outlet. Do not defeat the “grounding” type plug

since it is provided to ensure your safety.

Water and Moisture

Do not use this CCTV product near water - for example,

near a kitchen sink, wash bowl, bath tub, sprinkler, in a

wet basement or near a swimming pool, and the like

unless it is specifically marked “for use in wet locations”.

Accessories

Do not place this CCTV product on an unstable cart,

stand, tripod, bracket, or table. The CCTV product may

fall, causing serious injury to a child or adult, and serious damage to the appliance. Use only with a cart, stand,

tripod, bracket or table recommended by Pelco, or supplied by Pelco with the product. When mounting the

appliance, follow Pelco’s installation instructions, and

use only mounting accessories recommended by Pelco.

Cart & Stand

An appliance and cart combination should be moved

with care. Quick stops, excessive force, and uneven

surfaces may cause the appliance and cart combination

to overturn.

Power-Cord Protection

Power-supply cords should be routed so that they are

not likely to be walked on or pinched by items placed

upon or against them, paying particular attention to

cords at plugs, convenience receptacles, and the point

where they exit from the appliance.

Overloading

Do no overload wall outlets and extension cords as this

can result in a risk of fire or electric shock.

Object and Liquid Entry

Never push objects of any kind into this CCTV product

through openings as they may touch dangerous voltage

points or short-out parts that could result in a fire or

electric shock. Never spill liquid of any kind on the

CCTV product.

Servicing

Do not attempt to service this CCTV product yourself

as opening or removing covers may expose you to dangerous voltages or other hazards. Refer all servicing to

qualified service personnel.

Pelco Manual C501M-B (10/97) 1-1

Page 8

Damage Requiring Servicing

Unplug this CCTV product from the wall outlet and

refer servicing to qualified service personnel under the

following conditions:

a. When the power-supply cord or plug is damaged.

b. If liquid has been spilled, or objects have fallen

into the CCTV product.

c. If the CCTV product is not marked “Suitable for

Wet Locations” and it has been exposed to rain or

water.

d. If the CCTV product does not operate normally by

following the operating instructions. Adjust only

those controls that are covered by the operating

instructions as an improper adjustment of other

controls may result in damage, and will often require extensive work by a qualified technician to

restore the CCTV product to its normal operation.

e. If the CCTV product has been dropped or the cabi-

net has been damaged.

f. When the CCTV product exhibits a distinct change

in performance - this indicates a need for service.

Replacement Parts

When replacement parts are required, be sure the service technician has used replacement parts specified

by Pelco or have the same characteristics as the original part. Unauthorized substitutions may result in fire,

electric shock, or other hazards.

Safety Checks

Upon completion of any service or repairs to this CCTV

product, ask the service technician to perform safety

checks to determine that the CCTV product is in proper

operating condition.

WARNING

This product has been evaluated for INDOOR USE

ONLY unless it bears the marking FOR USE IN WET

LOCA TIONS.

W ARNING

To reduce the risk of electric shock hazard, do not remove the cover of the unit. This unit can not be serviced by the user and must be sent to a qualified service person for repair when it fails to function.

The Lightning Flash with an arrow

head symbol within an equilateral

triangle means that if the enclosure

is opened, electrical circuitry is exposed which imposes an electric

shock hazard to persons present.

The Exclamation Point within an

equilateral triangle means the operating instructions contain important

information on how to operate and

maintain the appliance.

This symbol represents an internal

protective grounding terminal. Such

a terminal must be connected to earth

ground prior to making any other

connections to the equipment.

1.2 REGULATORY NOTICES

Federal Communications Commission (FCC) Part 15

Information

NOTE: This equipment has been tested and

found to comply with the limits of a Class A

digital device, pursuant to part 15 of the FCC

rules. These limits are designed to provide reasonable protection against harmful interference

when equipment is operated in a commercial

environment. This equipment generates, uses,

and can radiate radio frequency energy and, if

not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to

cause harmful interference in which case the

user will be required to correct the interference

at his own expense.

89/336/EEC EMC Directive, EN50081-1, EN55022

WARNING: This is a Class A product. In a

domestic environment this product may cause

radio interference, in which case the user may

be required to take adequate measures.

1-2 Pelco Manual C501M-B (10/97)

Page 9

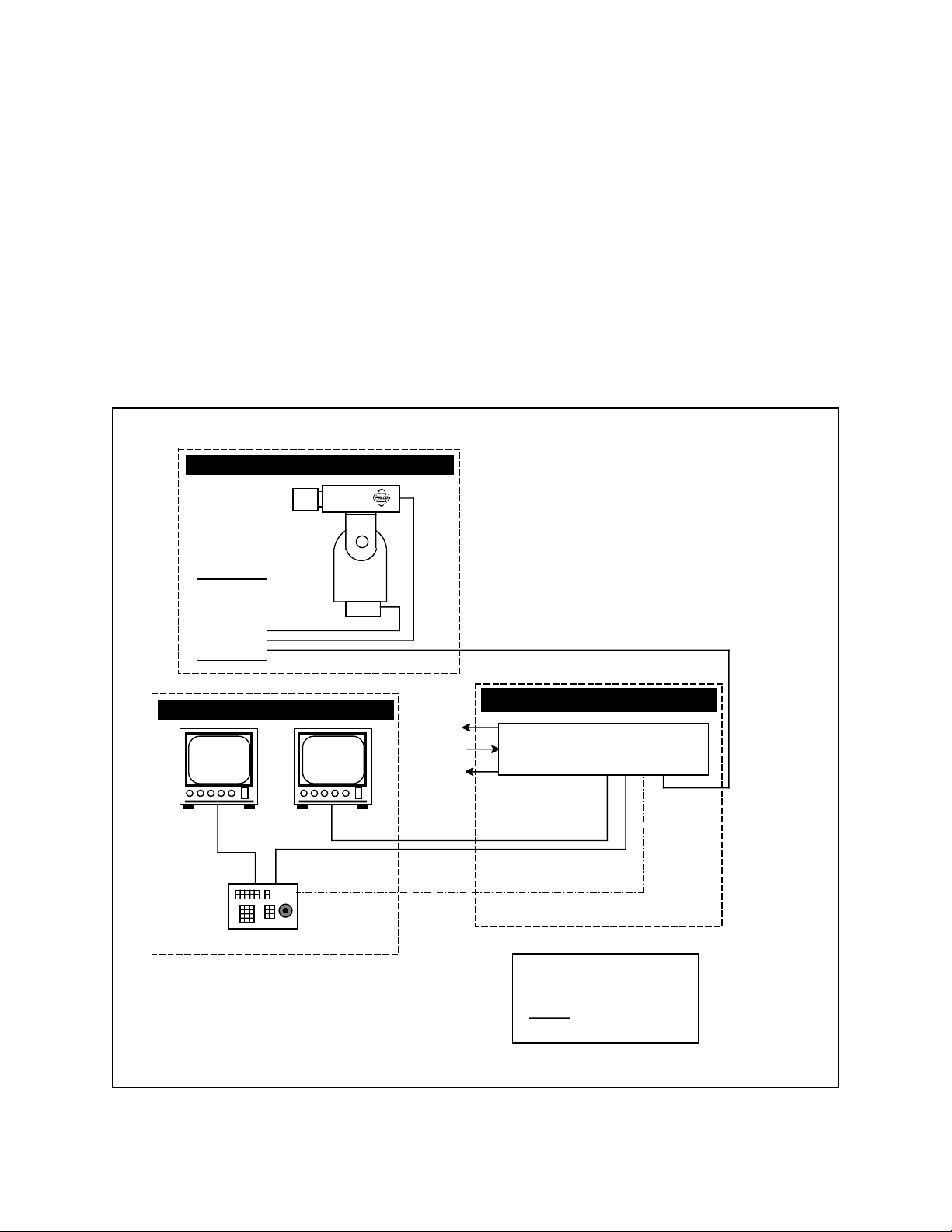

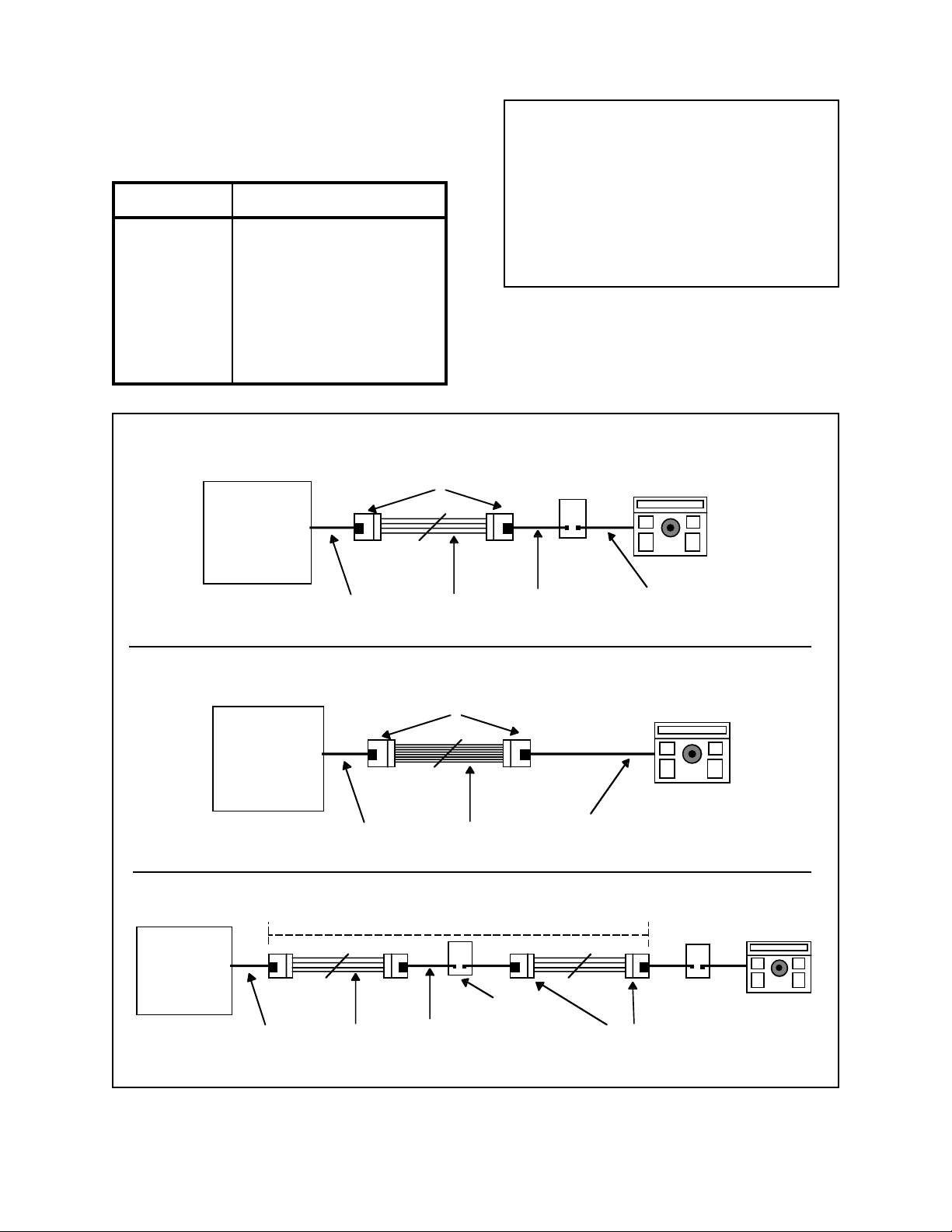

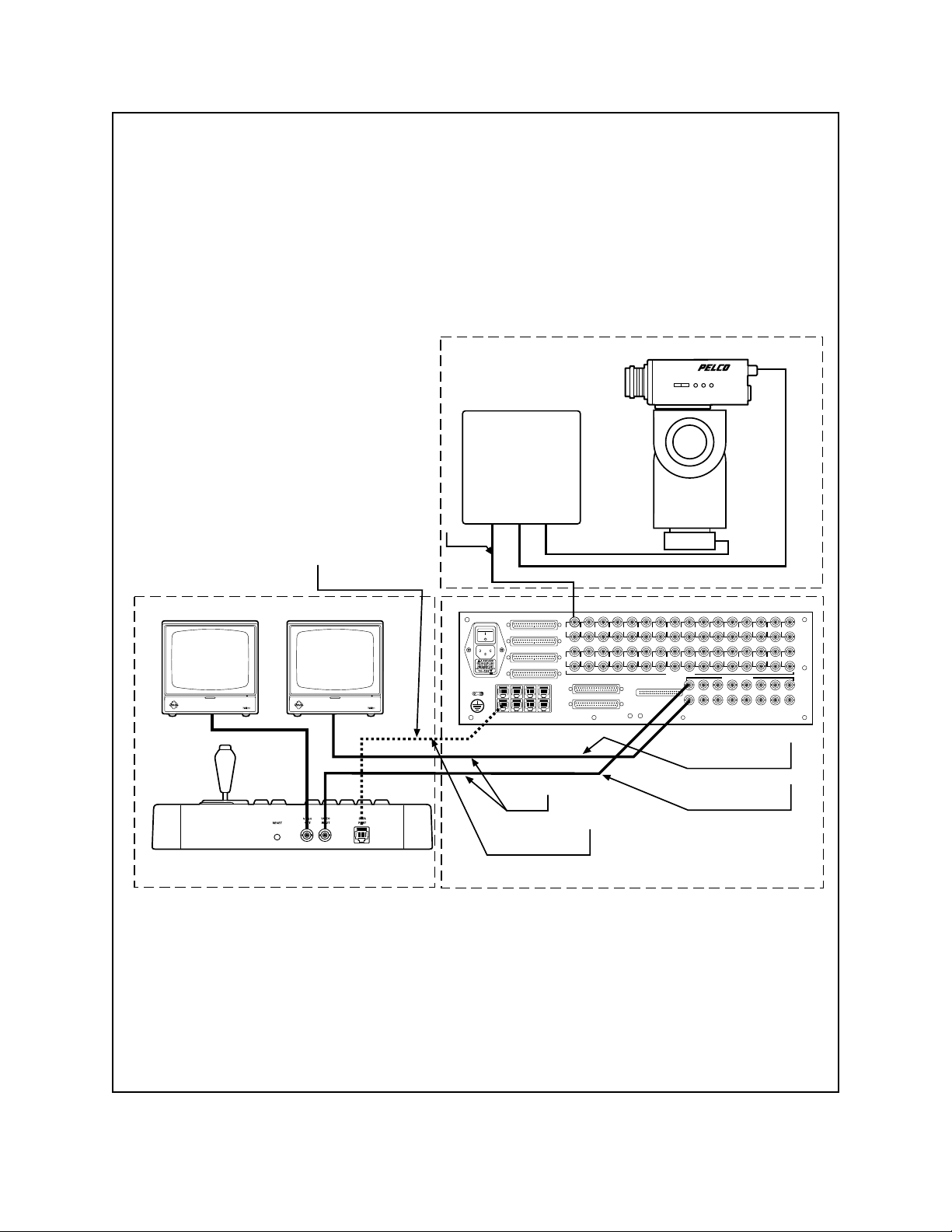

2.0 GENERAL DESCRIPTION

System 8500 is a microprocessor-based cross-point

video matrix switcher capable of handling up to 32 video

inputs to 16 monitor outputs (8 monitor outputs with

CM8502A-1), from as many as 8 independent keyboard/

controllers. It is completely compatible with all

Coaxitron® Receiver/Drivers for single coaxial control

of pan/tilts and motorized lens functions.

TYPICAL CAMERA LOCATION WITH PT&Z

VIDEO

The full-feature standard software package can be programmed by the user to custom tailor the System 8500

for each individual application. Included in the software package are system management features, password protection/priority, preset position options, tour

and event scheduling, pattern scanning and full titling

and time/date generation.

NOTE: System 8500 offers 32 PTZ control outputs. Any

number of these 32 can be Coaxitron-control, the remainder can be all Wiretron or all RS-422 depending on which

option board is being used.

RX/DR

TYPICAL CONTROL LOCATION

MON

1

DATA

MONITOR

KEYBOARD 1

PT&Z

MON

2

PELCO

32 RS422

OUTPUTS

OR

32 WIRETRON

OUTPUTS

32 ALARM

INPUTS

32 RELAY

OUTPUTS

UP TO

16

MONITORS

UP TO

8

KEYBOARDS

UP TO 32 VIDEO INPUTS

VIDEO & CONTROL DISTRIBUTION POINT

CM8500 CARD CAGE

MONITOR 2 VIDEO

OUTPUT

MONITOR 1 VIDEO OUTPUT

KEYBOARD 1 DATA/PWR LINE

8-conductor

flat phone cable

Coax Cable

Figure 1. CM8500 Configuration Diagram

Pelco Manual C501M-B (10/97) 2-1

Page 10

2.1 MODELS AND ASSOCIATED

EQUIPMENT

2.1.1 CPU/Card Cage/Power Supply

CM8502A-1 Card Cage capable of 32 inputs and

up to 8 monitor outputs. Each output requires a CM8504 I/O card.

(CM8502A-1 is shipped with one

CM8504 I/O card).

CM8502A-1-P AL CE-compliant version of CM8502A-1

CM8503A-1 Card Cage capable of 32 inputs and

up to 16 monitor outputs. Each

output requires a CM8504 I/O

card. (CM8503A-1 is shipped with

one CM8504 I/O card).

CM8503A-1-PAL CE-compliant version of CM8503A-1

2.1.2 Video Input/Output Matrix Card

CM8504 32 input by 1 output video matrix

card for I/O expansion in CM8502-1

and CM8503-1 Card Cages.

2.1.3 Keyboard Controllers

CM8505D Full-function desktop keyboard for

System 8500. Provides joystick control for pan/tilt functions, lens control

switches, auxiliary function switches,

numeric data entry keypad. Derives

power from main CPU/Card Cage.

(See section 4.3.2.3 for maximum

wire-run distance from CPU to keyboard.) Connects to CPU utilizing integral RJ-45 8-pin modular female

connector. A 25 foot interconnect

cable is included with all keyboards.

CM8505D-PAL CE-compliant version of CM8505D

CM8505R Full-function 19" EIA rack mount

keyboard.

CM9505UPS Remote power supply for CM8505

keyboards. For use when power supplied from CPU is inadequate due to

excessively long wire runs or when

CPU derived power is impractical or

impossible (i.e., fiber-optic transmission of RS-422 keyboard data). See

section 4.3.2.3 for recommended

wiring parameters.

NOTE: Future references in this manual to

the CM8502A-1, CM8503A-1, CM8505D and

CM9505UPS include the models that are CE

compliant.

CM9505UPS-X CE-compliant version of CM9505UPS

CM9505J Junction box set to adapt keyboard

RJ-45 8-pin male modular cord/

connector to multiconductor cable.

Set of two (2). Barrier strip to RJ45 8-pin female modular connector.

Also includes one pre-assembled 25

foot cable for CPU end.

CM9505IC-50 50 foot Keyboard-to-CPU extra

length cable pre-assembled with

modular RJ-45 connectors.

2-2 Pelco Manual C501M-B (10/97)

Page 11

2.1.4 Optional Feature Circuit Cards

2.1.5.1 Standard Receiver/Drivers

CM8506 Communication circuit card to allow

the CM8500 to communicate with

Wiretron Receiver/Drivers. Mounts

to Buffer Card.

CM8507 Communication circuit card to allow

the CM8500 to communicate with

Pelco RS-422 receiver/drivers (either

Spectra™, Intercept® or Legacy®).

Mounts to Buffer Card.

CM8532 32 alarm/32 relay circuit card kit to

allow for direct monitoring of 32

alarms and the use of 32 relay outputs programmable in software.

Mounts to backplane of CM8502-1/

CM8503-1.

2.1.5 Receiver/Drivers

NOTE: See Pelco specification sheet C550 for

additional information on Coaxitron® CX9000

Series Receiver/Drivers, available options and

accessories. (Also see programming instructions for additional information on configuring

the system for specific receiver/drivers.)

CX9024RX Coaxitron® outdoor receiver for 24

VAC pan/tilt units, 24 VAC camera

power, zoom lens control and auxiliary functions. (Requires 120 V AC input power.)

CX9024RX-PP Same as CX9024RX except designed

for use with preset position option for

preset capable pan/tilts and lenses.

Can store 32 preset position locations. The first eight are direct contact closure capable for call-up.

CX9024RXI Same as CX9024RX except designed

for indoor use.

CX9024RXI-12V Same as CX9024RXI except with 12

VDC camera power output.

CX9024RXI-PP Same as CX9024RX-PP except de-

signed for indoor use.

CX9115RX Coaxitron® outdoor receiver for 120

VAC pan/tilt units, 120 VAC camera

power, zoom lens control, and auxiliary functions. (Requires 120 V AC input power.)

NOTE: With Spectra™, the receiver/driver

is an integral part of the dome.

CX9115RX-PP Same as CX9024RX-PP except for

120 VAC pan/tilt and camera power

outputs.

CX9115RXI Same as CX9115RX except designed

for indoor use.

CX9115RXI-PP Same as CX9024RXI-PP except for

120 VAC pan/tilt and camera power

outputs.

CX9224RX Same as CX9024RX except for 24

VAC input power.

CX9224RX-PP Same as CX9024RX-PP except for

24 VAC input power .

CX9224RXI Same as CX9224RX except designed

for indoor use.

CX9224RXI-PP Same as CX9024RXI-PP except for

24 VAC input power .

Pelco Manual C501M-B (10/97) 2-3

Page 12

2.1.5.2 Intercept®/Legacy

Receiver/Drivers

®

DRD08 Dome receiver/driver for 8-inch In-

DRD14 Dome receiver/driver for 14-inch In-

LRD41 – Coaxitron® receiver/driver for

***

tercept® series domes. (Refer to

Specification Sheet C416 for specific

ordering information.)

***

tercept® series domes. (Refer to

Specification Sheet C454 for specific

ordering information.)

*** *

Legacy® series pan/tilts. (Refer to

Specification Sheet C277 for specific

ordering information.)

* Denotes different model numbers.

2.2 CERTIFICATIONS

The following CM8500 components are compliant with

FCC regulations, Part 15, Class A:

CM8502A-1 card cage

CM8503A-1 card cage

CM8504 video matrix card

CM9505UPS remote power supply

The following CM8500 components are compliant with

EEC regulations 89/336 EEC EMC Directive,

EN50081-1, EN55022:

CM8502A-1-PAL card cage

CM8503A-1-PAL card cage

CM8505D-PAL keyboard

CM9505UPS-X remote power supply

CM8504 video matrix card

2-4 Pelco Manual C501M-B (10/97)

Page 13

3.0 SPECIFICATIONS

3.1 CARD CAGE

3.1.1 General

Programmable switching duration: Minute, 1 second

Programmable number of steps/sequence: 32

Maximum number of sequences: 16

3.1.2 Video Inputs

Number of inputs: 32

Type: 75-ohm unbalanced terminating or looping; jumper selectable

Level: 1V peak-to-peak

Connector type: Panel-mount BNC

3.1.3 Video Outputs

Number: 1-16

Type: 75-ohm unbalanced

Level: 1V peak-to-peak nominal

Video fail detection:

Type: Vertical sync detector

Action: Switch to back up sync generator

Connector type: Panel-mount BNC

3.1.4 Video Specifications

Frequency response: ± 3 dB 20 Hz - 10 MHz

Gain: Zero dB (± 0.5 dB)

Differential gain: Typical 0.5% - Max. <1.0%

Differential phase: Typical 0.5% - Max. <1.0%

Field tilt: Typical 0.3% - Max. <0.5%

Line tilt: Typical 0.25% - Max. <0.5%

Hum: <-60 dB (below <1V p-p)

Signal to noise: > 60 dB

Cross talk (input-to-input): >-60 dB @ 10 MHz

Feedthrough (input-to-output): >60 dB @ 10 MHz

3.1.5 Character Generator

Display: White with black border

Programmable Label Descriptions: 20 Alphanumeric characters maximum

Pelco Manual C501M-B (10/97) 3-1

Page 14

3.1.6 Keyboard Interface

Protocol: Balanced differential 10V peak-to-peak

Number of ports: 8

Number of independent keyboards: 8 maximum

Baud Rate: 9600

Connector type: RJ-45 8-pin modular (female)

Cable type (supplied): 25 feet, flat, unshielded

(may be shielded)

Programmable: Y es; on-screen, menu-driven

3.1.7 Alarm Interface Inputs

Number of inputs: 32

Connector type: Two (2) 37-pin D-type female

Sensing: Normally open

3.1.8 Relay Follow Outputs

Number of outputs: 32

Connector type: Two (2) 50-pin D-type female

Contact configuration: Double pole, normally open or normally closed

Contact rating: 1A @ 24 VDC, 0.5A @ 120 VAC

3.1.9 Power Supply

Input voltage: 120/230 VAC, 50/60 Hz

Power consumption: 100 W

Ambient operating temperature range: 20° to 120°F (-7° to 49° C)

Humidity: 80% max.

Fusing: 120 VAC models: 2 A @ 250 VAC, 5 x 20 mm

230 VAC models: 1 A @ 250 VAC, 5 x 20 mm

Power on/off switch: Rocker type

3.1.10 Physical Specifications

Dimensions: 17.07"W x 5.25"H x 20.06"D

(43.36 cm x 13.34 cm x 50.95 cm)

Approximate Weight:

Fully-configured: 34 lbs (15.5 kg)

Card Cage Only: 24 lbs (11.0 kg)

Shipping Weight:

Fully-configured 37 lbs (16.8 kg)

Card Cage Only: 27 lbs (12.3 kg)

Construction: Cover - Steel, gray poly vinyl powder coat

3-2 Pelco Manual C501M-B (10/97)

Page 15

3.2 KEYBOARD

3.2.1 General

Numeric keypad: 12 keys; [0]-[9], [CLEAR], [SELECT]

Function keypad: 12 keys; [ESCAPE], [SEQ], [TOUR], [FLIP], [NEXT],

[CAM], [MON], [ALARM ACK], [RELAY TRIGGER],

[PREV],[PATTERN],[PRESET]

Lens function switch block: 6 momentary switches; [ZOOM WIDE], [ZOOM TELE],

[FOCUS NEAR], [FOCUS FAR], [IRIS CLOSE],

[IRIS OPEN]

Joystick: Vector-solving, variable-speed

3.2.2 Keyboard Electrical Specifications

Input voltage: ±12 VDC

Power consumption: 7W

Ambient operating temperature: 20° to 120°F (-7° to 49° C)

Humidity: 80% max

Connector type: RJ-45 8-pin modular (female)

3.2.3 Keyboard Communications

Protocol: Balanced differential 10V peak-to-peak

Number of ports: 1

Baud rate: 9600 baud

Connector type: RJ-45 8-pin modular (female)

3.2.4 Physical Specifications

Dimensions: 11.82"W x 4.10"H x 8.86"D

(30.02 cm x 10.41 cm x 22.50 cm)

Weight: 3 lbs 6 oz (1.6 kg)

Construction: Injection-molded plastic

Shielding: EMI and RFI shielded

Pelco Manual C501M-B (10/97) 3-3

Page 16

(This page intentionally left blank.)

3-4 Pelco Manual C501M-B (10/97)

Page 17

4.0 INSTALLATION

4.1 INSTALLATION PREPARATION

Before installing your CM8500 system, it is necessary

to know how the system will be configured. This information is needed not only for the hardware installation, but is also necessary when programming the

CM8500 system.

Section 5.5.1 contains important information and blank

forms that will assist you in preparing for the installation. Refer to this section prior to installing your

CM8500 system.

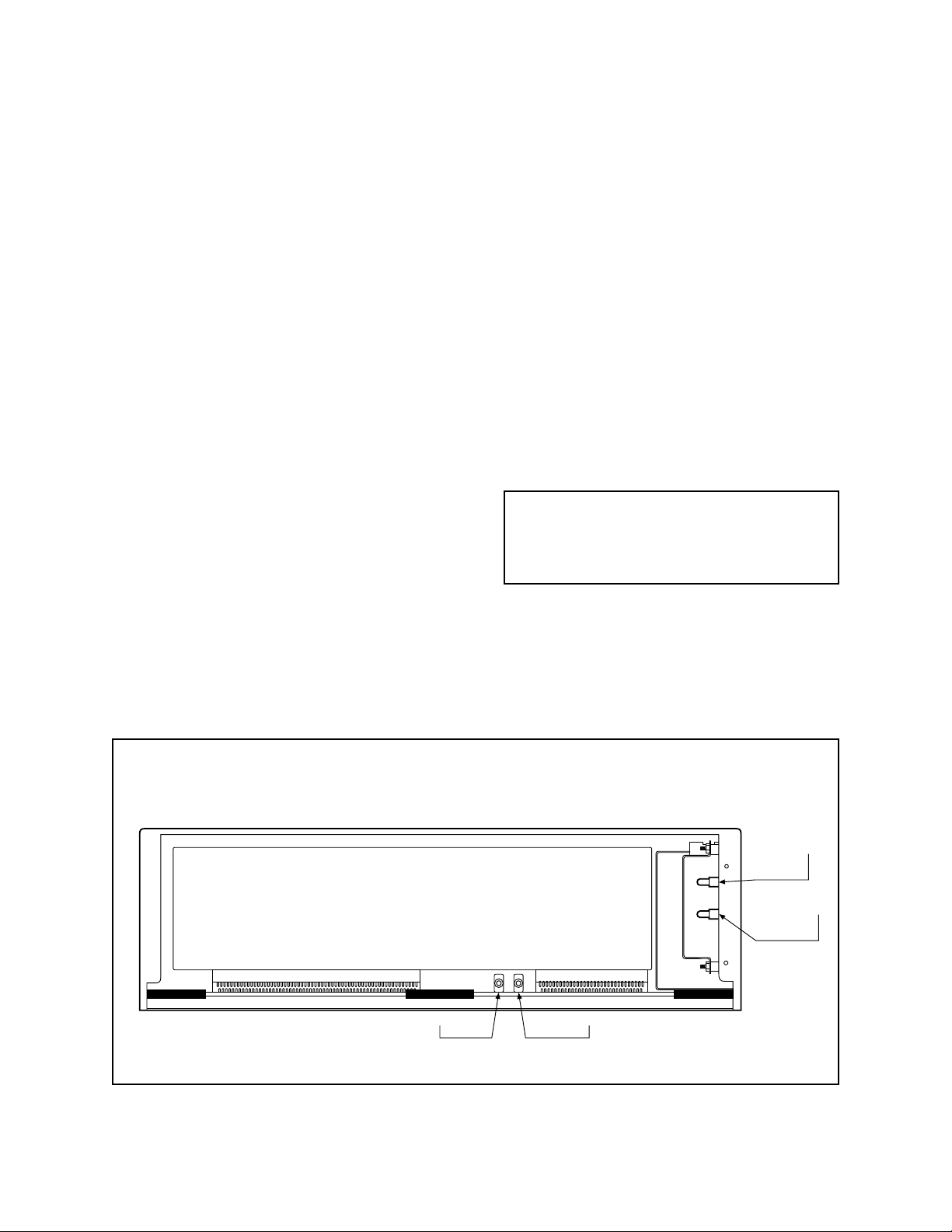

If you have the CM8505R keyboard controller, mount

it securely into a suitable equipment rack or frame, using the supplied rack mount screws and washers. Keep

in mind the visibility and accessibility of the control

functions while installing the keyboard.

4.3 SYSTEM HOOKUP

IMPORTANT NOTE: Remove the paper

between the battery contacts on the CPU card

if it has not been removed. Refer to Figure 8

and Sections 4.3.3.1.1 and 4.3.3.1.3.

4.3.1 General

4.2 MOUNTING

The CM8502A-1 and CM8503A-1 Card Cage assemblies come pre-assembled with all circuit cards installed

and tested, ready to mount in standard 19-inch EIA racking consoles. The card cage will take 5.25 inches (13.34

cm) of vertical rack space. If ordered, individual spare

circuit cards are shipped separately. See Section 4.3.3

for instructions on individual circuit card installation

and setup.

NOTE: If you are installing the card cage in

a 19-inch rack, remove the 6-32 flathead screw

from the top of the front panel. This will allow

you to remove the front panel after the card cage

is installed in the rack.

NOTE: After installing the card cage, connect the ground lug on the back panel to earth

ground. The ground lug is located on the left

side above the ground symbol .

NOTE: Make sure the fuse module on the

rear of the card cage is installed for the correct

voltage.

The System 8500 is a third-generation Coaxitron® system, and therefore only requires a single coaxial cable or

fiber* to be installed from the main card cage to each camera location. The Coaxitron® system will receive the video

signals from each individual camera and will use the same

coaxial cable to send data to the receiver/drivers located

at or near the camera sites. Fixed camera locations do

not require the receiver/driver unless the use of auxiliary

functions is desired. Camera power can be derived from

the receiver, which is normally powered by local 120

VAC. Refer to Pelco Specification Sheet C550 for details of receiver capabilities and requirements.

In addition to being a Coaxitron® system, the CM8500

also can support Pelco Wiretron receivers or Pelco Spectra™, Legacy® or Intercept® receivers that have been

configured for control via RS-422. Wiretron operation

requires the CM8506 option board; RS-422 Spectra™,

Legacy® and Intercept® receivers require the CM8507

option board.

* NOTE: Check with your fiber-optic equipment

manufacturer for specifications and type of

equipment appropriate for compatibility with

Pelco Coaxitron® transmitters and receivers.

Figure 2. CM8505R Dimension Drawing

Pelco Manual C501M-B (10/97) 4-1

Page 18

4.3.2 Keyboard to CPU Hookup

Up to eight (8) independent keyboards may be installed.

The backplane of the main card cage has eight (8) ports

that correspond to the keyboard inputs (refer to Figure

2A). If the supplied 8-conductor flat cable assembly is

used, it only requires that one end be plugged into a

port on the CPU and the other into the port on the rear

of the keyboard. (On the CM8505R keyboard, it doesn’t

matter which port you use on the keyboard. Two connectors are provided to support the daisy chaining of

keyboards, but this feature is not currently available.)

If user-supplied cabling is installed, then the CM9505J

adapter kit should be used to facilitate installation at

both the CPU and keyboard locations. (See Section

4.3.2.4 for wire-run distance specifications.)

FUSE 3AG (5X20)

250V 2A

RELAYS OUT 1-16

RELAYS OUT 17-32

ALARMS IN 1-16

ALARMS IN 17-32

1357

2468

KEYBOARDS

35791113151719212325272931

1

4 6 8 10 12 14 16 18 20 22 24 26 28 30 32

2

TWO WIRE CONTROL 1-16

TWO WIRE CONTROL 17-32

VIDEO INPUTS

EXTERNAL VIDEO IN

1357911

24681012

VIDEO OUTPUTS

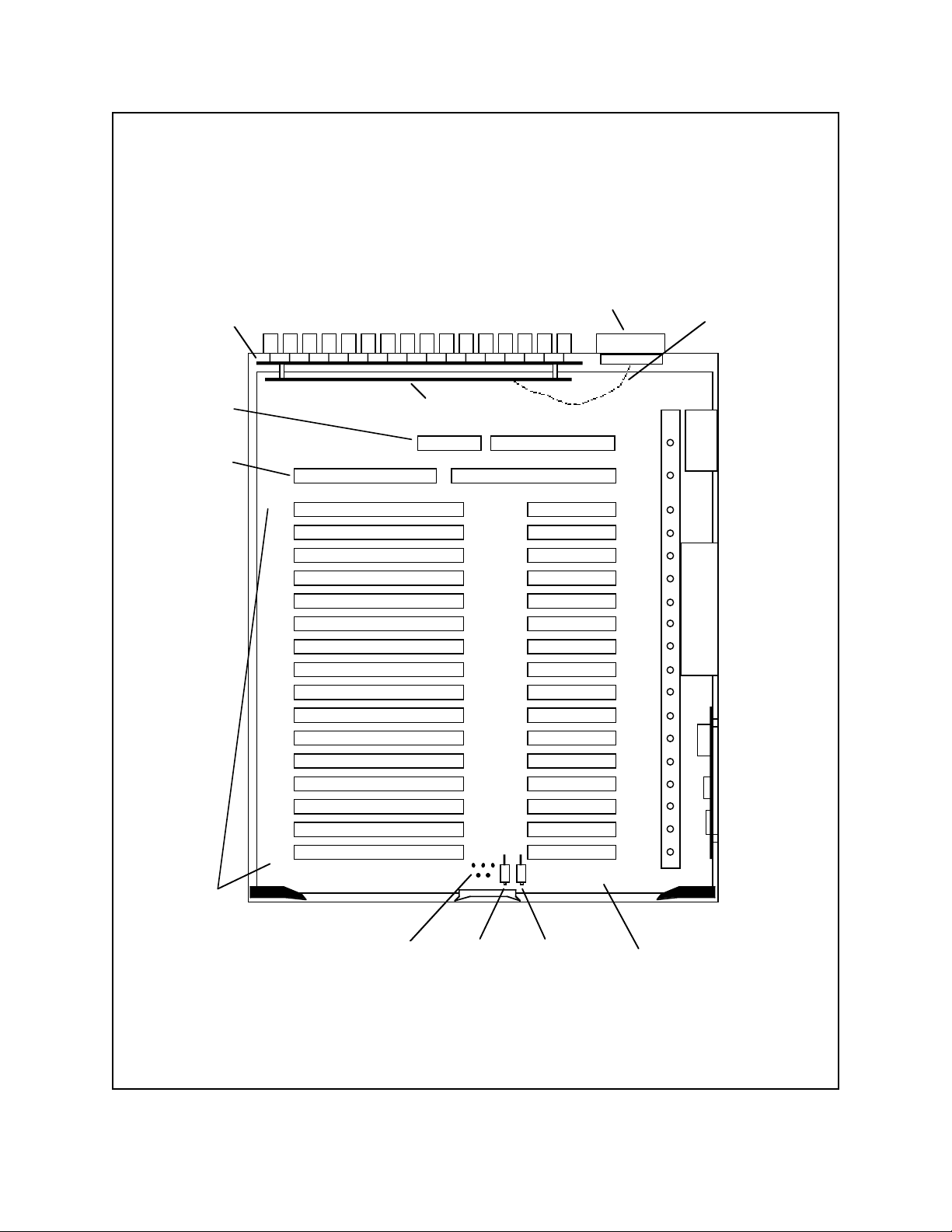

REAR VIEW CM8503A-1 CARD CAGE

VIDEO

RESET

OUT

VIDEO

INPUT

DATA

PORT

13 15

14 16

REAR VIEW, CM8505D KEYBOARD

LOOPING

VIDEO

VIDEO

OUTRESET

VIDEO

OUT

INPUT PWR/COM PWR/COM

REAR VIEW, CM8505R KEYBOARD

Figure 2A. CM8503-1 Card Cage and CM8505 Keyboard Back Panel Connector Layout

4-2 Pelco Manual C501M-B (10/97)

Page 19

4.3.2.1 CM9505UPS/CM9505J

Installation

4.3.2.3 CM9505J Wire/Pin

Configuration

The CM8502A-1 and CM8503A-1 Card Cages each

offer a total of eight (8) individual keyboard communications ports. Normally one keyboard utilizes one

communications port. Communications between each

keyboard and the CPU consists of two (2) balanced

differential data pairs and ±12 VDC supply voltages

together utilizing seven conductors. The keyboards are

supplied with 25-foot (63.5 cm) pretested interconnect cables with pre-assembled RJ-45 modular 8-pin

male connectors. Within many installations, it is necessary to install system keyboards at remote sites. The

CM9505J Junction Box allows you to convert the keyboard data cable into a set of cabling that can be run

through conduit (if necessary) for significantly greater

distances by eliminating the keyboard power connections and only running the data. The CM9505UPS reintroduces keyboard power at the keyboard end of the

cabling. See Figure 5. For distances of over 2,000 feet

(609.6 m), Pelco recommends using the CM9505UPS422 power supply/data repeater at the middle of the

run of wire in addition to the CM9505UPS.

4.3.2.2 Pin Configuration

Please refer to Figure 3 for specific pinout/wiring information and make connections accordingly.

NOTE: For data connection only, do not use

connection pins 3 thru 6.

Note that the pin assignments on the CM9505J wire

connection do not match the RJ-45 modular connector.

Make connections accordingly. (The color information

printed on the CM9505J PC board has no r elevance in

this application.)

Top View

PR 3 PR 1

PR 4

1

2

3

6

7

8

5

4

Pin 8

PR 2

Pin 1

Figure 4. Junction Box Pin Assignments

The pinout configuration is as listed on the following

table. Refer to Figure 3 for more information.

CPU Keyboard

Pin# Function Function Pin#

1 Data in + Data out + 1

2 Data in - Data out - 2

Pin 1

3 -12 VDC -12 VDC 3

4 +12 VDC +12 VDC 4

5 Ground Ground 5

6 Spare Spare 6

Pin 8

7 Data out - Data in - 7

8 Data out + Data in + 8

4.3.2.4 Cable Distances

12345678

The maximum distances allowed are governed primarily by the 12 VDC supply voltages needed to power

the active components of the keyboard. The RS-422

data lines far exceed the distance restrictions of the DC

power lines.

Figure 3. Data Cable Pin Assignments

Pelco Manual C501M-B (10/97) 4-3

Page 20

If the CPU is to supply power to the keyboards, the

distance limitations based on conductor size are shown

in the following table:

NOTE: The 8-conductor cable provided by

Pelco with the CM8505D, CM9505J or

CM9505UPS is 28 gauge.

Wire ga. ft/m

14 832 / 254

16 416 / 127

18 275 / 84

20 166 / 51

22 104 / 32

24 64 / 20

28 26 / 8

32 10 / 3

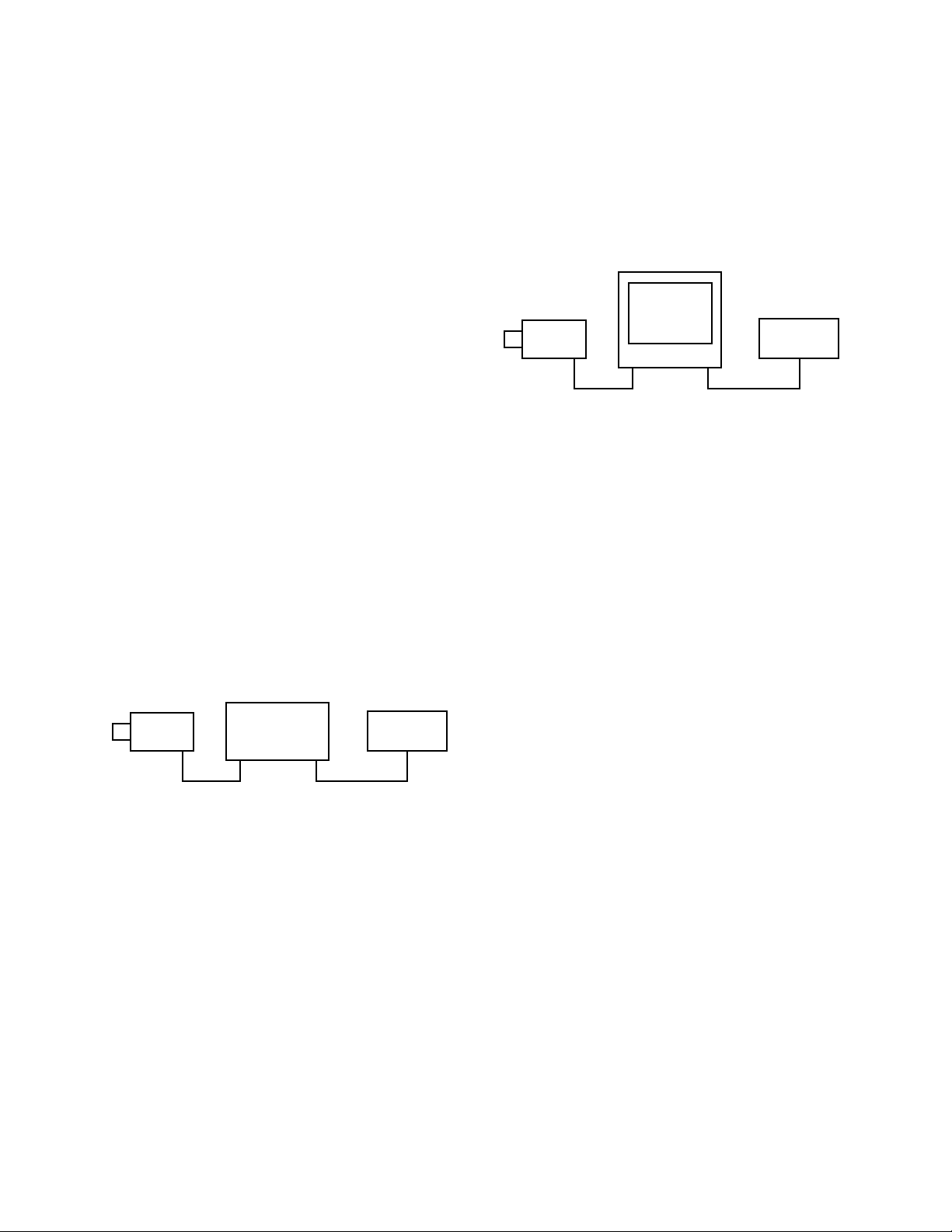

Data Configuration only with CM9505UPS

CM9505J

Junction Box

Matrix System

Card Cage

Data Cable Supplied

With Junction Box

User-Supplied

4-conductor

NOTE: When using the CM9505J with the

CM9505UPS , use pins 1, 2, 7, and 8 ONLY.

This will allow for data to be passed through,

and for power to be reintroduced at the

CM9505UPS.

Remote KeyboardCM9505UPS

Data Cable

Supplied With

UPS

Data Cable

Supplied With

Keyboard

Data and Power Configuration without CM9505UPS

Matrix System

Card Cage

Data Cable Supplied

With Junction Box

CM9505J

Junction Box

User-Supplied

8-conductor

Data Cable

Supplied With

Keyboard

Remote Keyboard

Data Configuration Only with CM9505UPS and CM9505UPS-422

Distance Greater Than 2,000 feet

Matrix System

Card Cage

CM9505UPS-422

Data Cable Supplied

With Junction Box

User-Supplied

4-conductor

Data Cable

Supplied With

UPS

CM9505J

Junction Box

Figure 5. CM9505UPS/CM9505J Configuration

CM9505UPS

4-4 Pelco Manual C501M-B (10/97)

Page 21

BACKPLANE

CPU

SLOT

ALARM / RELAY CONNECTORS

RIBBON

CABLES

(4)

ALARM / RELAY INTERFACE

BUFFER

CARD

SLOT

11

13

10

12

14

15

16

FAN

1

2

3

4

5

6

7

8

9

POWER

SUPPLY

VIDEO

INPUT/OUTPUT

SLOTS (1-16)

TEST

POINTS

RESET SFT CLR

MOTHER

BOARD

Figure 6. CM8503A-1 Card Cage Top View

Pelco Manual C501M-B (10/97) 4-5

Page 22

4.3.2.5 Interfacing Keyboard to CPU

Via Fiber, Modem or Microwave

The CM8500 utilizes a full duplex balanced differential communications scheme between keyboard and

CPU, similar to RS-422 except that voltage levels are

10 volts peak to peak. Call Pelco if there are any application related questions.

4.3.2.6 Keyboard Self-Test Program

LED will be illuminated. The Power On LED, when

on, indicates the unit On/Off switch is in the On position. The +5 VDC LED indicates the power supply is

operating.

Pressing the Reset button while the unit is operating

will cause the system to initialize and restart operation.

This is the same as cycling power. Pressing the SFT

CLR (Software Clear) button during normal operating

conditions does not affect operation.

This option not currently available.

4.3.3 CM8502A-1/CM8503A-1 Card

Cage Configuration

The CM8502A-1 Card Cage may be configured for one

to eight monitor outputs and the CM8503A-1 may be

configured for one to 16 monitor outputs by adding

CM8504 Input/Output Matrix Cards. Each CM8504

card allows the 8500 system to be expanded by one

monitor output. The input capacity (32 cameras) remains unchanged by the addition or deletion of CM8504

cards.

Figure 6 shows the board location for the CM8503A-1

Card Cage. The CM8502A-1 Card Cage board locations are identical, with the only difference being eight

(8) fewer video input/output slots. (Slots 9-16 are not

present in the CM8502A-1 version.) Refer to Figure 7

for the front view of the CM8502A-1/CM8503A-1 Card

Cages. When the power switch is in the On position,

both the green Power On LED and the red +5 VDC

The following procedure will erase all user-programmed

memory:

1. Hold in the RESET and SFT CLR buttons for five

seconds.

2. Release the RESET button.

3. Release the SFT CLR button.

CAUTION: Cycling power with the SFT

CLR button pushed will erase all userprogrammed memory. (Pressing the RESET button is the same as cycling power .)

+5 VDC

LED

VIDEO INPUT/OUTPUT MATRIX CARDS

RESET SFT CLR

PWR ON

LED

Figure 7. CM8502A-1/CM8503A-1 Card Cage Front View

4-6 Pelco Manual C501M-B (10/97)

Page 23

4.3.3.1 Removal/ Replacement of

Individual Circuit Cards

4.3.3.1.1 Motherboard Access

3. To remove an individual circuit board, pull up on

the metal ejector tabs. The card should easily slide

out of the card slots of the motherboard.

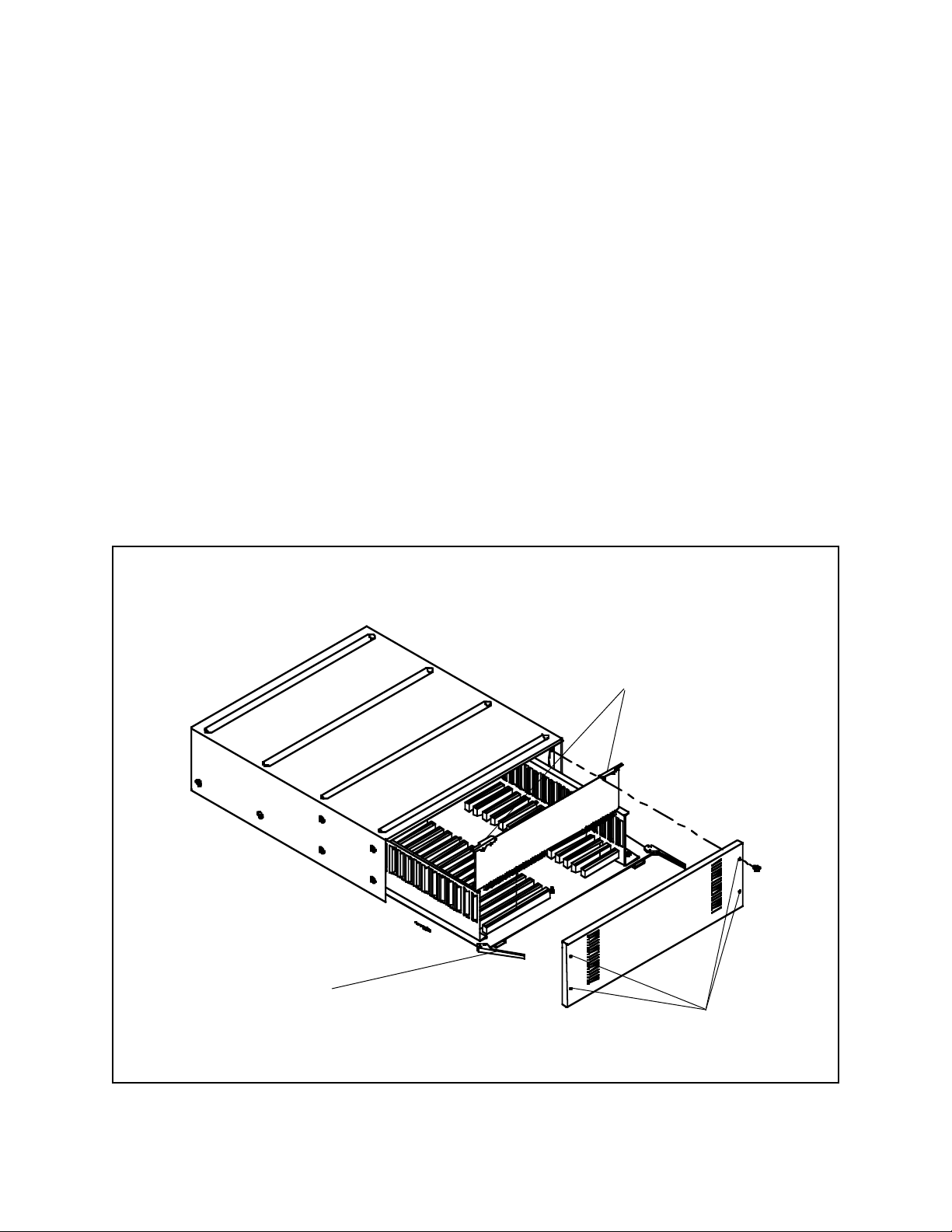

The CM8500 card cage has been designed with userconvenience and operational integrity foremost in mind.

The slide-out motherboard makes dependable electrical contact while providing an easy-to-service system

for circuit board upgrade and replacement.

To upgrade and/or replace circuit boards, perform the

following steps:

1. Remove the four (4) front cover screws from the

corners of the CM8500 card cage front panel and

remove the front panel.

2. Use the two (2) motherboard PCB ejectors to pull

and slide the main motherboard out of the card

cage.

4. T o install an individual circuit board on the mother board, gently press the contact edge of the circuit

board into the appropriate card slots on the motherboard. Make sure the metal ejector tabs lay down

flat against the circuit board before sliding the

motherboard back into the card cage.

5. After all boards have been replaced/added, slide

the motherboard back into the card cage unit and

lock the ejectors back into place.

6. Replace the front cover and reattach the four (4)

grey screws that were removed in Step 1.

Motherboard PCB

ejector tabs

Individual PCB

ejector tabs

Front panel

mounting screws

Figure 7a. Slide-out Motherboard Access

Pelco Manual C501M-B (10/97) 4-7

Page 24

WARNING: To reduce the risk of personal

injury due to electrical shock and also to prevent possible damage to the electronic circuitry ,

always remove power to the unit prior to removing or installing any printed circuit boards.

4.3.3.1.2 Insertion/Extraction of

the CM8504 I/O Card

Insert the CM8504 Input/Output card into the appropriate slot in the motherboard by grasping the white

handles, aligning the card with the card guides and pushing down firmly until the card seats in the edge connector. To remove the card, lift up the ejector handles.

4.3.3.1.3 Insertion/Extraction of

the CPU Card

The CPU Card occupies the first slot (slot closest to the

backplane) in the motherboard. T o install the CPU Card,

align the edge connector with the sockets and card

guides and press firmly into place. T o remove the card,

lift up the ejector handles.

4.3.3.1.4 Insertion/Extraction of

the Buffer Card

The Buffer Card occupies the second slot (from the

backplane) on the motherboard. To install the Buffer

Card, align the card with the socket and card guides

and press firmly into place. T o remove the card, lift up

the ejector handles.

Battery

Figure 8. CPU Card Component Location

4-8 Pelco Manual C501M-B (10/97)

Page 25

4.3.3.1.5 Installing Option Boards

The CM8500 is factory-equipped as a Coaxitron compatible only system (unless requested differently). The

CM8500 is also capable of transmitting two-wire control information in RS-422 or Wiretron formats. To

make use of the system’s two-wire capabilities, the appropriate Pelco CM8500 Option Board must be

installed to the system buffer board.

CM8506 CM8500 Wiretron compatible option

board

CM8507 CM8500 RS-422 compatible option

board

Both option boards install into the CM8500 system

using the same procedures. It is important to note that

only one option board can be installed, making the system either Coaxitron®/Wiretron compatible or

Coaxitron®/RS-422 compatible. The system cannot

work with all three information formats at the same

time.

NOTE: The CM8506/CM8507 option boards

are transmit-only units. Only the appropriate

control signals are generated from the option

boards.

4.3.3.1.6 Option Board Receiver

Connections

When working with CM8500 optional data formats,

keep the following in mind when making the two-wire

connections to the receivers.

The CM8500 system offers no receiver addressability.

Home runs are required for each receiver in the system, and each receiver (if addressability applies to the

receiver) must be set to address 1.

The following two-wire connections

must be made:

When using the CM8506 Wiretron compatible option board, the “+” output for the camera that is to be

controlled with a Wiretron receiver must be connected

to the “high” input on the Wiretron receiver. The “-”

output is to be connected to the “low” input on the

Wiretron receiver.

With the CM8507 RS-422 compatible option board,

the “+” output for the camera that is to be controlled

with an Intercept® or Legacy® receiver is to be connected to the “RX+” input on the Legacy® or Intercept® receiver. The “-” output is to be connected to

the “RX-” input on the Legacy® or Intercept® receiver .

Option Board Physical Installation

The option boards are easy to install and should take

only a minimum of time. After turning off system power

and removing the buffer board (see section 4.3.3.1.4),

notice on the un-populated side of the buffer board there

are three (3) plug-in connectors and five (5) hex

spacers. The populated side of the option board (either the CM8506 or CM8507) has the matching male

pin connections and five mounting holes.

Line the female plug-in connectors and standoffs on

the buffer board with the male pin connectors and

mounting holes on the option board. Gently press the

boards together making the plug in connections. Use

the five (5) supplied mounting screws to firmly secure

the option board to the buffer board.

Make the appropriate jumper settings on the buffer

board (each receiver that is compatible with the new

option board must have jumpers set on the buffer board

appropriately). Reinstall the new buffer board/option

board assembly into the CM8500 card cage. See section 4.3.3.2 for jumper setting information.

Again, make sure all addressable receivers are set to

address 1.

IMPORTANT: After the Option Board has

been installed, and the individual jumper selections have been made for each receiver, you

must program the system software to match

the individual receiver data formats. Refer to

Section 5.5.2.4 for Receiver T ypes Pr ogramming Screen information.

Pelco Manual C501M-B (10/97) 4-9

Page 26

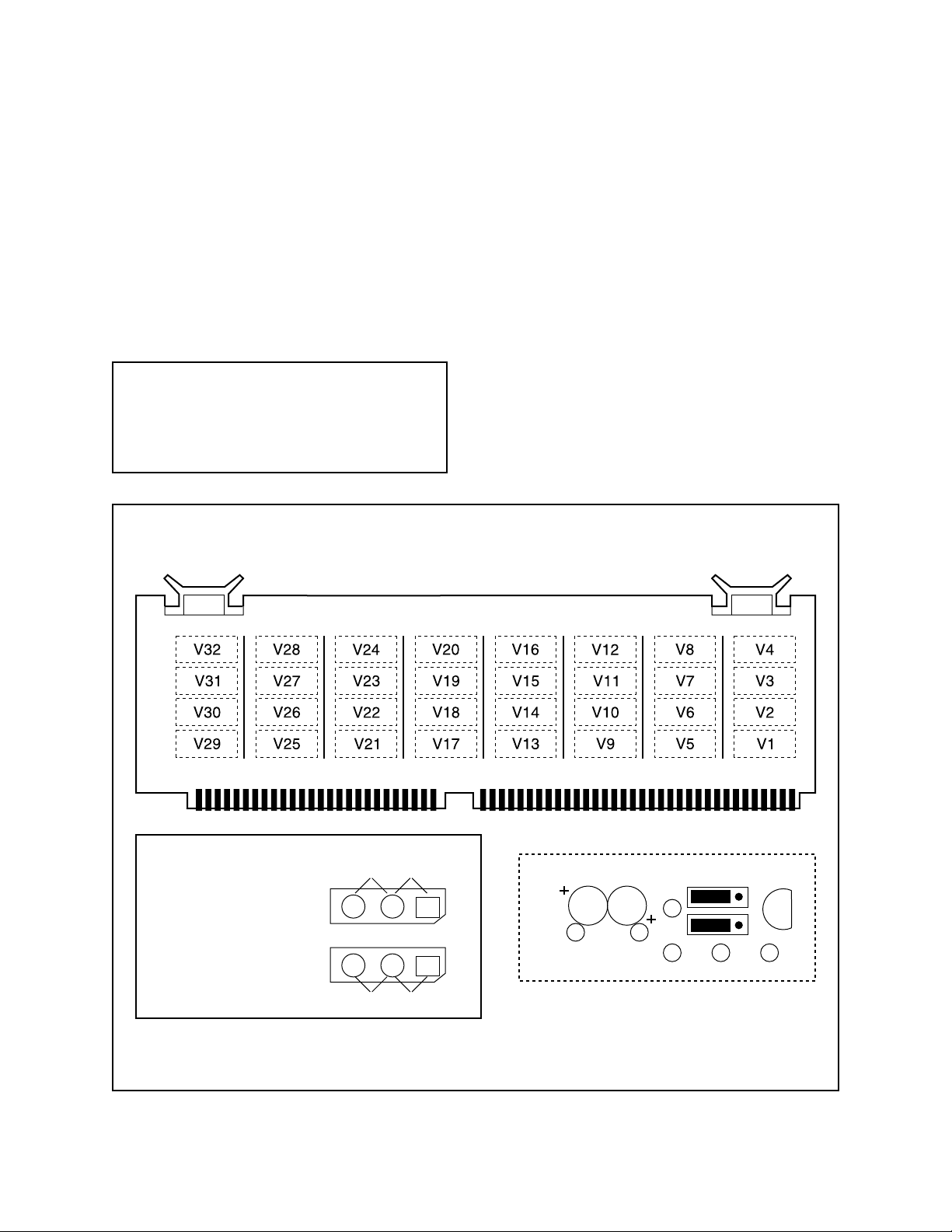

4.3.3.2 Setting Termination on

Video Inputs

4.3.3.3 Determining and Setting

Monitor Output Assignments

The termination settings for the 32 video inputs are individually assigned on the Buffer Card. There are 64

jumpers located on the component side of the board,

two jumpers for each video input (designated V1

through V32). Refer to Figure 9. The board will have

to be removed from the motherboard in order to change

the setting(s). Follow the instructions for board removal

and replacement in Section 4.3.3.1.4 and refer to Figure 9 when setting the jumpers. For more information,

refer to Section 4.3.3.4.2.

NOTE: Jumper positions 1 and 2 apply to the

terminating/looping status of the individual

video inputs. Jumper positions 3 and 4 apply to

the Coaxitron®/two-wire compatibility of the

individual receiver.

Monitor output numbers automatically correspond

to the slot that the Input/Output board is installed.

The first monitor slot is the one just forward of the

Buffer Card slot. The last monitor slot is located in

the forward-most position. No other settings are

necessary.

4.3.3.4 Camera Location to Video

Input Hookup

Since the CM8500 is a Coaxitron® system, each camera input that has a Coaxitron® receiver requires only a

single coaxial cable (or fiber) to transmit both video

and camera control signals. Follow camera manufacturers’ recommendations for maximum allowable distances for their equipment.

SECTION 100

JUMPER SETTINGS

12

1 - TERMINATING

2 - LOOPING

3 - COAXITRON

4 - 2-WIRE

34

TYPICAL FOR V1 THROUGH V32

Figure 9. Buffer Card and Jumper Locations

4-10 Pelco Manual C501M-B (10/97)

Page 27

4.3.3.4.1 Cable Selection

Coaxitron requires a high quality solid copper core coaxial cable with at least 95-percent copper braid shield.

Copper-clad steel center conductor is not recommended,

nor is aluminum shield. Such construction is generally

recognized as not being adequate for baseband CCTV

systems. This type of cabling is meant for RF MATV/

CATV type systems only.

4.3.3.4.2 Termination

If there is any equipment, such as a spot monitor, between the video input of the CM8500 and the video

output from your camera or receiver/driver, make sure

that these devices are set for looping, or high impedance. Terminate the video input to the CM8500. Here,

the CM8500 is the last piece of equipment.

Camera Monitor CM8500

Coaxitron is sensitive to improper termination and care

must be taken to ensure proper installation. When a

video output from a camera or receiver/driver goes directly to a video input of the CM8500, the video input

must be terminated with 75 ohms. However , if there is

more than one piece of equipment in the video path,

only the last piece of equipment is terminated. Terminating more than one piece of equipment (double termination) causes loss of signal.

For example, if a video input to the CM8500 is going

to be looped out to the input of another device, place

the jumper on the buffer card in the CM8500 in the

looping position and terminate the input of the device

receiving its signal from the CM8500. In this case the

CM8500 is between the video source and the final piece

of video input equipment.

Other

Camera CM8500 Video Equip.

Video

Video In

In Out

Video In

In Out

Looping 75-ohm

Input termination

Video devices placed between the CPU and receiver/

driver must be passively looping and not use an amplified looping scheme. Some quad devices and VCRs use

this scheme. The amplified devices are not bidirectional

and therefore do not pass the Coaxitron® control signals. Should these devices need to be installed they must

utilize video that has first looped through the matrix

inputs .

See Section 4.3.3.2 for setting the termination jumpers.

Looping 75-ohm

Input termination

Pelco Manual C501M-B (10/97) 4-11

Page 28

In this example, monitor 1 is “Data

Monitor,” but its use is not restricted to

programming functions. It can also be

utilized like any other system monitor and

has the additional capabilities of the “Data

Monitor.”

TYPICAL CAMERA LOCATION WITH PT&Z

RX/DR

VIDEO

2 TW PR &

3 CONDUCTOR

TYPICAL CONTROL LOCATION

MON 1

DATA

MONITOR

MON

2

KEYBOARD 1

COAX

FUSE 3AG (5X20)

250V 2A

KEYBOARD 1

DATA/PWR LINE

PT&Z

RELAYS OUT 1-16

RELAYS OUT 17-32

ALARMS IN 1-16

ALARMS IN 17-32

1357

2468

KEYBOARDS

35791113151719212325272931

1

4 6 8 10 12 14 16 18 20 22 24 26 28 30 32

2

TWO WIRE CONTROL 1-16

TWO WIRE CONTROL 17-32

EXTERNAL VIDEO IN

VIDEO INPUTS

1357911

24681012

VIDEO OUTPUTS

MONITOR 1

VIDEO OUTPUT

MONITOR 2

COAX

VIDEO OUTPUT

VIDEO & CONTROL DISTRIBUTION POINT

13 15

14 16

Figure 10. Data Monitor Hookup

4-12 Pelco Manual C501M-B (10/97)

Page 29

4.3.3.4.3 Ground Loops

One other precaution to take prior to final connections

being made is to check all input coaxial cables for the

presence of possible ground loop voltages. Sync, video,

control functions, and/or system electronics may be adversely affected by a ground loop condition. Call Pelco

if unable to correct any ground loop problems. Do not

connect cables to input connectors if ground loop voltages are present between CPU and camera sites or between camera sites through the CPU. Pelco manufactures the GIT100, ground isolation transformer, to help

alleviate ground loop problems in Coaxitron®-based

equipment. The use of fiber optics is also another means

to eliminate ground loops in a system.

4.3.3.4.4 Hookup

After ensuring that the above conditions have been met

and that all precautions have been observed, the coaxial inputs from the camera locations can be connected

to the input connectors on the backplane of the card

cage.

Be sure that each connection is secure and that the connectors are properly installed.

It is always good installation practice to mark or number all cabling. If system troubleshooting is necessary

and cables need to be disconnected, system downtime

can be minimized with a well organized cable identification system.

4.3.6 Installation/Connection of

CM8532 Alarm/Relay Interface

4.3.6.1 Alarm/Relay Interface Kit

Installation

The Alarm/Relay Interface Kit contains the Alarm/

Relay Interface Board (with ribbon cables attached)

and all hardware needed to secure the board and connectors. The Alarm/Relay Interface Board mounts

onto the Backplane of the CM8502-1 or CM8503-1

Card Cage (refer to Figure 6).

NOTE: To install the board, the top cover as

well as the CPU and buffer boards need to be

removed.

Connect the 10-pin connector from the Alarm/Relay

Interface board to the backplane of the matrix card cage.

Note that the connector is keyed and that the edges of

the connectors should match (i.e., that the connector

has not shifted over one way or the other).

Once connected, secure the Alarm/Relay Interface

Board to the standoffs with the hardware provided. Once

secured, remove the blank-off plate covering the connector slots and mount the alarm and relay interconnect ribbon cable connectors to the card cage. Refer to

the following information for the proper location of each

connector.

Alarm/Relay Interface Board Card Cage

4.3.4 Connecting Keyboard to

the Data Monitor

Each keyboard will utilize a system monitor output for

programming and keyboard feedback. Select one monitor output at the keyboard location to be the data monitor

and connect that output from the card cage to the keyboard video input connector. Connect the monitor output

from the keyboard to the appropriate monitor and ensure

correct termination (75 Ohm). Refer to Figure 10.

4.3.5 Connecting Other System

Monitors

All other system monitors may be interconnected to

the video output BNC terminal(s) of the card cage with

the appropriate length and type of coaxial cable or

fiber-optic interface equipment. The video output of

the CM8500 is a standard NTSC 1V p-p video signal.

Again, ensure for proper 75-Ohm termination at the

monitor(s) or other video processing equipment.

Pelco Manual C501M-B (10/97) 4-13

4.3.7 Alarm Input Connection

To connect alarm inputs to the system requires that the

alarm inputs first be wired into a 37-pin D-type connector (supplied by Pelco). Refer to Section 4.3.7.1

for the connector pin designations. Once wired, connect the connector to the appropriate location on the

back panel of the card cage.

P1 Relays Out 1-16

P2 Relays Out 17-32

P3 Alarms In 17-32

P4 Alarms In 1-16

Page 30

4.3.7.1 Alarm Interface 37-Pin Sub

“D” Connectors

The pin-out number assignments and configurations

shown below match the 37-pin ribbon cables used in

the alarm/relay interface.

Connector: Alarms In 1 - 16

Alarm No: Pin No:

1 In 1

1 Com 20

2 In 2

2 Com 21

3 In 3

3 Com 22

4 In 4

4 Com 23

5 In 5

5 Com 24

6 In 6

6 Com 25

37-Pin sub “D” connector (sockets).

Facing back of card cage.

Connector: Alarms In 17 - 32

Alarm No: Pin No:

17 In 1

17 Com 20

18 In 2

18 Com 21

19 In 3

19 Com 22

20 In 4

20 Com 23

21 In 5

21 Com 24

22 In 6

22 Com 25

7 In 7

7 Com 26

8 In 8

8 Com 27

9 In 9

9 Com 28

10 In 10

10 Com 29

11 In 11

11 Com 30

12 In 12

12 Com 31

13 In 13

13 Com 32

14 In 14

14 Com 33

15 In 15

15 Com 34

16 In 16

16 Com 35

23 In 7

23 Com 26

24 In 8

24 Com 27

25 In 9

25 Com 28

26 In 10

26 Com 29

27 In 11

27 Com 30

28 In 12

28 Com 31

29 In 13

29 Com 32

30 In 14

30 Com 33

31 In 15

31 Com 34

32 In 16

32 Com 35

4-14 Pelco Manual C501M-B (10/97)

Page 31

4.3.8 Relay Output Connection

4.3.8.1 Relay Interface Connector Pin

Assignments

The pin-out number assignments and configurations

shown below match the 50-pin ribbon cables used in

the alarm/relay interface.

IMPORTANT: Please note that the pin

assignments on the 50-pin connector are not

standard.

50-Pin sub “D” connector (sockets)

Facing back of card cage.

Connector: Relays Out 1-16

Relay No: Pin No:

1 NC 1

1 NO 2

1 Com 3

2 NC 4

2 NO 5

2 Com 6

3 NC 7

3 NO 8

3 Com 9

4 NC 10

4 NO 11

4 Com 12

5 NC 13

5 NO 14

5 Com 15

6 NC 16

6 NO 17

6 Com 18

7 NC 19

7 NO 20

7 Com 21

8 NC 22

8 NO 23

8 Com 24

Relay No: Pin No:

9 NC 25

9 NO 26

9 Com 27

10 NC 28

10 NO 29

10 Com 30

11 NC 31

11 NO 32

11 Com 33

12 NC 34

12 NO 35

12 Com 36

13 NC 37

13 NO 38

13 Com 39

14 NC 40

14 NO 41

14 Com 42

15 NC 43

15 NO 44

15 Com 45

16 NC 46

16 NO 47